80c1ceb978567d6acaa73ae2bfbc1e45.ppt

- Количество слайдов: 59

The Challenges in Upgrading Plant Automation for an Existing Wastewater Treatment Plant By Gary Parker, PE Burns & Mc. Donnell March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

The Challenges in Upgrading Plant Automation for an Existing Wastewater Treatment Plant By Gary Parker, PE Burns & Mc. Donnell March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Agenda l Background l Data Gathering l Control system documentation l Interviewing operator and maintenance personnel l Design Phase l Construction Phase l Control system startup March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Agenda l Background l Data Gathering l Control system documentation l Interviewing operator and maintenance personnel l Design Phase l Construction Phase l Control system startup March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

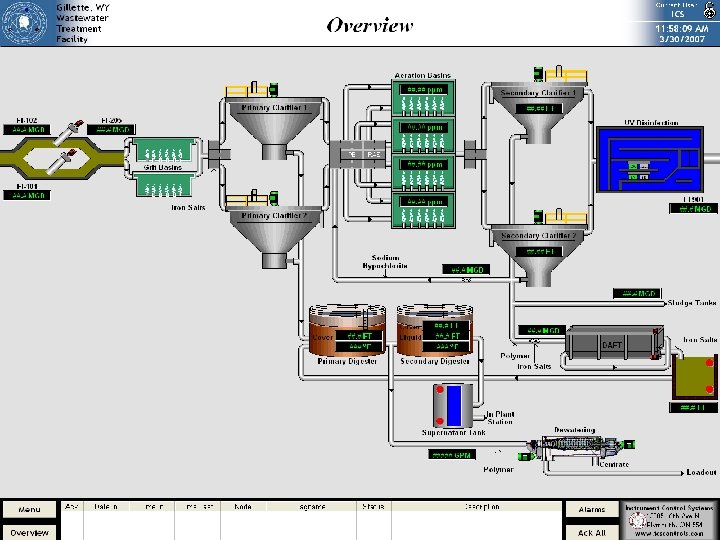

Background l Existing WWTP built mid 1980’s l Present capacity 5 MGD, 15 MGD future l Plant control system ¡ Local control panels in each process area ¡ Loop controllers, lights, pushbuttons l Remote monitoring of major plant alarms l Telephone dialers to call operators l Existing SCADA for remote sites March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Background l Existing WWTP built mid 1980’s l Present capacity 5 MGD, 15 MGD future l Plant control system ¡ Local control panels in each process area ¡ Loop controllers, lights, pushbuttons l Remote monitoring of major plant alarms l Telephone dialers to call operators l Existing SCADA for remote sites March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Data Gathering l Site survey l Collect control system documentation l Review O&M manuals l Review plans l Interview operations and maintenance staff for changes to plant controls March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Data Gathering l Site survey l Collect control system documentation l Review O&M manuals l Review plans l Interview operations and maintenance staff for changes to plant controls March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Existing Documentation l Shop drawings for each control panel l Notes from maintenance staff l Maintenance electrician with plant history left for another company l Memory test of operators l No P&IDs existed l Modifications not documented March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Existing Documentation l Shop drawings for each control panel l Notes from maintenance staff l Maintenance electrician with plant history left for another company l Memory test of operators l No P&IDs existed l Modifications not documented March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

