4387c03a251d9f695ba8521ca6671d2e.ppt

- Количество слайдов: 28

The Making of ATLAS Muon chambers @NIKHEF • • • The NIKHEF Muon Mission Drift tube wiring Chamber assembly X-ray scan of BOL-0 at CERN Status and Plans Marcel Vreeswijk (NIKHEF)

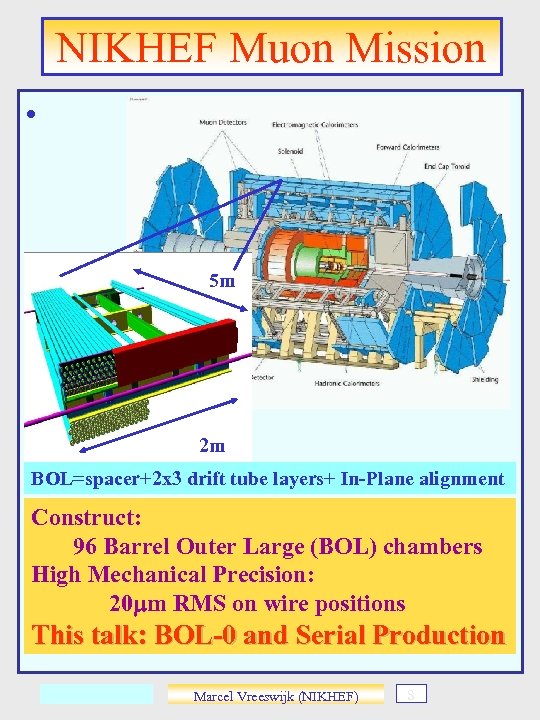

NIKHEF Muon Mission • 5 m 2 m BOL=spacer+2 x 3 drift tube layers+ In-Plane alignment Construct: 96 Barrel Outer Large (BOL) chambers High Mechanical Precision: 20 mm RMS on wire positions This talk: has expansion length o 0. 1 m in Xras West side BOL-0 and Serial Production Marcel Vreeswijk (NIKHEF) s

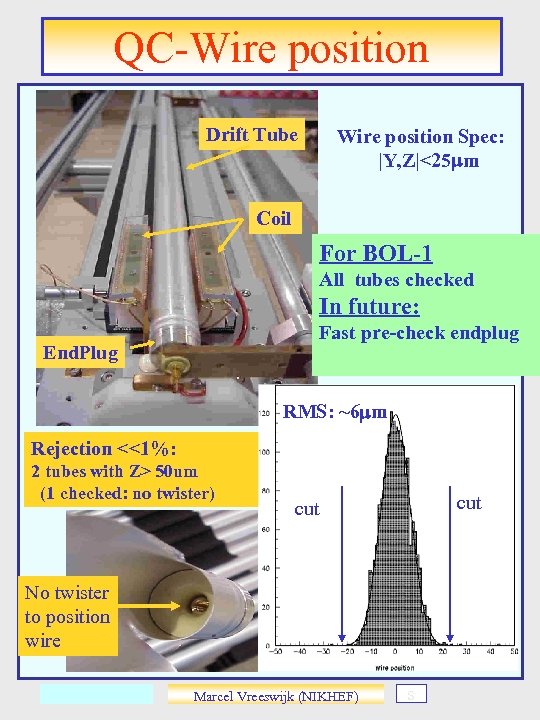

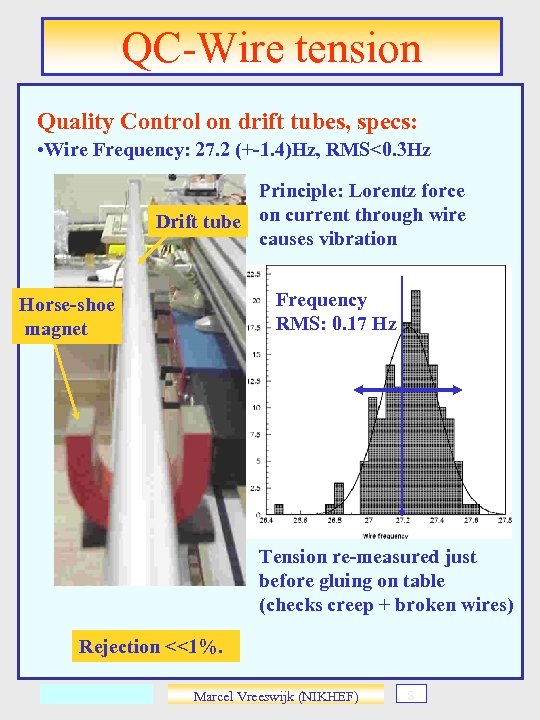

Tube wiring + QC • Drift tubes: • Extruded aluminum drift tubes (3 cm) • Wire (50 mm gold-plated tungsten) positioned by two end-plugs Endplug QC on drift tubes, specs: • Wire position: |Z, Y|<25 mm • Wire tension=> frequency 27. 2+-1. 4 Hz, RMS<0. 3 Hz • Leak rate: <2. 5 10 -8 bl/s • HV check: <20 n. A @3500 V Marcel Vreeswijk (NIKHEF)

QC-Wire position Drift Tube Wire position Spec: |Y, Z|<25 mm Coil For BOL-1 All tubes checked In future: Fast pre-check endplug End. Plug RMS: ~6 mm Rejection <<1%: 2 tubes with Z> 50 um (1 checked: no twister) cut No twister to position wire Marcel Vreeswijk (NIKHEF) s

