b8a9698d47e2b6eb9134c85e892e84c3.ppt

- Количество слайдов: 35

The Effect of an Oxygenated Additive on the Emulsification Characteristics of Diesel-Ethanol Blends Ms. Thanyatorn Isarachewa Asst. Prof. Apanee Luengnaruemitchai Captain Dr. Samai Jai-In The Petroleum and Petrochemical College, Chulalongkorn University, Thailand The Royal Thai Navy

The Effect of an Oxygenated Additive on the Emulsification Characteristics of Diesel-Ethanol Blends Ms. Thanyatorn Isarachewa Asst. Prof. Apanee Luengnaruemitchai Captain Dr. Samai Jai-In The Petroleum and Petrochemical College, Chulalongkorn University, Thailand The Royal Thai Navy

OUTLINE Introduction Background & Literature Review Objectives Methodology Results and Discussion Conclusions 2

OUTLINE Introduction Background & Literature Review Objectives Methodology Results and Discussion Conclusions 2

INTRODUCTION O il is s ri C 3

INTRODUCTION O il is s ri C 3

Motivation 1. Reduce Dependence on Imported Petroleum Fuels. 2. Increase Farm Income : Supply Management. 3. The growing global concern with environmental pollution. 4

Motivation 1. Reduce Dependence on Imported Petroleum Fuels. 2. Increase Farm Income : Supply Management. 3. The growing global concern with environmental pollution. 4

Alternative Energy which is currently promoted in Thailand Gasohol NGV Biodiesel PPC, Ms. Thanyatorn Isarachewa 5

Alternative Energy which is currently promoted in Thailand Gasohol NGV Biodiesel PPC, Ms. Thanyatorn Isarachewa 5

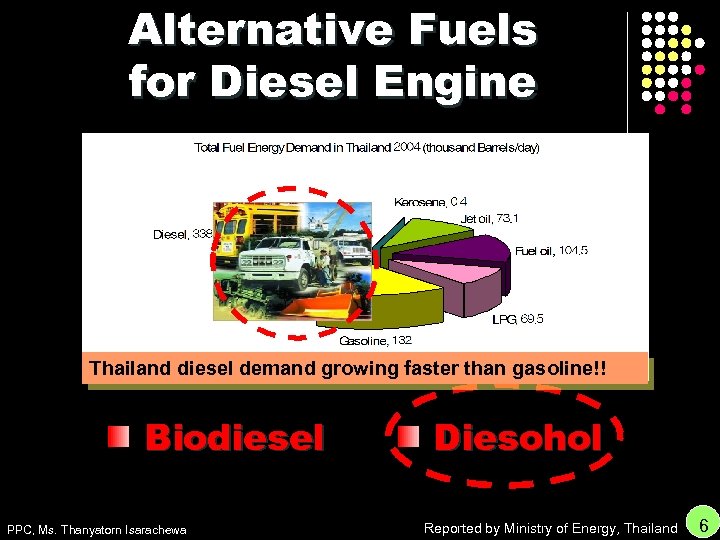

Alternative Fuels for Diesel Engine Thailand diesel demand growing faster than gasoline!! Biodiesel PPC, Ms. Thanyatorn Isarachewa Diesohol Reported by Ministry of Energy, Thailand 6

Alternative Fuels for Diesel Engine Thailand diesel demand growing faster than gasoline!! Biodiesel PPC, Ms. Thanyatorn Isarachewa Diesohol Reported by Ministry of Energy, Thailand 6

Advantages of Diesohol Impacts of Diesohol use. The alcohol component in the fuel: An alternative fuel for diesel substitution. Changes the combustion characteristics of the fuel. Reduce air pollutant Because alcohol is an oxygenate Oxygen atoms inside ethanol join forces with oxygen rtant o mhelp molecules in the airito p r n is a fewe ethanol iburn more completely. on o t ust bextrading sions m This s r co tor lea amount of oxygen te ac also helpsemi burn better l missiont f Be mfu diesel har when it is blended with ethanol. Introduces greater oxygen to fuel mixture improve the efficiency of combustion PPC, Ms. Thanyatorn Isarachewa www. eere. energy. gov/vehiclesandfuels 7

Advantages of Diesohol Impacts of Diesohol use. The alcohol component in the fuel: An alternative fuel for diesel substitution. Changes the combustion characteristics of the fuel. Reduce air pollutant Because alcohol is an oxygenate Oxygen atoms inside ethanol join forces with oxygen rtant o mhelp molecules in the airito p r n is a fewe ethanol iburn more completely. on o t ust bextrading sions m This s r co tor lea amount of oxygen te ac also helpsemi burn better l missiont f Be mfu diesel har when it is blended with ethanol. Introduces greater oxygen to fuel mixture improve the efficiency of combustion PPC, Ms. Thanyatorn Isarachewa www. eere. energy. gov/vehiclesandfuels 7

Impacts of Diesohol use. The alcohol component in the fuel: Disadvantages of Diesohol Fuel instability due to phase separation Low Cetane Number Low Flash Point Temperature PPC, Ms. Thanyatorn Isarachewa Ethanol-diesel fuel blends-a review, Hansen(2005) 8

Impacts of Diesohol use. The alcohol component in the fuel: Disadvantages of Diesohol Fuel instability due to phase separation Low Cetane Number Low Flash Point Temperature PPC, Ms. Thanyatorn Isarachewa Ethanol-diesel fuel blends-a review, Hansen(2005) 8

Letcher, T. M. , 1983. Diesel blends for diesel engines. ADDITIVES The price of commercial additives are still high and need to be imported. Improve solubility Improve fuel properties Eg. DALCO, PEOPS , SB 407 , GE Bet. Z AAE 05, Octimax 4930, and Beraid ED 10 The detail of additive components has not been revealed by any producer. 9

