9bd909e61407942122e8a9d9e39c07e6.ppt

- Количество слайдов: 30

The Project for renovation to increase the efficient use in Brewery by NEDO at Bia Thanh Hoa Brewery in Vietnam 13 th September, 2006 New Energy and Industrial Technology Development Organization (NEDO) Jakarta Office 1

The Project for renovation to increase the efficient use in Brewery by NEDO at Bia Thanh Hoa Brewery in Vietnam 13 th September, 2006 New Energy and Industrial Technology Development Organization (NEDO) Jakarta Office 1

Outline of the Project Objective Increase the efficient use of energy 2

Outline of the Project Objective Increase the efficient use of energy 2

Outline of the Project with CDM Objective of the project Renovation to increase the efficient use of energy in brewery at Bia Thanh Hoa in Vietnam Implementation VRC system: Vapor Re-Compression system=Steam recovery Improvement of refrigeration system: To save electric power and manage power demand Improvement of pasteurizer: To save steam and water anaerobic waste water treatment and biogas boiler: To generate steam and treat waste water 3

Outline of the Project with CDM Objective of the project Renovation to increase the efficient use of energy in brewery at Bia Thanh Hoa in Vietnam Implementation VRC system: Vapor Re-Compression system=Steam recovery Improvement of refrigeration system: To save electric power and manage power demand Improvement of pasteurizer: To save steam and water anaerobic waste water treatment and biogas boiler: To generate steam and treat waste water 3

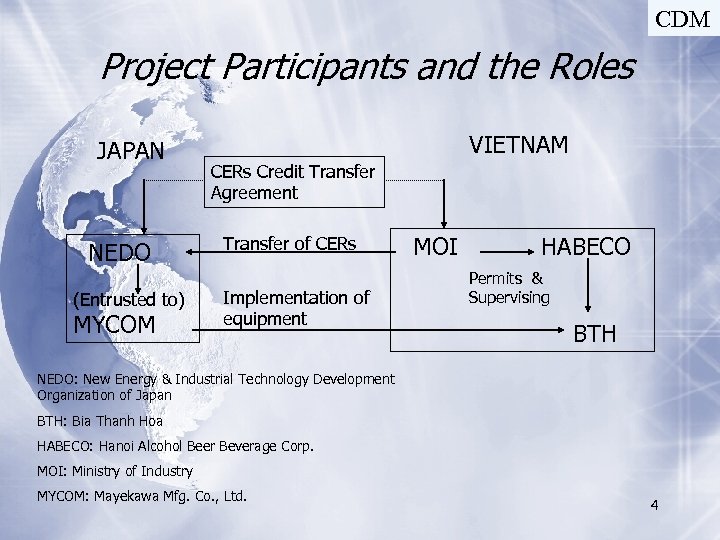

CDM Project Participants and the Roles JAPAN NEDO (Entrusted to) MYCOM VIETNAM CERs Credit Transfer Agreement Transfer of CERs Implementation of equipment MOI HABECO Permits & Supervising BTH NEDO: New Energy & Industrial Technology Development Organization of Japan BTH: Bia Thanh Hoa HABECO: Hanoi Alcohol Beer Beverage Corp. MOI: Ministry of Industry MYCOM: Mayekawa Mfg. Co. , Ltd. 4

CDM Project Participants and the Roles JAPAN NEDO (Entrusted to) MYCOM VIETNAM CERs Credit Transfer Agreement Transfer of CERs Implementation of equipment MOI HABECO Permits & Supervising BTH NEDO: New Energy & Industrial Technology Development Organization of Japan BTH: Bia Thanh Hoa HABECO: Hanoi Alcohol Beer Beverage Corp. MOI: Ministry of Industry MYCOM: Mayekawa Mfg. Co. , Ltd. 4

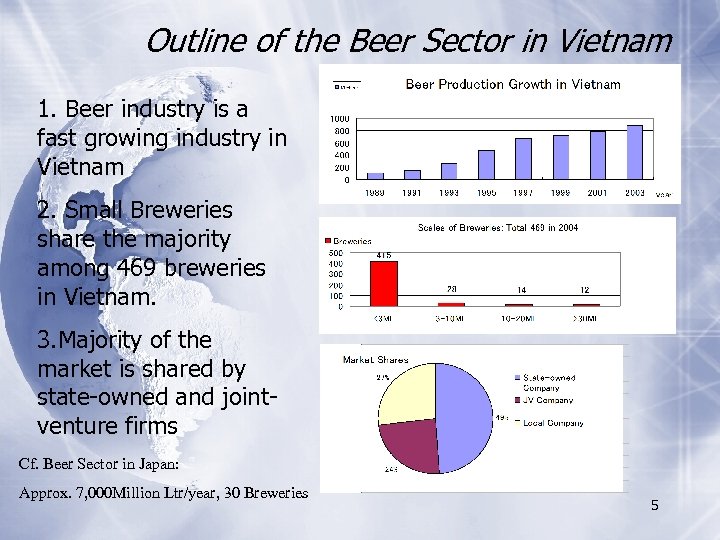

Outline of the Beer Sector in Vietnam 1. Beer industry is a fast growing industry in Vietnam 2. Small Breweries share the majority among 469 breweries in Vietnam. 3. Majority of the market is shared by state-owned and jointventure firms Cf. Beer Sector in Japan: Approx. 7, 000 Million Ltr/year, 30 Breweries 5

Outline of the Beer Sector in Vietnam 1. Beer industry is a fast growing industry in Vietnam 2. Small Breweries share the majority among 469 breweries in Vietnam. 3. Majority of the market is shared by state-owned and jointventure firms Cf. Beer Sector in Japan: Approx. 7, 000 Million Ltr/year, 30 Breweries 5

