2c6fc0209107acb616edff194ca70428.ppt

- Количество слайдов: 45

The Basics of Chemical & Biological Safety for Radiation Safety Professionals Robert Emery, Dr. PH, CHP, CIH, CSP, RBP, CHMM, CPP, ARM Vice President for Safety, Health, Environment, Risk Management & Quality Assurance The University of Texas Health Science Center at Houston Associate Professor of Occupational Health The University of Texas School of Public Health

Public Health Significance: Chemicals • Over 30 million American workers are exposed to hazardous chemicals in their workplaces. That is equivalent to 1 out 5 workers http: //www. osha. gov/dsg/hazcom/finalmsdsreport. html • Approximately 20, 000 cancer deaths and 40, 000 new cases of cancer each year in the U. S. are attributable to occupational exposure - http: //www. cdc. gov/niosh/topics/cancer/ • In 2001, out of 14, 500 reported cases of occupational respiratory conditions due to toxic agents, 2, 800 (19%) of them were reported from Health Services Industry. http: //www 2 a. cdc. gov/drds/World. Report. Data/Figure. Table. Details. asp? Figure. Table. ID= 959&Group. Ref. Number=T 11 -03

Public Health Significance: Bloodborne Biological Agents • Approximately 1, 000 accidental needlesticks occur per day nationwide. • The probability of contracting HBV from a needlestick injury is anywhere between 22 and 40 percent. • HBV can survive a week outside a living organism. • • http: //www. highbeam. com/doc/1 G 1 -62450723. html http: //www. traveldoc. com/download/needlestick. pdf

Industrial Hygiene • The art and science devoted to the anticipation, recognition, evaluation and control of all workplace environmental factors which may cause sickness, impaired health or significant discomfort among workers or the citizens of the community.

Elements of a Chemical Safety Program • Hazard Communication – 29 CFR 1910. 1200 • Laboratory Standard – 29 CFR 1910. 1450 • Occupational exposure monitoring – 29 CFR 1910. 1000 • Respiratory Protection – 29 CFR 1910. 134 • PPE – 29 CFR 1910. 132 • Emergency spill preparation and response – 29 CFR 1910. 120

Hazard Communication / Laboratory Standard • Performance standards • Development and implementation of Chemical Hygiene Plan • Primary emphasis on administrative controls to protect workers • Readily accessible

Chemical Hygiene Plan should include: • Responsibilities • Standard Operating Procedures • Plans for Controlling Chemical Exposures • Engineering Controls • Medical Consultation and Review • Chemical Hygiene Officer • Special Provisions for Hazardous Chemical Use

Who Should Be Trained and When? • Any employee that is assigned to a work area where hazardous chemicals are present. • At the time of an employee’s initial assignment • Prior to assignments involving new exposure situations • Refresher information and training – “. . . shall be determined by the employer. ”

What Must be Included? • The contents and appendices of the standard • The location, availability, and details of the written Chemical Hygiene Plan • The PEL’s for OSHA regulated substances or OEL’s for other hazardous chemicals • Signs and symptoms associated with exposure • Location and availability of reference material on the hazards, safe handling, storage, and disposal • Material Safety Data Sheets (MSDS) availability and location • Methods to detect presence or release of hazardous chemicals

Material Safety Data Sheets • Standard 16 section ANSI format • Provided by manufacturers and distributors • Required by 29 CFR 1910. 1200(g) • Contains specific information of chemical properties, hazards, storage, . . . etc. • Periodically updated by manufacturer

Dose-Response Relationships • Paracelsus (1493 -1541) “All substances are poisons; there is none which is not a poison. The right dose differentiates a poison…. ”

Evaluation of Toxicity • Lethal dose 50 or LD 50 usually in mg/kg • Lethal concentration 50 or LC 50 usually in ppm or mg/L or mg/m 3 • Lowest concentration to cause death in test animals: LDlo and LClo • The lower these values the more toxic the chemical

Risk Assessment for Hazardous Chemicals • • Identify chemicals and how used Consult sources of information Evaluate toxicity type Consider routes of exposure Evaluate quantitative toxicity information Decide how to minimize exposure Prepare for possible accidents/emergencies

