a55fbcb07fea2350070a56702b2a6aa8.ppt

- Количество слайдов: 20

The DM-Ice Test Detector Concept Mechanical Assembly Vessel Options Logistics Considerations Schedule Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

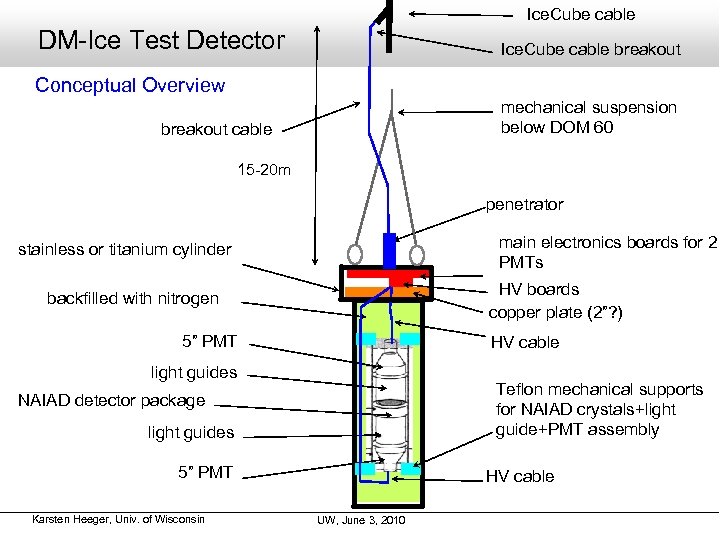

Ice. Cube cable DM-Ice Test Detector Ice. Cube cable breakout Conceptual Overview mechanical suspension below DOM 60 breakout cable 15 -20 m penetrator main electronics boards for 2 PMTs stainless or titanium cylinder HV boards copper plate (2”? ) backfilled with nitrogen 5” PMT HV cable light guides Teflon mechanical supports for NAIAD crystals+light guide+PMT assembly NAIAD detector package light guides 5” PMT Karsten Heeger, Univ. of Wisconsin HV cable UW, June 3, 2010

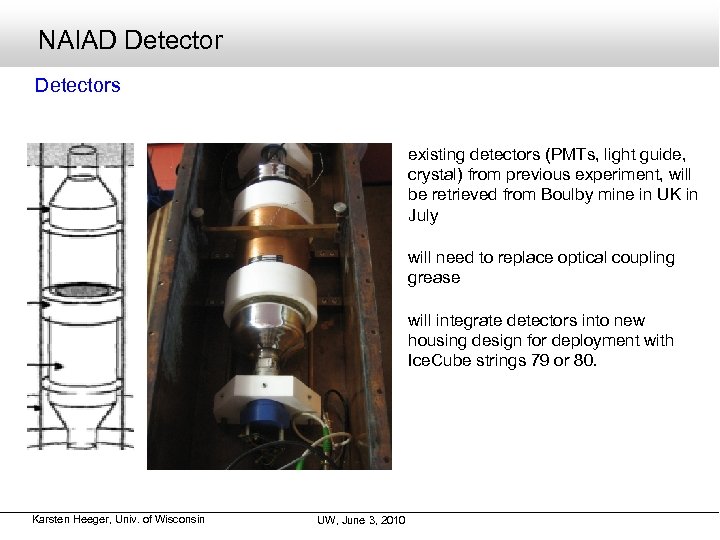

NAIAD Detectors existing detectors (PMTs, light guide, crystal) from previous experiment, will be retrieved from Boulby mine in UK in July will need to replace optical coupling grease will integrate detectors into new housing design for deployment with Ice. Cube strings 79 or 80. Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

