18f753eaa7f4ee4b00c6dce25cef10b9.ppt

- Количество слайдов: 21

The 5 Ps Project Procurement - Pace Price & Performance 1

The 5 Ps Project Procurement - Pace Price & Performance 1

CORE VALUES Excellence Trust Entreprene urship Care Integrity Innovation Respect 3

CORE VALUES Excellence Trust Entreprene urship Care Integrity Innovation Respect 3

Financial Highlights 2017 4

Financial Highlights 2017 4

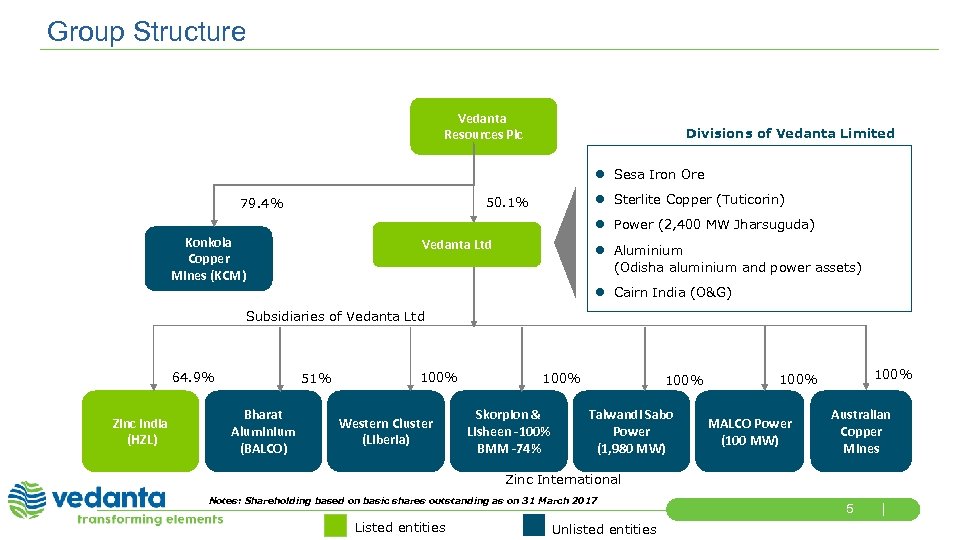

Group Structure Vedanta Resources Plc Divisions of Vedanta Limited l Sesa Iron Ore l Sterlite Copper (Tuticorin) 50. 1% 79. 4% l Power (2, 400 MW Jharsuguda) Konkola Copper Mines (KCM) Vedanta Ltd l Aluminium (Odisha aluminium and power assets) l Cairn India (O&G) Subsidiaries of Vedanta Ltd 64. 9% Zinc India (HZL) 51% Bharat Aluminium (BALCO) 100% Western Cluster (Liberia) 100% Skorpion & Lisheen -100% BMM -74% 100% Talwandi Sabo Power (1, 980 MW) 100% MALCO Power (100 MW) Australian Copper Mines Zinc International Notes: Shareholding based on basic shares outstanding as on 31 March 2017 Listed entities Unlisted entities 5

Group Structure Vedanta Resources Plc Divisions of Vedanta Limited l Sesa Iron Ore l Sterlite Copper (Tuticorin) 50. 1% 79. 4% l Power (2, 400 MW Jharsuguda) Konkola Copper Mines (KCM) Vedanta Ltd l Aluminium (Odisha aluminium and power assets) l Cairn India (O&G) Subsidiaries of Vedanta Ltd 64. 9% Zinc India (HZL) 51% Bharat Aluminium (BALCO) 100% Western Cluster (Liberia) 100% Skorpion & Lisheen -100% BMM -74% 100% Talwandi Sabo Power (1, 980 MW) 100% MALCO Power (100 MW) Australian Copper Mines Zinc International Notes: Shareholding based on basic shares outstanding as on 31 March 2017 Listed entities Unlisted entities 5

