07d4d48db1ab0173070bb641c07dce11.ppt

- Количество слайдов: 26

The development of the new generation ground wire for lightning protection of overhead transmission lines

The development of the new generation ground wire for lightning protection of overhead transmission lines

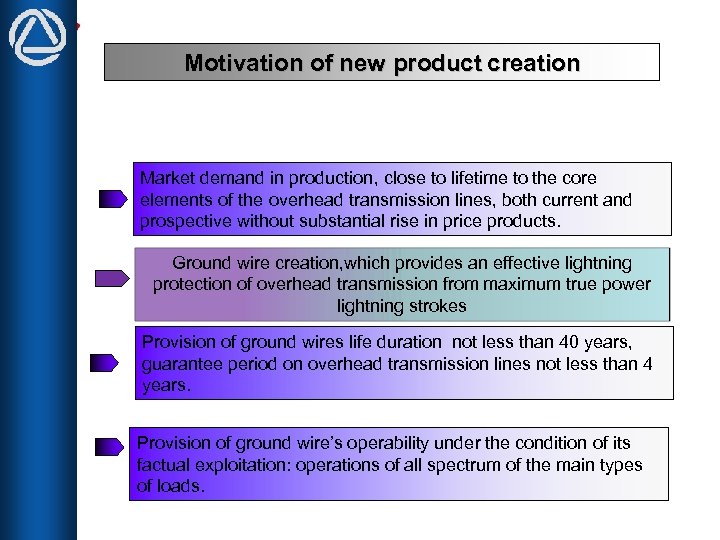

Motivation of new product creation Market demand in production, close to lifetime to the core elements of the overhead transmission lines, both current and prospective without substantial rise in price products. Ground wire creation, which provides an effective lightning protection of overhead transmission from maximum true power lightning strokes Provision of ground wires life duration not less than 40 years, guarantee period on overhead transmission lines not less than 4 years. Provision of ground wire’s operability under the condition of its factual exploitation: operations of all spectrum of the main types of loads.

Motivation of new product creation Market demand in production, close to lifetime to the core elements of the overhead transmission lines, both current and prospective without substantial rise in price products. Ground wire creation, which provides an effective lightning protection of overhead transmission from maximum true power lightning strokes Provision of ground wires life duration not less than 40 years, guarantee period on overhead transmission lines not less than 4 years. Provision of ground wire’s operability under the condition of its factual exploitation: operations of all spectrum of the main types of loads.

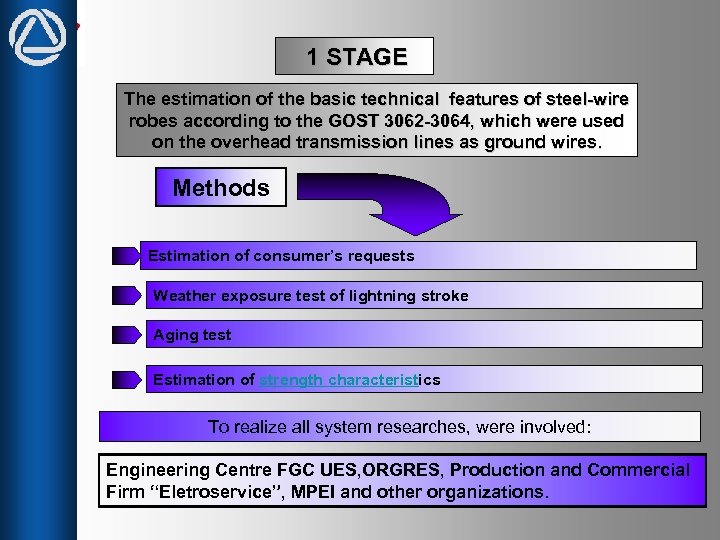

1 STAGE The estimation of the basic technical features of steel-wire robes according to the GOST 3062 -3064, which were used on the overhead transmission lines as ground wires. Methods Estimation of consumer’s requests Weather exposure test of lightning stroke Aging test Estimation of strength characteristics To realize all system researches, were involved: Engineering Centre FGC UES, ORGRES, Production and Commercial Firm “Eletroservice”, MPEI and other organizations.

1 STAGE The estimation of the basic technical features of steel-wire robes according to the GOST 3062 -3064, which were used on the overhead transmission lines as ground wires. Methods Estimation of consumer’s requests Weather exposure test of lightning stroke Aging test Estimation of strength characteristics To realize all system researches, were involved: Engineering Centre FGC UES, ORGRES, Production and Commercial Firm “Eletroservice”, MPEI and other organizations.

