cd5769469672ee1032c30f08a19ba79f.ppt

- Количество слайдов: 93

The NDA Prioritisation Process – Practitioners’ Workshop, August 2007 Mark Wareing, Decommissioning Strategy Manager

The NDA Prioritisation Process – Practitioners’ Workshop, August 2007 Mark Wareing, Decommissioning Strategy Manager

Why NDA Prioritisation Process • Requirement of Energy Act • Vehicle for stakeholder engagement • Provides a framework and common language to underpin decisions The Prioritisation Process is about communication 2

Why NDA Prioritisation Process • Requirement of Energy Act • Vehicle for stakeholder engagement • Provides a framework and common language to underpin decisions The Prioritisation Process is about communication 2

How Was It Developed • • Developed over past three years Wide range of stakeholders involved Tested as part of LTP 06 Used in full for first time for draft LTP 08 submission • Still some wrinkles to be sorted out 3

How Was It Developed • • Developed over past three years Wide range of stakeholders involved Tested as part of LTP 06 Used in full for first time for draft LTP 08 submission • Still some wrinkles to be sorted out 3

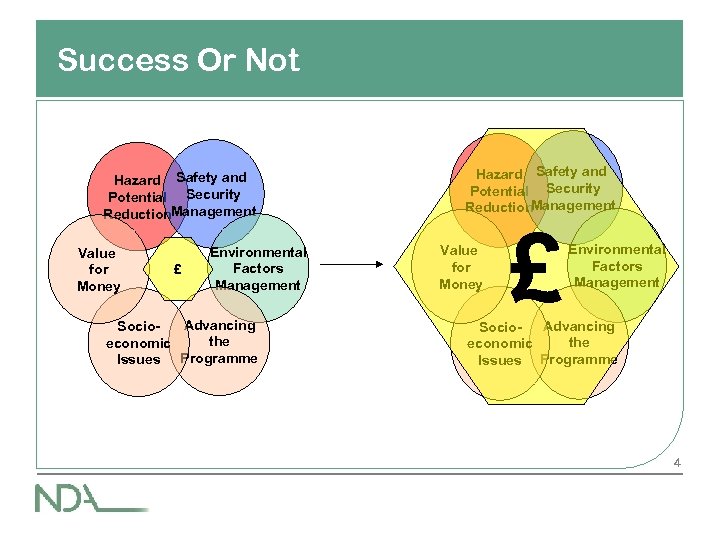

Success Or Not Hazard Safety and Potential Security Reduction. Management Value for Money £ Environmental Factors Management Advancing Sociothe economic Issues Programme 4

Success Or Not Hazard Safety and Potential Security Reduction. Management Value for Money £ Environmental Factors Management Advancing Sociothe economic Issues Programme 4

What Doesn’t it do • Commercial operations – Covered by energy Act • Remove requirement to think • Provide SLCs with a reason for not discharging their statutory duties. • Replace regulatory due process. Focuses on Why not How 5

What Doesn’t it do • Commercial operations – Covered by energy Act • Remove requirement to think • Provide SLCs with a reason for not discharging their statutory duties. • Replace regulatory due process. Focuses on Why not How 5

Process The process is made up of the following steps: • Assess facilities using Safety And Environmental Detriment (SED) Measure • Assess SED Reduction Projects using project benefit measure • Schedule to meet funding constraints based on legal requirements (safe and secure), existing commercial commitments and project benefit, taking account of: – Facility SED Score v Project Benefit Score – Appropriate regulator and stakeholder modifiers • Produce SED Reduction measure 6

Process The process is made up of the following steps: • Assess facilities using Safety And Environmental Detriment (SED) Measure • Assess SED Reduction Projects using project benefit measure • Schedule to meet funding constraints based on legal requirements (safe and secure), existing commercial commitments and project benefit, taking account of: – Facility SED Score v Project Benefit Score – Appropriate regulator and stakeholder modifiers • Produce SED Reduction measure 6

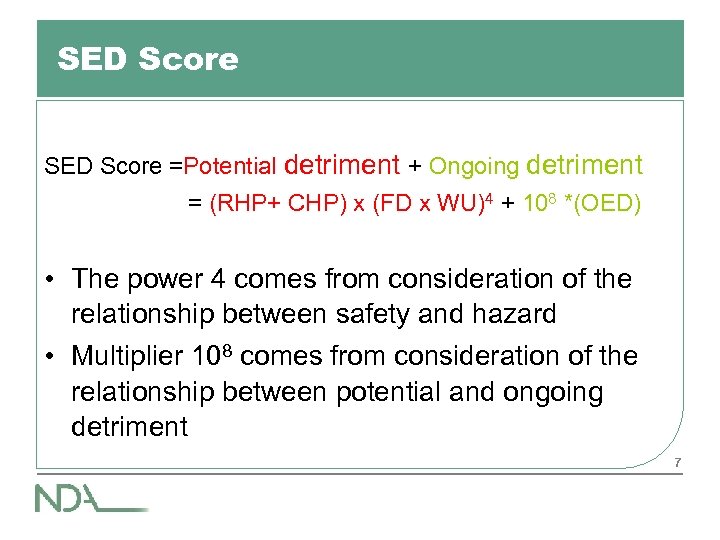

SED Score =Potential detriment + Ongoing detriment = (RHP+ CHP) x (FD x WU)4 + 108 *(OED) • The power 4 comes from consideration of the relationship between safety and hazard • Multiplier 108 comes from consideration of the relationship between potential and ongoing detriment 7

SED Score =Potential detriment + Ongoing detriment = (RHP+ CHP) x (FD x WU)4 + 108 *(OED) • The power 4 comes from consideration of the relationship between safety and hazard • Multiplier 108 comes from consideration of the relationship between potential and ongoing detriment 7

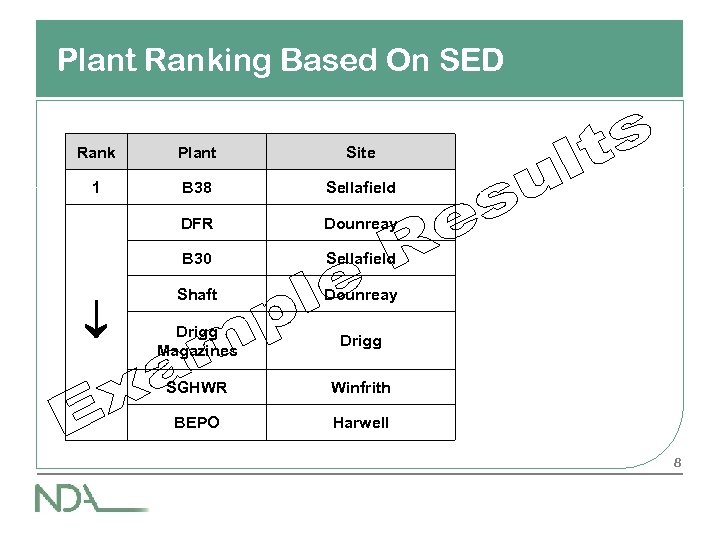

Plant Ranking Based On SED Rank Plant Site 1 B 38 Sellafield DFR Dounreay B 30 Sellafield Shaft Dounreay Drigg Magazines Drigg SGHWR Winfrith BEPO Harwell 8

Plant Ranking Based On SED Rank Plant Site 1 B 38 Sellafield DFR Dounreay B 30 Sellafield Shaft Dounreay Drigg Magazines Drigg SGHWR Winfrith BEPO Harwell 8

SED Reduction Project An SED Reduction project includes all the work necessary to take an inventory, or group of inventories, from their current state to an improved state. The SLCs are responsible for defining the SED Reduction Projects 9

SED Reduction Project An SED Reduction project includes all the work necessary to take an inventory, or group of inventories, from their current state to an improved state. The SLCs are responsible for defining the SED Reduction Projects 9

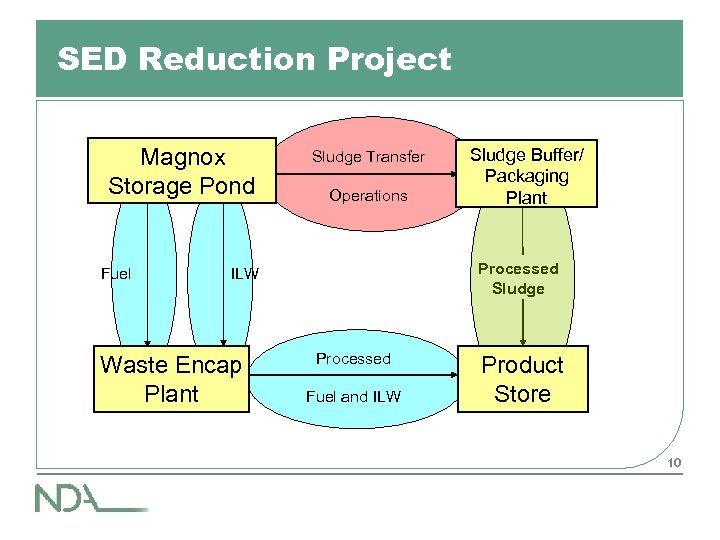

SED Reduction Project Magnox Storage Pond Fuel Sludge Transfer Operations Processed Sludge ILW Waste Encap Plant Sludge Buffer/ Packaging Plant Processed Fuel and ILW Product Store 10

SED Reduction Project Magnox Storage Pond Fuel Sludge Transfer Operations Processed Sludge ILW Waste Encap Plant Sludge Buffer/ Packaging Plant Processed Fuel and ILW Product Store 10

![Project Benefit = (∆HP vs t) + [(FD + Wud + (∆LD vs t)]/3 Project Benefit = (∆HP vs t) + [(FD + Wud + (∆LD vs t)]/3](https://present5.com/presentation/cd5769469672ee1032c30f08a19ba79f/image-11.jpg) Project Benefit = (∆HP vs t) + [(FD + Wud + (∆LD vs t)]/3 [(∆HP vs £) + (∆OFC vs t)]/2 + (OED vs t) + ∆ = Change in attribute • Looks at change against project cost and time • Scored using look up tables based on what is considered to be good • Attributes not weighted scored from 100 Note, ∆HP = (RHP 1+ CHP 1) - (RHP 2 + CHP 2) 11

Project Benefit = (∆HP vs t) + [(FD + Wud + (∆LD vs t)]/3 [(∆HP vs £) + (∆OFC vs t)]/2 + (OED vs t) + ∆ = Change in attribute • Looks at change against project cost and time • Scored using look up tables based on what is considered to be good • Attributes not weighted scored from 100 Note, ∆HP = (RHP 1+ CHP 1) - (RHP 2 + CHP 2) 11

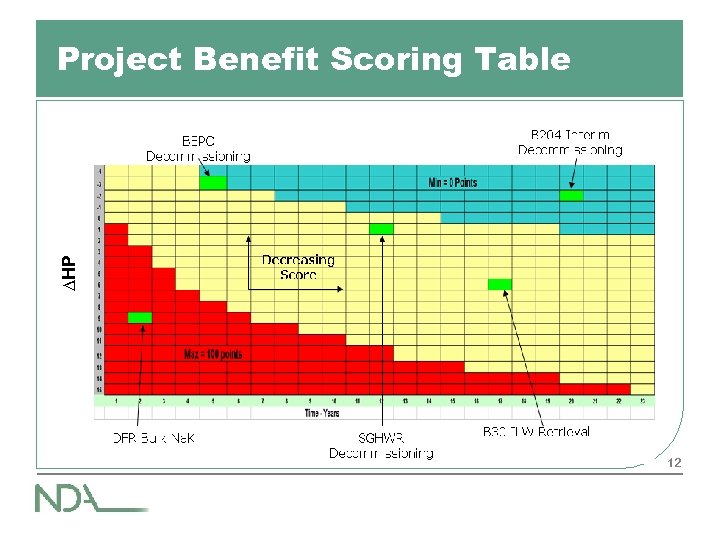

∆HP Project Benefit Scoring Table 12

∆HP Project Benefit Scoring Table 12

Low Project Benefit Score Projects for high SED facilities may have low benefit score for following reasons: • SED Reduction Project not defined correctly • Poor project strategy • Very complex problem which takes long time and costs a lot to resolve 13

Low Project Benefit Score Projects for high SED facilities may have low benefit score for following reasons: • SED Reduction Project not defined correctly • Poor project strategy • Very complex problem which takes long time and costs a lot to resolve 13

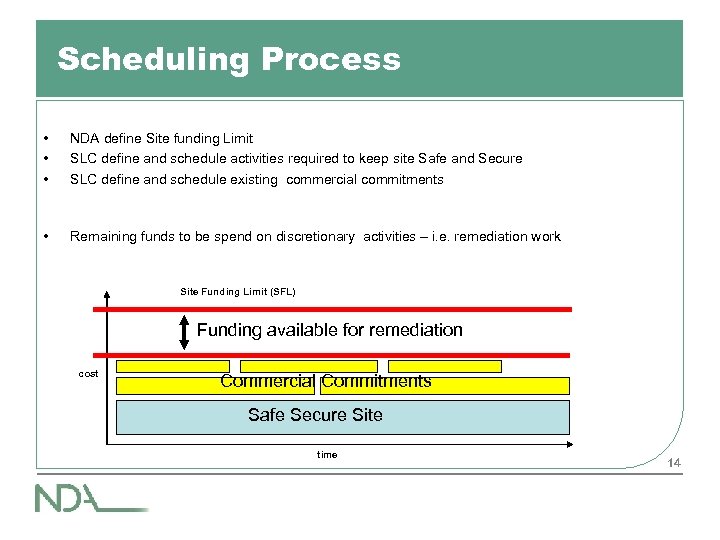

Scheduling Process • • • NDA define Site funding Limit SLC define and schedule activities required to keep site Safe and Secure SLC define and schedule existing commercial commitments • Remaining funds to be spend on discretionary activities – i. e. remediation work Site Funding Limit (SFL) Funding available for remediation cost Commercial Commitments Safe Secure Site time 14