Letcher, T. M. , 1983. Diesel blends for diesel engines. ADDITIVES The price of commercial additives are still high and need to be imported. Improve solubility Improve fuel properties Eg. DALCO, PEOPS , SB 407 , GE Bet. Z AAE 05, Octimax 4930, and Beraid ED 10 The detail of additive components has not been revealed by any producer. 9

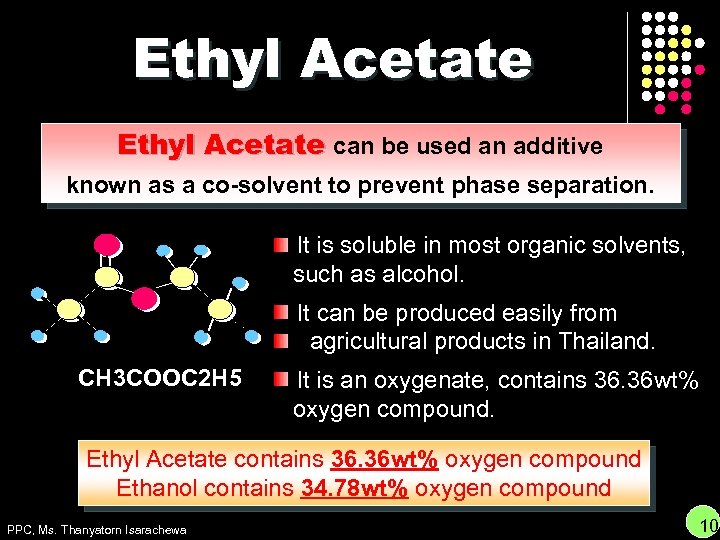

Ethyl Acetate can be used an additive known as a co-solvent to prevent phase separation. It is soluble in most organic solvents, such as alcohol. It can be produced easily from agricultural products in Thailand. CH 3 COOC 2 H 5 It is an oxygenate, contains 36. 36 wt% oxygen compound. Ethyl Acetate contains 36. 36 wt% oxygen compound Ethanol contains 34. 78 wt% oxygen compound PPC, Ms. Thanyatorn Isarachewa 10

Ethyl Acetate can be used an additive known as a co-solvent to prevent phase separation. It is soluble in most organic solvents, such as alcohol. It can be produced easily from agricultural products in Thailand. CH 3 COOC 2 H 5 It is an oxygenate, contains 36. 36 wt% oxygen compound. Ethyl Acetate contains 36. 36 wt% oxygen compound Ethanol contains 34. 78 wt% oxygen compound PPC, Ms. Thanyatorn Isarachewa 10

OBJECTIVES To study the use of ethyl acetate as an additive in stabilizing ethanol in diesel blends. To investigate the effect of an oxygenated additive on the emulsification characteristics of diesohol. To compare some basic fuel properties and emission of diesohol with diesel fuel. PPC, Ms. Thanyatorn Isarachewa 15

OBJECTIVES To study the use of ethyl acetate as an additive in stabilizing ethanol in diesel blends. To investigate the effect of an oxygenated additive on the emulsification characteristics of diesohol. To compare some basic fuel properties and emission of diesohol with diesel fuel. PPC, Ms. Thanyatorn Isarachewa 15

MATERIALS Diesel : Rayong Purifier Public Co. Ltd. , Ethanol : The Royal Chitralada Projects, J. T. Baker Co. Ltd. , Ethyl Acetate : White House Co. Ltd. , (95%, 99. 5%conc) (99. 9%conc) PPC, Ms. Thanyatorn Isarachewa 16

MATERIALS Diesel : Rayong Purifier Public Co. Ltd. , Ethanol : The Royal Chitralada Projects, J. T. Baker Co. Ltd. , Ethyl Acetate : White House Co. Ltd. , (95%, 99. 5%conc) (99. 9%conc) PPC, Ms. Thanyatorn Isarachewa 16

Methodology Outline 1. Splash-Blending 2. Stability Observation 2. 1 Effect of temperature 3. Turbidity Measurement 4. Fuel Properties Testing 5. Engine Test PPC, Ms. Thanyatorn Isarachewa 17

Methodology Outline 1. Splash-Blending 2. Stability Observation 2. 1 Effect of temperature 3. Turbidity Measurement 4. Fuel Properties Testing 5. Engine Test PPC, Ms. Thanyatorn Isarachewa 17

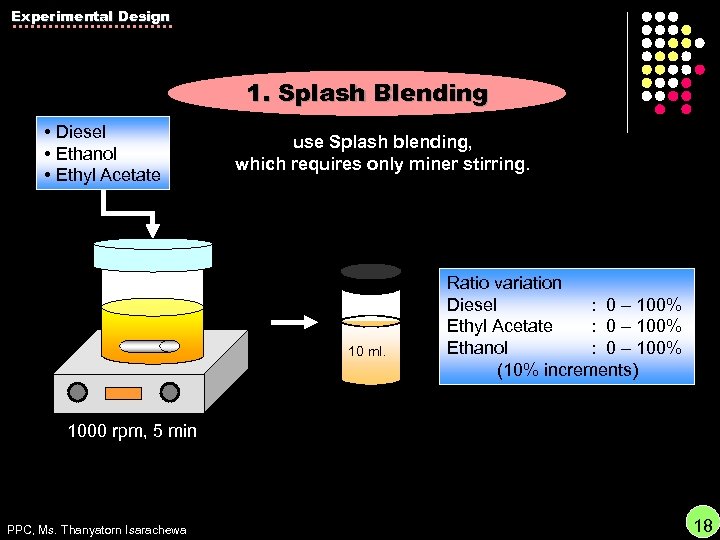

Experimental Design 1. Splash Blending • Diesel • Ethanol • Ethyl Acetate use Splash blending, which requires only miner stirring. 10 ml. Ratio variation Diesel : 0 – 100% Ethyl Acetate : 0 – 100% Ethanol : 0 – 100% (10% increments) 1000 rpm, 5 min PPC, Ms. Thanyatorn Isarachewa 18

