c807107b495433b80f321c0cee6dab30.ppt

- Количество слайдов: 56

“the well from hell”

“the well from hell”

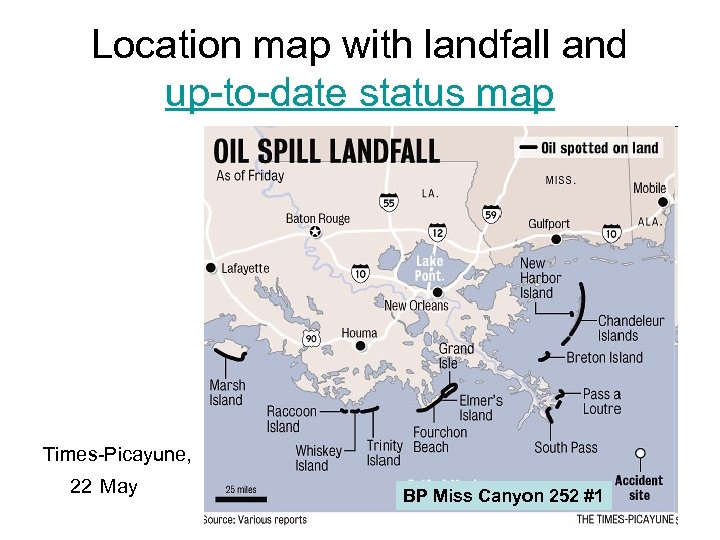

Location map with landfall and up-to-date status map Times-Picayune, 22 May BP Miss Canyon 252 #1

Location map with landfall and up-to-date status map Times-Picayune, 22 May BP Miss Canyon 252 #1

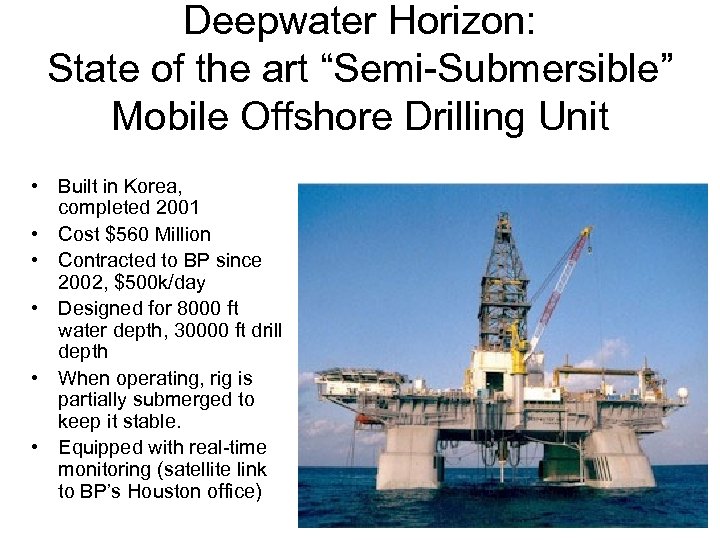

Deepwater Horizon: State of the art “Semi-Submersible” Mobile Offshore Drilling Unit • Built in Korea, completed 2001 • Cost $560 Million • Contracted to BP since 2002, $500 k/day • Designed for 8000 ft water depth, 30000 ft drill depth • When operating, rig is partially submerged to keep it stable. • Equipped with real-time monitoring (satellite link to BP’s Houston office)

Deepwater Horizon: State of the art “Semi-Submersible” Mobile Offshore Drilling Unit • Built in Korea, completed 2001 • Cost $560 Million • Contracted to BP since 2002, $500 k/day • Designed for 8000 ft water depth, 30000 ft drill depth • When operating, rig is partially submerged to keep it stable. • Equipped with real-time monitoring (satellite link to BP’s Houston office)

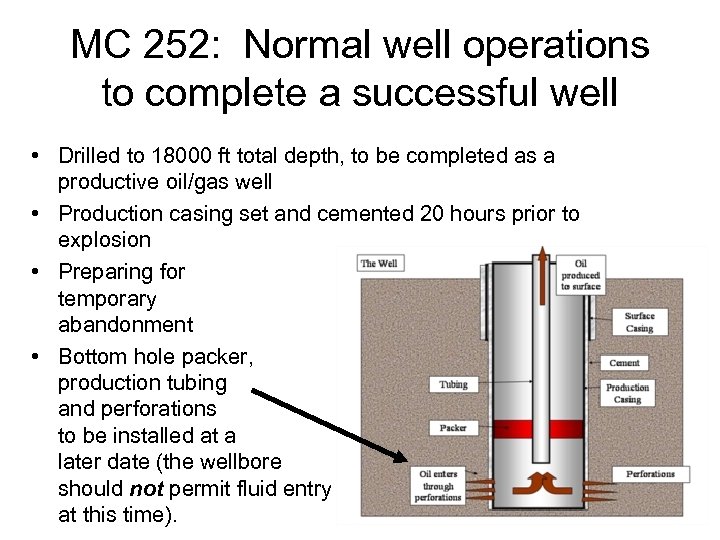

MC 252: Normal well operations to complete a successful well • Drilled to 18000 ft total depth, to be completed as a productive oil/gas well • Production casing set and cemented 20 hours prior to explosion • Preparing for temporary abandonment • Bottom hole packer, production tubing and perforations to be installed at a later date (the wellbore should not permit fluid entry at this time).

MC 252: Normal well operations to complete a successful well • Drilled to 18000 ft total depth, to be completed as a productive oil/gas well • Production casing set and cemented 20 hours prior to explosion • Preparing for temporary abandonment • Bottom hole packer, production tubing and perforations to be installed at a later date (the wellbore should not permit fluid entry at this time).

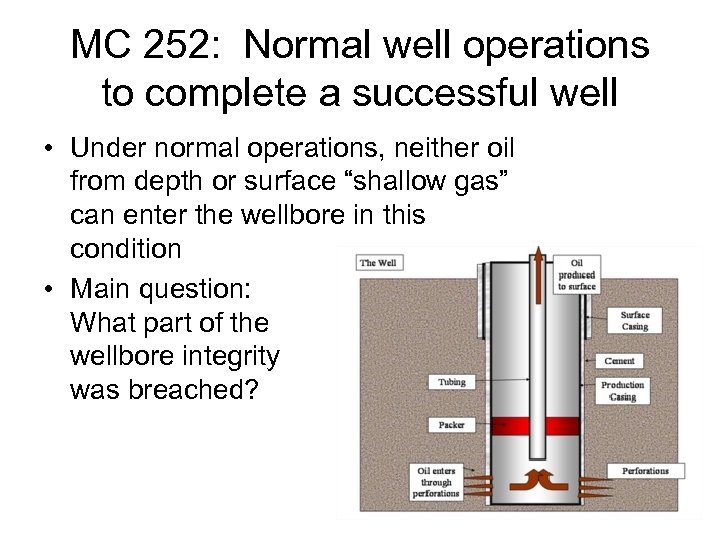

MC 252: Normal well operations to complete a successful well • Under normal operations, neither oil from depth or surface “shallow gas” can enter the wellbore in this condition • Main question: What part of the wellbore integrity was breached?

MC 252: Normal well operations to complete a successful well • Under normal operations, neither oil from depth or surface “shallow gas” can enter the wellbore in this condition • Main question: What part of the wellbore integrity was breached?

