807a24501f497887e386bfef30507b84.ppt

- Количество слайдов: 24

The EJECTOR Near-Bit Higher ROP & Longer Bit life

The EJECTOR Near-Bit The Ejector is a Near-bit sub, similar to a standard NB Tool, but it is designed and engineered for creating a vacuum effect at the bit formation interaction face thus expelling the cuttings readily as they are generated! The Ejector NB tool also increases the speed of cuttings traveling up the annulus. The Obvious and proven Benefits: Higher ROP & Longer Bit life

15. 03. 2018

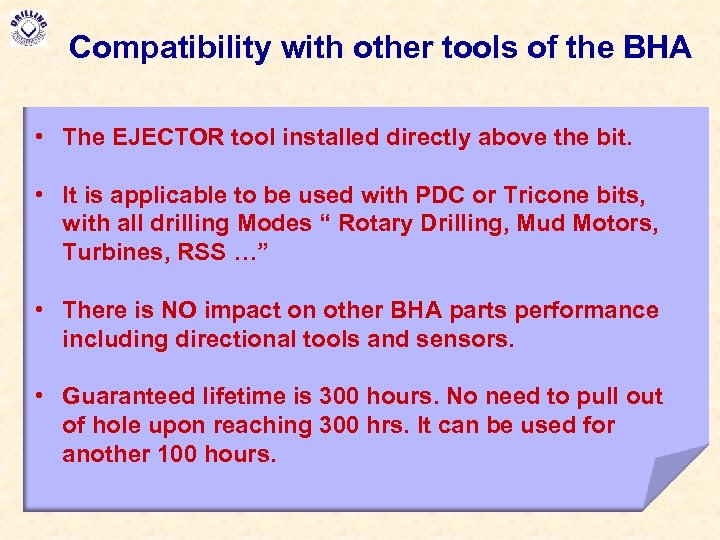

Compatibility with other tools of the BHA • The EJECTOR tool installed directly above the bit. • It is applicable to be used with PDC or Tricone bits, with all drilling Modes “ Rotary Drilling, Mud Motors, Turbines, RSS …” • There is NO impact on other BHA parts performance including directional tools and sensors. • Guaranteed lifetime is 300 hours. No need to pull out of hole upon reaching 300 hrs. It can be used for another 100 hours.

A Sample of The Tornado Tool 15. 03. 2018

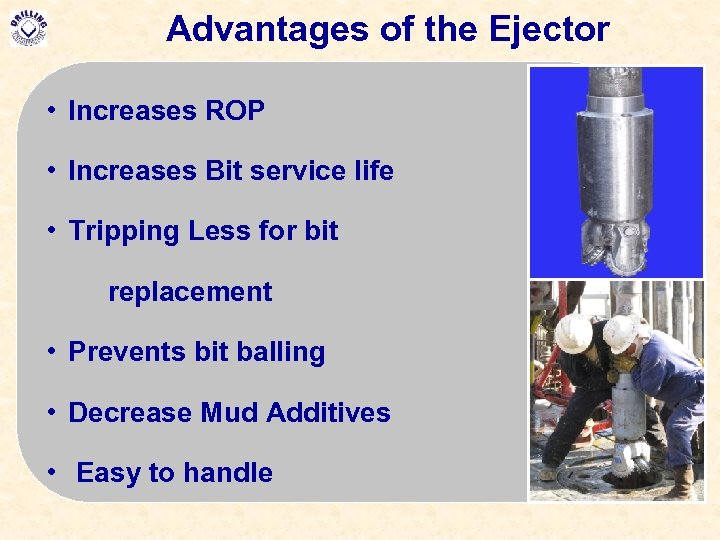

Advantages of the Ejector • Increases ROP • Increases Bit service life • Tripping Less for bit replacement • Prevents bit balling • Decrease Mud Additives • Easy to handle