Scheduling Process • • • NDA define Site funding Limit SLC define and schedule activities required to keep site Safe and Secure SLC define and schedule existing commercial commitments • Remaining funds to be spend on discretionary activities – i. e. remediation work Site Funding Limit (SFL) Funding available for remediation cost Commercial Commitments Safe Secure Site time 14

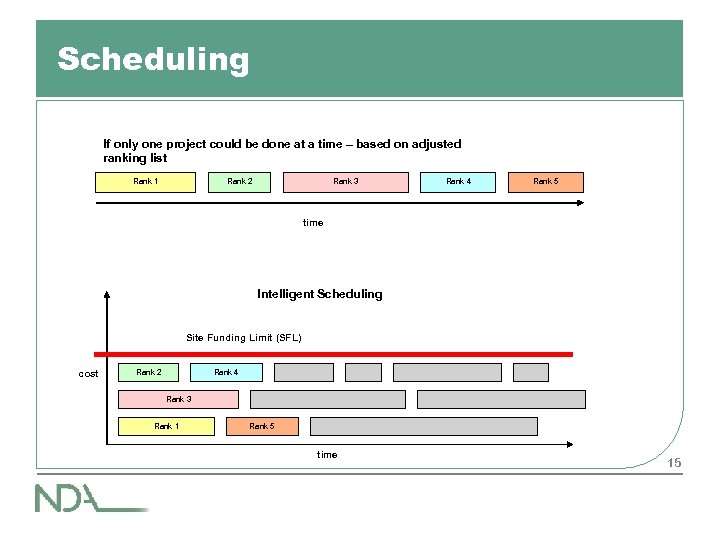

Scheduling If only one project could be done at a time – based on adjusted ranking list Rank 1 Rank 2 Rank 3 Rank 4 Rank 5 time Intelligent Scheduling Site Funding Limit (SFL) cost Rank 2 Rank 4 Rank 3 Rank 1 Rank 5 time 15

Scheduling If only one project could be done at a time – based on adjusted ranking list Rank 1 Rank 2 Rank 3 Rank 4 Rank 5 time Intelligent Scheduling Site Funding Limit (SFL) cost Rank 2 Rank 4 Rank 3 Rank 1 Rank 5 time 15

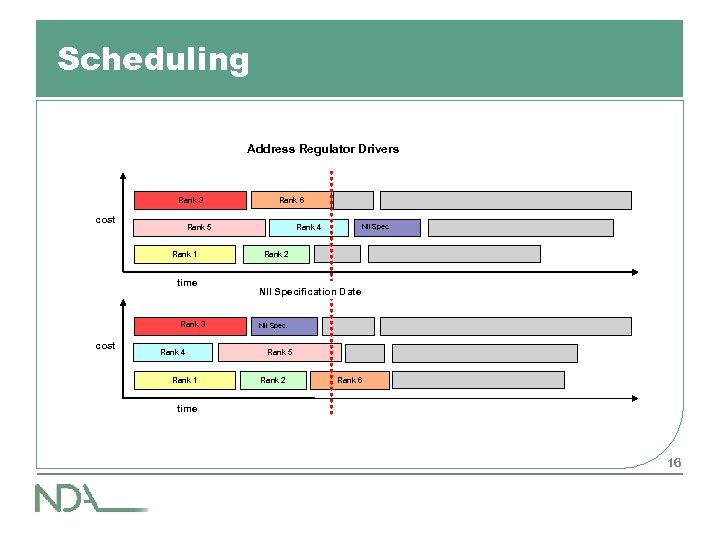

Scheduling Address Regulator Drivers Rank 3 cost Rank 5 Rank 1 time Rank 3 cost Rank 6 Rank 4 Rank 1 NII Spec. Rank 4 Rank 2 NII Specification Date NII Spec. Rank 5 Rank 2 Rank 6 time 16

Scheduling Address Regulator Drivers Rank 3 cost Rank 5 Rank 1 time Rank 3 cost Rank 6 Rank 4 Rank 1 NII Spec. Rank 4 Rank 2 NII Specification Date NII Spec. Rank 5 Rank 2 Rank 6 time 16

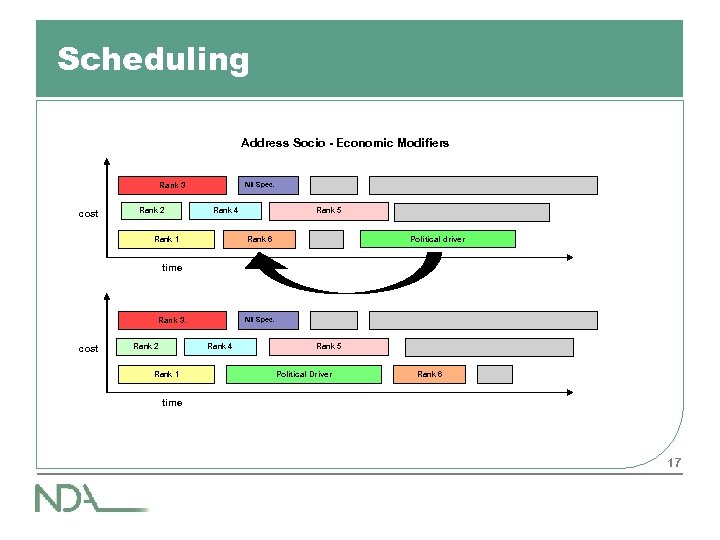

Scheduling Address Socio - Economic Modifiers NII Spec. Rank 3 cost Rank 2 Rank 4 Rank 5 Rank 6 Rank 1 Political driver time NII Spec. Rank 3. cost Rank 2 Rank 4 Rank 1 Rank 5 Political Driver Rank 6 time 17

Scheduling Address Socio - Economic Modifiers NII Spec. Rank 3 cost Rank 2 Rank 4 Rank 5 Rank 6 Rank 1 Political driver time NII Spec. Rank 3. cost Rank 2 Rank 4 Rank 1 Rank 5 Political Driver Rank 6 time 17

Scheduling Key thing is audit trail 18

Scheduling Key thing is audit trail 18

SED Reduction Measure • Calculated by recalculating SED scores at future points in time, based on Project Delivery Strategy • Can be used to assess value for money • Can be used to assess innovation 19

SED Reduction Measure • Calculated by recalculating SED scores at future points in time, based on Project Delivery Strategy • Can be used to assess value for money • Can be used to assess innovation 19

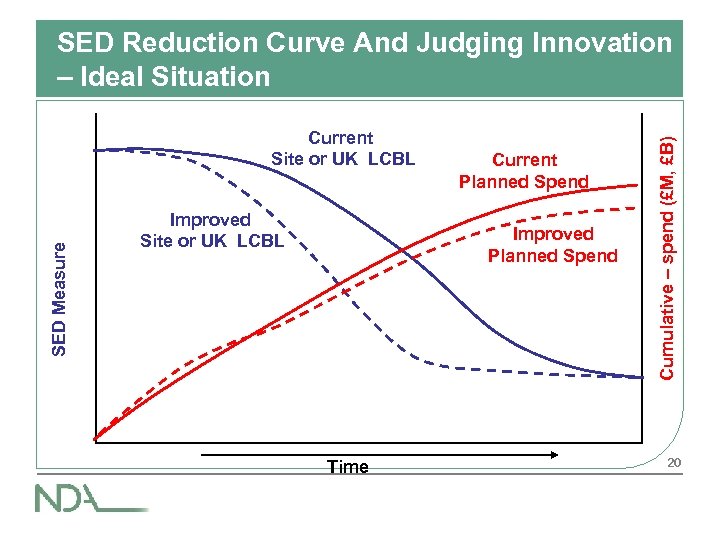

SED Measure Current Site or UK LCBL Improved Site or UK LCBL Current Planned Spend Improved Planned Spend Time Cumulative – spend (£M, £B) SED Reduction Curve And Judging Innovation – Ideal Situation 20

SED Measure Current Site or UK LCBL Improved Site or UK LCBL Current Planned Spend Improved Planned Spend Time Cumulative – spend (£M, £B) SED Reduction Curve And Judging Innovation – Ideal Situation 20

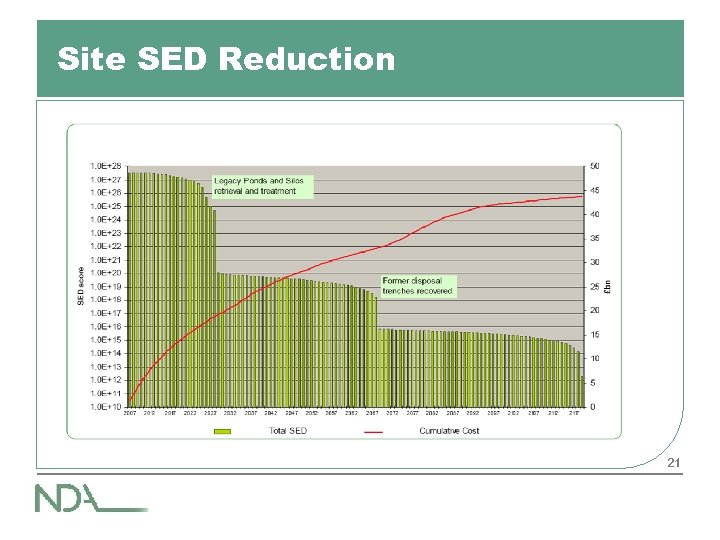

Site SED Reduction 21

Site SED Reduction 21

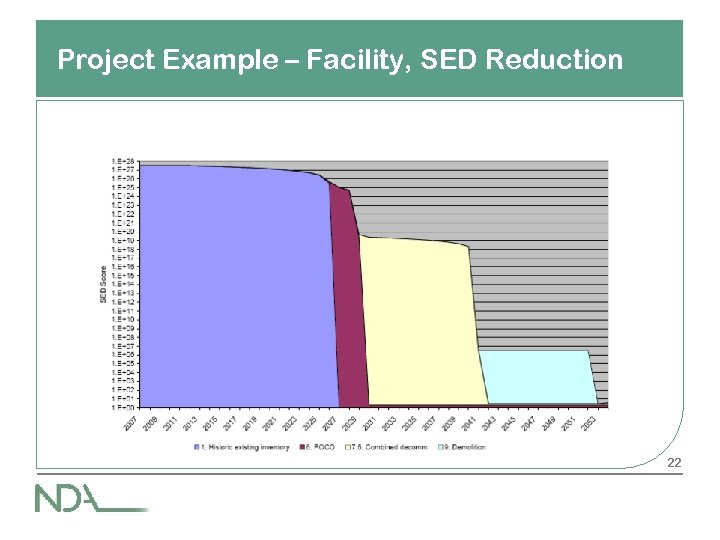

Project Example – Facility, SED Reduction 22

Project Example – Facility, SED Reduction 22

Draft LTP Submission • Process applied by all SLCs • Revised process for scoring contaminated land has provided more realistic scores • Chemical hazard raised some issues • OED score needs revision to deminimus score • Some inconsistency in results particularly from Magnox stations 23

Draft LTP Submission • Process applied by all SLCs • Revised process for scoring contaminated land has provided more realistic scores • Chemical hazard raised some issues • OED score needs revision to deminimus score • Some inconsistency in results particularly from Magnox stations 23

Results from Audit 07 Will Pearson, REACT

Results from Audit 07 Will Pearson, REACT

Output from audit process • Yearly process of audit to be carried out. • 5 audits carried out this year to ‘review’ output and identify good practice. • Technical Queries’ (TQ’s) raised to enable verification of submitted data and further capture of good practice. 25

Output from audit process • Yearly process of audit to be carried out. • 5 audits carried out this year to ‘review’ output and identify good practice. • Technical Queries’ (TQ’s) raised to enable verification of submitted data and further capture of good practice. 25

Key Messages • Data sets are largely complete – the sites have complied some very valuable archives of information. • Sites must start to consider what the data means – not necessarily to be undertaken by the practitioners themselves • Level of understanding is improving however there are some significant issues with consistency between similar sites. 26

Key Messages • Data sets are largely complete – the sites have complied some very valuable archives of information. • Sites must start to consider what the data means – not necessarily to be undertaken by the practitioners themselves • Level of understanding is improving however there are some significant issues with consistency between similar sites. 26

Key Messages • Significant amount of guidance and background information of the NDA website which is not being utilised by practitioners • Practitioners need to improve understanding of RHP and CHP to help improve consistency in SED scores • Need to continue to detach SED Reduction Projects from LTP DVs 27

