f9c8009c9c63ef05cf4a0cba446f7fb5.ppt

- Количество слайдов: 49

The Electric Materials Company Right the First Time On Time Every Time

The Electric Materials Company Right the First Time On Time Every Time

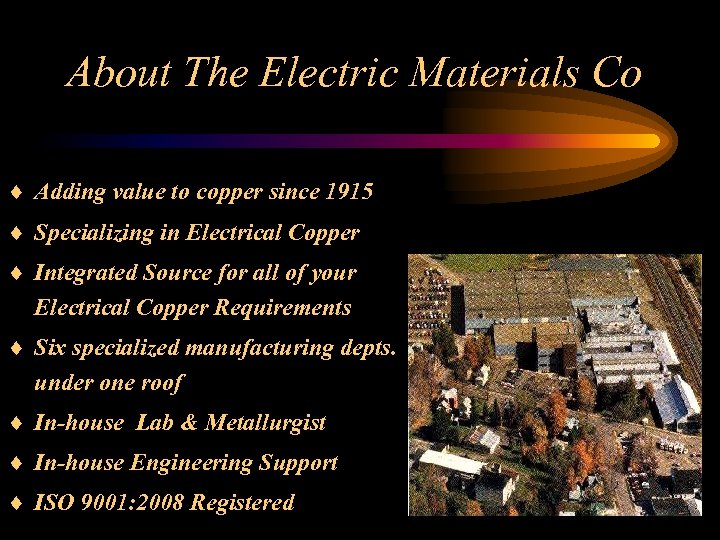

About The Electric Materials Co ¨ Adding value to copper since 1915 ¨ Specializing in Electrical Copper ¨ Integrated Source for all of your Electrical Copper Requirements ¨ Six specialized manufacturing depts. under one roof ¨ In-house Lab & Metallurgist ¨ In-house Engineering Support ¨ ISO 9001: 2008 Registered

About The Electric Materials Co ¨ Adding value to copper since 1915 ¨ Specializing in Electrical Copper ¨ Integrated Source for all of your Electrical Copper Requirements ¨ Six specialized manufacturing depts. under one roof ¨ In-house Lab & Metallurgist ¨ In-house Engineering Support ¨ ISO 9001: 2008 Registered

Markets Served • • Locomotive Mining Steel Mills US Navy Generator Motor Utility • • International Transit Authorities Transformer Switchgear Distributor Paper Mills Electrical Connector

Markets Served • • Locomotive Mining Steel Mills US Navy Generator Motor Utility • • International Transit Authorities Transformer Switchgear Distributor Paper Mills Electrical Connector

Quality at Electric Materials • ISO 9001: 2008 Registered • All Copper Certified to ASTM B-187 • Mica Test Reports - from Vendor plus In-house Inspection • Documented Inspection Throughout the Manufacturing Processes • Ongoing Training of Personnel

Quality at Electric Materials • ISO 9001: 2008 Registered • All Copper Certified to ASTM B-187 • Mica Test Reports - from Vendor plus In-house Inspection • Documented Inspection Throughout the Manufacturing Processes • Ongoing Training of Personnel

Manufacturing Departments ¨ Extrusion Mill ¨ Commutator ¨ Foundry ¨ Forge ¨ Machine Shop: Complete detail work ¨ Plating (Silver & Tin Electroplate)

Manufacturing Departments ¨ Extrusion Mill ¨ Commutator ¨ Foundry ¨ Forge ¨ Machine Shop: Complete detail work ¨ Plating (Silver & Tin Electroplate)

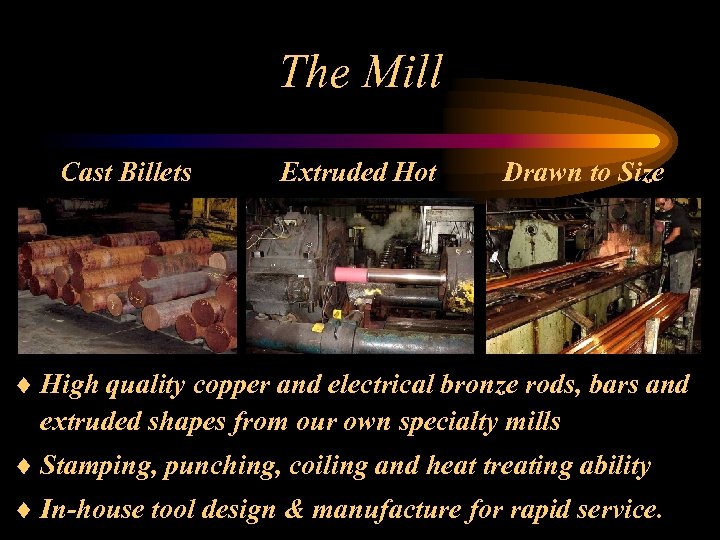

The Mill Cast Billets Extruded Hot Drawn to Size ¨ High quality copper and electrical bronze rods, bars and extruded shapes from our own specialty mills ¨ Stamping, punching, coiling and heat treating ability ¨ In-house tool design & manufacture for rapid service.