QC-Wire tension Quality Control on drift tubes, specs: • Wire Frequency: 27. 2 (+-1. 4)Hz, RMS<0. 3 Hz Principle: Lorentz force Drift tube on current through wire causes vibration Frequency RMS: 0. 17 Hz Horse-shoe magnet Tension re-measured just before gluing on table (checks creep + broken wires) Rejection <<1%. Marcel Vreeswijk (NIKHEF) s

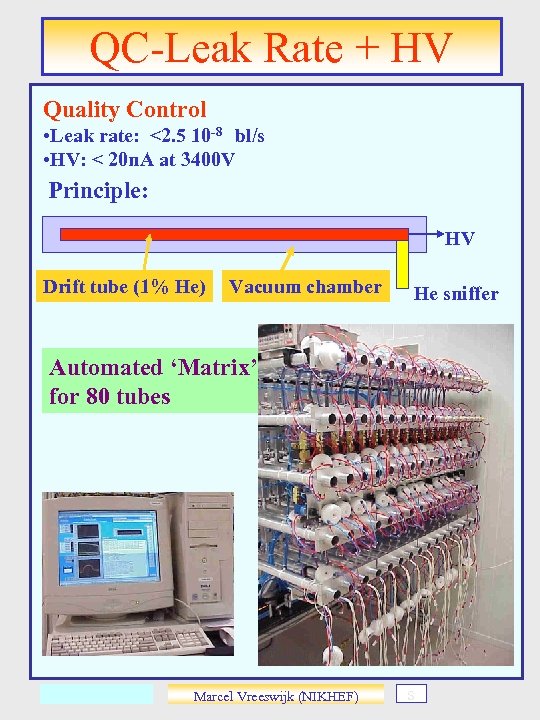

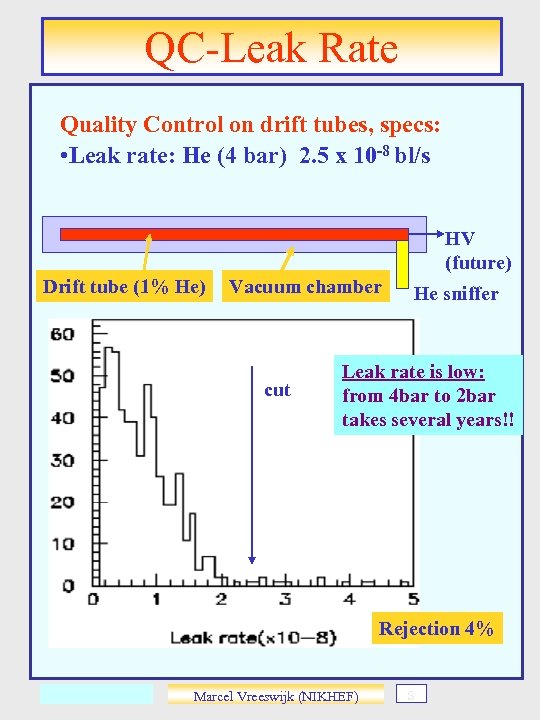

QC-Leak Rate + HV Quality Control • Leak rate: <2. 5 10 -8 bl/s • HV: < 20 n. A at 3400 V Principle: HV Drift tube (1% He) Vacuum chamber He sniffer Automated ‘Matrix’ for 80 tubes Marcel Vreeswijk (NIKHEF) s

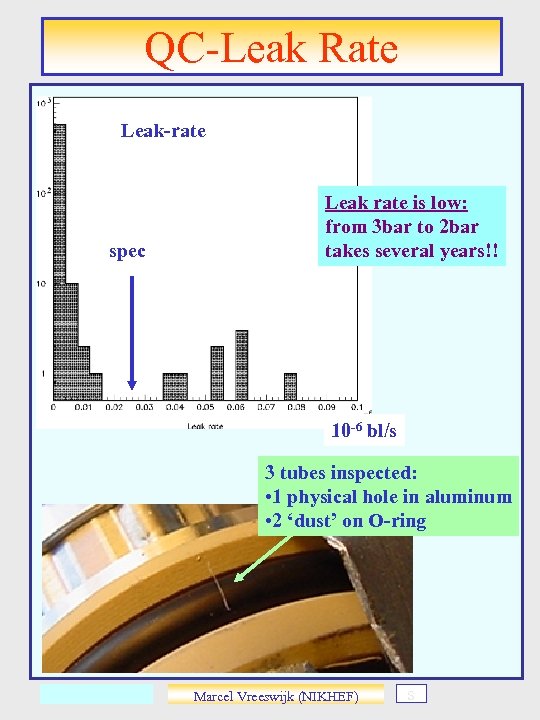

QC-Leak Rate Leak-rate spec Leak rate is low: from 3 bar to 2 bar takes several years!! Rejection 1% (!) 10 -6 bl/s 3 tubes inspected: • 1 physical hole in aluminum • 2 ‘dust’ on O-ring Marcel Vreeswijk (NIKHEF) s