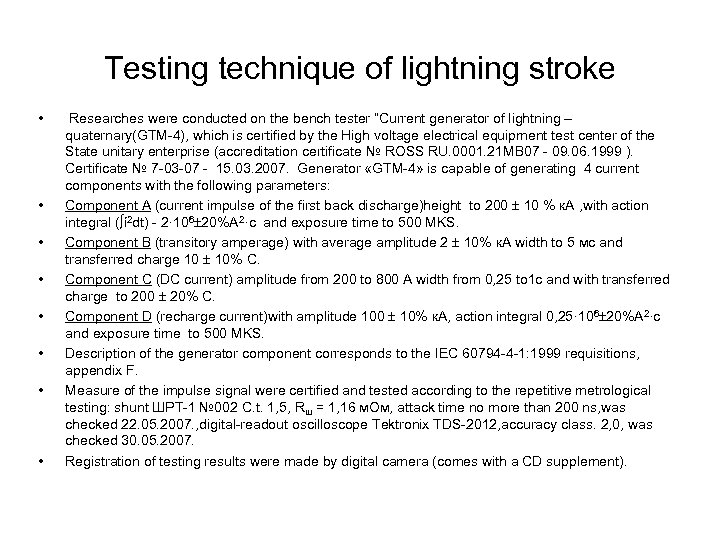

Testing technique of lightning stroke • • Researches were conducted on the bench tester “Current generator of lightning – quaternary(GTM-4), which is certified by the High voltage electrical equipment test center of the State unitary enterprise (accreditation certificate № ROSS RU. 0001. 21 MB 07 - 09. 06. 1999 ). Certificate № 7 -03 -07 - 15. 03. 2007. Generator «GTM-4» is capable of generating 4 current components with the following parameters: Component А (current impulse of the first back discharge)height to 200 10 % к. А , with action integral (∫ί 2 dt) - 2· 106 20%А 2·с and exposure time to 500 MKS. Component В (transitory amperage) with average amplitude 2 10% к. А width to 5 мс and transferred charge 10 10% C. Component С (DC current) amplitude from 200 to 800 А width from 0, 25 to 1 c and with transferred charge to 200 20% C. Component D (recharge current)with amplitude 100 10% к. А, action integral 0, 25· 106 20%А 2·с and exposure time to 500 MKS. Description of the generator component corresponds to the IEC 60794 -4 -1: 1999 requisitions, appendix F. Measure of the impulse signal were certified and tested according to the repetitive metrological testing: shunt ШРТ-1 № 002 C. t. 1, 5, Rш = 1, 16 м. Ом, attack time no more than 200 ns, was checked 22. 05. 2007. , digital-readout oscilloscope Tektronix TDS-2012, accuracy class. 2, 0, was checked 30. 05. 2007. Registration of testing results were made by digital camera (comes with a CD supplement).

Testing technique of lightning stroke • • Researches were conducted on the bench tester “Current generator of lightning – quaternary(GTM-4), which is certified by the High voltage electrical equipment test center of the State unitary enterprise (accreditation certificate № ROSS RU. 0001. 21 MB 07 - 09. 06. 1999 ). Certificate № 7 -03 -07 - 15. 03. 2007. Generator «GTM-4» is capable of generating 4 current components with the following parameters: Component А (current impulse of the first back discharge)height to 200 10 % к. А , with action integral (∫ί 2 dt) - 2· 106 20%А 2·с and exposure time to 500 MKS. Component В (transitory amperage) with average amplitude 2 10% к. А width to 5 мс and transferred charge 10 10% C. Component С (DC current) amplitude from 200 to 800 А width from 0, 25 to 1 c and with transferred charge to 200 20% C. Component D (recharge current)with amplitude 100 10% к. А, action integral 0, 25· 106 20%А 2·с and exposure time to 500 MKS. Description of the generator component corresponds to the IEC 60794 -4 -1: 1999 requisitions, appendix F. Measure of the impulse signal were certified and tested according to the repetitive metrological testing: shunt ШРТ-1 № 002 C. t. 1, 5, Rш = 1, 16 м. Ом, attack time no more than 200 ns, was checked 22. 05. 2007. , digital-readout oscilloscope Tektronix TDS-2012, accuracy class. 2, 0, was checked 30. 05. 2007. Registration of testing results were made by digital camera (comes with a CD supplement).

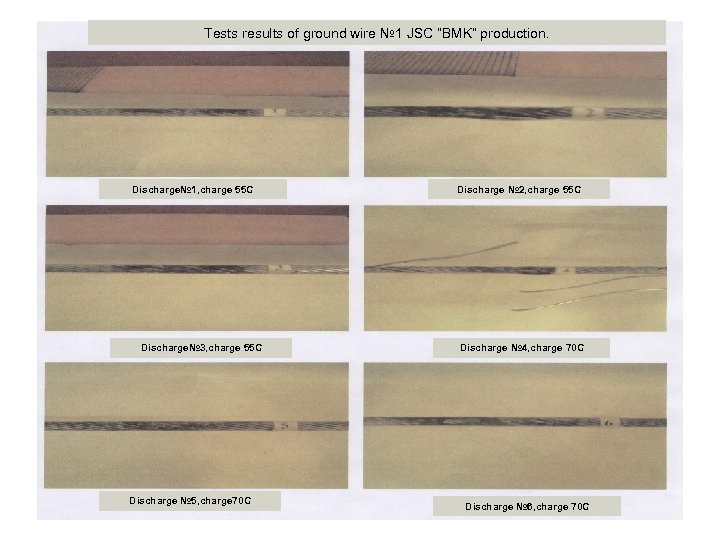

Tests results of ground wire № 1 JSC “BMK” production. Discharge№ 1, charge 55 C Discharge№ 3, charge 55 C Discharge № 5, charge 70 C Discharge № 2, charge 55 C Discharge № 4, charge 70 C Discharge № 6, charge 70 C

Tests results of ground wire № 1 JSC “BMK” production. Discharge№ 1, charge 55 C Discharge№ 3, charge 55 C Discharge № 5, charge 70 C Discharge № 2, charge 55 C Discharge № 4, charge 70 C Discharge № 6, charge 70 C

