4dca8c729354df366267217f65bae09b.ppt

- Количество слайдов: 35

The Control System of ITER Overview, status and PS integration CODAC team ITER IO ITER Control System – meeting – date © 2013, ITER Organization Page 1

The Control System of ITER Overview, status and PS integration CODAC team ITER IO ITER Control System – meeting – date © 2013, ITER Organization Page 1

Everything you always wanted to know about ITER I&C but were afraid to ask ü What the ITER Control System is ? ü Why do we need standards ? ü What are these standards ? ü How to get informed about ? ü How to procure and use them ? ü How to test and integrate the I&C systems ? ü What is already done by IO and is expected ? ITER Control System – meeting – date © 2013, ITER Organization Page 2

Everything you always wanted to know about ITER I&C but were afraid to ask ü What the ITER Control System is ? ü Why do we need standards ? ü What are these standards ? ü How to get informed about ? ü How to procure and use them ? ü How to test and integrate the I&C systems ? ü What is already done by IO and is expected ? ITER Control System – meeting – date © 2013, ITER Organization Page 2

Introduction to The Control System of ITER PCDH v 7 ITER Control System – meeting – date © 2013, ITER Organization Page 3

Introduction to The Control System of ITER PCDH v 7 ITER Control System – meeting – date © 2013, ITER Organization Page 3

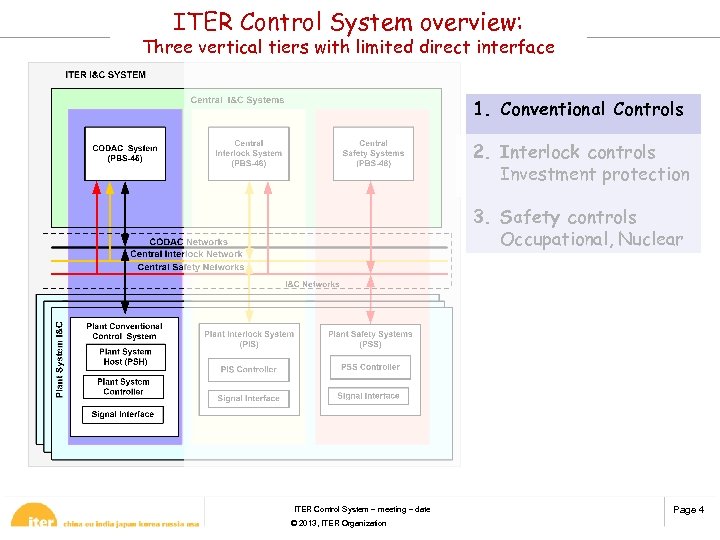

ITER Control System overview: Three vertical tiers with limited direct interface 1. Conventional Controls 2. Interlock controls Investment protection 3. Safety controls Occupational, Nuclear ITER Control System – meeting – date © 2013, ITER Organization Page 4

ITER Control System overview: Three vertical tiers with limited direct interface 1. Conventional Controls 2. Interlock controls Investment protection 3. Safety controls Occupational, Nuclear ITER Control System – meeting – date © 2013, ITER Organization Page 4

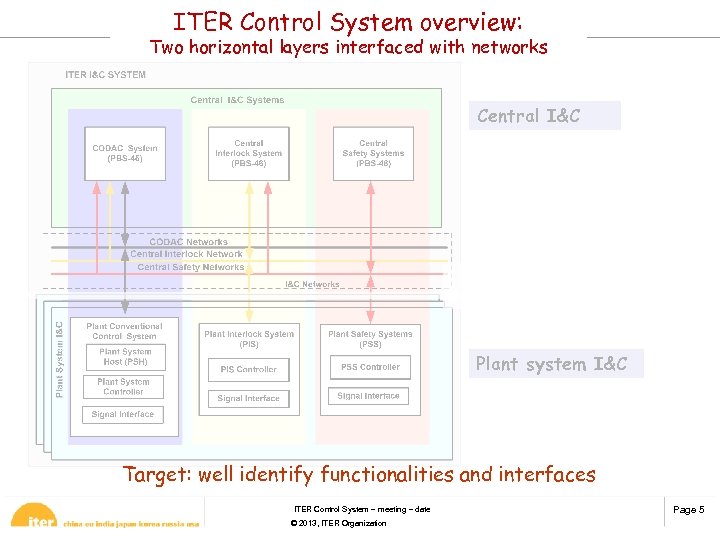

ITER Control System overview: Two horizontal layers interfaced with networks Central I&C Plant system I&C Target: well identify functionalities and interfaces ITER Control System – meeting – date © 2013, ITER Organization Page 5

ITER Control System overview: Two horizontal layers interfaced with networks Central I&C Plant system I&C Target: well identify functionalities and interfaces ITER Control System – meeting – date © 2013, ITER Organization Page 5

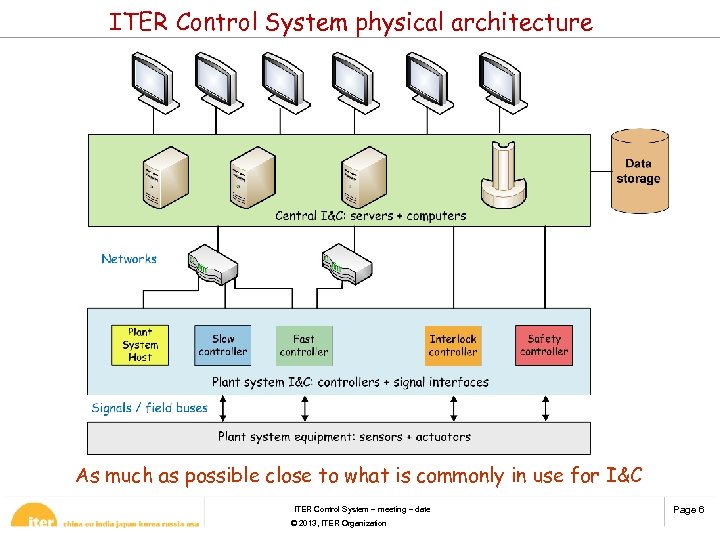

ITER Control System physical architecture As much as possible close to what is commonly in use for I&C ITER Control System – meeting – date © 2013, ITER Organization Page 6

ITER Control System physical architecture As much as possible close to what is commonly in use for I&C ITER Control System – meeting – date © 2013, ITER Organization Page 6