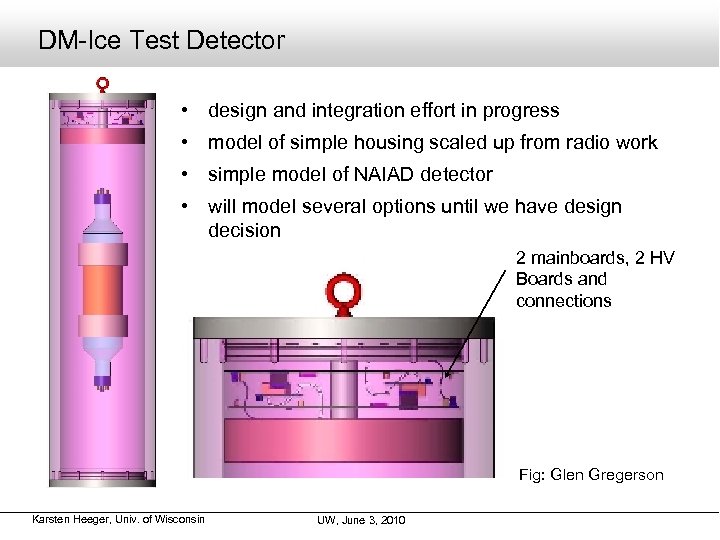

DM-Ice Test Detector • design and integration effort in progress • model of simple housing scaled up from radio work • simple model of NAIAD detector • will model several options until we have design decision 2 mainboards, 2 HV Boards and connections Fig: Glen Gregerson Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

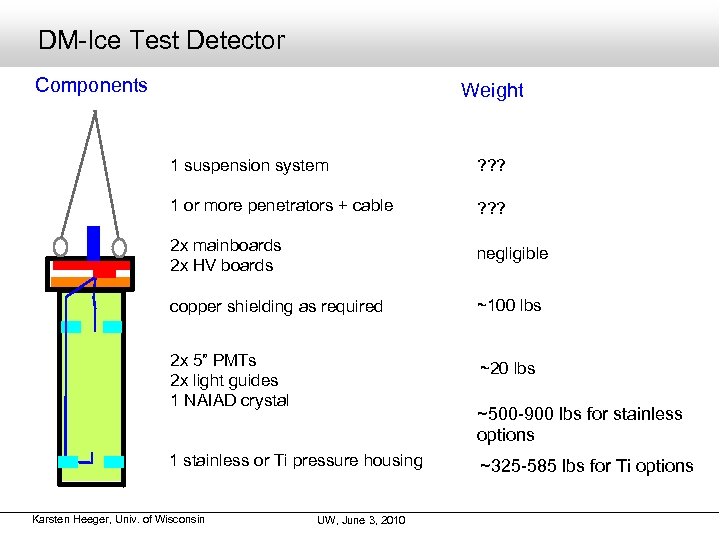

DM-Ice Test Detector Components Weight 1 suspension system ? ? ? 1 or more penetrators + cable ? ? ? 2 x mainboards 2 x HV boards negligible copper shielding as required ~100 lbs 2 x 5” PMTs 2 x light guides 1 NAIAD crystal ~20 lbs ~500 -900 lbs for stainless options 1 stainless or Ti pressure housing Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010 ~325 -585 lbs for Ti options