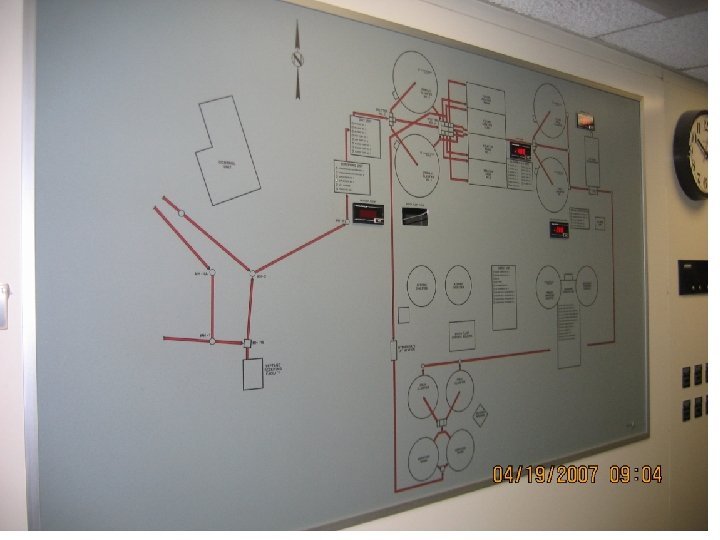

Existing Plant Controls l Main Graphic Panel CP-01 l Local control panels for ¡ Grit CP-03 ¡ Blower/RAS CP-07 ¡ Digester CP-11 ¡ Energy CP-12 ¡ In Plant pump station CP-14 March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Existing Plant Controls l Main Graphic Panel CP-01 l Local control panels for ¡ Grit CP-03 ¡ Blower/RAS CP-07 ¡ Digester CP-11 ¡ Energy CP-12 ¡ In Plant pump station CP-14 March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

