cad5840f644ae009daf82bebbd9e2885.ppt

- Количество слайдов: 1

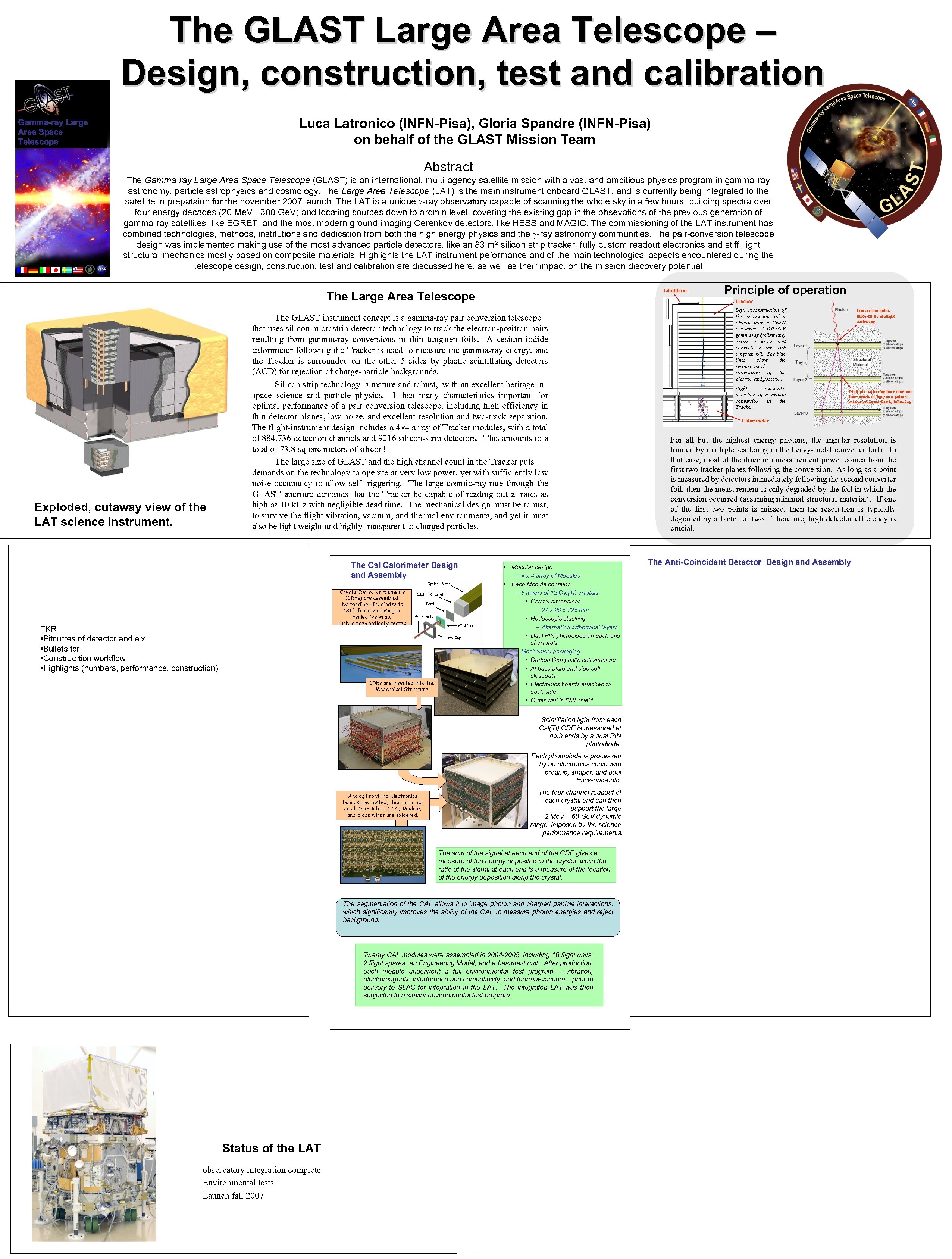

The GLAST Large Area Telescope – Design, construction, test and calibration Luca Latronico (INFN-Pisa), Gloria Spandre (INFN-Pisa) on behalf of the GLAST Mission Team Gamma-ray Large Area Space Telescope Abstract The Gamma-ray Large Area Space Telescope (GLAST) is an international, multi-agency satellite mission with a vast and ambitious physics program in gamma-ray astronomy, particle astrophysics and cosmology. The Large Area Telescope (LAT) is the main instrument onboard GLAST, and is currently being integrated to the satellite in prepataion for the november 2007 launch. The LAT is a unique g-ray observatory capable of scanning the whole sky in a few hours, building spectra over four energy decades (20 Me. V - 300 Ge. V) and locating sources down to arcmin level, covering the existing gap in the obsevations of the previous generation of gamma-ray satellites, like EGRET, and the most modern ground imaging Cerenkov detectors, like HESS and MAGIC. The commissioning of the LAT instrument has combined technologies, methods, institutions and dedication from both the high energy physics and the g-ray astronomy communities. The pair-conversion telescope design was implemented making use of the most advanced particle detectors, like an 83 m 2 silicon strip tracker, fully custom readout electronics and stiff, light structural mechanics mostly based on composite materials. Highlights the LAT instrument peformance and of the main technological aspects encountered during the telescope design, construction, test and calibration are discussed here, as well as their impact on the mission discovery potential Scintillator The Large Area Telescope Exploded, cutaway view of the LAT science instrument. Tracker The GLAST instrument concept is a gamma-ray pair conversion telescope that uses silicon microstrip detector technology to track the electron-positron pairs resulting from gamma-ray conversions in thin tungsten foils. A cesium iodide calorimeter following the Tracker is used to measure the gamma-ray energy, and the Tracker is surrounded on the other 5 sides by plastic scintillating detectors (ACD) for rejection of charge-particle backgrounds. Silicon strip technology is mature and robust, with an excellent heritage in space science and particle physics. It has many characteristics important for optimal performance of a pair conversion telescope, including high efficiency in thin detector planes, low noise, and excellent resolution and two-track separation. The flight-instrument design includes a 4 4 array of Tracker modules, with a total of 884, 736 detection channels and 9216 silicon-strip detectors. This amounts to a total of 73. 8 square meters of silicon! The large size of GLAST and the high channel count in the Tracker puts demands on the technology to operate at very low power, yet with sufficiently low noise occupancy to allow self triggering. The large cosmic-ray rate through the GLAST aperture demands that the Tracker be capable of reading out at rates as high as 10 k. Hz with negligible dead time. The mechanical design must be robust, to survive the flight vibration, vacuum, and thermal environments, and yet it must also be light weight and highly transparent to charged particles. The Cs. I Calorimeter Design and Assembly Optical Wrap Crystal Detector Elements (CDEs) are assembled by bonding PIN diodes to Cs. I(Tl) and enclosing in reflective wrap. Each is then optically tested. TKR • Pitcurres of detector and elx • Bullets for • Construc tion workflow • Highlights (numbers, performance, construction) Cs. I(Tl) Crystal Bond Wire leads PIN Diode End Cap CDEs are inserted into the Mechanical Structure • Modular design – 4 x 4 array of Modules • Each Module contains – 8 layers of 12 Cs. I(Tl) crystals • Crystal dimensions – 27 x 20 x 326 mm • Hodoscopic stacking – Alternating orthogonal layers • Dual PIN photodiode on each end of crystals – Mechanical packaging • Carbon Composite cell structure • Al base plate and side cell closeouts • Electronics boards attached to each side • Outer wall is EMI shield Scintillation light from each Cs. I(Tl) CDE is measured at both ends by a dual PIN photodiode. Each photodiode is processed by an electronics chain with preamp, shaper, and dual track-and-hold. Analog Front. End Electronics boards are tested, then mounted on all four sides