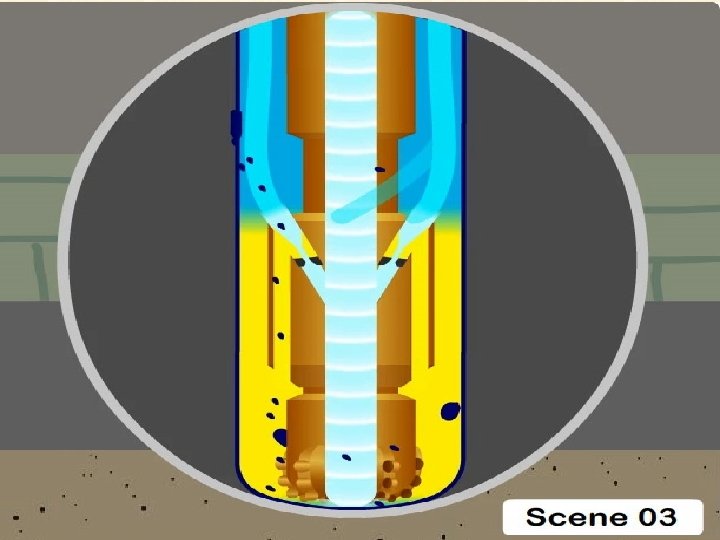

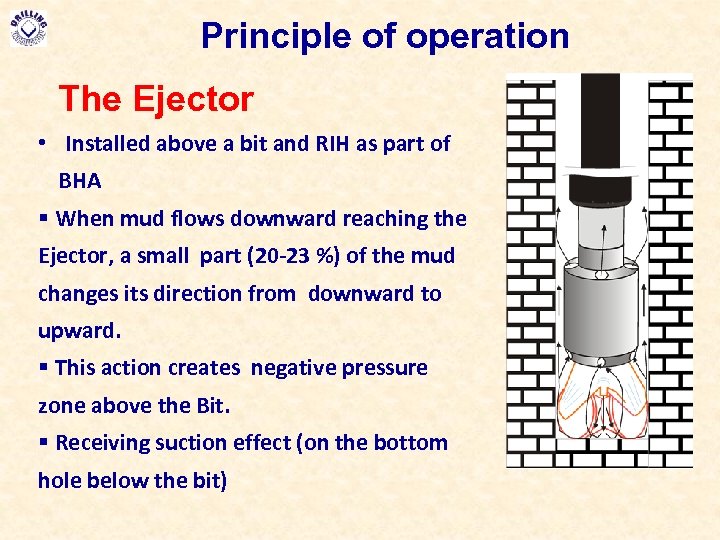

Principle of operation The Ejector • Installed above a bit and RIH as part of BHA § When mud flows downward reaching the Ejector, a small part (20 -23 %) of the mud changes its direction from downward to upward. § This action creates negative pressure zone above the Bit. § Receiving suction effect (on the bottom hole below the bit)

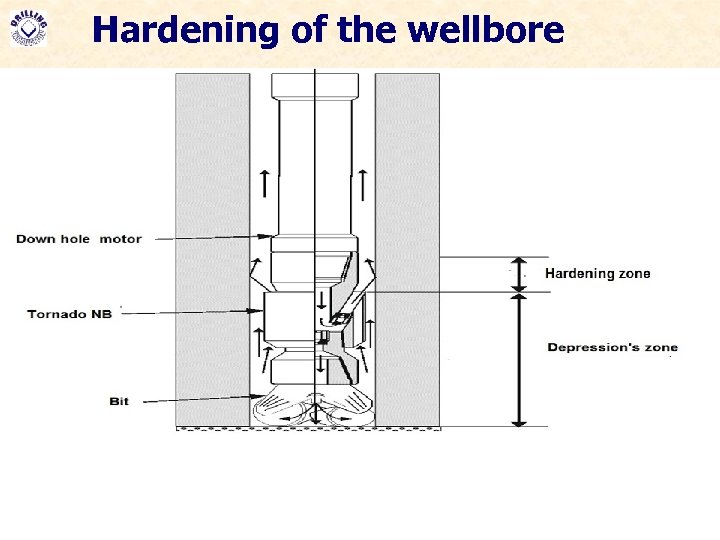

Hardening of the wellbore

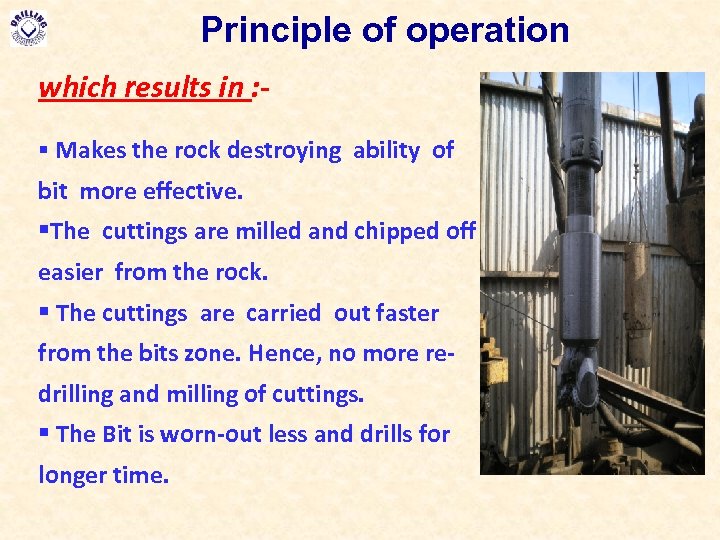

Principle of operation which results in : § Makes the rock destroying ability of bit more effective. §The cuttings are milled and chipped off easier from the rock. § The cuttings are carried out faster from the bits zone. Hence, no more redrilling and milling of cuttings. § The Bit is worn-out less and drills for longer time.