Key Messages • Significant amount of guidance and background information of the NDA website which is not being utilised by practitioners • Practitioners need to improve understanding of RHP and CHP to help improve consistency in SED scores • Need to continue to detach SED Reduction Projects from LTP DVs 27

Revision 3 of the Procedure • Revision 3 of EGPR 02 issued on 31 st July along with EGPR 02 WI 1 and WI 2 • Principle changes made – Wording changes to improve clarity – Mods to address technical issues with ∆HP – Additional guidance as appropriate – No changes to scoring processes, data requirements or equations – Deliverables guidance provided in EGG 06 – Hazard Baseline Specification 28

Revision 3 of the Procedure • Revision 3 of EGPR 02 issued on 31 st July along with EGPR 02 WI 1 and WI 2 • Principle changes made – Wording changes to improve clarity – Mods to address technical issues with ∆HP – Additional guidance as appropriate – No changes to scoring processes, data requirements or equations – Deliverables guidance provided in EGG 06 – Hazard Baseline Specification 28

Radiological Hazard Potential Background and Calculation

Radiological Hazard Potential Background and Calculation

Background • A measure of hazard potential • Factors in the RHP • How to calculate the RHP 30

Background • A measure of hazard potential • Factors in the RHP • How to calculate the RHP 30

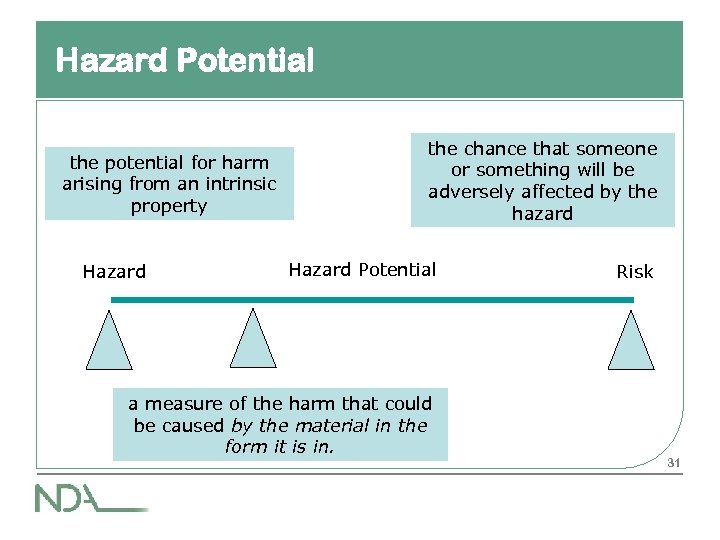

Hazard Potential the potential for harm arising from an intrinsic property Hazard the chance that someone or something will be adversely affected by the hazard Hazard Potential a measure of the harm that could be caused by the material in the form it is in. Risk 31

Hazard Potential the potential for harm arising from an intrinsic property Hazard the chance that someone or something will be adversely affected by the hazard Hazard Potential a measure of the harm that could be caused by the material in the form it is in. Risk 31

Definition and use • RHP is a measure of the hazard potential due to the radioactivity of materials • RHP measures hazard potential to both man and the environment • RHP may be used to – track the progress of hazard potential reduction within individual storage facilities, sites and across the UK – compare scenarios on the basis of their effectiveness in reducing hazard potential, as one criterion in the wider planning process. 32

Definition and use • RHP is a measure of the hazard potential due to the radioactivity of materials • RHP measures hazard potential to both man and the environment • RHP may be used to – track the progress of hazard potential reduction within individual storage facilities, sites and across the UK – compare scenarios on the basis of their effectiveness in reducing hazard potential, as one criterion in the wider planning process. 32

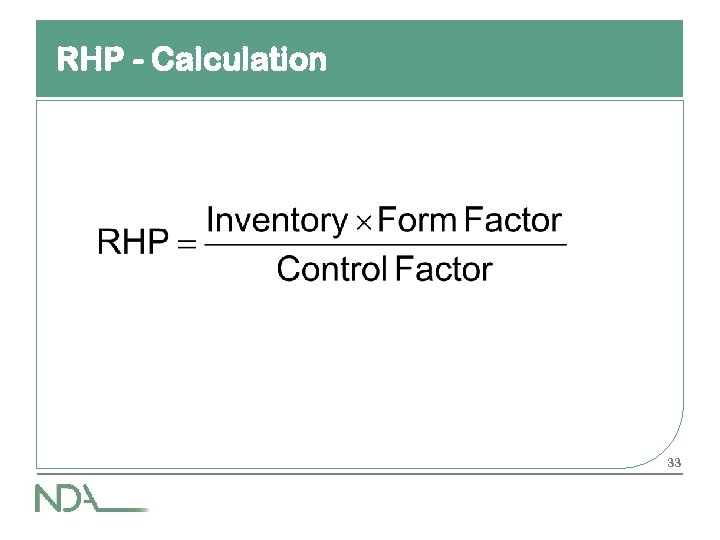

RHP - Calculation 33

RHP - Calculation 33

Inventory - background • A measure of the potential harm (“hazard”) from a set of radioisotopes • The amount of water required to dilute the radioisotopes to below annual limits on intake – Big numbers more harmful – Small numbers less harmful 34

Inventory - background • A measure of the potential harm (“hazard”) from a set of radioisotopes • The amount of water required to dilute the radioisotopes to below annual limits on intake – Big numbers more harmful – Small numbers less harmful 34

Inventory - calculation • Calculation – – Get inventory of material in TBq Multiply by SITP (m 3 water / TBq) from table Add results for all radioisotopes If material could be inhaled (gases, powders) apply correction • A MS Access based calculator is available for this purpose 35

Inventory - calculation • Calculation – – Get inventory of material in TBq Multiply by SITP (m 3 water / TBq) from table Add results for all radioisotopes If material could be inhaled (gases, powders) apply correction • A MS Access based calculator is available for this purpose 35

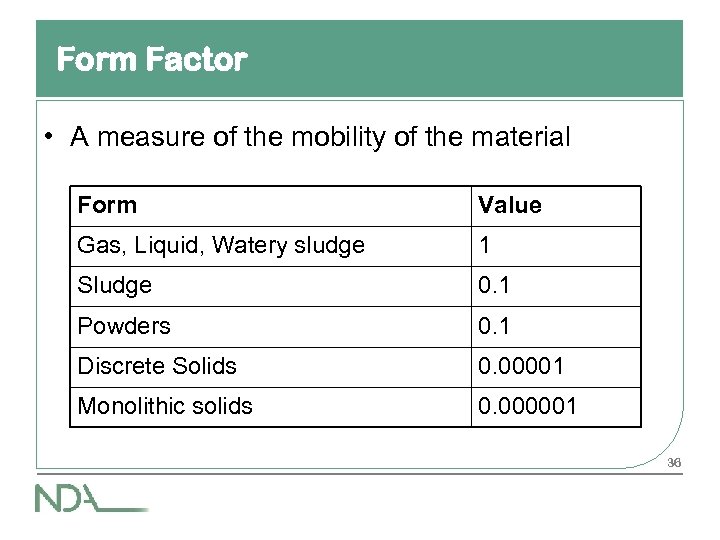

Form Factor • A measure of the mobility of the material Form Value Gas, Liquid, Watery sludge 1 Sludge 0. 1 Powders 0. 1 Discrete Solids 0. 00001 Monolithic solids 0. 000001 36

Form Factor • A measure of the mobility of the material Form Value Gas, Liquid, Watery sludge 1 Sludge 0. 1 Powders 0. 1 Discrete Solids 0. 00001 Monolithic solids 0. 000001 36

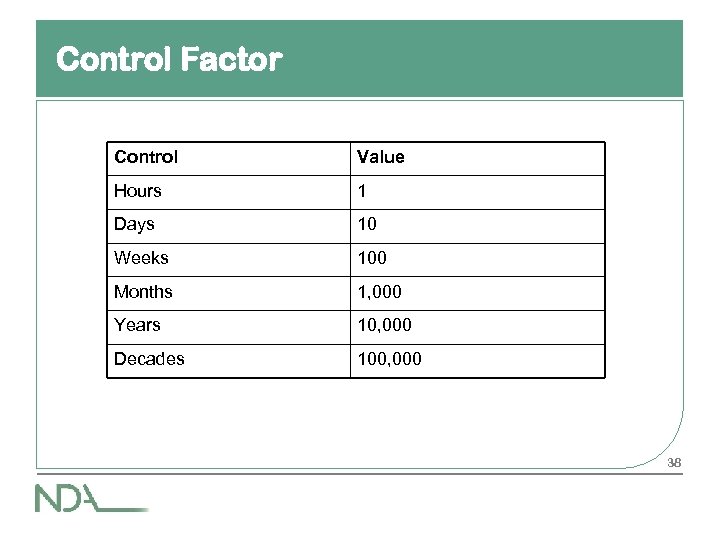

Control Factor • A measure of physical and chemical stability of the material • “What monitoring period would a design engineer propose at the design stage as being necessary to ensure containment, based on the intrinsic hazard of the material, the mode of storage, and how these might evolve? ” • NOT “How often do we monitor it? ” • EGR 009 gives full details 37

Control Factor • A measure of physical and chemical stability of the material • “What monitoring period would a design engineer propose at the design stage as being necessary to ensure containment, based on the intrinsic hazard of the material, the mode of storage, and how these might evolve? ” • NOT “How often do we monitor it? ” • EGR 009 gives full details 37

Control Factor Control Value Hours 1 Days 10 Weeks 100 Months 1, 000 Years 10, 000 Decades 100, 000 38

Control Factor Control Value Hours 1 Days 10 Weeks 100 Months 1, 000 Years 10, 000 Decades 100, 000 38

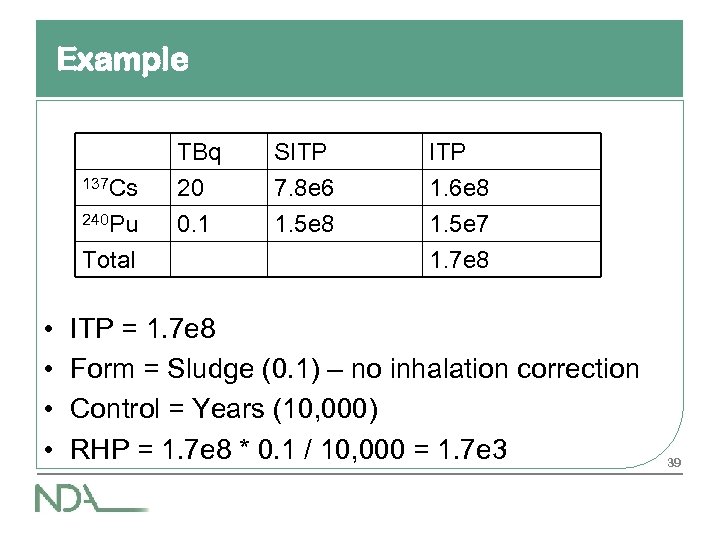

Example 137 Cs 240 Pu Total • • TBq 20 0. 1 SITP 7. 8 e 6 1. 5 e 8 ITP 1. 6 e 8 1. 5 e 7 1. 7 e 8 ITP = 1. 7 e 8 Form = Sludge (0. 1) – no inhalation correction Control = Years (10, 000) RHP = 1. 7 e 8 * 0. 1 / 10, 000 = 1. 7 e 3 39

Example 137 Cs 240 Pu Total • • TBq 20 0. 1 SITP 7. 8 e 6 1. 5 e 8 ITP 1. 6 e 8 1. 5 e 7 1. 7 e 8 ITP = 1. 7 e 8 Form = Sludge (0. 1) – no inhalation correction Control = Years (10, 000) RHP = 1. 7 e 8 * 0. 1 / 10, 000 = 1. 7 e 3 39

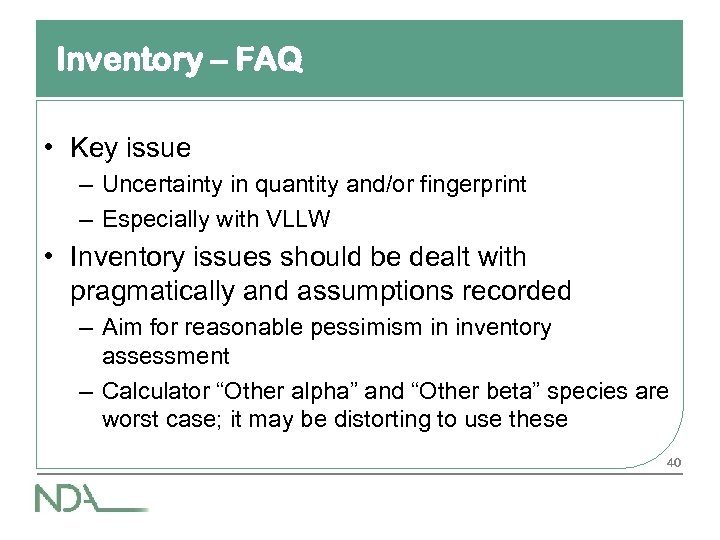

Inventory – FAQ • Key issue – Uncertainty in quantity and/or fingerprint – Especially with VLLW • Inventory issues should be dealt with pragmatically and assumptions recorded – Aim for reasonable pessimism in inventory assessment – Calculator “Other alpha” and “Other beta” species are worst case; it may be distorting to use these 40

