2fa414dbd10d8a2a70ac6a8ca72d313e.ppt

- Количество слайдов: 89

THE SAFE AND ECONOMIC STRUCTURAL HEALTH MANAGEMENT OF AIRTANKER AND LEAD AIRCRAFT INVOLVED IN FIREBOMBING OPERATIONS Presentation at 7 th Annual Wildland Fire Safety Summit, Toronto, Ontario, Canada 19 th July, 2003 Steve Hall (Celeris Aerospace Canada Inc. ) Dick Perry (Sandia National Laboratory) Joe Braun (Systems and Electronics Inc. ) SEI Systems & Electronics, Inc. 1

THE SAFE AND ECONOMIC STRUCTURAL HEALTH MANAGEMENT OF AIRTANKER AND LEAD AIRCRAFT INVOLVED IN FIREBOMBING OPERATIONS Presentation at 7 th Annual Wildland Fire Safety Summit, Toronto, Ontario, Canada 19 th July, 2003 Steve Hall (Celeris Aerospace Canada Inc. ) Dick Perry (Sandia National Laboratory) Joe Braun (Systems and Electronics Inc. ) SEI Systems & Electronics, Inc. 1

OVERVIEW ¿ Reasons for Structural Concerns Related to Aircraft Operating in the Firebombing Role l ¿ Addressing the Structural Concerns l l ¿ Potential causes of structural problems Rationale behind the procedures and processes that need to be implemented with particular reference to fatigue and damage tolerance Understanding the loads imposed on firebombing aircraft Structural Health Management of Aircraft Involved in the Firebombing Role l Short and longer term issues related to the safe and economic use of these aircraft ¡ Inspection, Maintenance and the Bottom Line ¿ ¿ ¿ Accumulating Knowledge Pending Activities Conclusions and Recommendations SEI Systems & Electronics, Inc. 2

OVERVIEW ¿ Reasons for Structural Concerns Related to Aircraft Operating in the Firebombing Role l ¿ Addressing the Structural Concerns l l ¿ Potential causes of structural problems Rationale behind the procedures and processes that need to be implemented with particular reference to fatigue and damage tolerance Understanding the loads imposed on firebombing aircraft Structural Health Management of Aircraft Involved in the Firebombing Role l Short and longer term issues related to the safe and economic use of these aircraft ¡ Inspection, Maintenance and the Bottom Line ¿ ¿ ¿ Accumulating Knowledge Pending Activities Conclusions and Recommendations SEI Systems & Electronics, Inc. 2

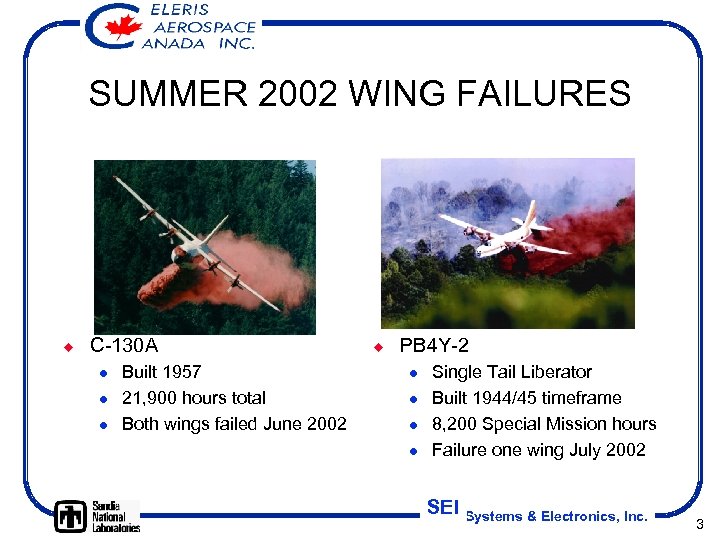

SUMMER 2002 WING FAILURES ¿ C-130 A l l l Built 1957 21, 900 hours total Both wings failed June 2002 ¿ PB 4 Y-2 l l Single Tail Liberator Built 1944/45 timeframe 8, 200 Special Mission hours Failure one wing July 2002 SEI Systems & Electronics, Inc. 3

SUMMER 2002 WING FAILURES ¿ C-130 A l l l Built 1957 21, 900 hours total Both wings failed June 2002 ¿ PB 4 Y-2 l l Single Tail Liberator Built 1944/45 timeframe 8, 200 Special Mission hours Failure one wing July 2002 SEI Systems & Electronics, Inc. 3

REASONS FOR CONCERN ¿ ¿ Resulted in the formation of the Blue Ribbon Commission by the USDA/FS and BLM which reported in December 2002 Number of recommendations/observations including l l Many of the aircraft involved in the firebombing role were not designed for this role Loads to which they have been subjected are largely unknown as is their current structural health status There is a need to harmonize the inspection and maintenance of firebombing aircraft with modern day certification approaches such as fatigue and damage tolerance Approach to funding, contracts and the ongoing and modernization of the fleet needs to be reviewed SEI Systems & Electronics, Inc. 4

REASONS FOR CONCERN ¿ ¿ Resulted in the formation of the Blue Ribbon Commission by the USDA/FS and BLM which reported in December 2002 Number of recommendations/observations including l l Many of the aircraft involved in the firebombing role were not designed for this role Loads to which they have been subjected are largely unknown as is their current structural health status There is a need to harmonize the inspection and maintenance of firebombing aircraft with modern day certification approaches such as fatigue and damage tolerance Approach to funding, contracts and the ongoing and modernization of the fleet needs to be reviewed SEI Systems & Electronics, Inc. 4

ADVERSE OPERATIONAL IMPLICATIONS ¿ C-130 A and PB 4 Y-2 Fleets immediately grounded l ¿ Major concerns about USDA/FS Beech Baron Lead Aircraft l ¿ ¿ ¿ Loss of approx 10 -12 Heavy Tankers Immediate need for replacement? Forest Service note that contracts will not be awarded to C-130 A and PB 4 Y-2 aircraft Heavy airtankers operating with a 15% reduction in payload for the 2003 fire season Unanticipated expenses associated with additional inspection and maintenance actions l Delayed contract award and operational availability SEI Systems & Electronics, Inc. 5

ADVERSE OPERATIONAL IMPLICATIONS ¿ C-130 A and PB 4 Y-2 Fleets immediately grounded l ¿ Major concerns about USDA/FS Beech Baron Lead Aircraft l ¿ ¿ ¿ Loss of approx 10 -12 Heavy Tankers Immediate need for replacement? Forest Service note that contracts will not be awarded to C-130 A and PB 4 Y-2 aircraft Heavy airtankers operating with a 15% reduction in payload for the 2003 fire season Unanticipated expenses associated with additional inspection and maintenance actions l Delayed contract award and operational availability SEI Systems & Electronics, Inc. 5

OVERVIEW OF FIREBOMBING AIRCRAFT CONFIGURATIONS AND OPERATIONS SEI Systems & Electronics, Inc. 6

OVERVIEW OF FIREBOMBING AIRCRAFT CONFIGURATIONS AND OPERATIONS SEI Systems & Electronics, Inc. 6

FIREBOMBING AIRCRAFT ¿ Heavy Air Tankers l l ¿ 2, 200 – 3, 000 gallons and above Translates to approximately 22, 000 to 30, 000 lbs retardant Air Tankers l l 800 – 1, 200 gallons Translates to approximately 8, 000 to 12, 000 lbs SEI Systems & Electronics, Inc. 7

FIREBOMBING AIRCRAFT ¿ Heavy Air Tankers l l ¿ 2, 200 – 3, 000 gallons and above Translates to approximately 22, 000 to 30, 000 lbs retardant Air Tankers l l 800 – 1, 200 gallons Translates to approximately 8, 000 to 12, 000 lbs SEI Systems & Electronics, Inc. 7

FIREBOMBING AIRCRAFT (cont) ¿ Lead Aircraft l l l ¿ Initial Survey of Fire for Escape Routes Guide Heavy Tankers in over fire Ensure Fire Prevention Officer has view of drop Spend far more time over the fire than do the air tankers SEI Systems & Electronics, Inc. 8

FIREBOMBING AIRCRAFT (cont) ¿ Lead Aircraft l l l ¿ Initial Survey of Fire for Escape Routes Guide Heavy Tankers in over fire Ensure Fire Prevention Officer has view of drop Spend far more time over the fire than do the air tankers SEI Systems & Electronics, Inc. 8

AIR TANKER CONFIGURATION Internal Tank External Tank Scoop SEI Systems & Electronics, Inc. 9

AIR TANKER CONFIGURATION Internal Tank External Tank Scoop SEI Systems & Electronics, Inc. 9

TYPES OF TANK ¿ Constant Flow l l l One pair doors Computer controlled Aperture changes to ensure constant flow ¡ Consistent “Coverage Level” ¿ Sequenced Doors l l l Two, four, eight or more Door sequence automatically selected Release percentage of load that is proportional to the number of doors ¡ Coverage Level not as consistent SEI Systems & Electronics, Inc. 10

TYPES OF TANK ¿ Constant Flow l l l One pair doors Computer controlled Aperture changes to ensure constant flow ¡ Consistent “Coverage Level” ¿ Sequenced Doors l l l Two, four, eight or more Door sequence automatically selected Release percentage of load that is proportional to the number of doors ¡ Coverage Level not as consistent SEI Systems & Electronics, Inc. 10

TYPES OF LOAD ¿ Retardant or Foam l l ¿ Pre-mixed or mixed on board Drop as a barrier to the fire Water l Dropping on the fire SEI Systems & Electronics, Inc. 11

TYPES OF LOAD ¿ Retardant or Foam l l ¿ Pre-mixed or mixed on board Drop as a barrier to the fire Water l Dropping on the fire SEI Systems & Electronics, Inc. 11

OPERATIONAL PROFILE AIR TANKERS ¿ Transit to fire l l Depends on distance, if relatively close often below 2000 ft AGL Holding pattern around the fire ¡ Generally around 1, 000 ft to 1, 500 ft around the fire l Drop Zone ¡ 150 ft AGL (or 150 ft parallel to terrain in mountainous drops) ¡ Airspeed around 110 – 120 knots u Flap often required (typically 50%, occasionally 100%) u Want available power when retracted ¡ Load, usually dropped in 50% increments, occasionally 100% l Drop Time ¡ Of the order of 4 -10 seconds depending on coverage level SEI Systems & Electronics, Inc. 12

OPERATIONAL PROFILE AIR TANKERS ¿ Transit to fire l l Depends on distance, if relatively close often below 2000 ft AGL Holding pattern around the fire ¡ Generally around 1, 000 ft to 1, 500 ft around the fire l Drop Zone ¡ 150 ft AGL (or 150 ft parallel to terrain in mountainous drops) ¡ Airspeed around 110 – 120 knots u Flap often required (typically 50%, occasionally 100%) u Want available power when retracted ¡ Load, usually dropped in 50% increments, occasionally 100% l Drop Time ¡ Of the order of 4 -10 seconds depending on coverage level SEI Systems & Electronics, Inc. 12

Potential Causes of Structural Problems SEI Systems & Electronics, Inc. 13

Potential Causes of Structural Problems SEI Systems & Electronics, Inc. 13

SPECIAL MISSION AIRCRAFT ¿ Aircraft that is operating in a role for which was not envisaged during its design l l l ¿ Low-level Roles Majority tend to operate in Low-level roles l l l ¿ Firebombing Aircraft ILS/VOR Calibration Pipeline/Geological Survey Crop-Spraying Atmospheric Research (Hurricane Hunters) Low-level consistent use below 2, 500 ft AGL High-Level Role Turbulent environment aircraft subject to an increased gust frequency Some roles involve increased manoeuvre spectrum for terrain avoidance Note that even when an aircraft has been designed for the environment, care is required regarding the source of the design loads l Lots of data for low-level data is transit data and is not usually representative of consistent low-level operation SEI Systems & Electronics, Inc. 14

SPECIAL MISSION AIRCRAFT ¿ Aircraft that is operating in a role for which was not envisaged during its design l l l ¿ Low-level Roles Majority tend to operate in Low-level roles l l l ¿ Firebombing Aircraft ILS/VOR Calibration Pipeline/Geological Survey Crop-Spraying Atmospheric Research (Hurricane Hunters) Low-level consistent use below 2, 500 ft AGL High-Level Role Turbulent environment aircraft subject to an increased gust frequency Some roles involve increased manoeuvre spectrum for terrain avoidance Note that even when an aircraft has been designed for the environment, care is required regarding the source of the design loads l Lots of data for low-level data is transit data and is not usually representative of consistent low-level operation SEI Systems & Electronics, Inc. 14

WHAT DO WE KNOW ABOUT SPECIAL MISSION SPECTRUM? ¿ Generally very little l Limited number of health monitoring programs completed to define the loads ¡ NRCC/IAR Circa Mid 1970’s - 1988 ¡ Limited NASA Work (Reliability Issue) ¡ FAA Collecting Low-level data, yet to be collated ¿ However, from the limited data available some initial trends have been identified which indicate an urgent need for further work SEI Systems & Electronics, Inc. 15

WHAT DO WE KNOW ABOUT SPECIAL MISSION SPECTRUM? ¿ Generally very little l Limited number of health monitoring programs completed to define the loads ¡ NRCC/IAR Circa Mid 1970’s - 1988 ¡ Limited NASA Work (Reliability Issue) ¡ FAA Collecting Low-level data, yet to be collated ¿ However, from the limited data available some initial trends have been identified which indicate an urgent need for further work SEI Systems & Electronics, Inc. 15

LOADING MECHANISMS ¿ Two mechanisms that have to be considered l High Load Exceedance or Overstressing the aircraft ¡ Over-g of the aircraft ¡ High Load at High Weight Concerns ¿ Long-term impact of cyclic loading l Fatigue and Damage Tolerance ¡ Repetitions of cyclic loading and its accumulated impact ¿ A major focus of past analyses of special mission aircraft has been the high load exceedance aspects l l Part of the picture and something of which we have to be constantly vigilant However, it is by no means the full picture, nor the major reason for the structural failures that have occurred SEI Systems & Electronics, Inc. 16