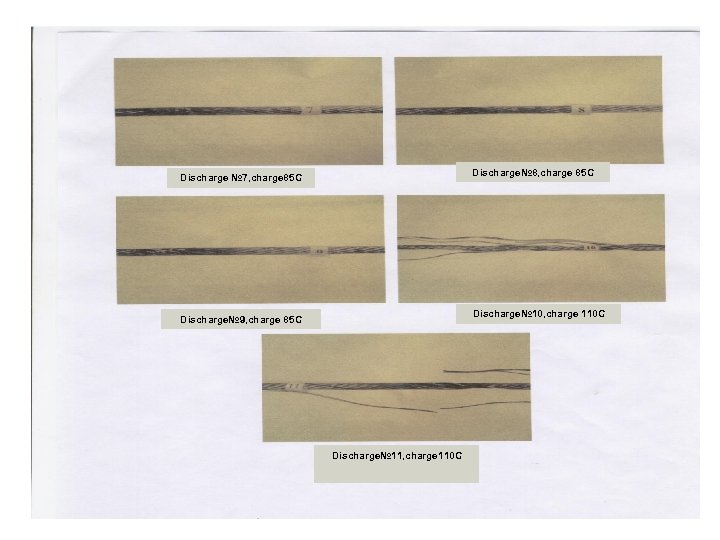

Discharge№ 8, charge 85 C Discharge № 7, charge 85 C Discharge№ 10, charge 110 C Discharge№ 9, charge 85 C Discharge№ 11, charge 110 C

Discharge№ 8, charge 85 C Discharge № 7, charge 85 C Discharge№ 10, charge 110 C Discharge№ 9, charge 85 C Discharge№ 11, charge 110 C

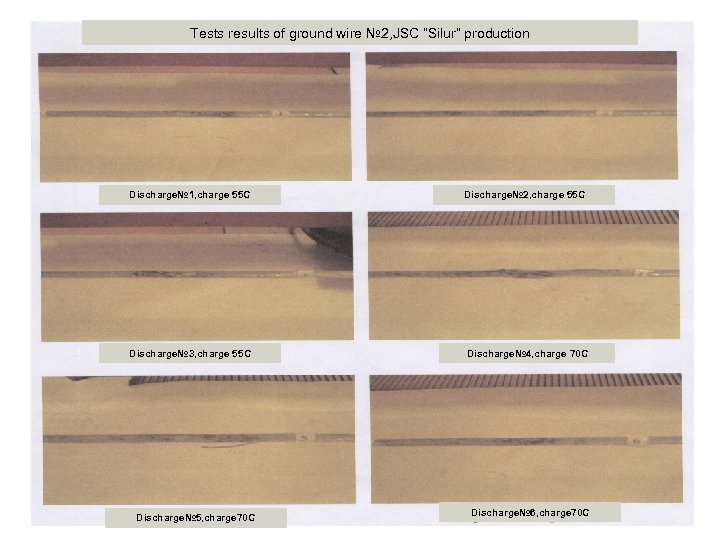

Tests results of ground wire № 2, JSC “Silur” production Discharge№ 1, charge 55 C Discharge№ 2, charge 55 C Discharge№ 3, charge 55 C Discharge№ 4, charge 70 C Discharge№ 5, charge 70 C Discharge№ 6, charge 70 C

Tests results of ground wire № 2, JSC “Silur” production Discharge№ 1, charge 55 C Discharge№ 2, charge 55 C Discharge№ 3, charge 55 C Discharge№ 4, charge 70 C Discharge№ 5, charge 70 C Discharge№ 6, charge 70 C

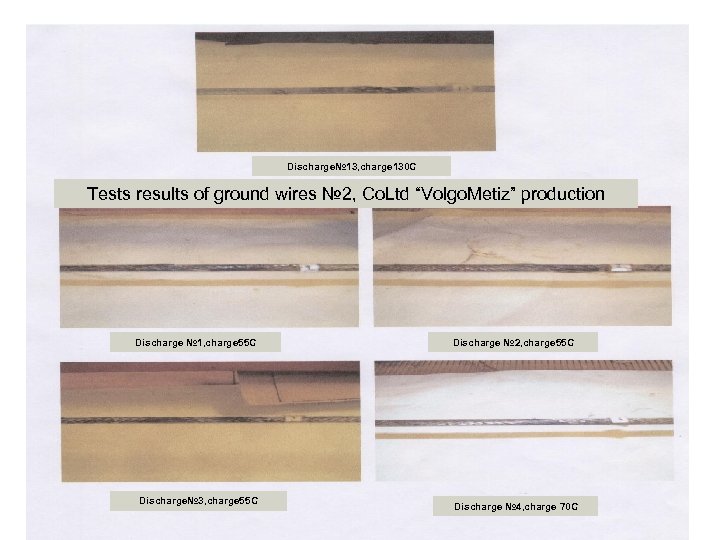

Discharge№ 13, charge 130 C Tests results of ground wires № 2, Co. Ltd “Volgo. Metiz” production Discharge № 1, charge 55 C Discharge№ 3, charge 55 C Discharge № 2, charge 55 C Discharge № 4, charge 70 C

Discharge№ 13, charge 130 C Tests results of ground wires № 2, Co. Ltd “Volgo. Metiz” production Discharge № 1, charge 55 C Discharge№ 3, charge 55 C Discharge № 2, charge 55 C Discharge № 4, charge 70 C