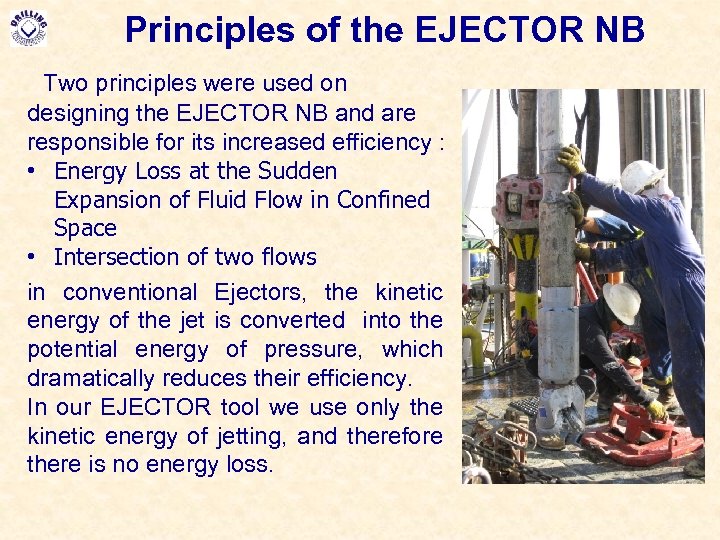

Principles of the EJECTOR NB Two principles were used on designing the EJECTOR NB and are responsible for its increased efficiency : • Energy Loss at the Sudden Expansion of Fluid Flow in Confined Space • Intersection of two flows in conventional Ejectors, the kinetic energy of the jet is converted into the potential energy of pressure, which dramatically reduces their efficiency. In our EJECTOR tool we use only the kinetic energy of jetting, and therefore there is no energy loss.

The EJECTOR’s Operational Limits § Flow rates as standard NB subs. § No restrictions on Press. & Temp § Accepts all mud weights. § WOB, Torque, Tensile and Compressive strengths same as standard NB subs. Mud intake should not contain solids more than 0. 15” in size

Selection of Bit Nozzles with EJECTOR Runs (processing of drilling parameters) DI uses in house created software for selecting bit nozzles specially for application when the EJECTOR NB is run. The nozzles sizes are selected based on the desired drilling parameters which is fed to the software. We make the software available for use in field conditions. Of course, the nozzles are selected only for the bit. The EJECTOR has its own fixed nozzles which are not changed.

Features of the EJECTOR - Totally Compatible with any BHA with any Bit “tricone , PDC” - Available for any bit’s size - Could be manufactured for any standard by Customer’s request - No impact on another tool of the BHA

List of International Clients • ADCO, UAE • PDO, Oman • AGOCO, Libya • Karasu Operating Company, Azerbaijan ﻳﺸﺘﻜﻲ • Russia – Gasprom-Burenie, Tatneft, Eurasia Perm Drilling Co. , Podsemburgas, etc. • LUKOIL Uzbekistan Operating Co. • ERIELL International Oil Service Group, Uzbekistan

Drilling Innovations work in the MENA area • • • An EJECTOR job for PDO, Oman. EJECTOR, Whipstock, curing losses for ADCO, UAE. EJECTOR jobs in AGOCO, Libya. Participating in ADIPEC 2008, 2010, 2012 Participating in the 2011 SPE/DGS Annual Technical Symposium and Exhibition, Al-Khobar, KSA.