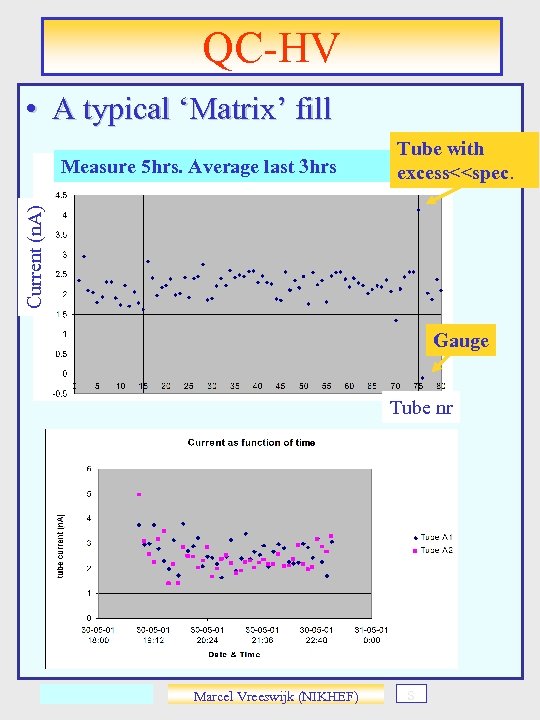

QC-HV • A typical ‘Matrix’ fill Current (n. A) Measure 5 hrs. Average last 3 hrs Tube with excess<<spec. Gauge Tube nr Marcel Vreeswijk (NIKHEF) s

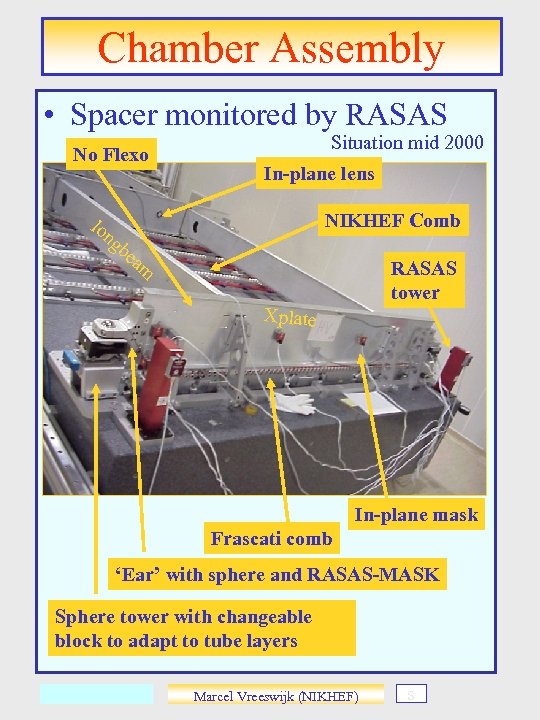

Chamber Assembly • Spacer monitored by RASAS No Flexo lo ng Situation mid 2000 In-plane lens NIKHEF Comb be am RASAS tower Xplate In-plane mask Frascati comb ‘Ear’ with sphere and RASAS-MASK Sphere tower with changeable block to adapt expansion length o 0. 1 m in Xras West side has to tube layers Marcel Vreeswijk (NIKHEF) s

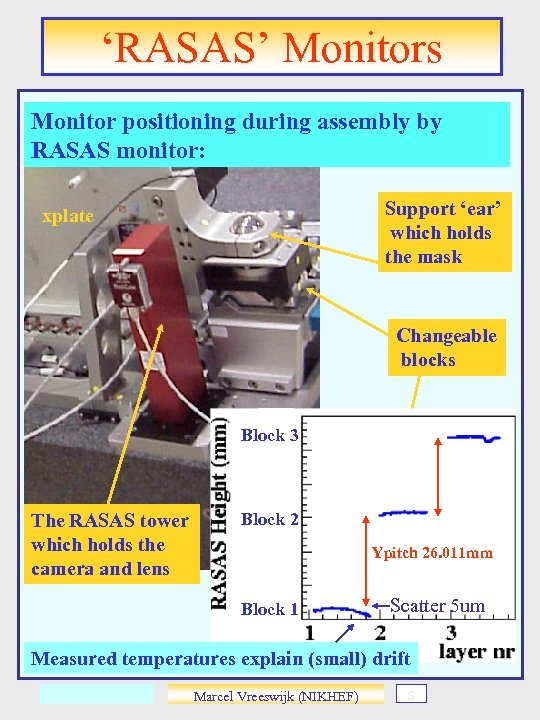

‘RASAS’ Monitors Monitor positioning during assembly by RASAS monitor: Support ‘ear’ which holds the mask xplate Changeable blocks Block 3 The RASAS tower which holds the camera and lens Block 2 Ypitch 26. 011 mm Block 1 Scatter 5 um Measured temperatures explain (small) drift Marcel Vreeswijk (NIKHEF) s