6

6

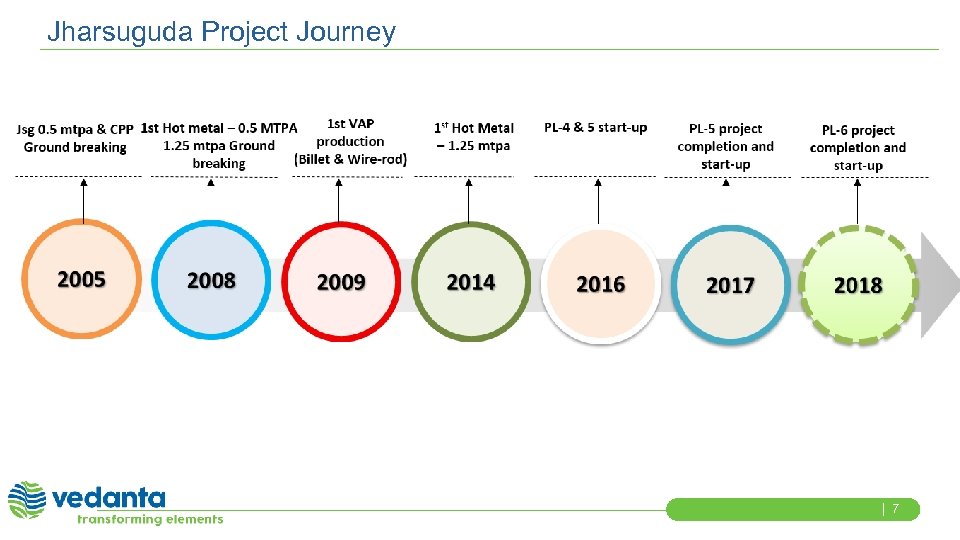

Jharsuguda Project Journey 7

Jharsuguda Project Journey 7

Jharsuguda Complex – Bird’s Eye View 4 X 600 MW TPP-2 Smelter-1 Capacity (MTPA) PL-1 PL-2 Total 0. 27 0. 55 Plant-1 : 0. 55 MTPA Plant-2 : 1. 25 MTPA Smelter-2 PL-3 PL-4 PL-5 PL-6 Total 9 X 135 MW TPP-1 Capacity (MTPA) 0. 32 0. 30 1. 25 8 8

Jharsuguda Complex – Bird’s Eye View 4 X 600 MW TPP-2 Smelter-1 Capacity (MTPA) PL-1 PL-2 Total 0. 27 0. 55 Plant-1 : 0. 55 MTPA Plant-2 : 1. 25 MTPA Smelter-2 PL-3 PL-4 PL-5 PL-6 Total 9 X 135 MW TPP-1 Capacity (MTPA) 0. 32 0. 30 1. 25 8 8

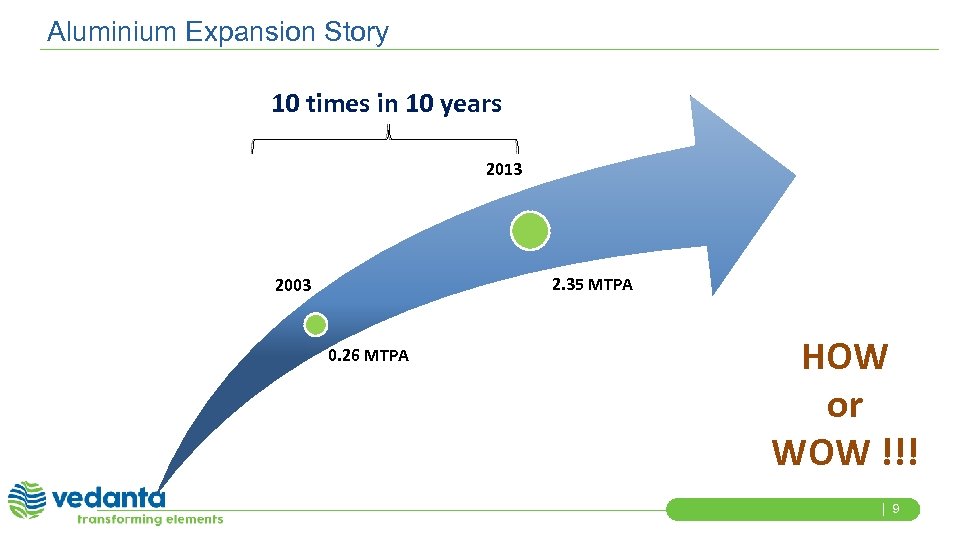

Aluminium Expansion Story 10 times in 10 years 2013 2. 35 MTPA 2003 0. 26 MTPA HOW or WOW !!! 9

Aluminium Expansion Story 10 times in 10 years 2013 2. 35 MTPA 2003 0. 26 MTPA HOW or WOW !!! 9