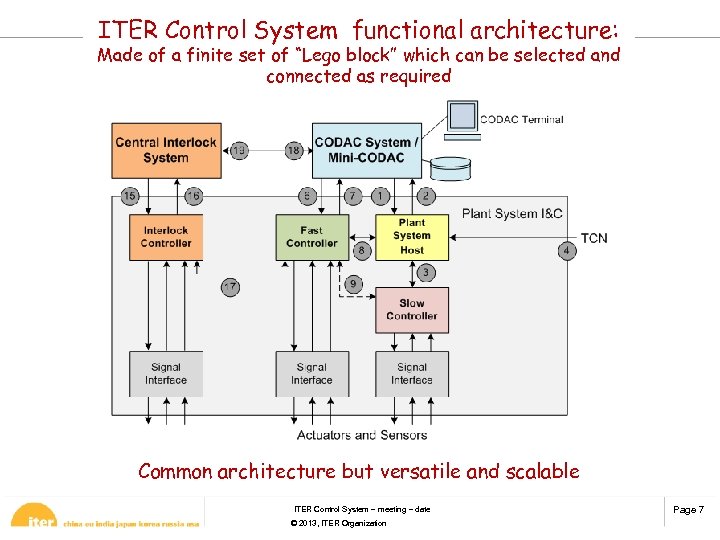

ITER Control System functional architecture: Made of a finite set of “Lego block” which can be selected and connected as required Common architecture but versatile and scalable ITER Control System – meeting – date © 2013, ITER Organization Page 7

ITER Control System functional architecture: Made of a finite set of “Lego block” which can be selected and connected as required Common architecture but versatile and scalable ITER Control System – meeting – date © 2013, ITER Organization Page 7

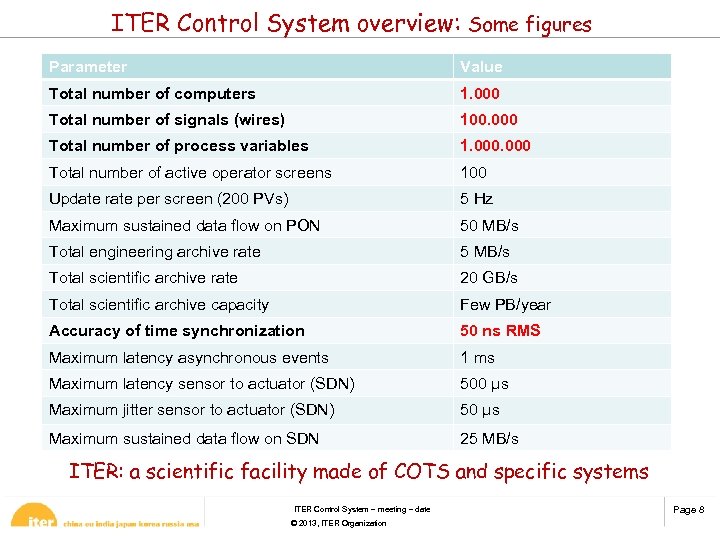

ITER Control System overview: Some figures Parameter Value Total number of computers 1. 000 Total number of signals (wires) 100. 000 Total number of process variables 1. 000 Total number of active operator screens 100 Update rate per screen (200 PVs) 5 Hz Maximum sustained data flow on PON 50 MB/s Total engineering archive rate 5 MB/s Total scientific archive rate 20 GB/s Total scientific archive capacity Few PB/year Accuracy of time synchronization 50 ns RMS Maximum latency asynchronous events 1 ms Maximum latency sensor to actuator (SDN) 500 µs Maximum jitter sensor to actuator (SDN) 50 µs Maximum sustained data flow on SDN 25 MB/s ITER: a scientific facility made of COTS and specific systems ITER Control System – meeting – date © 2013, ITER Organization Page 8

ITER Control System overview: Some figures Parameter Value Total number of computers 1. 000 Total number of signals (wires) 100. 000 Total number of process variables 1. 000 Total number of active operator screens 100 Update rate per screen (200 PVs) 5 Hz Maximum sustained data flow on PON 50 MB/s Total engineering archive rate 5 MB/s Total scientific archive rate 20 GB/s Total scientific archive capacity Few PB/year Accuracy of time synchronization 50 ns RMS Maximum latency asynchronous events 1 ms Maximum latency sensor to actuator (SDN) 500 µs Maximum jitter sensor to actuator (SDN) 50 µs Maximum sustained data flow on SDN 25 MB/s ITER: a scientific facility made of COTS and specific systems ITER Control System – meeting – date © 2013, ITER Organization Page 8

The ITER standards For I&C systems ITER Control System – meeting – date © 2013, ITER Organization Page 9

The ITER standards For I&C systems ITER Control System – meeting – date © 2013, ITER Organization Page 9

I&C standards: why? Statements: 1. Most of components or plant systems of ITER are procured “in-kind” from the seven ITER member partners. 2. These components will come with their own local control systems. 3. For integrated operation purpose, these local control system will be all interfaced to the Central I&C systems. 4. There will be a huge number of physical and functional interfaces. 5. After commissioning, ITER IO will have to maintain everything. Main challenge for I&C systems is the integration ITER Control System – meeting – date © 2013, ITER Organization Page 10

I&C standards: why? Statements: 1. Most of components or plant systems of ITER are procured “in-kind” from the seven ITER member partners. 2. These components will come with their own local control systems. 3. For integrated operation purpose, these local control system will be all interfaced to the Central I&C systems. 4. There will be a huge number of physical and functional interfaces. 5. After commissioning, ITER IO will have to maintain everything. Main challenge for I&C systems is the integration ITER Control System – meeting – date © 2013, ITER Organization Page 10

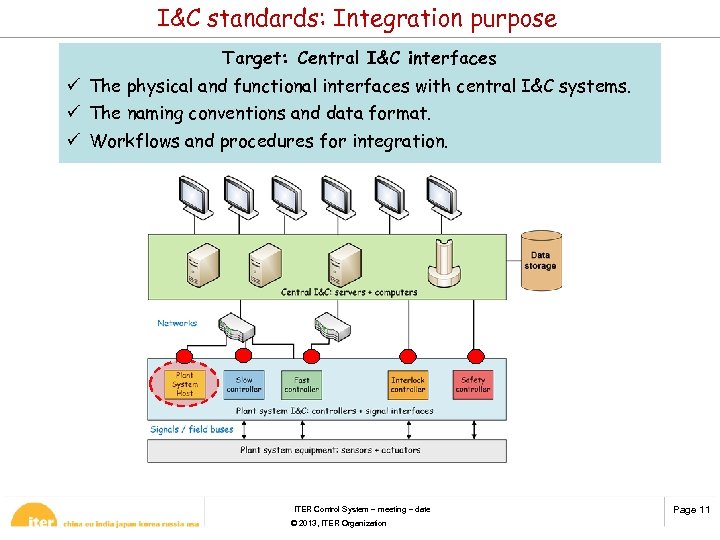

I&C standards: Integration purpose Target: Central I&C interfaces ü The physical and functional interfaces with central I&C systems. ü The naming conventions and data format. ü Workflows and procedures for integration. ITER Control System – meeting – date © 2013, ITER Organization Page 11