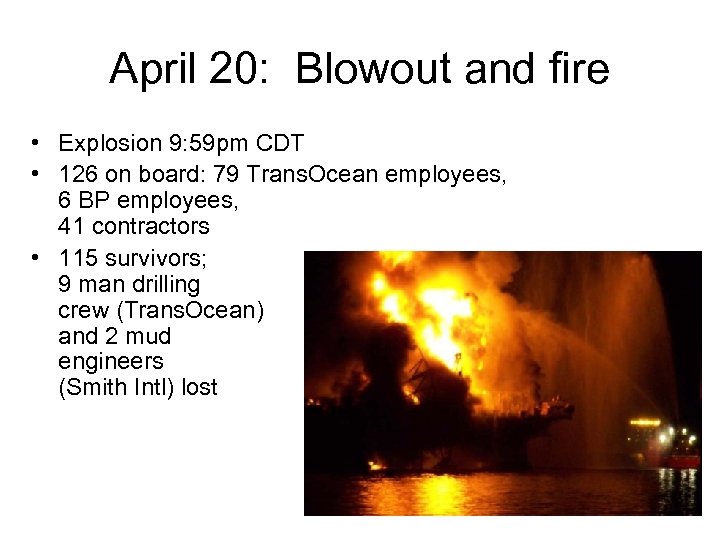

April 20: Blowout and fire • Explosion 9: 59 pm CDT • 126 on board: 79 Trans. Ocean employees, 6 BP employees, 41 contractors • 115 survivors; 9 man drilling crew (Trans. Ocean) and 2 mud engineers (Smith Intl) lost

April 20: Blowout and fire • Explosion 9: 59 pm CDT • 126 on board: 79 Trans. Ocean employees, 6 BP employees, 41 contractors • 115 survivors; 9 man drilling crew (Trans. Ocean) and 2 mud engineers (Smith Intl) lost

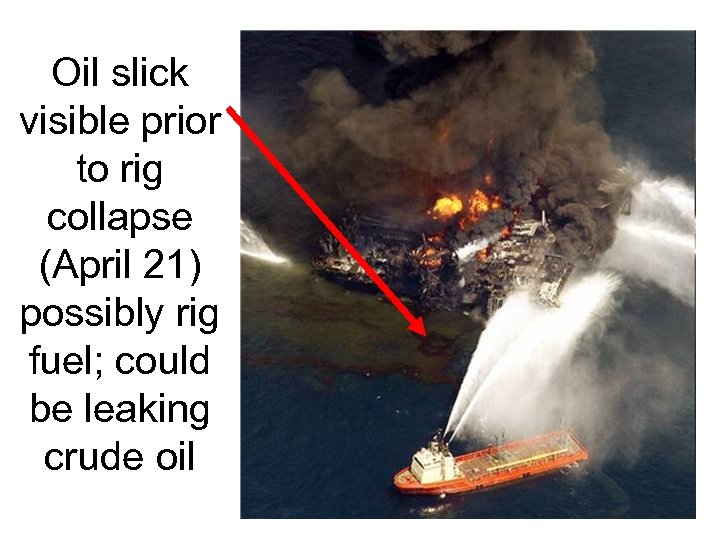

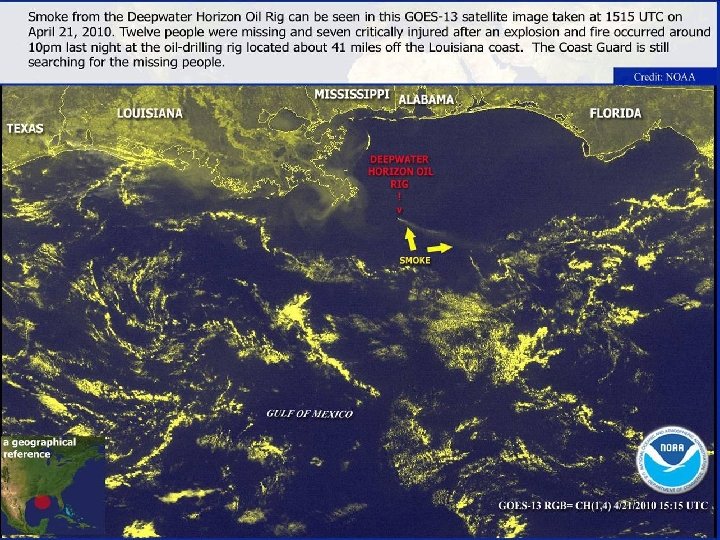

Oil slick visible prior to rig collapse (April 21) possibly rig fuel; could be leaking crude oil

Oil slick visible prior to rig collapse (April 21) possibly rig fuel; could be leaking crude oil

Second day on fire: Rig about to capsize

Second day on fire: Rig about to capsize

Video of the oil leaks • Multiple leak points: http: //www. youtube. com/watch? v=Rng. Yv 4 SYMCY • Comparison of before and after riser insertion tube: http: //www. youtube. com/watch? v=hyxj. Go. Bn-YM

Video of the oil leaks • Multiple leak points: http: //www. youtube. com/watch? v=Rng. Yv 4 SYMCY • Comparison of before and after riser insertion tube: http: //www. youtube. com/watch? v=hyxj. Go. Bn-YM

What happened and why? Areas of concern and who would bear responsibility • Routine BOP test followup (BP as operator, Trans. Ocean as drilling contractor, MMS exemptions) • Risky(? ) well plan (BP) • Integrity of casing cement (Halliburton) • Wellhead seal integrity (Trans. Ocean and Dril. Quip (supplier)) • Post-cementing test procedure and time allotted for cement to cure (BP) • Hurried preparation for temporary abandonment (BP) Continued

What happened and why? Areas of concern and who would bear responsibility • Routine BOP test followup (BP as operator, Trans. Ocean as drilling contractor, MMS exemptions) • Risky(? ) well plan (BP) • Integrity of casing cement (Halliburton) • Wellhead seal integrity (Trans. Ocean and Dril. Quip (supplier)) • Post-cementing test procedure and time allotted for cement to cure (BP) • Hurried preparation for temporary abandonment (BP) Continued

What happened and why? Areas of concern and who would responsibility • Prudent monitoring of wellbore condition during prep for temporary abandonment (Trans. Ocean) should trump any hurry • Blowout preventer (BOP) activation (Trans. Ocean) and mechanical failure (Cameron)

What happened and why? Areas of concern and who would responsibility • Prudent monitoring of wellbore condition during prep for temporary abandonment (Trans. Ocean) should trump any hurry • Blowout preventer (BOP) activation (Trans. Ocean) and mechanical failure (Cameron)

Plenty of blame to go around • This disaster was due to a series of errors and mistakes that compounded one another. • Had any one of these preventable problems been avoided, this disaster might have been averted. Details and analysis of events follow. Analysis taken from opinions at www. drillingahead. com, a social network for oil and gas drillers and engineers. Those pages are highlighted in light blue.

Plenty of blame to go around • This disaster was due to a series of errors and mistakes that compounded one another. • Had any one of these preventable problems been avoided, this disaster might have been averted. Details and analysis of events follow. Analysis taken from opinions at www. drillingahead. com, a social network for oil and gas drillers and engineers. Those pages are highlighted in light blue.