of CAL Module, and diode wires are soldered. The four-channel readout of each crystal end can then support the large 2 Me. V 60 Ge. V dynamic range imposed by the science performance requirements. The sum of the signal at each end of the CDE gives a measure of the energy deposited in the crystal, while the ratio of the signal at each end is a measure of the location of the energy deposition along the crystal. The segmentation of the CAL allows it to image photon and charged particle interactions, which significantly improves the ability of the CAL to measure photon energies and reject background. Twenty CAL modules were assembled in 2004 -2005, including 16 flight units, 2 flight spares, an Engineering Model, and a beamtest unit. After production, each module underwent a full environmental test program vibration, electromagnetic interference and compatibility, and thermal-vacuum prior to delivery to SLAC for integration in the LAT. The integrated LAT was then subjected to a similar environmental test program. Status of the LAT observatory integration complete Environmental tests Launch fall 2007 Principle of operation Left: reconstruction of the conversion of a photon from a CERN test beam. A 470 Me. V gamma ray (yellow line) enters a tower and converts in the sixth tungsten foil. The blue lines show the reconstructed trajectories of the electron and positron. Right: schematic depiction of a photon conversion in the Tracker. Conversion point, followed by multiple scattering Multiple scattering here does not hurt much, as long as a point is measured immediately following. Calorimeter For all but the highest energy photons, the angular resolution is limited by multiple scattering in the heavy-metal converter foils. In that case, most of the direction measurement power comes from the first two tracker planes following the conversion. As long as a point is measured by detectors immediately following the second converter foil, then the measurement is only degraded by the foil in which the conversion occurred (assuming minimal structural material). If one of the first two points is missed, then the resolution is typically degraded by a factor of two. Therefore, high detector efficiency is crucial. The Anti-Coincident Detector Design and Assembly

The GLAST Large Area Telescope – Design, construction, test and calibration Luca Latronico (INFN-Pisa), Gloria Spandre (INFN-Pisa) on behalf of the GLAST Mission Team Gamma-ray Large Area Space Telescope Abstract The Gamma-ray Large Area Space Telescope (GLAST) is an international, multi-agency satellite mission with a vast and ambitious physics program in gamma-ray astronomy, particle astrophysics and cosmology. The Large Area Telescope (LAT) is the main instrument onboard GLAST, and is currently being integrated to the satellite in prepataion for the november 2007 launch. The LAT is a unique g-ray observatory capable of scanning the whole sky in a few hours, building spectra over four energy decades (20 Me. V - 300 Ge. V) and locating sources down to arcmin level, covering the existing gap in the obsevations of the previous generation of gamma-ray satellites, like EGRET, and the most modern ground imaging Cerenkov detectors, like HESS and MAGIC. The commissioning of the LAT instrument has combined technologies, methods, institutions and dedication from both the high energy physics and the g-ray astronomy communities. The pair-conversion telescope design was implemented making use of the most advanced particle detectors, like an 83 m 2 silicon strip tracker, fully custom readout electronics and stiff, light structural mechanics mostly based on composite materials. Highlights the LAT instrument peformance and of the main technological aspects encountered during the telescope design, construction, test and calibration are discussed here, as well as their impact on the mission discovery potential Scintillator The Large Area Telescope Exploded, cutaway view of the LAT science instrument. Tracker The GLAST instrument concept is a gamma-ray pair conversion telescope that uses silicon microstrip detector technology to track the electron-positron pairs resulting from gamma-ray conversions in thin tungsten foils. A cesium iodide calorimeter following the Tracker is used to measure the gamma-ray energy, and the Tracker is surrounded on the other 5 sides by plastic scintillating detectors (ACD) for rejection of charge-particle backgrounds. Silicon strip technology is mature and robust, with an excellent heritage in space science and particle physics. It has many characteristics important for optimal performance of a pair conversion telescope, including high efficiency in thin detector planes, low noise, and excellent resolution and two-track separation. The flight-instrument design includes a 4 4 array of Tracker modules, with a total of 884, 736 detection channels and 9216 silicon-strip detectors. This amounts to a total of 73. 