8ddb0649f5a85b3702f8f81f3009b1b7.ppt

- Количество слайдов: 15

The Commercial Technologies for Maintenance Activities Program a joint NCMS/Do. D Partnership 1

The Commercial Technologies for Maintenance Activities Program a joint NCMS/Do. D Partnership 1

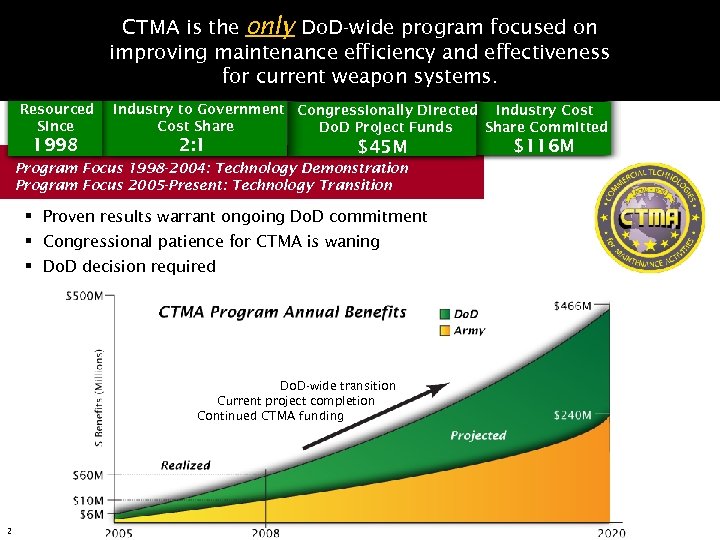

CTMA is the only Do. D-wide program focused on improving maintenance efficiency and effectiveness for current weapon systems. Resourced Since 1998 Industry to Government Congressionally Directed Industry Cost Share Committed Do. D Project Funds 2: 1 $45 M Program Focus 1998 -2004: Technology Demonstration Program Focus 2005 -Present: Technology Transition § Proven results warrant ongoing Do. D commitment § Congressional patience for CTMA is waning § Do. D decision required Do. D-wide transition Current project completion Continued CTMA funding 2 $116 M

CTMA is the only Do. D-wide program focused on improving maintenance efficiency and effectiveness for current weapon systems. Resourced Since 1998 Industry to Government Congressionally Directed Industry Cost Share Committed Do. D Project Funds 2: 1 $45 M Program Focus 1998 -2004: Technology Demonstration Program Focus 2005 -Present: Technology Transition § Proven results warrant ongoing Do. D commitment § Congressional patience for CTMA is waning § Do. D decision required Do. D-wide transition Current project completion Continued CTMA funding 2 $116 M

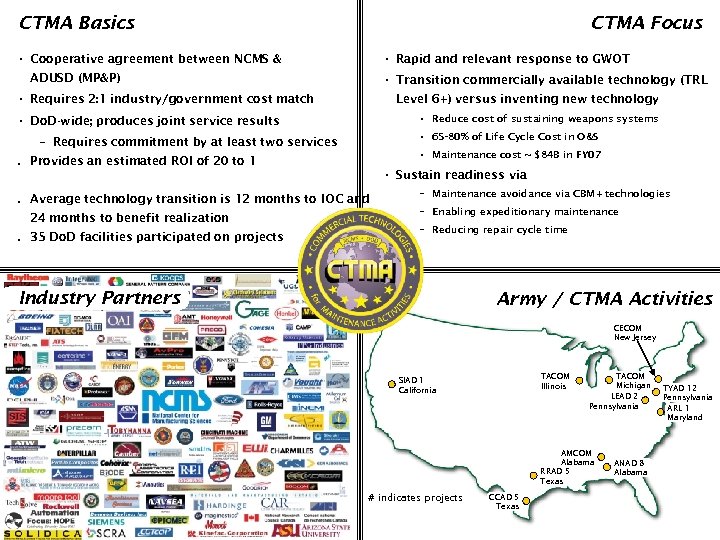

CTMA Basics CTMA Focus • Cooperative agreement between NCMS & ADUSD (MP&P) • Rapid and relevant response to GWOT • Transition commercially available technology (TRL Level 6+) versus inventing new technology • Requires 2: 1 industry/government cost match • Reduce cost of sustaining weapons systems • Do. D-wide; produces joint service results • 65 -80% of Life Cycle Cost in O&S – Requires commitment by at least two services • Maintenance cost ~ $84 B in FY 07 . Provides an estimated ROI of 20 to 1 • Sustain readiness via . Average technology transition is 12 months to IOC and 24 months to benefit realization. 35 Do. D facilities participated on projects – Maintenance avoidance via CBM+ technologies – Enabling expeditionary maintenance – Reducing repair cycle time Industry Partners Army / CTMA Activities CECOM New Jersey TACOM Illinois SIAD 1 California TACOM Michigan LEAD 2 Pennsylvania AMCOM Alabama RRAD 5 Texas # indicates projects 3 CCAD 5 Texas ANAD 8 Alabama TYAD 12 Pennsylvania ARL 1 Maryland

CTMA Basics CTMA Focus • Cooperative agreement between NCMS & ADUSD (MP&P) • Rapid and relevant response to GWOT • Transition commercially available technology (TRL Level 6+) versus inventing new technology • Requires 2: 1 industry/government cost match • Reduce cost of sustaining weapons systems • Do. D-wide; produces joint service results • 65 -80% of Life Cycle Cost in O&S – Requires commitment by at least two services • Maintenance cost ~ $84 B in FY 07 . Provides an estimated ROI of 20 to 1 • Sustain readiness via . Average technology transition is 12 months to IOC and 24 months to benefit realization. 35 Do. D facilities participated on projects – Maintenance avoidance via CBM+ technologies – Enabling expeditionary maintenance – Reducing repair cycle time Industry Partners Army / CTMA Activities CECOM New Jersey TACOM Illinois SIAD 1 California TACOM Michigan LEAD 2 Pennsylvania AMCOM Alabama RRAD 5 Texas # indicates projects 3 CCAD 5 Texas ANAD 8 Alabama TYAD 12 Pennsylvania ARL 1 Maryland

