e16c3e3247191708c30001e9be12b78c.ppt

- Количество слайдов: 19

The Open. O&M™ Initiative and MIMOSA Enabling Open Standards-based Operations and Maintenance Interoperability for Plants, Facilities and fleets Alan T. Johnston MIMOSA President Open. O&M™ Initiative Chair ISO TC 184 Manufacturing Asset Management Integration Task Force Chair High North Project MIMOSA Workshop Oslo, Norway September 15, 2008 Copyright 2008 MIMOSA

What is MIMOSA § MIMOSA is an alliance of Operations & Maintenance (O&M) • • • Solution providers End-users Original Equipment Manufacturers (OEM) § Advocating and developing industry-driven open standards to enable open standardsbased O&M interoperability • • Owner/operator (end-user) leadership Vendor support § Individually and in collaboration with other standards and industry organizations § MIMOSA has broad, long-standing ties to most international, national and Do. D interoperability efforts related to Physical Asset Life-cycle Management (of which CBM is a subset) via multiple formal ties to ANSI and ISO as well as multiple industry associations. (details in later slides) § Mimosa was formally organized in 1997 as a non-profit 501 (c) (6) trade association § Objective - enable a fundamental shift from a project-centric systems integration model to an industry-centric open-standards based interoperability model § MIMOSA, working in concert with ANSI, ISO and other consensus standards organizations provides a variety of standards and specifications focused on enabling open standardsbased O&M interoperability for people, processes and systems. MIMOSA has a particular focus on Physical Asset Life-cycle Management, of which CBM is a component. § Current activities are focused on providing a practical, incremental interoperability pathway from today’s IT/IS environment to the semantic web. Copyright 2008 MIMOSA

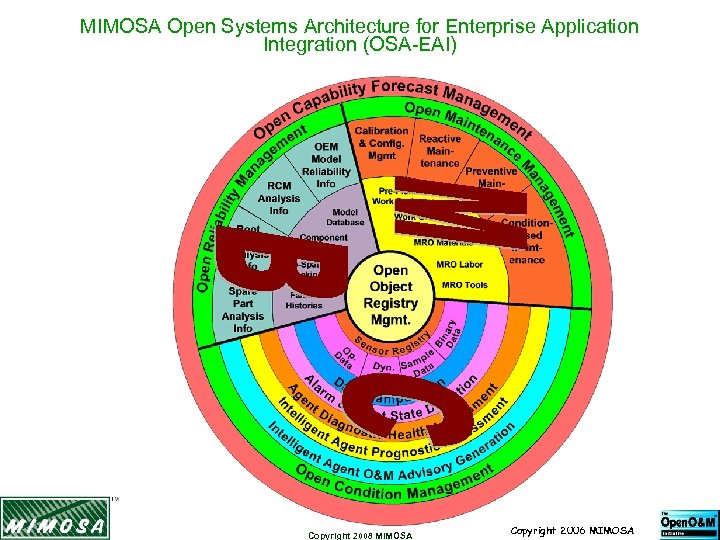

MIMOSA Open Systems Architecture for Enterprise Application Integration (OSA-EAI) Copyright 2008 MIMOSA Copyright 2006 MIMOSA