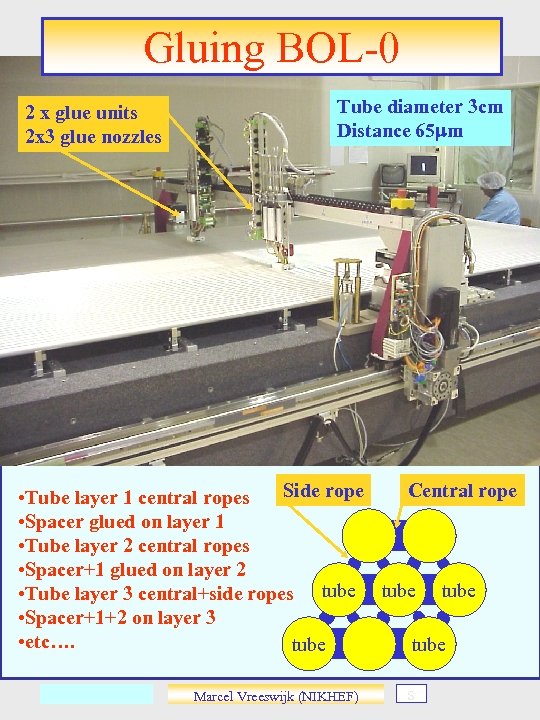

Gluing BOL-0 2 x glue units 2 x 3 glue nozzles Tube diameter 3 cm Distance 65 mm Side rope Central rope • Tube layer 1 central ropes • Spacer glued on layer 1 • Tube layer 2 central ropes • Spacer+1 glued on layer 2 • Tube layer 3 central+side ropes tube • Spacer+1+2 on layer 3 • etc…. tube Marcel Vreeswijk (NIKHEF) s

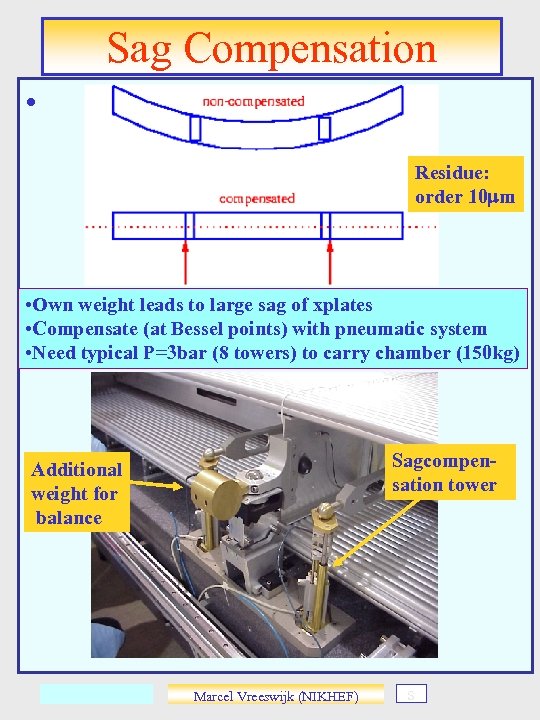

Sag Compensation • Residue: order 10 mm • Own weight leads to large sag of xplates • Compensate (at Bessel points) with pneumatic system • Need typical P=3 bar (8 towers) to carry chamber (150 kg) Sagcompensation tower Additional weight for balance Marcel Vreeswijk (NIKHEF) s

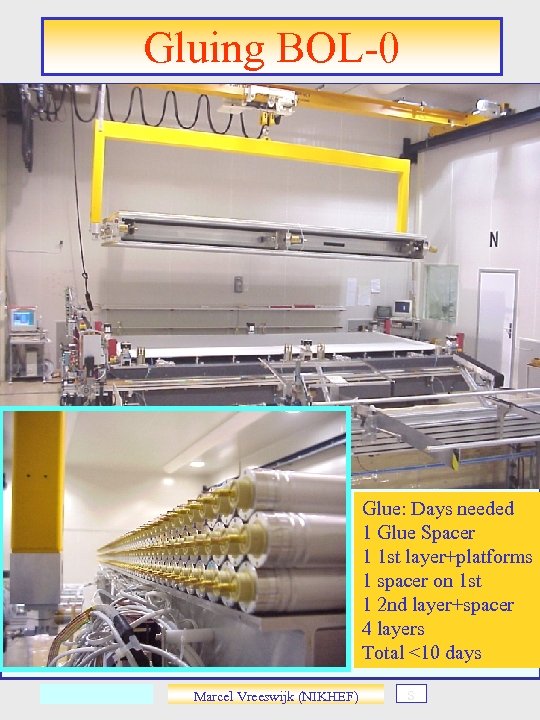

Gluing BOL-0 Glue: Days needed 1 Glue Spacer 1 1 st layer+platforms 1 spacer on 1 st 1 2 nd layer+spacer 4 layers Total <10 days Marcel Vreeswijk (NIKHEF) s

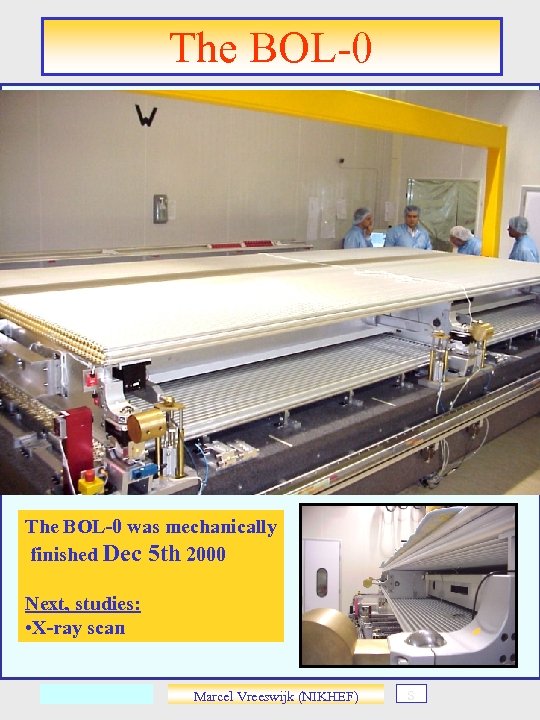

The BOL-0 was mechanically finished Dec 5 th 2000 Next, studies: • X-ray scan Marcel Vreeswijk (NIKHEF) s