8 square meters of silicon! The large size of GLAST and the high channel count in the Tracker puts demands on the technology to operate at very low power, yet with sufficiently low noise occupancy to allow self triggering. The large cosmic-ray rate through the GLAST aperture demands that the Tracker be capable of reading out at rates as high as 10 k. Hz with negligible dead time. The mechanical design must be robust, to survive the flight vibration, vacuum, and thermal environments, and yet it must also be light weight and highly transparent to charged particles. The Cs. I Calorimeter Design and Assembly Optical Wrap Crystal Detector Elements (CDEs) are assembled by bonding PIN diodes to Cs. I(Tl) and enclosing in reflective wrap. Each is then optically tested. TKR • Pitcurres of detector and elx • Bullets for • Construc tion workflow • Highlights (numbers, performance, construction) Cs. I(Tl) Crystal Bond Wire leads PIN Diode End Cap CDEs are inserted into the Mechanical Structure • Modular design – 4 x 4 array of Modules • Each Module contains – 8 layers of 12 Cs. I(Tl) crystals • Crystal dimensions – 27 x 20 x 326 mm • Hodoscopic stacking – Alternating orthogonal layers • Dual PIN photodiode on each end of crystals – Mechanical packaging • Carbon Composite cell structure • Al base plate and side cell closeouts • Electronics boards attached to each side • Outer wall is EMI shield Scintillation light from each Cs. I(Tl) CDE is measured at both ends by a dual PIN photodiode. Each photodiode is processed by an electronics chain with preamp, shaper, and dual track-and-hold. Analog Front. End Electronics boards are tested, then mounted on all four sides of CAL Module, and diode wires are soldered. The four-channel readout of each crystal end can then support the large 2 Me. V 60 Ge. V dynamic range imposed by the science performance requirements. The sum of the signal at each end of the CDE gives a measure of the energy deposited in the crystal, while the ratio of the signal at each end is a measure of the location of the energy deposition along the crystal. The segmentation of the CAL allows it to image photon and charged particle interactions, which significantly improves the ability of the CAL to measure photon energies and reject background. Twenty CAL modules were assembled in 2004 -2005, including 16 flight units, 2 flight spares, an Engineering Model, and a beamtest unit. After production, each module underwent a full environmental test program vibration, electromagnetic interference and compatibility, and thermal-vacuum prior to delivery to SLAC for integration in the LAT. The integrated LAT was then subjected to a similar environmental test program. Status of the LAT observatory integration complete Environmental tests Launch fall 2007 Principle of operation Left: reconstruction of the conversion of a photon from a CERN test beam. A 470 Me. V gamma ray (yellow line) enters a tower and converts in the sixth tungsten foil. The blue lines show the reconstructed trajectories of the electron and positron. Right: schematic depiction of a photon conversion in the Tracker. Conversion point, followed by multiple scattering Multiple scattering here does not hurt much, as long as a point is measured immediately following. Calorimeter For all but the highest energy photons, the angular resolution is limited by multiple scattering in the heavy-metal converter foils. In that case, most of the direction measurement power comes from the first two tracker planes following the conversion. As long as a point is measured by detectors immediately following the second converter foil, then the measurement is only degraded by the foil in which the conversion occurred (assuming minimal structural material). If one of the first two points is missed, then the resolution is typically degraded by a factor of two. Therefore, high detector efficiency is crucial. The Anti-Coincident Detector Design and Assembly