I&C standards: Integration purpose Target: Central I&C interfaces ü The physical and functional interfaces with central I&C systems. ü The naming conventions and data format. ü Workflows and procedures for integration. ITER Control System – meeting – date © 2013, ITER Organization Page 11

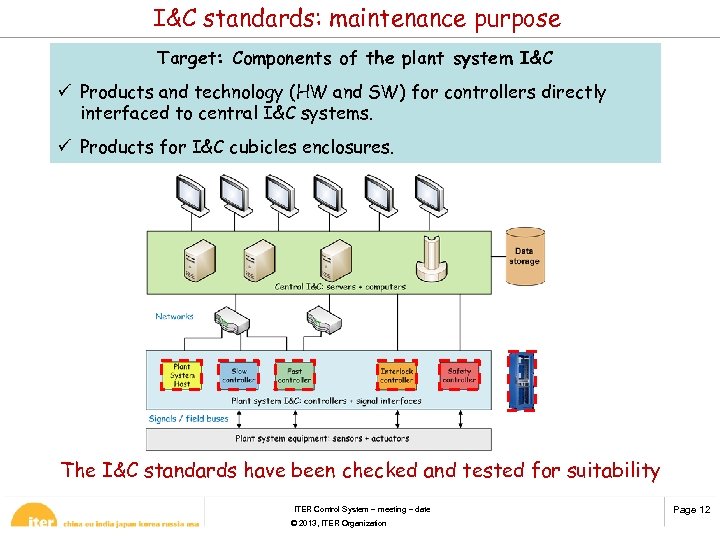

I&C standards: maintenance purpose Target: Components of the plant system I&C ü Products and technology (HW and SW) for controllers directly interfaced to central I&C systems. ü Products for I&C cubicles enclosures. The I&C standards have been checked and tested for suitability ITER Control System – meeting – date © 2013, ITER Organization Page 12

I&C standards: maintenance purpose Target: Components of the plant system I&C ü Products and technology (HW and SW) for controllers directly interfaced to central I&C systems. ü Products for I&C cubicles enclosures. The I&C standards have been checked and tested for suitability ITER Control System – meeting – date © 2013, ITER Organization Page 12

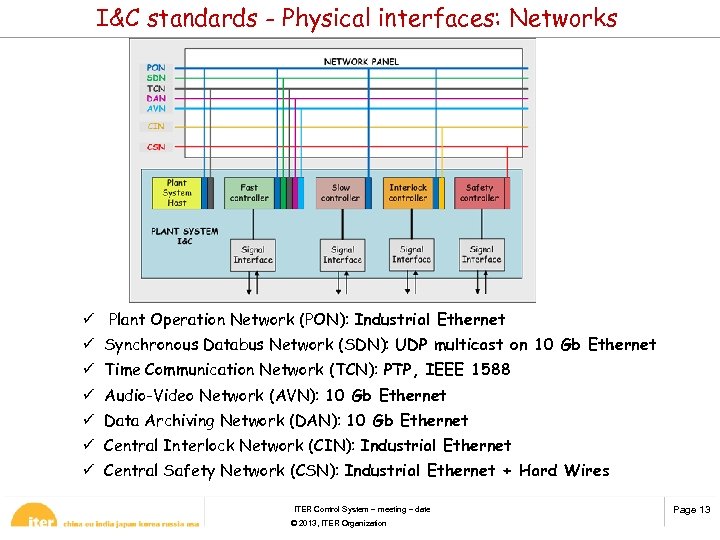

I&C standards - Physical interfaces: Networks ü Plant Operation Network (PON): Industrial Ethernet ü Synchronous Databus Network (SDN): UDP multicast on 10 Gb Ethernet ü Time Communication Network (TCN): PTP, IEEE 1588 ü Audio-Video Network (AVN): 10 Gb Ethernet ü Data Archiving Network (DAN): 10 Gb Ethernet ü Central Interlock Network (CIN): Industrial Ethernet ü Central Safety Network (CSN): Industrial Ethernet + Hard Wires ITER Control System – meeting – date © 2013, ITER Organization Page 13

I&C standards - Physical interfaces: Networks ü Plant Operation Network (PON): Industrial Ethernet ü Synchronous Databus Network (SDN): UDP multicast on 10 Gb Ethernet ü Time Communication Network (TCN): PTP, IEEE 1588 ü Audio-Video Network (AVN): 10 Gb Ethernet ü Data Archiving Network (DAN): 10 Gb Ethernet ü Central Interlock Network (CIN): Industrial Ethernet ü Central Safety Network (CSN): Industrial Ethernet + Hard Wires ITER Control System – meeting – date © 2013, ITER Organization Page 13

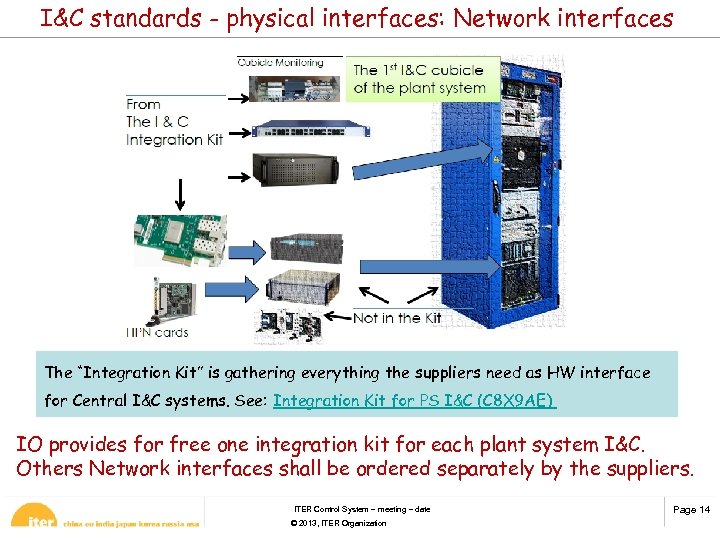

I&C standards - physical interfaces: Network interfaces The “Integration Kit” is gathering everything the suppliers need as HW interface for Central I&C systems. See: Integration Kit for PS I&C (C 8 X 9 AE) IO provides for free one integration kit for each plant system I&C. Others Network interfaces shall be ordered separately by the suppliers. ITER Control System – meeting – date © 2013, ITER Organization Page 14

I&C standards - physical interfaces: Network interfaces The “Integration Kit” is gathering everything the suppliers need as HW interface for Central I&C systems. See: Integration Kit for PS I&C (C 8 X 9 AE) IO provides for free one integration kit for each plant system I&C. Others Network interfaces shall be ordered separately by the suppliers. ITER Control System – meeting – date © 2013, ITER Organization Page 14