LOADING MECHANISMS ¿ Two mechanisms that have to be considered l High Load Exceedance or Overstressing the aircraft ¡ Over-g of the aircraft ¡ High Load at High Weight Concerns ¿ Long-term impact of cyclic loading l Fatigue and Damage Tolerance ¡ Repetitions of cyclic loading and its accumulated impact ¿ A major focus of past analyses of special mission aircraft has been the high load exceedance aspects l l Part of the picture and something of which we have to be constantly vigilant However, it is by no means the full picture, nor the major reason for the structural failures that have occurred SEI Systems & Electronics, Inc. 16

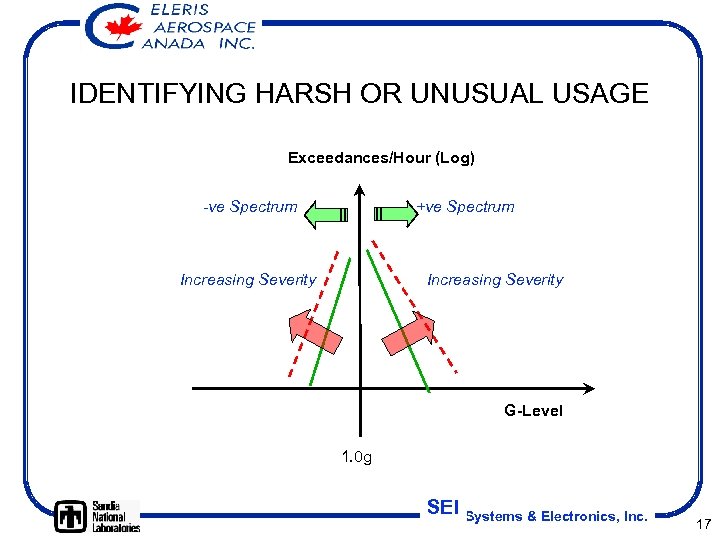

IDENTIFYING HARSH OR UNUSUAL USAGE Exceedances/Hour (Log) -ve Spectrum +ve Spectrum Increasing Severity G-Level 1. 0 g SEI Systems & Electronics, Inc. 17

IDENTIFYING HARSH OR UNUSUAL USAGE Exceedances/Hour (Log) -ve Spectrum +ve Spectrum Increasing Severity G-Level 1. 0 g SEI Systems & Electronics, Inc. 17

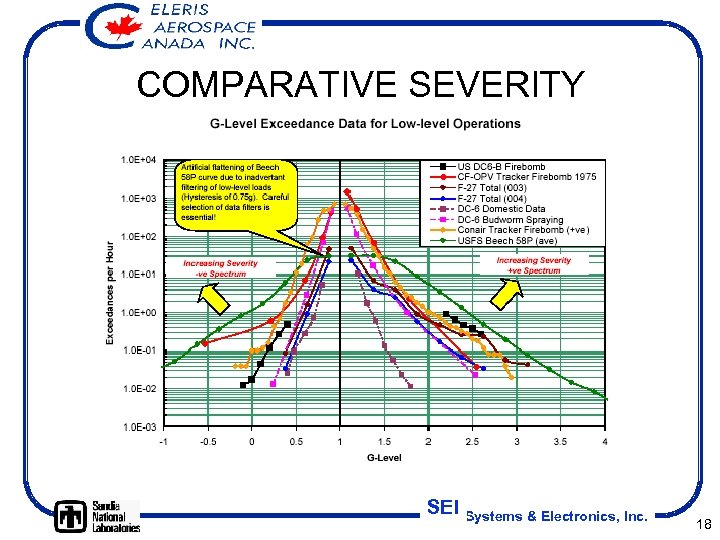

COMPARATIVE SEVERITY SEI Systems & Electronics, Inc. 18

COMPARATIVE SEVERITY SEI Systems & Electronics, Inc. 18

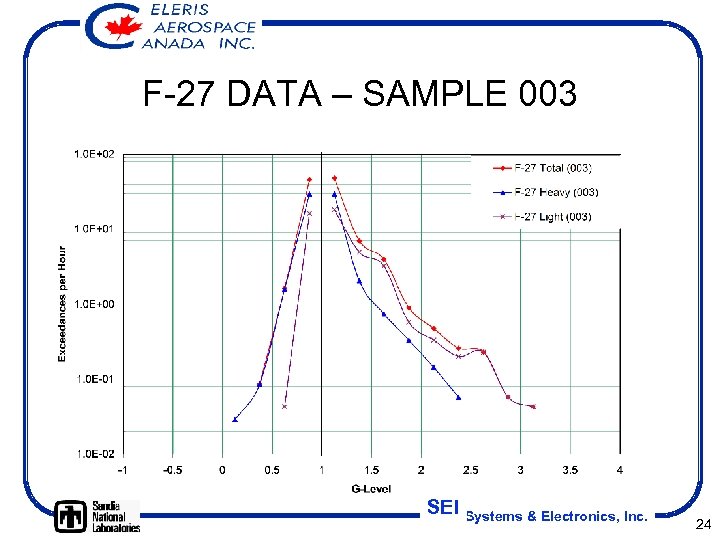

F-27 DATA – SAMPLE 003 SEI Systems & Electronics, Inc. 24

F-27 DATA – SAMPLE 003 SEI Systems & Electronics, Inc. 24

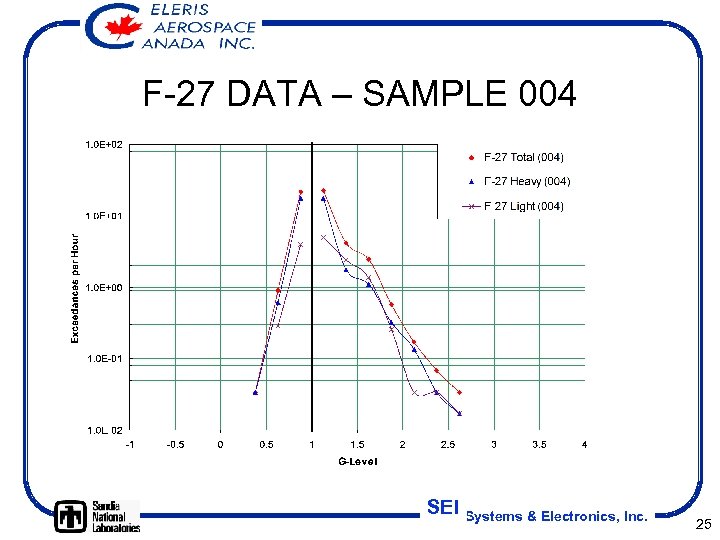

F-27 DATA – SAMPLE 004 SEI Systems & Electronics, Inc. 25

F-27 DATA – SAMPLE 004 SEI Systems & Electronics, Inc. 25

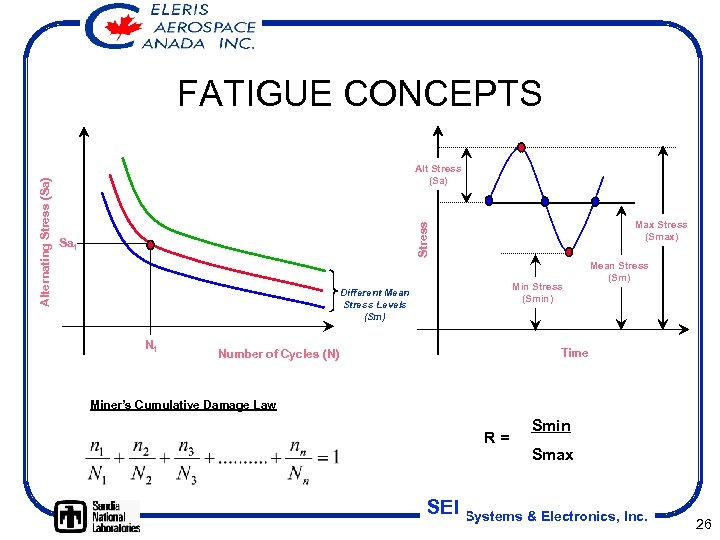

Alt Stress (Sa) Max Stress (Smax) Stress Alternating Stress (Sa) FATIGUE CONCEPTS Sa 1 Min Stress (Smin) Different Mean Stress Levels (Sm) N 1 Mean Stress (Sm) Time Number of Cycles (N) Miner’s Cumulative Damage Law R= Smin Smax SEI Systems & Electronics, Inc. 26

Alt Stress (Sa) Max Stress (Smax) Stress Alternating Stress (Sa) FATIGUE CONCEPTS Sa 1 Min Stress (Smin) Different Mean Stress Levels (Sm) N 1 Mean Stress (Sm) Time Number of Cycles (N) Miner’s Cumulative Damage Law R= Smin Smax SEI Systems & Electronics, Inc. 26

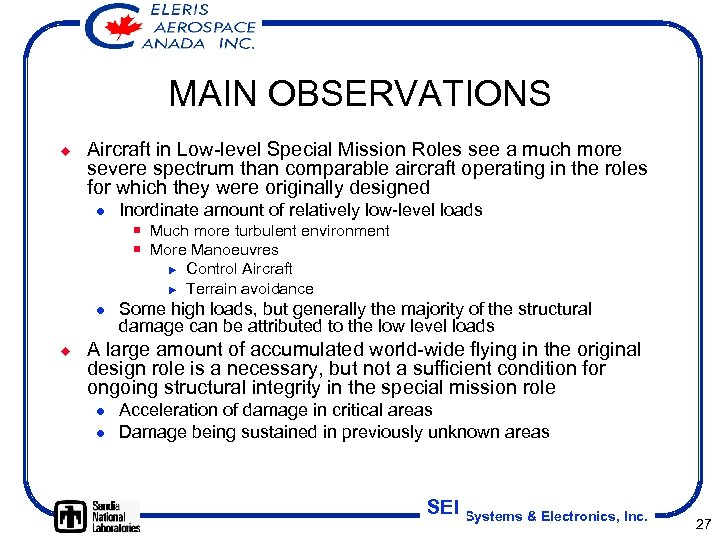

MAIN OBSERVATIONS ¿ Aircraft in Low-level Special Mission Roles see a much more severe spectrum than comparable aircraft operating in the roles for which they were originally designed l Inordinate amount of relatively low-level loads ¡ Much more turbulent environment ¡ More Manoeuvres u Control Aircraft u Terrain avoidance l ¿ Some high loads, but generally the majority of the structural damage can be attributed to the low level loads A large amount of accumulated world-wide flying in the original design role is a necessary, but not a sufficient condition for ongoing structural integrity in the special mission role l l Acceleration of damage in critical areas Damage being sustained in previously unknown areas SEI Systems & Electronics, Inc. 27

MAIN OBSERVATIONS ¿ Aircraft in Low-level Special Mission Roles see a much more severe spectrum than comparable aircraft operating in the roles for which they were originally designed l Inordinate amount of relatively low-level loads ¡ Much more turbulent environment ¡ More Manoeuvres u Control Aircraft u Terrain avoidance l ¿ Some high loads, but generally the majority of the structural damage can be attributed to the low level loads A large amount of accumulated world-wide flying in the original design role is a necessary, but not a sufficient condition for ongoing structural integrity in the special mission role l l Acceleration of damage in critical areas Damage being sustained in previously unknown areas SEI Systems & Electronics, Inc. 27

ADDRESSING THE STRUCTURAL CONCERNS SEI Systems & Electronics, Inc. 28

ADDRESSING THE STRUCTURAL CONCERNS SEI Systems & Electronics, Inc. 28

SO WHAT? ¿ ¿ The previous slides have illustrated that the limited data available suggests that from a cyclic loading perspective (fatigue) firebombing usage is more severe than many operational roles, including the roles for which the majority of the aircraft were designed The next issue that has to be addressed is what are the implications of these loads for individual aircraft structures? SEI Systems & Electronics, Inc. 29

SO WHAT? ¿ ¿ The previous slides have illustrated that the limited data available suggests that from a cyclic loading perspective (fatigue) firebombing usage is more severe than many operational roles, including the roles for which the majority of the aircraft were designed The next issue that has to be addressed is what are the implications of these loads for individual aircraft structures? SEI Systems & Electronics, Inc. 29

EVALUATING THE SIGNIFICANCE ¿ Identify areas in the structure that are likely to be adversely impacted by firebombing usage and assess exactly how they will respond l ¿ Structural Analysis/Certification terminology these are termed critical areas, Principal Structural Elements (PSE’s) or Structurally Significant Items (SSI’s) To do this we need to understand the cyclic stresses experienced at each location l Load is what is applied, stress is how the structure responds ¡ Typically we measure loads ¡ Mechanism of translating these to stresses (Use of “Transfer Functions”) u Detail structural configuration ¿ Evaluate the structural health at each location l l Where are we starting from, ie: what has happened in the past Where are we going, ie: based on the starting point how fast is future usage consuming the “health” of the structure? SEI Systems & Electronics, Inc. 30

EVALUATING THE SIGNIFICANCE ¿ Identify areas in the structure that are likely to be adversely impacted by firebombing usage and assess exactly how they will respond l ¿ Structural Analysis/Certification terminology these are termed critical areas, Principal Structural Elements (PSE’s) or Structurally Significant Items (SSI’s) To do this we need to understand the cyclic stresses experienced at each location l Load is what is applied, stress is how the structure responds ¡ Typically we measure loads ¡ Mechanism of translating these to stresses (Use of “Transfer Functions”) u Detail structural configuration ¿ Evaluate the structural health at each location l l Where are we starting from, ie: what has happened in the past Where are we going, ie: based on the starting point how fast is future usage consuming the “health” of the structure? SEI Systems & Electronics, Inc. 30