Discharge№ 11, charge 110 C

Discharge№ 11, charge 110 C

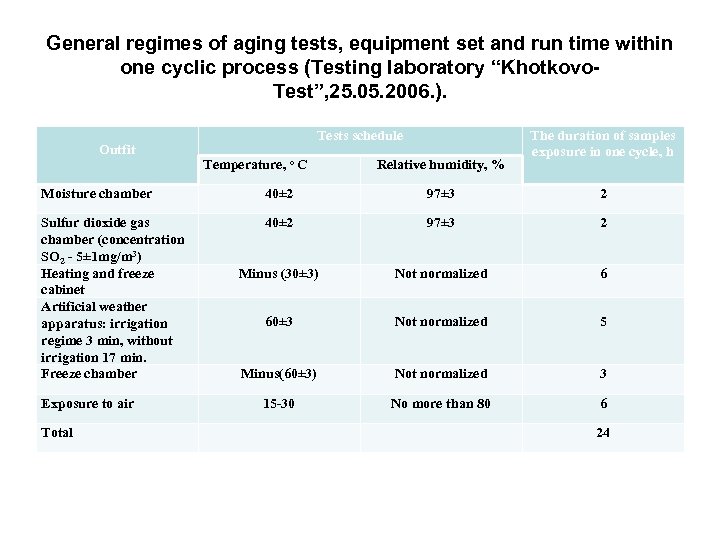

General regimes of aging tests, equipment set and run time within one cyclic process (Testing laboratory “Khotkovo. Test”, 25. 05. 2006. ). Outfit Tests schedule Temperature, о С Relative humidity, % The duration of samples exposure in one cycle, h Moisture chamber 40± 2 97± 3 2 Sulfur dioxide gas chamber (concentration SO 2 - 5± 1 mg/m 3) Heating and freeze cabinet Artificial weather apparatus: irrigation regime 3 min, without irrigation 17 min. Freeze chamber 40± 2 97± 3 2 Minus (30± 3) Not normalized 6 60± 3 Not normalized 5 Minus(60± 3) Not normalized 3 15 -30 No more than 80 6 Exposure to air Total 24

General regimes of aging tests, equipment set and run time within one cyclic process (Testing laboratory “Khotkovo. Test”, 25. 05. 2006. ). Outfit Tests schedule Temperature, о С Relative humidity, % The duration of samples exposure in one cycle, h Moisture chamber 40± 2 97± 3 2 Sulfur dioxide gas chamber (concentration SO 2 - 5± 1 mg/m 3) Heating and freeze cabinet Artificial weather apparatus: irrigation regime 3 min, without irrigation 17 min. Freeze chamber 40± 2 97± 3 2 Minus (30± 3) Not normalized 6 60± 3 Not normalized 5 Minus(60± 3) Not normalized 3 15 -30 No more than 80 6 Exposure to air Total 24

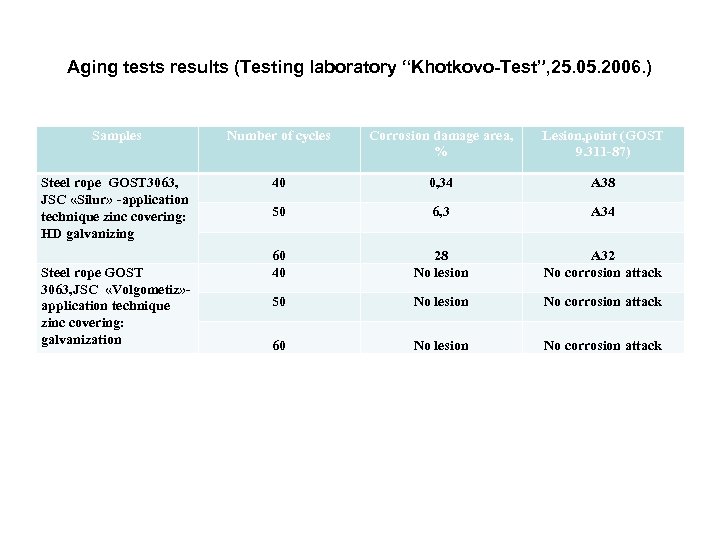

Aging tests results (Testing laboratory “Khotkovo-Test”, 25. 05. 2006. ) Samples Number of cycles Corrosion damage area, % Lesion, point (GOST 9. 311 -87) Steel rope GOST 3063, JSC «Silur» -application technique zinc covering: HD galvanizing 40 0, 34 А 38 50 6, 3 А 34 60 40 28 No lesion А 32 No corrosion attack 50 No lesion No corrosion attack 60 No lesion No corrosion attack Steel rope GOST 3063, JSC «Volgometiz» application technique zinc covering: galvanization

Aging tests results (Testing laboratory “Khotkovo-Test”, 25. 05. 2006. ) Samples Number of cycles Corrosion damage area, % Lesion, point (GOST 9. 311 -87) Steel rope GOST 3063, JSC «Silur» -application technique zinc covering: HD galvanizing 40 0, 34 А 38 50 6, 3 А 34 60 40 28 No lesion А 32 No corrosion attack 50 No lesion No corrosion attack 60 No lesion No corrosion attack Steel rope GOST 3063, JSC «Volgometiz» application technique zinc covering: galvanization

Basic conclusions about the study of steel ropes according to GOST 3062 -3064 The increase of working time in the process of galvanization (JSC «Sevestal-metiz» technology). The increase of lightning stroke durability in the process of the increase of preformation degree (JSC «Severstal-Metiz» technology). Total loss of service outage in the process of cumulative effect of discharge within the range 40 -85 C. The reduction of the aggregate breaking tension after the lightning exposure of all represented steel ropes.

Basic conclusions about the study of steel ropes according to GOST 3062 -3064 The increase of working time in the process of galvanization (JSC «Sevestal-metiz» technology). The increase of lightning stroke durability in the process of the increase of preformation degree (JSC «Severstal-Metiz» technology). Total loss of service outage in the process of cumulative effect of discharge within the range 40 -85 C. The reduction of the aggregate breaking tension after the lightning exposure of all represented steel ropes.

