98b6aae59afc82c390f62beaf505f075.ppt

- Количество слайдов: 54

The Manufacture of Fine Papers Spring Semester 1999 TEC 4562 Ink & Paper Substrates

The Manufacture of Fine Papers Spring Semester 1999 TEC 4562 Ink & Paper Substrates

Introduction n “The ability of humans to supplement their speech with the written word is an indication of a high degree of civilization. ” n From carvings on slabs of rock to paper, humans have been able to devise a form of communication that goes beyond speech.

Introduction n “The ability of humans to supplement their speech with the written word is an indication of a high degree of civilization. ” n From carvings on slabs of rock to paper, humans have been able to devise a form of communication that goes beyond speech.

The History of Paper n What civilization invented paper? – – – Ancient Egyptians? Moors or Arabs Persians? Aztecs? Japanese? Chinese?

The History of Paper n What civilization invented paper? – – – Ancient Egyptians? Moors or Arabs Persians? Aztecs? Japanese? Chinese?

Pre-Paper Media n The following is a list of pre-paper media developed by early humans: – – – – – Wood Metal Stone Leaves Ceramics Bark Papyrus Parchment Cloth

Pre-Paper Media n The following is a list of pre-paper media developed by early humans: – – – – – Wood Metal Stone Leaves Ceramics Bark Papyrus Parchment Cloth

Egyptians and Papyrus n The papyrus developed before 2, 200 B. C. by the Egyptians was not considered true paper. n The reason papyrus and the other materials did not qualify as paper was due to the way it is formed from a liquid suspension of individual fibers into a mat or sheet. n It was made by slicking the plant’s stalk from end-to-end into very thin blades and then laminating them into something of a weave. n It appears similar to cloth.

Egyptians and Papyrus n The papyrus developed before 2, 200 B. C. by the Egyptians was not considered true paper. n The reason papyrus and the other materials did not qualify as paper was due to the way it is formed from a liquid suspension of individual fibers into a mat or sheet. n It was made by slicking the plant’s stalk from end-to-end into very thin blades and then laminating them into something of a weave. n It appears similar to cloth.

The History of Paper n Although papyrus is not structured like the writing or printing surfaces in use today—it became the Latin word for paper. n Nearly 2, 000 years later, the Chinese created the first true or practical form of paper. n They did this by reducing raw material into individual fibers and then forming them into a mat or sheet.

The History of Paper n Although papyrus is not structured like the writing or printing surfaces in use today—it became the Latin word for paper. n Nearly 2, 000 years later, the Chinese created the first true or practical form of paper. n They did this by reducing raw material into individual fibers and then forming them into a mat or sheet.

The Inventor of Paper n It is widely accepted that Ts’ai Lun, a Chinese court official, invented paper in 105 AD.

The Inventor of Paper n It is widely accepted that Ts’ai Lun, a Chinese court official, invented paper in 105 AD.

Ts’ai Lun’s Paper n Mulberry Bark n Hemp Waste n Old Rags n Fish Nets

Ts’ai Lun’s Paper n Mulberry Bark n Hemp Waste n Old Rags n Fish Nets

The Wove Mold Process n This process was devised by the Chinese – Pulp was made by beating bark (Pulp Friction), which had been washed and boiled – During the washing and boiling process, the pulp fibers were separated using smooth-edged stones and sticks.

The Wove Mold Process n This process was devised by the Chinese – Pulp was made by beating bark (Pulp Friction), which had been washed and boiled – During the washing and boiling process, the pulp fibers were separated using smooth-edged stones and sticks.

The Laid Mold n Consisted of a flexible cover made of thin strips of bamboo held together with silk or some other similar thread n It was placed on a wooden frame. n The papermaker would hold the two together and dip them in a vat of water and fibers.

The Laid Mold n Consisted of a flexible cover made of thin strips of bamboo held together with silk or some other similar thread n It was placed on a wooden frame. n The papermaker would hold the two together and dip them in a vat of water and fibers.