Oil field terminology • Bbl – barrel of oil, 42 US gallons • BOP – blowout preventer • Drilling mud – heavy fluid used to control pressure while drilling and completing • Casing – large diameter pipe cemented into well at various depths for safety • Drillpipe – smaller pipe that connects drilling rig to drilling bit, removed when well is completed

Oil field terminology • Bbl – barrel of oil, 42 US gallons • BOP – blowout preventer • Drilling mud – heavy fluid used to control pressure while drilling and completing • Casing – large diameter pipe cemented into well at various depths for safety • Drillpipe – smaller pipe that connects drilling rig to drilling bit, removed when well is completed

Oil field terminology • Riser – used in offshore wells to protect drillpipe from seawater • BHP – bottom hole pressure (measured in mud weight equivalent (pounds per gallon) or pounds per square inch (psi)

Oil field terminology • Riser – used in offshore wells to protect drillpipe from seawater • BHP – bottom hole pressure (measured in mud weight equivalent (pounds per gallon) or pounds per square inch (psi)

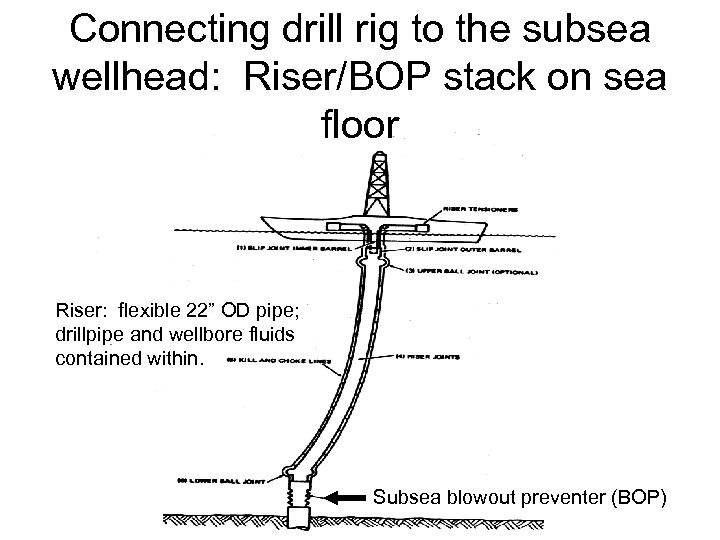

Connecting drill rig to the subsea wellhead: Riser/BOP stack on sea floor Riser: flexible 22” OD pipe; drillpipe and wellbore fluids contained within. Subsea blowout preventer (BOP)

Connecting drill rig to the subsea wellhead: Riser/BOP stack on sea floor Riser: flexible 22” OD pipe; drillpipe and wellbore fluids contained within. Subsea blowout preventer (BOP)

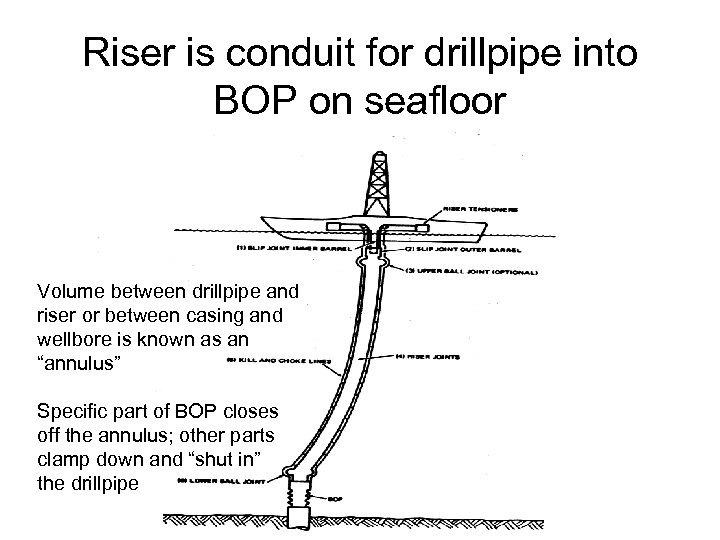

Riser is conduit for drillpipe into BOP on seafloor Volume between drillpipe and riser or between casing and wellbore is known as an “annulus” Specific part of BOP closes off the annulus; other parts clamp down and “shut in” the drillpipe

Riser is conduit for drillpipe into BOP on seafloor Volume between drillpipe and riser or between casing and wellbore is known as an “annulus” Specific part of BOP closes off the annulus; other parts clamp down and “shut in” the drillpipe

Analysis (1): Did the riser fail when the rig sunk? • “The riser did not burst or break. When the rig went down, it took the riser with it. From the schematics I've seen, it pretty much sticks up from the BOP about 1, 500', then is kinked downward to the gulf floor, and a good portion of it lies on or beneath the seabed. “ – independent analysis at www. drillingahead. com

Analysis (1): Did the riser fail when the rig sunk? • “The riser did not burst or break. When the rig went down, it took the riser with it. From the schematics I've seen, it pretty much sticks up from the BOP about 1, 500', then is kinked downward to the gulf floor, and a good portion of it lies on or beneath the seabed. “ – independent analysis at www. drillingahead. com

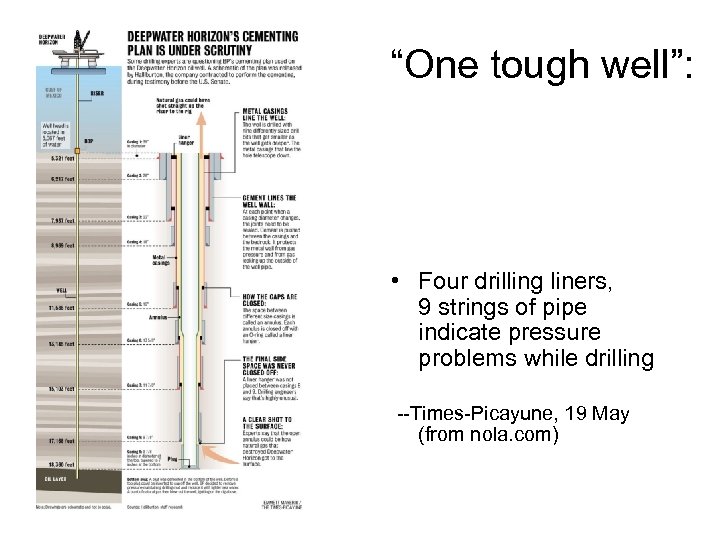

“One tough well”: • Four drilling liners, 9 strings of pipe indicate pressure problems while drilling --Times-Picayune, 19 May (from nola. com)

“One tough well”: • Four drilling liners, 9 strings of pipe indicate pressure problems while drilling --Times-Picayune, 19 May (from nola. com)

Analysis (2): BP’s well plan • “BP's well design had a fatal flaw (ie. long string production casing instead of liner and tieback). This casing design depends upon a 100% effective cement job in order to keep the production out of the annulus behind the production casing right up to the wellhead. ” -- drillingahead. com

Analysis (2): BP’s well plan • “BP's well design had a fatal flaw (ie. long string production casing instead of liner and tieback). This casing design depends upon a 100% effective cement job in order to keep the production out of the annulus behind the production casing right up to the wellhead. ” -- drillingahead. com