The Mill Cast Billets Extruded Hot Drawn to Size ¨ High quality copper and electrical bronze rods, bars and extruded shapes from our own specialty mills ¨ Stamping, punching, coiling and heat treating ability ¨ In-house tool design & manufacture for rapid service.

Rotor Bar

Rotor Bar

Commutator Department We use only Close tolerance Extruded Trapezoidal bar for increased Stability ¨ Start to finish capability ¨ Rebuild services ¨ Capable of handling 5 inch through 12 foot diameters. ¨ Spin Seasoning capabilities up to 100 inches radial. ¨ Non Contact Profiling available

Commutator Department We use only Close tolerance Extruded Trapezoidal bar for increased Stability ¨ Start to finish capability ¨ Rebuild services ¨ Capable of handling 5 inch through 12 foot diameters. ¨ Spin Seasoning capabilities up to 100 inches radial. ¨ Non Contact Profiling available

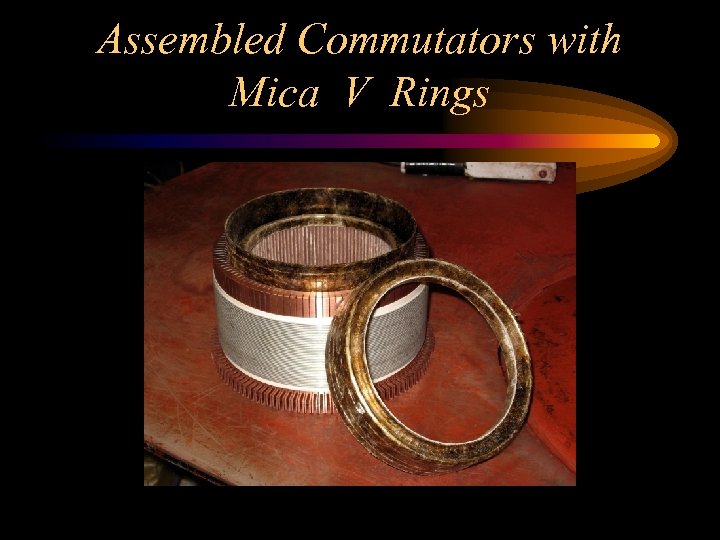

Assembled Commutators with Mica V Rings

Assembled Commutators with Mica V Rings