Inventory – FAQ • Key issue – Uncertainty in quantity and/or fingerprint – Especially with VLLW • Inventory issues should be dealt with pragmatically and assumptions recorded – Aim for reasonable pessimism in inventory assessment – Calculator “Other alpha” and “Other beta” species are worst case; it may be distorting to use these 40

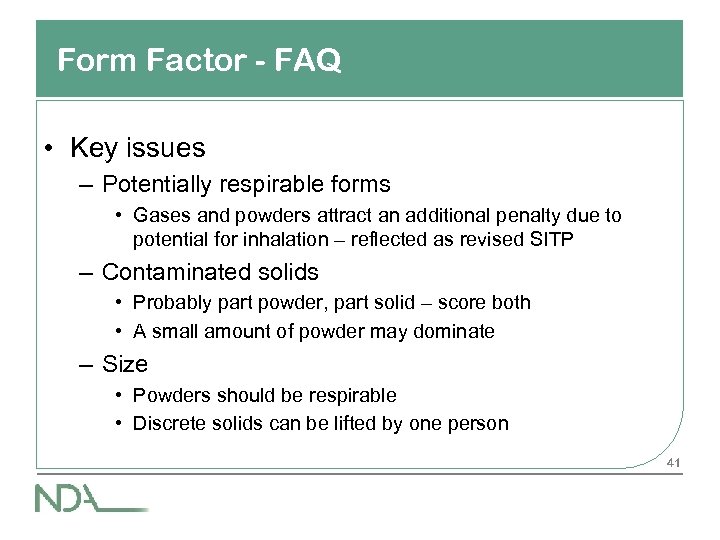

Form Factor - FAQ • Key issues – Potentially respirable forms • Gases and powders attract an additional penalty due to potential for inhalation – reflected as revised SITP – Contaminated solids • Probably part powder, part solid – score both • A small amount of powder may dominate – Size • Powders should be respirable • Discrete solids can be lifted by one person 41

Form Factor - FAQ • Key issues – Potentially respirable forms • Gases and powders attract an additional penalty due to potential for inhalation – reflected as revised SITP – Contaminated solids • Probably part powder, part solid – score both • A small amount of powder may dominate – Size • Powders should be respirable • Discrete solids can be lifted by one person 41

Control Factor - FAQ • This is the hardest factor to understand • Key issue – What is maximum intervention interval to retain control NOT what interval is actually used • Issues – Current plant condition is irrelevant; scored pristine – Maintaining control avoids bulk release (say, 1%); diffusion of species is not a loss of control – Ignore externally induced catastrophic events 42

Control Factor - FAQ • This is the hardest factor to understand • Key issue – What is maximum intervention interval to retain control NOT what interval is actually used • Issues – Current plant condition is irrelevant; scored pristine – Maintaining control avoids bulk release (say, 1%); diffusion of species is not a loss of control – Ignore externally induced catastrophic events 42

Control Factor - Process • There is a form to assist in assigning control factors – Define storage mode – Define material properties – Define storage features required to control material properties – Determine time to loss of control for each storage feature – Select minimum time to get control factor; but consider collocated materials 43

Control Factor - Process • There is a form to assist in assigning control factors – Define storage mode – Define material properties – Define storage features required to control material properties – Determine time to loss of control for each storage feature – Select minimum time to get control factor; but consider collocated materials 43

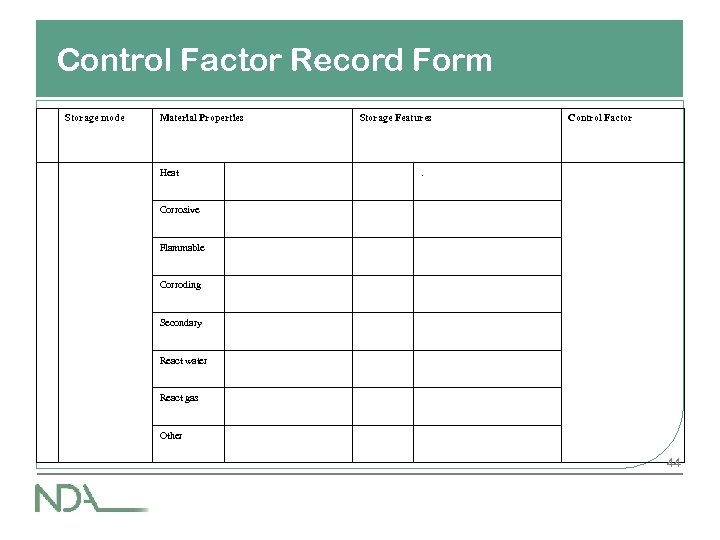

Control Factor Record Form Storage mode Material Properties Heat Storage Features Control Factor . Corrosive Flammable Corroding Secondary React water React gas Other 44

Control Factor Record Form Storage mode Material Properties Heat Storage Features Control Factor . Corrosive Flammable Corroding Secondary React water React gas Other 44

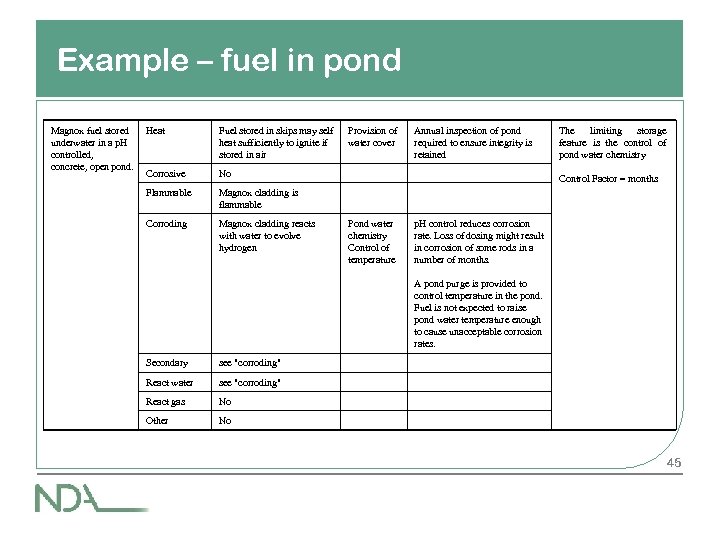

Example – fuel in pond Magnox fuel stored underwater in a p. H controlled, concrete, open pond. Heat Fuel stored in skips may self heat sufficiently to ignite if stored in air Corrosive No Flammable Magnox cladding is flammable Corroding Magnox cladding reacts with water to evolve hydrogen Provision of water cover Annual inspection of pond required to ensure integrity is retained The limiting storage feature is the control of pond water chemistry Control Factor = months Pond water chemistry Control of temperature p. H control reduces corrosion rate. Loss of dosing might result in corrosion of some rods in a number of months. A pond purge is provided to control temperature in the pond. Fuel is not expected to raise pond water temperature enough to cause unacceptable corrosion rates. Secondary see "corroding" React water see "corroding" React gas No Other No 45

Example – fuel in pond Magnox fuel stored underwater in a p. H controlled, concrete, open pond. Heat Fuel stored in skips may self heat sufficiently to ignite if stored in air Corrosive No Flammable Magnox cladding is flammable Corroding Magnox cladding reacts with water to evolve hydrogen Provision of water cover Annual inspection of pond required to ensure integrity is retained The limiting storage feature is the control of pond water chemistry Control Factor = months Pond water chemistry Control of temperature p. H control reduces corrosion rate. Loss of dosing might result in corrosion of some rods in a number of months. A pond purge is provided to control temperature in the pond. Fuel is not expected to raise pond water temperature enough to cause unacceptable corrosion rates. Secondary see "corroding" React water see "corroding" React gas No Other No 45

Chemical Hazard Potential Background and Calculation

Chemical Hazard Potential Background and Calculation

Background • • A measure of hazard potential Situations where CHP is required Factors in the CHP How to calculate the CHP 47

Background • • A measure of hazard potential Situations where CHP is required Factors in the CHP How to calculate the CHP 47

Definition and use • CHP is a measure of the hazard potential due to the chemical properties of materials • CHP measures hazard potential to both man and the environment • CHP may be used to – track the progress of hazard potential reduction within individual storage facilities, sites and across the UK – compare scenarios on the basis of their effectiveness in reducing hazard potential, as one criterion in the wider planning process. 48

Definition and use • CHP is a measure of the hazard potential due to the chemical properties of materials • CHP measures hazard potential to both man and the environment • CHP may be used to – track the progress of hazard potential reduction within individual storage facilities, sites and across the UK – compare scenarios on the basis of their effectiveness in reducing hazard potential, as one criterion in the wider planning process. 48

Situations where CHP is required • Rarely required • Required for – Legacy inventory • Not required for – Commercial stock – Stock supporting operations or decommissioning • In tests only a few significant items found – – – Asbestos Chemically contaminated land Sodium and Na. K Hex Uranium (added to RHP) 49

Situations where CHP is required • Rarely required • Required for – Legacy inventory • Not required for – Commercial stock – Stock supporting operations or decommissioning • In tests only a few significant items found – – – Asbestos Chemically contaminated land Sodium and Na. K Hex Uranium (added to RHP) 49

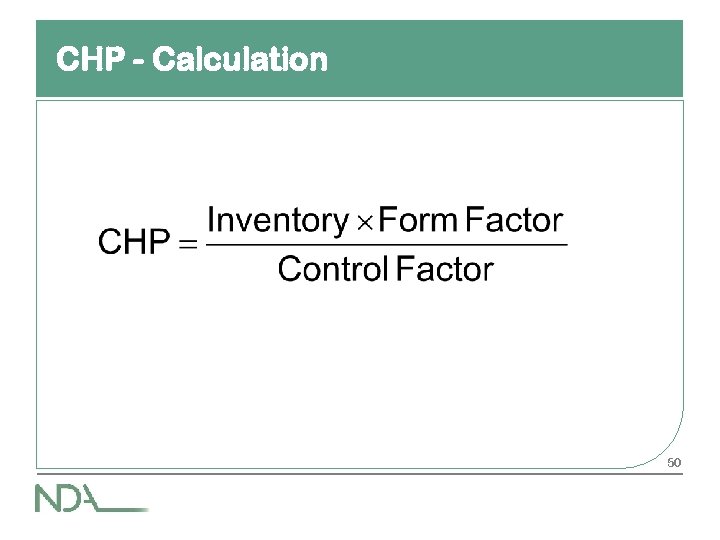

CHP - Calculation 50

CHP - Calculation 50

Inventory - background • A measure of the potential harm from chemicals – Toxicity – Flammability – Environmental damage • Based on COMAH regulations – Includes health, physico-chemical and environmental effects – Extrapolated to include a wider range of materials • EGR 011 gives full details 51

Inventory - background • A measure of the potential harm from chemicals – Toxicity – Flammability – Environmental damage • Based on COMAH regulations – Includes health, physico-chemical and environmental effects – Extrapolated to include a wider range of materials • EGR 011 gives full details 51

Inventory - calculation • Calculation – Get inventory of material in te – Determine extrapolated COMAH limit for each material – Calculate fraction = inventory / limit – Add fractions of COMAH limit for all materials – Multiply result by 1 e 11 52

Inventory - calculation • Calculation – Get inventory of material in te – Determine extrapolated COMAH limit for each material – Calculate fraction = inventory / limit – Add fractions of COMAH limit for all materials – Multiply result by 1 e 11 52

Form and Control Factors • These are unchanged and work exactly like the RHP 53

Form and Control Factors • These are unchanged and work exactly like the RHP 53

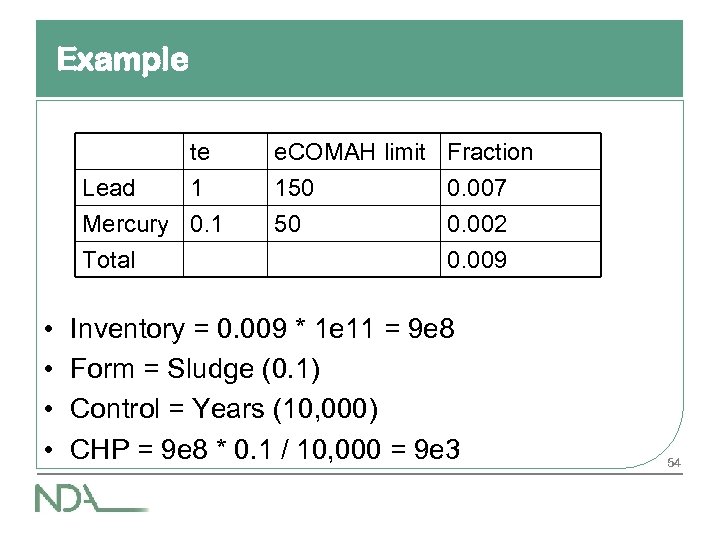

Example te Lead 1 Mercury 0. 1 Total • • e. COMAH limit Fraction 150 0. 007 50 0. 002 0. 009 Inventory = 0. 009 * 1 e 11 = 9 e 8 Form = Sludge (0. 1) Control = Years (10, 000) CHP = 9 e 8 * 0. 1 / 10, 000 = 9 e 3 54