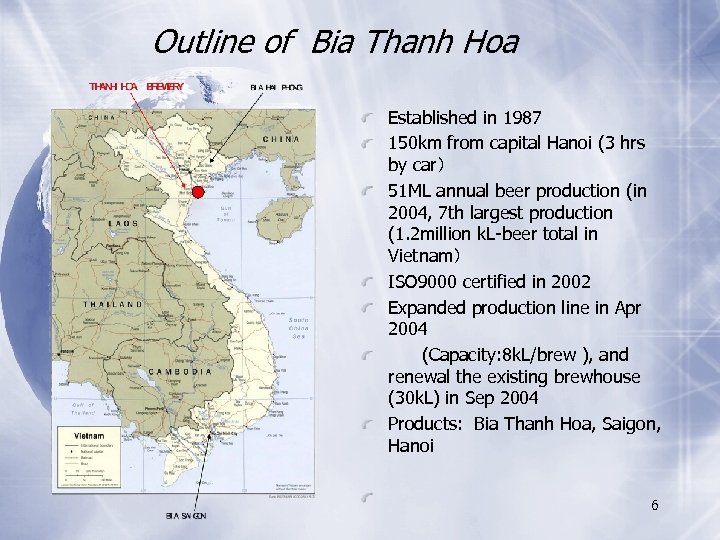

Outline of Bia Thanh Hoa Established in 1987 150 km from capital Hanoi (3 hrs by car) 51 ML annual beer production (in 2004, 7 th largest production (1. 2 million k. L-beer total in Vietnam) ISO 9000 certified in 2002 Expanded production line in Apr 2004 (Capacity: 8 k. L/brew ), and renewal the existing brewhouse (30 k. L) in Sep 2004 Products: Bia Thanh Hoa, Saigon, Hanoi 6

Outline of Bia Thanh Hoa Established in 1987 150 km from capital Hanoi (3 hrs by car) 51 ML annual beer production (in 2004, 7 th largest production (1. 2 million k. L-beer total in Vietnam) ISO 9000 certified in 2002 Expanded production line in Apr 2004 (Capacity: 8 k. L/brew ), and renewal the existing brewhouse (30 k. L) in Sep 2004 Products: Bia Thanh Hoa, Saigon, Hanoi 6

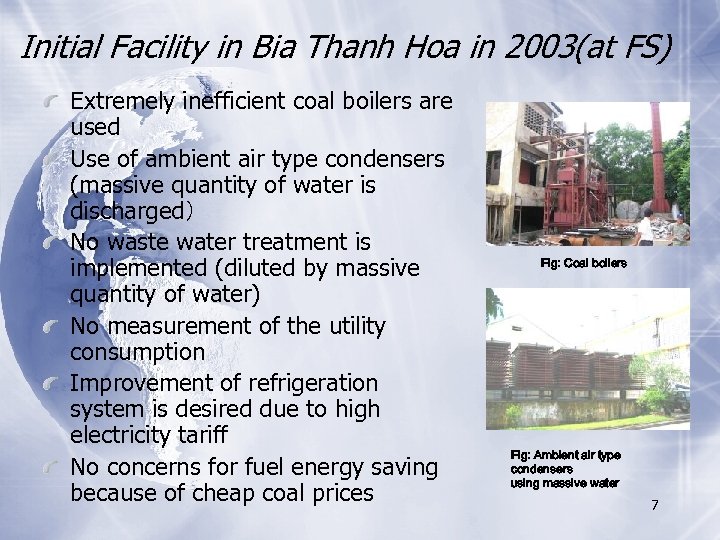

Initial Facility in Bia Thanh Hoa in 2003(at FS) Extremely inefficient coal boilers are used Use of ambient air type condensers (massive quantity of water is discharged) No waste water treatment is implemented (diluted by massive quantity of water) No measurement of the utility consumption Improvement of refrigeration system is desired due to high electricity tariff No concerns for fuel energy saving because of cheap coal prices Fig: Coal boilers Fig: Ambient air type condensers using massive water 7

Initial Facility in Bia Thanh Hoa in 2003(at FS) Extremely inefficient coal boilers are used Use of ambient air type condensers (massive quantity of water is discharged) No waste water treatment is implemented (diluted by massive quantity of water) No measurement of the utility consumption Improvement of refrigeration system is desired due to high electricity tariff No concerns for fuel energy saving because of cheap coal prices Fig: Coal boilers Fig: Ambient air type condensers using massive water 7

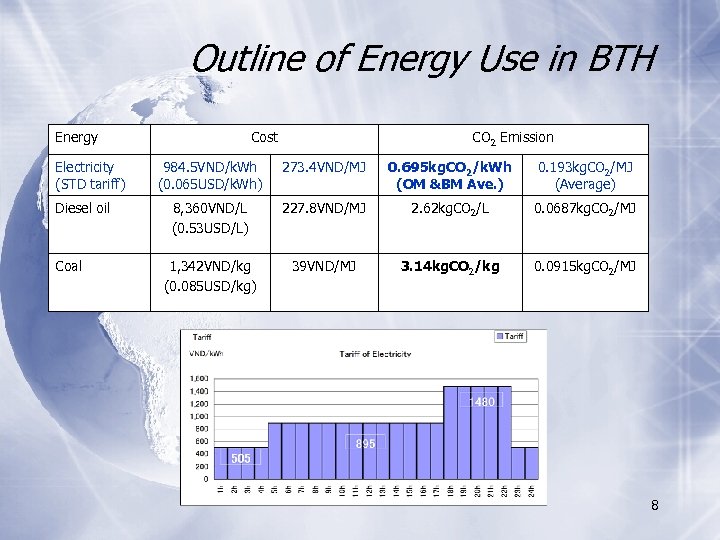

Outline of Energy Use in BTH Energy Electricity (STD tariff) Diesel oil Coal Cost CO 2 Emission 984. 5 VND/k. Wh (0. 065 USD/k. Wh) 273. 4 VND/MJ 0. 695 kg. CO 2/k. Wh (OM &BM Ave. ) 0. 193 kg. CO 2/MJ (Average) 8, 360 VND/L (0. 53 USD/L) 227. 8 VND/MJ 2. 62 kg. CO 2/L 0. 0687 kg. CO 2/MJ 1, 342 VND/kg (0. 085 USD/kg) 39 VND/MJ 3. 14 kg. CO 2/kg 0. 0915 kg. CO 2/MJ 8

Outline of Energy Use in BTH Energy Electricity (STD tariff) Diesel oil Coal Cost CO 2 Emission 984. 5 VND/k. Wh (0. 065 USD/k. Wh) 273. 4 VND/MJ 0. 695 kg. CO 2/k. Wh (OM &BM Ave. ) 0. 193 kg. CO 2/MJ (Average) 8, 360 VND/L (0. 53 USD/L) 227. 8 VND/MJ 2. 62 kg. CO 2/L 0. 0687 kg. CO 2/MJ 1, 342 VND/kg (0. 085 USD/kg) 39 VND/MJ 3. 14 kg. CO 2/kg 0. 0915 kg. CO 2/MJ 8