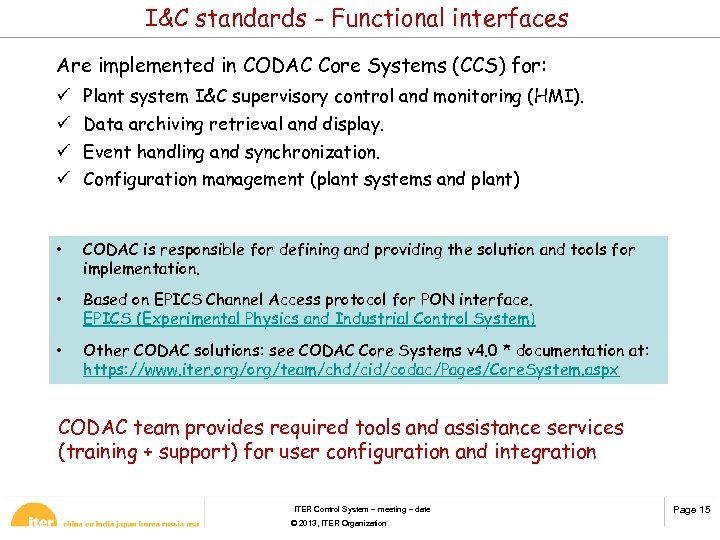

I&C standards - Functional interfaces Are implemented in CODAC Core Systems (CCS) for: ü ü Plant system I&C supervisory control and monitoring (HMI). • CODAC is responsible for defining and providing the solution and tools for implementation. • Based on EPICS Channel Access protocol for PON interface. EPICS (Experimental Physics and Industrial Control System) • Other CODAC solutions: see CODAC Core Systems v 4. 0 * documentation at: https: //www. iter. org/team/chd/cid/codac/Pages/Core. System. aspx Data archiving retrieval and display. Event handling and synchronization. Configuration management (plant systems and plant) CODAC team provides required tools and assistance services (training + support) for user configuration and integration ITER Control System – meeting – date © 2013, ITER Organization Page 15

I&C standards - Functional interfaces Are implemented in CODAC Core Systems (CCS) for: ü ü Plant system I&C supervisory control and monitoring (HMI). • CODAC is responsible for defining and providing the solution and tools for implementation. • Based on EPICS Channel Access protocol for PON interface. EPICS (Experimental Physics and Industrial Control System) • Other CODAC solutions: see CODAC Core Systems v 4. 0 * documentation at: https: //www. iter. org/team/chd/cid/codac/Pages/Core. System. aspx Data archiving retrieval and display. Event handling and synchronization. Configuration management (plant systems and plant) CODAC team provides required tools and assistance services (training + support) for user configuration and integration ITER Control System – meeting – date © 2013, ITER Organization Page 15

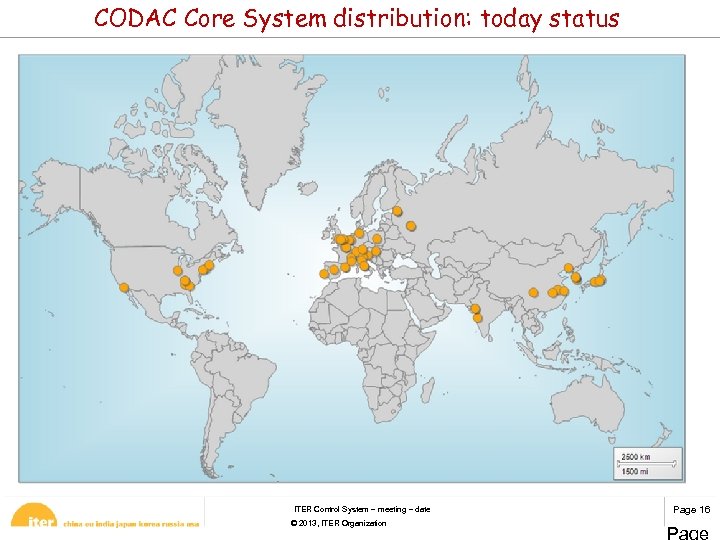

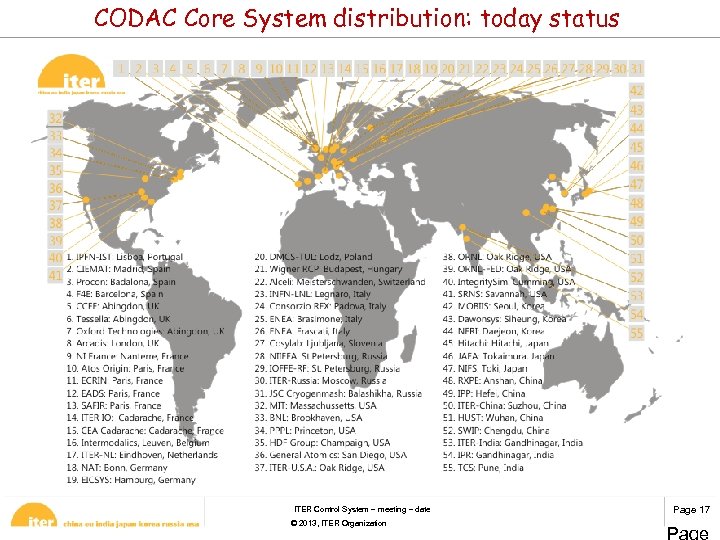

CODAC Core System distribution: today status ITER Control System – meeting – date © 2013, ITER Organization Page 16

CODAC Core System distribution: today status ITER Control System – meeting – date © 2013, ITER Organization Page 16

CODAC Core System distribution: today status ITER Control System – meeting – date © 2013, ITER Organization Page 17

CODAC Core System distribution: today status ITER Control System – meeting – date © 2013, ITER Organization Page 17