Example te Lead 1 Mercury 0. 1 Total • • e. COMAH limit Fraction 150 0. 007 50 0. 002 0. 009 Inventory = 0. 009 * 1 e 11 = 9 e 8 Form = Sludge (0. 1) Control = Years (10, 000) CHP = 9 e 8 * 0. 1 / 10, 000 = 9 e 3 54

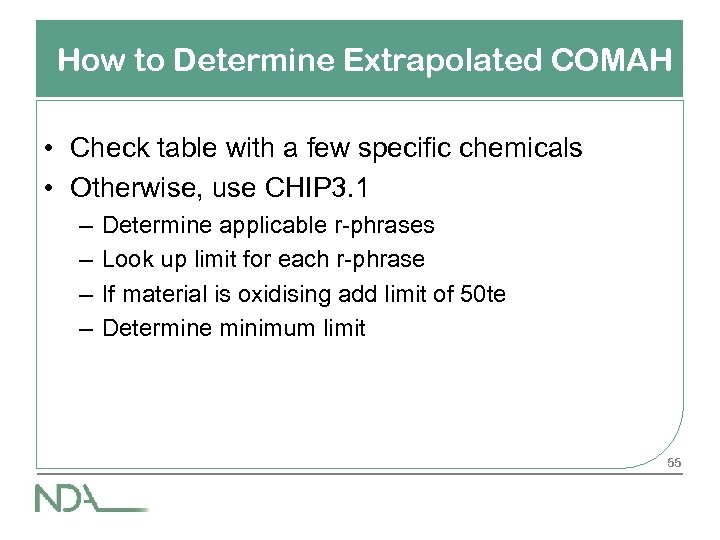

How to Determine Extrapolated COMAH • Check table with a few specific chemicals • Otherwise, use CHIP 3. 1 – – Determine applicable r-phrases Look up limit for each r-phrase If material is oxidising add limit of 50 te Determine minimum limit 55

How to Determine Extrapolated COMAH • Check table with a few specific chemicals • Otherwise, use CHIP 3. 1 – – Determine applicable r-phrases Look up limit for each r-phrase If material is oxidising add limit of 50 te Determine minimum limit 55

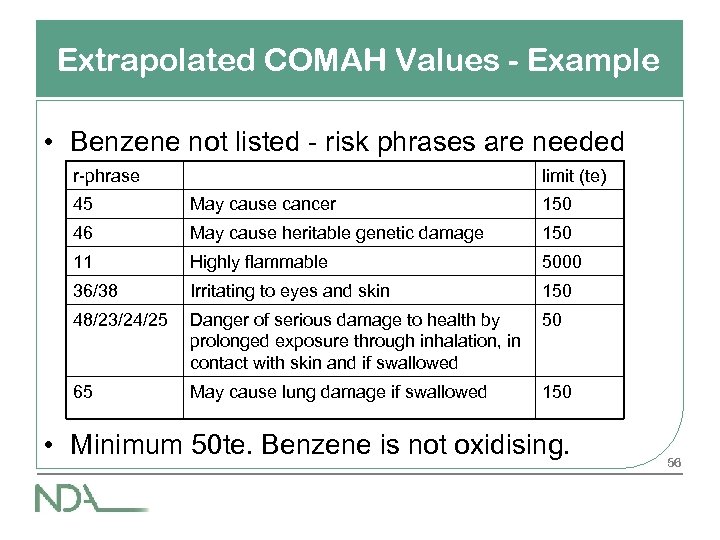

Extrapolated COMAH Values - Example • Benzene not listed - risk phrases are needed r-phrase limit (te) 45 May cause cancer 150 46 May cause heritable genetic damage 150 11 Highly flammable 5000 36/38 Irritating to eyes and skin 150 48/23/24/25 Danger of serious damage to health by prolonged exposure through inhalation, in contact with skin and if swallowed 50 65 May cause lung damage if swallowed 150 • Minimum 50 te. Benzene is not oxidising. 56

Extrapolated COMAH Values - Example • Benzene not listed - risk phrases are needed r-phrase limit (te) 45 May cause cancer 150 46 May cause heritable genetic damage 150 11 Highly flammable 5000 36/38 Irritating to eyes and skin 150 48/23/24/25 Danger of serious damage to health by prolonged exposure through inhalation, in contact with skin and if swallowed 50 65 May cause lung damage if swallowed 150 • Minimum 50 te. Benzene is not oxidising. 56

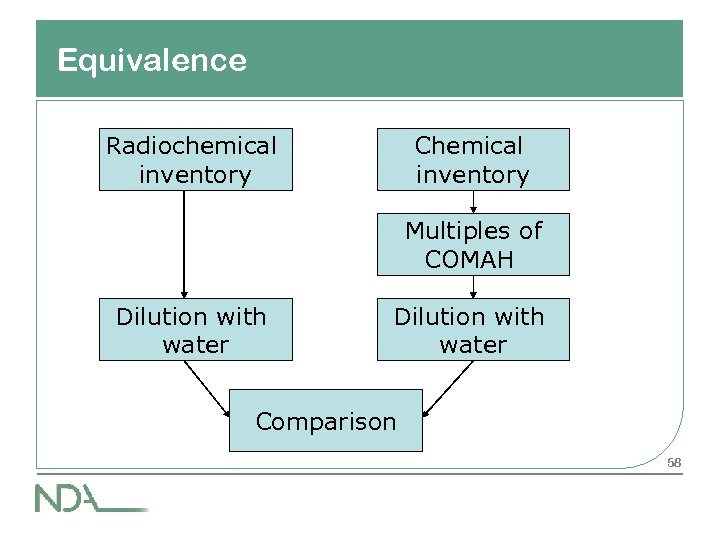

Origin of 1 e 11 Multiplier • The 1 e 11 puts CHP and RHP on a similar basis so mixed inventories can use CHP+RHP to get a total hazard inventory 57

Origin of 1 e 11 Multiplier • The 1 e 11 puts CHP and RHP on a similar basis so mixed inventories can use CHP+RHP to get a total hazard inventory 57

Equivalence Radiochemical inventory Chemical inventory Multiples of COMAH Dilution with water Comparison 58

Equivalence Radiochemical inventory Chemical inventory Multiples of COMAH Dilution with water Comparison 58

Potential Detriment for Contaminated Land Background and Calculation

Potential Detriment for Contaminated Land Background and Calculation

CHP/RHP • Relatively straightforward to calculate • Process for calculation of inventory is unchanged – CHP and RHP • Form – Probably a mixture of liquid, solid and sludge – Use software to assess, or assume all liquid • Control – Base control factor on rate of spread – Unlike other materials it may be necessary to score individual species separately to get meaningful result 60

CHP/RHP • Relatively straightforward to calculate • Process for calculation of inventory is unchanged – CHP and RHP • Form – Probably a mixture of liquid, solid and sludge – Use software to assess, or assume all liquid • Control – Base control factor on rate of spread – Unlike other materials it may be necessary to score individual species separately to get meaningful result 60

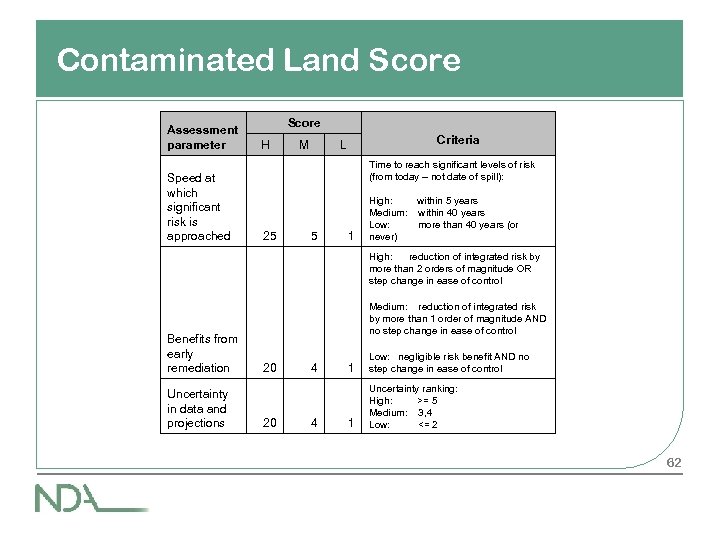

Potential Detriment Score • Facility Descriptor and Waste Uncertainty difficult to apply to contaminated land • An alternate, but analagous, system needed • Based on Safegrounds work 61

Potential Detriment Score • Facility Descriptor and Waste Uncertainty difficult to apply to contaminated land • An alternate, but analagous, system needed • Based on Safegrounds work 61

Contaminated Land Score Assessment parameter Speed at which significant risk is approached Score H M Criteria L Time to reach significant levels of risk (from today – not date of spill): 25 5 1 High: within 5 years Medium: within 40 years Low: more than 40 years (or never) High: reduction of integrated risk by more than 2 orders of magnitude OR step change in ease of control Benefits from early remediation Uncertainty in data and projections Medium: reduction of integrated risk by more than 1 order of magnitude AND no step change in ease of control 20 20 4 4 1 Low: negligible risk benefit AND no step change in ease of control 1 Uncertainty ranking: High: >= 5 Medium: 3, 4 Low: <= 2 62

Contaminated Land Score Assessment parameter Speed at which significant risk is approached Score H M Criteria L Time to reach significant levels of risk (from today – not date of spill): 25 5 1 High: within 5 years Medium: within 40 years Low: more than 40 years (or never) High: reduction of integrated risk by more than 2 orders of magnitude OR step change in ease of control Benefits from early remediation Uncertainty in data and projections Medium: reduction of integrated risk by more than 1 order of magnitude AND no step change in ease of control 20 20 4 4 1 Low: negligible risk benefit AND no step change in ease of control 1 Uncertainty ranking: High: >= 5 Medium: 3, 4 Low: <= 2 62

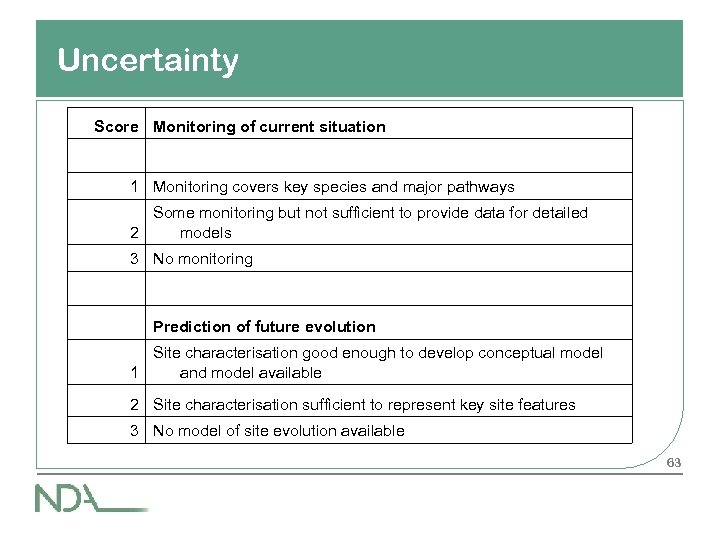

Uncertainty Score Monitoring of current situation 1 Monitoring covers key species and major pathways Some monitoring but not sufficient to provide data for detailed 2 models 3 No monitoring Prediction of future evolution Site characterisation good enough to develop conceptual model 1 and model available 2 Site characterisation sufficient to represent key site features 3 No model of site evolution available 63

Uncertainty Score Monitoring of current situation 1 Monitoring covers key species and major pathways Some monitoring but not sufficient to provide data for detailed 2 models 3 No monitoring Prediction of future evolution Site characterisation good enough to develop conceptual model 1 and model available 2 Site characterisation sufficient to represent key site features 3 No model of site evolution available 63

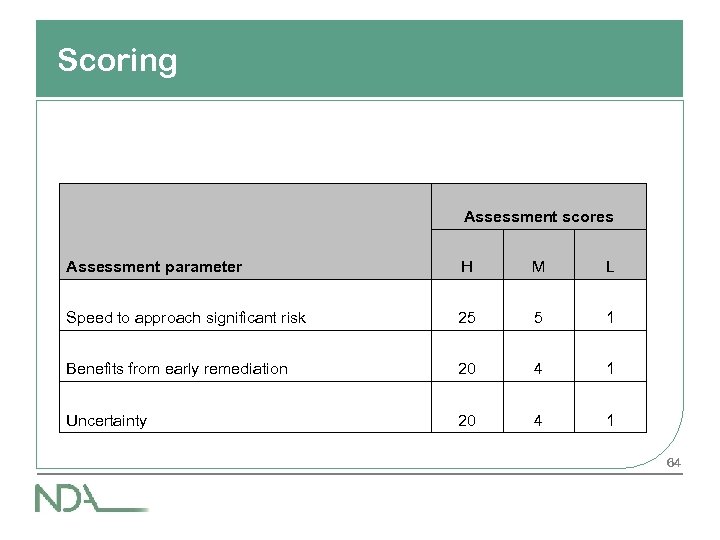

Scoring Assessment scores Assessment parameter H M L Speed to approach significant risk 25 5 1 Benefits from early remediation 20 4 1 Uncertainty 20 4 1 64