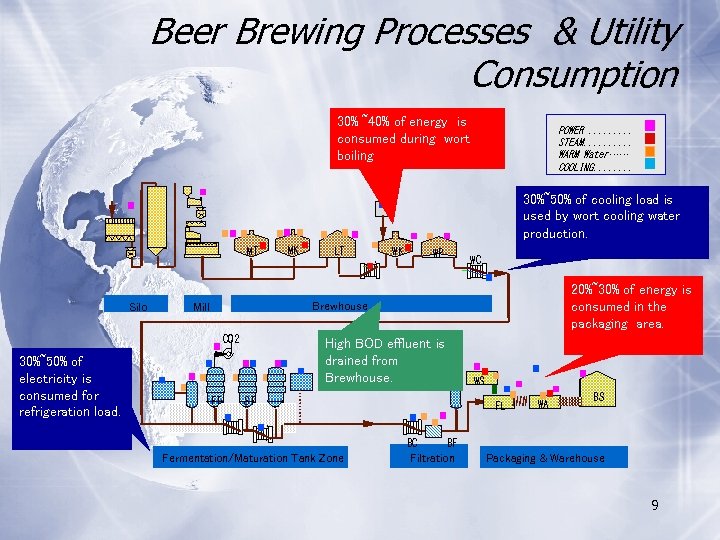

Beer Brewing Processes & Utility Consumption 30% ~40% of energy is consumed during wort boiling POWER. . STEAM. . WARM Water…… COOLING. . . . 30%~50% of cooling load is used by wort cooling water production. MT Silo LT WK WP WC 20%~30% of energy is consumed in the packaging area. Brewhouse Mill CO 2 30%~50% of electricity is consumed for refrigeration load. MK FT High BOD effluent is drained from Brewhouse. WS ST FL BC Fermentation/Maturation Tank Zone WA BS BF Filtration Packaging & Warehouse 9

Beer Brewing Processes & Utility Consumption 30% ~40% of energy is consumed during wort boiling POWER. . STEAM. . WARM Water…… COOLING. . . . 30%~50% of cooling load is used by wort cooling water production. MT Silo LT WK WP WC 20%~30% of energy is consumed in the packaging area. Brewhouse Mill CO 2 30%~50% of electricity is consumed for refrigeration load. MK FT High BOD effluent is drained from Brewhouse. WS ST FL BC Fermentation/Maturation Tank Zone WA BS BF Filtration Packaging & Warehouse 9

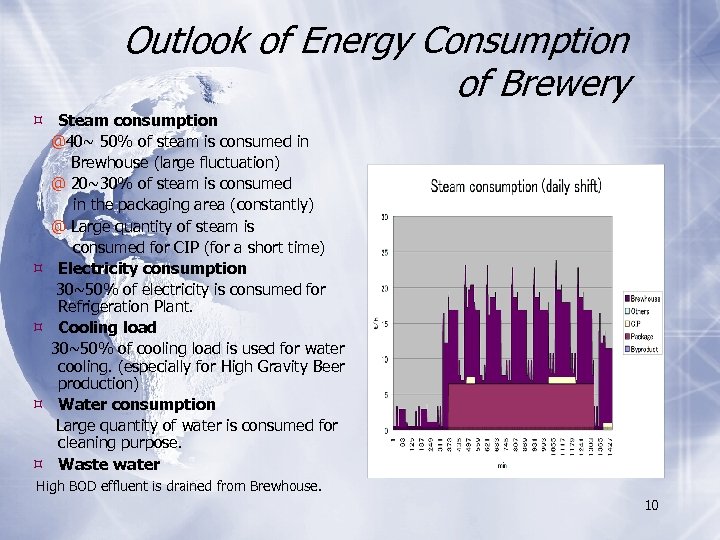

Outlook of Energy Consumption of Brewery Steam consumption @40~ 50% of steam is consumed in Brewhouse (large fluctuation) @ 20~30% of steam is consumed in the packaging area (constantly) @ Large quantity of steam is consumed for CIP (for a short time) Electricity consumption 30~50% of electricity is consumed for Refrigeration Plant. Cooling load 30~50% of cooling load is used for water cooling. (especially for High Gravity Beer production) Water consumption Large quantity of water is consumed for cleaning purpose. Waste water High BOD effluent is drained from Brewhouse. 10

Outlook of Energy Consumption of Brewery Steam consumption @40~ 50% of steam is consumed in Brewhouse (large fluctuation) @ 20~30% of steam is consumed in the packaging area (constantly) @ Large quantity of steam is consumed for CIP (for a short time) Electricity consumption 30~50% of electricity is consumed for Refrigeration Plant. Cooling load 30~50% of cooling load is used for water cooling. (especially for High Gravity Beer production) Water consumption Large quantity of water is consumed for cleaning purpose. Waste water High BOD effluent is drained from Brewhouse. 10

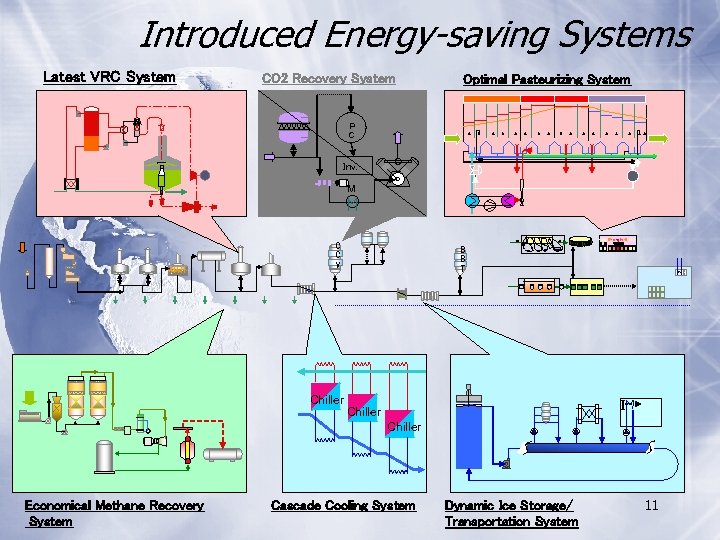

Introduced Energy-saving Systems Latest VRC System CO 2 Recovery System Optimal Pasteurizing System P C Inv. M C C V Chiller B B T Chiller Economical Methane Recovery System Cascade Cooling System Dynamic Ice Storage/ Transportation System 11