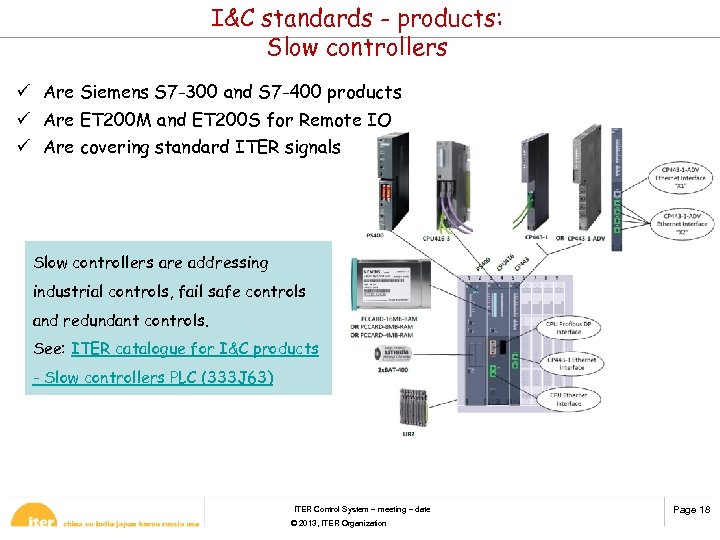

I&C standards - products: Slow controllers ü Are Siemens S 7 -300 and S 7 -400 products ü Are ET 200 M and ET 200 S for Remote IO ü Are covering standard ITER signals Slow controllers are addressing industrial controls, fail safe controls and redundant controls. See: ITER catalogue for I&C products - Slow controllers PLC (333 J 63) ITER Control System – meeting – date © 2013, ITER Organization Page 18

I&C standards - products: Slow controllers ü Are Siemens S 7 -300 and S 7 -400 products ü Are ET 200 M and ET 200 S for Remote IO ü Are covering standard ITER signals Slow controllers are addressing industrial controls, fail safe controls and redundant controls. See: ITER catalogue for I&C products - Slow controllers PLC (333 J 63) ITER Control System – meeting – date © 2013, ITER Organization Page 18

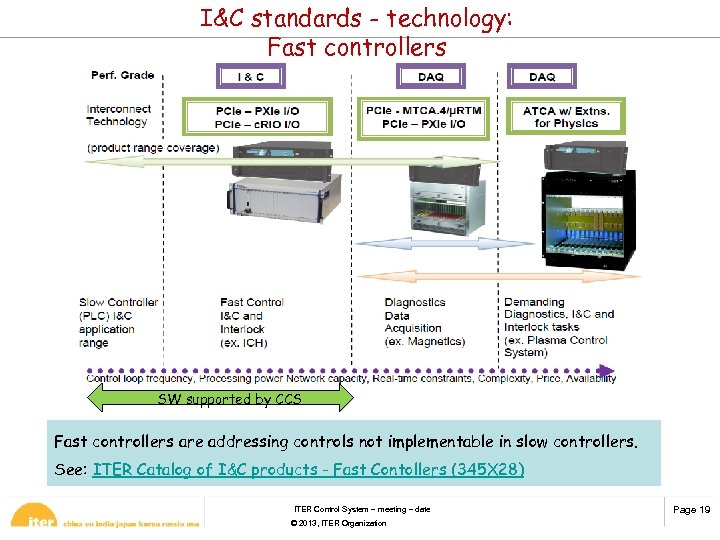

I&C standards - technology: Fast controllers SW supported by CCS Fast controllers are addressing controls not implementable in slow controllers. See: ITER Catalog of I&C products - Fast Contollers (345 X 28) ITER Control System – meeting – date © 2013, ITER Organization Page 19

I&C standards - technology: Fast controllers SW supported by CCS Fast controllers are addressing controls not implementable in slow controllers. See: ITER Catalog of I&C products - Fast Contollers (345 X 28) ITER Control System – meeting – date © 2013, ITER Organization Page 19

I&C standards: products details: I&C cubicle enclosures ü Are Schneider Electric products ü Address floor standing and wall mounted cubicles ü Address Standard and EMC protected. ITER standards enclosures are suited to interface the cable trays and are monitored by a standard system. See: ITER catalogue for I&C products - Cubicles (35 LXVZ) ITER Control System – meeting – date © 2013, ITER Organization Page 20

I&C standards: products details: I&C cubicle enclosures ü Are Schneider Electric products ü Address floor standing and wall mounted cubicles ü Address Standard and EMC protected. ITER standards enclosures are suited to interface the cable trays and are monitored by a standard system. See: ITER catalogue for I&C products - Cubicles (35 LXVZ) ITER Control System – meeting – date © 2013, ITER Organization Page 20

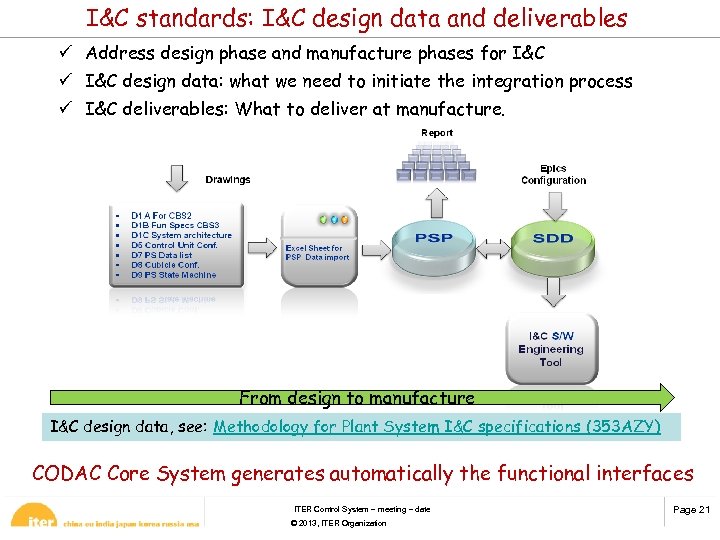

I&C standards: I&C design data and deliverables ü Address design phase and manufacture phases for I&C ü I&C design data: what we need to initiate the integration process ü I&C deliverables: What to deliver at manufacture. From design to manufacture I&C design data, see: Methodology for Plant System I&C specifications (353 AZY) CODAC Core System generates automatically the functional interfaces ITER Control System – meeting – date © 2013, ITER Organization Page 21

I&C standards: I&C design data and deliverables ü Address design phase and manufacture phases for I&C ü I&C design data: what we need to initiate the integration process ü I&C deliverables: What to deliver at manufacture. From design to manufacture I&C design data, see: Methodology for Plant System I&C specifications (353 AZY) CODAC Core System generates automatically the functional interfaces ITER Control System – meeting – date © 2013, ITER Organization Page 21

How to get informed and trained about ITER solutions for I&C ? ITER Control System – meeting – date © 2013, ITER Organization Page 22

How to get informed and trained about ITER solutions for I&C ? ITER Control System – meeting – date © 2013, ITER Organization Page 22

I&C standards repository = PCDH ü Plant Control Design Handbook (PCDH) defines methodology, standards, specifications and interfaces applicable to all ITER plant systems I&C. ü PCDH is an annex to Project Requirements (PR) and applicable to all Procurement Arrangements with I&C. ü All major project reviews are required to show that PCDH standards are followed. ITER Control System – meeting – date © 2013, ITER Organization Page 23