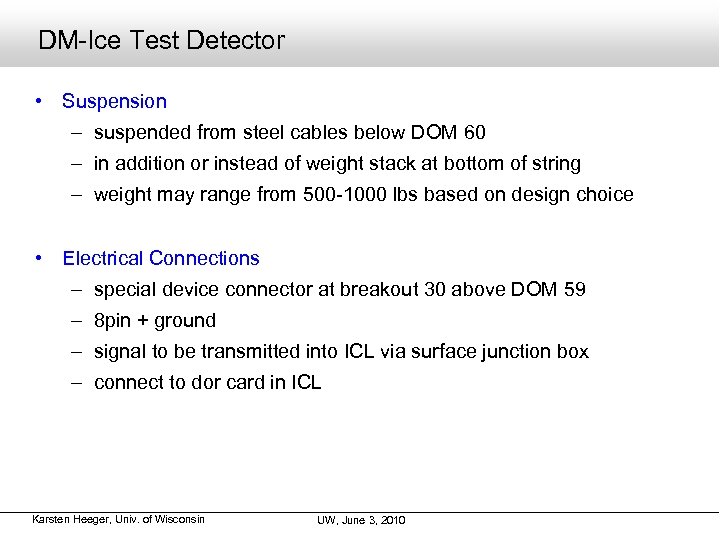

DM-Ice Test Detector • Suspension – suspended from steel cables below DOM 60 – in addition or instead of weight stack at bottom of string – weight may range from 500 -1000 lbs based on design choice • Electrical Connections – special device connector at breakout 30 above DOM 59 – 8 pin + ground – signal to be transmitted into ICL via surface junction box – connect to dor card in ICL Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

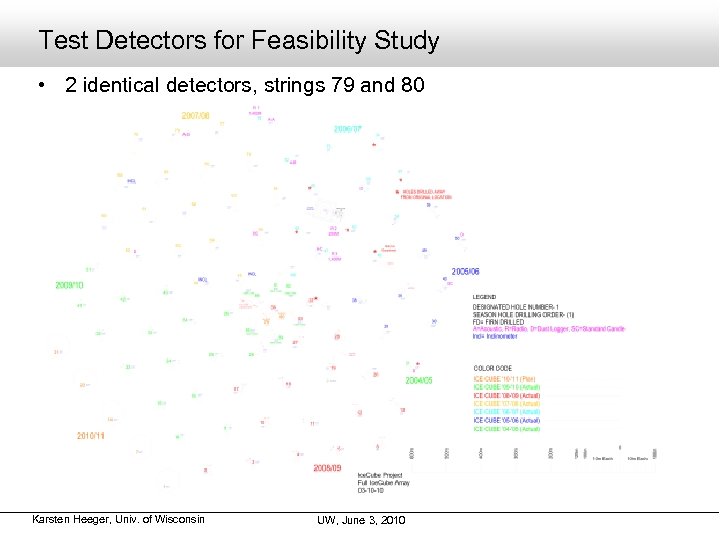

Test Detectors for Feasibility Study • 2 identical detectors, strings 79 and 80 Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

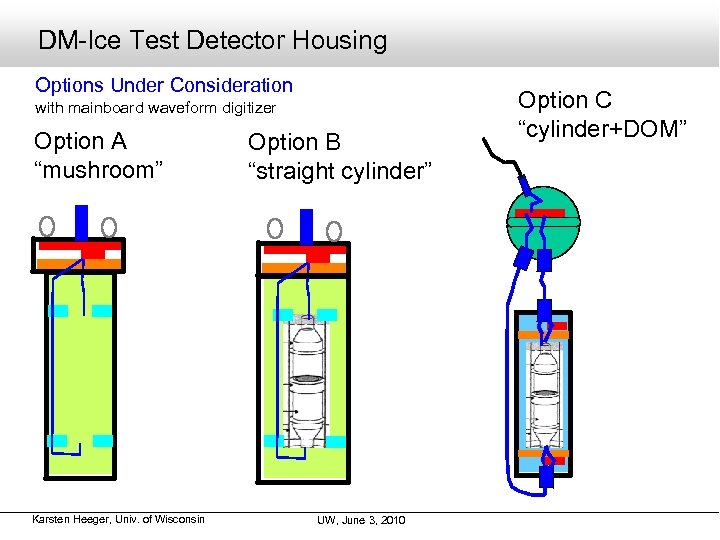

DM-Ice Test Detector Housing Options Under Consideration with mainboard waveform digitizer Option A “mushroom” Karsten Heeger, Univ. of Wisconsin Option B “straight cylinder” UW, June 3, 2010 Option C “cylinder+DOM”