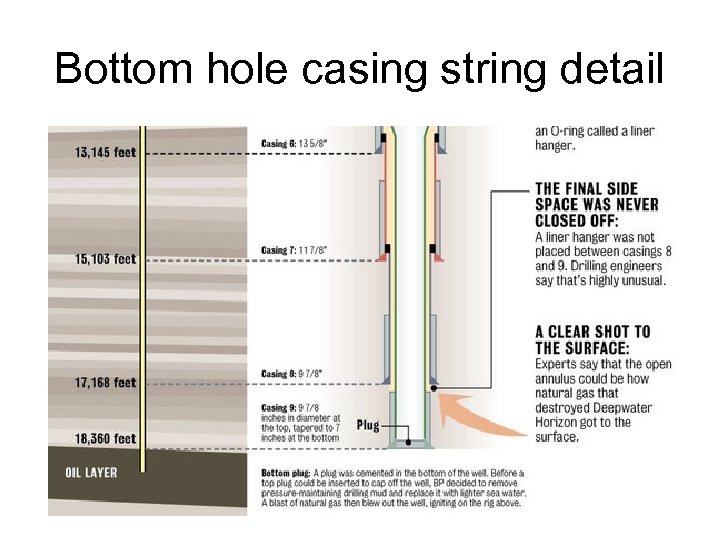

Bottom hole casing string detail

Bottom hole casing string detail

Trans. Ocean CEO testifies to Senate committee, 11 May • "At this point, drilling mud was no longer being used as a means of reservoir pressure containment; the cement and the casing were the barriers controlling pressure from the reservoir, " Newman said. "Indeed, at the time of the explosion, the rig crew, at the direction of the operator, was in the process of displacing drilling mud and replacing it with seawater. "

Trans. Ocean CEO testifies to Senate committee, 11 May • "At this point, drilling mud was no longer being used as a means of reservoir pressure containment; the cement and the casing were the barriers controlling pressure from the reservoir, " Newman said. "Indeed, at the time of the explosion, the rig crew, at the direction of the operator, was in the process of displacing drilling mud and replacing it with seawater. "

Known bottom hole pressure problems • Drilling mud: 14. 5 pounds per gallon (ppg), at total depth equates to 13000 psi at the bottom of the well • Prior to abandonment, cemented casing controls this pressure; drilling mud is displaced from drillpipe with seawater via routine pumping operation. • Seawater at 8. 3 ppg alone is incapable of withstanding that BHP. Any cement or casing failures at this time can cause well to start flowing.

Known bottom hole pressure problems • Drilling mud: 14. 5 pounds per gallon (ppg), at total depth equates to 13000 psi at the bottom of the well • Prior to abandonment, cemented casing controls this pressure; drilling mud is displaced from drillpipe with seawater via routine pumping operation. • Seawater at 8. 3 ppg alone is incapable of withstanding that BHP. Any cement or casing failures at this time can cause well to start flowing.

Trans. Ocean CEO testimony, 11 May • “… the one thing we do know is that on the evening of Apr. 20, there was a sudden, catastrophic failure of the cement, the casing, or both, " Newman said. "Without a failure of one of those elements, the explosion could not have occurred. It is also clear that the drill crew had very little, if any, time to react. The initial indications of trouble and the subsequent explosions were almost instantaneous. " -- Quoted in Oil and Gas Journal, 17 May 2010

Trans. Ocean CEO testimony, 11 May • “… the one thing we do know is that on the evening of Apr. 20, there was a sudden, catastrophic failure of the cement, the casing, or both, " Newman said. "Without a failure of one of those elements, the explosion could not have occurred. It is also clear that the drill crew had very little, if any, time to react. The initial indications of trouble and the subsequent explosions were almost instantaneous. " -- Quoted in Oil and Gas Journal, 17 May 2010

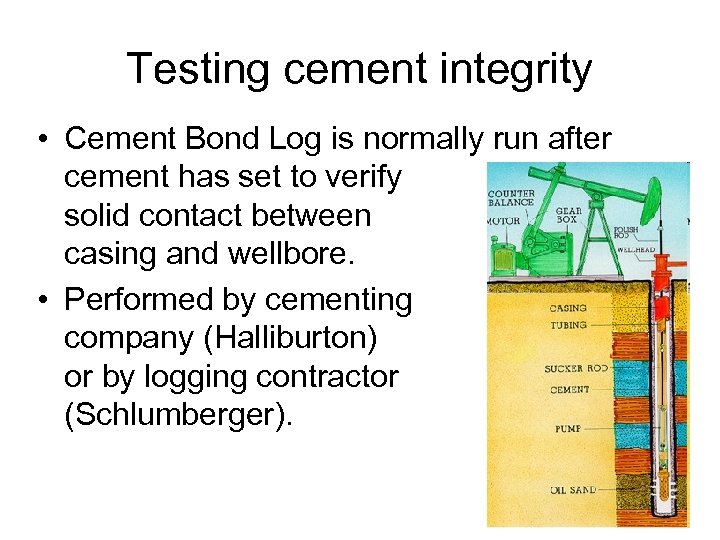

Testing cement integrity • Cement Bond Log is normally run after cement has set to verify solid contact between casing and wellbore. • Performed by cementing company (Halliburton) or by logging contractor (Schlumberger).

Testing cement integrity • Cement Bond Log is normally run after cement has set to verify solid contact between casing and wellbore. • Performed by cementing company (Halliburton) or by logging contractor (Schlumberger).

BP did not run Cement Bond Log… • “BP had a Schlumberger team and equipment for sending acoustic testing lines down the well "on standby" from April 18 to April 20. But BP never asked the Schlumberger crew to perform the acoustic test and sent its members back to Louisiana on a regularly scheduled helicopter flight at 11 a. m. ” -- Times-Picayune, 19 May (Nola. com)

BP did not run Cement Bond Log… • “BP had a Schlumberger team and equipment for sending acoustic testing lines down the well "on standby" from April 18 to April 20. But BP never asked the Schlumberger crew to perform the acoustic test and sent its members back to Louisiana on a regularly scheduled helicopter flight at 11 a. m. ” -- Times-Picayune, 19 May (Nola. com)

… despite known deepwater cementing issues … • Gas flow may occur after a cement job in deepwater environments that contain major hydrate zones. • Destabilization of hydrates after the cement job is confirmed by downhole cameras. • The gas flow could slow down in hours to days if the destabilization is not severe. • However, the consequences could be more severe in worse cases. Presented by Halliburton to AADE, 18 Nov 09

… despite known deepwater cementing issues … • Gas flow may occur after a cement job in deepwater environments that contain major hydrate zones. • Destabilization of hydrates after the cement job is confirmed by downhole cameras. • The gas flow could slow down in hours to days if the destabilization is not severe. • However, the consequences could be more severe in worse cases. Presented by Halliburton to AADE, 18 Nov 09

… in the presence of methane hydrates • Cement slurry should be placed in the entire annulus with no losses • Temperature increase during slurry hydration should not destabilize hydrates • There should be no influx of shallow water or gas into the annulus • The cement slurry should develop strength in the shortest time after placement Conclusion reached by Halliburton: Conditions in deepwater wells are not conducive to achieving all of these objectives simultaneously Presented by Halliburton to AADE, 18 Nov 09

… in the presence of methane hydrates • Cement slurry should be placed in the entire annulus with no losses • Temperature increase during slurry hydration should not destabilize hydrates • There should be no influx of shallow water or gas into the annulus • The cement slurry should develop strength in the shortest time after placement Conclusion reached by Halliburton: Conditions in deepwater wells are not conducive to achieving all of these objectives simultaneously Presented by Halliburton to AADE, 18 Nov 09