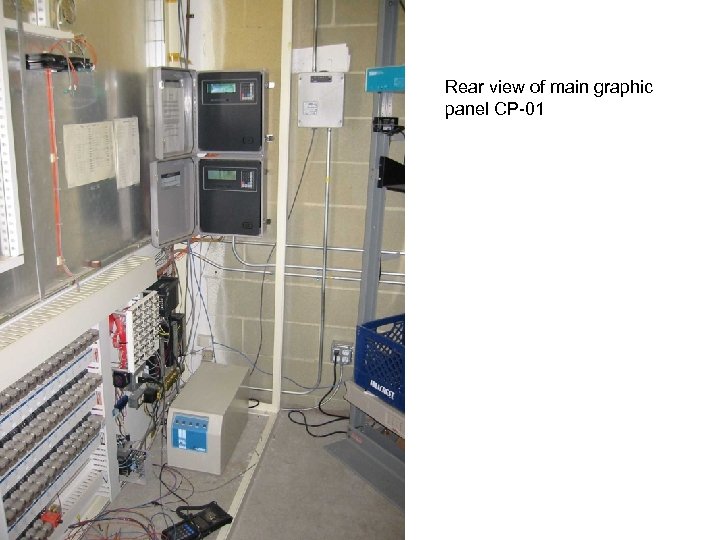

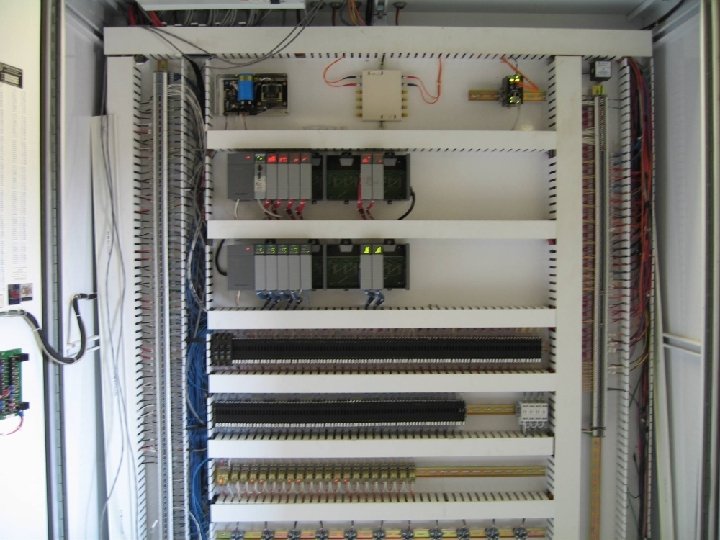

Rear view of main graphic panel CP-01

Rear view of main graphic panel CP-01

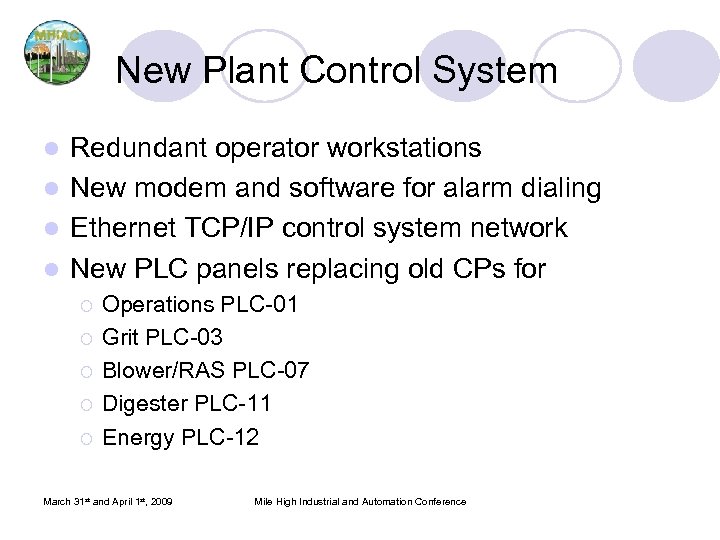

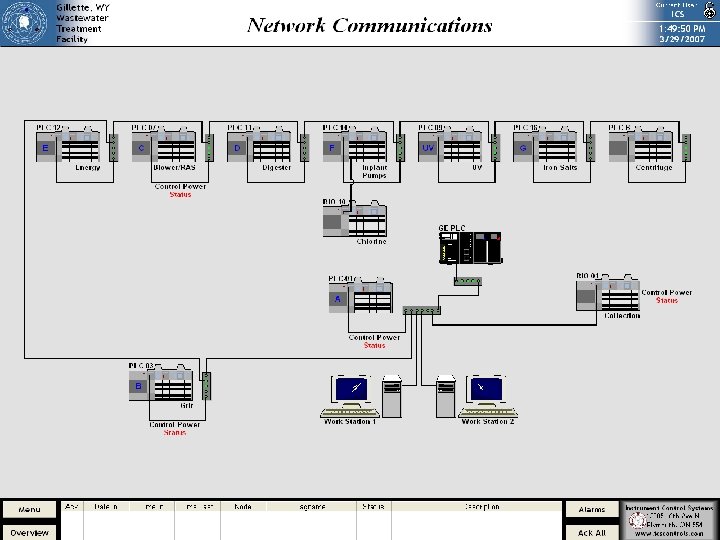

New Plant Control System Redundant operator workstations l New modem and software for alarm dialing l Ethernet TCP/IP control system network l New PLC panels replacing old CPs for l ¡ ¡ ¡ Operations PLC-01 Grit PLC-03 Blower/RAS PLC-07 Digester PLC-11 Energy PLC-12 March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

New Plant Control System Redundant operator workstations l New modem and software for alarm dialing l Ethernet TCP/IP control system network l New PLC panels replacing old CPs for l ¡ ¡ ¡ Operations PLC-01 Grit PLC-03 Blower/RAS PLC-07 Digester PLC-11 Energy PLC-12 March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

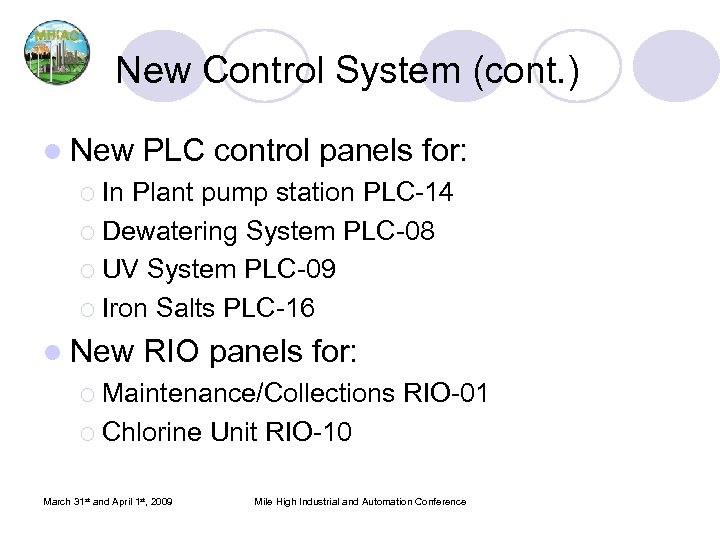

New Control System (cont. ) l New PLC control panels for: ¡ In Plant pump station PLC-14 ¡ Dewatering System PLC-08 ¡ UV System PLC-09 ¡ Iron Salts PLC-16 l New RIO panels for: ¡ Maintenance/Collections ¡ Chlorine March 31 st and April 1 st, 2009 RIO-01 Unit RIO-10 Mile High Industrial and Automation Conference