Introduced Energy-saving Systems Latest VRC System CO 2 Recovery System Optimal Pasteurizing System P C Inv. M C C V Chiller B B T Chiller Economical Methane Recovery System Cascade Cooling System Dynamic Ice Storage/ Transportation System 11

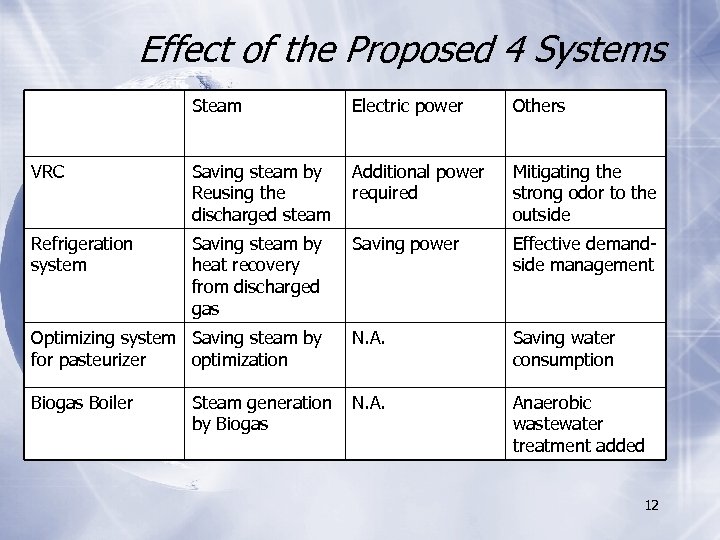

Effect of the Proposed 4 Systems Steam Electric power Others VRC Saving steam by Reusing the discharged steam Additional power required Mitigating the strong odor to the outside Refrigeration system Saving steam by heat recovery from discharged gas Saving power Effective demandside management Optimizing system Saving steam by for pasteurizer optimization N. A. Saving water consumption Biogas Boiler N. A. Anaerobic wastewater treatment added Steam generation by Biogas 12

Effect of the Proposed 4 Systems Steam Electric power Others VRC Saving steam by Reusing the discharged steam Additional power required Mitigating the strong odor to the outside Refrigeration system Saving steam by heat recovery from discharged gas Saving power Effective demandside management Optimizing system Saving steam by for pasteurizer optimization N. A. Saving water consumption Biogas Boiler N. A. Anaerobic wastewater treatment added Steam generation by Biogas 12

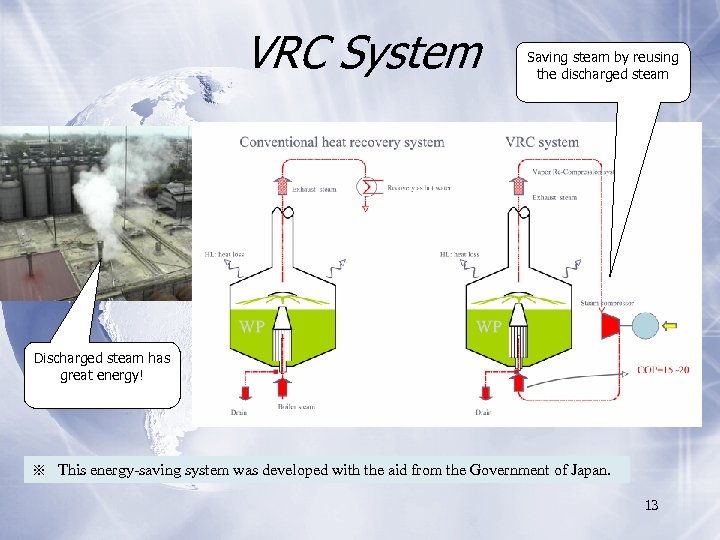

VRC System Saving steam by reusing the discharged steam Discharged steam has great energy! ※ This energy-saving system was developed with the aid from the Government of Japan. 13

VRC System Saving steam by reusing the discharged steam Discharged steam has great energy! ※ This energy-saving system was developed with the aid from the Government of Japan. 13

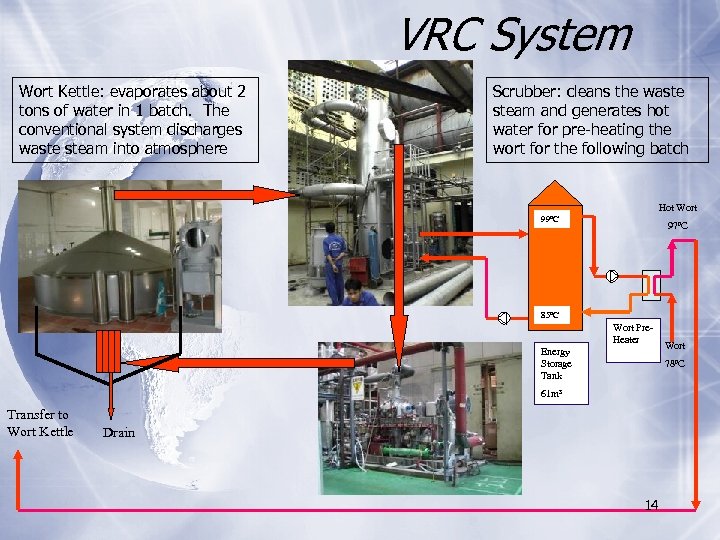

VRC System Wort Kettle: evaporates about 2 tons of water in 1 batch. The conventional system discharges waste steam into atmosphere Scrubber: cleans the waste steam and generates hot water for pre-heating the wort for the following batch Hot Wort 99ºC 97ºC 85ºC Wort Pre. Heater Energy Storage Tank 78ºC 61 m 3 Transfer to Wort Kettle Wort Drain 14

VRC System Wort Kettle: evaporates about 2 tons of water in 1 batch. The conventional system discharges waste steam into atmosphere Scrubber: cleans the waste steam and generates hot water for pre-heating the wort for the following batch Hot Wort 99ºC 97ºC 85ºC Wort Pre. Heater Energy Storage Tank 78ºC 61 m 3 Transfer to Wort Kettle Wort Drain 14