Scoring Assessment scores Assessment parameter H M L Speed to approach significant risk 25 5 1 Benefits from early remediation 20 4 1 Uncertainty 20 4 1 64

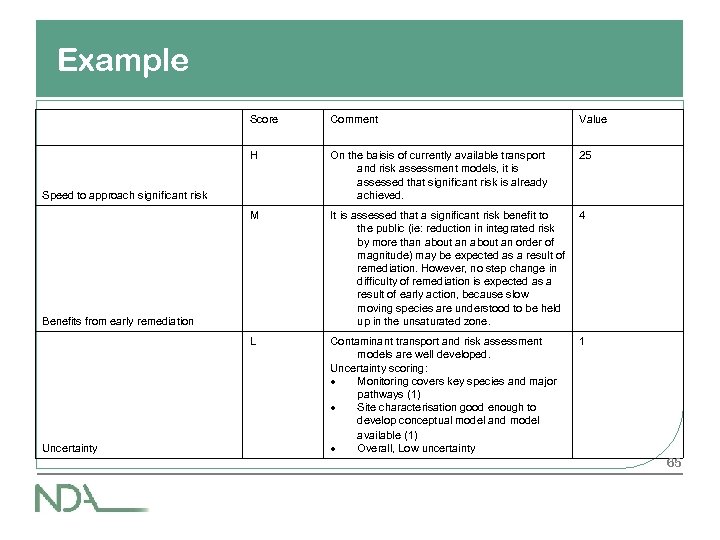

Example Score Comment Value H On the baisis of currently available transport and risk assessment models, it is assessed that significant risk is already achieved. 25 M It is assessed that a significant risk benefit to the public (ie: reduction in integrated risk by more than about an order of magnitude) may be expected as a result of remediation. However, no step change in difficulty of remediation is expected as a result of early action, because slow moving species are understood to be held up in the unsaturated zone. 4 L Contaminant transport and risk assessment models are well developed. Uncertainty scoring: Monitoring covers key species and major pathways (1) Site characterisation good enough to develop conceptual model and model available (1) Overall, Low uncertainty 1 Speed to approach significant risk Benefits from early remediation Uncertainty 65

Example Score Comment Value H On the baisis of currently available transport and risk assessment models, it is assessed that significant risk is already achieved. 25 M It is assessed that a significant risk benefit to the public (ie: reduction in integrated risk by more than about an order of magnitude) may be expected as a result of remediation. However, no step change in difficulty of remediation is expected as a result of early action, because slow moving species are understood to be held up in the unsaturated zone. 4 L Contaminant transport and risk assessment models are well developed. Uncertainty scoring: Monitoring covers key species and major pathways (1) Site characterisation good enough to develop conceptual model and model available (1) Overall, Low uncertainty 1 Speed to approach significant risk Benefits from early remediation Uncertainty 65

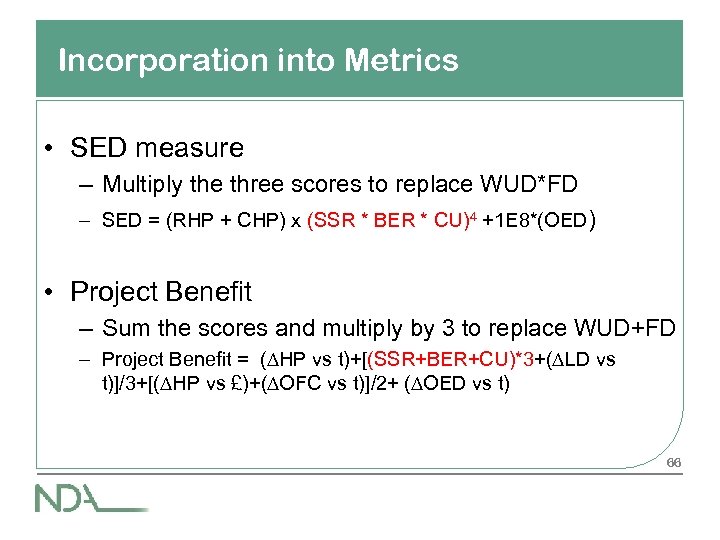

Incorporation into Metrics • SED measure – Multiply the three scores to replace WUD*FD – SED = (RHP + CHP) x (SSR * BER * CU)4 +1 E 8*(OED) • Project Benefit – Sum the scores and multiply by 3 to replace WUD+FD – Project Benefit = (∆HP vs t)+[(SSR+BER+CU)*3+(∆LD vs t)]/3+[(∆HP vs £)+(∆OFC vs t)]/2+ (∆OED vs t) 66

Incorporation into Metrics • SED measure – Multiply the three scores to replace WUD*FD – SED = (RHP + CHP) x (SSR * BER * CU)4 +1 E 8*(OED) • Project Benefit – Sum the scores and multiply by 3 to replace WUD+FD – Project Benefit = (∆HP vs t)+[(SSR+BER+CU)*3+(∆LD vs t)]/3+[(∆HP vs £)+(∆OFC vs t)]/2+ (∆OED vs t) 66

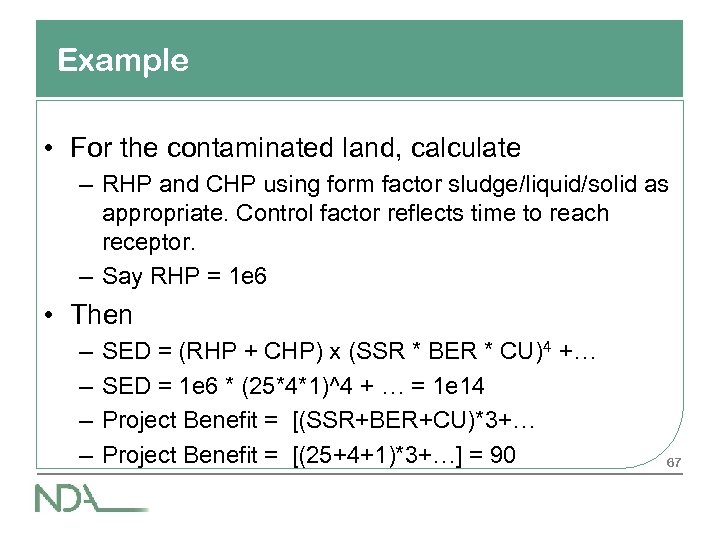

Example • For the contaminated land, calculate – RHP and CHP using form factor sludge/liquid/solid as appropriate. Control factor reflects time to reach receptor. – Say RHP = 1 e 6 • Then – – SED = (RHP + CHP) x (SSR * BER * CU)4 +… SED = 1 e 6 * (25*4*1)^4 + … = 1 e 14 Project Benefit = [(SSR+BER+CU)*3+… Project Benefit = [(25+4+1)*3+…] = 90 67

Example • For the contaminated land, calculate – RHP and CHP using form factor sludge/liquid/solid as appropriate. Control factor reflects time to reach receptor. – Say RHP = 1 e 6 • Then – – SED = (RHP + CHP) x (SSR * BER * CU)4 +… SED = 1 e 6 * (25*4*1)^4 + … = 1 e 14 Project Benefit = [(SSR+BER+CU)*3+… Project Benefit = [(25+4+1)*3+…] = 90 67

Facility Safety and Waste Uncertainty Descriptor Will Pearson, REACT

Facility Safety and Waste Uncertainty Descriptor Will Pearson, REACT

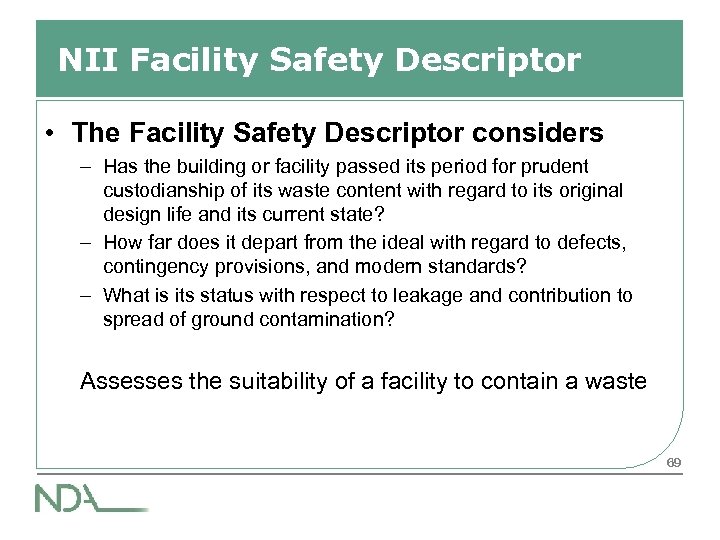

NII Facility Safety Descriptor • The Facility Safety Descriptor considers – Has the building or facility passed its period for prudent custodianship of its waste content with regard to its original design life and its current state? – How far does it depart from the ideal with regard to defects, contingency provisions, and modern standards? – What is its status with respect to leakage and contribution to spread of ground contamination? Assesses the suitability of a facility to contain a waste 69

NII Facility Safety Descriptor • The Facility Safety Descriptor considers – Has the building or facility passed its period for prudent custodianship of its waste content with regard to its original design life and its current state? – How far does it depart from the ideal with regard to defects, contingency provisions, and modern standards? – What is its status with respect to leakage and contribution to spread of ground contamination? Assesses the suitability of a facility to contain a waste 69

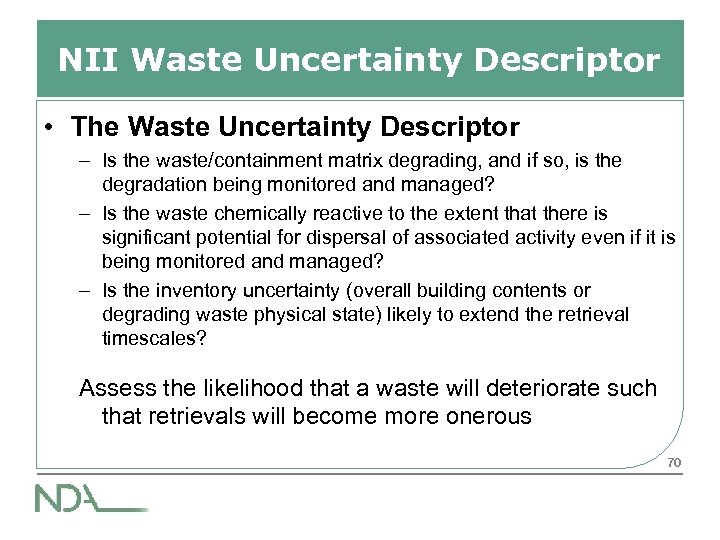

NII Waste Uncertainty Descriptor • The Waste Uncertainty Descriptor – Is the waste/containment matrix degrading, and if so, is the degradation being monitored and managed? – Is the waste chemically reactive to the extent that there is significant potential for dispersal of associated activity even if it is being monitored and managed? – Is the inventory uncertainty (overall building contents or degrading waste physical state) likely to extend the retrieval timescales? Assess the likelihood that a waste will deteriorate such that retrievals will become more onerous 70

NII Waste Uncertainty Descriptor • The Waste Uncertainty Descriptor – Is the waste/containment matrix degrading, and if so, is the degradation being monitored and managed? – Is the waste chemically reactive to the extent that there is significant potential for dispersal of associated activity even if it is being monitored and managed? – Is the inventory uncertainty (overall building contents or degrading waste physical state) likely to extend the retrieval timescales? Assess the likelihood that a waste will deteriorate such that retrievals will become more onerous 70

Application of FD & WUD • A pragmatic approach is required – best fit is sufficient • Decision by committee works best • Record assumptions and key comments • Where possible consider inter site reviews to improve consistency of application 71

Application of FD & WUD • A pragmatic approach is required – best fit is sufficient • Decision by committee works best • Record assumptions and key comments • Where possible consider inter site reviews to improve consistency of application 71

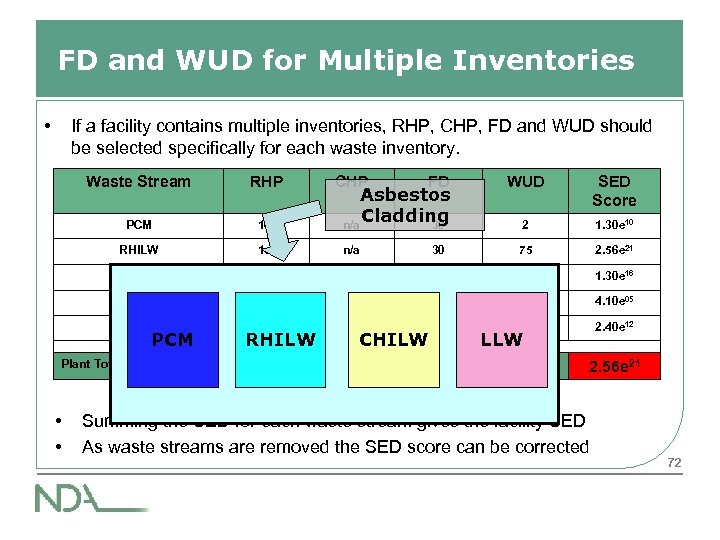

FD and WUD for Multiple Inventories • If a facility contains multiple inventories, RHP, CHP, FD and WUD should be selected specifically for each waste inventory. Waste Stream RHP PCM 1 e 3 Asbestos Cladding n/a 30 RHILW 1 e 8 n/a CHILW 1 e 5 LLW Asbestos PCM Plant Total • • WUD SED Score 2 1. 30 e 10 30 75 2. 56 e 21 n/a 8 75 1. 30 e 16 1 e-2 n/a 8 10 4. 10 e 05 n/a 1 e 4 70 10 2. 40 e 12 RHILW CHP FD CHILW LLW 2. 56 e 21 Summing the SED for each waste stream gives the facility SED As waste streams are removed the SED score can be corrected 72