New Control System (cont. ) l New PLC control panels for: ¡ In Plant pump station PLC-14 ¡ Dewatering System PLC-08 ¡ UV System PLC-09 ¡ Iron Salts PLC-16 l New RIO panels for: ¡ Maintenance/Collections ¡ Chlorine March 31 st and April 1 st, 2009 RIO-01 Unit RIO-10 Mile High Industrial and Automation Conference

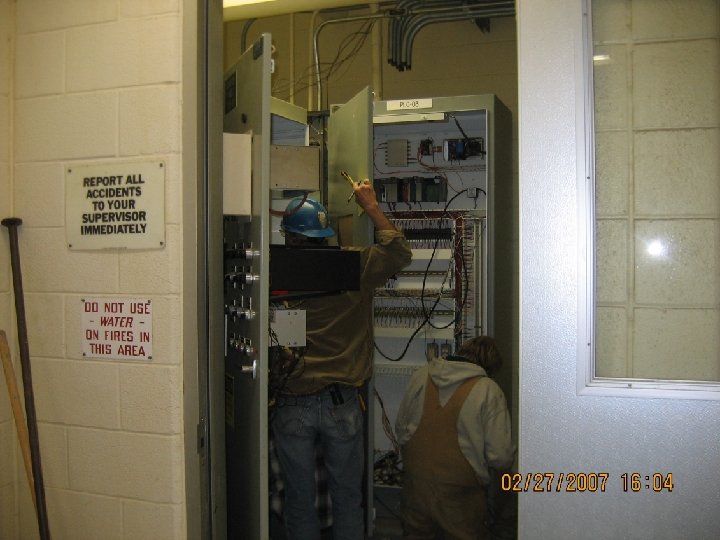

Construction Challenges l l l Constructing pathways for new control system network Replacing old control panels Tight space to remove and replace Keep old system operational Startup of new control system one point or one system at a time Training operators during and after installation March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Construction Challenges l l l Constructing pathways for new control system network Replacing old control panels Tight space to remove and replace Keep old system operational Startup of new control system one point or one system at a time Training operators during and after installation March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Construction Coordination l Daily coordination meetings l Operator assigned to contractor daily l Transfer one system at a time l Test each system before moving to the next system l Functional test each area upon completion l Point by point test from field device to operator workstation March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Construction Coordination l Daily coordination meetings l Operator assigned to contractor daily l Transfer one system at a time l Test each system before moving to the next system l Functional test each area upon completion l Point by point test from field device to operator workstation March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

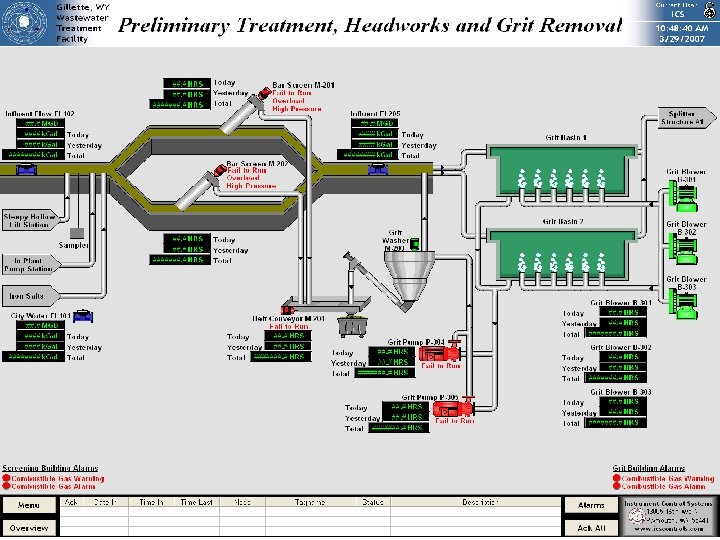

Grit Unit Automation l Alarm annunciator l Pilots lights l Pushbuttons l Methane gas detection l Screening equipment monitoring l Grit equipment monitoring l Primary clarifiers monitoring March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Grit Unit Automation l Alarm annunciator l Pilots lights l Pushbuttons l Methane gas detection l Screening equipment monitoring l Grit equipment monitoring l Primary clarifiers monitoring March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