2 Stage The development of ground wires for overhead transmission lines according to the STO (Standards of organization) 71915393–TU (Specifications) 062– 2008 Development peculiarity Novelty design of the ground wire according to 71915393–TU (Specifications) 062– 2008(ground wire)for the electric power transmission protection from direct lightning strokes consists in the lay consolidation technology, provision of line contact wires and line contact of wires provision, use of the wires outer layer of the plastic straining to enlarge contact area between outer and inner armor wires. This construction provides the reduction of linear extension (confirmation patent of the R. F. ). Galvanical method application of coating to a tolerance of +5% prevents zinc layer at increases current and elevated temperature (short circuit), (it increases service life, this product is different from the previous one). Utilize technology of the lay has no parallel in the Russian Federation, the technology of application of zinc coating is comparable to the technique, which is used by Volgograd plant - JSC Severstal-Metiz in a process of production cable and wire bridges. Constructive result 40 years of service life and 20 years of exploitation under the influence of all types of loads.

2 Stage The development of ground wires for overhead transmission lines according to the STO (Standards of organization) 71915393–TU (Specifications) 062– 2008 Development peculiarity Novelty design of the ground wire according to 71915393–TU (Specifications) 062– 2008(ground wire)for the electric power transmission protection from direct lightning strokes consists in the lay consolidation technology, provision of line contact wires and line contact of wires provision, use of the wires outer layer of the plastic straining to enlarge contact area between outer and inner armor wires. This construction provides the reduction of linear extension (confirmation patent of the R. F. ). Galvanical method application of coating to a tolerance of +5% prevents zinc layer at increases current and elevated temperature (short circuit), (it increases service life, this product is different from the previous one). Utilize technology of the lay has no parallel in the Russian Federation, the technology of application of zinc coating is comparable to the technique, which is used by Volgograd plant - JSC Severstal-Metiz in a process of production cable and wire bridges. Constructive result 40 years of service life and 20 years of exploitation under the influence of all types of loads.

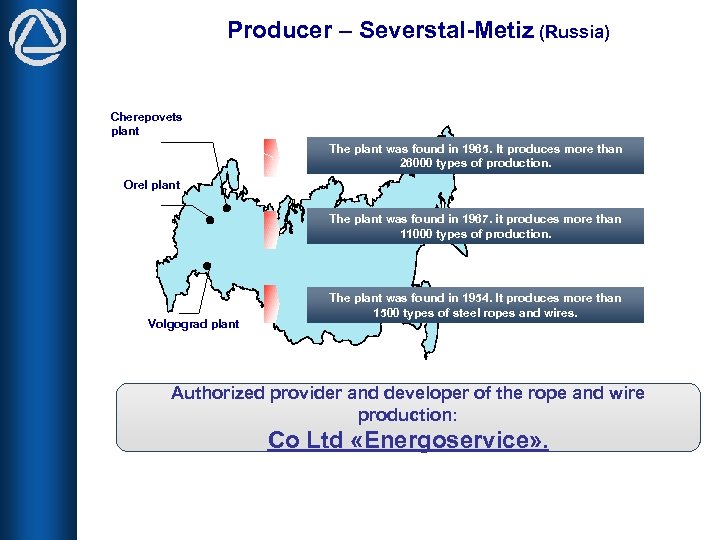

Producer – Severstal-Metiz (Russia) Cherepovets plant The plant was found in 1965. It produces more than 26000 types of production. Orel plant The plant was found in 1967. it produces more than 11000 types of production. Volgograd plant The plant was found in 1954. It produces more than 1500 types of steel ropes and wires. Authorized provider and developer of the rope and wire production: Co Ltd «Energoservice» .

Producer – Severstal-Metiz (Russia) Cherepovets plant The plant was found in 1965. It produces more than 26000 types of production. Orel plant The plant was found in 1967. it produces more than 11000 types of production. Volgograd plant The plant was found in 1954. It produces more than 1500 types of steel ropes and wires. Authorized provider and developer of the rope and wire production: Co Ltd «Energoservice» .

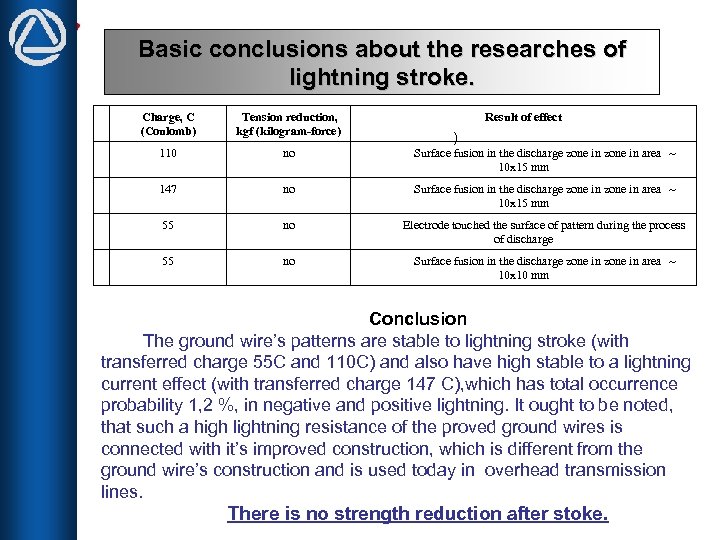

Basic conclusions about the researches of lightning stroke. Charge, C (Coulomb) Tension reduction, kgf (kilogram-force) Result of effect 110 no Surface fusion in the discharge zone in area ~ 10 х15 mm 147 no Surface fusion in the discharge zone in area ~ 10 х15 mm 55 no Electrode touched the surface of pattern during the process of discharge 55 no Surface fusion in the discharge zone in area ~ 10 х10 mm ) Conclusion The ground wire’s patterns are stable to lightning stroke (with transferred charge 55 C and 110 C) and also have high stable to a lightning current effect (with transferred charge 147 C), which has total occurrence probability 1, 2 %, in negative and positive lightning. It ought to be noted, that such a high lightning resistance of the proved ground wires is connected with it’s improved construction, which is different from the ground wire’s construction and is used today in overhead transmission lines. There is no strength reduction after stoke.