I&C standards repository = PCDH ü Plant Control Design Handbook (PCDH) defines methodology, standards, specifications and interfaces applicable to all ITER plant systems I&C. ü PCDH is an annex to Project Requirements (PR) and applicable to all Procurement Arrangements with I&C. ü All major project reviews are required to show that PCDH standards are followed. ITER Control System – meeting – date © 2013, ITER Organization Page 23

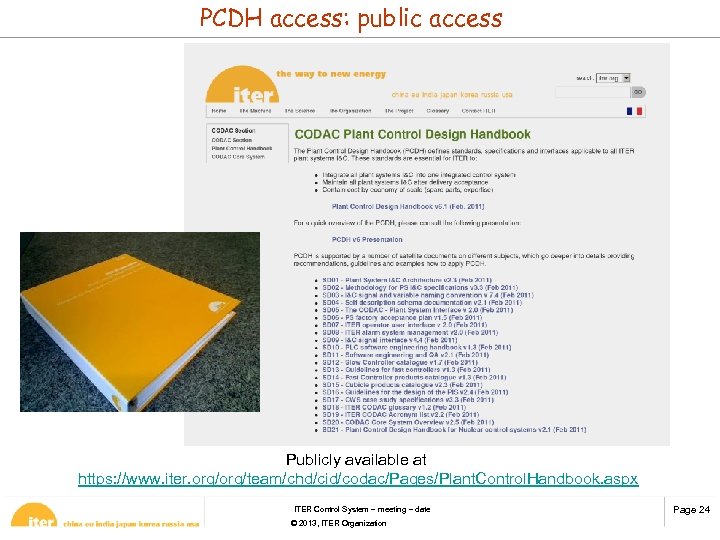

PCDH access: public access Publicly available at https: //www. iter. org/team/chd/cid/codac/Pages/Plant. Control. Handbook. aspx ITER Control System – meeting – date © 2013, ITER Organization Page 24

PCDH access: public access Publicly available at https: //www. iter. org/team/chd/cid/codac/Pages/Plant. Control. Handbook. aspx ITER Control System – meeting – date © 2013, ITER Organization Page 24

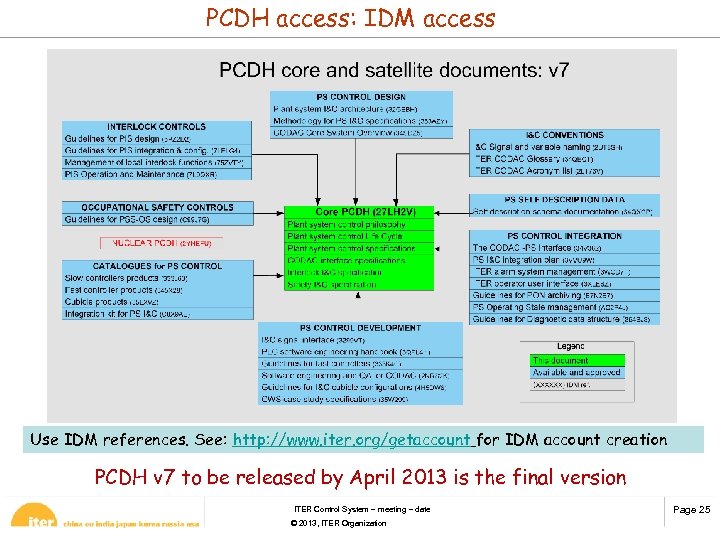

PCDH access: IDM access Use IDM references. See: http: //www. iter. org/getaccount for IDM account creation PCDH v 7 to be released by April 2013 is the final version ITER Control System – meeting – date © 2013, ITER Organization Page 25

PCDH access: IDM access Use IDM references. See: http: //www. iter. org/getaccount for IDM account creation PCDH v 7 to be released by April 2013 is the final version ITER Control System – meeting – date © 2013, ITER Organization Page 25

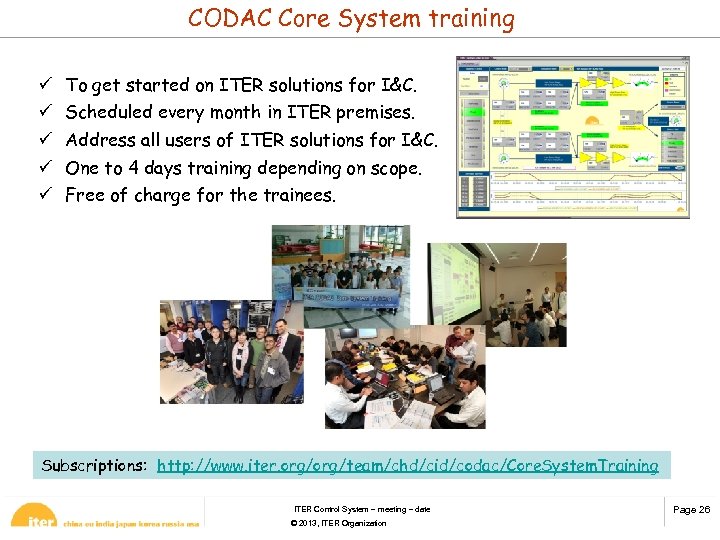

CODAC Core System training ü ü ü To get started on ITER solutions for I&C. Scheduled every month in ITER premises. Address all users of ITER solutions for I&C. One to 4 days training depending on scope. Free of charge for the trainees. Subscriptions: http: //www. iter. org/team/chd/cid/codac/Core. System. Training ITER Control System – meeting – date © 2013, ITER Organization Page 26

CODAC Core System training ü ü ü To get started on ITER solutions for I&C. Scheduled every month in ITER premises. Address all users of ITER solutions for I&C. One to 4 days training depending on scope. Free of charge for the trainees. Subscriptions: http: //www. iter. org/team/chd/cid/codac/Core. System. Training ITER Control System – meeting – date © 2013, ITER Organization Page 26

How to procure and use ITER standards for I&C ? ITER Control System – meeting – date © 2013, ITER Organization Page 27

How to procure and use ITER standards for I&C ? ITER Control System – meeting – date © 2013, ITER Organization Page 27