Project Execution deliverables Safety Quality Cost Project Procurement Timeline 10

Project Execution deliverables Safety Quality Cost Project Procurement Timeline 10

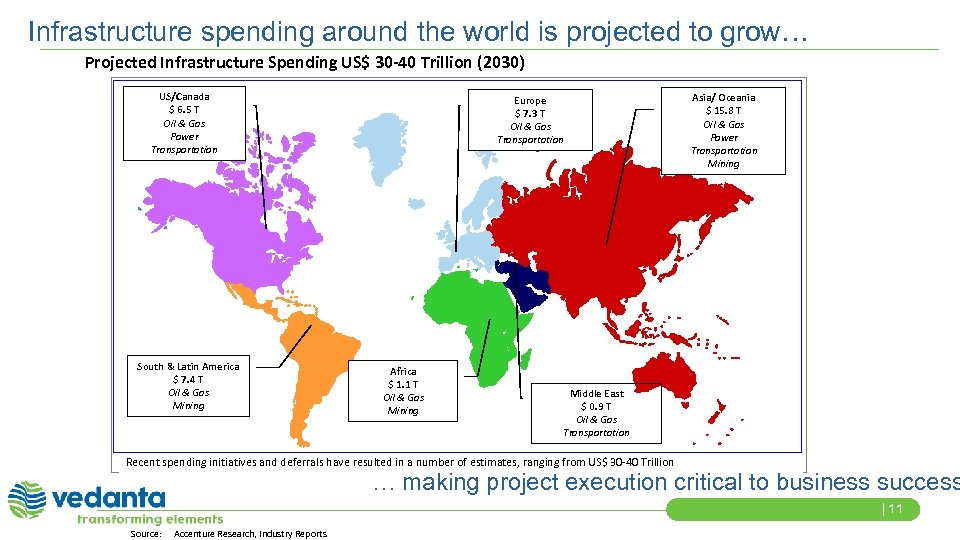

Infrastructure spending around the world is projected to grow… Projected Infrastructure Spending US$ 30 -40 Trillion (2030) US/Canada $ 6. 5 T Oil & Gas Power Transportation South & Latin America $ 7. 4 T Oil & Gas Mining Europe $ 7. 3 T Oil & Gas Transportation Africa $ 1. 1 T Oil & Gas Mining Asia/ Oceania $ 15. 8 T Oil & Gas Power Transportation Mining Middle East $ 0. 9 T Oil & Gas Transportation Recent spending initiatives and deferrals have resulted in a number of estimates, ranging from US$ 30 -40 Trillion … making project execution critical to business success 11 Source: Accenture Research, Industry Reports

Infrastructure spending around the world is projected to grow… Projected Infrastructure Spending US$ 30 -40 Trillion (2030) US/Canada $ 6. 5 T Oil & Gas Power Transportation South & Latin America $ 7. 4 T Oil & Gas Mining Europe $ 7. 3 T Oil & Gas Transportation Africa $ 1. 1 T Oil & Gas Mining Asia/ Oceania $ 15. 8 T Oil & Gas Power Transportation Mining Middle East $ 0. 9 T Oil & Gas Transportation Recent spending initiatives and deferrals have resulted in a number of estimates, ranging from US$ 30 -40 Trillion … making project execution critical to business success 11 Source: Accenture Research, Industry Reports