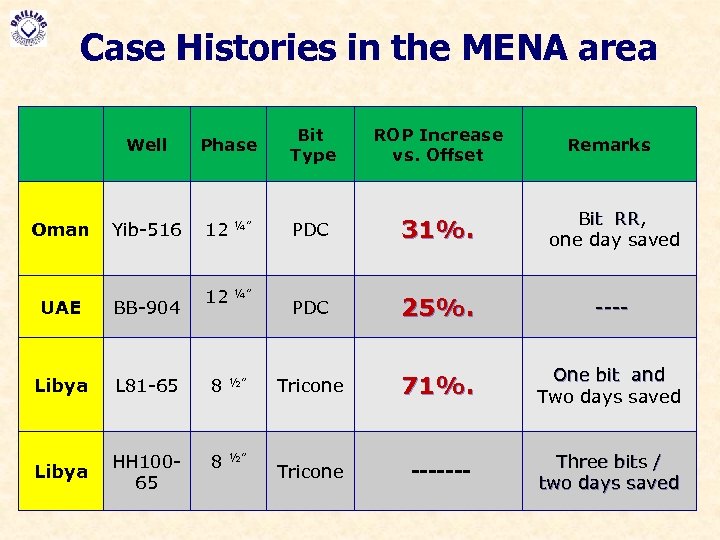

Case Histories in the MENA area Well Oman Yib-516 Phase 12 ¼” UAE BB-904 Libya L 81 -65 8 ½” Libya HH 10065 8 ½” Bit Type ROP Increase vs. Offset PDC 31%. Bit RR, one day saved PDC 25%. ---- Tricone 71%. One bit and Two days saved Tricone ------- Three bits / two days saved Remarks

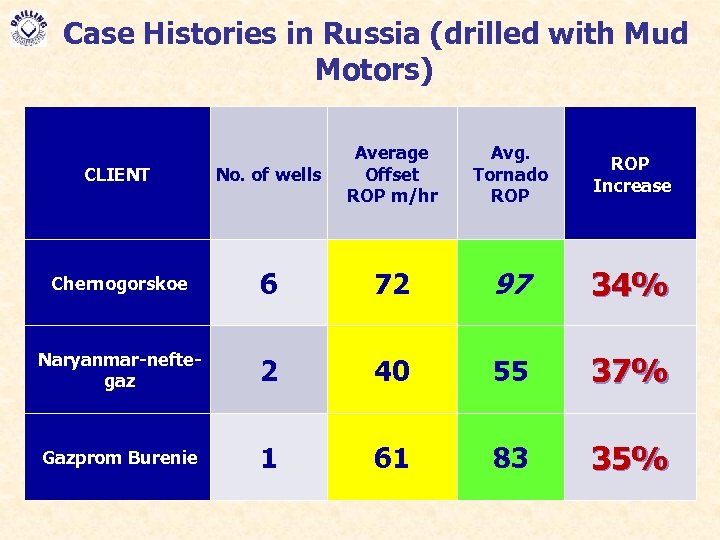

Case Histories in Russia (drilled with Mud Motors) CLIENT No. of wells Average Offset ROP m/hr Avg. Tornado ROP Increase Chernogorskoe 6 72 97 34% Naryanmar-neftegaz 2 40 55 37% Gazprom Burenie 1 61 83 35%

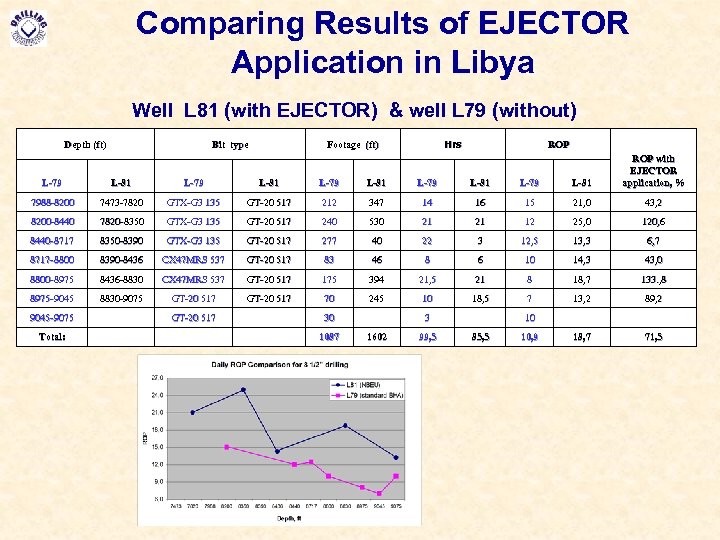

Comparing Results of EJECTOR Application in Libya Well L 81 (with EJECTOR) & well L 79 (without) Depth (ft) Bit type Hrs Footage (ft) ROP L-79 L-81 L-79 L-81 ROP with EJECTOR application, % 7988 -8200 7473 -7820 GTX-G 3 135 GT-20 517 212 347 14 16 15 21, 0 43, 2 8200 -8440 7820 -8350 GTX-G 3 135 GT-20 517 240 530 21 21 12 25, 0 120, 6 8440 -8717 8350 -8390 GTX-G 3 135 GT-20 517 277 40 22 3 12, 5 12, 13, 3 13, 6, 7 8717 -8800 8390 -8436 CX 47 MRS 537 GT-20 517 83 46 8 6 10 14, 3 43, 0 8800 -8975 8436 -8830 CX 47 MRS 537 GT-20 517 175 394 21, 5 21 8 18, 7 133. , 8 8975 -9045 8830 -9075 GT-20 517 70 245 10 18, 5 7 13, 2 13, 89, 2 18, 7 71, 5 9045 -9075 GT-20 517 Total: 30 1087 3 1602 99, 5 10 85, 5 10, 9 10,