Experimental Design 1. Splash Blending • Diesel • Ethanol • Ethyl Acetate use Splash blending, which requires only miner stirring. 10 ml. Ratio variation Diesel : 0 – 100% Ethyl Acetate : 0 – 100% Ethanol : 0 – 100% (10% increments) 1000 rpm, 5 min PPC, Ms. Thanyatorn Isarachewa 18

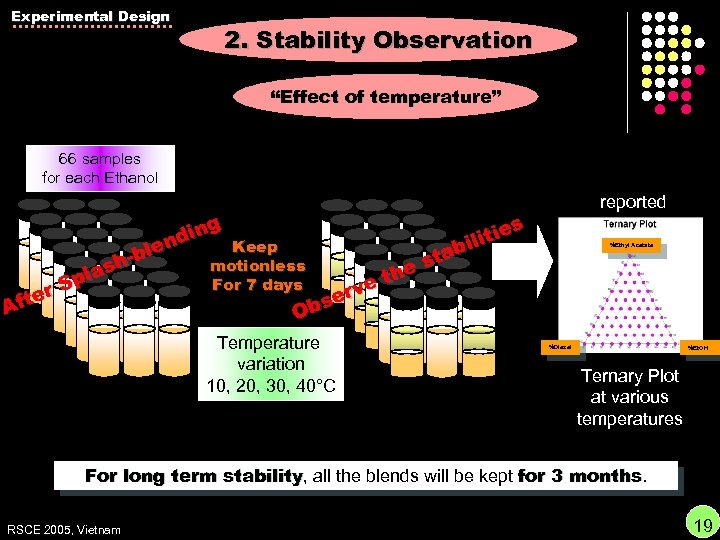

Experimental Design 2. Stability Observation “Effect of temperature” 66 samples for each Ethanol reported es ing d liti n i Keep ble tab s motionless ash l the p For 7 days r. S rve e bse Aft O Temperature variation 10, 20, 30, 40°C %Ethyl Acetate %Diesel %Et. OH Ternary Plot at various temperatures For long term stability, all the blends will be kept for 3 months. stability months RSCE 2005, Vietnam 19

Experimental Design 2. Stability Observation “Effect of temperature” 66 samples for each Ethanol reported es ing d liti n i Keep ble tab s motionless ash l the p For 7 days r. S rve e bse Aft O Temperature variation 10, 20, 30, 40°C %Ethyl Acetate %Diesel %Et. OH Ternary Plot at various temperatures For long term stability, all the blends will be kept for 3 months. stability months RSCE 2005, Vietnam 19

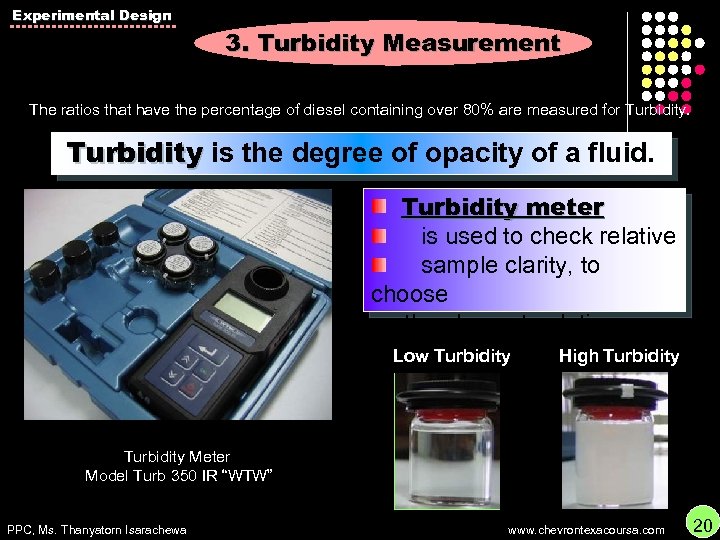

Experimental Design 3. Turbidity Measurement The ratios that have the percentage of diesel containing over 80% are measured for Turbidity is the degree of opacity of a fluid. Turbidity meter is used to check relative sample clarity, to choose the clearest solution. Low Turbidity High Turbidity Meter Model Turb 350 IR “WTW” PPC, Ms. Thanyatorn Isarachewa www. chevrontexacoursa. com 20

Experimental Design 3. Turbidity Measurement The ratios that have the percentage of diesel containing over 80% are measured for Turbidity is the degree of opacity of a fluid. Turbidity meter is used to check relative sample clarity, to choose the clearest solution. Low Turbidity High Turbidity Meter Model Turb 350 IR “WTW” PPC, Ms. Thanyatorn Isarachewa www. chevrontexacoursa. com 20

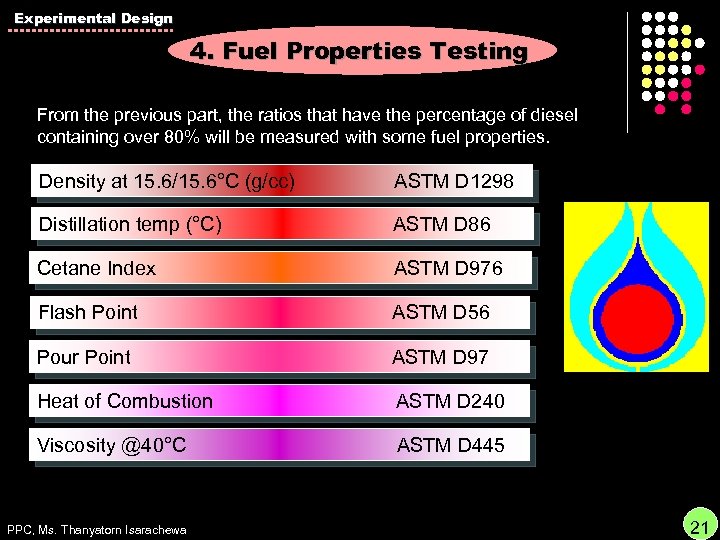

Experimental Design 4. Fuel Properties Testing From the previous part, the ratios that have the percentage of diesel containing over 80% will be measured with some fuel properties. Density at 15. 6/15. 6°C (g/cc) ASTM D 1298 Distillation temp (°C) ASTM D 86 Cetane Index ASTM D 976 Flash Point ASTM D 56 Pour Point ASTM D 97 Heat of Combustion ASTM D 240 Viscosity @40°C ASTM D 445 PPC, Ms. Thanyatorn Isarachewa 21