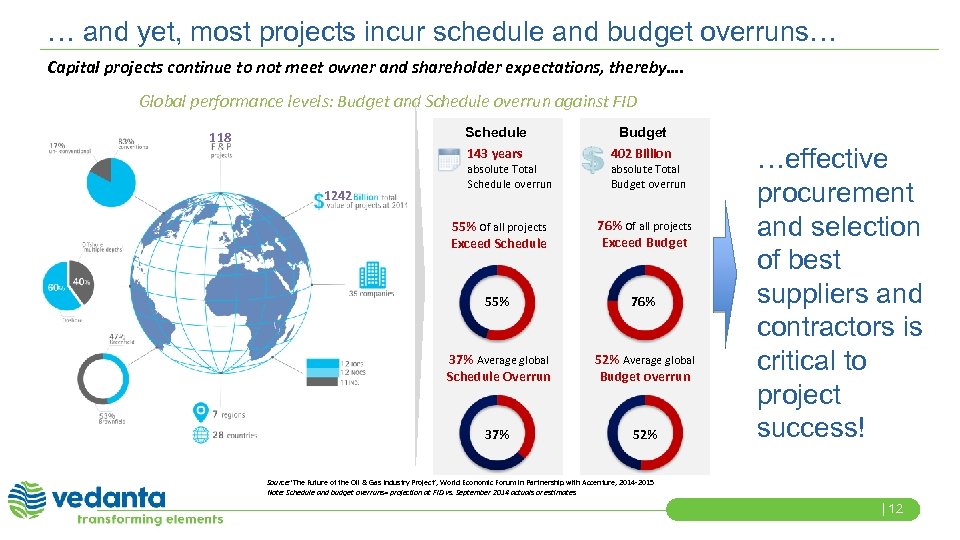

… and yet, most projects incur schedule and budget overruns… Capital projects continue to not meet owner and shareholder expectations, thereby…. Global performance levels: Budget and Schedule overrun against FID Schedule 402 Billion 55% of all projects Exceed Schedule 76% of all projects Exceed Budget 55% 76% 37% Average global Schedule Overrun 52% Average global Budget overrun 37% 1242 Budget 143 years 118 52% absolute Total Schedule overrun absolute Total Budget overrun …effective procurement and selection of best suppliers and contractors is critical to project success! Source: ‘The Future of the Oil & Gas Industry Project’, World Economic Forum in Partnership with Accenture, 2014 -2015 Note: Schedule and budget overruns= projection at FID vs. September 2014 actuals or estimates 12

… and yet, most projects incur schedule and budget overruns… Capital projects continue to not meet owner and shareholder expectations, thereby…. Global performance levels: Budget and Schedule overrun against FID Schedule 402 Billion 55% of all projects Exceed Schedule 76% of all projects Exceed Budget 55% 76% 37% Average global Schedule Overrun 52% Average global Budget overrun 37% 1242 Budget 143 years 118 52% absolute Total Schedule overrun absolute Total Budget overrun …effective procurement and selection of best suppliers and contractors is critical to project success! Source: ‘The Future of the Oil & Gas Industry Project’, World Economic Forum in Partnership with Accenture, 2014 -2015 Note: Schedule and budget overruns= projection at FID vs. September 2014 actuals or estimates 12

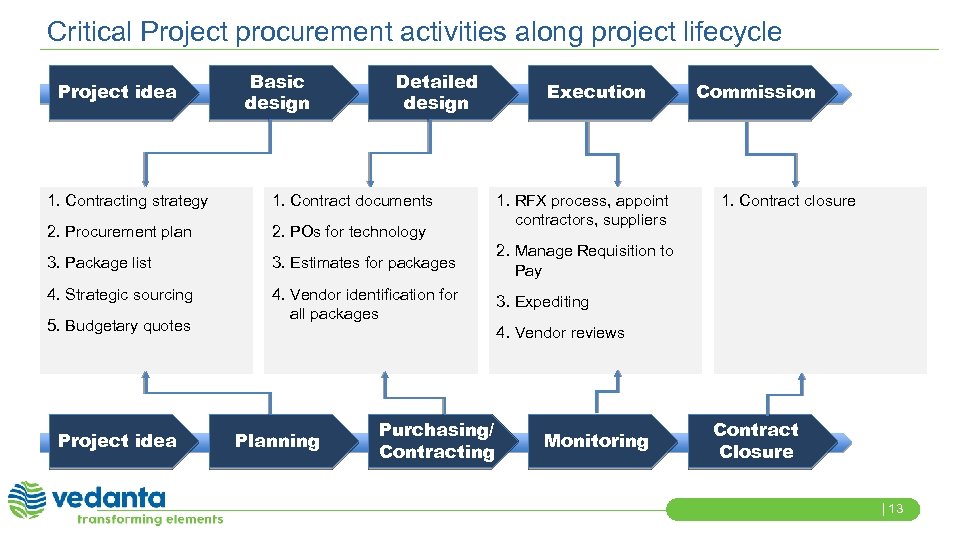

Critical Project procurement activities along project lifecycle Project idea Basic design Detailed design Execution 1. Contracting strategy 1. Contract documents 2. Procurement plan 2. POs for technology 3. Package list 3. Estimates for packages 2. Manage Requisition to Pay 4. Strategic sourcing 4. Vendor identification for all packages 3. Expediting 5. Budgetary quotes Project idea 1. RFX process, appoint contractors, suppliers Commission 1. Contract closure 4. Vendor reviews Planning Purchasing/ Contracting Monitoring Contract Closure 13