Army Resourcing Options 1. 2. 3. 4. Resourced by. PMs/PEOs PM/PEO directed Resourced in Working Capital Fund rate Materiel Command/Depot directed Resourced by Sustainment Accounts “ 4” code directed Combinations of above

Army Resourcing Options 1. 2. 3. 4. Resourced by. PMs/PEOs PM/PEO directed Resourced in Working Capital Fund rate Materiel Command/Depot directed Resourced by Sustainment Accounts “ 4” code directed Combinations of above

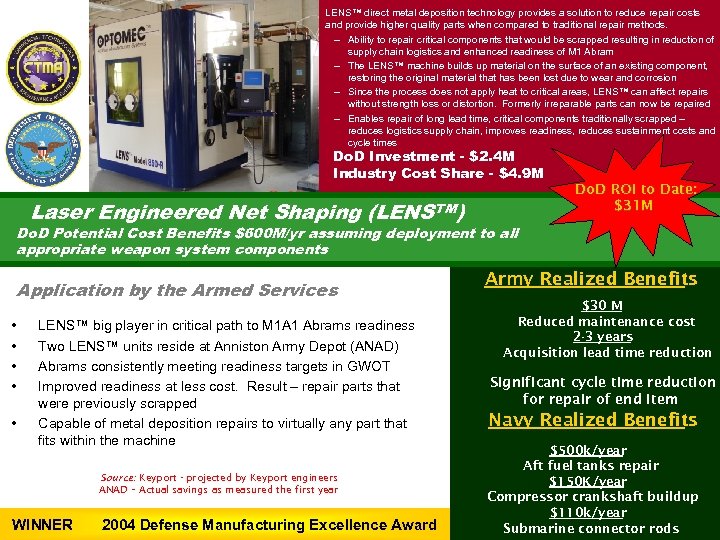

LENS™ direct metal deposition technology provides a solution to reduce repair costs and provide higher quality parts when compared to traditional repair methods. – Ability to repair critical components that would be scrapped resulting in reduction of supply chain logistics and enhanced readiness of M 1 Abram – The LENS™ machine builds up material on the surface of an existing component, restoring the original material that has been lost due to wear and corrosion – Since the process does not apply heat to critical areas, LENS™ can affect repairs without strength loss or distortion. Formerly irreparable parts can now be repaired – Enables repair of long lead time, critical components traditionally scrapped – reduces logistics supply chain, improves readiness, reduces sustainment costs and cycle times Do. D Investment - $2. 4 M Industry Cost Share - $4. 9 M Laser Engineered Net Shaping (LENSTM) Do. D ROI to Date: $31 M Do. D Potential Cost Benefits $600 M/yr assuming deployment to all appropriate weapon system components Application by the Armed Services • • • LENS™ big player in critical path to M 1 A 1 Abrams readiness Two LENS™ units reside at Anniston Army Depot (ANAD) Abrams consistently meeting readiness targets in GWOT Improved readiness at less cost. Result – repair parts that were previously scrapped Capable of metal deposition repairs to virtually any part that fits within the machine Source: Keyport - projected by Keyport engineers ANAD – Actual savings as measured the first year WINNER 2004 Defense Manufacturing Excellence Award Army Realized Benefits $30 M Reduced maintenance cost 2 -3 years Acquisition lead time reduction Significant cycle time reduction for repair of end item Navy Realized Benefits $500 k/year Aft fuel tanks repair $150 K/year Compressor crankshaft buildup $110 k/year Submarine connector rods

LENS™ direct metal deposition technology provides a solution to reduce repair costs and provide higher quality parts when compared to traditional repair methods. – Ability to repair critical components that would be scrapped resulting in reduction of supply chain logistics and enhanced readiness of M 1 Abram – The LENS™ machine builds up material on the surface of an existing component, restoring the original material that has been lost due to wear and corrosion – Since the process does not apply heat to critical areas, LENS™ can affect repairs without strength loss or distortion. Formerly irreparable parts can now be repaired – Enables repair of long lead time, critical components traditionally scrapped – reduces logistics supply chain, improves readiness, reduces sustainment costs and cycle times Do. D Investment - $2. 4 M Industry Cost Share - $4. 9 M Laser Engineered Net Shaping (LENSTM) Do. D ROI to Date: $31 M Do. D Potential Cost Benefits $600 M/yr assuming deployment to all appropriate weapon system components Application by the Armed Services • • • LENS™ big player in critical path to M 1 A 1 Abrams readiness Two LENS™ units reside at Anniston Army Depot (ANAD) Abrams consistently meeting readiness targets in GWOT Improved readiness at less cost. Result – repair parts that were previously scrapped Capable of metal deposition repairs to virtually any part that fits within the machine Source: Keyport - projected by Keyport engineers ANAD – Actual savings as measured the first year WINNER 2004 Defense Manufacturing Excellence Award Army Realized Benefits $30 M Reduced maintenance cost 2 -3 years Acquisition lead time reduction Significant cycle time reduction for repair of end item Navy Realized Benefits $500 k/year Aft fuel tanks repair $150 K/year Compressor crankshaft buildup $110 k/year Submarine connector rods

