84121b2ef0ac724a43636ca1f4a444a5.ppt

- Количество слайдов: 19

The 2017 International Conference on Applications of Nuclear Techniques, Crete, Greece Recent Developments in High Resolution Gamma Ray Cargo Inspection Technology “With special thanks to the late Dr. Victor Verbinski, the inventor of modern Gamma Ray Cargo Imaging” David Taylor 1, Dr. Victor Orphan 2, Eric Ackerman 2, James Christian 3 Eduardo Padilla 4, Rhett Barnes 2, Ryan Shyffer 2, Geprge Mansfield 2, James Winso 2, , U. Shirwadkar 3 , P. Bennett 3 , J. Tower 3, Kanai Shah 3 1. 2. 3. 4. Department of Homeland Security, Washington, D. C. , USA Spectral Labs Incorporated, San Diego, CA, USA Radiation Monitoring Devices, Watertown, MA, USA Sandia National Laboratory, Albuquerque, NM, USA Supported by: DHS, Science and Technology Directorate, Borders and Maritime Security Division under contract D 15 PC 00264

The 2017 International Conference on Applications of Nuclear Techniques, Crete, Greece Recent Developments in High Resolution Gamma Ray Cargo Inspection Technology “With special thanks to the late Dr. Victor Verbinski, the inventor of modern Gamma Ray Cargo Imaging” David Taylor 1, Dr. Victor Orphan 2, Eric Ackerman 2, James Christian 3 Eduardo Padilla 4, Rhett Barnes 2, Ryan Shyffer 2, Geprge Mansfield 2, James Winso 2, , U. Shirwadkar 3 , P. Bennett 3 , J. Tower 3, Kanai Shah 3 1. 2. 3. 4. Department of Homeland Security, Washington, D. C. , USA Spectral Labs Incorporated, San Diego, CA, USA Radiation Monitoring Devices, Watertown, MA, USA Sandia National Laboratory, Albuquerque, NM, USA Supported by: DHS, Science and Technology Directorate, Borders and Maritime Security Division under contract D 15 PC 00264

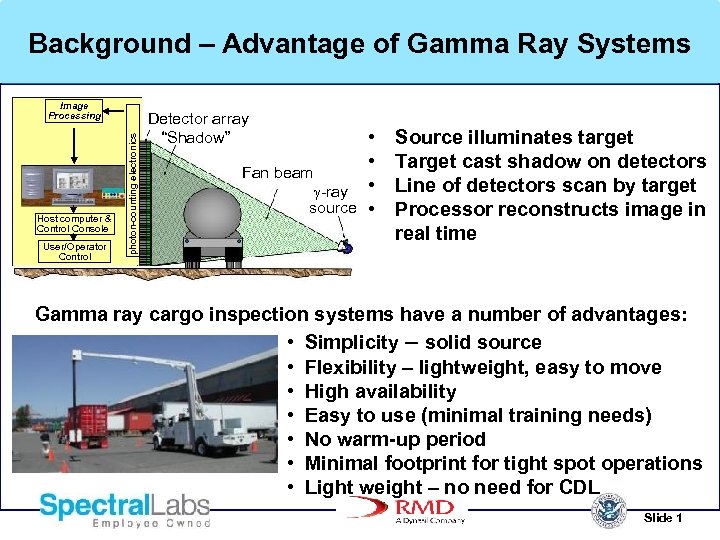

Background – Advantage of Gamma Ray Systems Host computer & Control Console User/Operator Control photon-counting electronics Image Processing Detector array “Shadow” Fan beam g-ray source • • Source illuminates target Target cast shadow on detectors Line of detectors scan by target Processor reconstructs image in real time Gamma ray cargo inspection systems have a number of advantages: • Simplicity – solid source • Flexibility – lightweight, easy to move • High availability • Easy to use (minimal training needs) • No warm-up period • Minimal footprint for tight spot operations • Light weight – no need for CDL Slide 1

Background – Advantage of Gamma Ray Systems Host computer & Control Console User/Operator Control photon-counting electronics Image Processing Detector array “Shadow” Fan beam g-ray source • • Source illuminates target Target cast shadow on detectors Line of detectors scan by target Processor reconstructs image in real time Gamma ray cargo inspection systems have a number of advantages: • Simplicity – solid source • Flexibility – lightweight, easy to move • High availability • Easy to use (minimal training needs) • No warm-up period • Minimal footprint for tight spot operations • Light weight – no need for CDL Slide 1