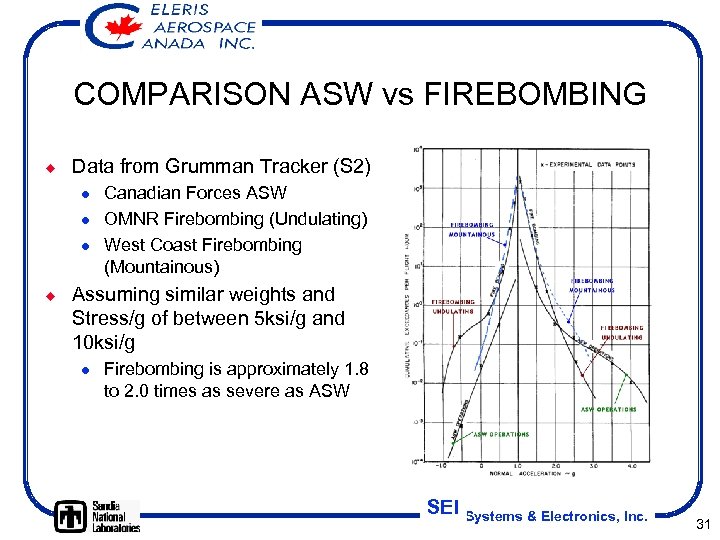

COMPARISON ASW vs FIREBOMBING ¿ Data from Grumman Tracker (S 2) l l l ¿ Canadian Forces ASW OMNR Firebombing (Undulating) West Coast Firebombing (Mountainous) Assuming similar weights and Stress/g of between 5 ksi/g and 10 ksi/g l Firebombing is approximately 1. 8 to 2. 0 times as severe as ASW SEI Systems & Electronics, Inc. 31

COMPARISON ASW vs FIREBOMBING ¿ Data from Grumman Tracker (S 2) l l l ¿ Canadian Forces ASW OMNR Firebombing (Undulating) West Coast Firebombing (Mountainous) Assuming similar weights and Stress/g of between 5 ksi/g and 10 ksi/g l Firebombing is approximately 1. 8 to 2. 0 times as severe as ASW SEI Systems & Electronics, Inc. 31

CHALLENGES OF SPECIAL MISSION AIRCRAFT ¿ Generally older aircraft l May or may not be supported by the OEM or a type certificate holder ¡ Frequently not supportive or consider it not cost-effective to generate data for this role ¡ Liability/Risk issues l l l Engineering data is often limited Regular data collection and validation is not easy as aircraft are frequently geographically dispersed Frequently not equipped with a data-bus that facilitates the straightforward capture of many parameters SEI Systems & Electronics, Inc. 32

CHALLENGES OF SPECIAL MISSION AIRCRAFT ¿ Generally older aircraft l May or may not be supported by the OEM or a type certificate holder ¡ Frequently not supportive or consider it not cost-effective to generate data for this role ¡ Liability/Risk issues l l l Engineering data is often limited Regular data collection and validation is not easy as aircraft are frequently geographically dispersed Frequently not equipped with a data-bus that facilitates the straightforward capture of many parameters SEI Systems & Electronics, Inc. 32

HOW DO YOU GO ABOUT EVALUATING THE ONGOING STRUCTURAL HEALTH OF AN AIRCRAFT? What do you measure, what criteria do you use? SEI Systems & Electronics, Inc. 33

HOW DO YOU GO ABOUT EVALUATING THE ONGOING STRUCTURAL HEALTH OF AN AIRCRAFT? What do you measure, what criteria do you use? SEI Systems & Electronics, Inc. 33

ACTIONS INITIATED ¿ ¿ USDA/FS & Sandia Laboratory inspection base-lining program Development of Structural Health Management Plans by some operators l ¿ Instrumentation of a C-130 A Aircraft and development of initial firebombing profiles l ¿ Including generic and specific parameters Sponsored by the FAA and TBM/IAR Initial instrumentation and limited preliminary analysis of North American Based Airtankers l Sponsored by the USDA/FS and Sandia Laboratories ¡ 2003 – P 2, P 3, DC-7 and possibly CV-580 ¡ 2004 – Additional aircraft SEI Systems & Electronics, Inc. 34

ACTIONS INITIATED ¿ ¿ USDA/FS & Sandia Laboratory inspection base-lining program Development of Structural Health Management Plans by some operators l ¿ Instrumentation of a C-130 A Aircraft and development of initial firebombing profiles l ¿ Including generic and specific parameters Sponsored by the FAA and TBM/IAR Initial instrumentation and limited preliminary analysis of North American Based Airtankers l Sponsored by the USDA/FS and Sandia Laboratories ¡ 2003 – P 2, P 3, DC-7 and possibly CV-580 ¡ 2004 – Additional aircraft SEI Systems & Electronics, Inc. 34

BASELINE INSPECTION PROGRAM SEI Systems & Electronics, Inc. 35

BASELINE INSPECTION PROGRAM SEI Systems & Electronics, Inc. 35

PURPOSE ¿ Reduce risk of major structural failure l l ¿ One time for 2003 season Enhanced Inspection Program Determine the condition of the fleet l l l Basis for continuing program for long-term airworthiness Standardization among contractors and types Identify best practices SEI Systems & Electronics, Inc. 36

PURPOSE ¿ Reduce risk of major structural failure l l ¿ One time for 2003 season Enhanced Inspection Program Determine the condition of the fleet l l l Basis for continuing program for long-term airworthiness Standardization among contractors and types Identify best practices SEI Systems & Electronics, Inc. 36

PROCESS ¿ Documentation search l l ¿ Historical information OEM and other user documents Site visits to all large air tanker contractors l l l Inspection documentation Inspection practice Damage histories SEI Systems & Electronics, Inc. 37

PROCESS ¿ Documentation search l l ¿ Historical information OEM and other user documents Site visits to all large air tanker contractors l l l Inspection documentation Inspection practice Damage histories SEI Systems & Electronics, Inc. 37

SANDIA FINDINGS ¿ Damage Tolerance Assessment l P-3 ¡ US Navy missions most relevant to P-3 C ¡ Full scale fatigue testing (P-3 C, 2002 -2003) l P-2 V ¡ No relevant data identified l C-54 -DC, DC-6, DC-7 ¡ SID on DC-6 only ¡ 1992 ¡ Based on service history SEI Systems & Electronics, Inc. 38

SANDIA FINDINGS ¿ Damage Tolerance Assessment l P-3 ¡ US Navy missions most relevant to P-3 C ¡ Full scale fatigue testing (P-3 C, 2002 -2003) l P-2 V ¡ No relevant data identified l C-54 -DC, DC-6, DC-7 ¡ SID on DC-6 only ¡ 1992 ¡ Based on service history SEI Systems & Electronics, Inc. 38

SANDIA FINDINGS (cont) ¿ Inspection Programs (AIPs) l l l Wide variation in depth and detail of AIPs No FAA process for standardization or periodic review Wide variation in use of NDI beyond visual inspection SEI Systems & Electronics, Inc. 39

SANDIA FINDINGS (cont) ¿ Inspection Programs (AIPs) l l l Wide variation in depth and detail of AIPs No FAA process for standardization or periodic review Wide variation in use of NDI beyond visual inspection SEI Systems & Electronics, Inc. 39

SANDIA FINDINGS (cont) ¿ ¿ Existing history data and inspection practice are less effective than true damage tolerance assessment as air tanker time builds in relation to prior mission time Flight environment and loads data are essential elements of a damage tolerance based continuing airworthiness program, for both current and future air tankers SEI Systems & Electronics, Inc. 40

SANDIA FINDINGS (cont) ¿ ¿ Existing history data and inspection practice are less effective than true damage tolerance assessment as air tanker time builds in relation to prior mission time Flight environment and loads data are essential elements of a damage tolerance based continuing airworthiness program, for both current and future air tankers SEI Systems & Electronics, Inc. 40

IMPLEMENTING A STRUCTURAL HEALTH MONITORING PROGRAM SEI Systems & Electronics, Inc. 41

IMPLEMENTING A STRUCTURAL HEALTH MONITORING PROGRAM SEI Systems & Electronics, Inc. 41

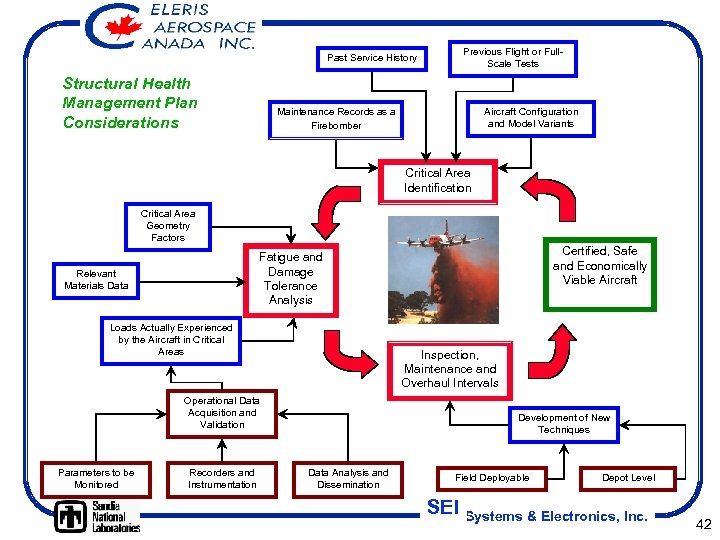

Past Service History Structural Health Management Plan Considerations Previous Flight or Full. Scale Tests Maintenance Records as a Firebomber Aircraft Configuration and Model Variants Critical Area Identification Critical Area Geometry Factors Relevant Materials Data Loads Actually Experienced by the Aircraft in Critical Areas Inspection, Maintenance and Overhaul Intervals Operational Data Acquisition and Validation Parameters to be Monitored Certified, Safe and Economically Viable Aircraft Fatigue and Damage Tolerance Analysis Recorders and Instrumentation Development of New Techniques Data Analysis and Dissemination Field Deployable Depot Level SEI Systems & Electronics, Inc. 42

Past Service History Structural Health Management Plan Considerations Previous Flight or Full. Scale Tests Maintenance Records as a Firebomber Aircraft Configuration and Model Variants Critical Area Identification Critical Area Geometry Factors Relevant Materials Data Loads Actually Experienced by the Aircraft in Critical Areas Inspection, Maintenance and Overhaul Intervals Operational Data Acquisition and Validation Parameters to be Monitored Certified, Safe and Economically Viable Aircraft Fatigue and Damage Tolerance Analysis Recorders and Instrumentation Development of New Techniques Data Analysis and Dissemination Field Deployable Depot Level SEI Systems & Electronics, Inc. 42

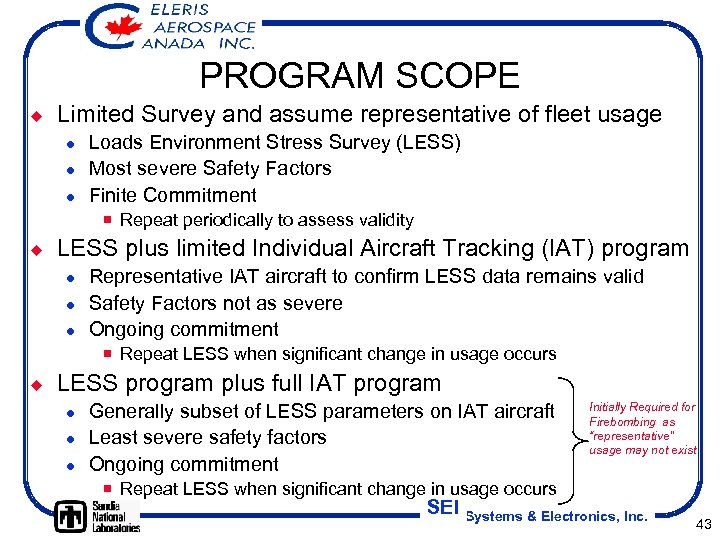

PROGRAM SCOPE ¿ Limited Survey and assume representative of fleet usage l l l Loads Environment Stress Survey (LESS) Most severe Safety Factors Finite Commitment ¡ Repeat periodically to assess validity ¿ LESS plus limited Individual Aircraft Tracking (IAT) program l l l Representative IAT aircraft to confirm LESS data remains valid Safety Factors not as severe Ongoing commitment ¡ Repeat LESS when significant change in usage occurs ¿ LESS program plus full IAT program l l l Generally subset of LESS parameters on IAT aircraft Least severe safety factors Ongoing commitment Initially Required for Firebombing as “representative” usage may not exist ¡ Repeat LESS when significant change in usage occurs SEI Systems & Electronics, Inc. 43

PROGRAM SCOPE ¿ Limited Survey and assume representative of fleet usage l l l Loads Environment Stress Survey (LESS) Most severe Safety Factors Finite Commitment ¡ Repeat periodically to assess validity ¿ LESS plus limited Individual Aircraft Tracking (IAT) program l l l Representative IAT aircraft to confirm LESS data remains valid Safety Factors not as severe Ongoing commitment ¡ Repeat LESS when significant change in usage occurs ¿ LESS program plus full IAT program l l l Generally subset of LESS parameters on IAT aircraft Least severe safety factors Ongoing commitment Initially Required for Firebombing as “representative” usage may not exist ¡ Repeat LESS when significant change in usage occurs SEI Systems & Electronics, Inc. 43

SELECTING PARAMETERS ¿ Principle # 1: l Minimize parameters to be monitored ¡ Even though cost of additional channels and sensors relatively cheap l Avoid “If we are not sure let’s monitor it syndrome” ¡ AKA “More data has to be better” SEI Systems & Electronics, Inc. 44

SELECTING PARAMETERS ¿ Principle # 1: l Minimize parameters to be monitored ¡ Even though cost of additional channels and sensors relatively cheap l Avoid “If we are not sure let’s monitor it syndrome” ¡ AKA “More data has to be better” SEI Systems & Electronics, Inc. 44