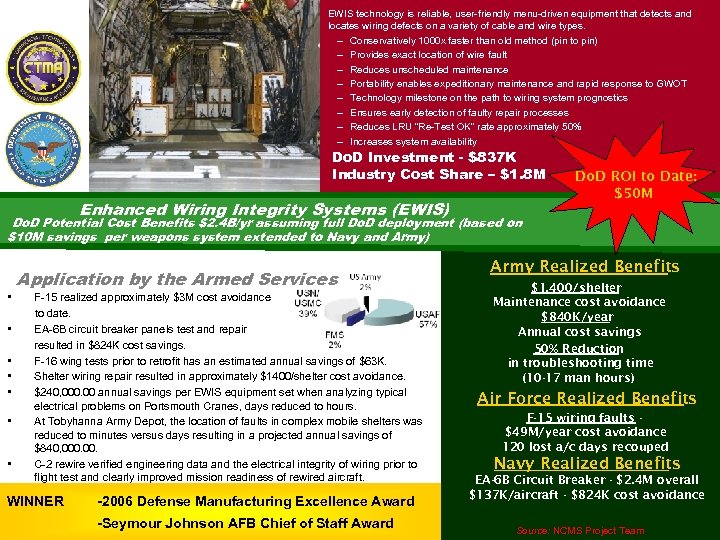

~50% reduction in troubleshooting EWIS technology is reliable, user-friendly menu-driven equipment that detects and locates wiring defects on a variety of cable and wire types. time – Conservatively 1000 x faster than old method (pin to pin) – Provides exact location of wire fault Increased readiness and fewer – Reduces unscheduled maintenance mission aborts due to wiring GWOT – Portability enables expeditionary maintenance and rapid response toincidents – Technology milestone on the path to wiring system prognostics – Ensures early detection of faulty repair processes 9, 336 man-hours saved in F-16 repair – Reduces LRU “Re-Test OK” rate approximately 50% in the first six months – Increases system availability Do. D Investment - $837 K F-15 realized $3 M cost avoidance to Industry Cost Share – $1. 8 M Do. D ROI to Date: date $50 M Enhanced Wiring Integrity Systems (EWIS) Do. D Potential Cost Benefits $2. 4 B/yr assuming full Do. D deployment (based on $10 M savings per weapons system extended to Navy and Army) Application by the Armed Services • • F-15 realized approximately $3 M cost avoidance to date. EA-6 B circuit breaker panels test and repair resulted in $824 K cost savings. F-16 wing tests prior to retrofit has an estimated annual savings of $63 K. Shelter wiring repair resulted in approximately $1400/shelter cost avoidance. $240, 000. 00 annual savings per EWIS equipment set when analyzing typical electrical problems on Portsmouth Cranes, days reduced to hours. At Tobyhanna Army Depot, the location of faults in complex mobile shelters was reduced to minutes versus days resulting in a projected annual savings of $840, 000. C-2 rewire verified engineering data and the electrical integrity of wiring prior to flight test and clearly improved mission readiness of rewired aircraft. WINNER -2006 Defense Manufacturing Excellence Award -Seymour Johnson AFB Chief of Staff Award Army Realized Benefits $1, 400/shelter Maintenance cost avoidance $840 K/year Annual cost savings 50% Reduction in troubleshooting time (10 -17 man hours) Air Force Realized Benefits F-15 wiring faults $49 M/year cost avoidance 120 lost a/c days recouped Navy Realized Benefits EA-6 B Circuit Breaker - $2. 4 M overall $137 K/aircraft - $824 K cost avoidance Source: NCMS Project Team

~50% reduction in troubleshooting EWIS technology is reliable, user-friendly menu-driven equipment that detects and locates wiring defects on a variety of cable and wire types. time – Conservatively 1000 x faster than old method (pin to pin) – Provides exact location of wire fault Increased readiness and fewer – Reduces unscheduled maintenance mission aborts due to wiring GWOT – Portability enables expeditionary maintenance and rapid response toincidents – Technology milestone on the path to wiring system prognostics – Ensures early detection of faulty repair processes 9, 336 man-hours saved in F-16 repair – Reduces LRU “Re-Test OK” rate approximately 50% in the first six months – Increases system availability Do. D Investment - $837 K F-15 realized $3 M cost avoidance to Industry Cost Share – $1. 8 M Do. D ROI to Date: date $50 M Enhanced Wiring Integrity Systems (EWIS) Do. D Potential Cost Benefits $2. 4 B/yr assuming full Do. D deployment (based on $10 M savings per weapons system extended to Navy and Army) Application by the Armed Services • • F-15 realized approximately $3 M cost avoidance to date. EA-6 B circuit breaker panels test and repair resulted in $824 K cost savings. F-16 wing tests prior to retrofit has an estimated annual savings of $63 K. Shelter wiring repair resulted in approximately $1400/shelter cost avoidance. $240, 000. 00 annual savings per EWIS equipment set when analyzing typical electrical problems on Portsmouth Cranes, days reduced to hours. At Tobyhanna Army Depot, the location of faults in complex mobile shelters was reduced to minutes versus days resulting in a projected annual savings of $840, 000. C-2 rewire verified engineering data and the electrical integrity of wiring prior to flight test and clearly improved mission readiness of rewired aircraft. WINNER -2006 Defense Manufacturing Excellence Award -Seymour Johnson AFB Chief of Staff Award Army Realized Benefits $1, 400/shelter Maintenance cost avoidance $840 K/year Annual cost savings 50% Reduction in troubleshooting time (10 -17 man hours) Air Force Realized Benefits F-15 wiring faults $49 M/year cost avoidance 120 lost a/c days recouped Navy Realized Benefits EA-6 B Circuit Breaker - $2. 4 M overall $137 K/aircraft - $824 K cost avoidance Source: NCMS Project Team