Critical Project procurement activities along project lifecycle Project idea Basic design Detailed design Execution 1. Contracting strategy 1. Contract documents 2. Procurement plan 2. POs for technology 3. Package list 3. Estimates for packages 2. Manage Requisition to Pay 4. Strategic sourcing 4. Vendor identification for all packages 3. Expediting 5. Budgetary quotes Project idea 1. RFX process, appoint contractors, suppliers Commission 1. Contract closure 4. Vendor reviews Planning Purchasing/ Contracting Monitoring Contract Closure 13

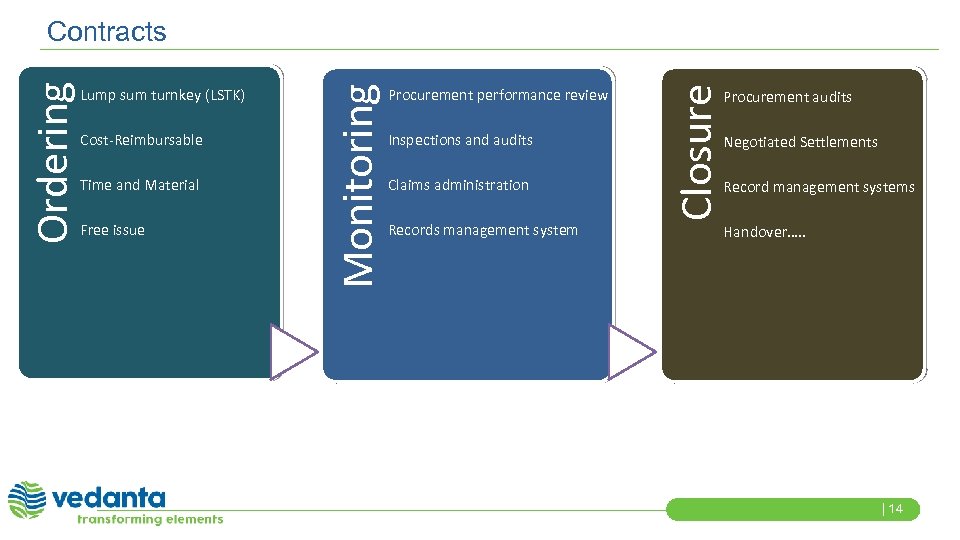

Cost-Reimbursable Time and Material Free issue Procurement performance review Inspections and audits Claims administration Records management system Closure Lump sum turnkey (LSTK) Monitoring Ordering Contracts Procurement audits Negotiated Settlements Record management systems Handover…. . 14

Cost-Reimbursable Time and Material Free issue Procurement performance review Inspections and audits Claims administration Records management system Closure Lump sum turnkey (LSTK) Monitoring Ordering Contracts Procurement audits Negotiated Settlements Record management systems Handover…. . 14

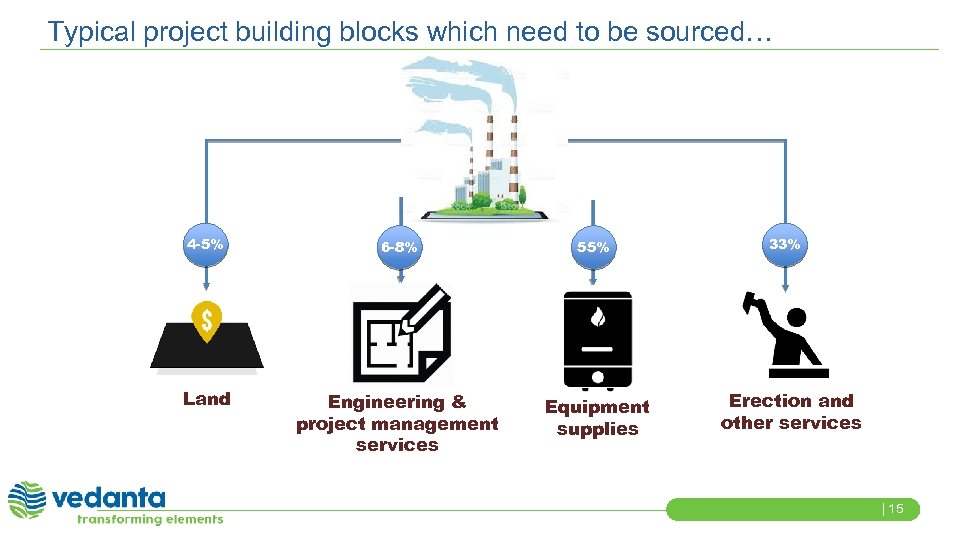

Typical project building blocks which need to be sourced… 4 -5% 6 -8% 55% Land Engineering & project management services Equipment supplies 33% Erection and other services 15