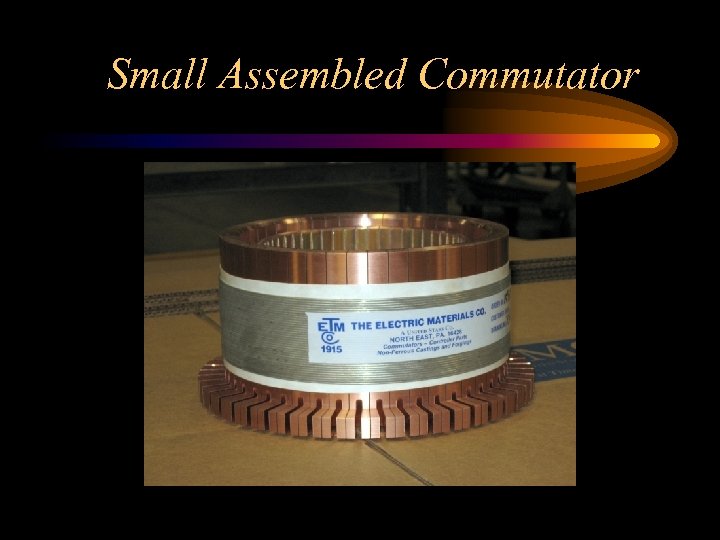

Small Assembled Commutator

Small Assembled Commutator

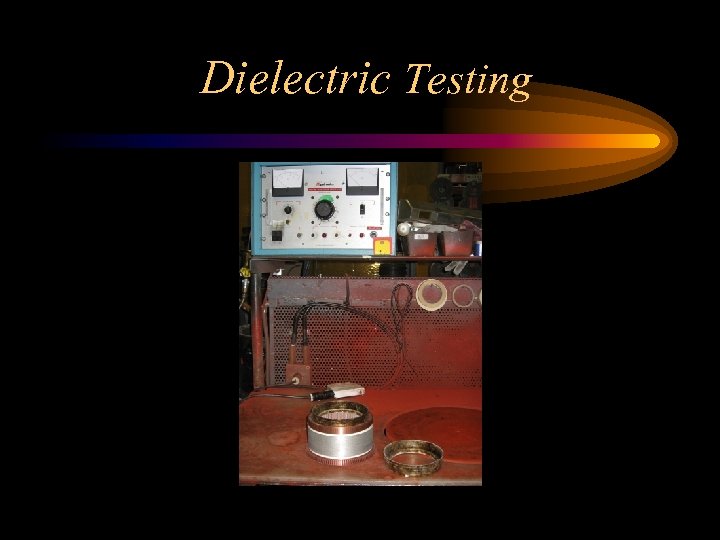

Dielectric Testing

Dielectric Testing

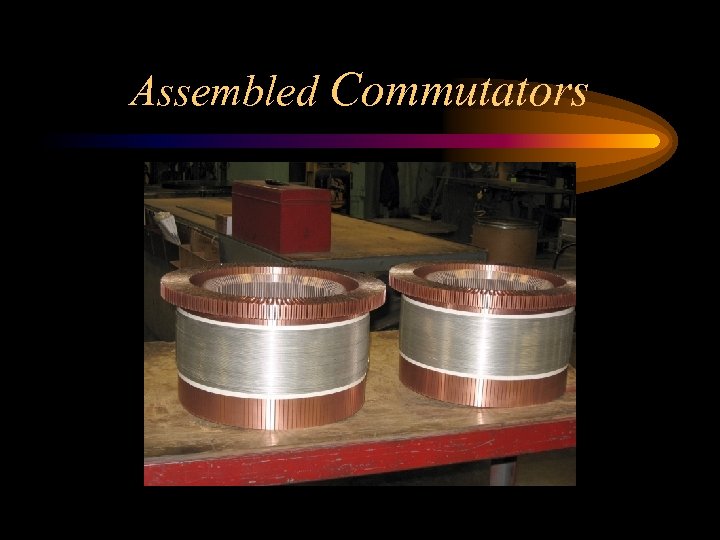

Assembled Commutators

Assembled Commutators

Commutator Stability Guaranteed Spin Seasoning: Up to 10, 000 rpm!

Commutator Stability Guaranteed Spin Seasoning: Up to 10, 000 rpm!

Quality Control: Final Dimensional & Electrical Testing on 100% of all Commutators

Quality Control: Final Dimensional & Electrical Testing on 100% of all Commutators

Complete Commutator for High Performance Application

Complete Commutator for High Performance Application

Glass Bound Commutators: Custom built to your specifications

Glass Bound Commutators: Custom built to your specifications

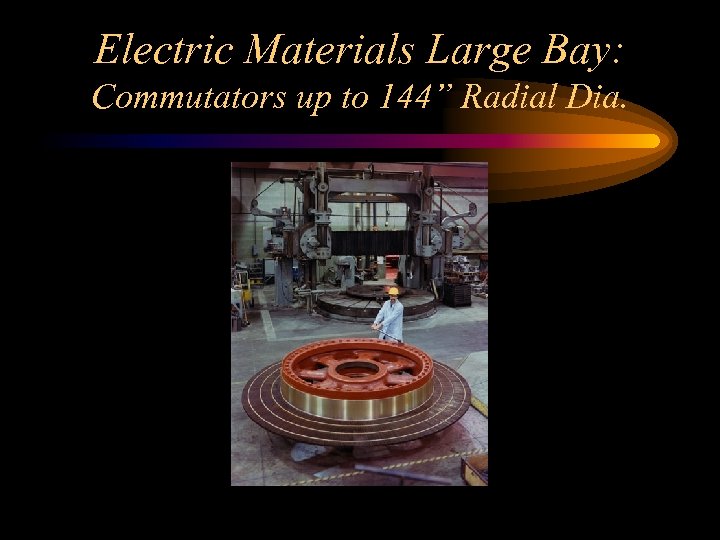

Electric Materials Large Bay: Commutators up to 144” Radial Dia.

Electric Materials Large Bay: Commutators up to 144” Radial Dia.