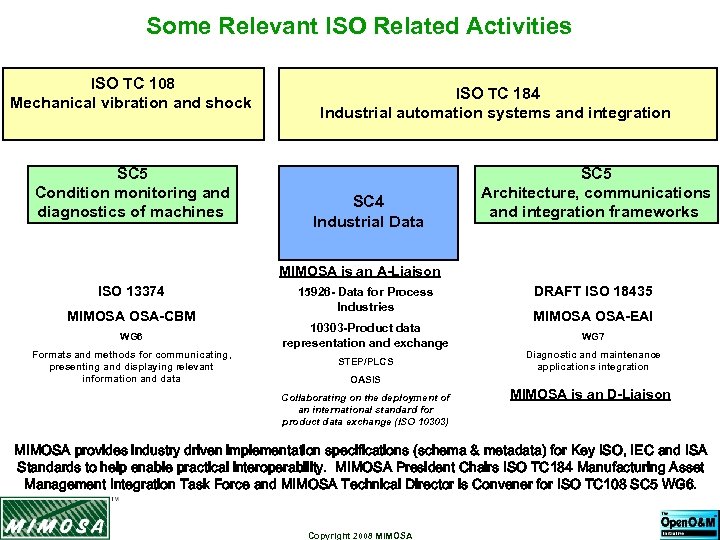

Some Relevant ISO Related Activities ISO TC 108 Mechanical vibration and shock SC 5 Condition monitoring and diagnostics of machines ISO TC 184 Industrial automation systems and integration SC 4 Industrial Data SC 5 Architecture, communications and integration frameworks MIMOSA is an A-Liaison ISO 13374 MIMOSA OSA-CBM WG 6 Formats and methods for communicating, presenting and displaying relevant information and data 15926 - Data for Process Industries 10303 -Product data representation and exchange STEP/PLCS DRAFT ISO 18435 MIMOSA OSA-EAI WG 7 Diagnostic and maintenance applications integration OASIS Collaborating on the deployment of an international standard for product data exchange (ISO 10303) MIMOSA is an D-Liaison MIMOSA provides industry driven implementation specifications (schema & metadata) for Key ISO, IEC and ISA Standards to help enable practical interoperability. MIMOSA President Chairs ISO TC 184 Manufacturing Asset Management Integration Task Force and MIMOSA Technical Director is Convener for ISO TC 108 SC 5 WG 6. Copyright 2008 MIMOSA

Opportunity For Global Colaboration § § CIEAM - Asia Pacific / Australia Region Open. O&M FIATECH POSC Caesar Copyright 2008 MIMOSA

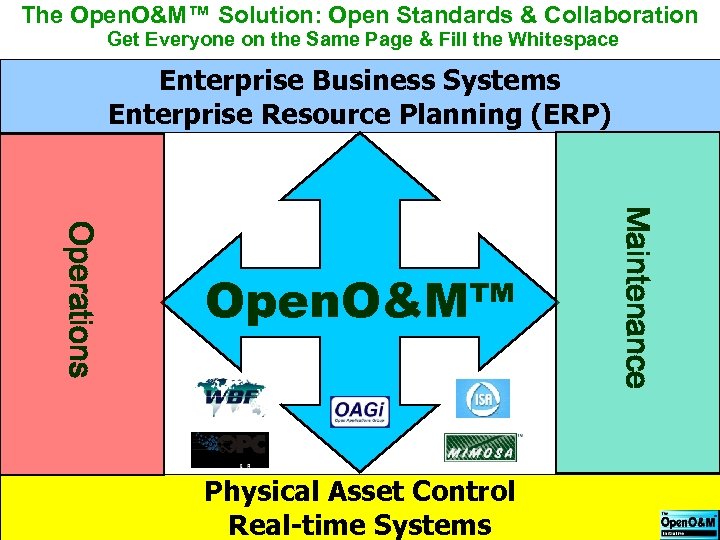

The Open. O&M™ Solution: Open Standards & Collaboration Get Everyone on the Same Page & Fill the Whitespace Enterprise Business Systems Enterprise Resource Planning (ERP) Physical Asset Control Real-time Systems Copyright 2008 MIMOSA Maintenance Operations Open. O&M™