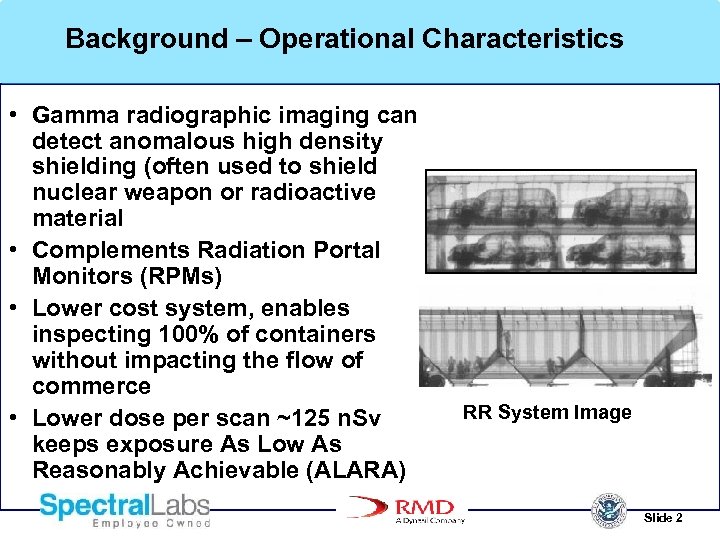

Background – Operational Characteristics • Gamma radiographic imaging can detect anomalous high density shielding (often used to shield nuclear weapon or radioactive material • Complements Radiation Portal Monitors (RPMs) • Lower cost system, enables inspecting 100% of containers without impacting the flow of commerce • Lower dose per scan ~125 n. Sv keeps exposure As Low As Reasonably Achievable (ALARA) RR System Image Slide 2

Background – Operational Characteristics • Gamma radiographic imaging can detect anomalous high density shielding (often used to shield nuclear weapon or radioactive material • Complements Radiation Portal Monitors (RPMs) • Lower cost system, enables inspecting 100% of containers without impacting the flow of commerce • Lower dose per scan ~125 n. Sv keeps exposure As Low As Reasonably Achievable (ALARA) RR System Image Slide 2

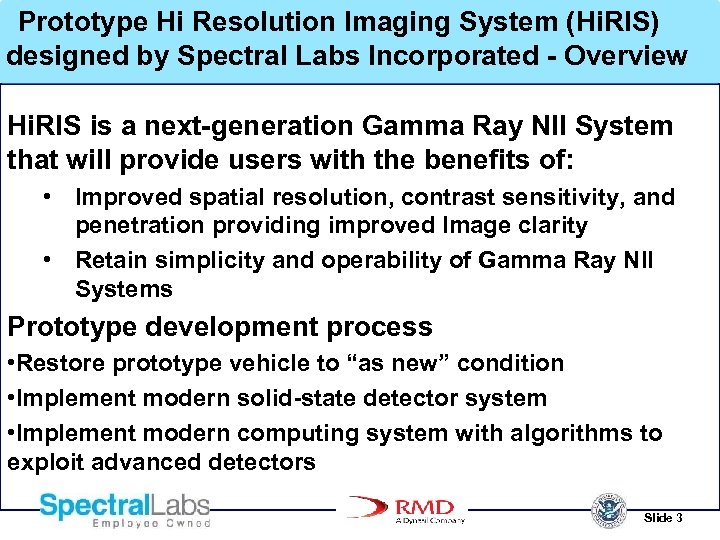

Prototype Hi Resolution Imaging System (Hi. RIS) designed by Spectral Labs Incorporated - Overview Hi. RIS is a next-generation Gamma Ray NII System that will provide users with the benefits of: • Improved spatial resolution, contrast sensitivity, and penetration providing improved Image clarity • Retain simplicity and operability of Gamma Ray NII Systems Prototype development process • Restore prototype vehicle to “as new” condition • Implement modern solid-state detector system • Implement modern computing system with algorithms to exploit advanced detectors Slide 3

Prototype Hi Resolution Imaging System (Hi. RIS) designed by Spectral Labs Incorporated - Overview Hi. RIS is a next-generation Gamma Ray NII System that will provide users with the benefits of: • Improved spatial resolution, contrast sensitivity, and penetration providing improved Image clarity • Retain simplicity and operability of Gamma Ray NII Systems Prototype development process • Restore prototype vehicle to “as new” condition • Implement modern solid-state detector system • Implement modern computing system with algorithms to exploit advanced detectors Slide 3