Working with Hazardous Chemicals • • • Hazards are not always known New chemicals are often generated Be prepared for accidents Limit access to areas with chemicals Wash hands before leaving work area • Assume mixtures are more toxic than individual components

Minimize Chemical Exposures • Wear eye protection: glasses, goggles, face shields • Use laboratory hoods • Be careful when handling syringes filled with chemicals • Wear appropriate gloves • Keep body covered: pants, lab coat, appropriate shoes • Use respiratory protection as a last resort

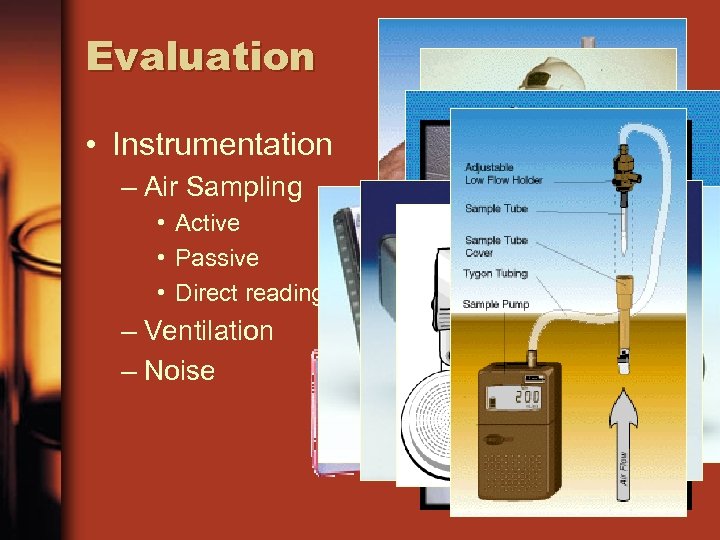

Evaluation • Instrumentation – Air Sampling • Active • Passive • Direct reading – Ventilation – Noise

Sampling Strategy • Determine what types of exposure hazards are present • Assess the sources and degree of exposure to each significant hazard • Select methods and equipment, perform calibrations and assure that adequate quality control exists • Evaluate and interpret the sampling data • Apply results to minimize the hazards that might be present

Permissible Exposure Limit (PEL) • Published by OSHA – Legally enforceable • Originally extracted from the 1968 TLVs • Typically slow to change

Threshold Limit Value (TLV) • Published annually by ACGIH • Threshold Limit Value-Time Weighted Average (TLV-TWA) – Time weighted concentration for a conventional 8 -hour work day and a 40 hour work week, to which nearly all workers may be exposed, day after day without adverse effects

Threshold Limit Value (TLV) • Threshold Limit Value-Short Term Exposure Limit (TLV-STEL) – 15 minute TWA, maximal concentration to which workers can be exposed for a period of up to 15 minutes without suffering from any adverse effects – < 15 minutes & not be repeated more than four times daily with at least 60 minutes between successive exposures in this range • Threshold Limit Value-Ceiling (TLV-C) – Concentration that should not be exceeded during any part of the working exposure

Control • Engineering – Design specifications – Isolation – Ventilation • Administrative – Scheduling – Location – Substitution

Control • Personal Protective Equipment – Respirators – Chemical barriers • Gloves, lab-coats, boots – Safety goggles or glasses

Hazardous Chemical Waste • Resource Conservation and Recovery Act (EPA) • Waste Characterization • Mixed waste

References • Prudent Practices in the Laboratory, Handling and Disposal of Chemicals. National Research Council. Washington, D. C. : National Academy Press, 1995. • Hall, Stephen K. Chemical Safety in the Laboratory. Boca Raton, FL: CRC Press, 1994. • Threshold Limit Values for Chemical Substances and Physical Agents and Biological Exposure Indices. Cincinnati, OH: ACGIH, 2009. • CRC Handbook of Laboratory Safety. A. Keith Furr, CRC Press. • OSHA Hazard Communication Standard 29 CFR 1910. 1200 • OSHA Laboratory Standard 29 CFR 1910. 1450 • OSHA Hazardous waste operations and emergency response 29 CFR 1910. 120