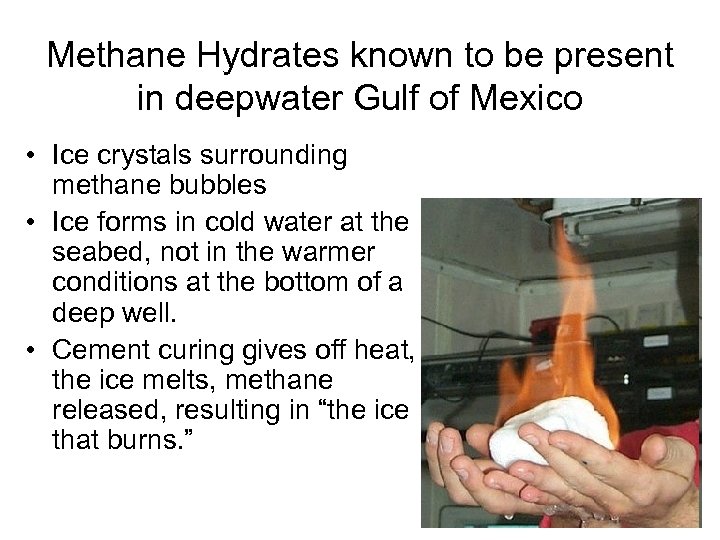

Methane Hydrates known to be present in deepwater Gulf of Mexico • Ice crystals surrounding methane bubbles • Ice forms in cold water at the seabed, not in the warmer conditions at the bottom of a deep well. • Cement curing gives off heat, the ice melts, methane released, resulting in “the ice that burns. ”

Methane Hydrates known to be present in deepwater Gulf of Mexico • Ice crystals surrounding methane bubbles • Ice forms in cold water at the seabed, not in the warmer conditions at the bottom of a deep well. • Cement curing gives off heat, the ice melts, methane released, resulting in “the ice that burns. ”

Analysis (3): Cementing • “This flaw was "enabled" with an equally fatal cement design. The 51 bbl cement job was too small to begin with and was undoubtedly very contaminated by the time it reached the casing shoe, ie. being pumped 18, 360 ft through 3 different sized inside diameters …. Any experienced cement hand would have counseled against it and would have recommended running a liner just to get the cement in place uncontaminated. ” -- drillingahead. com

Analysis (3): Cementing • “This flaw was "enabled" with an equally fatal cement design. The 51 bbl cement job was too small to begin with and was undoubtedly very contaminated by the time it reached the casing shoe, ie. being pumped 18, 360 ft through 3 different sized inside diameters …. Any experienced cement hand would have counseled against it and would have recommended running a liner just to get the cement in place uncontaminated. ” -- drillingahead. com

Damages during prior operations? • At the top of each liner, a rubber packer is installed to seal the joint with the liner above. • Mike Williams … claimed that the blowout preventer was then damaged when a crewman accidentally moved a joystick, applying hundreds of thousands of pounds of force [? ]. Pieces of rubber were found in the drilling fluid, which he said implied damage to a crucial seal. But a supervisor declared the find to be “not a big deal”, Mr Williams alleged. --http: //www. timesonline. co. uk/tol/news/world/us_and_americas/ article 7128842. ece

Damages during prior operations? • At the top of each liner, a rubber packer is installed to seal the joint with the liner above. • Mike Williams … claimed that the blowout preventer was then damaged when a crewman accidentally moved a joystick, applying hundreds of thousands of pounds of force [? ]. Pieces of rubber were found in the drilling fluid, which he said implied damage to a crucial seal. But a supervisor declared the find to be “not a big deal”, Mr Williams alleged. --http: //www. timesonline. co. uk/tol/news/world/us_and_americas/ article 7128842. ece

Analysis (4): What were the exact order of procedures? • “monitoring the volumes and rates that fluids are pumped and returned from a well is the number one cardinal rule to maintaining constant BHP and control of the well. ” • “Probably … taking the well returns to the rig and pumping them to the workboat at the same time made it difficult to measure and track the returns rate. ” • “If the fluid was going to the boat from the same tank it was being received from the well - it would be very difficult to determine pit gain or loss with any degree of accuracy. ”

Analysis (4): What were the exact order of procedures? • “monitoring the volumes and rates that fluids are pumped and returned from a well is the number one cardinal rule to maintaining constant BHP and control of the well. ” • “Probably … taking the well returns to the rig and pumping them to the workboat at the same time made it difficult to measure and track the returns rate. ” • “If the fluid was going to the boat from the same tank it was being received from the well - it would be very difficult to determine pit gain or loss with any degree of accuracy. ”

Analysis (5) “Nature always finds the hidden flaw” • “it may be true that BP had the misfortune to have two bad things happen - bad primary cement job (ask here how long they [waited for cement to cure]? ), and to also have the wellhead seals fail (ask here why displace the well to seawater until the cement plug is hard and why was the riser open during the displacement? )” -- drillingahead. com

Analysis (5) “Nature always finds the hidden flaw” • “it may be true that BP had the misfortune to have two bad things happen - bad primary cement job (ask here how long they [waited for cement to cure]? ), and to also have the wellhead seals fail (ask here why displace the well to seawater until the cement plug is hard and why was the riser open during the displacement? )” -- drillingahead. com

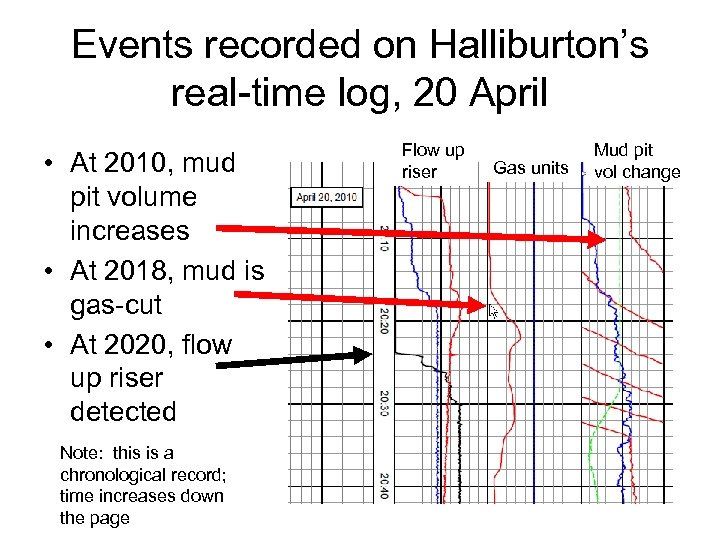

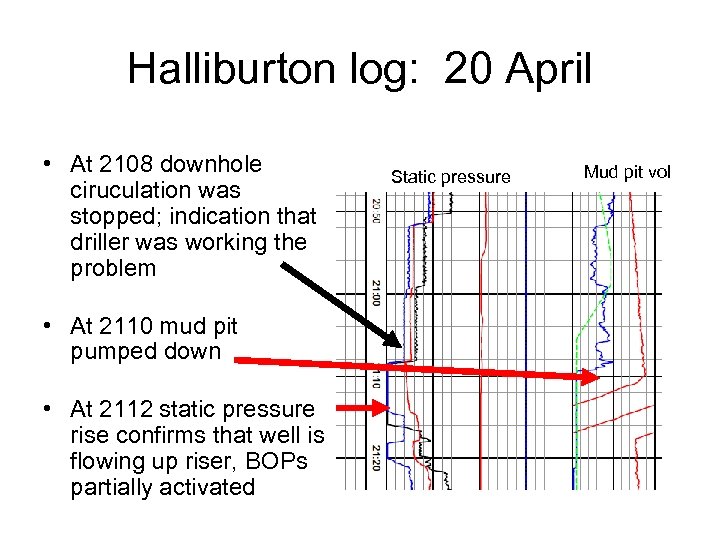

Events recorded on Halliburton’s real-time log, 20 April • At 2010, mud pit volume increases • At 2018, mud is gas-cut • At 2020, flow up riser detected Note: this is a chronological record; time increases down the page Flow up riser Gas units Mud pit vol change