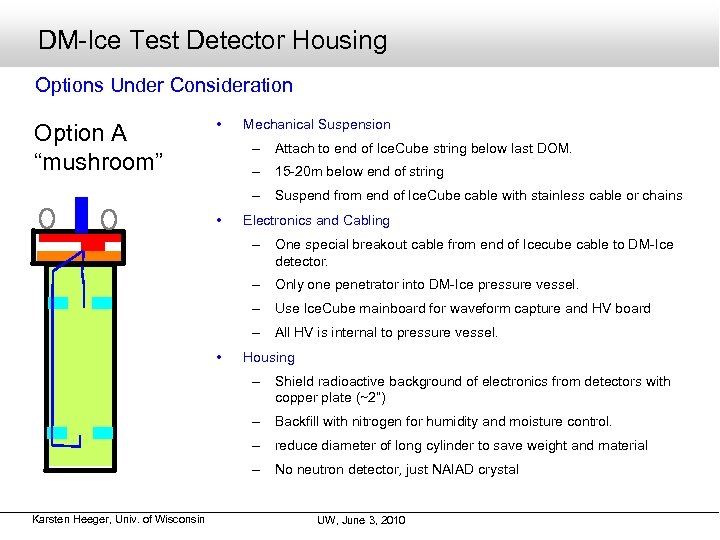

DM-Ice Test Detector Housing Options Under Consideration Option A “mushroom” • Mechanical Suspension – Attach to end of Ice. Cube string below last DOM. – 15 -20 m below end of string – Suspend from end of Ice. Cube cable with stainless cable or chains • Electronics and Cabling – One special breakout cable from end of Icecube cable to DM-Ice detector. – Only one penetrator into DM-Ice pressure vessel. – Use Ice. Cube mainboard for waveform capture and HV board – All HV is internal to pressure vessel. • Housing – Shield radioactive background of electronics from detectors with copper plate (~2”) – Backfill with nitrogen for humidity and moisture control. – reduce diameter of long cylinder to save weight and material – No neutron detector, just NAIAD crystal Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

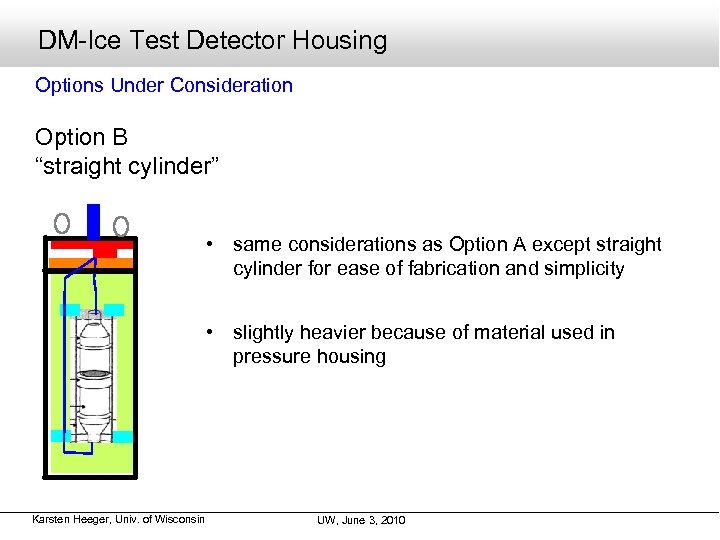

DM-Ice Test Detector Housing Options Under Consideration Option B “straight cylinder” • same considerations as Option A except straight cylinder for ease of fabrication and simplicity • slightly heavier because of material used in pressure housing Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