The Basics of Biological Safety for Radiation Safety Professionals Robert Emery, Dr. PH, CHP, CIH, CSP, RBP, CHMM, CPP, ARM Vice President for Safety, Health, Environment, Risk Management & Quality Assurance The University of Texas Health Science Center at Houston Associate Professor of Occupational Health The University of Texas School of Public Health

What Is Biological Safety? • The field of biosafety promotes infection control, safe laboratory practices, procedures, and proper use of containment equipment and facilities; and provides advice on laboratory design as it relates to biological and infectious agents

Where HPs May Encounter Biological Hazards • • Healthcare institutions Research institution Bioassay samples Emergency response Mixed waste Other duties as assigned Etc.

Areas of Biosafety • Bloodborne pathogens (BBP) – OSHA Bloodborne Pathogens Standard 29 CFR 1910. 1030 • Biological waste disposal – State regulations concerning biological waste disposal • Laboratory Safety – Biosafety in Microbiological and Biomedical Laboratories 5 th ed. CDC/NIH • Infectious substance and diagnostic specimen shipping – IATA, DOT, & USPS Dangerous Goods Regulations

Areas of Biosafety • Recombinant DNA (r. DNA) – NIH Guidelines on Recombinant DNA Molecules • Respiratory Protection – 29 CFR 1910. 134 (139 TB standard repealed) • Bioterrorism – Select Agents, 42 CFR 73 (human), 9 CFR 121 (animal); 7 CFR 331 (plant) • Mold and indoor air quality – Mold Assessment and Remediation 25 TAC 1 295 J – Indoor Air Quality 25 TAC 1 297 A • Occupational safety and health in the use of research animals

Risk Assessment • Process to determine the appropriate containment level and procedures • Factors include: • Pathogenicity, route of transmission, concentration, origin, availability of prophylaxis, experience, r. DNA work, genes of interest, replication competence, etc…

Hazard Classifications of Microbial Agents (1 -4) • Risk Group 1 – Minimal hazard to humans, not known to cause disease in healthy adults • Risk Group 2 – Agents associated with disease which is rarely serious or there is treatment available, generally oral or inoculation hazards

Hazard Classifications of Microbial Agents (1 -4) • Risk Group 3 – High individual risk, associated with serious disease which may or may not have treatment, generally aerosol transmission hazard • Risk Group 4 – Serious or lethal disease for which there is not usually a therapeutic intervention, generally dangerous and exotic viruses

Biosafety in Microbiological and Biomedical Laboratories (BMBL) Download 5 th Ed HHS Publication No. (CDC) 938395 at www. cdc. gov and search “BMBL 5 th”

BMBL Contents • • • Principles of Biosafety Laboratory Biosafety Level Criteria Animal Biosafety Level Criteria Risk Assessment Recommended Biosafety Levels Biological Agent Summaries

Biological Safety Levels • Biosafety levels are combinations of facilities and practices: Level 1: basic lab, good lab practices Level 2: limited lab access, specific training and practices Level 3: containment (biosafety cabinet), specific training and practices Level 4: full containment, specific facility, training and practices