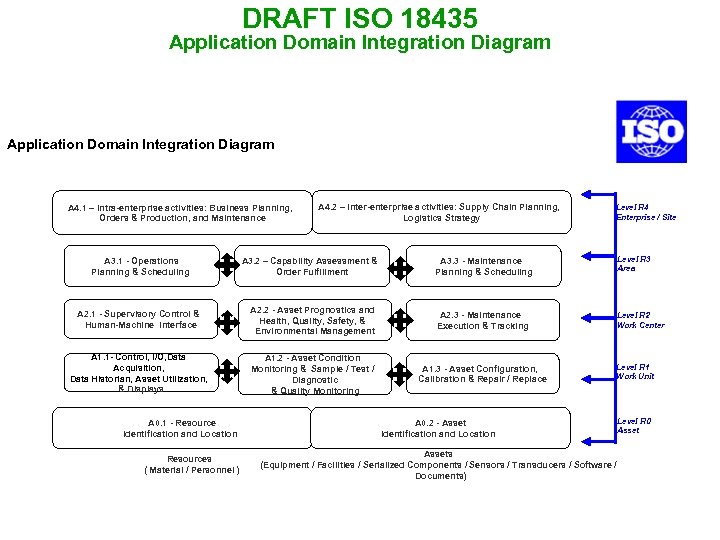

DRAFT ISO 18435 Application Domain Integration Diagram A 4. 1 – Intra-enterprise activities: Business Planning, Orders & Production, and Maintenance A 3. 1 - Operations Planning & Scheduling A 4. 2 – Inter-enterprise activities: Supply Chain Planning, Logistics Strategy A 3. 2 – Capability Assessment & Order Fulfillment A 3. 3 - Maintenance Planning & Scheduling Level R 3 Area Level R 2 Work Center A 2. 1 - Supervisory Control & Human-Machine Interface A 2. 2 - Asset Prognostics and Health, Quality, Safety, & Environmental Management A 2. 3 - Maintenance Execution & Tracking A 1. 1 - Control, I/O, Data Acquisition, Data Historian, Asset Utilization, & Displays A 1. 2 - Asset Condition Monitoring & Sample / Test / Diagnostic & Quality Monitoring A 1. 3 - Asset Configuration, Calibration & Repair / Replace A 0. 1 - Resource Identification and Location Resources ( Material / Personnel ) Level R 4 Enterprise / Site Level R 1 Work Unit A 0. 2 - Asset Identification and Location Assets (Equipment / Facilities / Serialized Components / Sensors / Transducers / Software / Documents) Level R 0 Asset

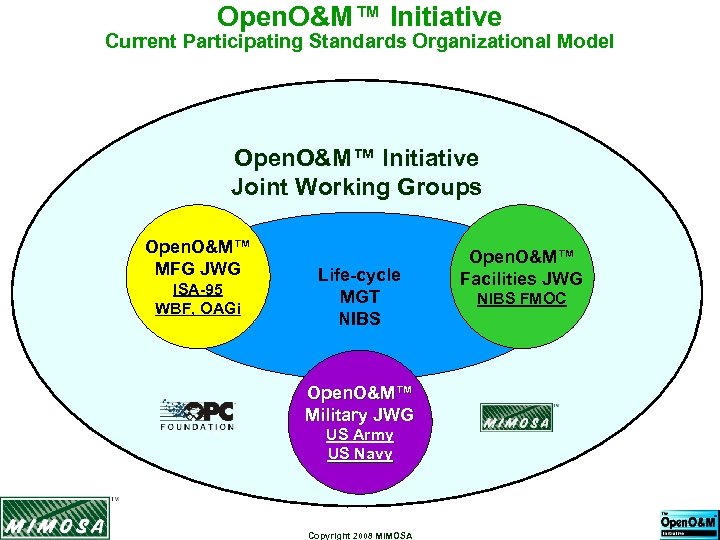

Open. O&M™ Initiative Current Participating Standards Organizational Model Open. O&M™ Initiative Joint Working Groups Open. O&M™ MFG JWG ISA-95 WBF, OAGi Life-cycle MGT NIBS Open. O&M™ Military JWG US Army US Navy Copyright 2008 MIMOSA Open. O&M™ Facilities JWG NIBS FMOC