Events recorded on Halliburton’s real-time log, 20 April • At 2010, mud pit volume increases • At 2018, mud is gas-cut • At 2020, flow up riser detected Note: this is a chronological record; time increases down the page Flow up riser Gas units Mud pit vol change

Halliburton log: 20 April • At 2108 downhole ciruculation was stopped; indication that driller was working the problem • At 2110 mud pit pumped down • At 2112 static pressure rise confirms that well is flowing up riser, BOPs partially activated Static pressure Mud pit vol

Halliburton log: 20 April • At 2108 downhole ciruculation was stopped; indication that driller was working the problem • At 2110 mud pit pumped down • At 2112 static pressure rise confirms that well is flowing up riser, BOPs partially activated Static pressure Mud pit vol

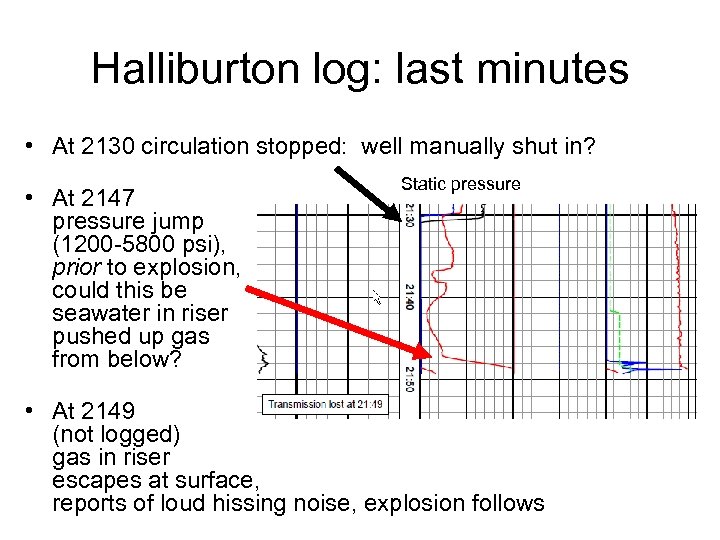

Halliburton log: last minutes • At 2130 circulation stopped: well manually shut in? • At 2147 pressure jump (1200 -5800 psi), prior to explosion, could this be seawater in riser pushed up gas from below? Static pressure • At 2149 (not logged) gas in riser escapes at surface, reports of loud hissing noise, explosion follows

Halliburton log: last minutes • At 2130 circulation stopped: well manually shut in? • At 2147 pressure jump (1200 -5800 psi), prior to explosion, could this be seawater in riser pushed up gas from below? Static pressure • At 2149 (not logged) gas in riser escapes at surface, reports of loud hissing noise, explosion follows

Analysis (6): well control procedure • “With a gas & oil influx rising in the annulus increasing the pressure in the annulus - BP further lightened the weight of the casing string by displacing with seawater - the entire production became buoyant and lifted allowing the seals to become unseated which allowed the gas & oil into the BOP's and riser. ” --drillingahead. com

Analysis (6): well control procedure • “With a gas & oil influx rising in the annulus increasing the pressure in the annulus - BP further lightened the weight of the casing string by displacing with seawater - the entire production became buoyant and lifted allowing the seals to become unseated which allowed the gas & oil into the BOP's and riser. ” --drillingahead. com

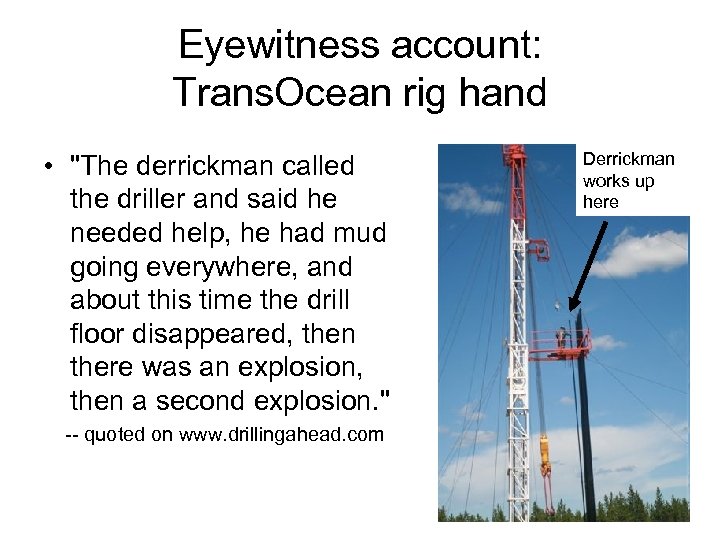

Eyewitness account: Trans. Ocean rig hand • "The derrickman called the driller and said he needed help, he had mud going everywhere, and about this time the drill floor disappeared, then there was an explosion, then a second explosion. " -- quoted on www. drillingahead. com Derrickman works up here

Eyewitness account: Trans. Ocean rig hand • "The derrickman called the driller and said he needed help, he had mud going everywhere, and about this time the drill floor disappeared, then there was an explosion, then a second explosion. " -- quoted on www. drillingahead. com Derrickman works up here

Captain of the nearby workboat Damon Bankston • Shortly after 9 p. m. CDT, "my mate advised there was mud coming off the rig. It looked like it was a black rain coming down, " Landry said. • Landry said he heard something else that concerned him: the loud hiss of a high-pressure release of air and gas that lasted for 30 seconds or more. … this was the sound of a surge of methane rushing up the drill pipe which engulfed the rig's deck in highly-flammable gas. --- money. cnn. com, 11 May

Captain of the nearby workboat Damon Bankston • Shortly after 9 p. m. CDT, "my mate advised there was mud coming off the rig. It looked like it was a black rain coming down, " Landry said. • Landry said he heard something else that concerned him: the loud hiss of a high-pressure release of air and gas that lasted for 30 seconds or more. … this was the sound of a surge of methane rushing up the drill pipe which engulfed the rig's deck in highly-flammable gas. --- money. cnn. com, 11 May

Captain of the Damon Bankston • The rig's captain, Curt Kuchta, said his crew had slammed a "kill switch" on the drill deck meant to activate an underwater blowout preventer that is designed as a failsafe method of shutting off the well. • "He said they pressed the kill switch, " Landry said. "They didn't know if it worked. " Driller’s control panel on modern rig

Captain of the Damon Bankston • The rig's captain, Curt Kuchta, said his crew had slammed a "kill switch" on the drill deck meant to activate an underwater blowout preventer that is designed as a failsafe method of shutting off the well. • "He said they pressed the kill switch, " Landry said. "They didn't know if it worked. " Driller’s control panel on modern rig

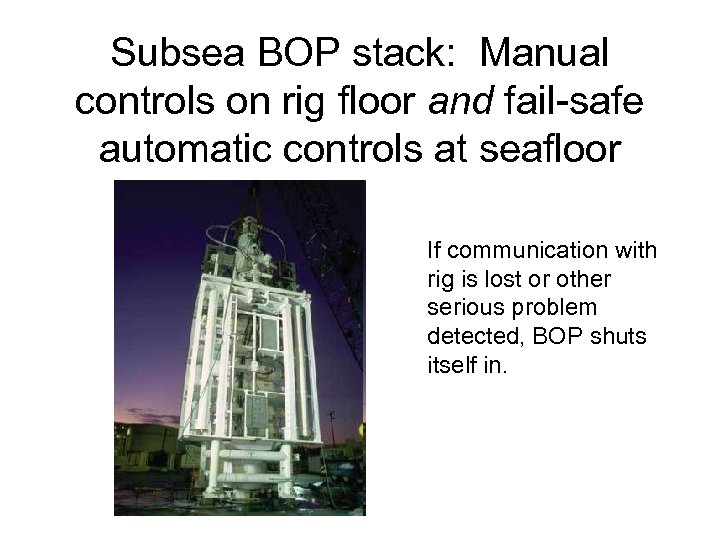

Subsea BOP stack: Manual controls on rig floor and fail-safe automatic controls at seafloor If communication with rig is lost or other serious problem detected, BOP shuts itself in.