The Laid Mold (continued) n The papermaker would lift the mold and let the water drain away. n This formed the sheet. n The layer of wet paper and light bamboo were lifted from the wooden frame and placed on a smooth stone with the wet fiber mat facing down. n The light bamboo matting was then rolled from the paper leaving a wrinkle-free sheet to be dried. n The mold was reusable.

The Laid Mold (continued) n The papermaker would lift the mold and let the water drain away. n This formed the sheet. n The layer of wet paper and light bamboo were lifted from the wooden frame and placed on a smooth stone with the wet fiber mat facing down. n The light bamboo matting was then rolled from the paper leaving a wrinkle-free sheet to be dried. n The mold was reusable.

Therefore, n the Laid Mold was considered better than the Wove Mold

Therefore, n the Laid Mold was considered better than the Wove Mold

Historical significance of paper. . . n Early use as a symbol for money to burn over graves of the dead n 175 A. D. - Paper replaced silk as a medium for writing. n 610 A. D. the Japanese began to make paper n 750 A. D. the battle fought between Muslims and Chinese at Samarkand in Turkestan (now part of Uzbekistan at formerly part of the Soviet Union) spurred the development of paper outside China’s domain.

Historical significance of paper. . . n Early use as a symbol for money to burn over graves of the dead n 175 A. D. - Paper replaced silk as a medium for writing. n 610 A. D. the Japanese began to make paper n 750 A. D. the battle fought between Muslims and Chinese at Samarkand in Turkestan (now part of Uzbekistan at formerly part of the Soviet Union) spurred the development of paper outside China’s domain.

n 875 A. D. - First known use of toilet paper. n Late 900’s - Playing cards invented. n Mid 15 th century - Johannes Gutenburg’s invention of movable type spurred the production for paper necessary for the production of books.

n 875 A. D. - First known use of toilet paper. n Late 900’s - Playing cards invented. n Mid 15 th century - Johannes Gutenburg’s invention of movable type spurred the production for paper necessary for the production of books.

The “Paper Renaissance” 17 th to 19 th Century Europe n France was the center of paper production. . . – Exported papers to all of Europe – It possessed the best papermakers and the finest equipment in the world. n France also experienced internal struggle and unrest during the 17 th century. . . – This caused their papermakers to flee to England, Holland America. – The skilled French papermakers contributed to the English and Dutch paper manufacturers, thus, transforming them into the “foremost paper manufacturers in Europe. ”

The “Paper Renaissance” 17 th to 19 th Century Europe n France was the center of paper production. . . – Exported papers to all of Europe – It possessed the best papermakers and the finest equipment in the world. n France also experienced internal struggle and unrest during the 17 th century. . . – This caused their papermakers to flee to England, Holland America. – The skilled French papermakers contributed to the English and Dutch paper manufacturers, thus, transforming them into the “foremost paper manufacturers in Europe. ”

America’s First Paper Mill n Built in 1690 by William Rittenhouse n Location: Philadelphia n Since that time, America has become the world’s largest producer of paper and pulp products

America’s First Paper Mill n Built in 1690 by William Rittenhouse n Location: Philadelphia n Since that time, America has become the world’s largest producer of paper and pulp products

Fibers for Papermaking n Fibers are defined as “. . . tough threadlike substances capable of being spun or woven, whether they be natural (vegetable, mineral, animal) or man-made. ” n In papermaking, animal fibers are not used at all, and mineral fibers are used only occasionally. n Vegetable fibers (cellulose) wet easily in a water medium and will form a strong bond to each other when dried in contact.

Fibers for Papermaking n Fibers are defined as “. . . tough threadlike substances capable of being spun or woven, whether they be natural (vegetable, mineral, animal) or man-made. ” n In papermaking, animal fibers are not used at all, and mineral fibers are used only occasionally. n Vegetable fibers (cellulose) wet easily in a water medium and will form a strong bond to each other when dried in contact.