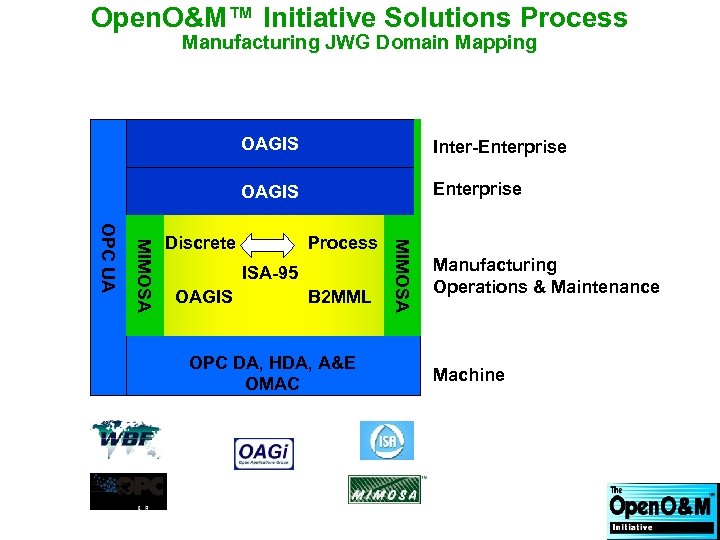

Open. O&M™ Initiative Solutions Process Manufacturing JWG Domain Mapping OAGIS Inter-Enterprise OAGIS Enterprise ISA-95 OAGIS B 2 MML OPC DA, HDA, A&E OMAC MIMOSA OPC UA Process Discrete Manufacturing Operations & Maintenance Machine

Owner/Operator Leadership With Vendor Support Selected Supporting Organizations-Petrochemical and Oil and Gas Industry Copyright 2008 MIMOSA

Slides From MIMOSA/Open. O&M Meetings at BP in Houston 8/25/2008 Copyright 2008 MIMOSA