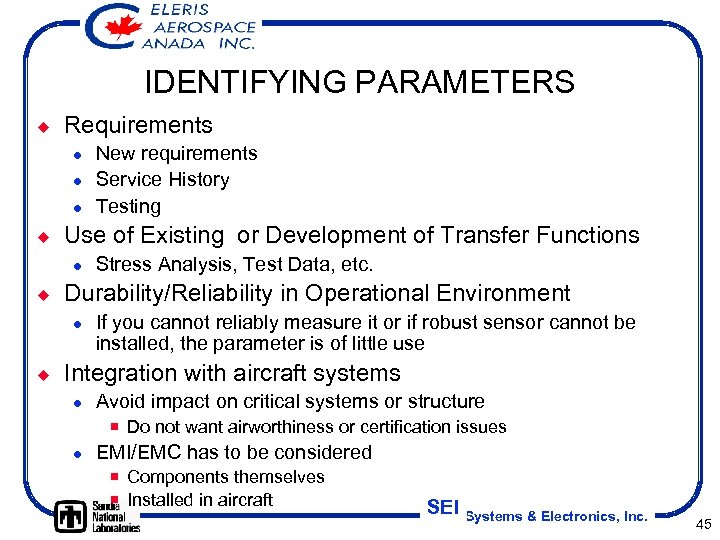

IDENTIFYING PARAMETERS ¿ Requirements l l l ¿ Use of Existing or Development of Transfer Functions l ¿ Stress Analysis, Test Data, etc. Durability/Reliability in Operational Environment l ¿ New requirements Service History Testing If you cannot reliably measure it or if robust sensor cannot be installed, the parameter is of little use Integration with aircraft systems l Avoid impact on critical systems or structure ¡ Do not want airworthiness or certification issues l EMI/EMC has to be considered ¡ Components themselves ¡ Installed in aircraft SEI Systems & Electronics, Inc. 45

IDENTIFYING PARAMETERS ¿ Requirements l l l ¿ Use of Existing or Development of Transfer Functions l ¿ Stress Analysis, Test Data, etc. Durability/Reliability in Operational Environment l ¿ New requirements Service History Testing If you cannot reliably measure it or if robust sensor cannot be installed, the parameter is of little use Integration with aircraft systems l Avoid impact on critical systems or structure ¡ Do not want airworthiness or certification issues l EMI/EMC has to be considered ¡ Components themselves ¡ Installed in aircraft SEI Systems & Electronics, Inc. 45

GENERIC vs SPECIFIC PARAMETERS ¿ Generic parameters are “universal” parameters that characterize the phenomena being measured l ¿ Specific parameters are parameters which represent the actual response of the structure to the phenomena l l ¿ Vertical Centre-of-Gravity Acceleration (Nzcg) Strain gauge readings measured at specific locations on a structure Location specific Ideally, require as many generic parameters as practicable l Practice: Require a combination of both SEI Systems & Electronics, Inc. 46

GENERIC vs SPECIFIC PARAMETERS ¿ Generic parameters are “universal” parameters that characterize the phenomena being measured l ¿ Specific parameters are parameters which represent the actual response of the structure to the phenomena l l ¿ Vertical Centre-of-Gravity Acceleration (Nzcg) Strain gauge readings measured at specific locations on a structure Location specific Ideally, require as many generic parameters as practicable l Practice: Require a combination of both SEI Systems & Electronics, Inc. 46

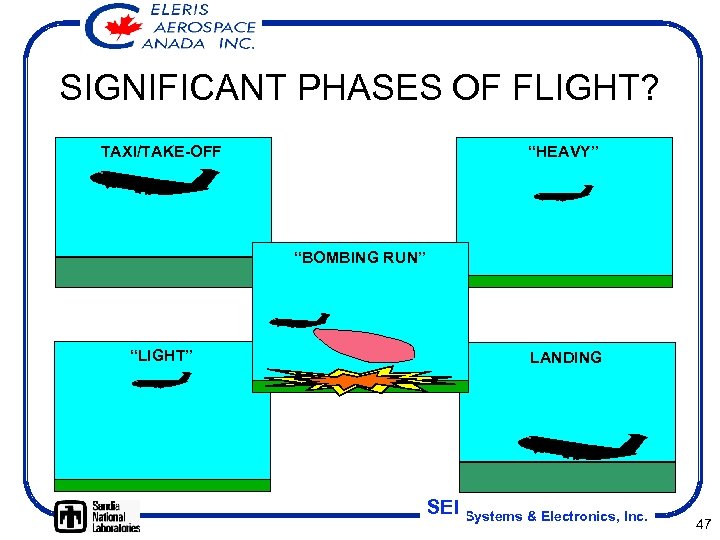

SIGNIFICANT PHASES OF FLIGHT? TAXI/TAKE-OFF “HEAVY” “BOMBING RUN” “LIGHT” LANDING SEI Systems & Electronics, Inc. 47

SIGNIFICANT PHASES OF FLIGHT? TAXI/TAKE-OFF “HEAVY” “BOMBING RUN” “LIGHT” LANDING SEI Systems & Electronics, Inc. 47

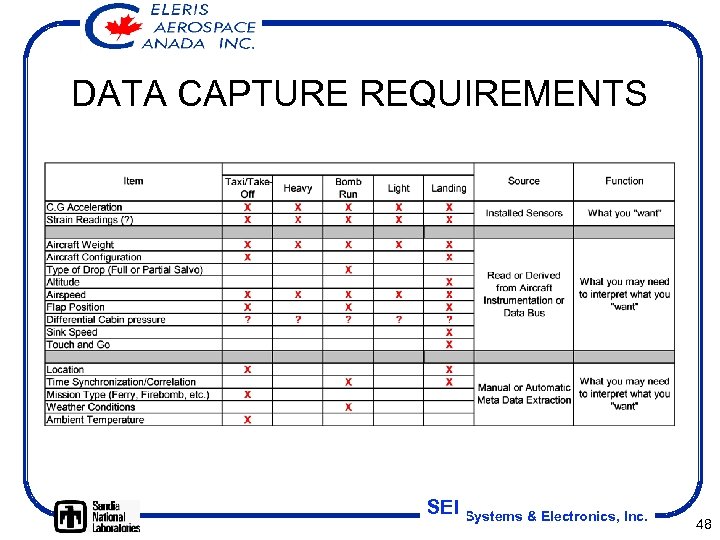

DATA CAPTURE REQUIREMENTS SEI Systems & Electronics, Inc. 48

DATA CAPTURE REQUIREMENTS SEI Systems & Electronics, Inc. 48

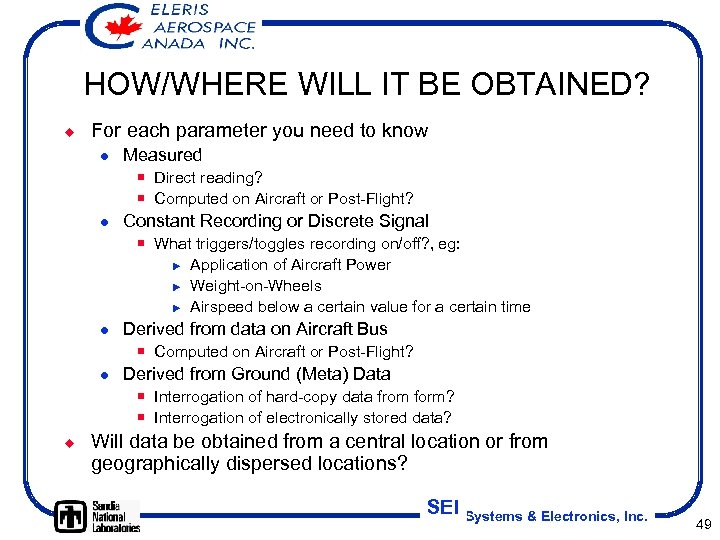

HOW/WHERE WILL IT BE OBTAINED? ¿ For each parameter you need to know l Measured ¡ Direct reading? ¡ Computed on Aircraft or Post-Flight? l Constant Recording or Discrete Signal ¡ What triggers/toggles recording on/off? , eg: u Application of Aircraft Power u Weight-on-Wheels u Airspeed below a certain value for a certain time l Derived from data on Aircraft Bus ¡ Computed on Aircraft or Post-Flight? l Derived from Ground (Meta) Data ¡ Interrogation of hard-copy data from form? ¡ Interrogation of electronically stored data? ¿ Will data be obtained from a central location or from geographically dispersed locations? SEI Systems & Electronics, Inc. 49

HOW/WHERE WILL IT BE OBTAINED? ¿ For each parameter you need to know l Measured ¡ Direct reading? ¡ Computed on Aircraft or Post-Flight? l Constant Recording or Discrete Signal ¡ What triggers/toggles recording on/off? , eg: u Application of Aircraft Power u Weight-on-Wheels u Airspeed below a certain value for a certain time l Derived from data on Aircraft Bus ¡ Computed on Aircraft or Post-Flight? l Derived from Ground (Meta) Data ¡ Interrogation of hard-copy data from form? ¡ Interrogation of electronically stored data? ¿ Will data be obtained from a central location or from geographically dispersed locations? SEI Systems & Electronics, Inc. 49

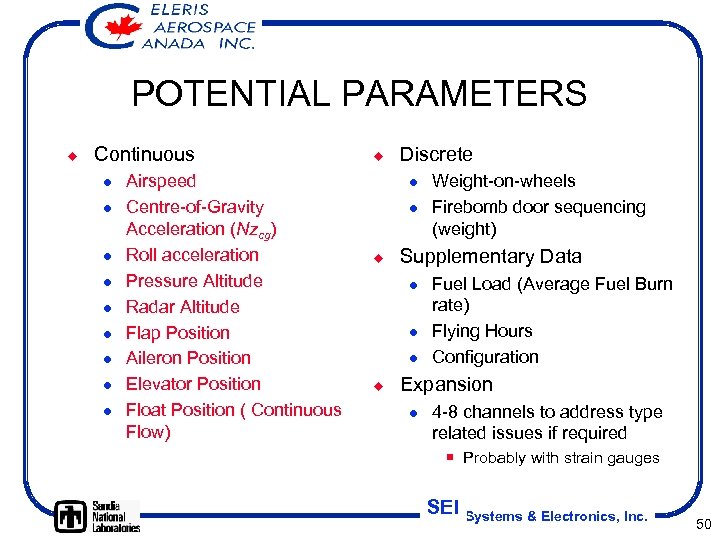

POTENTIAL PARAMETERS ¿ Continuous l l l l l Airspeed Centre-of-Gravity Acceleration (Nzcg) Roll acceleration Pressure Altitude Radar Altitude Flap Position Aileron Position Elevator Position Float Position ( Continuous Flow) ¿ Discrete l l ¿ Supplementary Data l l l ¿ Weight-on-wheels Firebomb door sequencing (weight) Fuel Load (Average Fuel Burn rate) Flying Hours Configuration Expansion l 4 -8 channels to address type related issues if required ¡ Probably with strain gauges SEI Systems & Electronics, Inc. 50

POTENTIAL PARAMETERS ¿ Continuous l l l l l Airspeed Centre-of-Gravity Acceleration (Nzcg) Roll acceleration Pressure Altitude Radar Altitude Flap Position Aileron Position Elevator Position Float Position ( Continuous Flow) ¿ Discrete l l ¿ Supplementary Data l l l ¿ Weight-on-wheels Firebomb door sequencing (weight) Fuel Load (Average Fuel Burn rate) Flying Hours Configuration Expansion l 4 -8 channels to address type related issues if required ¡ Probably with strain gauges SEI Systems & Electronics, Inc. 50

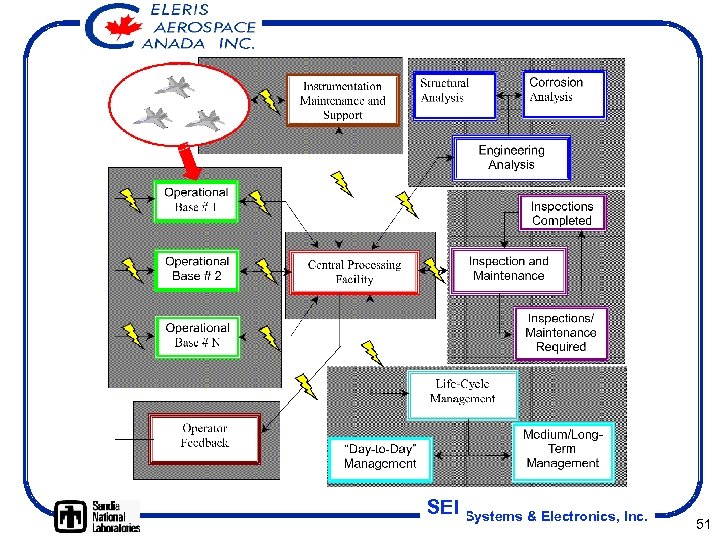

SEI Systems & Electronics, Inc. 51

SEI Systems & Electronics, Inc. 51

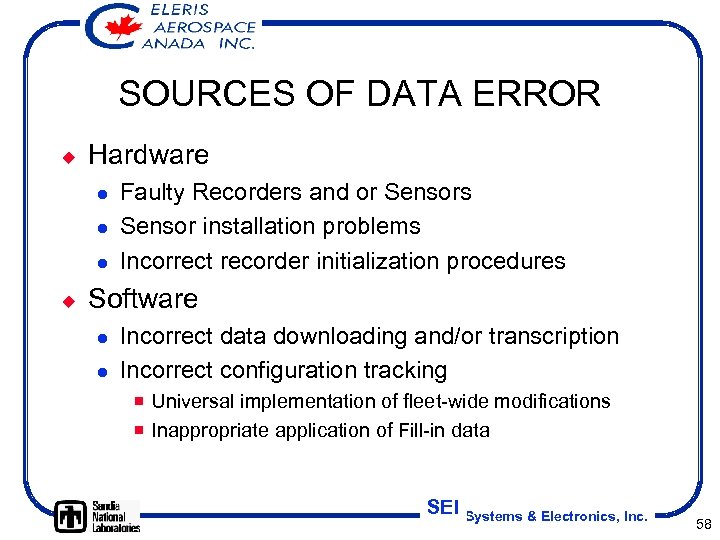

SOURCES OF DATA ERROR ¿ Hardware l l l ¿ Faulty Recorders and or Sensors Sensor installation problems Incorrect recorder initialization procedures Software l l Incorrect data downloading and/or transcription Incorrect configuration tracking ¡ Universal implementation of fleet-wide modifications ¡ Inappropriate application of Fill-in data SEI Systems & Electronics, Inc. 58

SOURCES OF DATA ERROR ¿ Hardware l l l ¿ Faulty Recorders and or Sensors Sensor installation problems Incorrect recorder initialization procedures Software l l Incorrect data downloading and/or transcription Incorrect configuration tracking ¡ Universal implementation of fleet-wide modifications ¡ Inappropriate application of Fill-in data SEI Systems & Electronics, Inc. 58