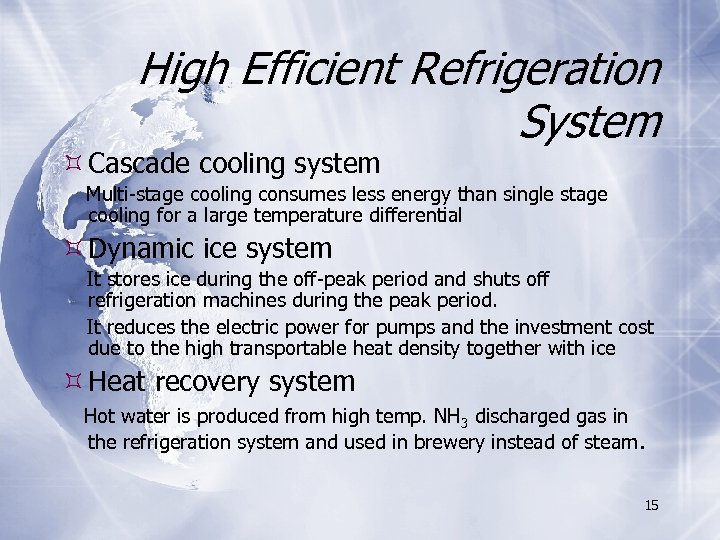

High Efficient Refrigeration System Cascade cooling system Multi-stage cooling consumes less energy than single stage cooling for a large temperature differential Dynamic ice system It stores ice during the off-peak period and shuts off refrigeration machines during the peak period. It reduces the electric power for pumps and the investment cost due to the high transportable heat density together with ice Heat recovery system Hot water is produced from high temp. NH 3 discharged gas in the refrigeration system and used in brewery instead of steam. 15

High Efficient Refrigeration System Cascade cooling system Multi-stage cooling consumes less energy than single stage cooling for a large temperature differential Dynamic ice system It stores ice during the off-peak period and shuts off refrigeration machines during the peak period. It reduces the electric power for pumps and the investment cost due to the high transportable heat density together with ice Heat recovery system Hot water is produced from high temp. NH 3 discharged gas in the refrigeration system and used in brewery instead of steam. 15

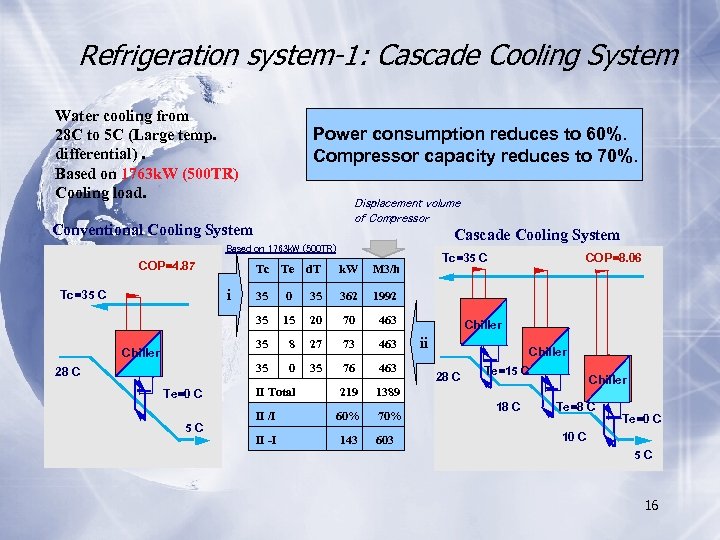

Refrigeration system-1: Cascade Cooling System Water cooling from 28 C to 5 C (Large temp. differential). Based on 1763 k. W (500 TR) Cooling load. Power consumption reduces to 60%. Compressor capacity reduces to 70%. Displacement volume of Compressor Conventional Cooling System Based on 1763 k. W (500 TR) COP=4. 87 Tc Te=0 C 5 C k. W 35 0 35 362 20 70 463 8 27 73 463 0 35 76 463 219 1389 II /I 60% 70% II -I 143 COP=8. 06 1992 15 Tc=35 C M 3/h 35 28 C d. T 35 Chiller Te 35 i Tc=35 C Cascade Cooling System II Total 603 Chiller ii Chiller 28 C Te=15 C 18 C Chiller Te=8 C Te=0 C 10 C 5 C 16

Refrigeration system-1: Cascade Cooling System Water cooling from 28 C to 5 C (Large temp. differential). Based on 1763 k. W (500 TR) Cooling load. Power consumption reduces to 60%. Compressor capacity reduces to 70%. Displacement volume of Compressor Conventional Cooling System Based on 1763 k. W (500 TR) COP=4. 87 Tc Te=0 C 5 C k. W 35 0 35 362 20 70 463 8 27 73 463 0 35 76 463 219 1389 II /I 60% 70% II -I 143 COP=8. 06 1992 15 Tc=35 C M 3/h 35 28 C d. T 35 Chiller Te 35 i Tc=35 C Cascade Cooling System II Total 603 Chiller ii Chiller 28 C Te=15 C 18 C Chiller Te=8 C Te=0 C 10 C 5 C 16

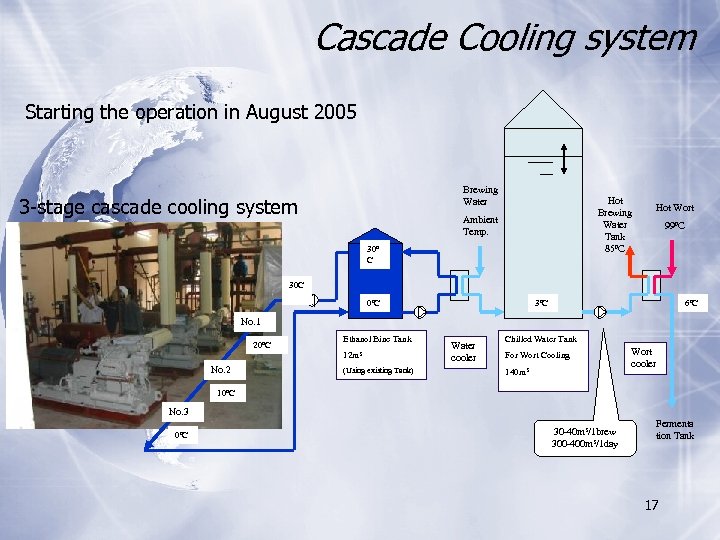

Cascade Cooling system Starting the operation in August 2005 Brewing Water 3 -stage cascade cooling system Hot Brewing Water Tank 85ºC Ambient Temp. 30º C Hot Wort 99ºC 30 C 0ºC 3ºC 6ºC No. 1 20ºC Ethanol Bine Tank 12 m 3 No. 2 (Using existing Tank) Water cooler Chilled Water Tank For Wort Cooling 140 m 3 Wort cooler 10ºC No. 3 0ºC 30 -40 m 3/1 brew 300 -400 m 3/1 day Fermenta tion Tank 17