Rapid Manufacturing fabrication methods for replacement and repair of legacy parts are case studied to: § Evaluate and define materials and process factors, § Address part qualification, and specification approval for ADF-RP technologies, and § Create CAD, stl or STEP files for future use. ADF-RP processes include laser sintering (LS), electron beam melting (EBM), stereo-lithography (SLA), fused deposition modeling (FDM), direct metal deposition (DMD), and ultrasonic consolidation. Do. D Investment - $1. 4 M Industry Cost Share - $4. 2 M Rapid Manufacturing and Repair Do. D Potential Cost Benefits $25 M/yr assuming extending technology to Field Level Fluid Analysis similar Do. D components and castings Application by the Armed Services Technology Transfer: • Inserted 12 pieces of ADF-FP equipment into Do. D Maintenance facilities and 12 pieces of ADF-RP equipment for initial piloting at industrial partners – conducted >70 case studies to date. • Rapid manufacturing technologies are being quickly deployed in European and Asian manufacturing communities. Source: Based on commercial industrial experience and over 36 conducted case studies to date WINNER 2005 Defense Manufacturing Excellence Award Realized Benefits Total Annual Cost Avoidance Of $3. 5 M 310 weeks Saved on non-availability of parts per year 50% 75% Raw material and labor cost avoidance 50% - 70% Cycle time reduction for part repair and replacement Greatly reduces repair turnaround time and directly effects diminishing mfg. sources and material shortages (DMSMS)

Rapid Manufacturing fabrication methods for replacement and repair of legacy parts are case studied to: § Evaluate and define materials and process factors, § Address part qualification, and specification approval for ADF-RP technologies, and § Create CAD, stl or STEP files for future use. ADF-RP processes include laser sintering (LS), electron beam melting (EBM), stereo-lithography (SLA), fused deposition modeling (FDM), direct metal deposition (DMD), and ultrasonic consolidation. Do. D Investment - $1. 4 M Industry Cost Share - $4. 2 M Rapid Manufacturing and Repair Do. D Potential Cost Benefits $25 M/yr assuming extending technology to Field Level Fluid Analysis similar Do. D components and castings Application by the Armed Services Technology Transfer: • Inserted 12 pieces of ADF-FP equipment into Do. D Maintenance facilities and 12 pieces of ADF-RP equipment for initial piloting at industrial partners – conducted >70 case studies to date. • Rapid manufacturing technologies are being quickly deployed in European and Asian manufacturing communities. Source: Based on commercial industrial experience and over 36 conducted case studies to date WINNER 2005 Defense Manufacturing Excellence Award Realized Benefits Total Annual Cost Avoidance Of $3. 5 M 310 weeks Saved on non-availability of parts per year 50% 75% Raw material and labor cost avoidance 50% - 70% Cycle time reduction for part repair and replacement Greatly reduces repair turnaround time and directly effects diminishing mfg. sources and material shortages (DMSMS)

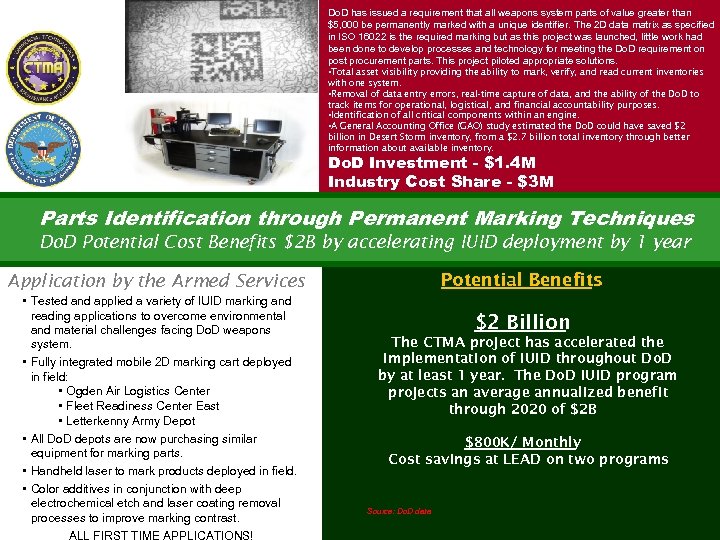

Do. D has issued a requirement that all weapons system parts of value greater than $5, 000 be permanently marked with a unique identifier. The 2 D data matrix as specified in ISO 16022 is the required marking but as this project was launched, little work had been done to develop processes and technology for meeting the Do. D requirement on post procurement parts. This project piloted appropriate solutions. • Total asset visibility providing the ability to mark, verify, and read current inventories with one system. • Removal of data entry errors, real-time capture of data, and the ability of the Do. D to track items for operational, logistical, and financial accountability purposes. • Identification of all critical components within an engine. • A General Accounting Office (GAO) study estimated the Do. D could have saved $2 billion in Desert Storm inventory, from a $2. 7 billion total inventory through better information about available inventory. Do. D Investment - $1. 4 M Industry Cost Share - $3 M Parts Identification through Permanent Marking Techniques Field Level Fluid Analysis Do. D Potential Cost Benefits $2 B by accelerating IUID deployment by 1 year Potential Benefits Application by the Armed Services • Tested and applied a variety of IUID marking and reading applications to overcome environmental and material challenges facing Do. D weapons system. • Fully integrated mobile 2 D marking cart deployed in field: • Ogden Air Logistics Center • Fleet Readiness Center East • Letterkenny Army Depot • All Do. D depots are now purchasing similar equipment for marking parts. • Handheld laser to mark products deployed in field. • Color additives in conjunction with deep electrochemical etch and laser coating removal processes to improve marking contrast. ALL FIRST TIME APPLICATIONS! $2 Billion The CTMA project has accelerated the implementation of IUID throughout Do. D by at least 1 year. The Do. D IUID program projects an average annualized benefit through 2020 of $2 B $800 K/ Monthly Cost savings at LEAD on two programs Source: Do. D data