Four Types of Cellulose Fibers n Seed Hair Fibers – Cotton fibers n Bast Fibers – Flax plant – Only 5% of the flax plant is usable for paper manufacturing n Grass Fibers – – Wheat straw Bagasse fiber (extracted from sugar cane stalks) Esparto grass Kenaf plant n Wood Fibers

Four Types of Cellulose Fibers n Seed Hair Fibers – Cotton fibers n Bast Fibers – Flax plant – Only 5% of the flax plant is usable for paper manufacturing n Grass Fibers – – Wheat straw Bagasse fiber (extracted from sugar cane stalks) Esparto grass Kenaf plant n Wood Fibers

Seed Hair Fibers—Cotton Plant n Cotton fibers are very expensive. n Used primarily for bank notes, high grade writing papers, maps— anything that requires exceptional strength and durability.

Seed Hair Fibers—Cotton Plant n Cotton fibers are very expensive. n Used primarily for bank notes, high grade writing papers, maps— anything that requires exceptional strength and durability.

Bast Fibers n Obtained from the flax plant. n Located inside the stem. n Only 5% usable for papermaking. n Hemp and jute are other forms of bast fibers. n Hemp has been used for cigarette and Bible papers.

Bast Fibers n Obtained from the flax plant. n Located inside the stem. n Only 5% usable for papermaking. n Hemp and jute are other forms of bast fibers. n Hemp has been used for cigarette and Bible papers.

Bast Fibers (continued) n Jute obtained from new burlap cuttings or other sources… – It is used for heavy duty shipping tags and heavy pattern boards.

Bast Fibers (continued) n Jute obtained from new burlap cuttings or other sources… – It is used for heavy duty shipping tags and heavy pattern boards.

Grass Fibers n Wheat Straw – Absorbs water readily. – Was used during World War II in England due to a severe shortage of pulpwood. n Bagasse fiber – Made from crushed stalks of sugar cane. – Used as a source of fuel for Sugar Mills. n Esparto Plant – Has very little strength and does not split into fibrils easily. – Impractical for use in the United States because of the distance from the source of supply.

Grass Fibers n Wheat Straw – Absorbs water readily. – Was used during World War II in England due to a severe shortage of pulpwood. n Bagasse fiber – Made from crushed stalks of sugar cane. – Used as a source of fuel for Sugar Mills. n Esparto Plant – Has very little strength and does not split into fibrils easily. – Impractical for use in the United States because of the distance from the source of supply.

Grass Fibers (continued) n Kenaf plant – Shows great potential for papermaking. – May produce 5 to 7 times more pulp/acre than pine. – Grows to maturity in 120 days compared to 20 years for most trees.

Grass Fibers (continued) n Kenaf plant – Shows great potential for papermaking. – May produce 5 to 7 times more pulp/acre than pine. – Grows to maturity in 120 days compared to 20 years for most trees.

Wood Fibers n 95% of all paper is made from wood fibers. n Deciduous hardwood trees, e. g. , Oak, Gum, Maple, Aspen, etc. n Coniferous softwood trees, e. g. , Pine, Spruce, Fir, etc. (the softwoods produce a stronger pulp).

Wood Fibers n 95% of all paper is made from wood fibers. n Deciduous hardwood trees, e. g. , Oak, Gum, Maple, Aspen, etc. n Coniferous softwood trees, e. g. , Pine, Spruce, Fir, etc. (the softwoods produce a stronger pulp).

Wood Procurement n 39% of the available forests in the United States are in the South. n Private citizens own 3 quarters of land. n Paper industry uses specially designed equipment to harvest & prepare crops of trees: – Power chain saws – Skidders-forest tractors are used for opening sections of land. – Specially designed combines. – Mechanized tree shears. – Cranes, clamp trucks, truck dumpers. – Slashers saws. – Debarking drums.