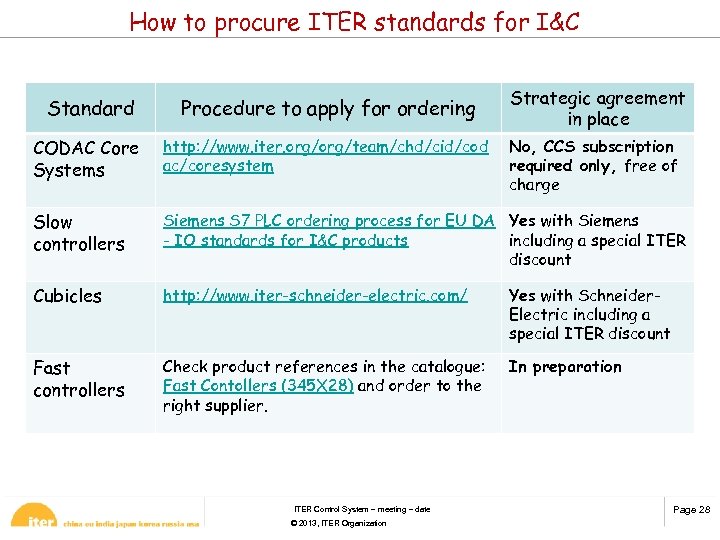

How to procure ITER standards for I&C Strategic agreement in place Standard Procedure to apply for ordering CODAC Core Systems http: //www. iter. org/team/chd/cid/cod ac/coresystem Slow controllers Siemens S 7 PLC ordering process for EU DA Yes with Siemens - IO standards for I&C products including a special ITER discount Cubicles http: //www. iter-schneider-electric. com/ Yes with Schneider. Electric including a special ITER discount Fast controllers Check product references in the catalogue: Fast Contollers (345 X 28) and order to the right supplier. In preparation ITER Control System – meeting – date © 2013, ITER Organization No, CCS subscription required only, free of charge Page 28

How to procure ITER standards for I&C Strategic agreement in place Standard Procedure to apply for ordering CODAC Core Systems http: //www. iter. org/team/chd/cid/cod ac/coresystem Slow controllers Siemens S 7 PLC ordering process for EU DA Yes with Siemens - IO standards for I&C products including a special ITER discount Cubicles http: //www. iter-schneider-electric. com/ Yes with Schneider. Electric including a special ITER discount Fast controllers Check product references in the catalogue: Fast Contollers (345 X 28) and order to the right supplier. In preparation ITER Control System – meeting – date © 2013, ITER Organization No, CCS subscription required only, free of charge Page 28

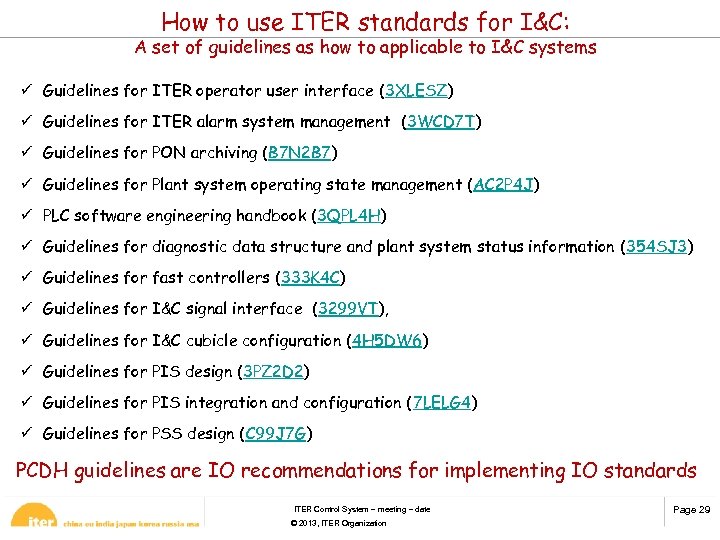

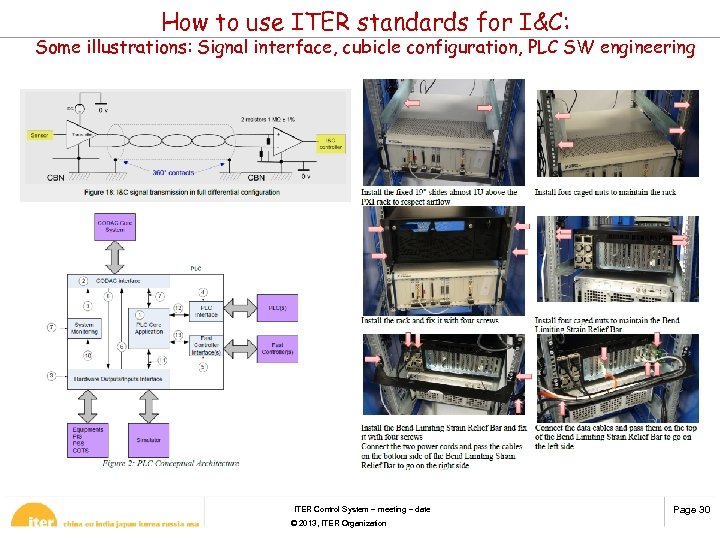

How to use ITER standards for I&C: A set of guidelines as how to applicable to I&C systems ü Guidelines for ITER operator user interface (3 XLESZ) ü Guidelines for ITER alarm system management (3 WCD 7 T) ü Guidelines for PON archiving (B 7 N 2 B 7) ü Guidelines for Plant system operating state management (AC 2 P 4 J) ü PLC software engineering handbook (3 QPL 4 H) ü Guidelines for diagnostic data structure and plant system status information (354 SJ 3) ü Guidelines for fast controllers (333 K 4 C) ü Guidelines for I&C signal interface (3299 VT), ü Guidelines for I&C cubicle configuration (4 H 5 DW 6) ü Guidelines for PIS design (3 PZ 2 D 2) ü Guidelines for PIS integration and configuration (7 LELG 4) ü Guidelines for PSS design (C 99 J 7 G) PCDH guidelines are IO recommendations for implementing IO standards ITER Control System – meeting – date © 2013, ITER Organization Page 29

How to use ITER standards for I&C: A set of guidelines as how to applicable to I&C systems ü Guidelines for ITER operator user interface (3 XLESZ) ü Guidelines for ITER alarm system management (3 WCD 7 T) ü Guidelines for PON archiving (B 7 N 2 B 7) ü Guidelines for Plant system operating state management (AC 2 P 4 J) ü PLC software engineering handbook (3 QPL 4 H) ü Guidelines for diagnostic data structure and plant system status information (354 SJ 3) ü Guidelines for fast controllers (333 K 4 C) ü Guidelines for I&C signal interface (3299 VT), ü Guidelines for I&C cubicle configuration (4 H 5 DW 6) ü Guidelines for PIS design (3 PZ 2 D 2) ü Guidelines for PIS integration and configuration (7 LELG 4) ü Guidelines for PSS design (C 99 J 7 G) PCDH guidelines are IO recommendations for implementing IO standards ITER Control System – meeting – date © 2013, ITER Organization Page 29

How to use ITER standards for I&C: Some illustrations: Signal interface, cubicle configuration, PLC SW engineering ITER Control System – meeting – date © 2013, ITER Organization Page 30