Experimental Design 4. Fuel Properties Testing From the previous part, the ratios that have the percentage of diesel containing over 80% will be measured with some fuel properties. Density at 15. 6/15. 6°C (g/cc) ASTM D 1298 Distillation temp (°C) ASTM D 86 Cetane Index ASTM D 976 Flash Point ASTM D 56 Pour Point ASTM D 97 Heat of Combustion ASTM D 240 Viscosity @40°C ASTM D 445 PPC, Ms. Thanyatorn Isarachewa 21

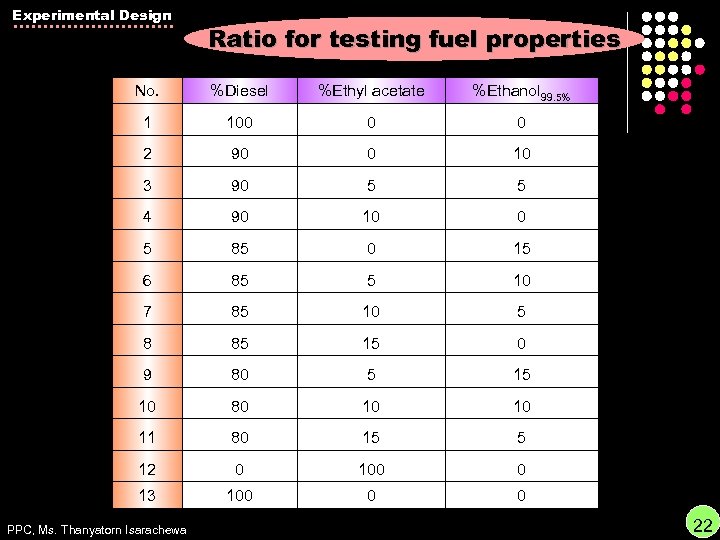

Experimental Design Ratio for testing fuel properties No. %Diesel %Ethyl acetate %Ethanol 99. 5% 1 100 0 0 2 90 0 10 3 90 5 5 4 90 10 0 5 85 0 15 6 85 5 10 7 85 10 5 8 85 15 0 9 80 5 15 10 80 10 10 11 80 15 5 12 0 100 0 13 100 0 0 PPC, Ms. Thanyatorn Isarachewa 22

Experimental Design Ratio for testing fuel properties No. %Diesel %Ethyl acetate %Ethanol 99. 5% 1 100 0 0 2 90 0 10 3 90 5 5 4 90 10 0 5 85 0 15 6 85 5 10 7 85 10 5 8 85 15 0 9 80 5 15 10 80 10 10 11 80 15 5 12 0 100 0 13 100 0 0 PPC, Ms. Thanyatorn Isarachewa 22

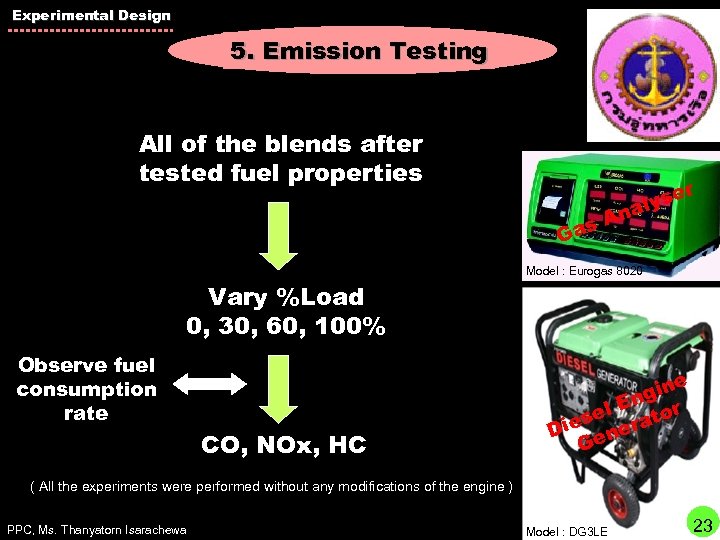

Experimental Design 5. Emission Testing All of the blends after tested fuel properties r e lys Ana s Ga Model : Eurogas 8020 Vary %Load 0, 30, 60, 100% Observe fuel consumption rate CO, NOx, HC e gin l En tor e ies nera D Ge ( All the experiments were performed without any modifications of the engine ) PPC, Ms. Thanyatorn Isarachewa Model : DG 3 LE 23

Experimental Design 5. Emission Testing All of the blends after tested fuel properties r e lys Ana s Ga Model : Eurogas 8020 Vary %Load 0, 30, 60, 100% Observe fuel consumption rate CO, NOx, HC e gin l En tor e ies nera D Ge ( All the experiments were performed without any modifications of the engine ) PPC, Ms. Thanyatorn Isarachewa Model : DG 3 LE 23

Results and Discussion Developed Ternary Diagram PPC, Ms. Thanyatorn Isarachewa 24

Results and Discussion Developed Ternary Diagram PPC, Ms. Thanyatorn Isarachewa 24