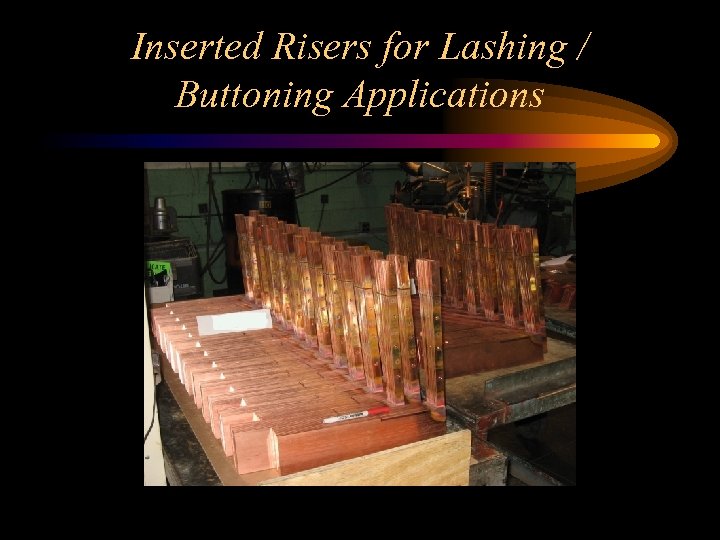

Inserted Risers for Lashing / Buttoning Applications

Inserted Risers for Lashing / Buttoning Applications

Large Commutator for Steel Mill Motor Application

Large Commutator for Steel Mill Motor Application

Custom Packaging & Crating available

Custom Packaging & Crating available

Collector Ring/Slip Rings

Collector Ring/Slip Rings

Foundry Specializing in high conductivity copper, copper alloys, and aluminum castings ¨ Ability to handle small to large volume orders, ranging in capacity from ounces to 600 lbs. ¨

Foundry Specializing in high conductivity copper, copper alloys, and aluminum castings ¨ Ability to handle small to large volume orders, ranging in capacity from ounces to 600 lbs. ¨

Centrifugally Cast Rings: 7” to 45” Dia. Centrifugal Caster Cast & Machined Finished Rings Matching of electrical or chemical properties to existing end rings ¨ Machined in-house to exact specifications ¨

Centrifugally Cast Rings: 7” to 45” Dia. Centrifugal Caster Cast & Machined Finished Rings Matching of electrical or chemical properties to existing end rings ¨ Machined in-house to exact specifications ¨

Slotted Rotor End Rings

Slotted Rotor End Rings

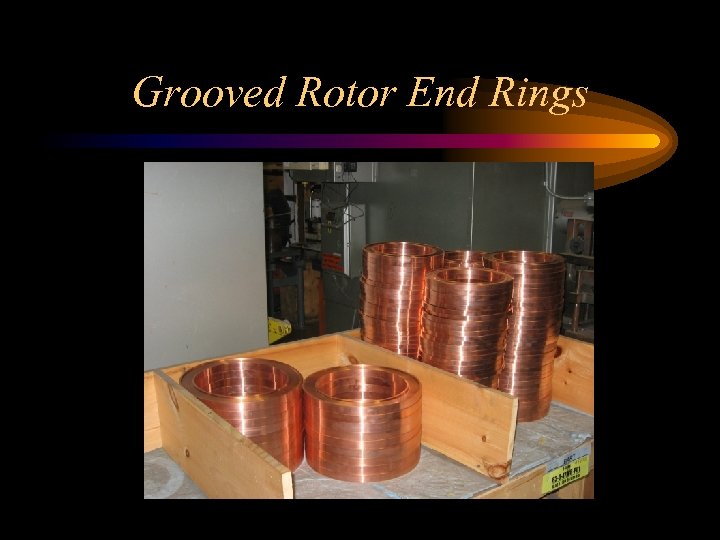

Grooved Rotor End Rings

Grooved Rotor End Rings

Centrifugally Cast Rings in a variety of Alloys to meet your specifications

Centrifugally Cast Rings in a variety of Alloys to meet your specifications

Staging area for machined Rings

Staging area for machined Rings

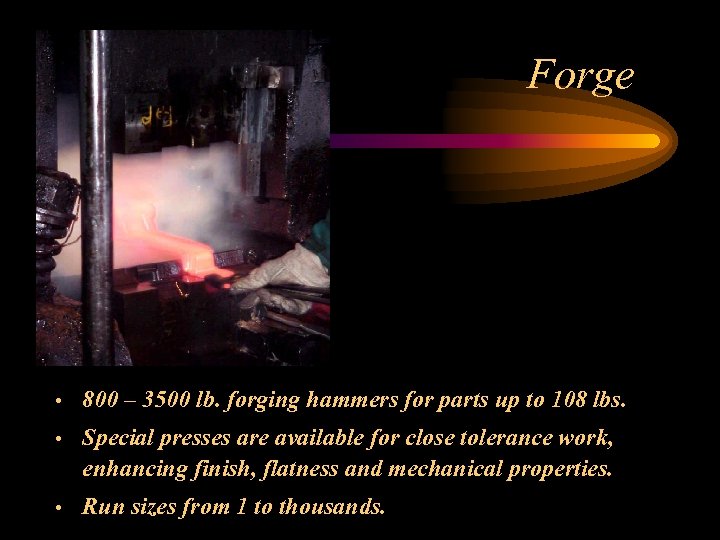

Forge High quality forgings in high conductivity copper, chrome copper, and brass or bronze are available to meet your requirements

Forge High quality forgings in high conductivity copper, chrome copper, and brass or bronze are available to meet your requirements

Forge • 800 – 3500 lb. forging hammers for parts up to 108 lbs. • Special presses are available for close tolerance work, enhancing finish, flatness and mechanical properties. • Run sizes from 1 to thousands.