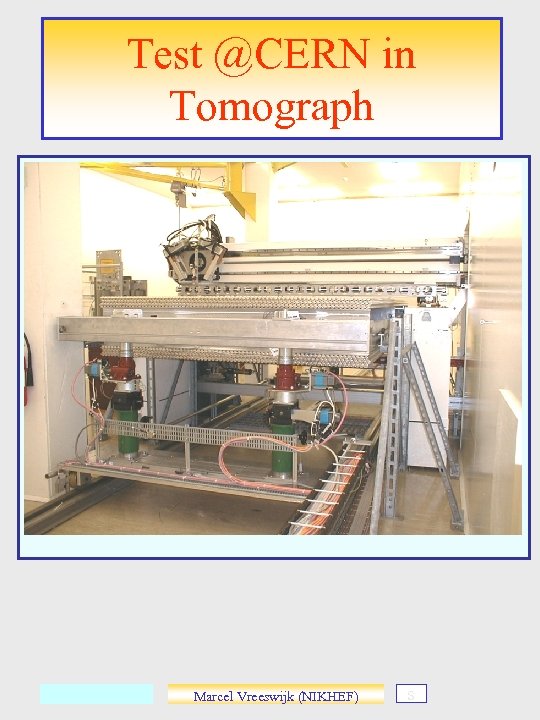

Test @CERN in Tomograph Marcel Vreeswijk (NIKHEF) s

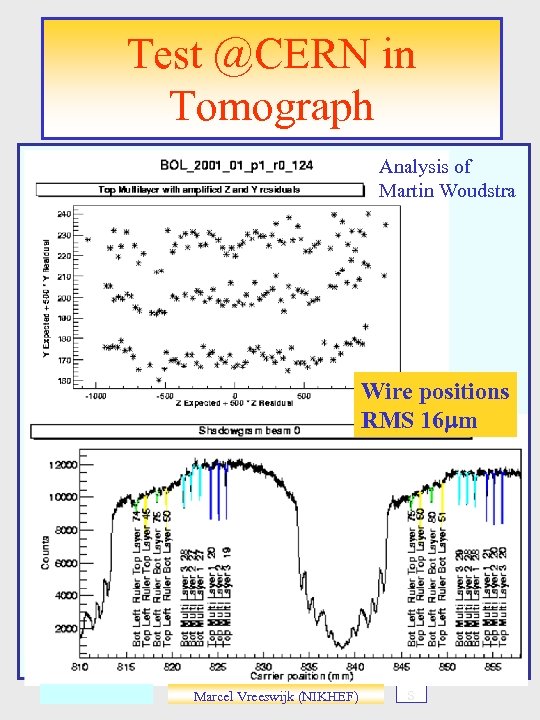

Test @CERN in Tomograph Analysis of Martin Woudstra Wire positions RMS 16 mm Marcel Vreeswijk (NIKHEF) s

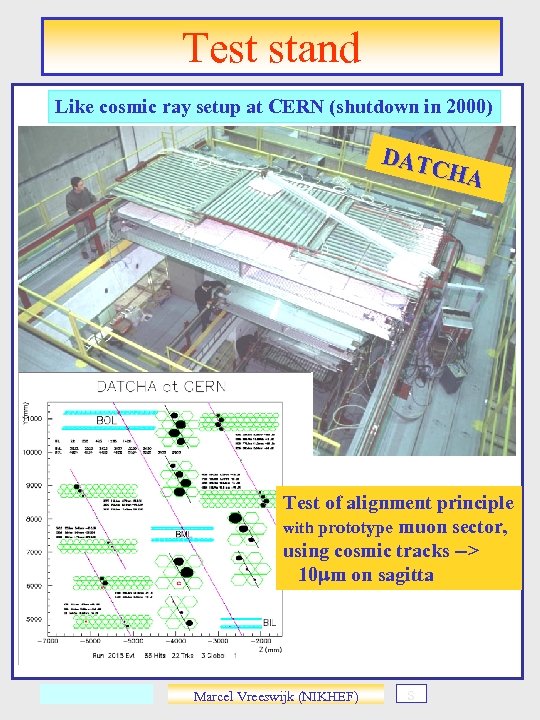

Test stand Like cosmic ray setup at CERN (shutdown in 2000) DAT CHA Test of alignment principle with prototype muon sector, using cosmic tracks --> 10 mm on sagitta Marcel Vreeswijk (NIKHEF) s