TYPES OF DATA ACQUISITION ERROR ¿ Two general classifications l Logical Errors - Errors that can easily be identified as right or wrong ¡ Range checks ¡ Event response frequency l Potential Errors - Errors which only become apparent over time and/or require detailed analysis by skilled personnel ¡ Strain gauge drift SEI Systems & Electronics, Inc. 59

TYPES OF DATA ACQUISITION ERROR ¿ Two general classifications l Logical Errors - Errors that can easily be identified as right or wrong ¡ Range checks ¡ Event response frequency l Potential Errors - Errors which only become apparent over time and/or require detailed analysis by skilled personnel ¡ Strain gauge drift SEI Systems & Electronics, Inc. 59

FINAL DATA VALIDATION ¿ ¿ Confirming initial (logical error) checks performed at operational bases Evaluating potential error checks l Strain gauge drift ¡ Over time, implicit need for historical data ¡ Have to compare like data, implicit need to track data by configuration u Tracking initialization readings a good first start ¿ Statistical Validation l l Beware of self-fulfilling prophecy Look for change in usage ¡ Value of Exceedance curves and other tools SEI Systems & Electronics, Inc. 60

FINAL DATA VALIDATION ¿ ¿ Confirming initial (logical error) checks performed at operational bases Evaluating potential error checks l Strain gauge drift ¡ Over time, implicit need for historical data ¡ Have to compare like data, implicit need to track data by configuration u Tracking initialization readings a good first start ¿ Statistical Validation l l Beware of self-fulfilling prophecy Look for change in usage ¡ Value of Exceedance curves and other tools SEI Systems & Electronics, Inc. 60

OPERATIONAL ENVIRONMENT ¿ ¿ Primary requirement is to provide a minimal increase in operational workload You will not get the data you require if: l Acquisition equipment requires: ¡ ¡ ¿ Too much hand holding Takes too much time to download Is not straightforward to use Cannot easily be maintained or supported Benefits of collecting data you do not require!!! SEI Systems & Electronics, Inc. 61

OPERATIONAL ENVIRONMENT ¿ ¿ Primary requirement is to provide a minimal increase in operational workload You will not get the data you require if: l Acquisition equipment requires: ¡ ¡ ¿ Too much hand holding Takes too much time to download Is not straightforward to use Cannot easily be maintained or supported Benefits of collecting data you do not require!!! SEI Systems & Electronics, Inc. 61

PRELIMINARY CHARACTERIZATION OF FIREBOMBING ROLE TBM/IAR/FAA C-130 A FLARE PROGRAM (YUMA ARIZONA February, 2003) SEI Systems & Electronics, Inc. 62

PRELIMINARY CHARACTERIZATION OF FIREBOMBING ROLE TBM/IAR/FAA C-130 A FLARE PROGRAM (YUMA ARIZONA February, 2003) SEI Systems & Electronics, Inc. 62

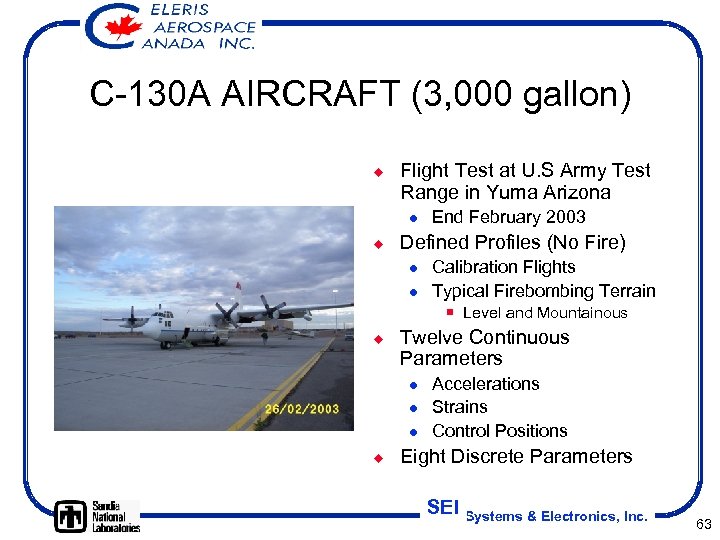

C-130 A AIRCRAFT (3, 000 gallon) ¿ Flight Test at U. S Army Test Range in Yuma Arizona l ¿ End February 2003 Defined Profiles (No Fire) l l Calibration Flights Typical Firebombing Terrain ¡ Level and Mountainous ¿ Twelve Continuous Parameters l l l ¿ Accelerations Strains Control Positions Eight Discrete Parameters SEI Systems & Electronics, Inc. 63

C-130 A AIRCRAFT (3, 000 gallon) ¿ Flight Test at U. S Army Test Range in Yuma Arizona l ¿ End February 2003 Defined Profiles (No Fire) l l Calibration Flights Typical Firebombing Terrain ¡ Level and Mountainous ¿ Twelve Continuous Parameters l l l ¿ Accelerations Strains Control Positions Eight Discrete Parameters SEI Systems & Electronics, Inc. 63

REMOVABLE TANK INSTALLATION SEI Systems & Electronics, Inc. 64

REMOVABLE TANK INSTALLATION SEI Systems & Electronics, Inc. 64

RECORDER HARDWARE SEI Systems & Electronics, Inc. 65

RECORDER HARDWARE SEI Systems & Electronics, Inc. 65

CONTROL POSITIONS SEI Systems & Electronics, Inc. 66

CONTROL POSITIONS SEI Systems & Electronics, Inc. 66

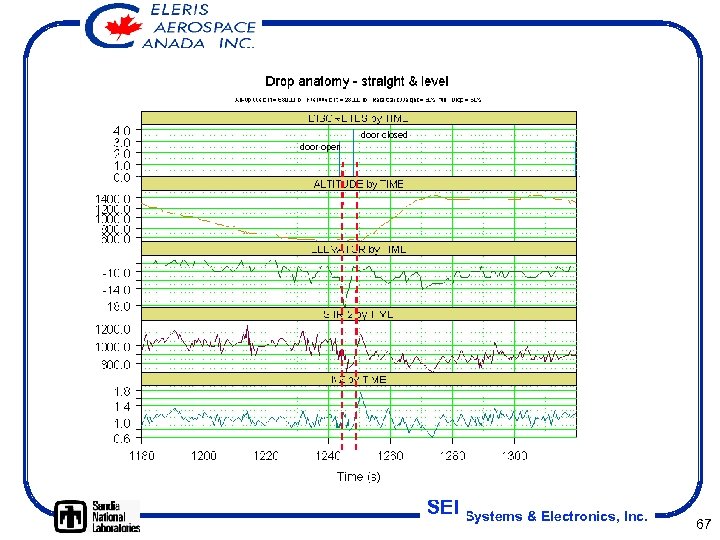

door closed door open SEI Systems & Electronics, Inc. 67

door closed door open SEI Systems & Electronics, Inc. 67

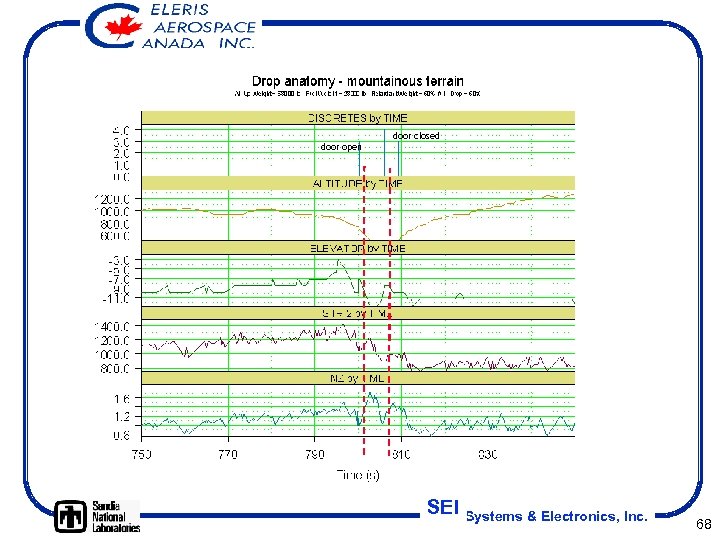

door closed door open SEI Systems & Electronics, Inc. 68

door closed door open SEI Systems & Electronics, Inc. 68

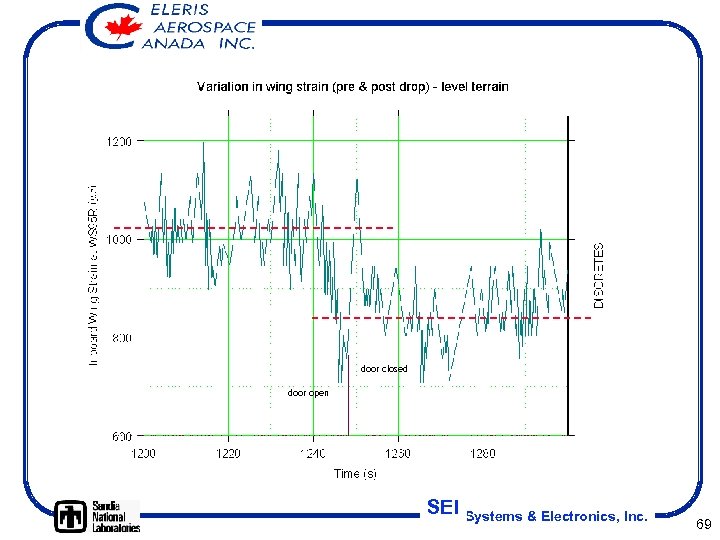

door closed door open SEI Systems & Electronics, Inc. 69

door closed door open SEI Systems & Electronics, Inc. 69

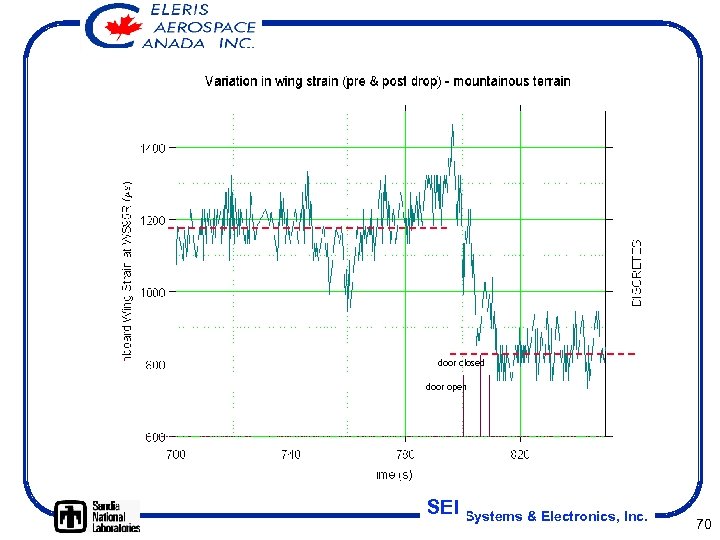

door closed door open SEI Systems & Electronics, Inc. 70

door closed door open SEI Systems & Electronics, Inc. 70

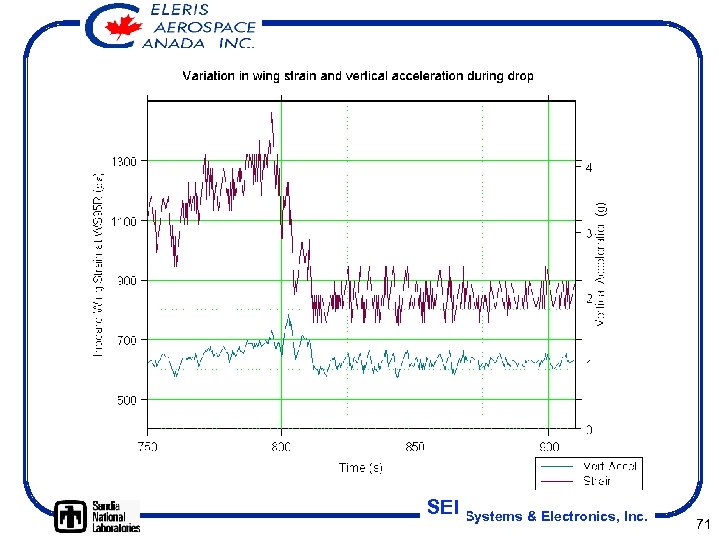

SEI Systems & Electronics, Inc. 71

SEI Systems & Electronics, Inc. 71

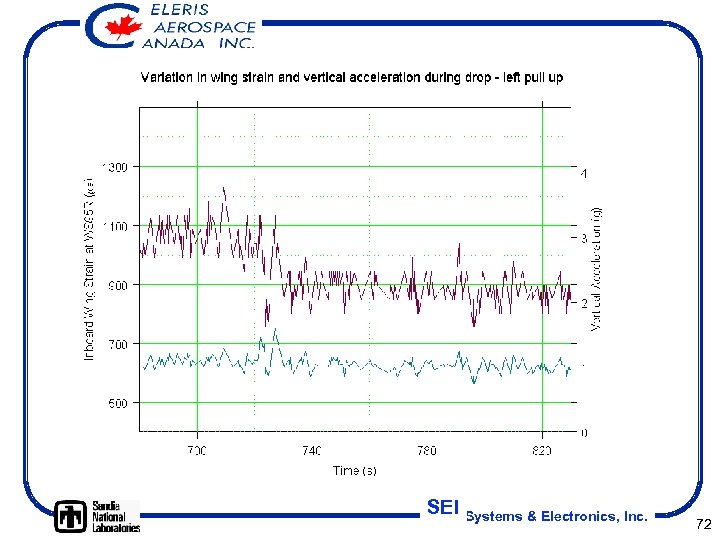

SEI Systems & Electronics, Inc. 72

SEI Systems & Electronics, Inc. 72

OPERATIONAL DATA ACQUISITION ACTIVITIES 2003 FIRE SEASON SEI Systems & Electronics, Inc. 73