Forge • 800 – 3500 lb. forging hammers for parts up to 108 lbs. • Special presses are available for close tolerance work, enhancing finish, flatness and mechanical properties. • Run sizes from 1 to thousands.

Detail – Secondary Machining New CNC Machine Centers ¨ New Robotic Work Cell ¨ Finish machining to your specifications ¨ In-house Silver & Tin Electroplating ¨

Detail – Secondary Machining New CNC Machine Centers ¨ New Robotic Work Cell ¨ Finish machining to your specifications ¨ In-house Silver & Tin Electroplating ¨

Custom OEM Product Silver Plated and packaged for shipping

Custom OEM Product Silver Plated and packaged for shipping

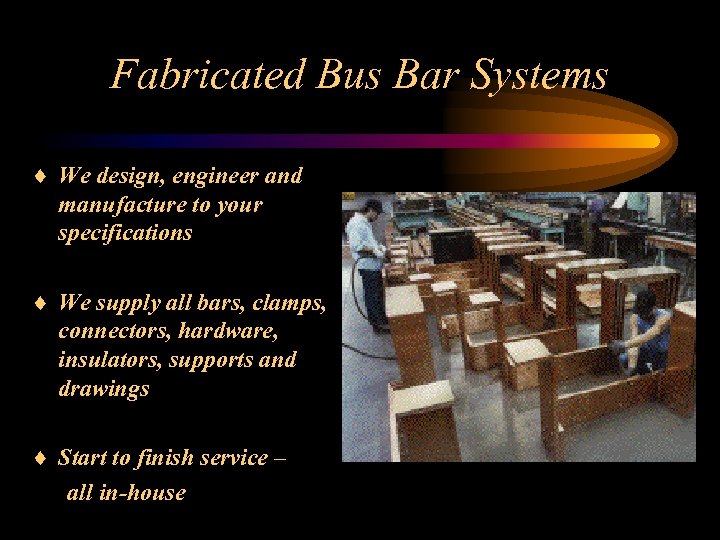

Fabricated Bus Bar Systems ¨ We design, engineer and manufacture to your specifications ¨ We supply all bars, clamps, connectors, hardware, insulators, supports and drawings ¨ Start to finish service – all in-house

Fabricated Bus Bar Systems ¨ We design, engineer and manufacture to your specifications ¨ We supply all bars, clamps, connectors, hardware, insulators, supports and drawings ¨ Start to finish service – all in-house

Nonstop Service: Temco Express ¨ Non Stop Emergency Service ¨ Commutator Repair / Manufacture ¨ Extrusions, Castings, Forgings ¨ Your job quoted with YOUR lead-time, shipped when YOU need it

Nonstop Service: Temco Express ¨ Non Stop Emergency Service ¨ Commutator Repair / Manufacture ¨ Extrusions, Castings, Forgings ¨ Your job quoted with YOUR lead-time, shipped when YOU need it

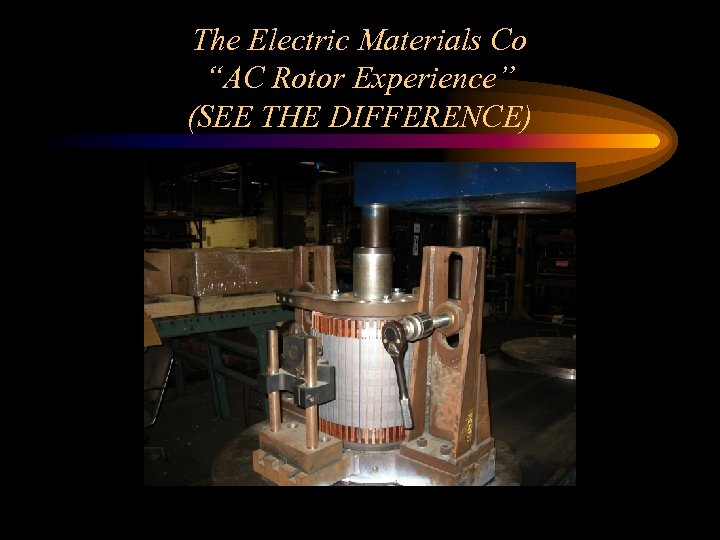

The Electric Materials Co “AC Rotor Experience” (SEE THE DIFFERENCE)

The Electric Materials Co “AC Rotor Experience” (SEE THE DIFFERENCE)