Typical project building blocks which need to be sourced… 4 -5% 6 -8% 55% Land Engineering & project management services Equipment supplies 33% Erection and other services 15

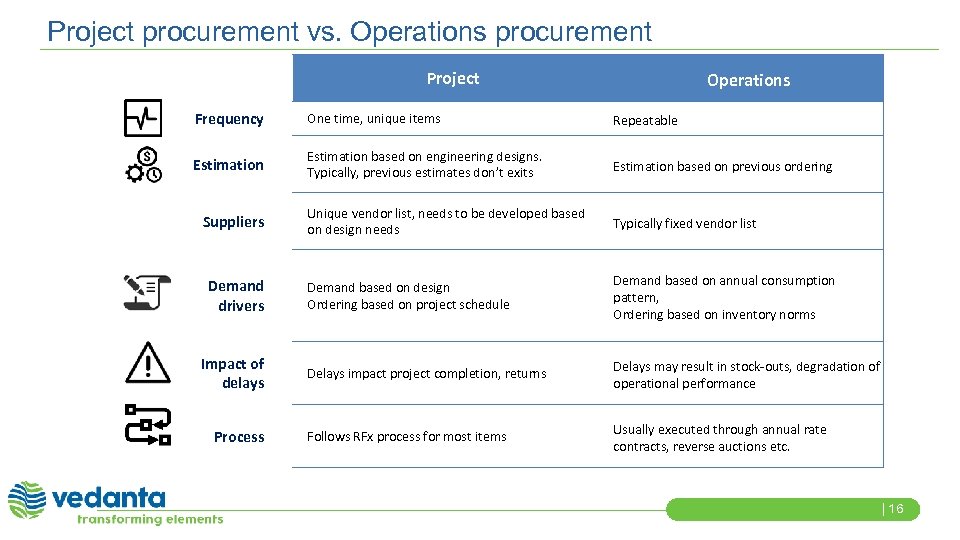

Project procurement vs. Operations procurement Project Operations Frequency One time, unique items Repeatable Estimation based on engineering designs. Typically, previous estimates don’t exits Estimation based on previous ordering Unique vendor list, needs to be developed based on design needs Typically fixed vendor list Demand based on design Ordering based on project schedule Demand based on annual consumption pattern, Ordering based on inventory norms Delays impact project completion, returns Delays may result in stock-outs, degradation of operational performance Follows RFx process for most items Usually executed through annual rate contracts, reverse auctions etc. Suppliers Demand drivers Impact of delays Process 16

Project procurement vs. Operations procurement Project Operations Frequency One time, unique items Repeatable Estimation based on engineering designs. Typically, previous estimates don’t exits Estimation based on previous ordering Unique vendor list, needs to be developed based on design needs Typically fixed vendor list Demand based on design Ordering based on project schedule Demand based on annual consumption pattern, Ordering based on inventory norms Delays impact project completion, returns Delays may result in stock-outs, degradation of operational performance Follows RFx process for most items Usually executed through annual rate contracts, reverse auctions etc. Suppliers Demand drivers Impact of delays Process 16