Subsea BOP stack: Manual controls on rig floor and fail-safe automatic controls at seafloor If communication with rig is lost or other serious problem detected, BOP shuts itself in.

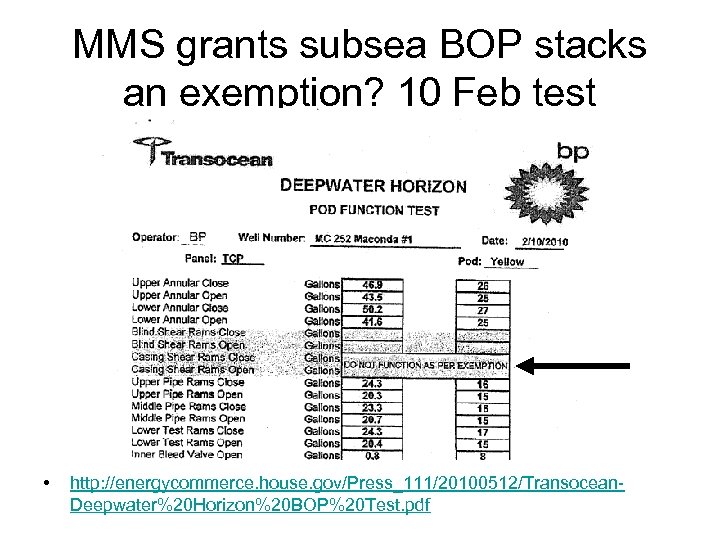

MMS grants subsea BOP stacks an exemption? 10 Feb test • http: //energycommerce. house. gov/Press_111/20100512/Transocean. Deepwater%20 Horizon%20 BOP%20 Test. pdf

MMS grants subsea BOP stacks an exemption? 10 Feb test • http: //energycommerce. house. gov/Press_111/20100512/Transocean. Deepwater%20 Horizon%20 BOP%20 Test. pdf

No backup needed for the automatic kill system? • In 2003, U. S. regulators decided remotecontrolled safeguards needed more study. A report commissioned by the MMS said "acoustic systems are not recommended because they tend to be very costly. " (WSJ, 28 April) … it decided the remote device wasn't needed because rigs had other back-up plans to cut off a well. " (WSJ)

No backup needed for the automatic kill system? • In 2003, U. S. regulators decided remotecontrolled safeguards needed more study. A report commissioned by the MMS said "acoustic systems are not recommended because they tend to be very costly. " (WSJ, 28 April) … it decided the remote device wasn't needed because rigs had other back-up plans to cut off a well. " (WSJ)

Trans. Ocean studied prior BOP failures • “Floating drilling rig downtime due to poor BOP reliability is a common and very costly issue confronting all offshore drilling contractors. . Depending on the drilling contract in place and the nature of the downtime cause, BOP failure can result in substantial revenue loss” -- http: //media. mcclatchydc. com/static/pdf/Les-oilspill-ABSC. pdf

Trans. Ocean studied prior BOP failures • “Floating drilling rig downtime due to poor BOP reliability is a common and very costly issue confronting all offshore drilling contractors. . Depending on the drilling contract in place and the nature of the downtime cause, BOP failure can result in substantial revenue loss” -- http: //media. mcclatchydc. com/static/pdf/Les-oilspill-ABSC. pdf

BOP Problems Continue • “A 2008 paper co-authored by Jeff S. Shepard, ” [a Trans. Ocean manager], "cautioned that "BOP shear rams may also have difficulty shearing today's highstrength, high-toughness drill-pipe” --http: //www. courthousenews. com/2010/05/14/27286. htm

BOP Problems Continue • “A 2008 paper co-authored by Jeff S. Shepard, ” [a Trans. Ocean manager], "cautioned that "BOP shear rams may also have difficulty shearing today's highstrength, high-toughness drill-pipe” --http: //www. courthousenews. com/2010/05/14/27286. htm

BOP problems addressed by UNOCAL moving this equipment to the surface (SBOP) • In a study … 7, 200 subsea BOP days were considered in water depths greater than 1, 312 ft. … 31 BOP failures occurred that had the potential for uncontrolled flow. This translates to 4. 1 incidents per 1, 000 BOP days. • In comparison, Unocal has recorded four incidents that had the potential for uncontrolled flow over 1, 360 SBOP days. This yields 2. 9 incidents per 1, 000 SBOPdays. -- http: //www. iadc. org/dcpi/dc-julyaug 03/July 3 -surface%20 BOP. pdf

BOP problems addressed by UNOCAL moving this equipment to the surface (SBOP) • In a study … 7, 200 subsea BOP days were considered in water depths greater than 1, 312 ft. … 31 BOP failures occurred that had the potential for uncontrolled flow. This translates to 4. 1 incidents per 1, 000 BOP days. • In comparison, Unocal has recorded four incidents that had the potential for uncontrolled flow over 1, 360 SBOP days. This yields 2. 9 incidents per 1, 000 SBOPdays. -- http: //www. iadc. org/dcpi/dc-julyaug 03/July 3 -surface%20 BOP. pdf

![No question that the BOP failed • “oil was flowing into the [BOP] at No question that the BOP failed • “oil was flowing into the [BOP] at](https://present5.com/presentation/c807107b495433b80f321c0cee6dab30/image-48.jpg) No question that the BOP failed • “oil was flowing into the [BOP] at 8, 000 to 9, 000 psi and flowing out into the Gulf at around 2, 650 psi. ” http: //blog. al. com/live/2010/05/national_incident_commander_oi_1. h tml

No question that the BOP failed • “oil was flowing into the [BOP] at 8, 000 to 9, 000 psi and flowing out into the Gulf at around 2, 650 psi. ” http: //blog. al. com/live/2010/05/national_incident_commander_oi_1. h tml

Conclusion: The Trans. Ocean driller did his job to the end, knowing he was in imminent grave danger. If the activated BOP worked as designed at this point, the fire could still have taken the rig with the losses, but the well’s subsequent flow (and resulting massive oil spill) would have stopped.

Conclusion: The Trans. Ocean driller did his job to the end, knowing he was in imminent grave danger. If the activated BOP worked as designed at this point, the fire could still have taken the rig with the losses, but the well’s subsequent flow (and resulting massive oil spill) would have stopped.