Basic conclusions about the researches of lightning stroke. Charge, C (Coulomb) Tension reduction, kgf (kilogram-force) Result of effect 110 no Surface fusion in the discharge zone in area ~ 10 х15 mm 147 no Surface fusion in the discharge zone in area ~ 10 х15 mm 55 no Electrode touched the surface of pattern during the process of discharge 55 no Surface fusion in the discharge zone in area ~ 10 х10 mm ) Conclusion The ground wire’s patterns are stable to lightning stroke (with transferred charge 55 C and 110 C) and also have high stable to a lightning current effect (with transferred charge 147 C), which has total occurrence probability 1, 2 %, in negative and positive lightning. It ought to be noted, that such a high lightning resistance of the proved ground wires is connected with it’s improved construction, which is different from the ground wire’s construction and is used today in overhead transmission lines. There is no strength reduction after stoke.

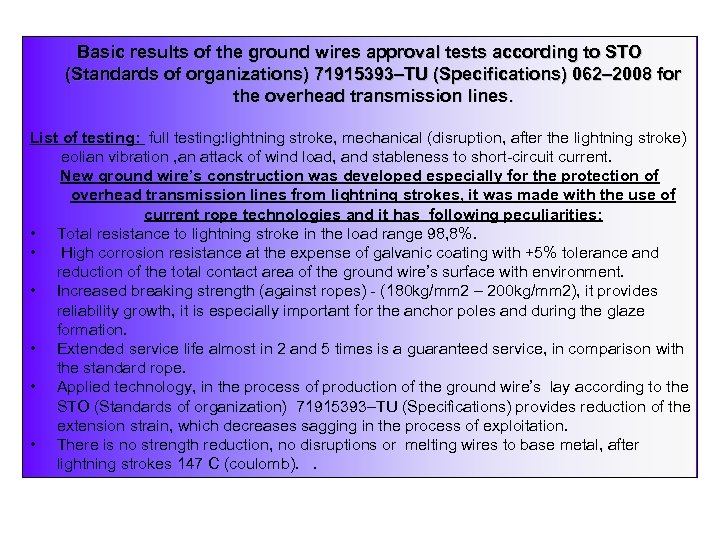

Basic results of the ground wires approval tests according to STO (Standards of organizations) 71915393–TU (Specifications) 062– 2008 for the overhead transmission lines. List of testing: full testing: lightning stroke, mechanical (disruption, after the lightning stroke) eolian vibration , an attack of wind load, and stableness to short-circuit current. New ground wire’s construction was developed especially for the protection of overhead transmission lines from lightning strokes, it was made with the use of current rope technologies and it has following peculiarities: • Total resistance to lightning stroke in the load range 98, 8%. • High corrosion resistance at the expense of galvanic coating with +5% tolerance and reduction of the total contact area of the ground wire’s surface with environment. • Increased breaking strength (against ropes) - (180 kg/mm 2 – 200 kg/mm 2), it provides reliability growth, it is especially important for the anchor poles and during the glaze formation. • Extended service life almost in 2 and 5 times is a guaranteed service, in comparison with the standard rope. • Applied technology, in the process of production of the ground wire’s lay according to the STO (Standards of organization) 71915393–TU (Specifications) provides reduction of the extension strain, which decreases sagging in the process of exploitation. • There is no strength reduction, no disruptions or melting wires to base metal, after lightning strokes 147 C (coulomb). .

Basic results of the ground wires approval tests according to STO (Standards of organizations) 71915393–TU (Specifications) 062– 2008 for the overhead transmission lines. List of testing: full testing: lightning stroke, mechanical (disruption, after the lightning stroke) eolian vibration , an attack of wind load, and stableness to short-circuit current. New ground wire’s construction was developed especially for the protection of overhead transmission lines from lightning strokes, it was made with the use of current rope technologies and it has following peculiarities: • Total resistance to lightning stroke in the load range 98, 8%. • High corrosion resistance at the expense of galvanic coating with +5% tolerance and reduction of the total contact area of the ground wire’s surface with environment. • Increased breaking strength (against ropes) - (180 kg/mm 2 – 200 kg/mm 2), it provides reliability growth, it is especially important for the anchor poles and during the glaze formation. • Extended service life almost in 2 and 5 times is a guaranteed service, in comparison with the standard rope. • Applied technology, in the process of production of the ground wire’s lay according to the STO (Standards of organization) 71915393–TU (Specifications) provides reduction of the extension strain, which decreases sagging in the process of exploitation. • There is no strength reduction, no disruptions or melting wires to base metal, after lightning strokes 147 C (coulomb). .

Main points of specifications to the ground wire МЗ-В-OЖ- Н-Р* STO (Standards of organization) 71915393 -TU (Specifications) 0622008, which realization is guaranteed by plant JSC «Severstal-Metiz» Ground wires should be up to quality of the standard and STO (Standards of organization) 56947007 -29. 060. 50. 015 -2008 Technical requirements JSC “FGC UES”. • Ground wires ( marking groups 1770 n/mm 2 (180 kgf/mm 2), 1870 n/mm 2 (190 kgf/mm 2), 1970 n/mm 2 (200 kgf/mm 2)) are made from galvanized wire, according to the GOST 7372 -79, gauge of zinc covering should correspond to the “ОЖ”(extra hard) group with the positive tolerance 5%. • Ground wires are made length at least 500 meters. • Ground wire should be resistant to impulse of the lightning discharge, which size (in Coulombs) is defined by the ground wire suspension, according to the consumer requirements and is installed by manufacturer (if it has an appendix – tensile load, according to the STO (Standards of organization) 56947007 -29. 060. 50. 015 -2008 Technical requirements JSC «FGC UES» , at least 85 C. • Ground wire should be resistant to thermal influence of short circuit current, appearing in the process of the ground wire’s exploitation with single and double phase to earth fault, which size and time is installed by manufacturer according to the STO (Standards of organization) 56947007 -29. 060. 50. 015 -2008 Technical requirements JSC «FGC UES» . (Lightning protection – premium quality – extra hard – nonspinning – straighten)*