Do. D has issued a requirement that all weapons system parts of value greater than $5, 000 be permanently marked with a unique identifier. The 2 D data matrix as specified in ISO 16022 is the required marking but as this project was launched, little work had been done to develop processes and technology for meeting the Do. D requirement on post procurement parts. This project piloted appropriate solutions. • Total asset visibility providing the ability to mark, verify, and read current inventories with one system. • Removal of data entry errors, real-time capture of data, and the ability of the Do. D to track items for operational, logistical, and financial accountability purposes. • Identification of all critical components within an engine. • A General Accounting Office (GAO) study estimated the Do. D could have saved $2 billion in Desert Storm inventory, from a $2. 7 billion total inventory through better information about available inventory. Do. D Investment - $1. 4 M Industry Cost Share - $3 M Parts Identification through Permanent Marking Techniques Field Level Fluid Analysis Do. D Potential Cost Benefits $2 B by accelerating IUID deployment by 1 year Potential Benefits Application by the Armed Services • Tested and applied a variety of IUID marking and reading applications to overcome environmental and material challenges facing Do. D weapons system. • Fully integrated mobile 2 D marking cart deployed in field: • Ogden Air Logistics Center • Fleet Readiness Center East • Letterkenny Army Depot • All Do. D depots are now purchasing similar equipment for marking parts. • Handheld laser to mark products deployed in field. • Color additives in conjunction with deep electrochemical etch and laser coating removal processes to improve marking contrast. ALL FIRST TIME APPLICATIONS! $2 Billion The CTMA project has accelerated the implementation of IUID throughout Do. D by at least 1 year. The Do. D IUID program projects an average annualized benefit through 2020 of $2 B $800 K/ Monthly Cost savings at LEAD on two programs Source: Do. D data

Hard chromium plating provides superior wear resistance for a wide variety of surface geometries. While considerable effort has been expended over the past several years to develop alternative processes to hard chrome plating that can match its performance and flexibility, itis not likely to be superseded in the foreseeable future for many critical applications. This project piloted a new “no mask” process in which a customized rack and anode fixture replaces masking, resulting in reduced labor for masking, faster plating times and more uniform chromium deposits. CH-47 horizontal pin and cover support were targeted in the pilot. Do. D Investment - $455 K Industry Cost Share - $888 K No-Mask Hard Chrome Plating Do. D Potential Cost Benefits $15 M/yr assuming deployment at the 7 organic plating facilities. Realized Benefits Application by the Armed Services Technology Transfer: Widely adopted by CCAD in production use. NAVAIR-North Island has identified eight additional parts. Adoption of nomask tooling will result in potential cost avoidance of $15 million per year. Similar savings possible for all Do. D plating facilities that plate hard chrome. Project currently underway to apply this technology to nickel plating. Source: benefit data provided by CCAD Enables maintainers to respond to >200% surge in demand $5 M to date at CCAD and FRCSW $4. 8 M/year throughout Dod Annual labor savings / 83% decreased labor cost / part 200% Increase in plating equipment capacity 60% Reduction in component cycle time

Hard chromium plating provides superior wear resistance for a wide variety of surface geometries. While considerable effort has been expended over the past several years to develop alternative processes to hard chrome plating that can match its performance and flexibility, itis not likely to be superseded in the foreseeable future for many critical applications. This project piloted a new “no mask” process in which a customized rack and anode fixture replaces masking, resulting in reduced labor for masking, faster plating times and more uniform chromium deposits. CH-47 horizontal pin and cover support were targeted in the pilot. Do. D Investment - $455 K Industry Cost Share - $888 K No-Mask Hard Chrome Plating Do. D Potential Cost Benefits $15 M/yr assuming deployment at the 7 organic plating facilities. Realized Benefits Application by the Armed Services Technology Transfer: Widely adopted by CCAD in production use. NAVAIR-North Island has identified eight additional parts. Adoption of nomask tooling will result in potential cost avoidance of $15 million per year. Similar savings possible for all Do. D plating facilities that plate hard chrome. Project currently underway to apply this technology to nickel plating. Source: benefit data provided by CCAD Enables maintainers to respond to >200% surge in demand $5 M to date at CCAD and FRCSW $4. 8 M/year throughout Dod Annual labor savings / 83% decreased labor cost / part 200% Increase in plating equipment capacity 60% Reduction in component cycle time