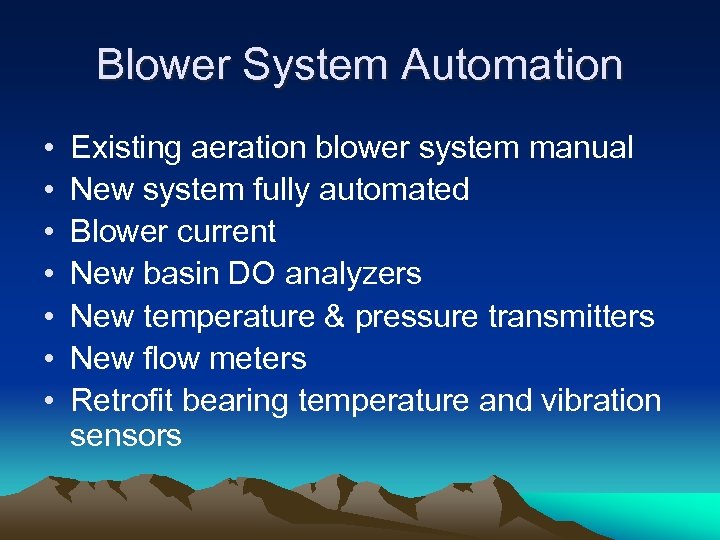

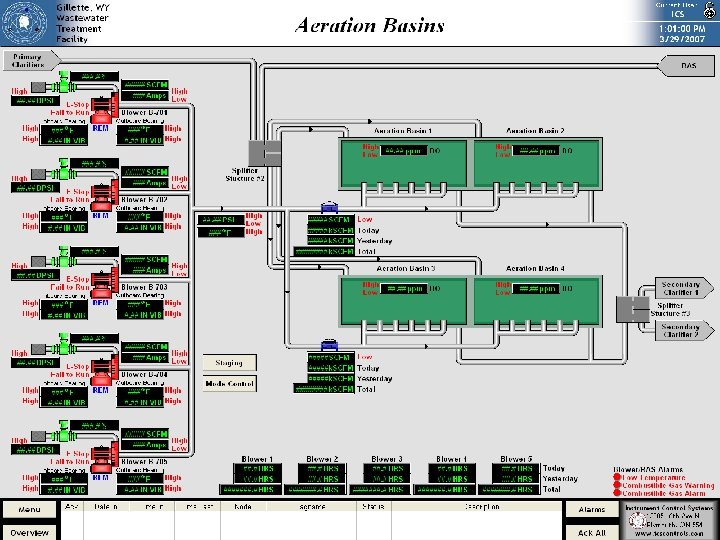

Blower System Automation • • Existing aeration blower system manual New system fully automated Blower current New basin DO analyzers New temperature & pressure transmitters New flow meters Retrofit bearing temperature and vibration sensors

Blower System Automation • • Existing aeration blower system manual New system fully automated Blower current New basin DO analyzers New temperature & pressure transmitters New flow meters Retrofit bearing temperature and vibration sensors

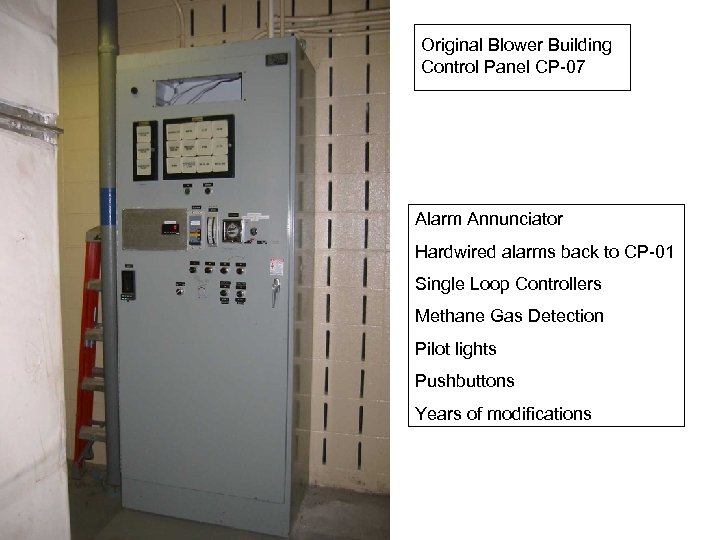

Original Blower Building Control Panel CP-07 Alarm Annunciator Hardwired alarms back to CP-01 Single Loop Controllers Methane Gas Detection Pilot lights Pushbuttons Years of modifications