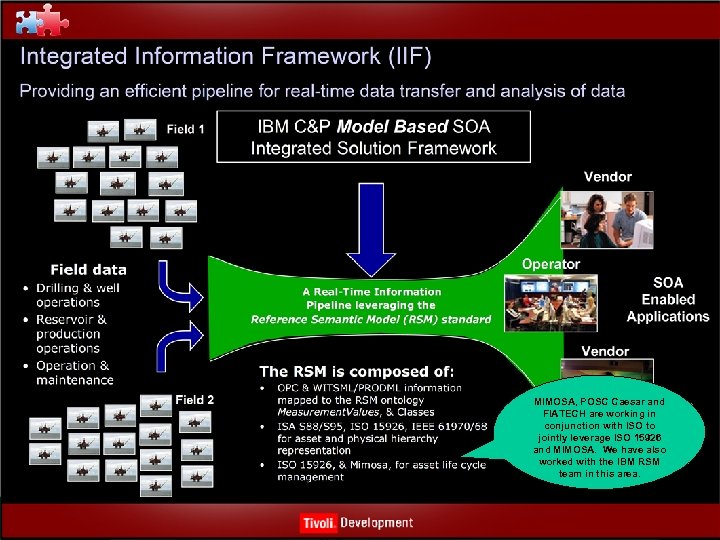

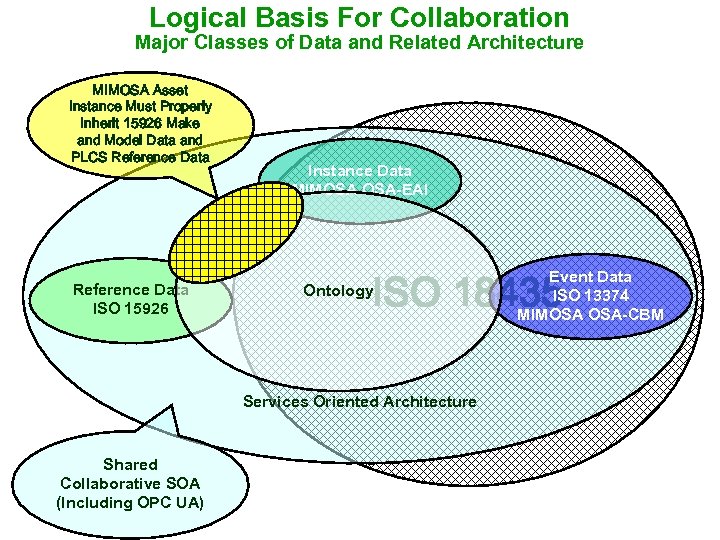

MIMOSA, POSC Caesar and FIATECH are working in conjunction with ISO to jointly leverage ISO 15926 and MIMOSA. We have also worked with the IBM RSM team in this area. Copyright 2008 MIMOSA

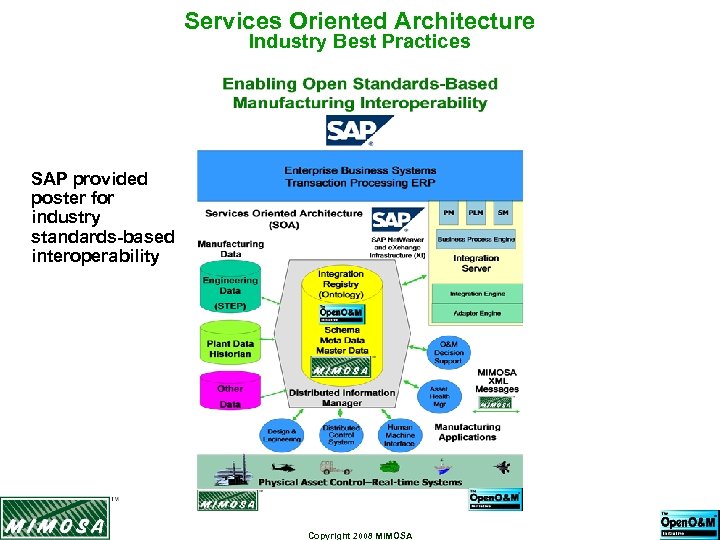

Services Oriented Architecture Industry Best Practices SAP provided poster for industry standards-based interoperability Copyright 2008 MIMOSA

The Open. O&M™ Initiative Enabling Open Standards-Based Interoperability A Collaborative, Consensus-based Solutions Process ØIndustry Requirements-driven ØOwner/Operator Leadership ØParticipation of Key Standards Organizations ØVendor Supported Key Objectives v. To enable a shift from a product and project-centric systems integration model to an industry-centric, open standards-based interoperability model. v. To enable critical global infrastructure to be modeled, monitored and managed in a cohesive and practical fashion. v. Supporting emerging operational and enterprise risk management requirements for reliability, safety and quality (requires increasing levels of interoperability) Copyright 2008 MIMOSA