FD and WUD for Multiple Inventories • If a facility contains multiple inventories, RHP, CHP, FD and WUD should be selected specifically for each waste inventory. Waste Stream RHP PCM 1 e 3 Asbestos Cladding n/a 30 RHILW 1 e 8 n/a CHILW 1 e 5 LLW Asbestos PCM Plant Total • • WUD SED Score 2 1. 30 e 10 30 75 2. 56 e 21 n/a 8 75 1. 30 e 16 1 e-2 n/a 8 10 4. 10 e 05 n/a 1 e 4 70 10 2. 40 e 12 RHILW CHP FD CHILW LLW 2. 56 e 21 Summing the SED for each waste stream gives the facility SED As waste streams are removed the SED score can be corrected 72

Assessment of Ongoing Environmental Detriment Will Pearson, REACT

Assessment of Ongoing Environmental Detriment Will Pearson, REACT

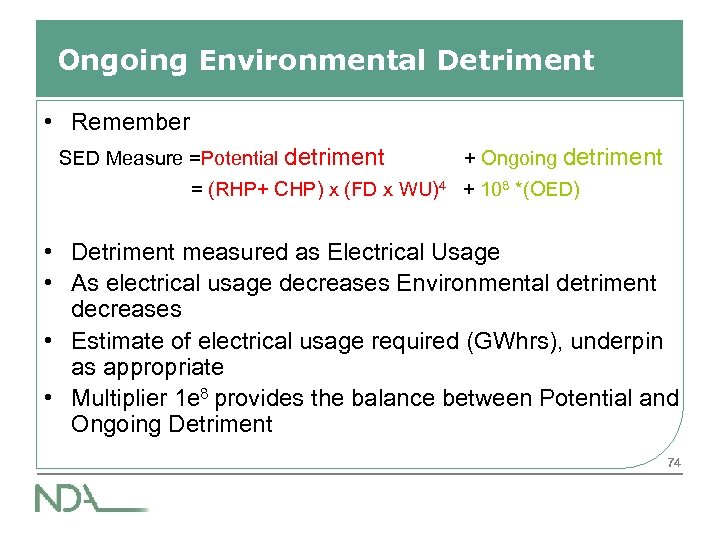

Ongoing Environmental Detriment • Remember SED Measure =Potential detriment + Ongoing detriment = (RHP+ CHP) x (FD x WU)4 + 108 *(OED) • Detriment measured as Electrical Usage • As electrical usage decreases Environmental detriment decreases • Estimate of electrical usage required (GWhrs), underpin as appropriate • Multiplier 1 e 8 provides the balance between Potential and Ongoing Detriment 74

Ongoing Environmental Detriment • Remember SED Measure =Potential detriment + Ongoing detriment = (RHP+ CHP) x (FD x WU)4 + 108 *(OED) • Detriment measured as Electrical Usage • As electrical usage decreases Environmental detriment decreases • Estimate of electrical usage required (GWhrs), underpin as appropriate • Multiplier 1 e 8 provides the balance between Potential and Ongoing Detriment 74

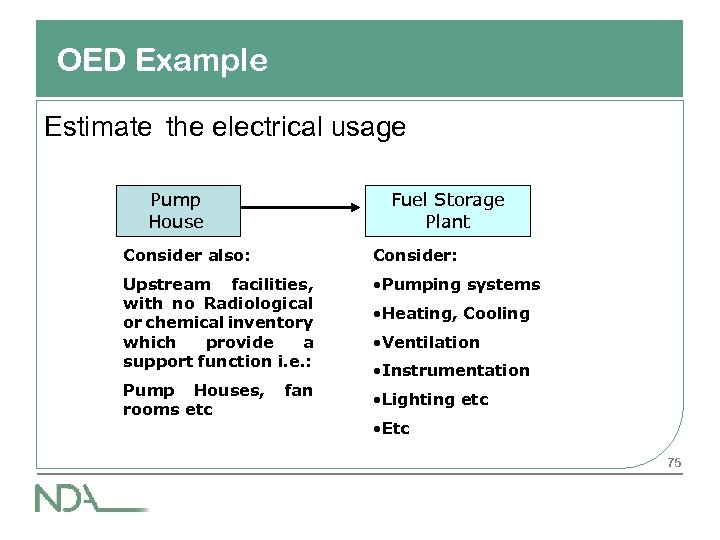

OED Example Estimate the electrical usage Pump House Fuel Storage Plant Consider also: Consider: Upstream facilities, with no Radiological or chemical inventory which provide a support function i. e. : • Pumping systems Pump Houses, rooms etc fan • Heating, Cooling • Ventilation • Instrumentation • Lighting etc • Etc 75

OED Example Estimate the electrical usage Pump House Fuel Storage Plant Consider also: Consider: Upstream facilities, with no Radiological or chemical inventory which provide a support function i. e. : • Pumping systems Pump Houses, rooms etc fan • Heating, Cooling • Ventilation • Instrumentation • Lighting etc • Etc 75

OED Assessment • Use pragmatism where direct measurement is not possible - consider allocation of Site OED pro rata • Only need to score in the range of >0. 1 Gwhr • Values less than 0. 1 Gwhr need not be considered • Ensure that OED is only associated with Care and Maintenance activities. 76

OED Assessment • Use pragmatism where direct measurement is not possible - consider allocation of Site OED pro rata • Only need to score in the range of >0. 1 Gwhr • Values less than 0. 1 Gwhr need not be considered • Ensure that OED is only associated with Care and Maintenance activities. 76

SED Reduction Project, Definition and Assessment Will Pearson, REACT

SED Reduction Project, Definition and Assessment Will Pearson, REACT

SED Reduction Projects - Definition Safety and Environmental Detriment Reduction Project: “The entire work scope which takes a waste inventory from its current condition to an improved condition” I. e. all the work required to change an inventories Form Factor or Control Factor. SED Reduction Projects deliver a reduction in the SED of a specific waste inventory. 78

SED Reduction Projects - Definition Safety and Environmental Detriment Reduction Project: “The entire work scope which takes a waste inventory from its current condition to an improved condition” I. e. all the work required to change an inventories Form Factor or Control Factor. SED Reduction Projects deliver a reduction in the SED of a specific waste inventory. 78

Why define SED Reduction Projects ? • Projects deliver SED reduction not facilities, therefore prioritisation must consider the benefit a project delivers • Defining SED Reduction Projects allows SLCs to target the right things and also test different approaches • Enables SLC to define ‘break points’ in the decommissioning strategy for each facility as the decommissioning challenge changes • Encourages SLC to think about how things can be done more efficiently • NOTE - LTP DVs do not necessarily align with the definition of SED Reduction Project so can not be directly substituted 79

Why define SED Reduction Projects ? • Projects deliver SED reduction not facilities, therefore prioritisation must consider the benefit a project delivers • Defining SED Reduction Projects allows SLCs to target the right things and also test different approaches • Enables SLC to define ‘break points’ in the decommissioning strategy for each facility as the decommissioning challenge changes • Encourages SLC to think about how things can be done more efficiently • NOTE - LTP DVs do not necessarily align with the definition of SED Reduction Project so can not be directly substituted 79

What does a SED Reduction Project Include? • All enabling work • The waste retrieval/processing operations • R&D and trials • Civil construction work required to support the SED Reduction Project strategy, i. e. support plants (waste store, process plant etc) • Operation of supporting facilities e. g. effluent treatment plant. 80

What does a SED Reduction Project Include? • All enabling work • The waste retrieval/processing operations • R&D and trials • Civil construction work required to support the SED Reduction Project strategy, i. e. support plants (waste store, process plant etc) • Operation of supporting facilities e. g. effluent treatment plant. 80

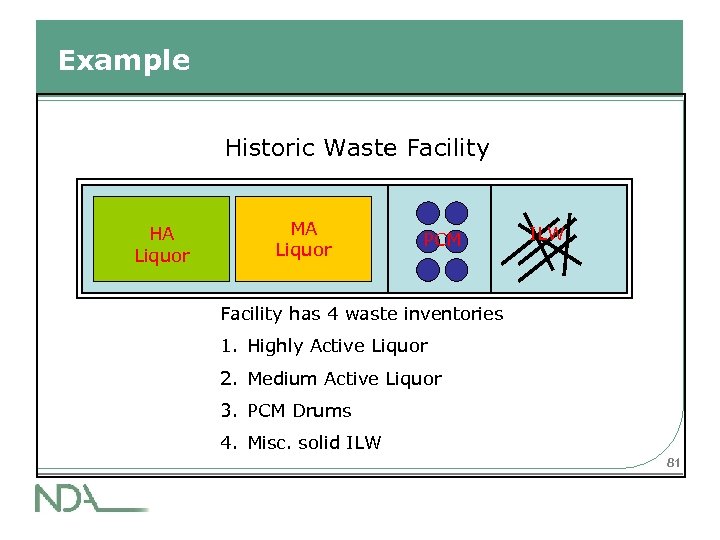

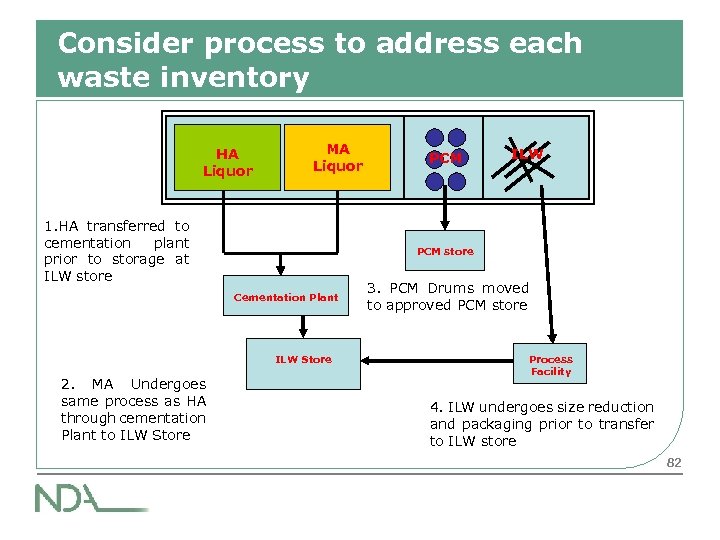

Example Historic Waste Facility HA Liquor MA Liquor PCM ILW Facility has 4 waste inventories 1. Highly Active Liquor 2. Medium Active Liquor 3. PCM Drums 4. Misc. solid ILW 81

Example Historic Waste Facility HA Liquor MA Liquor PCM ILW Facility has 4 waste inventories 1. Highly Active Liquor 2. Medium Active Liquor 3. PCM Drums 4. Misc. solid ILW 81

Consider process to address each waste inventory HA Liquor MA Liquor 1. HA transferred to cementation plant prior to storage at ILW store ILW PCM store Cementation Plant ILW Store 2. MA Undergoes same process as HA through cementation Plant to ILW Store PCM 3. PCM Drums moved to approved PCM store Process Facility 4. ILW undergoes size reduction and packaging prior to transfer to ILW store 82

Consider process to address each waste inventory HA Liquor MA Liquor 1. HA transferred to cementation plant prior to storage at ILW store ILW PCM store Cementation Plant ILW Store 2. MA Undergoes same process as HA through cementation Plant to ILW Store PCM 3. PCM Drums moved to approved PCM store Process Facility 4. ILW undergoes size reduction and packaging prior to transfer to ILW store 82

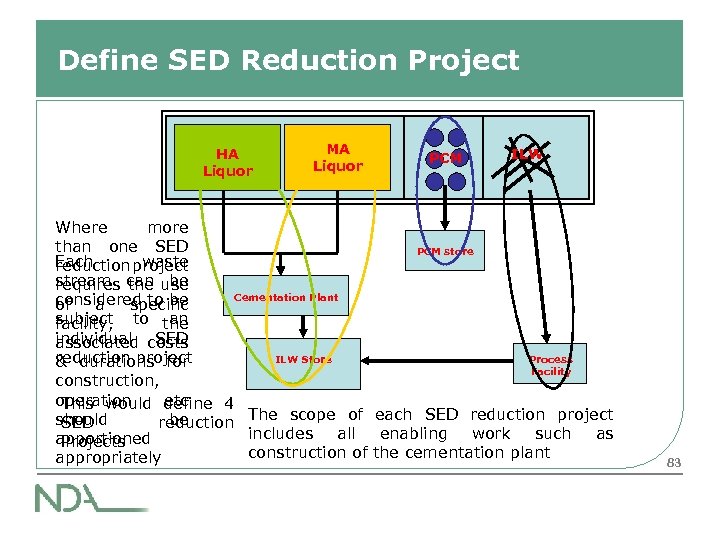

Define SED Reduction Project HA Liquor MA Liquor PCM ILW Where more than one SED PCM store Each waste reduction project stream can use requires the be Cementation Plant considered to be of a specific subject to the an facility, individual costs associated SED reduction project ILW Store Process & durations for Facility construction, operation etc This would define 4 should be SED reduction The scope of each SED reduction project includes all enabling work such as apportioned Projects construction of the cementation plant appropriately 83