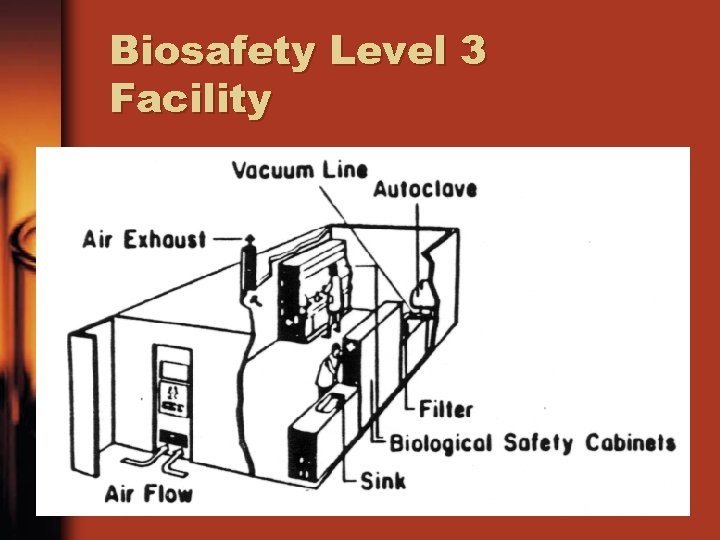

Biosafety Level 3 Facility

Biological Safety Cabinets (BSC) • BSC Class I: negative pressure ventilated cabinet; no product protection • BSC Class II: HEPA filtered exhaust: provides product and personnel protection. 2 types – A & B • BSC Class III: fully contained glove box

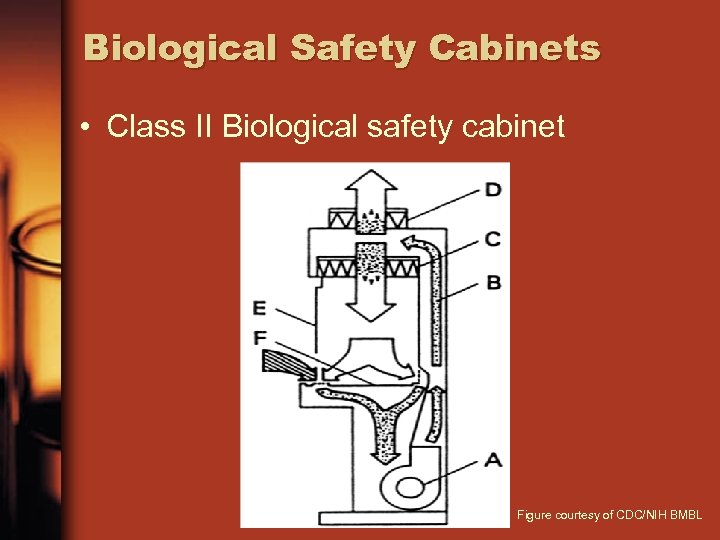

Biological Safety Cabinets • Class II Biological safety cabinet Figure courtesy of CDC/NIH BMBL

BBP Standard • • • 29 CFR 1910. 1030 Exposure Control Plan Exposure determination Work practices Standard / Universal Precautions HBV vaccination Labeling Potentially infectious waste handling Medical evaluation Training

Microbial Sampling • Not routinely done or recommended • • • Source Air Bulk Culturable versus Non-culturable Building should be evaluated under normal operating conditions • Note conditions during sampling • Results generally reported in CFU (colony forming units) • No standards for results comparison

The Select Agent Rule

Emerging Issue - Select Agents and Bioterrorism • Antiterrorism and Effective Death Penalty Act of 1996 (PL 104 -132) • Invoke transport requirements, and prohibited possession as weapons • USA PATRIOT Act (PL 107 -56) – Effective 10/16/01 • Outlawed the possession of 49 Select Agents for any use: peaceful, research, or intentional • Outlawed use if a “restricted person” • Public Health Security and Bioterrorism Preparedness and Response Act of 2002 – Effective 6/12/02 • Select Agent regulations

Summary • Biosafety is much more than the bloodborne pathogens standard • Risk assessment process is the key to properly classifying and reviewing work with infectious agents or r. DNA • Sampling not routinely recommended • Emerging field!

References • American Biological Safety Association www. absa. org • Biosafety in Microbiological and Biomedical Laboratories, 5 th ed. CDC/NIH 2007. • Guidelines for Research Involving Recombinant DNA Molecules (NIH Guidelines) April 2002. • OSHA, Occupational Exposure to Bloodborne Pathogens 29 CFR 1910. 1030 • ABSA risk group classifications http: //www. absa. org/riskgroups/index. htm • Health Canada MSDS for Biological Agents http: //www. hc-sc. gc. ca/pphb-dgspsp/msdsftss/index. html • Biological Safety Principles and Practices 3 rd Edition. Diane Fleming & Debra Hunt. ASM Press.

2c6fc0209107acb616edff194ca70428.ppt