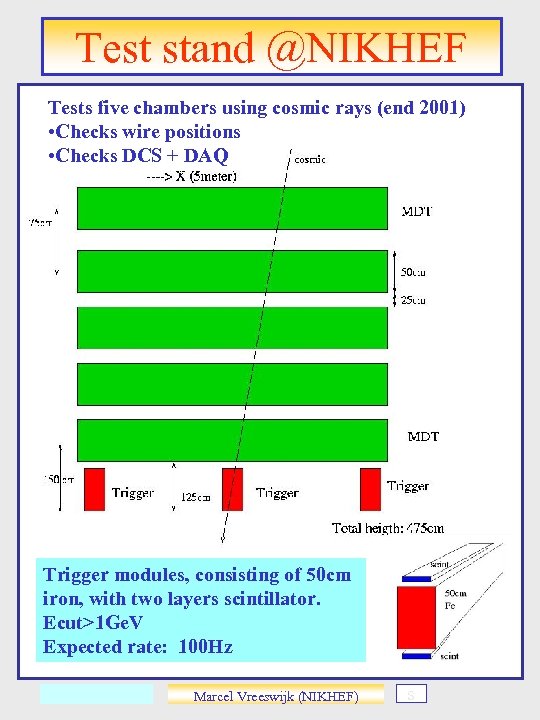

Test stand @NIKHEF Tests five chambers using cosmic rays (end 2001) • Checks wire positions • Checks DCS + DAQ Trigger modules, consisting of 50 cm iron, with two layers scintillator. Ecut>1 Ge. V Expected rate: 100 Hz Marcel Vreeswijk (NIKHEF) s

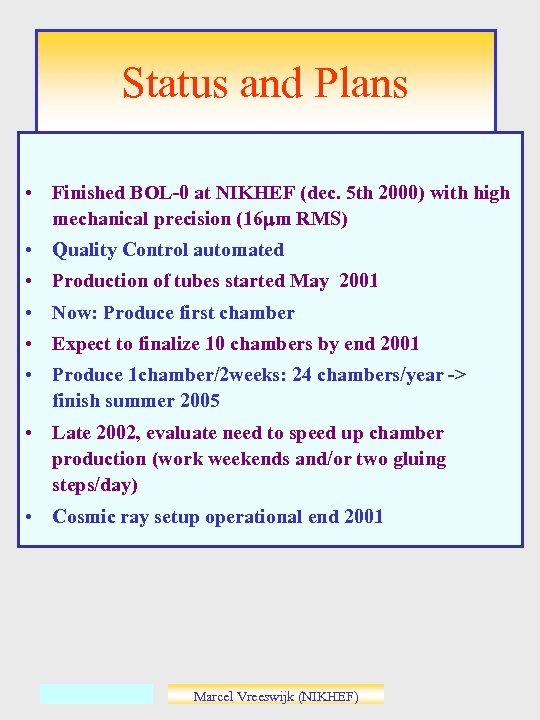

Status and Plans • Finished BOL-0 at NIKHEF (dec. 5 th 2000) with high mechanical precision (16 mm RMS) • Quality Control automated • Production of tubes started May 2001 • Now: Produce first chamber • Expect to finalize 10 chambers by end 2001 • Produce 1 chamber/2 weeks: 24 chambers/year -> finish summer 2005 • Late 2002, evaluate need to speed up chamber production (work weekends and/or two gluing steps/day) • Cosmic ray setup operational end 2001 Marcel Vreeswijk (NIKHEF)

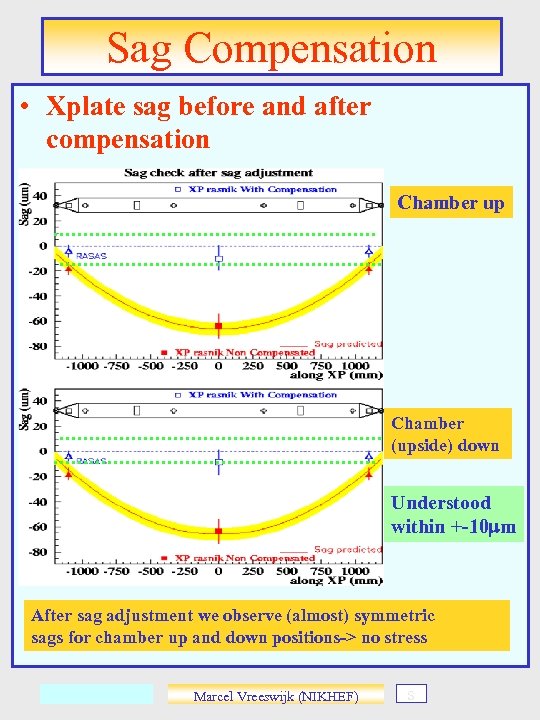

Sag Compensation • Xplate sag before and after compensation Chamber up Chamber (upside) down Understood within +-10 mm After sag adjustment we observe (almost) symmetric sags for chamber up and down positions-> no stress Marcel Vreeswijk (NIKHEF) s

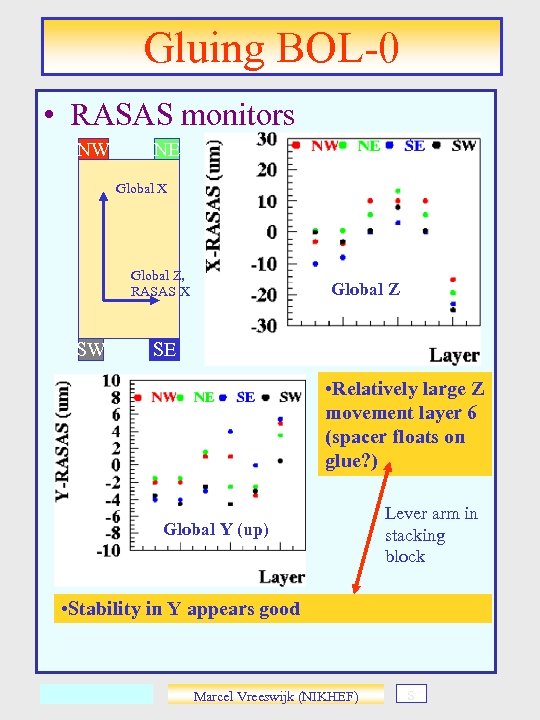

Gluing BOL-0 • RASAS monitors NW NE Global X Global Z, RASAS X SW Global Z SE • Relatively large Z movement layer 6 (spacer floats on glue? ) Global Y (up) Lever arm in stacking block • Stability in Y appears good Marcel Vreeswijk (NIKHEF) s