Main points of specifications to the ground wire МЗ-В-OЖ- Н-Р* STO (Standards of organization) 71915393 -TU (Specifications) 0622008, which realization is guaranteed by plant JSC «Severstal-Metiz» Ground wires should be up to quality of the standard and STO (Standards of organization) 56947007 -29. 060. 50. 015 -2008 Technical requirements JSC “FGC UES”. • Ground wires ( marking groups 1770 n/mm 2 (180 kgf/mm 2), 1870 n/mm 2 (190 kgf/mm 2), 1970 n/mm 2 (200 kgf/mm 2)) are made from galvanized wire, according to the GOST 7372 -79, gauge of zinc covering should correspond to the “ОЖ”(extra hard) group with the positive tolerance 5%. • Ground wires are made length at least 500 meters. • Ground wire should be resistant to impulse of the lightning discharge, which size (in Coulombs) is defined by the ground wire suspension, according to the consumer requirements and is installed by manufacturer (if it has an appendix – tensile load, according to the STO (Standards of organization) 56947007 -29. 060. 50. 015 -2008 Technical requirements JSC «FGC UES» , at least 85 C. • Ground wire should be resistant to thermal influence of short circuit current, appearing in the process of the ground wire’s exploitation with single and double phase to earth fault, which size and time is installed by manufacturer according to the STO (Standards of organization) 56947007 -29. 060. 50. 015 -2008 Technical requirements JSC «FGC UES» . (Lightning protection – premium quality – extra hard – nonspinning – straighten)*

• Ground wire should be resistant to the eolian vibration at least 100 million cycles, which frequency should correspond to resonating frequency with wind speed from 4 to 8 ms (Frequency = 830/diameter of the ground wire in mm ± 10 Hz), with appendix of the tension load, which is installed by manufacturer, according to the STO (Standards of organization) 5694700729. 060. 50. 015 -2008 Technical requirements JSC «FGC UES» . • Ground wire should be resistant to the pitching (eolian vibration), in the process of its exploitation and under the influence of crosscut wind flow, alternate aerodynamic lift is appeared, which can create self-sustained oscillations, with the correlation of parallel and torsion motions of rope, STO (Standards of organization) 56947007 -29. 060. 50. 015 -2008 Technical requirements JSC «FGC UES» . • All others technical requirements should correspond to the GOST requirements 3241 -91 and STO (Standards of organization) 5694700729. 060. 50. 015 -2008 Technical requirements JSC «FGC UES» . • In accordance with article 13. 2, Technical requirements JSC «FGC UES» guarantee service life of the ground wires should form at least 20 years, from the moment of commencement of operation.

• Ground wire should be resistant to the eolian vibration at least 100 million cycles, which frequency should correspond to resonating frequency with wind speed from 4 to 8 ms (Frequency = 830/diameter of the ground wire in mm ± 10 Hz), with appendix of the tension load, which is installed by manufacturer, according to the STO (Standards of organization) 5694700729. 060. 50. 015 -2008 Technical requirements JSC «FGC UES» . • Ground wire should be resistant to the pitching (eolian vibration), in the process of its exploitation and under the influence of crosscut wind flow, alternate aerodynamic lift is appeared, which can create self-sustained oscillations, with the correlation of parallel and torsion motions of rope, STO (Standards of organization) 56947007 -29. 060. 50. 015 -2008 Technical requirements JSC «FGC UES» . • All others technical requirements should correspond to the GOST requirements 3241 -91 and STO (Standards of organization) 5694700729. 060. 50. 015 -2008 Technical requirements JSC «FGC UES» . • In accordance with article 13. 2, Technical requirements JSC «FGC UES» guarantee service life of the ground wires should form at least 20 years, from the moment of commencement of operation.

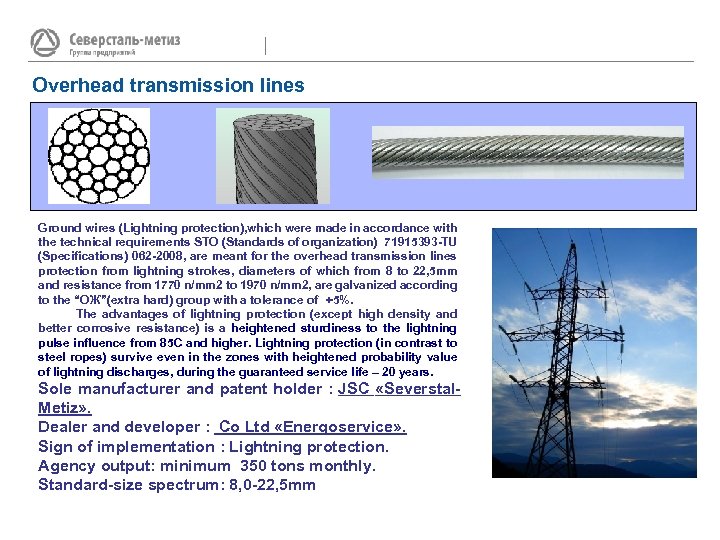

Overhead transmission lines Ground wires (Lightning protection), which were made in accordance with the technical requirements STO (Standards of organization) 71915393 -TU (Specifications) 062 -2008, are meant for the overhead transmission lines protection from lightning strokes, diameters of which from 8 to 22, 5 mm and resistance from 1770 n/mm 2 to 1970 n/mm 2, are galvanized according to the “ОЖ”(extra hard) group with a tolerance of +5%. The advantages of lightning protection (except high density and better corrosive resistance) is a heightened sturdiness to the lightning pulse influence from 85 C and higher. Lightning protection (in contrast to steel ropes) survive even in the zones with heightened probability value of lightning discharges, during the guaranteed service life – 20 years. Sole manufacturer and patent holder : JSC «Severstal. Metiz» . Dealer and developer : Co Ltd «Energoservice» . Sign of implementation : Lightning protection. Agency output: minimum 350 tons monthly. Standard-size spectrum: 8, 0 -22, 5 mm