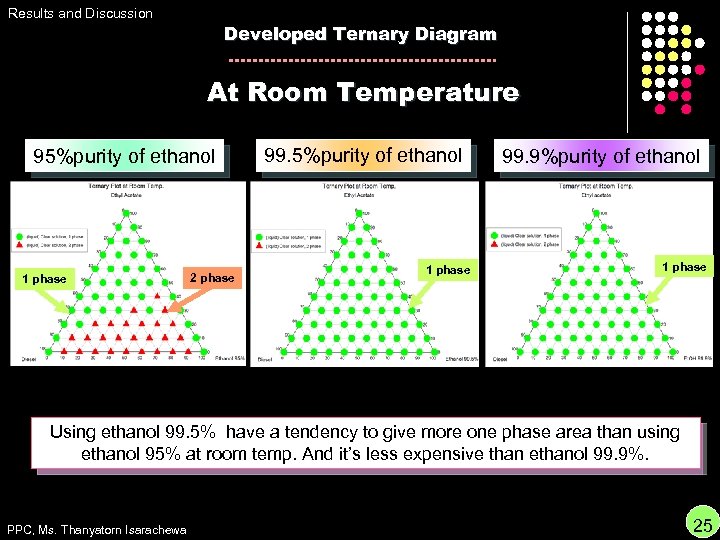

Results and Discussion Developed Ternary Diagram At Room Temperature 95%purity of ethanol 1 phase 2 phase 99. 5%purity of ethanol 1 phase 99. 9%purity of ethanol 1 phase Solubility of diesel fuelhave a tendencyand ethanol 99. 5%, 99. 9% is not limited. Using ethanol 99. 5% in ethyl acetate to give more one phase area than using However solubility of diesel fuel in it’s less expensiveethanol 95% is limited. ethanol 95% at room temp. And ethyl acetate and than ethanol 99. 9%. PPC, Ms. Thanyatorn Isarachewa 25

Results and Discussion Developed Ternary Diagram At Room Temperature 95%purity of ethanol 1 phase 2 phase 99. 5%purity of ethanol 1 phase 99. 9%purity of ethanol 1 phase Solubility of diesel fuelhave a tendencyand ethanol 99. 5%, 99. 9% is not limited. Using ethanol 99. 5% in ethyl acetate to give more one phase area than using However solubility of diesel fuel in it’s less expensiveethanol 95% is limited. ethanol 95% at room temp. And ethyl acetate and than ethanol 99. 9%. PPC, Ms. Thanyatorn Isarachewa 25

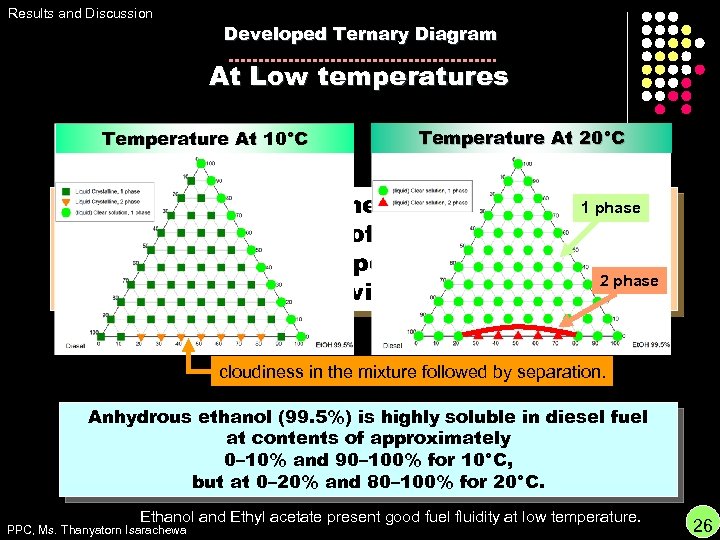

Results and Discussion Developed Ternary Diagram At Low temperatures Temperature At 10°C Temperature At 20°C The interest of the ethyl acetate is phase 1 to prevent any risk of mixture separation 1 phase 2 temperature drops, when thephase 2 phase make it suitable for winter fuel formulation. cloudiness in the mixture followed by separation. Anhydrous ethanol (99. 5%) is highly soluble in diesel fuel at contents of approximately 0– 10% and 90– 100% for 10°C, but at 0– 20% and 80– 100% for 20°C. Ethanol and Ethyl acetate present good fuel fluidity at low temperature. PPC, Ms. Thanyatorn Isarachewa 26

Results and Discussion Developed Ternary Diagram At Low temperatures Temperature At 10°C Temperature At 20°C The interest of the ethyl acetate is phase 1 to prevent any risk of mixture separation 1 phase 2 temperature drops, when thephase 2 phase make it suitable for winter fuel formulation. cloudiness in the mixture followed by separation. Anhydrous ethanol (99. 5%) is highly soluble in diesel fuel at contents of approximately 0– 10% and 90– 100% for 10°C, but at 0– 20% and 80– 100% for 20°C. Ethanol and Ethyl acetate present good fuel fluidity at low temperature. PPC, Ms. Thanyatorn Isarachewa 26

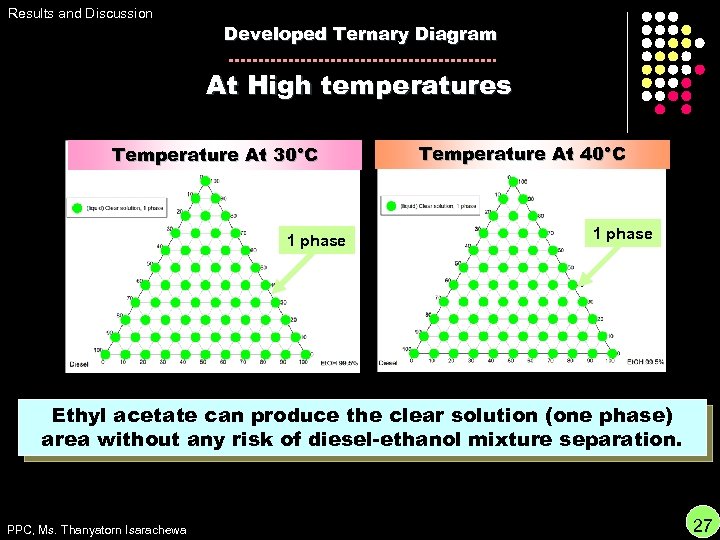

Results and Discussion Developed Ternary Diagram At High temperatures Temperature At 30°C 1 phase Temperature At 40°C 1 phase Ethyl acetate can produce the clear solution (one phase) area without any risk of diesel-ethanol mixture separation. PPC, Ms. Thanyatorn Isarachewa 27