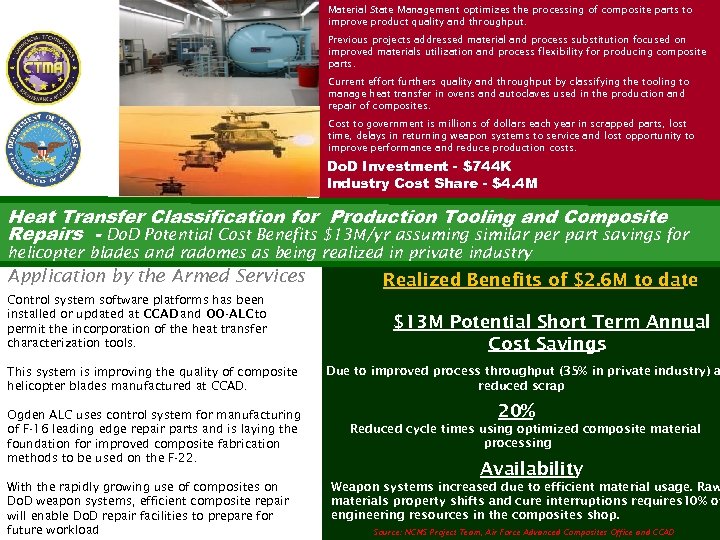

Material State Management optimizes the processing of composite parts to improve product quality and throughput. Previous projects addressed material and process substitution focused on improved materials utilization and process flexibility for producing composite parts. Current effort furthers quality and throughput by classifying the tooling to manage heat transfer in ovens and autoclaves used in the production and repair of composites. Cost to government is millions of dollars each year in scrapped parts, lost time, delays in returning weapon systems to service and lost opportunity to improve performance and reduce production costs. Do. D Investment - $744 K Industry Cost Share - $4. 4 M Heat Transfer Classification for Production Tooling and Composite Repairs - Do. D Potential Cost Benefits $13 M/yr assuming similar per part savings for helicopter blades and radomes as being realized in private industry Application by the Armed Services Control system software platforms has been installed or updated at CCAD and OO-ALC to permit the incorporation of the heat transfer characterization tools. This system is improving the quality of composite helicopter blades manufactured at CCAD. Ogden ALC uses control system for manufacturing of F-16 leading edge repair parts and is laying the foundation for improved composite fabrication methods to be used on the F-22. With the rapidly growing use of composites on Do. D weapon systems, efficient composite repair will enable Do. D repair facilities to prepare for future workload Realized Benefits of $2. 6 M to date $13 M Potential Short Term Annual Cost Savings Due to improved process throughput (35% in private industry) a reduced scrap 20% Reduced cycle times using optimized composite material processing Availability Weapon systems increased due to efficient material usage. Raw materials property shifts and cure interruptions requires 10% of engineering resources in the composites shop. Source: NCMS Project Team, Air Force Advanced Composites Office and CCAD

Material State Management optimizes the processing of composite parts to improve product quality and throughput. Previous projects addressed material and process substitution focused on improved materials utilization and process flexibility for producing composite parts. Current effort furthers quality and throughput by classifying the tooling to manage heat transfer in ovens and autoclaves used in the production and repair of composites. Cost to government is millions of dollars each year in scrapped parts, lost time, delays in returning weapon systems to service and lost opportunity to improve performance and reduce production costs. Do. D Investment - $744 K Industry Cost Share - $4. 4 M Heat Transfer Classification for Production Tooling and Composite Repairs - Do. D Potential Cost Benefits $13 M/yr assuming similar per part savings for helicopter blades and radomes as being realized in private industry Application by the Armed Services Control system software platforms has been installed or updated at CCAD and OO-ALC to permit the incorporation of the heat transfer characterization tools. This system is improving the quality of composite helicopter blades manufactured at CCAD. Ogden ALC uses control system for manufacturing of F-16 leading edge repair parts and is laying the foundation for improved composite fabrication methods to be used on the F-22. With the rapidly growing use of composites on Do. D weapon systems, efficient composite repair will enable Do. D repair facilities to prepare for future workload Realized Benefits of $2. 6 M to date $13 M Potential Short Term Annual Cost Savings Due to improved process throughput (35% in private industry) a reduced scrap 20% Reduced cycle times using optimized composite material processing Availability Weapon systems increased due to efficient material usage. Raw materials property shifts and cure interruptions requires 10% of engineering resources in the composites shop. Source: NCMS Project Team, Air Force Advanced Composites Office and CCAD

Freedom e. Log® enabling technology is a web-based, interactive, on-demand, electronic log that makes visible and tracks all critical production performance criteria. • Shop floor status board • Machine daily view details • Multi-year summaries Developed and implemented Freedom e. Log® system at RRAD to legacy production equipment in order to reduce the cycle time and improve the repeatability or organically manufactured treads. • Document production patterns • Log equipment utilization and downtime verification • Actual vs. theoretical labor hours Smart Machine Pilot Project Do. D Investment - $831 K Industry Cost Share - $1919 K Do. D-Wide Potential Cost Benefits $57 M assuming Level Fluid Analysis Field 1% savings on current Do. D depot maintenance cost of $5. 7 B Application by the Armed Services Technology Transfer: • Planning underway for a commercial deployment in the Rubber Products building at Red River Army Depot. Potential there for expanded deployment. • Pilots installed at WR-ALC and PHNSY Source: Based on commercial industrial experience of Mag Industries and data from RRAD Potential Benefits Depots currently lack Total Asset Visibility for organic manufacturing assets. This technology provides unbiased, rea time view of factory status and health. Industry realizes up to 40% improvement in machine utilizatio yielding as much as 5% improvement in production efficiency Helped RRAD Rubber Products respond to large, war-driven workload increase 25 x 6 Roadwheel - Abrams Tank - 200% average increase 26 x 6 Roadwheel - M 88 - greater than 200% increase 24 x 3. 75 steel Roadwheel - BFV - 80% / 100% increase T-157 I Track Shoe - BFV and MLRS - 60% / 100% increase T-107 Track Shoe - M 88 - 150% / 250% increase Do. D wide deployment could conservatively yield 1% savings o current $5. 7 B depot maintenance cost.