Define SED Reduction Project HA Liquor MA Liquor PCM ILW Where more than one SED PCM store Each waste reduction project stream can use requires the be Cementation Plant considered to be of a specific subject to the an facility, individual costs associated SED reduction project ILW Store Process & durations for Facility construction, operation etc This would define 4 should be SED reduction The scope of each SED reduction project includes all enabling work such as apportioned Projects construction of the cementation plant appropriately 83

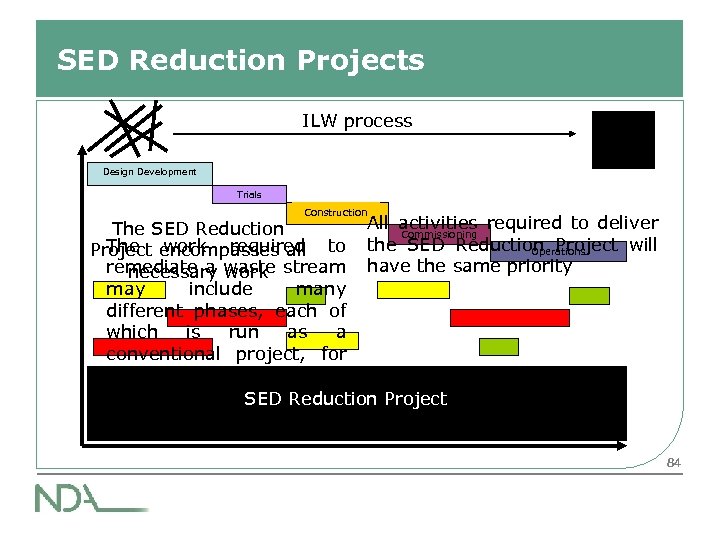

SED Reduction Projects ILW process Design Development Trials Construction All activities required to deliver The SED Reduction Commissioning The encompasses all to the SED Reduction Project will work required Operations Project remediate a waste stream have the same priority necessary work may include many different phases, each of which is run as a conventional project, for example SED Reduction Project 84

SED Reduction Projects ILW process Design Development Trials Construction All activities required to deliver The SED Reduction Commissioning The encompasses all to the SED Reduction Project will work required Operations Project remediate a waste stream have the same priority necessary work may include many different phases, each of which is run as a conventional project, for example SED Reduction Project 84

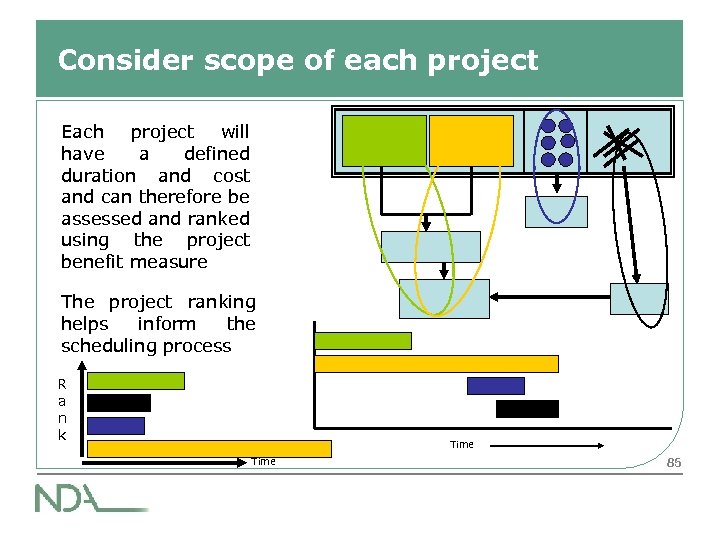

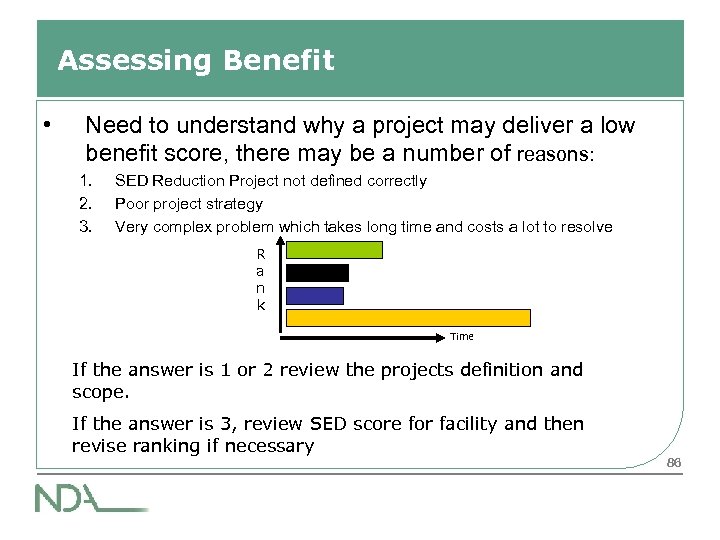

Consider scope of each project Each project will have a defined duration and cost and can therefore be assessed and ranked using the project benefit measure The project ranking helps inform the scheduling process R a n k Time 85

Consider scope of each project Each project will have a defined duration and cost and can therefore be assessed and ranked using the project benefit measure The project ranking helps inform the scheduling process R a n k Time 85

Assessing Benefit • Need to understand why a project may deliver a low benefit score, there may be a number of reasons: 1. 2. 3. SED Reduction Project not defined correctly Poor project strategy Very complex problem which takes long time and costs a lot to resolve R a n k Time If the answer is 1 or 2 review the projects definition and scope. If the answer is 3, review SED score for facility and then revise ranking if necessary 86

Assessing Benefit • Need to understand why a project may deliver a low benefit score, there may be a number of reasons: 1. 2. 3. SED Reduction Project not defined correctly Poor project strategy Very complex problem which takes long time and costs a lot to resolve R a n k Time If the answer is 1 or 2 review the projects definition and scope. If the answer is 3, review SED score for facility and then revise ranking if necessary 86

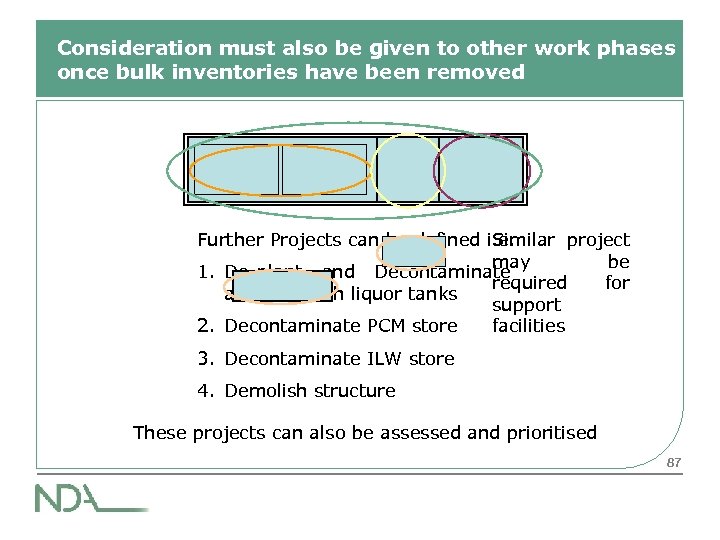

Consideration must also be given to other work phases once bulk inventories have been removed Further Projects can be defined i. e. Similar project may be 1. De-plant and Decontaminate required for and demolish liquor tanks support 2. Decontaminate PCM store facilities 3. Decontaminate ILW store 4. Demolish structure These projects can also be assessed and prioritised 87

Consideration must also be given to other work phases once bulk inventories have been removed Further Projects can be defined i. e. Similar project may be 1. De-plant and Decontaminate required for and demolish liquor tanks support 2. Decontaminate PCM store facilities 3. Decontaminate ILW store 4. Demolish structure These projects can also be assessed and prioritised 87

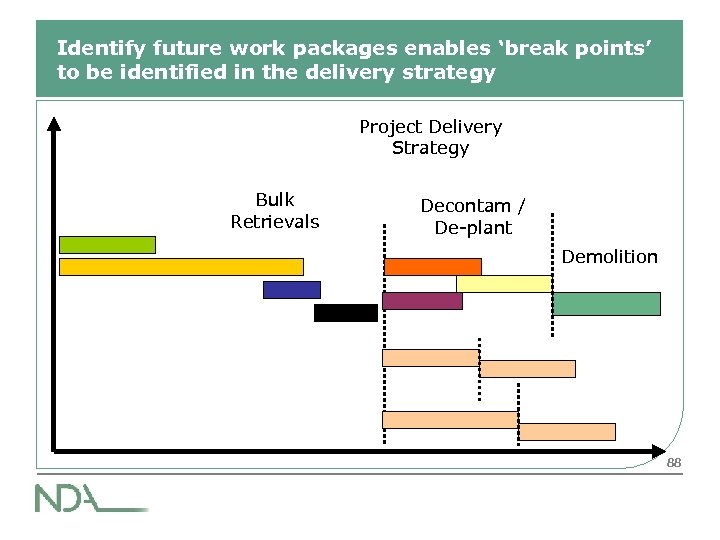

Identify future work packages enables ‘break points’ to be identified in the delivery strategy Project Delivery Strategy Bulk Retrievals Decontam / De-plant Demolition 88

Identify future work packages enables ‘break points’ to be identified in the delivery strategy Project Delivery Strategy Bulk Retrievals Decontam / De-plant Demolition 88

Hazard Potential Reduction • Project Benefit Measure assesses hazard potential reduction verses time and cost the greater the time or cost the lower the benefit. • Requires working knowledge of RHP and CHP • Note that where (RHP + CHP)1 - (RHP +CHP)2 = 0, the hazard reduction is zero the project should therefore score 0 for both (∆HP vs t) and (∆HP vs £). 89

Hazard Potential Reduction • Project Benefit Measure assesses hazard potential reduction verses time and cost the greater the time or cost the lower the benefit. • Requires working knowledge of RHP and CHP • Note that where (RHP + CHP)1 - (RHP +CHP)2 = 0, the hazard reduction is zero the project should therefore score 0 for both (∆HP vs t) and (∆HP vs £). 89

Legacy Dose, Ongoing Facility Cost and Electrical Usage • Legacy dose, ongoing facility cost and electrical usage, all included to provide indication of the benefit the SED Reduction Project has on the mortgage cost of a historic plant • All require estimates of the benefit (reduction) not an accurate assessment • Record assumptions and calculations as appropriate to help future assessment/revision Note this is not an exact science – use appropriate estimates 90

Legacy Dose, Ongoing Facility Cost and Electrical Usage • Legacy dose, ongoing facility cost and electrical usage, all included to provide indication of the benefit the SED Reduction Project has on the mortgage cost of a historic plant • All require estimates of the benefit (reduction) not an accurate assessment • Record assumptions and calculations as appropriate to help future assessment/revision Note this is not an exact science – use appropriate estimates 90

Ongoing Electrical Usage • Included in Project Benefit Measure to assess Environmental detriment associated with a facility • Consider the effect that the SED Reduction Project will have on the electrical usage of all facilities associated with the waste being addressed • Provide suitable underpinning data to support estimates • Scored using a scoring grid 91

Ongoing Electrical Usage • Included in Project Benefit Measure to assess Environmental detriment associated with a facility • Consider the effect that the SED Reduction Project will have on the electrical usage of all facilities associated with the waste being addressed • Provide suitable underpinning data to support estimates • Scored using a scoring grid 91

Modifiers • Not all issues important to stakeholders can be prioritised using the SED and Project Benefit Measures • Therefore Modifiers are required to address significant stakeholder issues and prioritise • Provide underpinning data to justify use of a modifier 92

Modifiers • Not all issues important to stakeholders can be prioritised using the SED and Project Benefit Measures • Therefore Modifiers are required to address significant stakeholder issues and prioritise • Provide underpinning data to justify use of a modifier 92

PCP - 07 Requirements • list facilities in order of priority based on the Safety and Environmental Detriment (SED) - Don’t identify scores, just ranked positions • List Safety and Environmental Detriment Reduction Projects in order of priority based on the Project Benefit Measure - SED Improvement Projects, only projects that are ongoing or are capable of commencing within the next 5 years should be considered. • Provide SED Reduction Curve on Site Long Range Graphic 93

PCP - 07 Requirements • list facilities in order of priority based on the Safety and Environmental Detriment (SED) - Don’t identify scores, just ranked positions • List Safety and Environmental Detriment Reduction Projects in order of priority based on the Project Benefit Measure - SED Improvement Projects, only projects that are ongoing or are capable of commencing within the next 5 years should be considered. • Provide SED Reduction Curve on Site Long Range Graphic 93