Cascade Cooling system Starting the operation in August 2005 Brewing Water 3 -stage cascade cooling system Hot Brewing Water Tank 85ºC Ambient Temp. 30º C Hot Wort 99ºC 30 C 0ºC 3ºC 6ºC No. 1 20ºC Ethanol Bine Tank 12 m 3 No. 2 (Using existing Tank) Water cooler Chilled Water Tank For Wort Cooling 140 m 3 Wort cooler 10ºC No. 3 0ºC 30 -40 m 3/1 brew 300 -400 m 3/1 day Fermenta tion Tank 17

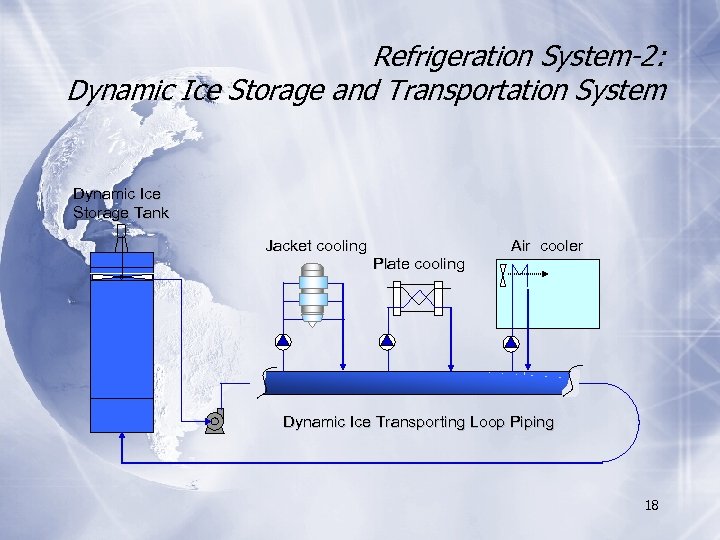

Refrigeration System-2: Dynamic Ice Storage and Transportation System Dynamic Ice Storage Tank Jacket cooling Plate cooling Air cooler Dynamic Ice Transporting Loop Piping 18

Refrigeration System-2: Dynamic Ice Storage and Transportation System Dynamic Ice Storage Tank Jacket cooling Plate cooling Air cooler Dynamic Ice Transporting Loop Piping 18

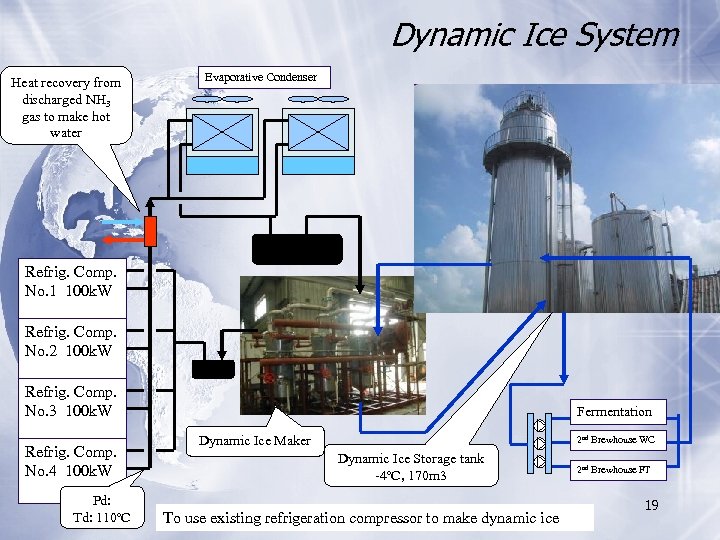

Dynamic Ice System Heat recovery from discharged NH 3 gas to make hot water Evaporative Condenser Refrig. Comp. No. 1 100 k. W Refrig. Comp. No. 2 100 k. W Refrig. Comp. No. 3 100 k. W Refrig. Comp. No. 4 100 k. W Pd: Td: 110ºC Fermentation Dynamic Ice Maker 2 nd Brewhouse WC Dynamic Ice Storage tank -4ºC, 170 m 3 To use existing refrigeration compressor to make dynamic ice 2 nd Brewhouse FT 19

Dynamic Ice System Heat recovery from discharged NH 3 gas to make hot water Evaporative Condenser Refrig. Comp. No. 1 100 k. W Refrig. Comp. No. 2 100 k. W Refrig. Comp. No. 3 100 k. W Refrig. Comp. No. 4 100 k. W Pd: Td: 110ºC Fermentation Dynamic Ice Maker 2 nd Brewhouse WC Dynamic Ice Storage tank -4ºC, 170 m 3 To use existing refrigeration compressor to make dynamic ice 2 nd Brewhouse FT 19

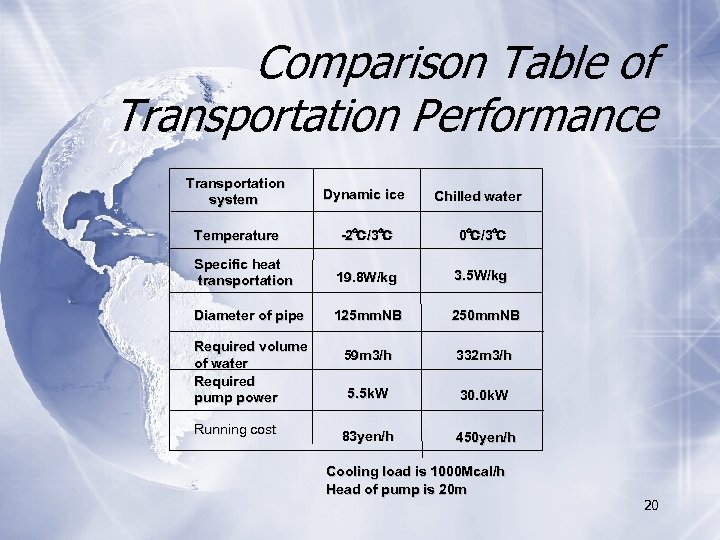

Comparison Table of Transportation Performance Transportation system Dynamic ice Temperature -2℃/3℃ -2℃ /3℃ Specific heat transportation Diameter of pipe Required volume of water Required pump power Running cost 19. 8 W/kg Chilled water 0℃/3℃ 3. 5 W/kg 125 mm. NB 250 mm. NB 59 m 3/h 332 m 3/h 5. 5 k. W 30. 0 k. W 83 yen/h 450 yen/h Cooling load is 1000 Mcal/h Head of pump is 20 m 20