Results and Discussion Developed Ternary Diagram At High temperatures Temperature At 30°C 1 phase Temperature At 40°C 1 phase Ethyl acetate can produce the clear solution (one phase) area without any risk of diesel-ethanol mixture separation. PPC, Ms. Thanyatorn Isarachewa 27

Results and Discussion Turbidity Measurement PPC, Ms. Thanyatorn Isarachewa 28

Results and Discussion Turbidity Measurement PPC, Ms. Thanyatorn Isarachewa 28

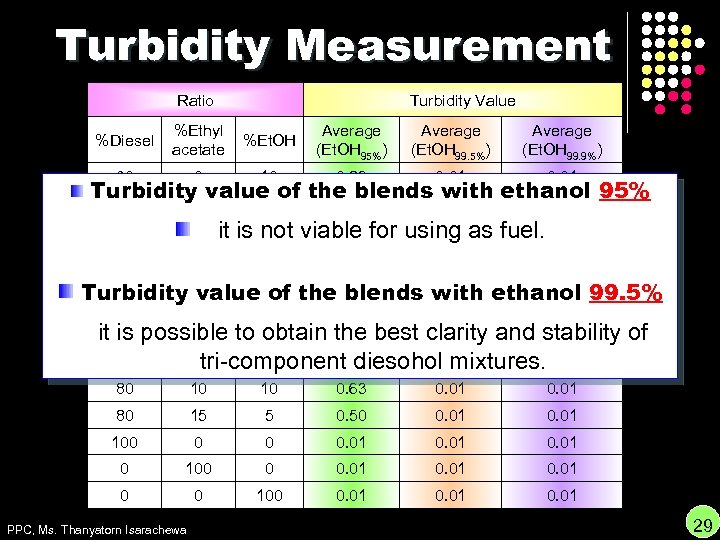

Turbidity Measurement Ratio Turbidity Value %Diesel %Ethyl acetate %Et. OH Average (Et. OH 95%) Average (Et. OH 99. 9%) 90 0 10 0. 26 0. 01 90 10 85 0 15 0. 56 0. 01 85 5 10 0. 58 0. 01 85 10 5 3. 02 0. 01 80 10 10 0. 63 0. 01 80 15 5 0. 50 0. 01 100 0 0 0. 01 0 100 0 0. 01 0 0 100 0. 01 Turbidity 5 value of the blends 0. 01 with ethanol 95% 90 5 0. 33 0. 01 0 0. 67 0. 01 it is not viable for using as fuel. 0. 01 Turbidity value of the blends with ethanol 99. 5% it 85 possible to obtain the best clarity and stability of is 15 0 0. 92 0. 01 80 5 tri-component diesohol mixtures. 0. 01 15 0. 59 0. 01 PPC, Ms. Thanyatorn Isarachewa 29

Turbidity Measurement Ratio Turbidity Value %Diesel %Ethyl acetate %Et. OH Average (Et. OH 95%) Average (Et. OH 99. 9%) 90 0 10 0. 26 0. 01 90 10 85 0 15 0. 56 0. 01 85 5 10 0. 58 0. 01 85 10 5 3. 02 0. 01 80 10 10 0. 63 0. 01 80 15 5 0. 50 0. 01 100 0 0 0. 01 0 100 0 0. 01 0 0 100 0. 01 Turbidity 5 value of the blends 0. 01 with ethanol 95% 90 5 0. 33 0. 01 0 0. 67 0. 01 it is not viable for using as fuel. 0. 01 Turbidity value of the blends with ethanol 99. 5% it 85 possible to obtain the best clarity and stability of is 15 0 0. 92 0. 01 80 5 tri-component diesohol mixtures. 0. 01 15 0. 59 0. 01 PPC, Ms. Thanyatorn Isarachewa 29