Freedom e. Log® enabling technology is a web-based, interactive, on-demand, electronic log that makes visible and tracks all critical production performance criteria. • Shop floor status board • Machine daily view details • Multi-year summaries Developed and implemented Freedom e. Log® system at RRAD to legacy production equipment in order to reduce the cycle time and improve the repeatability or organically manufactured treads. • Document production patterns • Log equipment utilization and downtime verification • Actual vs. theoretical labor hours Smart Machine Pilot Project Do. D Investment - $831 K Industry Cost Share - $1919 K Do. D-Wide Potential Cost Benefits $57 M assuming Level Fluid Analysis Field 1% savings on current Do. D depot maintenance cost of $5. 7 B Application by the Armed Services Technology Transfer: • Planning underway for a commercial deployment in the Rubber Products building at Red River Army Depot. Potential there for expanded deployment. • Pilots installed at WR-ALC and PHNSY Source: Based on commercial industrial experience of Mag Industries and data from RRAD Potential Benefits Depots currently lack Total Asset Visibility for organic manufacturing assets. This technology provides unbiased, rea time view of factory status and health. Industry realizes up to 40% improvement in machine utilizatio yielding as much as 5% improvement in production efficiency Helped RRAD Rubber Products respond to large, war-driven workload increase 25 x 6 Roadwheel - Abrams Tank - 200% average increase 26 x 6 Roadwheel - M 88 - greater than 200% increase 24 x 3. 75 steel Roadwheel - BFV - 80% / 100% increase T-157 I Track Shoe - BFV and MLRS - 60% / 100% increase T-107 Track Shoe - M 88 - 150% / 250% increase Do. D wide deployment could conservatively yield 1% savings o current $5. 7 B depot maintenance cost.

Cold Spray technology – investigate several technologies and processes for high velocity spray of metal particles to apply corrosion protective coatings and also as a repair technology through build-up of metal surfaces. • Corrosion protection is a $2 B problem to Do. D. Cold Spray technology could reduce cost by 1% or $20 M Do. D Investment - $451 K Industry Cost Share - $978 K Kinetic Spray Metal Deposition Do. D Potential Cost Benefits $100 M/yr assuming full Do. D deployment Field Level Fluid Analysis addressing 1% of $10 B/yr cost of corrosion Potential Benefits Application by the Armed Services Fleet Readiness Center (FRC) East, N. Carolina, reports a H 8. 5% 53 helicopter gearbox repair cost avoidance of approximately $80 K per year (average of four housings per year). FRC has Cost reduction per part received Kinetic Spray equipment, a Cold Gas Technology CGT 4000/17 USMC Maintenance Depot at Albany reports that the Marine Corps Light Armored Vehicle (LAV), fleet on Okinawa cost avoidance of one 1010 steel bulkhead component is estimated to be approximately $100 K per year. Vandenberg Air Force Base, CA, US Space Command, to repair corrosion of missile silos. US Army Fort Hood, TX to repair mast support of radar pod on Apache helicopters. Patrick Air Force Base, FL to repair IVD Aluminum coating on F-15 landing gear. WINNER 2007 Defense Manufacturing Excellence Award 60% Overall process cycle time improvement Metal deposition coatings are far superior to painted coatings, and this project developed the first fieldable technology for applying metal coatings Source: Centerline Limited

Cold Spray technology – investigate several technologies and processes for high velocity spray of metal particles to apply corrosion protective coatings and also as a repair technology through build-up of metal surfaces. • Corrosion protection is a $2 B problem to Do. D. Cold Spray technology could reduce cost by 1% or $20 M Do. D Investment - $451 K Industry Cost Share - $978 K Kinetic Spray Metal Deposition Do. D Potential Cost Benefits $100 M/yr assuming full Do. D deployment Field Level Fluid Analysis addressing 1% of $10 B/yr cost of corrosion Potential Benefits Application by the Armed Services Fleet Readiness Center (FRC) East, N. Carolina, reports a H 8. 5% 53 helicopter gearbox repair cost avoidance of approximately $80 K per year (average of four housings per year). FRC has Cost reduction per part received Kinetic Spray equipment, a Cold Gas Technology CGT 4000/17 USMC Maintenance Depot at Albany reports that the Marine Corps Light Armored Vehicle (LAV), fleet on Okinawa cost avoidance of one 1010 steel bulkhead component is estimated to be approximately $100 K per year. Vandenberg Air Force Base, CA, US Space Command, to repair corrosion of missile silos. US Army Fort Hood, TX to repair mast support of radar pod on Apache helicopters. Patrick Air Force Base, FL to repair IVD Aluminum coating on F-15 landing gear. WINNER 2007 Defense Manufacturing Excellence Award 60% Overall process cycle time improvement Metal deposition coatings are far superior to painted coatings, and this project developed the first fieldable technology for applying metal coatings Source: Centerline Limited

3 FAST technology is focused on delivering a tool that maintainers can use to assess their fluids (lubricant, hydraulics, transmission) in near real-time. – Initial needs statement provided by Army ground maintainers in Iraq – Provides an expeditionary fluid analysis capability – Supplements AOAP lab analysis by developing same capability for in-field use – Increase the capabilities of maintainers in the field (expeditionary maintenance) – Condition based maintenance for fluids supported with on-demand testing, rather than on hard-time or hard-mileage intervals. – Speed up and streamline the maintenance of fluid-wetted components – Portable 3 FAST tools revitalize the way our military maintains its equipment Do. D Investment - $1 M Industry Cost Share - $2. 2 M Fast Field Fluid Assessment Tools (3 FAST) Field Level Fluid Analysis Do. D Potential Cost Benefits $15 M/yr (assuming broad cross service adoption) Application by the Armed Services Projected Applications for project technology in development • Do. D Aviation equipment –Rotary and fixed wing aircraft –Tug, tractor, AGPU • Ground equipment –All tactical vehicles –HMMWV, HEMTT –Hauled 10 ton tractor trailer –PLS – palletized loading system –LAV 25, EFV • Power generation equipment (15 – 60 kilowatts) Source: Numbers were developed • All engineering equipment by Dr. Ed Urbansky, JOAP-TSC –M 9 ACE, backhoe, bulldozer Potential Benefits $3 M/year Centralized oil testing curtailed $4 -6 M/year Saved in waste oil reduction $6 M/year Ensure correct fluid type in components $3 M/year Reduced logistics/supply chain in theater