OPERATIONAL DATA ACQUISITION ACTIVITIES 2003 FIRE SEASON SEI Systems & Electronics, Inc. 73

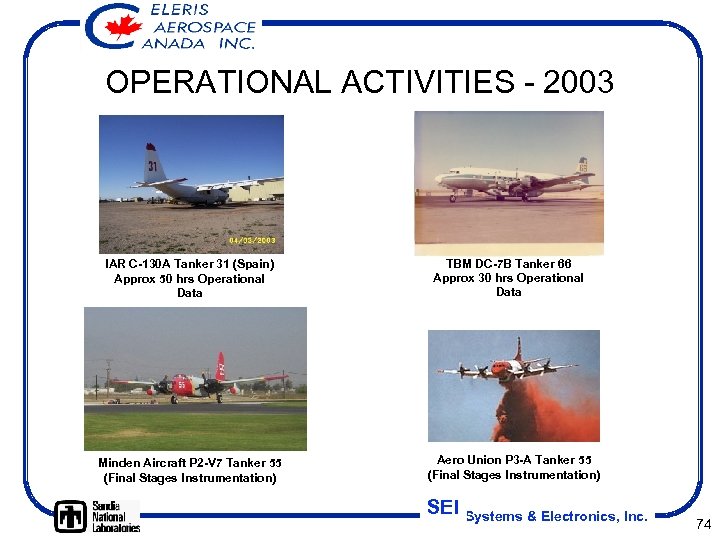

OPERATIONAL ACTIVITIES - 2003 IAR C-130 A Tanker 31 (Spain) Approx 50 hrs Operational Data Minden Aircraft P 2 -V 7 Tanker 55 (Final Stages Instrumentation) TBM DC-7 B Tanker 66 Approx 30 hrs Operational Data Aero Union P 3 -A Tanker 55 (Final Stages Instrumentation) SEI Systems & Electronics, Inc. 74

OPERATIONAL ACTIVITIES - 2003 IAR C-130 A Tanker 31 (Spain) Approx 50 hrs Operational Data Minden Aircraft P 2 -V 7 Tanker 55 (Final Stages Instrumentation) TBM DC-7 B Tanker 66 Approx 30 hrs Operational Data Aero Union P 3 -A Tanker 55 (Final Stages Instrumentation) SEI Systems & Electronics, Inc. 74

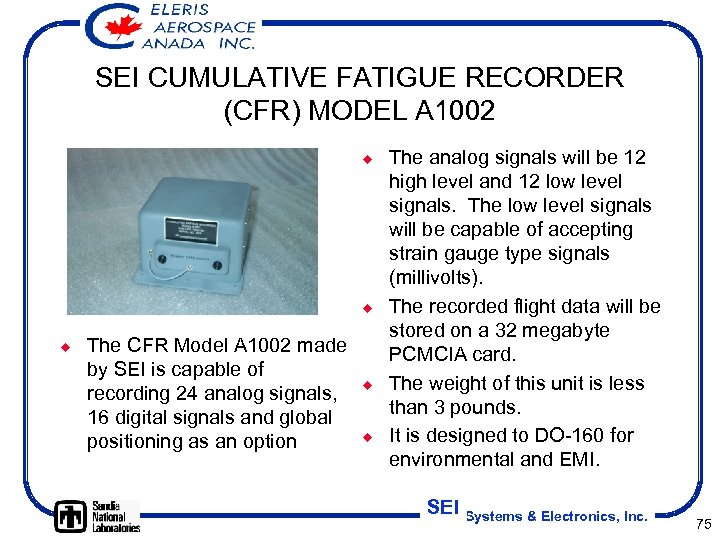

SEI CUMULATIVE FATIGUE RECORDER (CFR) MODEL A 1002 ¿ ¿ ¿ The CFR Model A 1002 made by SEI is capable of recording 24 analog signals, 16 digital signals and global positioning as an option ¿ ¿ The analog signals will be 12 high level and 12 low level signals. The low level signals will be capable of accepting strain gauge type signals (millivolts). The recorded flight data will be stored on a 32 megabyte PCMCIA card. The weight of this unit is less than 3 pounds. It is designed to DO-160 for environmental and EMI. SEI Systems & Electronics, Inc. 75

SEI CUMULATIVE FATIGUE RECORDER (CFR) MODEL A 1002 ¿ ¿ ¿ The CFR Model A 1002 made by SEI is capable of recording 24 analog signals, 16 digital signals and global positioning as an option ¿ ¿ The analog signals will be 12 high level and 12 low level signals. The low level signals will be capable of accepting strain gauge type signals (millivolts). The recorded flight data will be stored on a 32 megabyte PCMCIA card. The weight of this unit is less than 3 pounds. It is designed to DO-160 for environmental and EMI. SEI Systems & Electronics, Inc. 75

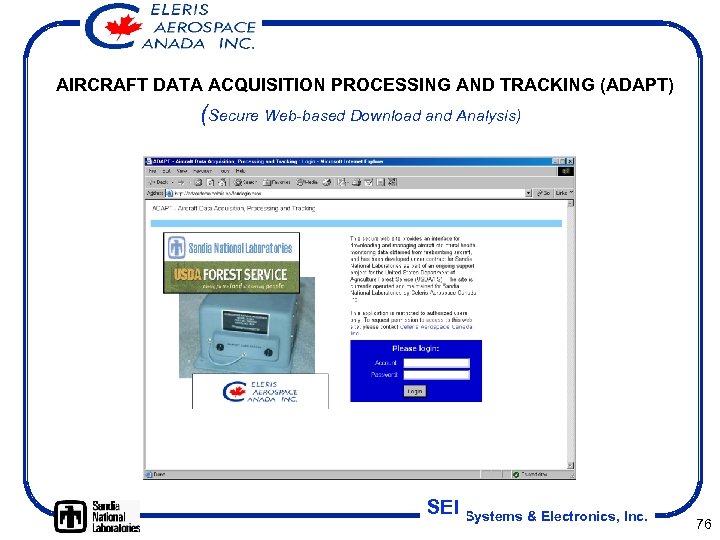

AIRCRAFT DATA ACQUISITION PROCESSING AND TRACKING (ADAPT) (Secure Web-based Download and Analysis) SEI Systems & Electronics, Inc. 76

AIRCRAFT DATA ACQUISITION PROCESSING AND TRACKING (ADAPT) (Secure Web-based Download and Analysis) SEI Systems & Electronics, Inc. 76

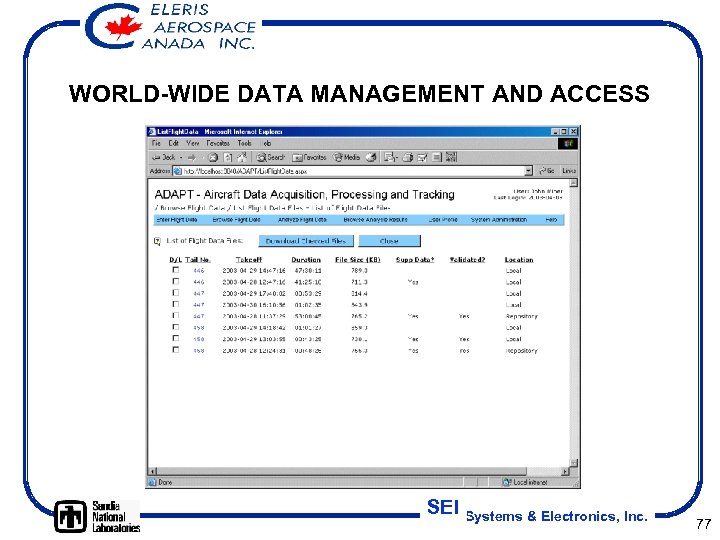

WORLD-WIDE DATA MANAGEMENT AND ACCESS SEI Systems & Electronics, Inc. 77

WORLD-WIDE DATA MANAGEMENT AND ACCESS SEI Systems & Electronics, Inc. 77

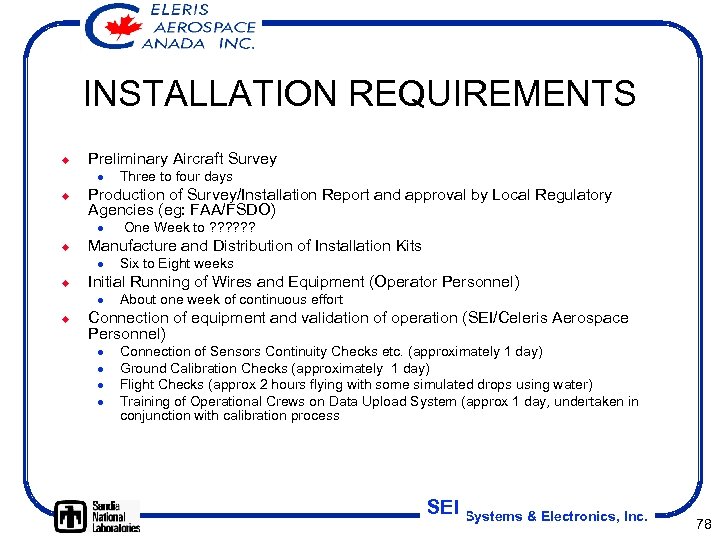

INSTALLATION REQUIREMENTS ¿ Preliminary Aircraft Survey l ¿ Production of Survey/Installation Report and approval by Local Regulatory Agencies (eg: FAA/FSDO) l ¿ Six to Eight weeks Initial Running of Wires and Equipment (Operator Personnel) l ¿ One Week to ? ? ? Manufacture and Distribution of Installation Kits l ¿ Three to four days About one week of continuous effort Connection of equipment and validation of operation (SEI/Celeris Aerospace Personnel) l l Connection of Sensors Continuity Checks etc. (approximately 1 day) Ground Calibration Checks (approximately 1 day) Flight Checks (approx 2 hours flying with some simulated drops using water) Training of Operational Crews on Data Upload System (approx 1 day, undertaken in conjunction with calibration process SEI Systems & Electronics, Inc. 78

INSTALLATION REQUIREMENTS ¿ Preliminary Aircraft Survey l ¿ Production of Survey/Installation Report and approval by Local Regulatory Agencies (eg: FAA/FSDO) l ¿ Six to Eight weeks Initial Running of Wires and Equipment (Operator Personnel) l ¿ One Week to ? ? ? Manufacture and Distribution of Installation Kits l ¿ Three to four days About one week of continuous effort Connection of equipment and validation of operation (SEI/Celeris Aerospace Personnel) l l Connection of Sensors Continuity Checks etc. (approximately 1 day) Ground Calibration Checks (approximately 1 day) Flight Checks (approx 2 hours flying with some simulated drops using water) Training of Operational Crews on Data Upload System (approx 1 day, undertaken in conjunction with calibration process SEI Systems & Electronics, Inc. 78

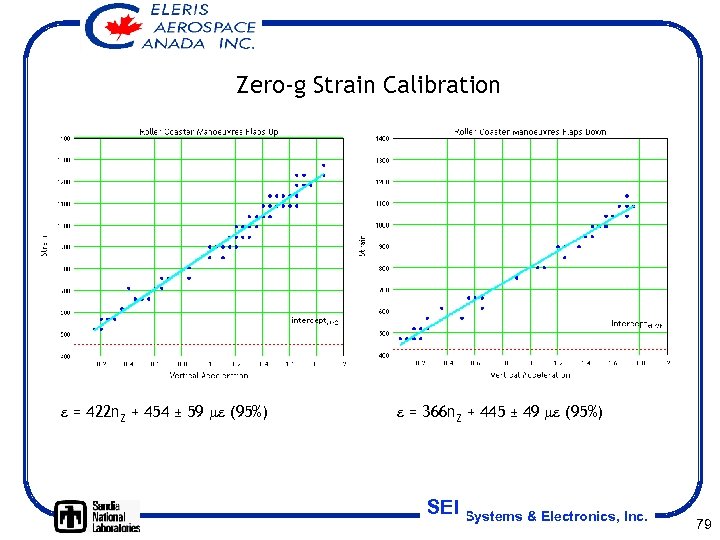

Zero-g Strain Calibration e = 422 n. Z + 454 ± 59 me (95%) e = 366 n. Z + 445 ± 49 me (95%) SEI Systems & Electronics, Inc. 79

Zero-g Strain Calibration e = 422 n. Z + 454 ± 59 me (95%) e = 366 n. Z + 445 ± 49 me (95%) SEI Systems & Electronics, Inc. 79

C-130 A SPANISH DATA SEI Systems & Electronics, Inc. 80

C-130 A SPANISH DATA SEI Systems & Electronics, Inc. 80

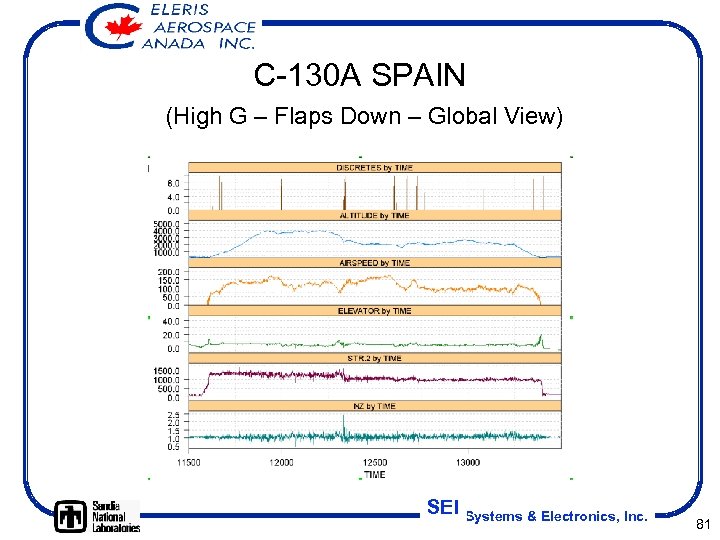

C-130 A SPAIN (High G – Flaps Down – Global View) SEI Systems & Electronics, Inc. 81

C-130 A SPAIN (High G – Flaps Down – Global View) SEI Systems & Electronics, Inc. 81