Results and Discussion Test Fuel Properties PPC, Ms. Thanyatorn Isarachewa 30

Results and Discussion Test Fuel Properties PPC, Ms. Thanyatorn Isarachewa 30

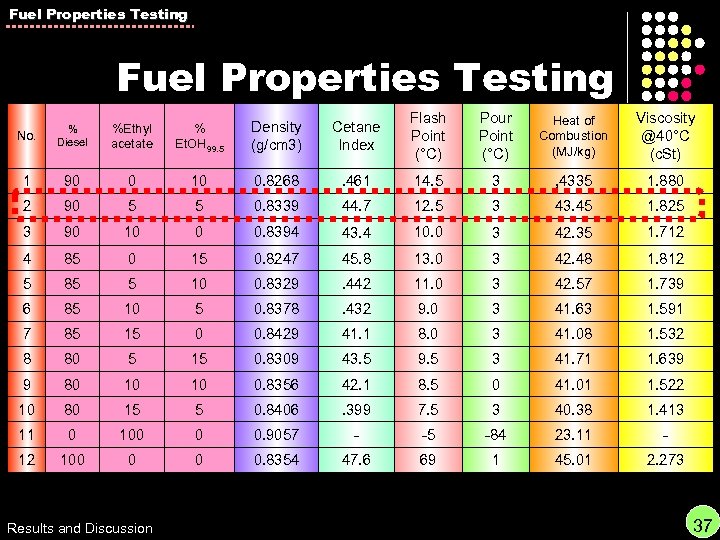

Fuel Properties Testing No. % Diesel %Ethyl acetate % Et. OH 99. 5 Density (g/cm 3) Cetane Index Flash Point (°C) Pour Point (°C) Heat of Combustion (MJ/kg) Viscosity @40°C (c. St) 1 90 0 10 0. 8268 . 461 14. 5 3 , 4335 1. 880 2 90 5 5 0. 8339 44. 7 12. 5 3 43. 45 1. 825 3 90 10 0 0. 8394 43. 4 10. 0 3 42. 35 1. 712 4 85 0 15 0. 8247 45. 8 13. 0 3 42. 48 1. 812 5 85 5 10 0. 8329 . 442 11. 0 3 42. 57 1. 739 6 85 10 5 0. 8378 . 432 9. 0 3 41. 63 1. 591 7 85 15 0 0. 8429 41. 1 8. 0 3 41. 08 1. 532 8 80 5 15 0. 8309 43. 5 9. 5 3 41. 71 1. 639 9 80 10 10 0. 8356 42. 1 8. 5 0 41. 01 1. 522 10 80 15 5 0. 8406 . 399 7. 5 3 40. 38 1. 413 11 0 100 0 0. 9057 - -5 -84 23. 11 - 12 100 0 0 0. 8354 47. 6 69 1 45. 01 2. 273 Results and Discussion 37

Fuel Properties Testing No. % Diesel %Ethyl acetate % Et. OH 99. 5 Density (g/cm 3) Cetane Index Flash Point (°C) Pour Point (°C) Heat of Combustion (MJ/kg) Viscosity @40°C (c. St) 1 90 0 10 0. 8268 . 461 14. 5 3 , 4335 1. 880 2 90 5 5 0. 8339 44. 7 12. 5 3 43. 45 1. 825 3 90 10 0 0. 8394 43. 4 10. 0 3 42. 35 1. 712 4 85 0 15 0. 8247 45. 8 13. 0 3 42. 48 1. 812 5 85 5 10 0. 8329 . 442 11. 0 3 42. 57 1. 739 6 85 10 5 0. 8378 . 432 9. 0 3 41. 63 1. 591 7 85 15 0 0. 8429 41. 1 8. 0 3 41. 08 1. 532 8 80 5 15 0. 8309 43. 5 9. 5 3 41. 71 1. 639 9 80 10 10 0. 8356 42. 1 8. 5 0 41. 01 1. 522 10 80 15 5 0. 8406 . 399 7. 5 3 40. 38 1. 413 11 0 100 0 0. 9057 - -5 -84 23. 11 - 12 100 0 0 0. 8354 47. 6 69 1 45. 01 2. 273 Results and Discussion 37

Results and Discussion Engine Test 38

Results and Discussion Engine Test 38

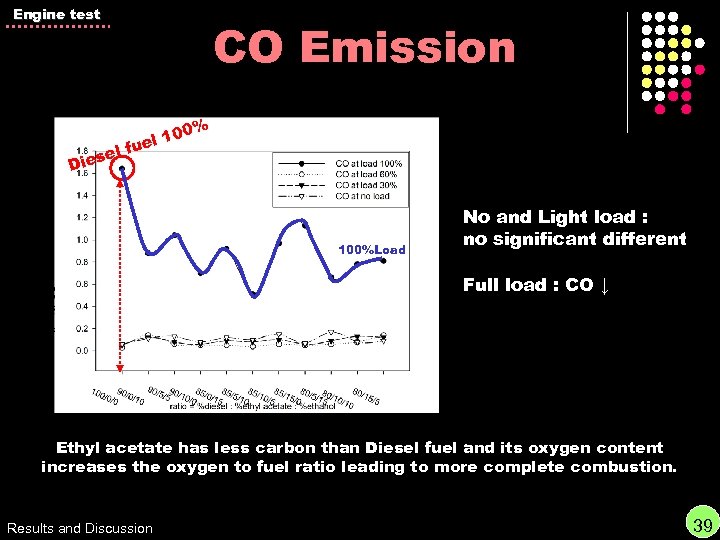

Engine test CO Emission 0% l 10 ue lf se Die 100%Load No and Light load : no significant different Full load : CO ↓ Ethyl acetate has less carbon than Diesel fuel and its oxygen content increases the oxygen to fuel ratio leading to more complete combustion. Results and Discussion 39

Engine test CO Emission 0% l 10 ue lf se Die 100%Load No and Light load : no significant different Full load : CO ↓ Ethyl acetate has less carbon than Diesel fuel and its oxygen content increases the oxygen to fuel ratio leading to more complete combustion. Results and Discussion 39

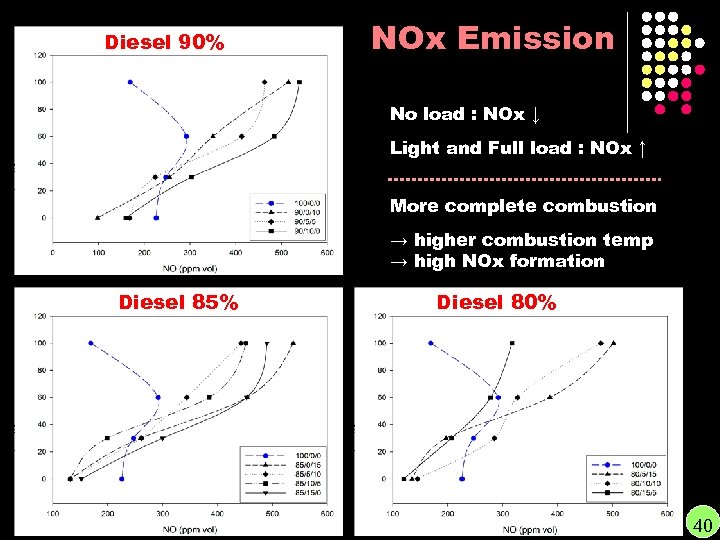

Diesel 90% NOx Emission No load : NOx ↓ Light and Full load : NOx ↑ More complete combustion → higher combustion temp → high NOx formation Diesel 85% Diesel 80% 40