Wood Procurement n 39% of the available forests in the United States are in the South. n Private citizens own 3 quarters of land. n Paper industry uses specially designed equipment to harvest & prepare crops of trees: – Power chain saws – Skidders-forest tractors are used for opening sections of land. – Specially designed combines. – Mechanized tree shears. – Cranes, clamp trucks, truck dumpers. – Slashers saws. – Debarking drums.

Pulping n The objective of pulping is to separate the wood into individual fibers. n Three broad classifications of pulping methods: – – – Mechanical (groundwood) Chemical Combination (chemi-mechanical)

Pulping n The objective of pulping is to separate the wood into individual fibers. n Three broad classifications of pulping methods: – – – Mechanical (groundwood) Chemical Combination (chemi-mechanical)

Mechnical Pulping Processes n Stone Groundwood – Mechanical process used to rip fibers from the logs – Slurry of pulp formed from the grounded mix. – Can be made from either hardwood or softwood. n Refiner-Mechanical Pulping – Wood chips are pumped into rotating disks causing internal friction that generates heat. – The heat from the refiner softens lignin. n Thermo-Mechanical Pulping n Chemi-Mechanical Pulp

Mechnical Pulping Processes n Stone Groundwood – Mechanical process used to rip fibers from the logs – Slurry of pulp formed from the grounded mix. – Can be made from either hardwood or softwood. n Refiner-Mechanical Pulping – Wood chips are pumped into rotating disks causing internal friction that generates heat. – The heat from the refiner softens lignin. n Thermo-Mechanical Pulping n Chemi-Mechanical Pulp

To Make Groundwood Pulp. . . n The bark is removed from the logs. n Then, the cut logs are forced by hydraulic or steam pressure against a revolving grinding stone in the presence of water. n This treatment converts the wood into a pulp consisting of minute particles of both fibrous and nonfibrous portions of wood. n The nonfibrous materials deteriorate when left for some time in contact with air. n Therefore, paper made from this kind of pulp lacks permanency.

To Make Groundwood Pulp. . . n The bark is removed from the logs. n Then, the cut logs are forced by hydraulic or steam pressure against a revolving grinding stone in the presence of water. n This treatment converts the wood into a pulp consisting of minute particles of both fibrous and nonfibrous portions of wood. n The nonfibrous materials deteriorate when left for some time in contact with air. n Therefore, paper made from this kind of pulp lacks permanency.

Groundwood Pulp n This type of pulp is not as strong as chemical pulp. n Groundwood pulp has to be mixed with other pulps, e. g. , Newsprint—contains 80% groundwood pulp and 20% chemical pulp. n It is highly suitable for products such as wallpaper, paper towels, or lightweight catalog papers. n It is unexcelled in its ability to produce papers with high opacity, smoothness and ink receptivity.

Groundwood Pulp n This type of pulp is not as strong as chemical pulp. n Groundwood pulp has to be mixed with other pulps, e. g. , Newsprint—contains 80% groundwood pulp and 20% chemical pulp. n It is highly suitable for products such as wallpaper, paper towels, or lightweight catalog papers. n It is unexcelled in its ability to produce papers with high opacity, smoothness and ink receptivity.

Thermo-Mechanical Pulp n To make TMP, wood chips or sawdust are first softened by steam and then subjected, under pressure, to the defibering action of a a disktype refiner. n This causes the fibers to completely separate from each other and suffer less damage than those produced by the conventional groundwood pulp process. n TMP is cleaner and stronger when compared with groundwood pulp.

Thermo-Mechanical Pulp n To make TMP, wood chips or sawdust are first softened by steam and then subjected, under pressure, to the defibering action of a a disktype refiner. n This causes the fibers to completely separate from each other and suffer less damage than those produced by the conventional groundwood pulp process. n TMP is cleaner and stronger when compared with groundwood pulp.