Original Blower Building Control Panel CP-07 Alarm Annunciator Hardwired alarms back to CP-01 Single Loop Controllers Methane Gas Detection Pilot lights Pushbuttons Years of modifications

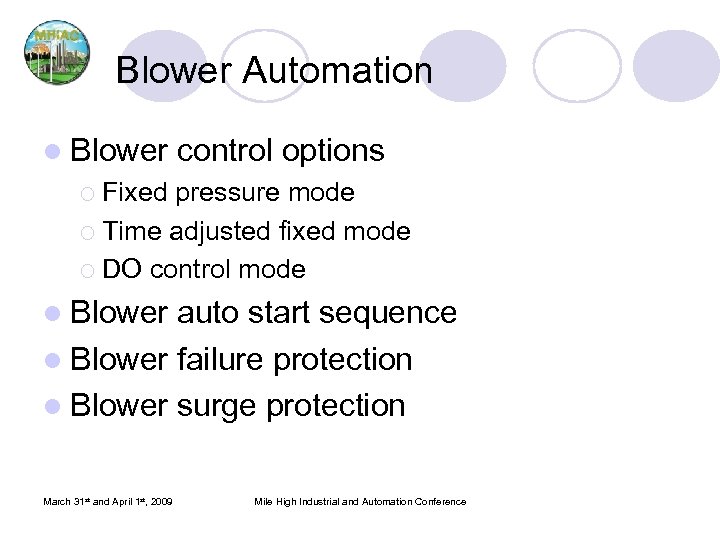

Blower Automation l Blower control options ¡ Fixed pressure mode ¡ Time adjusted fixed mode ¡ DO control mode l Blower auto start sequence l Blower failure protection l Blower surge protection March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Blower Automation l Blower control options ¡ Fixed pressure mode ¡ Time adjusted fixed mode ¡ DO control mode l Blower auto start sequence l Blower failure protection l Blower surge protection March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