Diesel 90% NOx Emission No load : NOx ↓ Light and Full load : NOx ↑ More complete combustion → higher combustion temp → high NOx formation Diesel 85% Diesel 80% 40

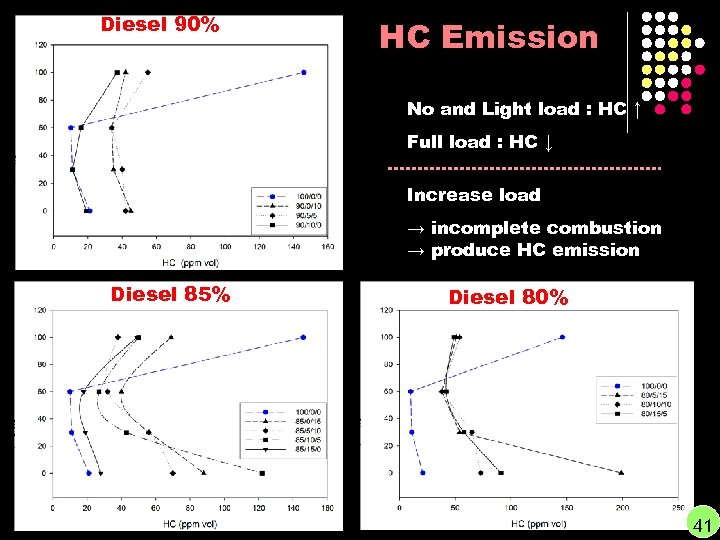

Diesel 90% HC Emission No and Light load : HC ↑ Full load : HC ↓ Increase load → incomplete combustion → produce HC emission Diesel 85% Diesel 80% 41

Diesel 90% HC Emission No and Light load : HC ↑ Full load : HC ↓ Increase load → incomplete combustion → produce HC emission Diesel 85% Diesel 80% 41

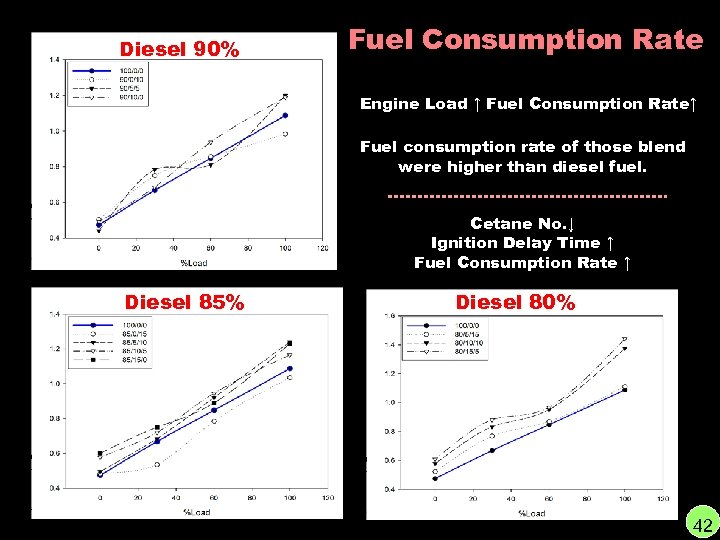

Diesel 90% Fuel Consumption Rate Engine Load ↑ Fuel Consumption Rate↑ Fuel consumption rate of those blend were higher than diesel fuel. Cetane No. ↓ Ignition Delay Time ↑ Fuel Consumption Rate ↑ Diesel 85% Diesel 80% 42

Diesel 90% Fuel Consumption Rate Engine Load ↑ Fuel Consumption Rate↑ Fuel consumption rate of those blend were higher than diesel fuel. Cetane No. ↓ Ignition Delay Time ↑ Fuel Consumption Rate ↑ Diesel 85% Diesel 80% 42

Conclusions 1. Using anhydrous ethanol are thus more suitable than 95% ethanol for use as fuel. 2. In general, blends containing 90%diesel, 5%ethyl acetate and 5% ethanol has very close fuel properties compared to diesel fuel. 3. The presence of oxygenated compounds, ethanol and ethyl acetate, in diesel fuel significantly influences engine emissions and also the fuel consumption. 4. For further research, it’s necessary to evaluate the economic of ethyl acetate production for currently available in commercial use. PPC, Ms. Thanyatorn Isarachewa 43

Conclusions 1. Using anhydrous ethanol are thus more suitable than 95% ethanol for use as fuel. 2. In general, blends containing 90%diesel, 5%ethyl acetate and 5% ethanol has very close fuel properties compared to diesel fuel. 3. The presence of oxygenated compounds, ethanol and ethyl acetate, in diesel fuel significantly influences engine emissions and also the fuel consumption. 4. For further research, it’s necessary to evaluate the economic of ethyl acetate production for currently available in commercial use. PPC, Ms. Thanyatorn Isarachewa 43

Acknowledgements The Petroleum and Petrochemical College Energy Conservation Promotion Fund for Local and Research supported by Energy Policy and Planning Office, Ministry of Energy The PPC consortium The Royal Chitralada Projects The Royal Thai Navy Rayong Purifier Public Company PTT Public Company My Friends and family PPC, Ms. Thanyatorn Isarachewa 44

Acknowledgements The Petroleum and Petrochemical College Energy Conservation Promotion Fund for Local and Research supported by Energy Policy and Planning Office, Ministry of Energy The PPC consortium The Royal Chitralada Projects The Royal Thai Navy Rayong Purifier Public Company PTT Public Company My Friends and family PPC, Ms. Thanyatorn Isarachewa 44

THANK YOU PPC, Ms. Thanyatorn Isarachewa

THANK YOU PPC, Ms. Thanyatorn Isarachewa