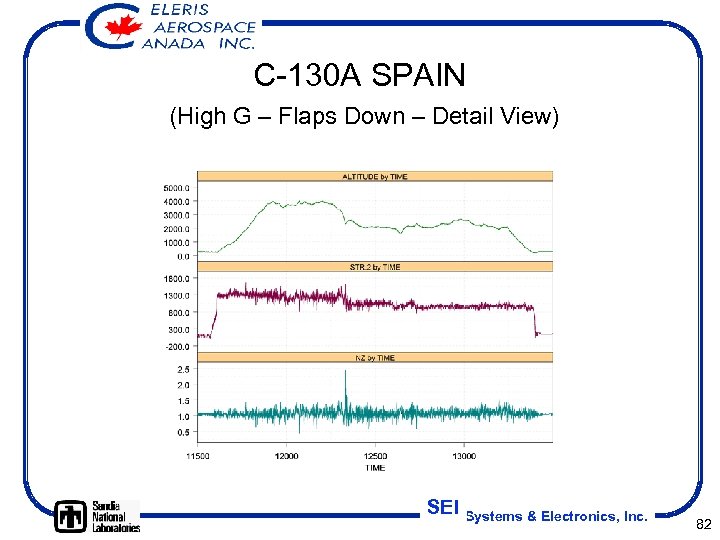

C-130 A SPAIN (High G – Flaps Down – Detail View) SEI Systems & Electronics, Inc. 82

C-130 A SPAIN (High G – Flaps Down – Detail View) SEI Systems & Electronics, Inc. 82

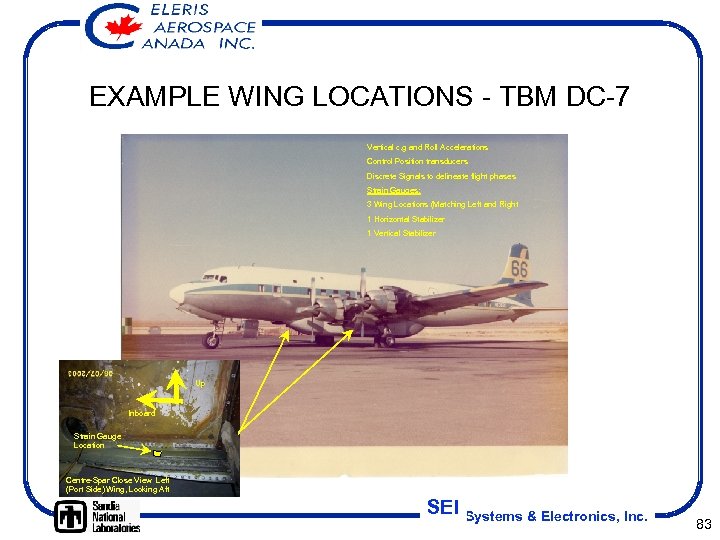

EXAMPLE WING LOCATIONS - TBM DC-7 Vertical c. g and Roll Accelerations Control Position transducers Discrete Signals to delineate flight phases Strain Gauges: 3 Wing Locations (Matching Left and Right 1 Horizontal Stabilizer 1 Vertical Stabilizer Up Inboard Strain Gauge Location Centre-Spar Close View Left (Port Side) Wing, Looking Aft SEI Systems & Electronics, Inc. 83

EXAMPLE WING LOCATIONS - TBM DC-7 Vertical c. g and Roll Accelerations Control Position transducers Discrete Signals to delineate flight phases Strain Gauges: 3 Wing Locations (Matching Left and Right 1 Horizontal Stabilizer 1 Vertical Stabilizer Up Inboard Strain Gauge Location Centre-Spar Close View Left (Port Side) Wing, Looking Aft SEI Systems & Electronics, Inc. 83

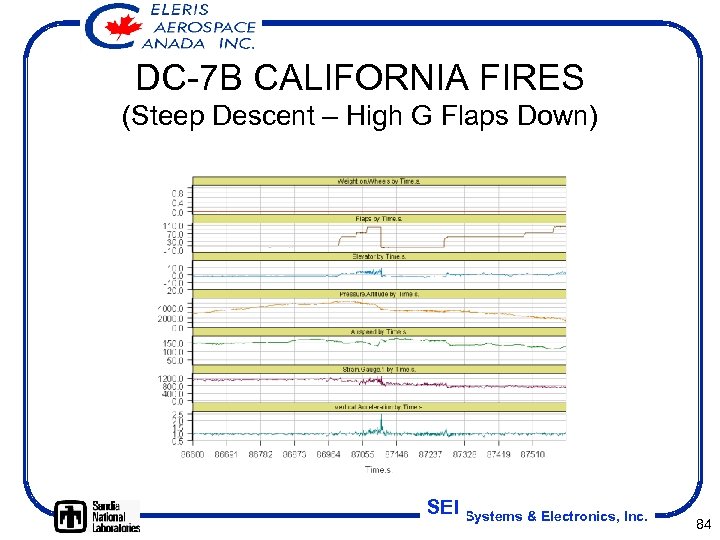

DC-7 B CALIFORNIA FIRES (Steep Descent – High G Flaps Down) SEI Systems & Electronics, Inc. 84

DC-7 B CALIFORNIA FIRES (Steep Descent – High G Flaps Down) SEI Systems & Electronics, Inc. 84

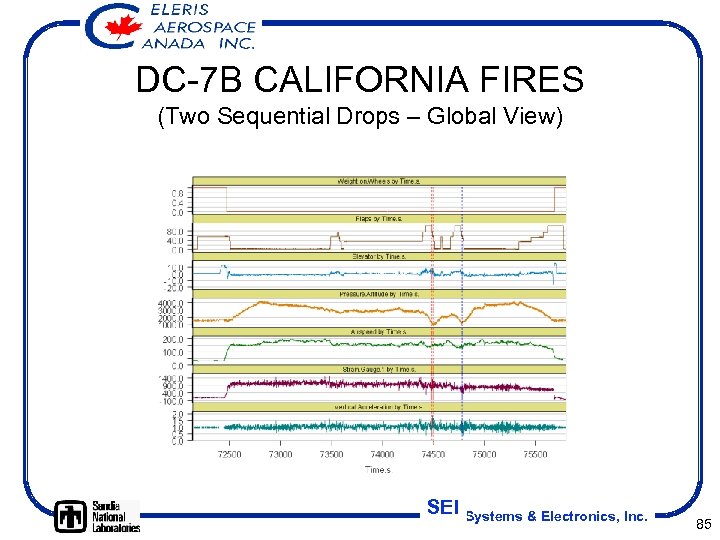

DC-7 B CALIFORNIA FIRES (Two Sequential Drops – Global View) SEI Systems & Electronics, Inc. 85

DC-7 B CALIFORNIA FIRES (Two Sequential Drops – Global View) SEI Systems & Electronics, Inc. 85

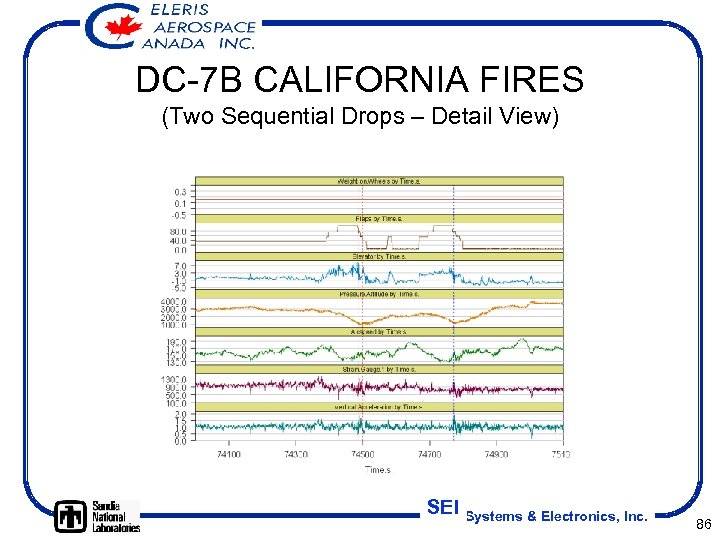

DC-7 B CALIFORNIA FIRES (Two Sequential Drops – Detail View) SEI Systems & Electronics, Inc. 86

DC-7 B CALIFORNIA FIRES (Two Sequential Drops – Detail View) SEI Systems & Electronics, Inc. 86

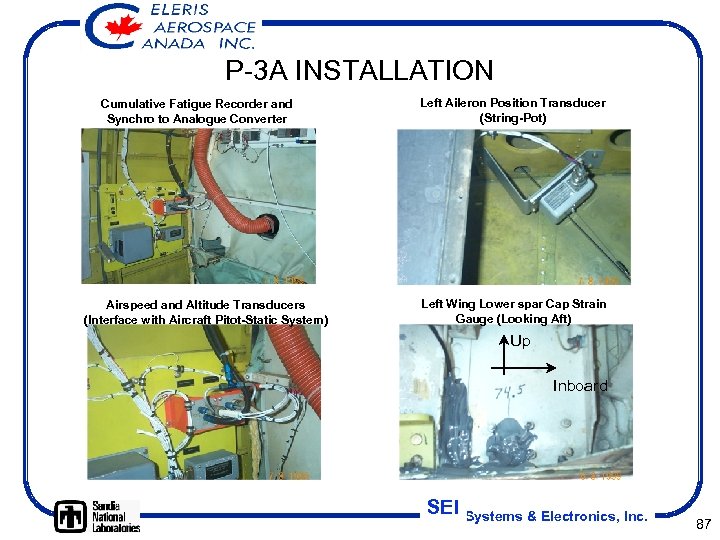

P-3 A INSTALLATION Cumulative Fatigue Recorder and Synchro to Analogue Converter Airspeed and Altitude Transducers (Interface with Aircraft Pitot-Static System) Left Aileron Position Transducer (String-Pot) Left Wing Lower spar Cap Strain Gauge (Looking Aft) Up Inboard SEI Systems & Electronics, Inc. 87

P-3 A INSTALLATION Cumulative Fatigue Recorder and Synchro to Analogue Converter Airspeed and Altitude Transducers (Interface with Aircraft Pitot-Static System) Left Aileron Position Transducer (String-Pot) Left Wing Lower spar Cap Strain Gauge (Looking Aft) Up Inboard SEI Systems & Electronics, Inc. 87

LESSONS LEARNED - IMPLEMENTATION ¿ Preferable to do the installation in the off-season l l ¿ Should be starting now for 2004 Funding for these type of activities can be challenging Need for consistency in approval process l Depending on experience of local regulatory authorities approval can take anywhere from one to ten plus weeks ¡ Central area in regulatory agencies with expertize in the installation of structural health monitoring systems ¿ Remote support capability for troubleshooting is essential l ¿ Take advantage of inherent remote support capabilities of Windows XP Regular Data downloading essential l l Every one to two days when active on fire as large amounts of significant structural activity Essential to make this a bullet proof and straightforward process with minimal data footprint (slower modem connection compressed files) SEI Systems & Electronics, Inc. 88

LESSONS LEARNED - IMPLEMENTATION ¿ Preferable to do the installation in the off-season l l ¿ Should be starting now for 2004 Funding for these type of activities can be challenging Need for consistency in approval process l Depending on experience of local regulatory authorities approval can take anywhere from one to ten plus weeks ¡ Central area in regulatory agencies with expertize in the installation of structural health monitoring systems ¿ Remote support capability for troubleshooting is essential l ¿ Take advantage of inherent remote support capabilities of Windows XP Regular Data downloading essential l l Every one to two days when active on fire as large amounts of significant structural activity Essential to make this a bullet proof and straightforward process with minimal data footprint (slower modem connection compressed files) SEI Systems & Electronics, Inc. 88

LESSONS LEARNED – PRELIMINARY DATA ¿ G-Levels limits particularly with flaps down are exceeded on a frequent basis l ¿ However, CORRESPONDING STRAIN/STRESS LEVELS ARE NOT THAT HIGH l l l ¿ G has traditionally been used as a proxy for strain Transport aircraft conservative but OK Firebombing where large instantaneous change in weight it may be inappropriate For Firebombing harsh or unusual usage should be based on combined G and strain criteria? l ¿ Appears to be during or after drop Should ensure safe operation but minimize unnecessary in-field inspections and or change-out of aircraft Better feel for this aspect once additional data has been collected during the 2004 fire season SEI Systems & Electronics, Inc. 89

LESSONS LEARNED – PRELIMINARY DATA ¿ G-Levels limits particularly with flaps down are exceeded on a frequent basis l ¿ However, CORRESPONDING STRAIN/STRESS LEVELS ARE NOT THAT HIGH l l l ¿ G has traditionally been used as a proxy for strain Transport aircraft conservative but OK Firebombing where large instantaneous change in weight it may be inappropriate For Firebombing harsh or unusual usage should be based on combined G and strain criteria? l ¿ Appears to be during or after drop Should ensure safe operation but minimize unnecessary in-field inspections and or change-out of aircraft Better feel for this aspect once additional data has been collected during the 2004 fire season SEI Systems & Electronics, Inc. 89

OBSERVATIONS RELATED TO LONGER-TERM ISSUES SEI Systems & Electronics, Inc. 90

OBSERVATIONS RELATED TO LONGER-TERM ISSUES SEI Systems & Electronics, Inc. 90

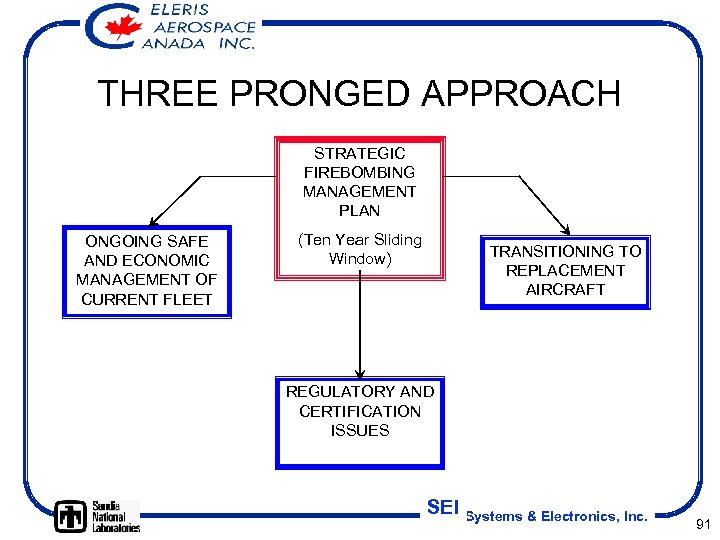

THREE PRONGED APPROACH STRATEGIC FIREBOMBING MANAGEMENT PLAN ONGOING SAFE AND ECONOMIC MANAGEMENT OF CURRENT FLEET (Ten Year Sliding Window) TRANSITIONING TO REPLACEMENT AIRCRAFT REGULATORY AND CERTIFICATION ISSUES SEI Systems & Electronics, Inc. 91