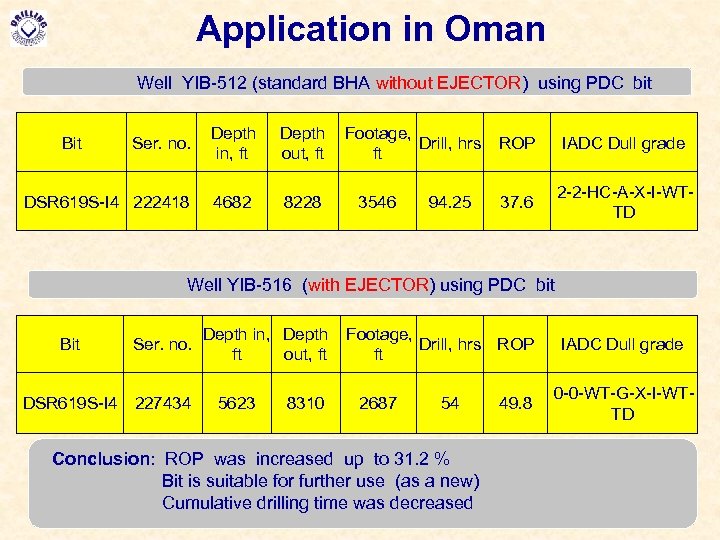

Application in Oman Well YIB-512 (standard BHA without EJECTOR) using PDC bit Bit Ser. no. DSR 619 S-I 4 222418 Depth in, ft Depth out, ft 4682 8228 Footage, Drill, hrs ft 3546 94. 25 ROP IADC Dull grade 37. 6 2 -2 -HC-A-X-I-WTTD Well YIB-516 (with EJECTOR) using PDC bit Bit Ser. no. DSR 619 S-I 4 227434 Depth in, Depth ft out, ft 5623 8310 Footage, Drill, hrs ROP ft 2687 54 Conclusion: ROP was increased up to 31. 2 % Bit is suitable for further use (as a new) Cumulative drilling time was decreased 49. 8 IADC Dull grade 0 -0 -WT-G-X-I-WTTD

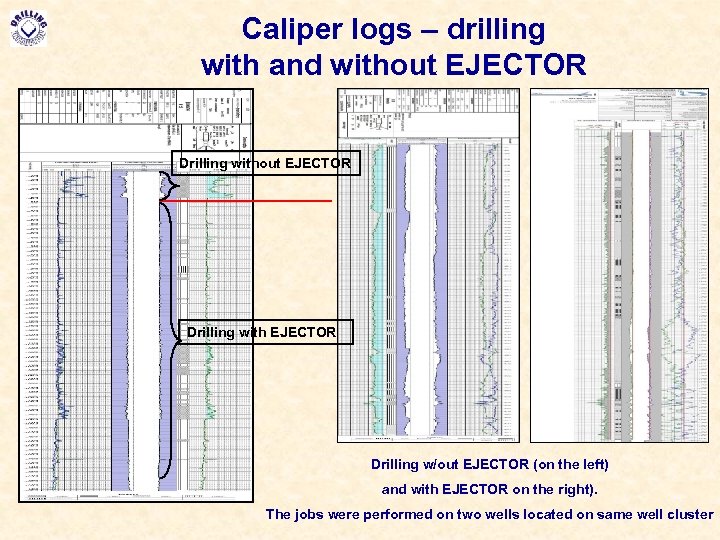

Caliper logs – drilling with and without EJECTOR Drilling with EJECTOR Drilling w/out EJECTOR (on the left) and with EJECTOR on the right). The jobs were performed on two wells located on same well cluster

Accepted by SPE conference 2011 SPE/DGS Annual Technical Symposium and Exhibition Al-Khobar, Saudi Arabia SPE 149113. Methods of Drilling Rate increase, Near Bit EJECTOR application 15. 03. 2018

Results obtained by various EJECTOR applications The main benefits achieved by using the near bit EJECTOR tool in all the areas drilled were as follows: - Increased ROP - Reduced Number of bits - Decreased Overall drilling time - Obtained better wellbore condition with no washouts

API & ISO certification • Drilling Innovation is ISO & OHSAS certified. • EJECTOR tool connecting threads are cut according to API standard.

THANK YOU for your attention

807a24501f497887e386bfef30507b84.ppt