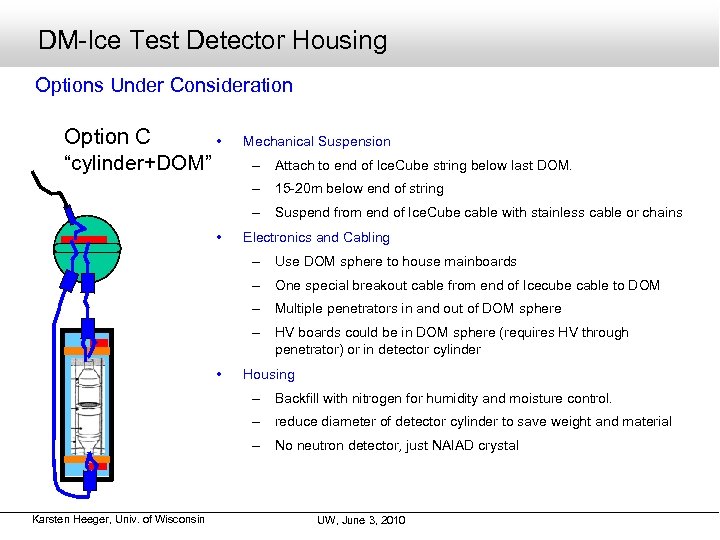

DM-Ice Test Detector Housing Options Under Consideration Option C • “cylinder+DOM” Mechanical Suspension – Attach to end of Ice. Cube string below last DOM. – 15 -20 m below end of string – Suspend from end of Ice. Cube cable with stainless cable or chains • Electronics and Cabling – Use DOM sphere to house mainboards – One special breakout cable from end of Icecube cable to DOM – Multiple penetrators in and out of DOM sphere – HV boards could be in DOM sphere (requires HV through penetrator) or in detector cylinder • Housing – Backfill with nitrogen for humidity and moisture control. – reduce diameter of detector cylinder to save weight and material – No neutron detector, just NAIAD crystal Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

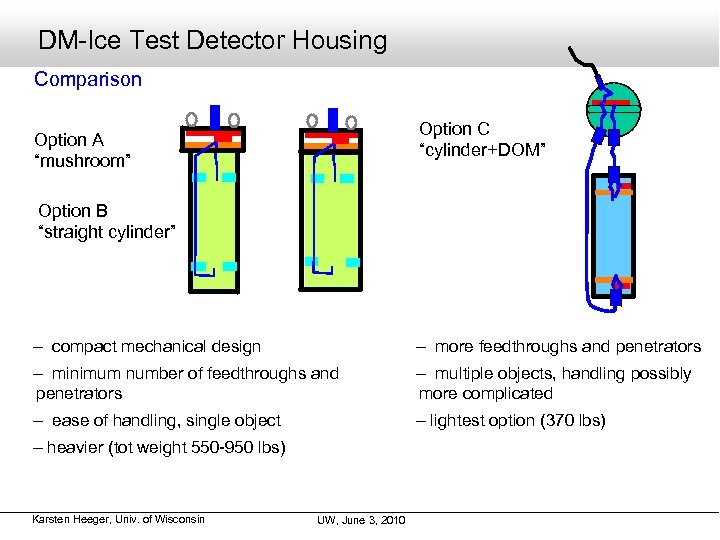

DM-Ice Test Detector Housing Comparison Option C “cylinder+DOM” Option A “mushroom” Option B “straight cylinder” – compact mechanical design – more feedthroughs and penetrators – minimum number of feedthroughs and penetrators – multiple objects, handling possibly more complicated – ease of handling, single object – lightest option (370 lbs) – heavier (tot weight 550 -950 lbs) Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