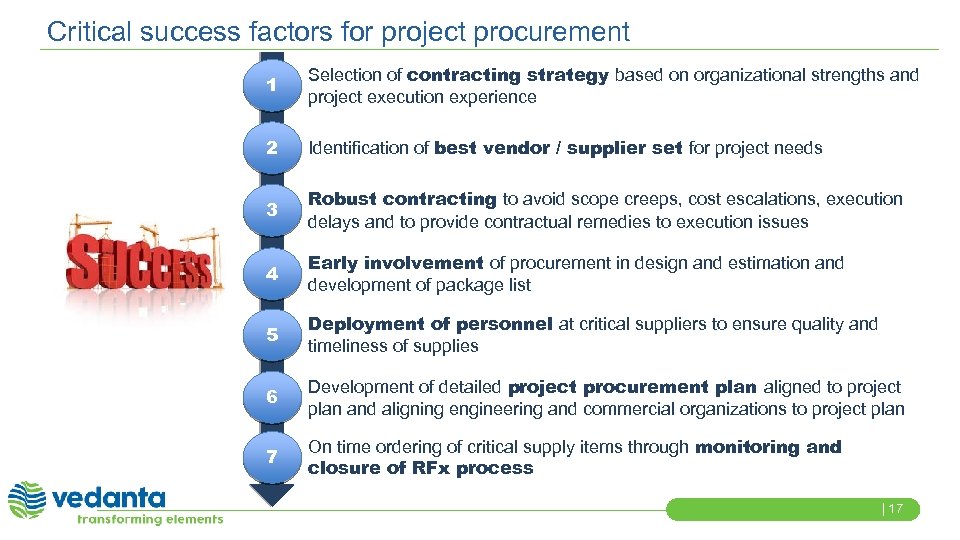

Critical success factors for project procurement 1 Selection of contracting strategy based on organizational strengths and project execution experience 2 Identification of best vendor / supplier set for project needs 3 Robust contracting to avoid scope creeps, cost escalations, execution delays and to provide contractual remedies to execution issues 4 Early involvement of procurement in design and estimation and development of package list 5 Deployment of personnel at critical suppliers to ensure quality and timeliness of supplies 6 Development of detailed project procurement plan aligned to project plan and aligning engineering and commercial organizations to project plan 7 On time ordering of critical supply items through monitoring and closure of RFx process 17

Critical success factors for project procurement 1 Selection of contracting strategy based on organizational strengths and project execution experience 2 Identification of best vendor / supplier set for project needs 3 Robust contracting to avoid scope creeps, cost escalations, execution delays and to provide contractual remedies to execution issues 4 Early involvement of procurement in design and estimation and development of package list 5 Deployment of personnel at critical suppliers to ensure quality and timeliness of supplies 6 Development of detailed project procurement plan aligned to project plan and aligning engineering and commercial organizations to project plan 7 On time ordering of critical supply items through monitoring and closure of RFx process 17

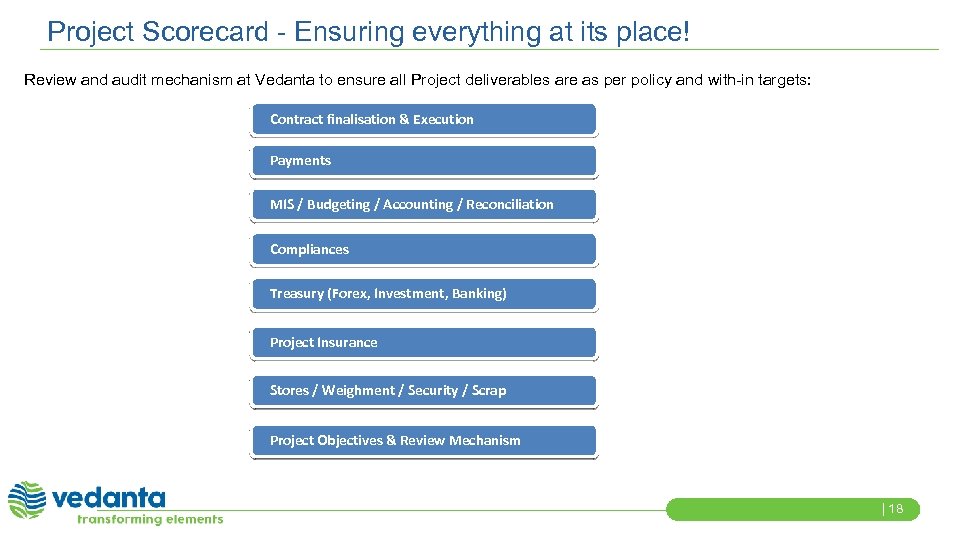

Project Scorecard - Ensuring everything at its place! Review and audit mechanism at Vedanta to ensure all Project deliverables are as per policy and with-in targets: Contract finalisation & Execution Payments MIS / Budgeting / Accounting / Reconciliation Compliances Treasury (Forex, Investment, Banking) Project Insurance Stores / Weighment / Security / Scrap Project Objectives & Review Mechanism 18