Overhead transmission lines Ground wires (Lightning protection), which were made in accordance with the technical requirements STO (Standards of organization) 71915393 -TU (Specifications) 062 -2008, are meant for the overhead transmission lines protection from lightning strokes, diameters of which from 8 to 22, 5 mm and resistance from 1770 n/mm 2 to 1970 n/mm 2, are galvanized according to the “ОЖ”(extra hard) group with a tolerance of +5%. The advantages of lightning protection (except high density and better corrosive resistance) is a heightened sturdiness to the lightning pulse influence from 85 C and higher. Lightning protection (in contrast to steel ropes) survive even in the zones with heightened probability value of lightning discharges, during the guaranteed service life – 20 years. Sole manufacturer and patent holder : JSC «Severstal. Metiz» . Dealer and developer : Co Ltd «Energoservice» . Sign of implementation : Lightning protection. Agency output: minimum 350 tons monthly. Standard-size spectrum: 8, 0 -22, 5 mm

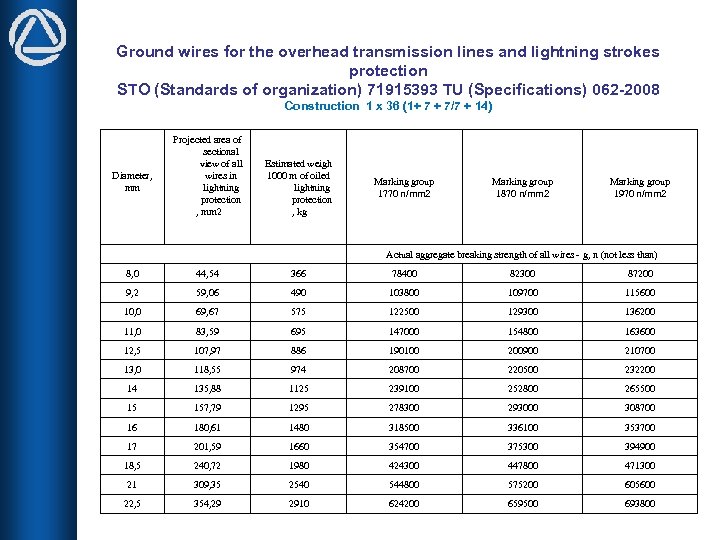

Ground wires for the overhead transmission lines and lightning strokes protection STO (Standards of organization) 71915393 TU (Specifications) 062 -2008 Construction 1 х 36 (1+ 7 + 7/7 + 14) Diameter, mm Projected area of sectional view of all wires in lightning protection , mm 2 Estimated weigh 1000 m of oiled lightning protection , kg Marking group 1770 n/mm 2 Marking group 1870 n/mm 2 Marking group 1970 n/mm 2 Actual aggregate breaking strength of all wires - g, n (not less than) 8, 0 44, 54 366 78400 82300 87200 9, 2 59, 06 490 103800 109700 115600 10, 0 69, 67 575 122500 129300 136200 11, 0 83, 59 695 147000 154800 163600 12, 5 107, 97 886 190100 200900 210700 13, 0 118, 55 974 208700 220500 232200 14 135, 88 1125 239100 252800 265500 15 157, 79 1295 278300 293000 308700 16 180, 61 1480 318500 336100 353700 17 201, 59 1660 354700 375300 394900 18, 5 240, 72 1980 424300 447800 471300 21 309, 35 2540 544800 575200 605600 22, 5 354, 29 2910 624200 659500 693800

Ground wires for the overhead transmission lines and lightning strokes protection STO (Standards of organization) 71915393 TU (Specifications) 062 -2008 Construction 1 х 36 (1+ 7 + 7/7 + 14) Diameter, mm Projected area of sectional view of all wires in lightning protection , mm 2 Estimated weigh 1000 m of oiled lightning protection , kg Marking group 1770 n/mm 2 Marking group 1870 n/mm 2 Marking group 1970 n/mm 2 Actual aggregate breaking strength of all wires - g, n (not less than) 8, 0 44, 54 366 78400 82300 87200 9, 2 59, 06 490 103800 109700 115600 10, 0 69, 67 575 122500 129300 136200 11, 0 83, 59 695 147000 154800 163600 12, 5 107, 97 886 190100 200900 210700 13, 0 118, 55 974 208700 220500 232200 14 135, 88 1125 239100 252800 265500 15 157, 79 1295 278300 293000 308700 16 180, 61 1480 318500 336100 353700 17 201, 59 1660 354700 375300 394900 18, 5 240, 72 1980 424300 447800 471300 21 309, 35 2540 544800 575200 605600 22, 5 354, 29 2910 624200 659500 693800

“Severstal-Metiz” and “Energoservice” express gratitude for kind attention! We are always glad to cooperate!

“Severstal-Metiz” and “Energoservice” express gratitude for kind attention! We are always glad to cooperate!