THREE PRONGED APPROACH STRATEGIC FIREBOMBING MANAGEMENT PLAN ONGOING SAFE AND ECONOMIC MANAGEMENT OF CURRENT FLEET (Ten Year Sliding Window) TRANSITIONING TO REPLACEMENT AIRCRAFT REGULATORY AND CERTIFICATION ISSUES SEI Systems & Electronics, Inc. 91

FLEET REPLACEMENT ¿ Based on current financial and practical limitations current fleet replacement is realistically five to seven and more likely ten years away ¡ Implies have to address issues related to current aircraft as there is no “short-term” fix ¿ Two Implications l l There is a need to monitor the existing fleet as it is going to be around for some time Efforts devoted to doing this will not be wasted as the data collected will both help to ensure ongoing safety and provide a basis of selection for future firebombing aircraft ¡ Prior to conversion and usage SEI Systems & Electronics, Inc. 92

FLEET REPLACEMENT ¿ Based on current financial and practical limitations current fleet replacement is realistically five to seven and more likely ten years away ¡ Implies have to address issues related to current aircraft as there is no “short-term” fix ¿ Two Implications l l There is a need to monitor the existing fleet as it is going to be around for some time Efforts devoted to doing this will not be wasted as the data collected will both help to ensure ongoing safety and provide a basis of selection for future firebombing aircraft ¡ Prior to conversion and usage SEI Systems & Electronics, Inc. 92

REGULATORY AND CERTIFICATION ISSUES ¿ Regulatory and Certification Authorities have to be involved in the process as ultimately they determine the airworthiness criteria against which the aircraft will be evaluated l ¿ Direct impact of their cost and economic viability There a number of issues which need to be addressed with the industry to ensure safe, economic and practical provision of firebombing services l Change Product Rule (CPR) ¡ Impact/Implications on future aircraft conversions l Pending NPRM on evaluation basis of operational aircraft over the next ten years ¡ Impact/Implications for existing firebombing fleet l Access to engineering and support data ¡ In the light of liability/risk concerns versus potential revenue streams ¡ Relevance of this data from an aging aircraft perspective ¿ Agreed Firebombing Certification Methodology? l Based on a recognition of the unique and challenging demands of this role SEI Systems & Electronics, Inc. 93

REGULATORY AND CERTIFICATION ISSUES ¿ Regulatory and Certification Authorities have to be involved in the process as ultimately they determine the airworthiness criteria against which the aircraft will be evaluated l ¿ Direct impact of their cost and economic viability There a number of issues which need to be addressed with the industry to ensure safe, economic and practical provision of firebombing services l Change Product Rule (CPR) ¡ Impact/Implications on future aircraft conversions l Pending NPRM on evaluation basis of operational aircraft over the next ten years ¡ Impact/Implications for existing firebombing fleet l Access to engineering and support data ¡ In the light of liability/risk concerns versus potential revenue streams ¡ Relevance of this data from an aging aircraft perspective ¿ Agreed Firebombing Certification Methodology? l Based on a recognition of the unique and challenging demands of this role SEI Systems & Electronics, Inc. 93

TRANSITIONING TO REPLACEMENT AIRCRAFT ¿ Fleet Replacement l Suitable Aircraft ¡ Capability to carry/deliver the retardant ¡ Evaluating the ability of the structure to perform in the firebombing role u Development of a firebombing specification ? ? ¿ Economic Basis l l l Investment in alternate aircraft Ongoing monitoring of firebombing aircraft Fatigue and Damage Tolerance Basis ¡ Maintenance and Inspection Intervals l Delivery and Payment Models Significant re-thinking of these issues as it would appear that the costs associated with the Blue Ribbon panel recommendations are not compatible with the current levels of funding SEI Systems & Electronics, Inc. 94

TRANSITIONING TO REPLACEMENT AIRCRAFT ¿ Fleet Replacement l Suitable Aircraft ¡ Capability to carry/deliver the retardant ¡ Evaluating the ability of the structure to perform in the firebombing role u Development of a firebombing specification ? ? ¿ Economic Basis l l l Investment in alternate aircraft Ongoing monitoring of firebombing aircraft Fatigue and Damage Tolerance Basis ¡ Maintenance and Inspection Intervals l Delivery and Payment Models Significant re-thinking of these issues as it would appear that the costs associated with the Blue Ribbon panel recommendations are not compatible with the current levels of funding SEI Systems & Electronics, Inc. 94

ADDITIONAL OBSERVATIONS ¿ ¿ Addressing all the issues related to the ongoing safe and economic operation of firebombing aircraft is a task for which no one organization would appear to have sufficient resources Although this environment is a competitive one, there are significant economic benefits to collaboration on issues that effect everyone l l l ¿ Now that the USDA/FS and SNL have developed the Infrastructure they are prepared to let other organizations can take advantage of this infrastructure on a cost recovery basis l ¿ Common recorder usage Common data collection and validation Combined efforts for fatigue and damage tolerance analysis of similar aircraft types Cost-effective way of implementation that allows everybody to benefit from generic data and trends Coordination of efforts and regular exchange of information between regulatory agencies, client organizations and operators l Wealth of experience distributed through a variety of forums ¡ Can a system of meetings and working groups be set-up to disseminate information and develop policies and procedures that would be beneficial to all? SEI Systems & Electronics, Inc. 95

ADDITIONAL OBSERVATIONS ¿ ¿ Addressing all the issues related to the ongoing safe and economic operation of firebombing aircraft is a task for which no one organization would appear to have sufficient resources Although this environment is a competitive one, there are significant economic benefits to collaboration on issues that effect everyone l l l ¿ Now that the USDA/FS and SNL have developed the Infrastructure they are prepared to let other organizations can take advantage of this infrastructure on a cost recovery basis l ¿ Common recorder usage Common data collection and validation Combined efforts for fatigue and damage tolerance analysis of similar aircraft types Cost-effective way of implementation that allows everybody to benefit from generic data and trends Coordination of efforts and regular exchange of information between regulatory agencies, client organizations and operators l Wealth of experience distributed through a variety of forums ¡ Can a system of meetings and working groups be set-up to disseminate information and develop policies and procedures that would be beneficial to all? SEI Systems & Electronics, Inc. 95

THE MISSING LINKS ¿ ¿ Predominantly focused on large airtankers Other aircraft involved in firebombing operations may be just as critical as they all work in a similar environment l l Smaller multi-engine and single engine airtankers Lead Aircraft Spotter (Bird-dog? ) aircraft Rotary Wing Aircraft SEI Systems & Electronics, Inc. 96

THE MISSING LINKS ¿ ¿ Predominantly focused on large airtankers Other aircraft involved in firebombing operations may be just as critical as they all work in a similar environment l l Smaller multi-engine and single engine airtankers Lead Aircraft Spotter (Bird-dog? ) aircraft Rotary Wing Aircraft SEI Systems & Electronics, Inc. 96

PENDING ACTIVITIES ¿ Collect data from existing instrumented aircraft and hopefully instrument more aircraft during the 2004 fire season l l ¿ Develop a consistent and coherent certification and operational monitoring mechanism in collaboration with regulatory agencies and operators l l ¿ Make best use of resources Avoid frustration Develop a certification and fatigue/damage tolerance template using data from the existing program l l ¿ Funding Provisions are a challenge – more reliance on inter-agency collaboration? These activities need to be commenced within the next month Confidence and consistency of approach Cost-Effective as approval of a plethora of approaches will not be required Develop collaborative efforts with other North American and non North American Agencies l l Benefits of accumulating data to characterize the firebombing role quicker Shared lessons learnt improve both safety and the cost-effectiveness of implementation SEI Systems & Electronics, Inc. 97

PENDING ACTIVITIES ¿ Collect data from existing instrumented aircraft and hopefully instrument more aircraft during the 2004 fire season l l ¿ Develop a consistent and coherent certification and operational monitoring mechanism in collaboration with regulatory agencies and operators l l ¿ Make best use of resources Avoid frustration Develop a certification and fatigue/damage tolerance template using data from the existing program l l ¿ Funding Provisions are a challenge – more reliance on inter-agency collaboration? These activities need to be commenced within the next month Confidence and consistency of approach Cost-Effective as approval of a plethora of approaches will not be required Develop collaborative efforts with other North American and non North American Agencies l l Benefits of accumulating data to characterize the firebombing role quicker Shared lessons learnt improve both safety and the cost-effectiveness of implementation SEI Systems & Electronics, Inc. 97

CONCLUSIONS/RECOMMENDATIONS ¿ There is an urgent safety and economic need to fully characterize the loads experienced in the firebombing role l l Existing Aircraft Develop specifications for future aircraft ¿ Due to the variability of operation, individual aircraft (total fleet) tracking systems should be implemented as soon as possible ¿ Initial data acquisition should be expanded to lead aircraft as soon as possible l ¿ ¿ Programs to assess how best lower capacity multi-engine aircraft, single engine aircraft and rotary wing aircraft can best be monitored should be explored as soon as possible A consistent and coherent certification and evaluation mechanism should be developed between contracting agencies, regulatory agencies and operators as soon as practicable l ¿ Appear to experience the most severe usage and yet are currently not monitored Validation through a template based on analysis of one or more existing aircraft types The establishment of a Strategic Firebombing Structural Health Management Plan (Rolling Ten Year Window) for the Acquisition and Ongoing Operation of all Fixed and Rotary-wing Aircraft Involved in Firebombing Roles is essential if the ongoing safe and economic operation of current and existing fleets is to be ensured l Reflect, current and future requirements together with associated funding levels ¡ ¿ It is hard to envisage how the approaches recommended by the Blue Ribbon panel as a consequence of the 2002 heavy airtanker accidents can be implemented within the current funding structure Inter-agency and International collaboration for the assessment of aircraft in the firebombing role will provide the quickest and most-cost-effective method of addressing the many common challenges that are faced by all agencies using aircraft in this role SEI Systems & Electronics, Inc. 98

CONCLUSIONS/RECOMMENDATIONS ¿ There is an urgent safety and economic need to fully characterize the loads experienced in the firebombing role l l Existing Aircraft Develop specifications for future aircraft ¿ Due to the variability of operation, individual aircraft (total fleet) tracking systems should be implemented as soon as possible ¿ Initial data acquisition should be expanded to lead aircraft as soon as possible l ¿ ¿ Programs to assess how best lower capacity multi-engine aircraft, single engine aircraft and rotary wing aircraft can best be monitored should be explored as soon as possible A consistent and coherent certification and evaluation mechanism should be developed between contracting agencies, regulatory agencies and operators as soon as practicable l ¿ Appear to experience the most severe usage and yet are currently not monitored Validation through a template based on analysis of one or more existing aircraft types The establishment of a Strategic Firebombing Structural Health Management Plan (Rolling Ten Year Window) for the Acquisition and Ongoing Operation of all Fixed and Rotary-wing Aircraft Involved in Firebombing Roles is essential if the ongoing safe and economic operation of current and existing fleets is to be ensured l Reflect, current and future requirements together with associated funding levels ¡ ¿ It is hard to envisage how the approaches recommended by the Blue Ribbon panel as a consequence of the 2002 heavy airtanker accidents can be implemented within the current funding structure Inter-agency and International collaboration for the assessment of aircraft in the firebombing role will provide the quickest and most-cost-effective method of addressing the many common challenges that are faced by all agencies using aircraft in this role SEI Systems & Electronics, Inc. 98

ACKNOWLEDGEMENTS ¿ TBM, IAR who have initiated and supported a lot of this recent work l l ¿ FAA, USDA/FS and Sandia Laboratories for their ongoing support of the recent work l l ¿ Woody Grantham/Fritz Wester (IAR) Norm Stubbs (TBM) John Howford, Tom Defiore, Carl Gray, Todd Martin and Steve Edgar of FAA Tony Kern and Ron Livingston of USDA/FS Staff members at Celeris Aerospace and SEI who have established an infrastructure for structural health monitoring of heavy airtankers and lead aircraft in an incredibly short timeframe SEI Systems & Electronics, Inc. 99

ACKNOWLEDGEMENTS ¿ TBM, IAR who have initiated and supported a lot of this recent work l l ¿ FAA, USDA/FS and Sandia Laboratories for their ongoing support of the recent work l l ¿ Woody Grantham/Fritz Wester (IAR) Norm Stubbs (TBM) John Howford, Tom Defiore, Carl Gray, Todd Martin and Steve Edgar of FAA Tony Kern and Ron Livingston of USDA/FS Staff members at Celeris Aerospace and SEI who have established an infrastructure for structural health monitoring of heavy airtankers and lead aircraft in an incredibly short timeframe SEI Systems & Electronics, Inc. 99

CONTACTING THE PRESENTER ¿ Celeris Aerospace Canada Inc. 880 Taylor Creek Drive Orleans, Ontario CANADA, K 1 C 1 T 1 Tel: FAX: (613) 837 -1161 (613) 834 -6420 Internet Steve Hall - halls@celeris. ca Webpage - http: //www. celeris. ca SEI Systems & Electronics, Inc. 100

CONTACTING THE PRESENTER ¿ Celeris Aerospace Canada Inc. 880 Taylor Creek Drive Orleans, Ontario CANADA, K 1 C 1 T 1 Tel: FAX: (613) 837 -1161 (613) 834 -6420 Internet Steve Hall - halls@celeris. ca Webpage - http: //www. celeris. ca SEI Systems & Electronics, Inc. 100