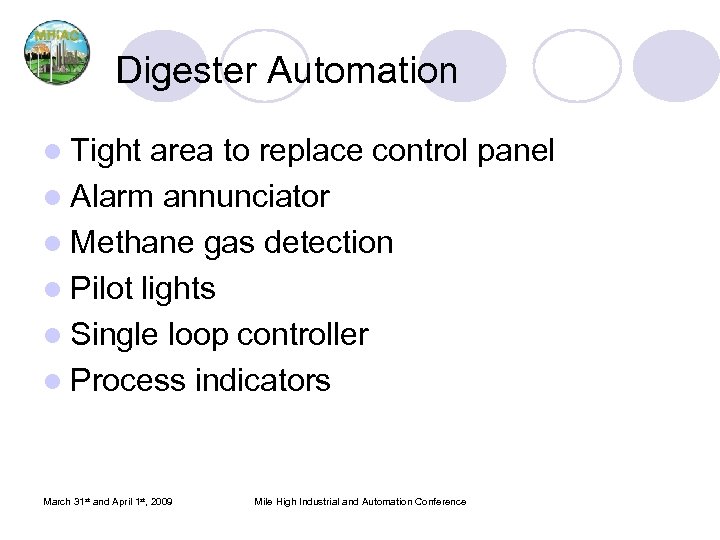

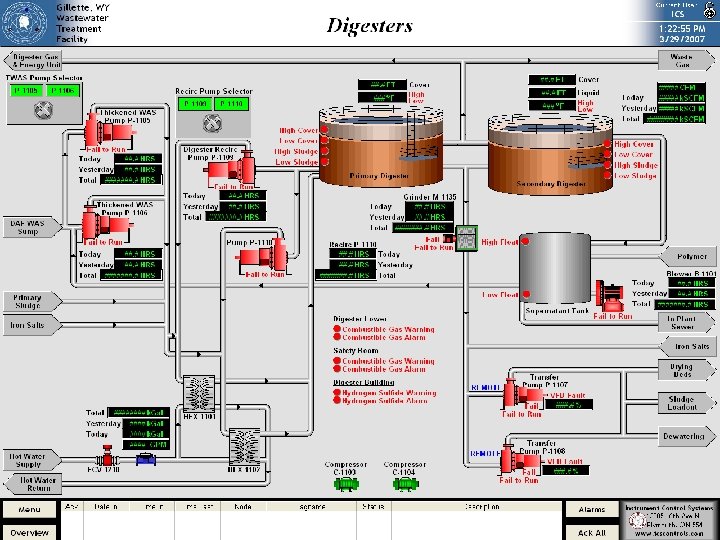

Digester Automation l Tight area to replace control panel l Alarm annunciator l Methane gas detection l Pilot lights l Single loop controller l Process indicators March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Digester Automation l Tight area to replace control panel l Alarm annunciator l Methane gas detection l Pilot lights l Single loop controller l Process indicators March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

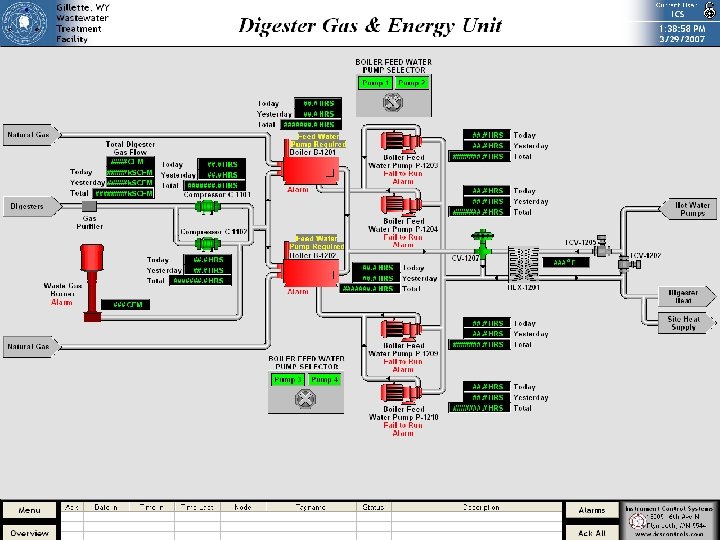

Energy Unit Automation l Temperature single loop controllers l Manual pump control through switches l Boiler monitoring l Digester gas for boilers l Remote alarms to CP-01 March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Energy Unit Automation l Temperature single loop controllers l Manual pump control through switches l Boiler monitoring l Digester gas for boilers l Remote alarms to CP-01 March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

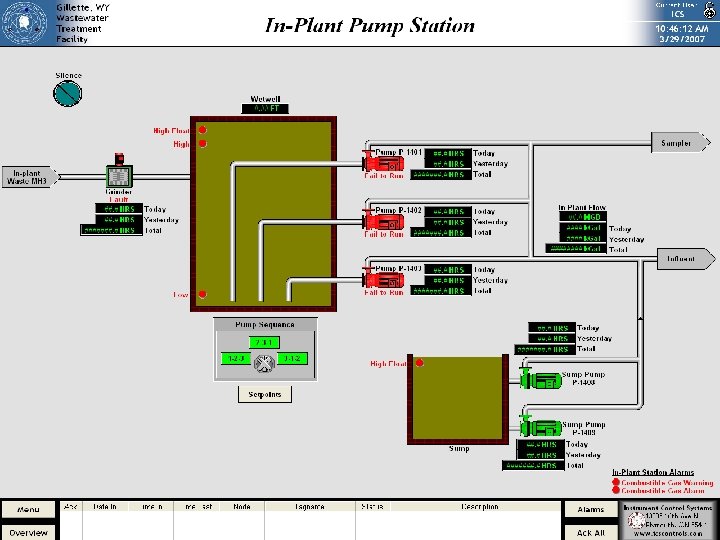

In Plant Pump Station Automation l Pump control l Wetwell level monitoring through bubbler l Grinder monitoring l Sump pump monitoring l Remote alarms to CP-01 March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