Chemical Pulp n Chemicals are used to reduce wood chips into fibers. n This process separates each fiber from its bonding material—lignin. – The adhesive qualities of lignin holds cellulose fibers together.

Chemical Pulp n Chemicals are used to reduce wood chips into fibers. n This process separates each fiber from its bonding material—lignin. – The adhesive qualities of lignin holds cellulose fibers together.

Bleaching n The purpose of bleaching is to remove stains caused by lignin. n Major bleaching agents – chlorine, sodium hypochlorite, hydrogen peroxide, chlorine-dioxide, and oxygen. n Chlorine gas is one of the different bleaching systems that are used to remove lignin that remains in the pulp. – Chlorine gas is passed into the pulp-water mixture. – The gas reacts with whatever lignin that is left and becomes chlorinated. – The chlorinated lignin is then removed when treated with the caustic soda Na. OH (Sodium Hypochlorite)

Bleaching n The purpose of bleaching is to remove stains caused by lignin. n Major bleaching agents – chlorine, sodium hypochlorite, hydrogen peroxide, chlorine-dioxide, and oxygen. n Chlorine gas is one of the different bleaching systems that are used to remove lignin that remains in the pulp. – Chlorine gas is passed into the pulp-water mixture. – The gas reacts with whatever lignin that is left and becomes chlorinated. – The chlorinated lignin is then removed when treated with the caustic soda Na. OH (Sodium Hypochlorite)

Fourdrinier Paper Making Machine n Nicolas Louis Robert invented the papermaking machine in 1798. n Sealy Fourdrinier and Robert improved the original design of the papermaking machine to produce paper with a felt side and a wire side. n The paper is formed at the wet end of the machine—after the pulp-water mixture has been refined. – Fillers – Coloring material – Sizing

Fourdrinier Paper Making Machine n Nicolas Louis Robert invented the papermaking machine in 1798. n Sealy Fourdrinier and Robert improved the original design of the papermaking machine to produce paper with a felt side and a wire side. n The paper is formed at the wet end of the machine—after the pulp-water mixture has been refined. – Fillers – Coloring material – Sizing

The Headbox n The headbox spreads pulp and water mix evenly over the moving wire. – The pulp-water mixture containing the added fibers, coloring material and size is diluted with water to make “slurry” containing ½ % to 1 % of cellulose fibers. – The headbox must maintain the uniform delivery of dispersion of fibers across the width of the machine.

The Headbox n The headbox spreads pulp and water mix evenly over the moving wire. – The pulp-water mixture containing the added fibers, coloring material and size is diluted with water to make “slurry” containing ½ % to 1 % of cellulose fibers. – The headbox must maintain the uniform delivery of dispersion of fibers across the width of the machine.

The Fourdrinier Wire n The fourdrinier wire causes the forming of paper at the wet end of the machine. – It is the section of the papermaking machine made up of a fine woven screen to let water drain away causing the pulp to remain to form a thin mat. – Suction boxes remove water as the mat moves along the wire. – Synthetic plastic fiber wires are used in modern papermaking machines. n When the mat had left this stage of production it contains 75% water.

The Fourdrinier Wire n The fourdrinier wire causes the forming of paper at the wet end of the machine. – It is the section of the papermaking machine made up of a fine woven screen to let water drain away causing the pulp to remain to form a thin mat. – Suction boxes remove water as the mat moves along the wire. – Synthetic plastic fiber wires are used in modern papermaking machines. n When the mat had left this stage of production it contains 75% water.

Presses n During this stage of production, the mat enters wet rollers carried by felt blankets to reduce the amount of water to 60 - 65%. n It is during this stage that the thin mat or paper begins to form a web or long ribbon. n The paper continues through press rolls and felt blankets to remove water.

Presses n During this stage of production, the mat enters wet rollers carried by felt blankets to reduce the amount of water to 60 - 65%. n It is during this stage that the thin mat or paper begins to form a web or long ribbon. n The paper continues through press rolls and felt blankets to remove water.