Analysis (7): BOP failure and failure to react • “When the blind/shear rams were closed - they couldn't quite cut cleanly through the production casing and the 3 -1/2" tubing. ” • “Basic well control procedures were overlooked (ie. we are now in a cased hole situation - what could possibly happen? ), and the rapidly expanding gas resulting in classic kick signs of rapid increase in returns rate and pit gains - were not recognized and acted upon. ” -- drillingahead. com

Analysis (7): BOP failure and failure to react • “When the blind/shear rams were closed - they couldn't quite cut cleanly through the production casing and the 3 -1/2" tubing. ” • “Basic well control procedures were overlooked (ie. we are now in a cased hole situation - what could possibly happen? ), and the rapidly expanding gas resulting in classic kick signs of rapid increase in returns rate and pit gains - were not recognized and acted upon. ” -- drillingahead. com

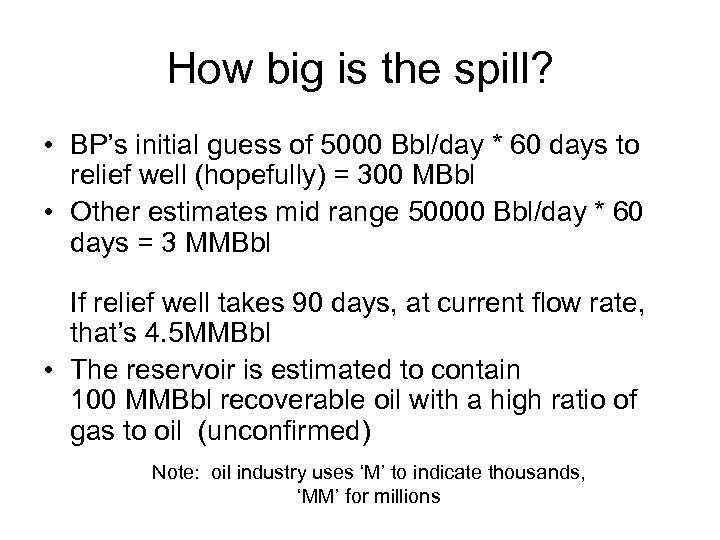

How big is the spill? • BP’s initial guess of 5000 Bbl/day * 60 days to relief well (hopefully) = 300 MBbl • Other estimates mid range 50000 Bbl/day * 60 days = 3 MMBbl If relief well takes 90 days, at current flow rate, that’s 4. 5 MMBbl • The reservoir is estimated to contain 100 MMBbl recoverable oil with a high ratio of gas to oil (unconfirmed) Note: oil industry uses ‘M’ to indicate thousands, ‘MM’ for millions

How big is the spill? • BP’s initial guess of 5000 Bbl/day * 60 days to relief well (hopefully) = 300 MBbl • Other estimates mid range 50000 Bbl/day * 60 days = 3 MMBbl If relief well takes 90 days, at current flow rate, that’s 4. 5 MMBbl • The reservoir is estimated to contain 100 MMBbl recoverable oil with a high ratio of gas to oil (unconfirmed) Note: oil industry uses ‘M’ to indicate thousands, ‘MM’ for millions

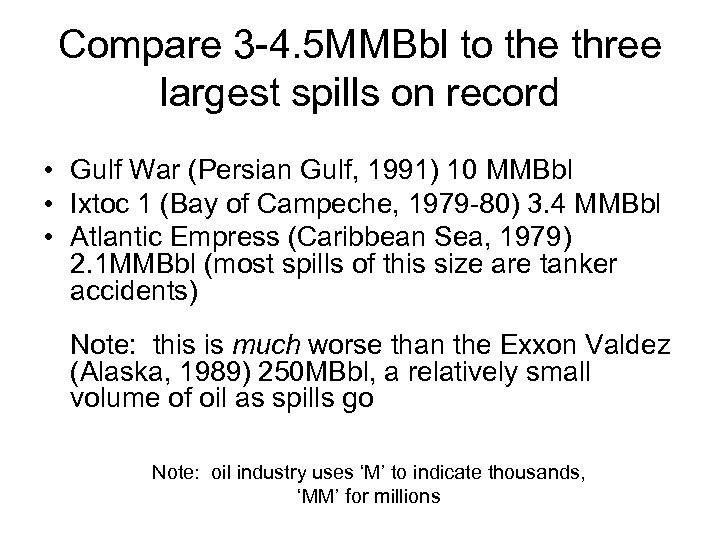

Compare 3 -4. 5 MMBbl to the three largest spills on record • Gulf War (Persian Gulf, 1991) 10 MMBbl • Ixtoc 1 (Bay of Campeche, 1979 -80) 3. 4 MMBbl • Atlantic Empress (Caribbean Sea, 1979) 2. 1 MMBbl (most spills of this size are tanker accidents) Note: this is much worse than the Exxon Valdez (Alaska, 1989) 250 MBbl, a relatively small volume of oil as spills go Note: oil industry uses ‘M’ to indicate thousands, ‘MM’ for millions

Compare 3 -4. 5 MMBbl to the three largest spills on record • Gulf War (Persian Gulf, 1991) 10 MMBbl • Ixtoc 1 (Bay of Campeche, 1979 -80) 3. 4 MMBbl • Atlantic Empress (Caribbean Sea, 1979) 2. 1 MMBbl (most spills of this size are tanker accidents) Note: this is much worse than the Exxon Valdez (Alaska, 1989) 250 MBbl, a relatively small volume of oil as spills go Note: oil industry uses ‘M’ to indicate thousands, ‘MM’ for millions

Beware: there’s lots of overstatement going on! • Brian Williams, 5/25: “this well could give off oil, unfettered, for the rest of our lives” • NO offshore oil field has EVER produced that much or flowed for that long. • Most blowouts that are left uncontrolled eventually die on their own: High flow rates damage the oil reservoir.

Beware: there’s lots of overstatement going on! • Brian Williams, 5/25: “this well could give off oil, unfettered, for the rest of our lives” • NO offshore oil field has EVER produced that much or flowed for that long. • Most blowouts that are left uncontrolled eventually die on their own: High flow rates damage the oil reservoir.

What didn’t happen • North Korean torpedo attack • Secret conspiracy between BP and government to thwart offshore drilling • Secret government weapons test

What didn’t happen • North Korean torpedo attack • Secret conspiracy between BP and government to thwart offshore drilling • Secret government weapons test

What can’t happen • Use explosives to blow it up – just makes a small hole much bigger • Use a nuclear weapon – this isn’t a movie • Use a submarine – at 5000’ water depth? • Government take over operations – neither DOE nor MMS have drilling expertise • “Mother of all gushers could kill Earth’s oceans” – check those volume comparisons again!

What can’t happen • Use explosives to blow it up – just makes a small hole much bigger • Use a nuclear weapon – this isn’t a movie • Use a submarine – at 5000’ water depth? • Government take over operations – neither DOE nor MMS have drilling expertise • “Mother of all gushers could kill Earth’s oceans” – check those volume comparisons again!

Additional information • One easy-to-read explanation of offshore oil exploration and drilling; another and yet another • Live video feed from seafloor • Video of rig fire and sinking • Official response site • EPA spill site • NOAA spill science • List of over 200 deepwater (>1000’) oil and gas discoveries in the Gulf of Mexico

Additional information • One easy-to-read explanation of offshore oil exploration and drilling; another and yet another • Live video feed from seafloor • Video of rig fire and sinking • Official response site • EPA spill site • NOAA spill science • List of over 200 deepwater (>1000’) oil and gas discoveries in the Gulf of Mexico