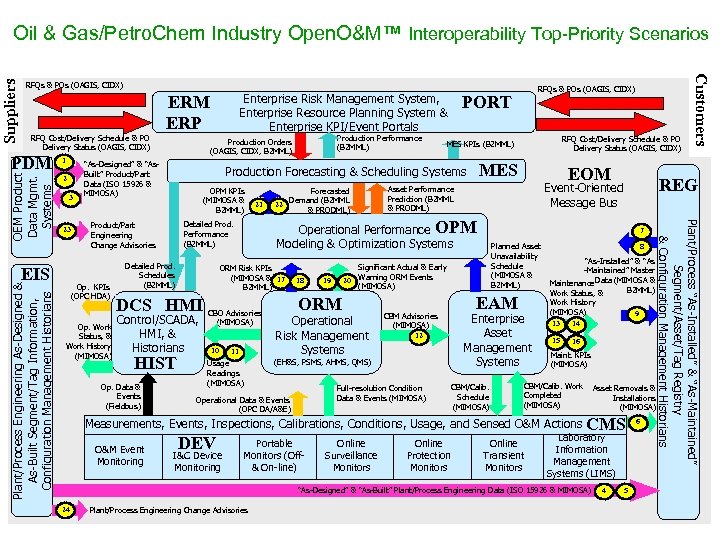

RFQs & POs (OAGIS, CIDX) RFQ Cost/Delivery Schedule & PO Delivery Status (OAGIS, CIDX) 1 2 3 23 Plant/Process Engineering As-Designed & As-Built Segment/Tag Information, Configuration Management Historians EIS “As-Designed” & “As. Built” Product/Part Data (ISO 15926 & MIMOSA) OPM KPIs (MIMOSA & B 2 MML) Op. Work Status, & Work History (MIMOSA) 21 ORM Risk KPIs (MIMOSA & 17 B 2 MML) DCS HMI CBO Advisories Control/SCADA, HMI, & Historians HIST Op. Data & Events (Fieldbus) MES (MIMOSA) 10 11 Usage Readings (MIMOSA) 18 ORM Operational Risk Management Systems CBM Advisories (MIMOSA) 12 (EH&S, PSMS, AHMS, QMS) Full-resolution Condition Data & Events (MIMOSA) Operational Data & Events (OPC DA/A&E) REG Event-Oriented Message Bus 7 Planned Asset Unavailability Schedule (MIMOSA & B 2 MML) Significant Actual & Early 20 Warning ORM Events (MIMOSA) 19 EOM Asset Performance Prediction (B 2 MML & PRODML) Operational Performance OPM Modeling & Optimization Systems Detailed Prod. Performance (B 2 MML) Detailed Prod. Schedules (B 2 MML) Forecasted Demand (B 2 MML 22 & PRODML) RFQ Cost/Delivery Schedule & PO Delivery Status (OAGIS, CIDX) MES KPIs (B 2 MML) Production Forecasting & Scheduling Systems Product/Part Engineering Change Advisories Op. KPIs (OPC HDA) Production Performance (B 2 MML) Production Orders (OAGIS, CIDX, B 2 MML) RFQs & POs (OAGIS, CIDX) PORT EAM Enterprise Asset Management Systems CBM/Calib. Schedule (MIMOSA) 8 “As-Installed” & “As -Maintained” Master Maintenance Data (MIMOSA & B 2 MML) Work Status, & Work History (MIMOSA) 13 14 15 9 16 Maint. KPIs (MIMOSA) CBM/Calib. Work Completed (MIMOSA) Asset Removals & Installations (MIMOSA) Measurements, Events, Inspections, Calibrations, Conditions, Usage, and Sensed O&M Actions CMS O&M Event Monitoring DEV I&C Device Monitoring Portable Monitors (Off& On-line) Online Surveillance Monitors Online Protection Monitors Online Transient Monitors Laboratory Information Management Systems (LIMS) “As-Designed” & “As-Built” Plant/Process Engineering Data (ISO 15926 & MIMOSA) 24 Plant/Process Engineering Change Advisories 4 5 6 Plant/Process “As-Installed” & “As-Maintained” Segment/Asset/Tag Registry & Configuration Management Historians OEM Product Data Mgmt. Systems PDM Enterprise Risk Management System, Enterprise Resource Planning System & Enterprise KPI/Event Portals ERM ERP Customers Suppliers Oil & Gas/Petro. Chem Industry Open. O&M™ Interoperability Top-Priority Scenarios

Logical Basis For Collaboration Major Classes of Data and Related Architecture MIMOSA Asset Instance Must Properly Inherit 15926 Make and Model Data and PLCS Reference Data ISO 15926 Instance Data MIMOSA OSA-EAI ISO 18435 Ontology Services Oriented Architecture Shared Collaborative SOA (Including OPC UA) Event Data ISO 13374 MIMOSA OSA-CBM

e16c3e3247191708c30001e9be12b78c.ppt