Dryers n Steam heated cylinders dry paper to 5% moisture.

Dryers n Steam heated cylinders dry paper to 5% moisture.

Size Presses n Size press applies 10 % starch solution to both sides of paper.

Size Presses n Size press applies 10 % starch solution to both sides of paper.

Dryers n Second dryer unit removes moisture applied to sheet in size press.

Dryers n Second dryer unit removes moisture applied to sheet in size press.

Calender-Reel n Polished rollers iron and control thickness of sheet. Reel winds paper on mandrel.

Calender-Reel n Polished rollers iron and control thickness of sheet. Reel winds paper on mandrel.

Winder n Winder unwinds paper from mandrel, passes sheet across slitter to trim edges and cut paper to final width.

Winder n Winder unwinds paper from mandrel, passes sheet across slitter to trim edges and cut paper to final width.

Twin Wire Machines n This method of papermaking was developed to improve the efficiency of the fourdrinier design. n Two vertical sides restrain the furnish to permit the extraction of water from both sides of the paper. n Increase machine speeds and reduction in drying.

Twin Wire Machines n This method of papermaking was developed to improve the efficiency of the fourdrinier design. n Two vertical sides restrain the furnish to permit the extraction of water from both sides of the paper. n Increase machine speeds and reduction in drying.

Cylinder Machine n This type of machine is designed for making extremely heavyweight paper and/or multi-ply products used in the manufacture of corrugated containers, folding cartons, and solid fiber boxes. n All layers for multi-ply products can be manufactured with all layers formed in a single continuous operation. n Two types of cylinder vats: contraflow and direct flow.

Cylinder Machine n This type of machine is designed for making extremely heavyweight paper and/or multi-ply products used in the manufacture of corrugated containers, folding cartons, and solid fiber boxes. n All layers for multi-ply products can be manufactured with all layers formed in a single continuous operation. n Two types of cylinder vats: contraflow and direct flow.

Paper (handout) 1. The Chinese are given credit for inventing the technique of papermaking. 2. To make a continuous supply of wood, the basic raw material for making paper, paper companies operate tree farms. 3. Pulp fibers are obtained from, woody fibrous materials, and reclaimed products are made from these materials. 4. Wood pulp sources are divided between softwood (coniferous) and hardwood (deciduous).

Paper (handout) 1. The Chinese are given credit for inventing the technique of papermaking. 2. To make a continuous supply of wood, the basic raw material for making paper, paper companies operate tree farms. 3. Pulp fibers are obtained from, woody fibrous materials, and reclaimed products are made from these materials. 4. Wood pulp sources are divided between softwood (coniferous) and hardwood (deciduous).

Paper (handout) continued 5. All paper fibers are made of a compound called cellulose. 6. Lignin serves as a binder and support for the cellulose fibers of woody plants. 7. Groundwood pulp process uses almost all of the substance in wood to make paper. 8. The manufacturer of chemical pulp uses chemical action to dissolve some of the wood’s substances to make higher quality paper.

Paper (handout) continued 5. All paper fibers are made of a compound called cellulose. 6. Lignin serves as a binder and support for the cellulose fibers of woody plants. 7. Groundwood pulp process uses almost all of the substance in wood to make paper. 8. The manufacturer of chemical pulp uses chemical action to dissolve some of the wood’s substances to make higher quality paper.

Paper (handout) continued 9. The chemical-mechanical pulp method combines mechanical and cooking separation processes. 10. Opacity refers to the amount of light that can be seen through a sheet of paper. 11. In all three pulping methods, washing is used to remove all traces of chemicals and dirt from wood fibers. 12. True. Groundwood pulp is often referred to as mechnical pulp because it has been reduced to fibers by a mechanical grinding process.