In Plant Pump Station Automation l Pump control l Wetwell level monitoring through bubbler l Grinder monitoring l Sump pump monitoring l Remote alarms to CP-01 March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

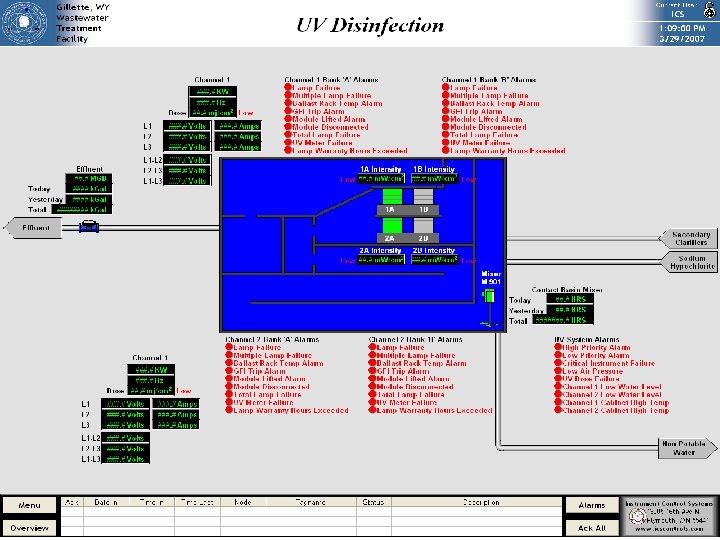

New UV System l Retrofit UV system in existing effluent chlorine contact basin l Enclose outdoor basin l Interface packaged controls into plant control network l Demolish gaseous chlorine system l New sodium hypochlorite system March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

New UV System l Retrofit UV system in existing effluent chlorine contact basin l Enclose outdoor basin l Interface packaged controls into plant control network l Demolish gaseous chlorine system l New sodium hypochlorite system March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

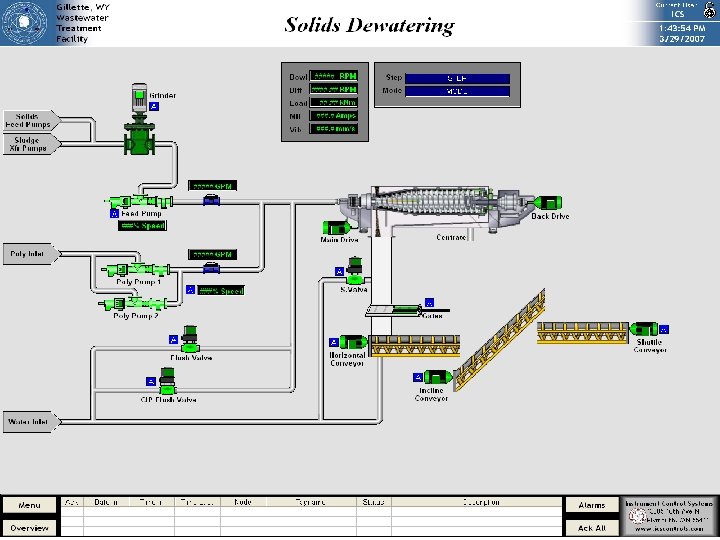

New Dewatering Building l New centrifuge equipment l Integrate packaged controls into plant control system l Owner prepurchased centrifuge equipment l Soilds pump control over control system network in Digester building l Solids loadout conveyor system March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

New Dewatering Building l New centrifuge equipment l Integrate packaged controls into plant control system l Owner prepurchased centrifuge equipment l Soilds pump control over control system network in Digester building l Solids loadout conveyor system March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Thank You l Questions? Gary Parker, PE Burns & Mc. Donnell gparker@burnsmcd. com 303 -474 -2241 March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference

Thank You l Questions? Gary Parker, PE Burns & Mc. Donnell gparker@burnsmcd. com 303 -474 -2241 March 31 st and April 1 st, 2009 Mile High Industrial and Automation Conference