3 FAST technology is focused on delivering a tool that maintainers can use to assess their fluids (lubricant, hydraulics, transmission) in near real-time. – Initial needs statement provided by Army ground maintainers in Iraq – Provides an expeditionary fluid analysis capability – Supplements AOAP lab analysis by developing same capability for in-field use – Increase the capabilities of maintainers in the field (expeditionary maintenance) – Condition based maintenance for fluids supported with on-demand testing, rather than on hard-time or hard-mileage intervals. – Speed up and streamline the maintenance of fluid-wetted components – Portable 3 FAST tools revitalize the way our military maintains its equipment Do. D Investment - $1 M Industry Cost Share - $2. 2 M Fast Field Fluid Assessment Tools (3 FAST) Field Level Fluid Analysis Do. D Potential Cost Benefits $15 M/yr (assuming broad cross service adoption) Application by the Armed Services Projected Applications for project technology in development • Do. D Aviation equipment –Rotary and fixed wing aircraft –Tug, tractor, AGPU • Ground equipment –All tactical vehicles –HMMWV, HEMTT –Hauled 10 ton tractor trailer –PLS – palletized loading system –LAV 25, EFV • Power generation equipment (15 – 60 kilowatts) Source: Numbers were developed • All engineering equipment by Dr. Ed Urbansky, JOAP-TSC –M 9 ACE, backhoe, bulldozer Potential Benefits $3 M/year Centralized oil testing curtailed $4 -6 M/year Saved in waste oil reduction $6 M/year Ensure correct fluid type in components $3 M/year Reduced logistics/supply chain in theater

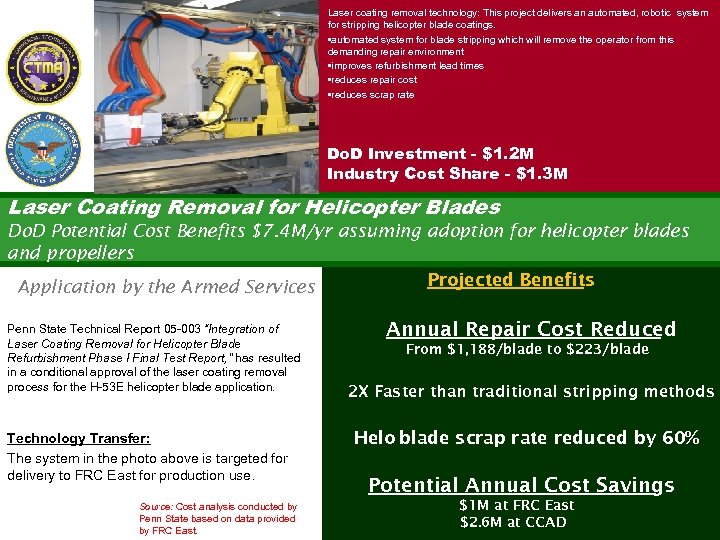

Laser coating removal technology: This project delivers an automated, robotic system for stripping helicopter blade coatings. • automated system for blade stripping which will remove the operator from this demanding repair environment • improves refurbishment lead times • reduces repair cost • reduces scrap rate Do. D Investment - $1. 2 M Industry Cost Share - $1. 3 M Laser Coating Removal for Helicopter Blades Do. D Potential Cost Benefits $7. 4 M/yr assuming adoption for helicopter blades Field Level Fluid Analysis and propellers Application by the Armed Services Penn State Technical Report 05 -003 “Integration of Laser Coating Removal for Helicopter Blade Refurbishment Phase I Final Test Report, ” has resulted in a conditional approval of the laser coating removal process for the H-53 E helicopter blade application. Technology Transfer: The system in the photo above is targeted for delivery to FRC East for production use. Source: Cost analysis conducted by Penn State based on data provided by FRC East. Projected Benefits Annual Repair Cost Reduced From $1, 188/blade to $223/blade 2 X Faster than traditional stripping methods Helo blade scrap rate reduced by 60% Potential Annual Cost Savings $1 M at FRC East $2. 6 M at CCAD

Laser coating removal technology: This project delivers an automated, robotic system for stripping helicopter blade coatings. • automated system for blade stripping which will remove the operator from this demanding repair environment • improves refurbishment lead times • reduces repair cost • reduces scrap rate Do. D Investment - $1. 2 M Industry Cost Share - $1. 3 M Laser Coating Removal for Helicopter Blades Do. D Potential Cost Benefits $7. 4 M/yr assuming adoption for helicopter blades Field Level Fluid Analysis and propellers Application by the Armed Services Penn State Technical Report 05 -003 “Integration of Laser Coating Removal for Helicopter Blade Refurbishment Phase I Final Test Report, ” has resulted in a conditional approval of the laser coating removal process for the H-53 E helicopter blade application. Technology Transfer: The system in the photo above is targeted for delivery to FRC East for production use. Source: Cost analysis conducted by Penn State based on data provided by FRC East. Projected Benefits Annual Repair Cost Reduced From $1, 188/blade to $223/blade 2 X Faster than traditional stripping methods Helo blade scrap rate reduced by 60% Potential Annual Cost Savings $1 M at FRC East $2. 6 M at CCAD

Contact Greg Kilchenstein ADUSD (MP&P) greg. kilchenstein@osd. mil (703) 614 -0862 Chuck Ryan VP Technology, NCMS chuckr@ncms. org (734) 995 -4905

Contact Greg Kilchenstein ADUSD (MP&P) greg. kilchenstein@osd. mil (703) 614 -0862 Chuck Ryan VP Technology, NCMS chuckr@ncms. org (734) 995 -4905