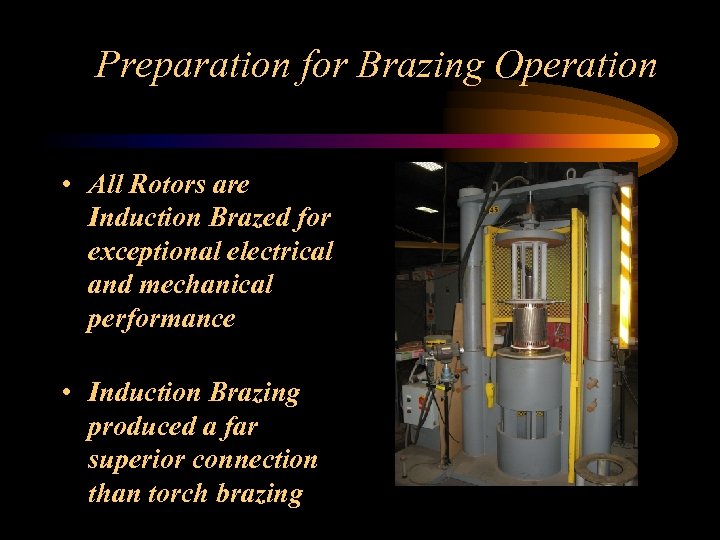

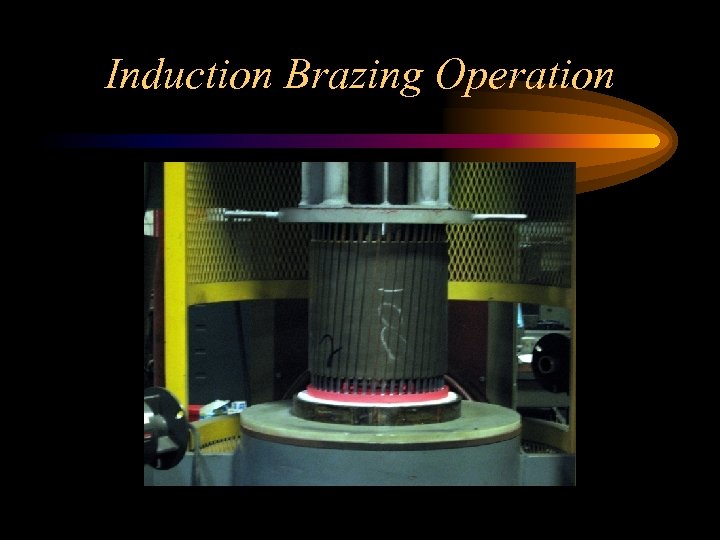

Preparation for Brazing Operation • All Rotors are Induction Brazed for exceptional electrical and mechanical performance • Induction Brazing produced a far superior connection than torch brazing

Preparation for Brazing Operation • All Rotors are Induction Brazed for exceptional electrical and mechanical performance • Induction Brazing produced a far superior connection than torch brazing