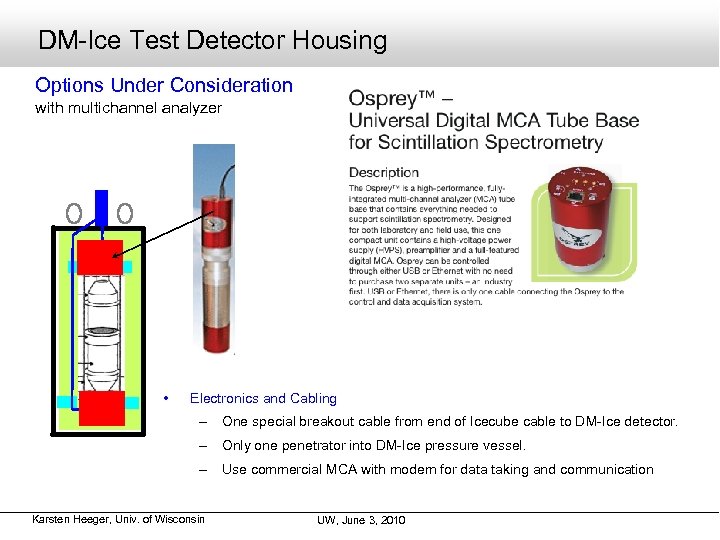

DM-Ice Test Detector Housing Options Under Consideration with multichannel analyzer • Electronics and Cabling – One special breakout cable from end of Icecube cable to DM-Ice detector. – Only one penetrator into DM-Ice pressure vessel. – Use commercial MCA with modem for data taking and communication Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

Logistics of DM-Ice Detector • Shipment – by air from Madison by Oct 22, 2010 – special shipping box, expected total weight ~ 800 -1000 lbs per detector – constrains on shipping box (pallet size) • Storage – on surface, do not worry about cosmic activation for feasibility study – temperature variations from +30 to -40 deg C OK • Pre-deployment tests at Pole – unpacking from shipping box and visual inspection of outside – suspend detector from lifting eyes or set up in stand – HV electrical test and readout of detector’s PMT signal in test station • Handling at Pole – forklift with boom for positioning – frame or crate with wheels for easy of movement – winch inside tents for pre-deployment tests and for deployment? • Anticipated deployment date – Dec 15, 2010 Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

Special Equipment for DM-Ice Detector Deployment • Equipment Needs for Transport and Handling – watertight shipping and storage box – frame with wheels for handling and positioning – boom forklift? – frame or winch in test tent for detector handling during pre-deployment tests – frame or winch in TOS for detector handling during deployment activities • Equipment Needs for Pre-Deployment Tests – power supply – DAQ – computer setup at Pole – can we use existing facilities for predeployment tests? • ICL • OML Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

Logistics of DM-Ice Detector • Assumptions in planning transport and handling of detector feasibility study – ensure mechanical integrity of detector – maximize integration and testing time in Madison to minimize risk of failure – do not worry about cosmogenic activation during air shipment for this feasibility study – allow pre-deployment functionality tests at Pole – minimize storage time on ice (as much as reasonably possible) Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

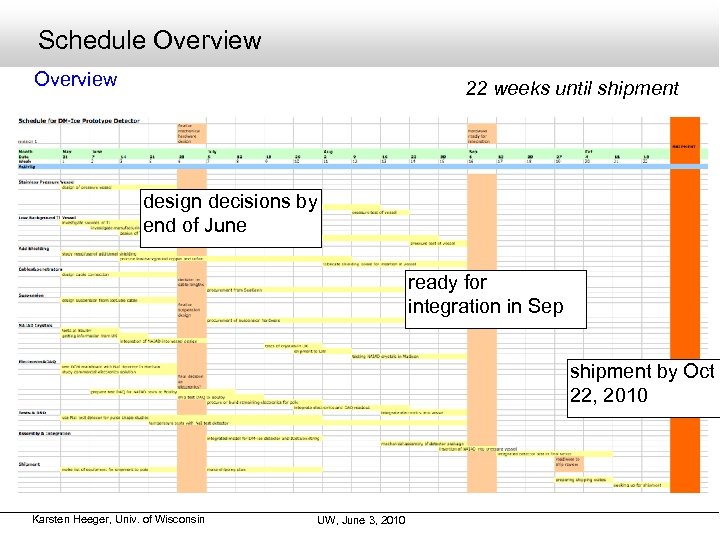

Schedule Overview 22 weeks until shipment design decisions by end of June ready for integration in Sep shipment by Oct 22, 2010 Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