Comparison Table of Transportation Performance Transportation system Dynamic ice Temperature -2℃/3℃ -2℃ /3℃ Specific heat transportation Diameter of pipe Required volume of water Required pump power Running cost 19. 8 W/kg Chilled water 0℃/3℃ 3. 5 W/kg 125 mm. NB 250 mm. NB 59 m 3/h 332 m 3/h 5. 5 k. W 30. 0 k. W 83 yen/h 450 yen/h Cooling load is 1000 Mcal/h Head of pump is 20 m 20

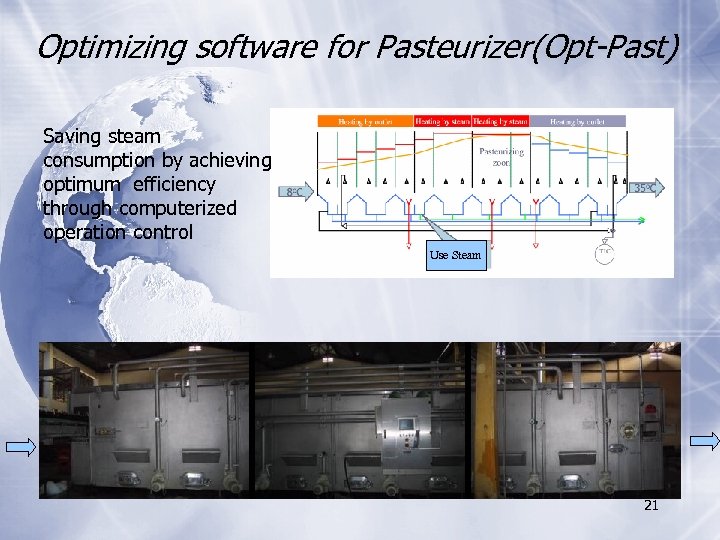

Optimizing software for Pasteurizer(Opt-Past) Saving steam consumption by achieving optimum efficiency through computerized operation control Use Steam 21

Optimizing software for Pasteurizer(Opt-Past) Saving steam consumption by achieving optimum efficiency through computerized operation control Use Steam 21

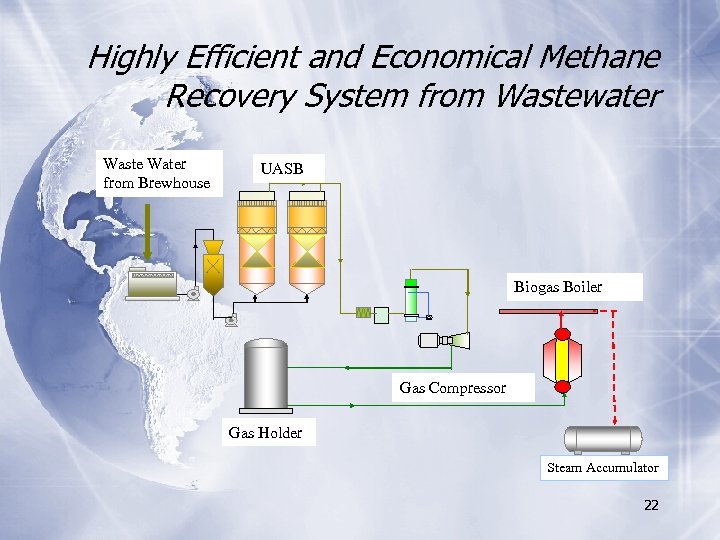

Highly Efficient and Economical Methane Recovery System from Wastewater Waste Water from Brewhouse UASB Biogas Boiler Gas Compressor Gas Holder Steam Accumulator 22

Highly Efficient and Economical Methane Recovery System from Wastewater Waste Water from Brewhouse UASB Biogas Boiler Gas Compressor Gas Holder Steam Accumulator 22

Effects of Energy-saving: CO 2 emission reduction: 3, 386 Toe/yr 10, 376 Ton/yr 23

Effects of Energy-saving: CO 2 emission reduction: 3, 386 Toe/yr 10, 376 Ton/yr 23

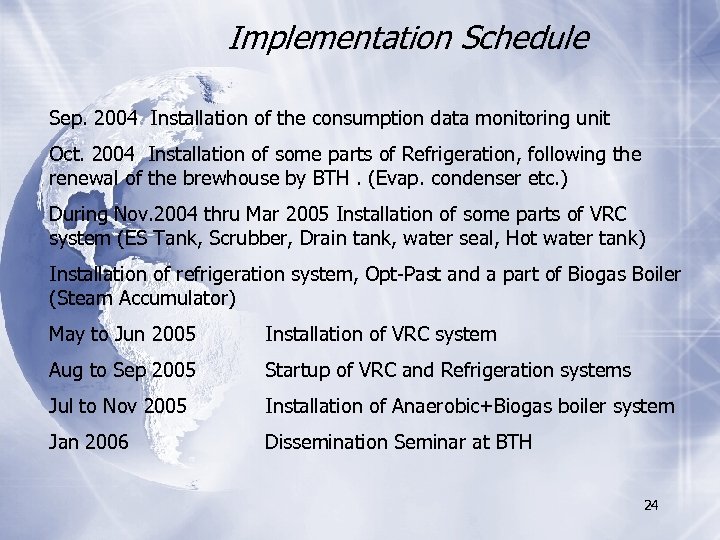

Implementation Schedule Sep. 2004 Installation of the consumption data monitoring unit Oct. 2004 Installation of some parts of Refrigeration, following the renewal of the brewhouse by BTH. (Evap. condenser etc. ) During Nov. 2004 thru Mar 2005 Installation of some parts of VRC system (ES Tank, Scrubber, Drain tank, water seal, Hot water tank) Installation of refrigeration system, Opt-Past and a part of Biogas Boiler (Steam Accumulator) May to Jun 2005 Installation of VRC system Aug to Sep 2005 Startup of VRC and Refrigeration systems Jul to Nov 2005 Installation of Anaerobic+Biogas boiler system Jan 2006 Dissemination Seminar at BTH 24