Induction Brazing Work Center

Induction Brazing Work Center

Induction Brazing Operation

Induction Brazing Operation

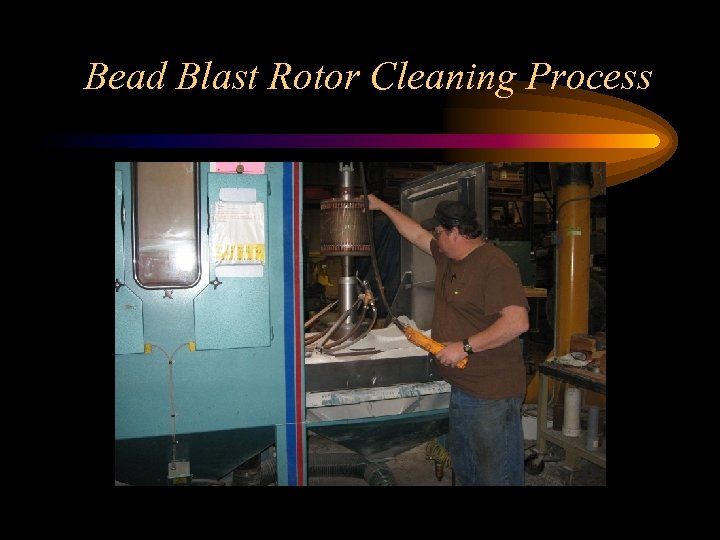

Bead Blast Rotor Cleaning Process

Bead Blast Rotor Cleaning Process

Bead Blast Operation in progress

Bead Blast Operation in progress

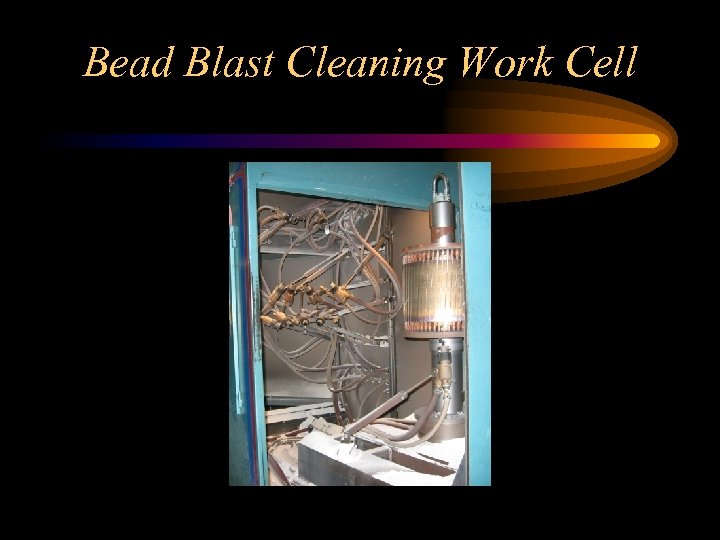

Bead Blast Cleaning Work Cell

Bead Blast Cleaning Work Cell

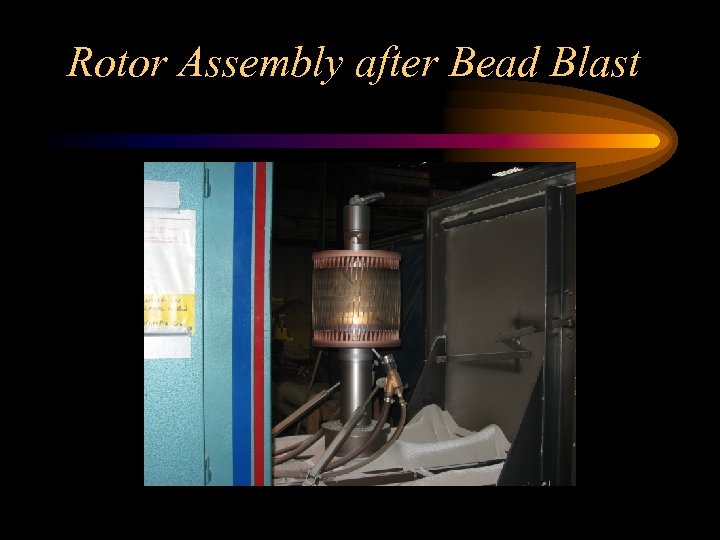

Rotor Assembly after Bead Blast

Rotor Assembly after Bead Blast

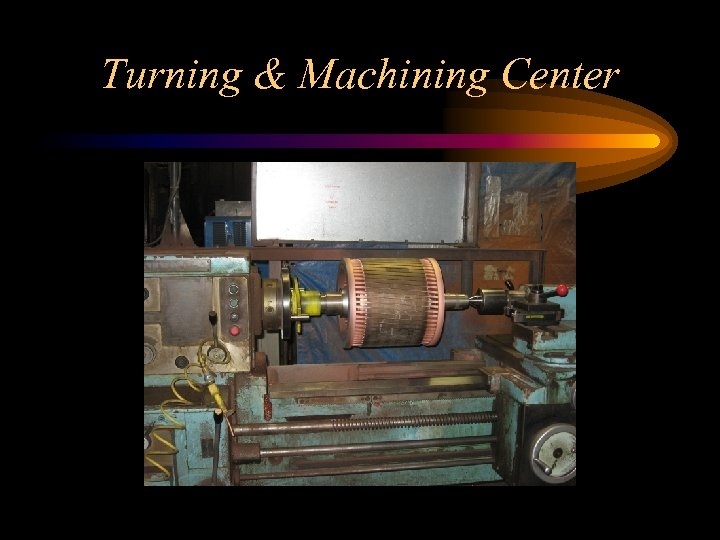

Turning & Machining Center

Turning & Machining Center