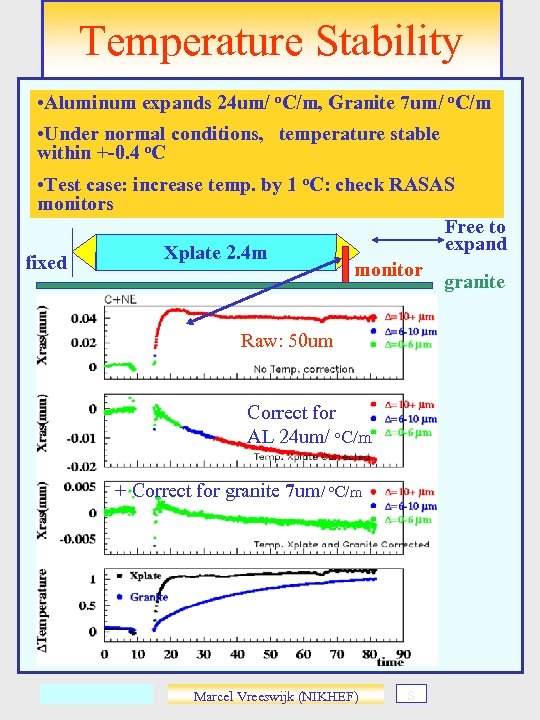

Temperature Stability • Aluminum expands 24 um/ o. C/m, Granite 7 um/ o. C/m • Under normal conditions, temperature stable within +-0. 4 o. C • Test case: increase temp. by 1 o. C: check RASAS monitors Free to expand Xplate 2. 4 m fixed monitor granite Raw: 50 um Correct for AL 24 um/ o. C/m + Correct for granite 7 um/ o. C/m Marcel Vreeswijk (NIKHEF) s

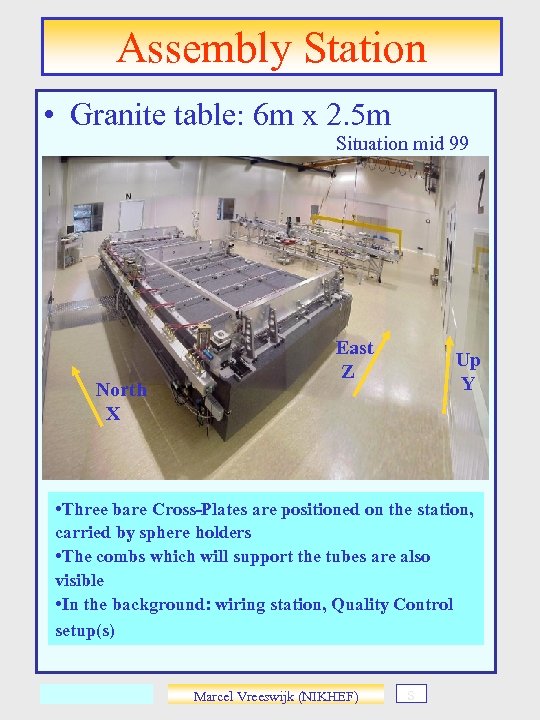

Assembly Station • Granite table: 6 m x 2. 5 m Situation mid 99 North X East Z Up Y • Three bare Cross-Plates are positioned on the station, carried by sphere holders • The combs which will support the tubes are also visible • In the background: wiring station, Quality Control setup(s) West side has expansion length o 0. 1 m in Xras Marcel Vreeswijk (NIKHEF) s

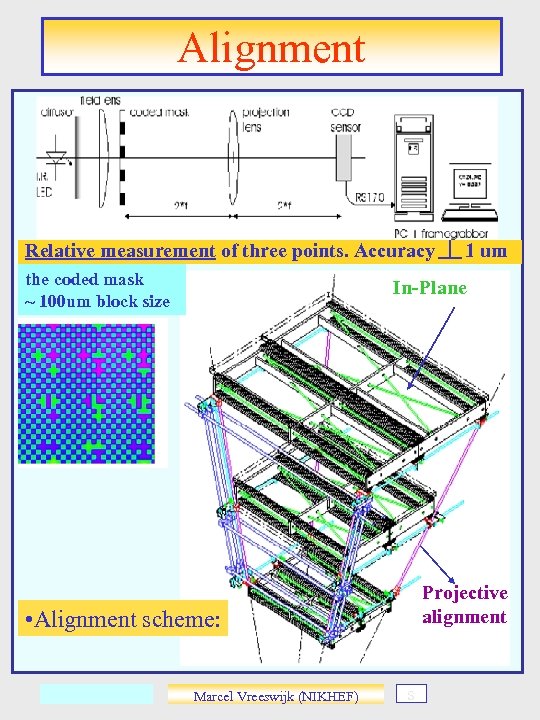

Alignment Relative measurement of three points. Accuracy the coded mask ~ 100 um block size 1 um In-Plane Projective alignment • Alignment scheme: West side has expansion length o 0. 1 m in Xras Marcel Vreeswijk (NIKHEF) s