Project Scorecard - Ensuring everything at its place! Review and audit mechanism at Vedanta to ensure all Project deliverables are as per policy and with-in targets: Contract finalisation & Execution Payments MIS / Budgeting / Accounting / Reconciliation Compliances Treasury (Forex, Investment, Banking) Project Insurance Stores / Weighment / Security / Scrap Project Objectives & Review Mechanism 18

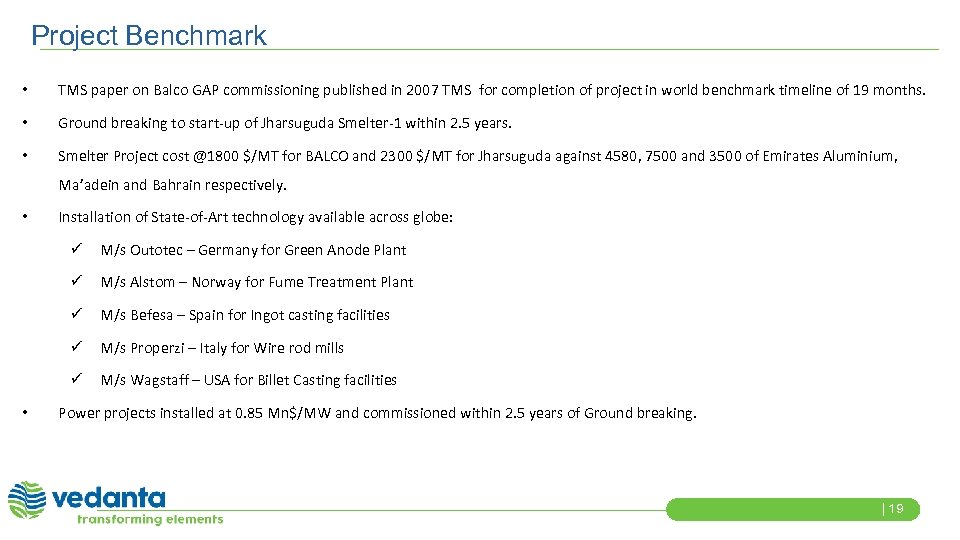

Project Benchmark • TMS paper on Balco GAP commissioning published in 2007 TMS for completion of project in world benchmark timeline of 19 months. • Ground breaking to start-up of Jharsuguda Smelter-1 within 2. 5 years. • Smelter Project cost @1800 $/MT for BALCO and 2300 $/MT for Jharsuguda against 4580, 7500 and 3500 of Emirates Aluminium, Ma’adein and Bahrain respectively. • Installation of State-of-Art technology available across globe: ü ü M/s Alstom – Norway for Fume Treatment Plant ü M/s Befesa – Spain for Ingot casting facilities ü M/s Properzi – Italy for Wire rod mills ü • M/s Outotec – Germany for Green Anode Plant M/s Wagstaff – USA for Billet Casting facilities Power projects installed at 0. 85 Mn$/MW and commissioned within 2. 5 years of Ground breaking. 19

Project Benchmark • TMS paper on Balco GAP commissioning published in 2007 TMS for completion of project in world benchmark timeline of 19 months. • Ground breaking to start-up of Jharsuguda Smelter-1 within 2. 5 years. • Smelter Project cost @1800 $/MT for BALCO and 2300 $/MT for Jharsuguda against 4580, 7500 and 3500 of Emirates Aluminium, Ma’adein and Bahrain respectively. • Installation of State-of-Art technology available across globe: ü ü M/s Alstom – Norway for Fume Treatment Plant ü M/s Befesa – Spain for Ingot casting facilities ü M/s Properzi – Italy for Wire rod mills ü • M/s Outotec – Germany for Green Anode Plant M/s Wagstaff – USA for Billet Casting facilities Power projects installed at 0. 85 Mn$/MW and commissioned within 2. 5 years of Ground breaking. 19

Vedanta Procurement Success Strategy It is not the lowest cost, it’s all about the RIGHT COST !!! Delivered by the 2 Ps – People with Passion. 20

Vedanta Procurement Success Strategy It is not the lowest cost, it’s all about the RIGHT COST !!! Delivered by the 2 Ps – People with Passion. 20

Thank You 21

Thank You 21