Paper (handout) continued 9. The chemical-mechanical pulp method combines mechanical and cooking separation processes. 10. Opacity refers to the amount of light that can be seen through a sheet of paper. 11. In all three pulping methods, washing is used to remove all traces of chemicals and dirt from wood fibers. 12. True. Groundwood pulp is often referred to as mechnical pulp because it has been reduced to fibers by a mechanical grinding process.

Paper (handout) continued 13. The pulp selected for bleaching is treated with chlorine and similar chemical solutions to whiten the paper fibers. 14. The primary purpose of adding fillers to the pulp is to strengthen its properties. 15. Sizing is used to helpl make paper less absorbent and more water repellent, so it will not allow ink to spread. 16. Dyes and pigments are added to pulp during washing to give paper color.

Paper (handout) continued 13. The pulp selected for bleaching is treated with chlorine and similar chemical solutions to whiten the paper fibers. 14. The primary purpose of adding fillers to the pulp is to strengthen its properties. 15. Sizing is used to helpl make paper less absorbent and more water repellent, so it will not allow ink to spread. 16. Dyes and pigments are added to pulp during washing to give paper color.

Paper (handout) continued 17. The forming of paper starts at the wet end of the papermaking machine. Then processed pulp, which is 99% water, flows rapidly over an apron the width of the machine onto a moving mesh wire screen. 18. Where the paper touches the screen, it shows a mesh pattern. This is called the wire side of the paper.

Paper (handout) continued 17. The forming of paper starts at the wet end of the papermaking machine. Then processed pulp, which is 99% water, flows rapidly over an apron the width of the machine onto a moving mesh wire screen. 18. Where the paper touches the screen, it shows a mesh pattern. This is called the wire side of the paper.

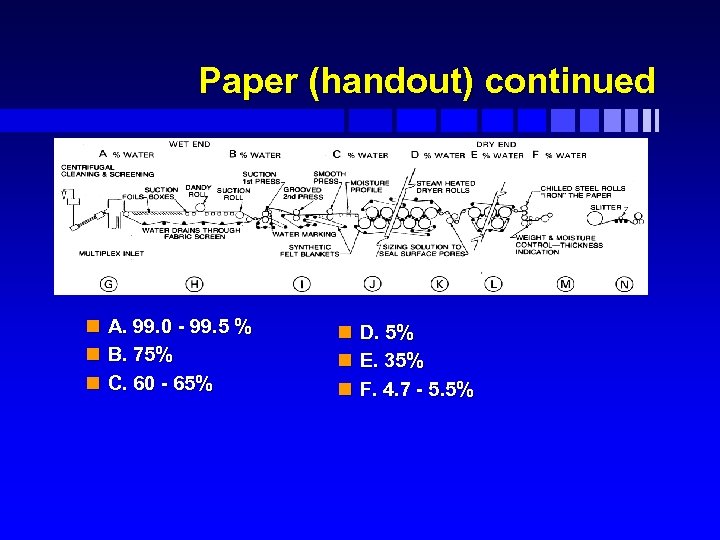

Paper (handout) continued 19. Identify the water content and machine sections of a typical papermaking machine operation in the mill. n A. 99. 0 - 99. 5 % n B. 75% n C. 60 - 65% n n n D. 5% E. 35% F. 4. 7 - 5. 5%

Paper (handout) continued 19. Identify the water content and machine sections of a typical papermaking machine operation in the mill. n A. 99. 0 - 99. 5 % n B. 75% n C. 60 - 65% n n n D. 5% E. 35% F. 4. 7 - 5. 5%