Implementation Schedule Sep. 2004 Installation of the consumption data monitoring unit Oct. 2004 Installation of some parts of Refrigeration, following the renewal of the brewhouse by BTH. (Evap. condenser etc. ) During Nov. 2004 thru Mar 2005 Installation of some parts of VRC system (ES Tank, Scrubber, Drain tank, water seal, Hot water tank) Installation of refrigeration system, Opt-Past and a part of Biogas Boiler (Steam Accumulator) May to Jun 2005 Installation of VRC system Aug to Sep 2005 Startup of VRC and Refrigeration systems Jul to Nov 2005 Installation of Anaerobic+Biogas boiler system Jan 2006 Dissemination Seminar at BTH 24

Technology Transfer Hardware Main equipment is made in Japan but the parts assembly and packaging are worked on by Vietnamese manufacturers under the supervision of Mayekawa. Software Human-machine interface improvement Group Activity (KAIZEN) Improve the motivation & increase Efficiency 25

Technology Transfer Hardware Main equipment is made in Japan but the parts assembly and packaging are worked on by Vietnamese manufacturers under the supervision of Mayekawa. Software Human-machine interface improvement Group Activity (KAIZEN) Improve the motivation & increase Efficiency 25

Hardware Technology Transferred Technologies Developed in Japan after Oil-crisis in 1978 VRC: developed technology under Moonlight Project Cascade system Dynamic ice System Anaerobic waste water treatment system (high temp. ) ※ Main equipments are made in Japan, while the parts assembly and packaging are worked on by Vietnamese manufacturers under the supervision of Mayekawa. 26

Hardware Technology Transferred Technologies Developed in Japan after Oil-crisis in 1978 VRC: developed technology under Moonlight Project Cascade system Dynamic ice System Anaerobic waste water treatment system (high temp. ) ※ Main equipments are made in Japan, while the parts assembly and packaging are worked on by Vietnamese manufacturers under the supervision of Mayekawa. 26

Software Technology Transfer Process control and operation are fully automated in breweries in Japan. However, employees are more involved in the manual operation of the process rather than fully automated operation in Vietnam. Involvement of operator in the manual operation must be considered in designing the operation and control system and through training. 27

Software Technology Transfer Process control and operation are fully automated in breweries in Japan. However, employees are more involved in the manual operation of the process rather than fully automated operation in Vietnam. Involvement of operator in the manual operation must be considered in designing the operation and control system and through training. 27

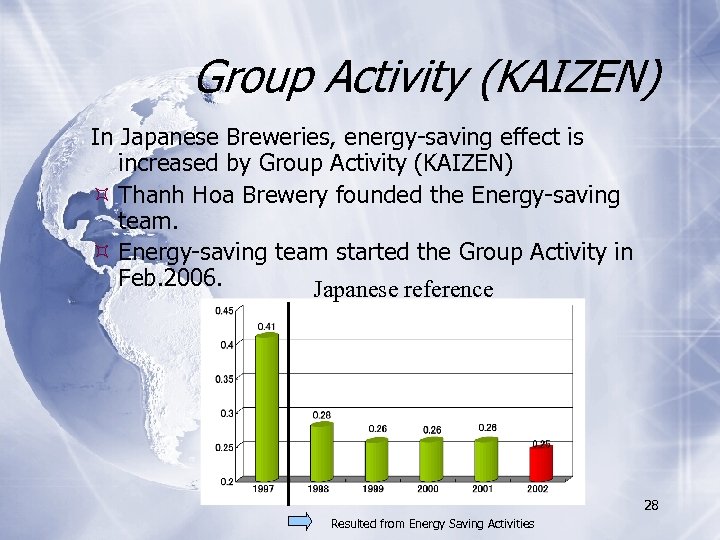

Group Activity (KAIZEN) In Japanese Breweries, energy-saving effect is increased by Group Activity (KAIZEN) Thanh Hoa Brewery founded the Energy-saving team started the Group Activity in Feb. 2006. Japanese reference 28 Resulted from Energy Saving Activities

Group Activity (KAIZEN) In Japanese Breweries, energy-saving effect is increased by Group Activity (KAIZEN) Thanh Hoa Brewery founded the Energy-saving team started the Group Activity in Feb. 2006. Japanese reference 28 Resulted from Energy Saving Activities

Dissemination The final objective of the project is the dissemination of energy saving technologies in Vietnam. For this purpose, breweries and beverage companies will be invited to inspect the actual reference and effectiveness of energy saving systems installed in BTH 29

Dissemination The final objective of the project is the dissemination of energy saving technologies in Vietnam. For this purpose, breweries and beverage companies will be invited to inspect the actual reference and effectiveness of energy saving systems installed in BTH 29

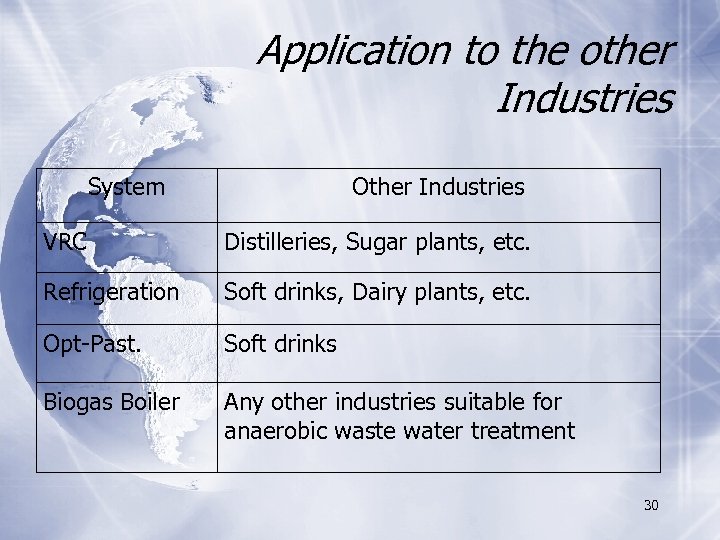

Application to the other Industries System Other Industries VRC Distilleries, Sugar plants, etc. Refrigeration Soft drinks, Dairy plants, etc. Opt-Past. Soft drinks Biogas Boiler Any other industries suitable for anaerobic waste water treatment 30

Application to the other Industries System Other Industries VRC Distilleries, Sugar plants, etc. Refrigeration Soft drinks, Dairy plants, etc. Opt-Past. Soft drinks Biogas Boiler Any other industries suitable for anaerobic waste water treatment 30