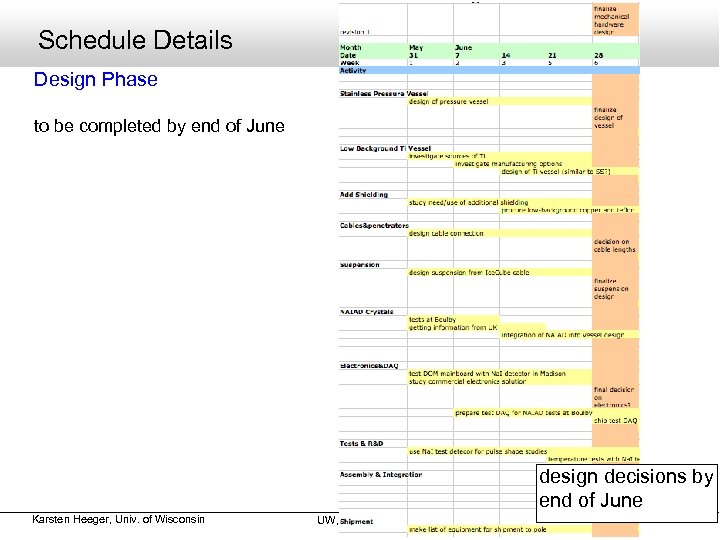

Schedule Details Design Phase to be completed by end of June design decisions by end of June Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

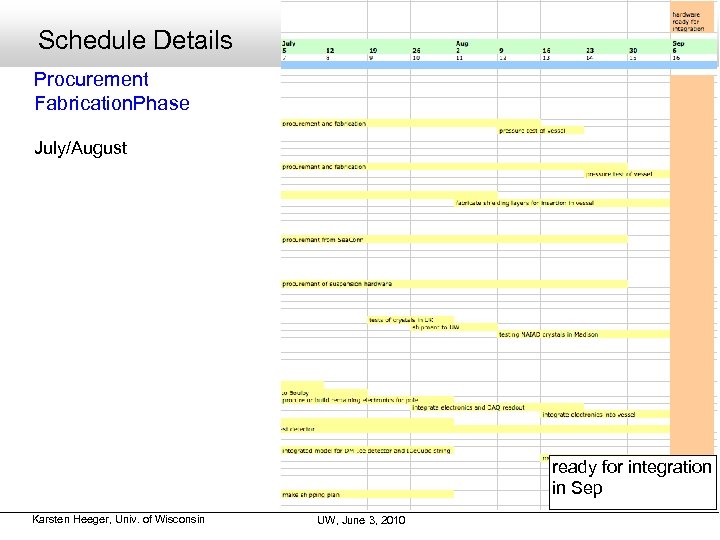

Schedule Details Procurement Fabrication. Phase July/August ready for integration in Sep Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

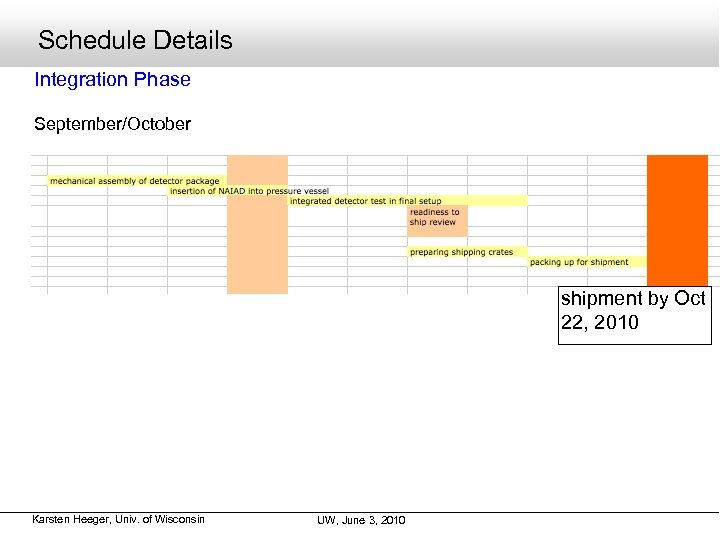

Schedule Details Integration Phase September/October shipment by Oct 22, 2010 Karsten Heeger, Univ. of Wisconsin UW, June 3, 2010

a55fbcb07fea2350070a56702b2a6aa8.ppt