How to use ITER standards for I&C: Some illustrations: Signal interface, cubicle configuration, PLC SW engineering ITER Control System – meeting – date © 2013, ITER Organization Page 30

How to test and integrate I&C system at ITER ? ITER Control System – meeting – date © 2013, ITER Organization Page 31

How to test and integrate I&C system at ITER ? ITER Control System – meeting – date © 2013, ITER Organization Page 31

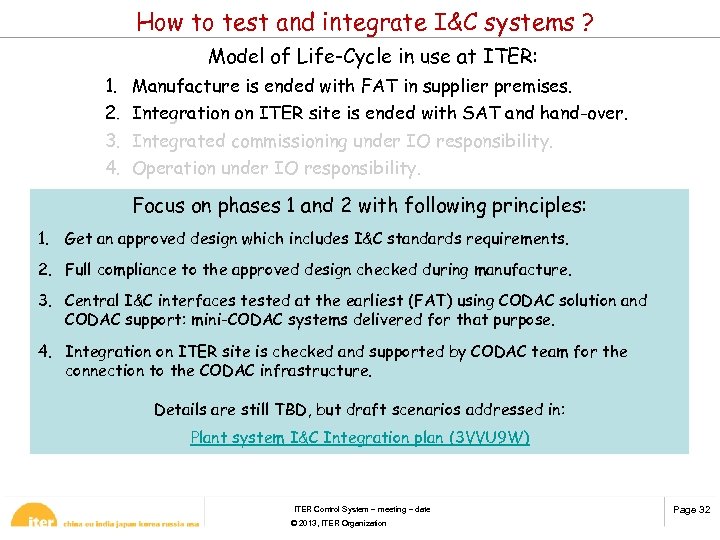

How to test and integrate I&C systems ? Model of Life-Cycle in use at ITER: 1. 2. 3. 4. Manufacture is ended with FAT in supplier premises. Integration on ITER site is ended with SAT and hand-over. Integrated commissioning under IO responsibility. Operation under IO responsibility. Focus on phases 1 and 2 with following principles: 1. Get an approved design which includes I&C standards requirements. 2. Full compliance to the approved design checked during manufacture. 3. Central I&C interfaces tested at the earliest (FAT) using CODAC solution and CODAC support: mini-CODAC systems delivered for that purpose. 4. Integration on ITER site is checked and supported by CODAC team for the connection to the CODAC infrastructure. Details are still TBD, but draft scenarios addressed in: Plant system I&C Integration plan (3 VVU 9 W) ITER Control System – meeting – date © 2013, ITER Organization Page 32

How to test and integrate I&C systems ? Model of Life-Cycle in use at ITER: 1. 2. 3. 4. Manufacture is ended with FAT in supplier premises. Integration on ITER site is ended with SAT and hand-over. Integrated commissioning under IO responsibility. Operation under IO responsibility. Focus on phases 1 and 2 with following principles: 1. Get an approved design which includes I&C standards requirements. 2. Full compliance to the approved design checked during manufacture. 3. Central I&C interfaces tested at the earliest (FAT) using CODAC solution and CODAC support: mini-CODAC systems delivered for that purpose. 4. Integration on ITER site is checked and supported by CODAC team for the connection to the CODAC infrastructure. Details are still TBD, but draft scenarios addressed in: Plant system I&C Integration plan (3 VVU 9 W) ITER Control System – meeting – date © 2013, ITER Organization Page 32

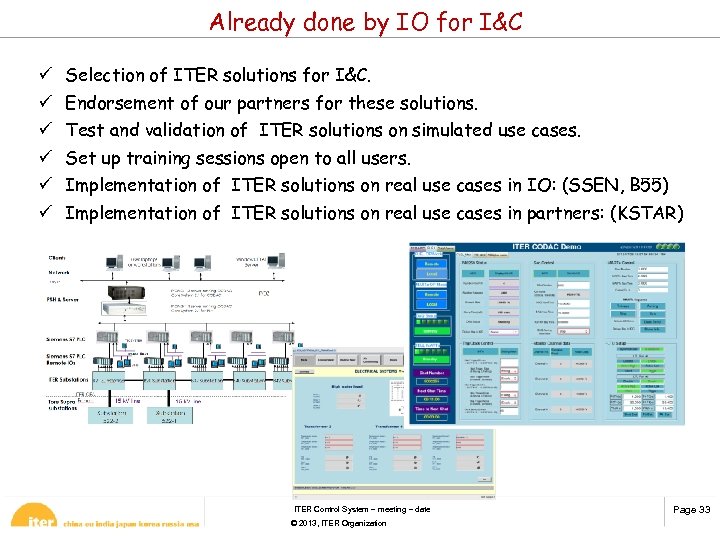

Already done by IO for I&C ü ü ü Selection of ITER solutions for I&C. Endorsement of our partners for these solutions. Test and validation of ITER solutions on simulated use cases. Set up training sessions open to all users. Implementation of ITER solutions on real use cases in IO: (SSEN, B 55) Implementation of ITER solutions on real use cases in partners: (KSTAR) ITER Control System – meeting – date © 2013, ITER Organization Page 33

Already done by IO for I&C ü ü ü Selection of ITER solutions for I&C. Endorsement of our partners for these solutions. Test and validation of ITER solutions on simulated use cases. Set up training sessions open to all users. Implementation of ITER solutions on real use cases in IO: (SSEN, B 55) Implementation of ITER solutions on real use cases in partners: (KSTAR) ITER Control System – meeting – date © 2013, ITER Organization Page 33

Conclusion ü ITER project has Selected I&C standard solutions, architectures and interfaces for risk reduction and cost saving at procurement integration. ü The suitability of these solutions has been checked against user reviews and real use cases implementation. ü ITER CODAC is now offering support and training services for helping the suppliers and users in implementing these solutions. ü Opportunities for the industry shall be investigated mainly with the procurement suppliers and with IO for procurement integration. ITER IO is ready for dealing with I&C business for the detailed design and manufacture phases ITER Control System – meeting – date © 2013, ITER Organization Page 34

Conclusion ü ITER project has Selected I&C standard solutions, architectures and interfaces for risk reduction and cost saving at procurement integration. ü The suitability of these solutions has been checked against user reviews and real use cases implementation. ü ITER CODAC is now offering support and training services for helping the suppliers and users in implementing these solutions. ü Opportunities for the industry shall be investigated mainly with the procurement suppliers and with IO for procurement integration. ITER IO is ready for dealing with I&C business for the detailed design and manufacture phases ITER Control System – meeting – date © 2013, ITER Organization Page 34

Thank you for your attention ITER Control System – meeting – date © 2013, ITER Organization Page 35

Thank you for your attention ITER Control System – meeting – date © 2013, ITER Organization Page 35