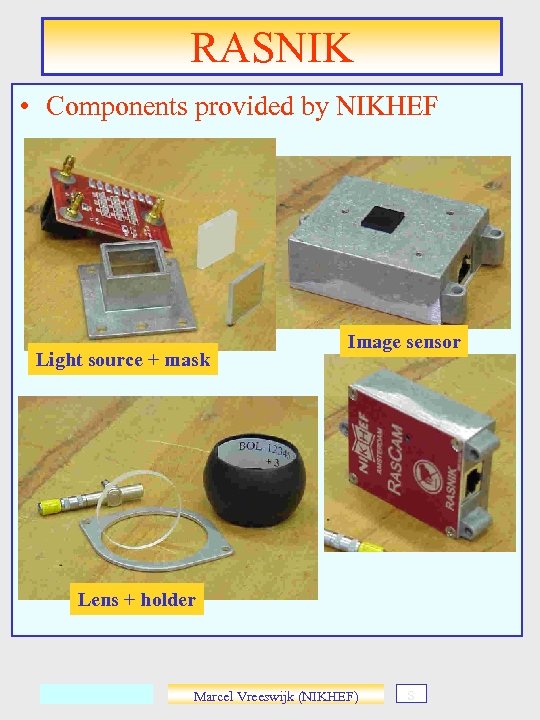

RASNIK • Components provided by NIKHEF Light source + mask Image sensor Lens + holder Marcel Vreeswijk (NIKHEF) s

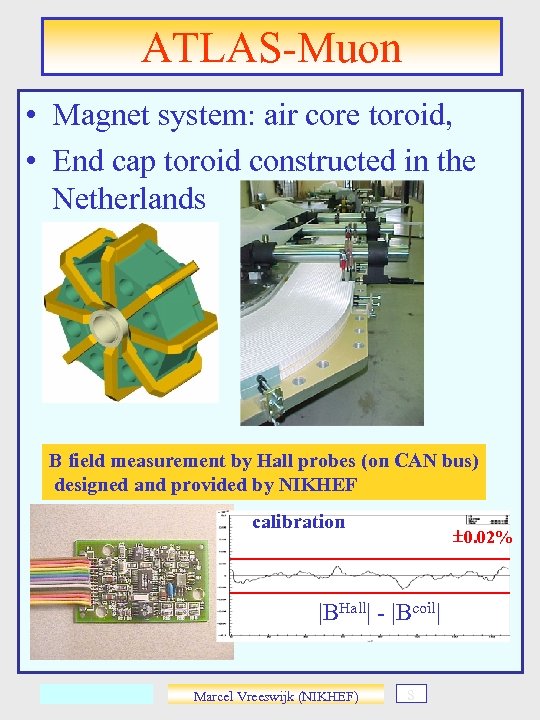

ATLAS-Muon • Magnet system: air core toroid, • End cap toroid constructed in the Netherlands B field measurement by Hall probes (on CAN bus) designed and provided by NIKHEF calibration 0. 02% |BHall| - |Bcoil| West side has expansion length o 0. 1 m in Xras Marcel Vreeswijk (NIKHEF) s

QC-Leak Rate Quality Control on drift tubes, specs: • Leak rate: He (4 bar) 2. 5 x 10 -8 bl/s HV (future) Drift tube (1% He) Vacuum chamber cut He sniffer Leak rate is low: from 4 bar to 2 bar takes several years!! Rejection 4% Marcel Vreeswijk (NIKHEF) s

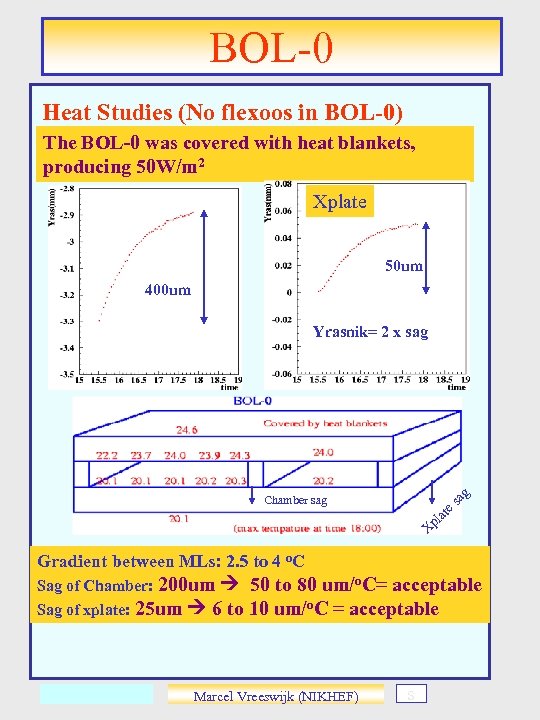

BOL-0 Heat Studies (No flexoos in BOL-0) The BOL-0 was covered with heat blankets, producing 50 W/m 2 Xplate Inplane 50 um 400 um Yrasnik= 2 x sag g Chamber sag at pl X a es Gradient between MLs: 2. 5 to 4 o. C Sag of Chamber: 200 um Sag of xplate: 25 um 6 to 50 to 80 um/o. C= acceptable 10 um/o. C = acceptable Marcel Vreeswijk (NIKHEF) s

4387c03a251d9f695ba8521ca6671d2e.ppt