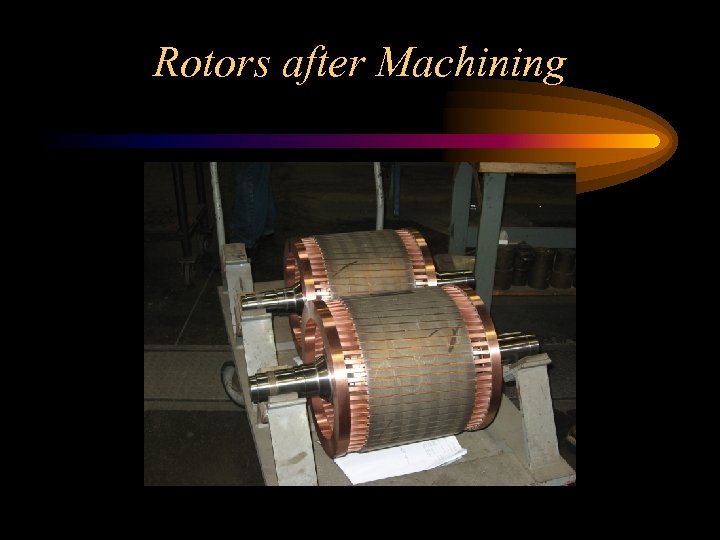

Rotors after Machining

Rotors after Machining

100% Quality Control

100% Quality Control

Ultrasonic Inspection

Ultrasonic Inspection

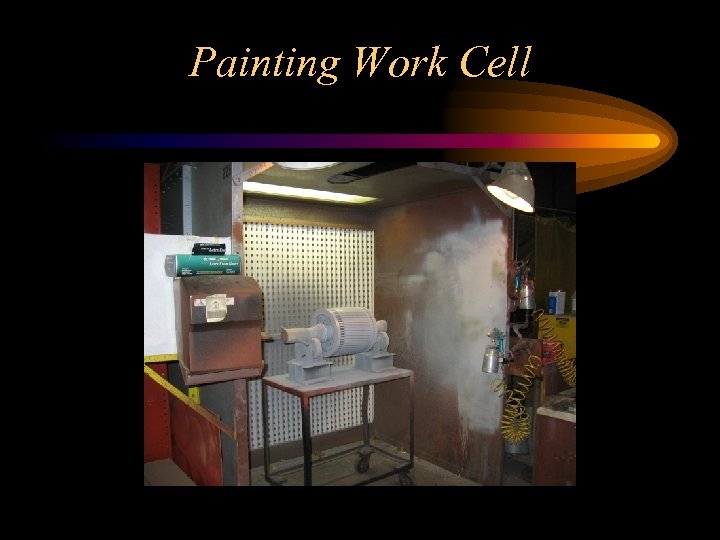

Painting Work Cell

Painting Work Cell

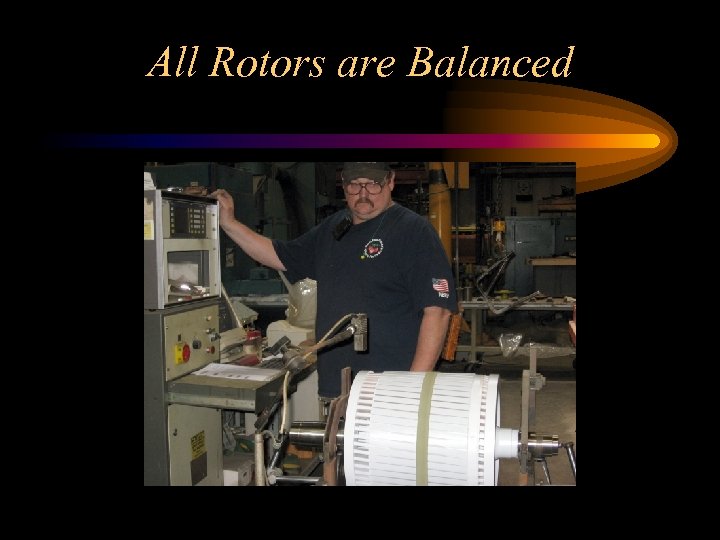

All Rotors are Balanced

All Rotors are Balanced

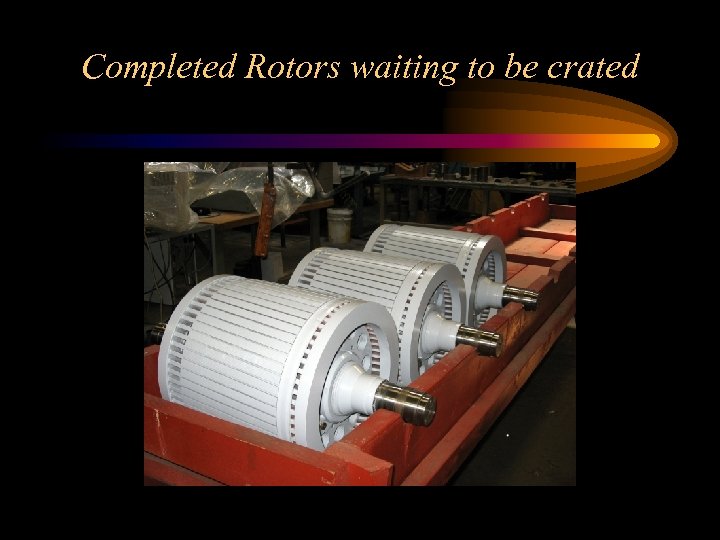

Completed Rotors waiting to be crated

Completed Rotors waiting to be crated

Thank You for Your Interest in The Electric Materials Company www. elecmat. com

Thank You for Your Interest in The Electric Materials Company www. elecmat. com