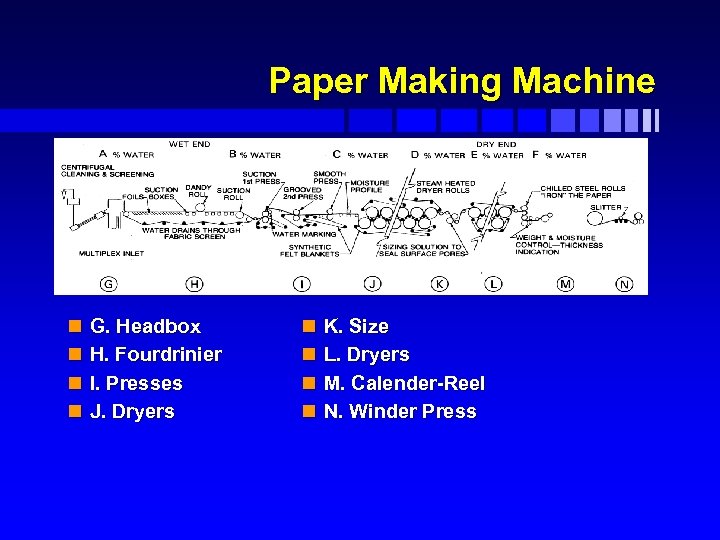

Paper Making Machine n n G. Headbox H. Fourdrinier I. Presses J. Dryers n n K. Size L. Dryers M. Calender-Reel N. Winder Press

Paper Making Machine n n G. Headbox H. Fourdrinier I. Presses J. Dryers n n K. Size L. Dryers M. Calender-Reel N. Winder Press

Paper (handout) continued 20. As the paper starts to form, the pulp passes under a dandy roll to produce a surface finish on the paper. The roll is made of mesh wire. 21. The paper begins to form into a web, or long ribbon as it passes through the papermaking machine. 22. The ribbon of paper continues through press rolls and felt blankets, which remove more water.

Paper (handout) continued 20. As the paper starts to form, the pulp passes under a dandy roll to produce a surface finish on the paper. The roll is made of mesh wire. 21. The paper begins to form into a web, or long ribbon as it passes through the papermaking machine. 22. The ribbon of paper continues through press rolls and felt blankets, which remove more water.

Paper (handout) continued 23. The side of the paper that is in contact with the felt blanket is called the felt side of the paper. 24. Calender rolls are made of smooth iron to polish the paper and give it a very smooth finish. 25. Sheet-fed offset paper must have more strength than other printer processes because of the tackier ink. 26. The basis weights of paper generally used for web offset range from about 20 - 80 pound.

Paper (handout) continued 23. The side of the paper that is in contact with the felt blanket is called the felt side of the paper. 24. Calender rolls are made of smooth iron to polish the paper and give it a very smooth finish. 25. Sheet-fed offset paper must have more strength than other printer processes because of the tackier ink. 26. The basis weights of paper generally used for web offset range from about 20 - 80 pound.

Paper (handout) continued 27. Joining the ends of two rolls of paper is referred to as splicing. 28. There are eight paper properties which must be considered for each job: 3 Grain 3 Finish 3 Pick Resistance 3 Brightness and Basis weight 3 Flatness 3 Ink setting and sizing 3 Moisture absorbency and resistance 3 Opacity

Paper (handout) continued 27. Joining the ends of two rolls of paper is referred to as splicing. 28. There are eight paper properties which must be considered for each job: 3 Grain 3 Finish 3 Pick Resistance 3 Brightness and Basis weight 3 Flatness 3 Ink setting and sizing 3 Moisture absorbency and resistance 3 Opacity

29. Fibers tend to align themselves in the paper as it passes through the machine. This alignment of fiber is referred to as the grain of the paper. 30. Tear strength in paper increases with increased fiber strength. 31. The term finish refers to any action performed to the surface of the sheet of printing paper that affects its surface. 32. Coated papers are exceptionally smooth, since they are subjected to an additional smoothing process.

29. Fibers tend to align themselves in the paper as it passes through the machine. This alignment of fiber is referred to as the grain of the paper. 30. Tear strength in paper increases with increased fiber strength. 31. The term finish refers to any action performed to the surface of the sheet of printing paper that affects its surface. 32. Coated papers are exceptionally smooth, since they are subjected to an additional smoothing process.