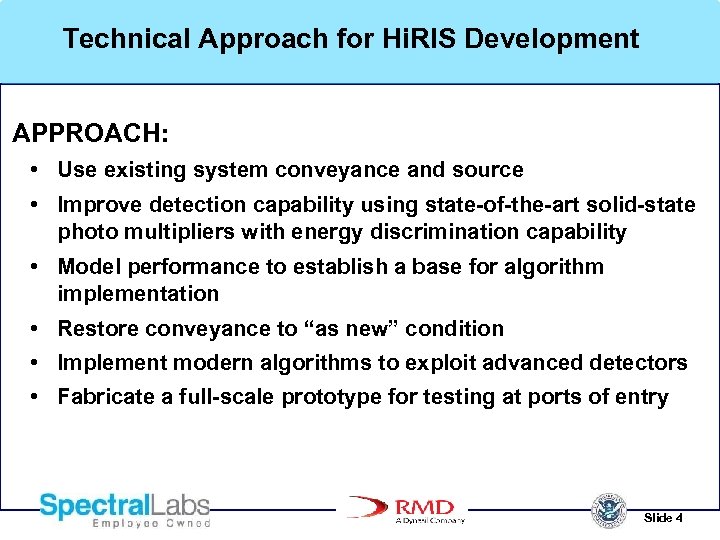

Technical Approach for Hi. RIS Development APPROACH: • Use existing system conveyance and source • Improve detection capability using state-of-the-art solid-state photo multipliers with energy discrimination capability • Model performance to establish a base for algorithm implementation • Restore conveyance to “as new” condition • Implement modern algorithms to exploit advanced detectors • Fabricate a full-scale prototype for testing at ports of entry Slide 4

Technical Approach for Hi. RIS Development APPROACH: • Use existing system conveyance and source • Improve detection capability using state-of-the-art solid-state photo multipliers with energy discrimination capability • Model performance to establish a base for algorithm implementation • Restore conveyance to “as new” condition • Implement modern algorithms to exploit advanced detectors • Fabricate a full-scale prototype for testing at ports of entry Slide 4

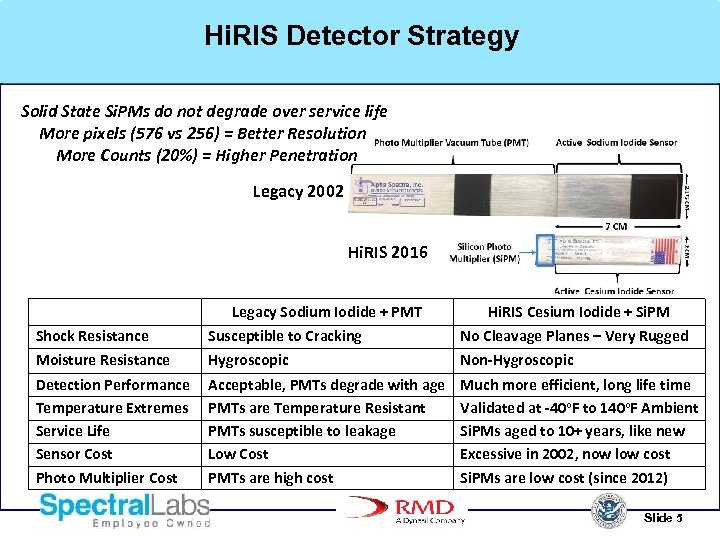

Hi. RIS Detector Strategy Solid State Si. PMs do not degrade over service life More pixels (576 vs 256) = Better Resolution More Counts (20%) = Higher Penetration Legacy 2002 Hi. RIS 2016 Shock Resistance Moisture Resistance Legacy Sodium Iodide + PMT Susceptible to Cracking Hygroscopic Hi. RIS Cesium Iodide + Si. PM No Cleavage Planes – Very Rugged Non-Hygroscopic Detection Performance Temperature Extremes Service Life Sensor Cost Photo Multiplier Cost Acceptable, PMTs degrade with age PMTs are Temperature Resistant PMTs susceptible to leakage Low Cost PMTs are high cost Much more efficient, long life time Validated at -40 o. F to 140 o. F Ambient Si. PMs aged to 10+ years, like new Excessive in 2002, now low cost Si. PMs are low cost (since 2012) Slide 5

Hi. RIS Detector Strategy Solid State Si. PMs do not degrade over service life More pixels (576 vs 256) = Better Resolution More Counts (20%) = Higher Penetration Legacy 2002 Hi. RIS 2016 Shock Resistance Moisture Resistance Legacy Sodium Iodide + PMT Susceptible to Cracking Hygroscopic Hi. RIS Cesium Iodide + Si. PM No Cleavage Planes – Very Rugged Non-Hygroscopic Detection Performance Temperature Extremes Service Life Sensor Cost Photo Multiplier Cost Acceptable, PMTs degrade with age PMTs are Temperature Resistant PMTs susceptible to leakage Low Cost PMTs are high cost Much more efficient, long life time Validated at -40 o. F to 140 o. F Ambient Si. PMs aged to 10+ years, like new Excessive in 2002, now low cost Si. PMs are low cost (since 2012) Slide 5

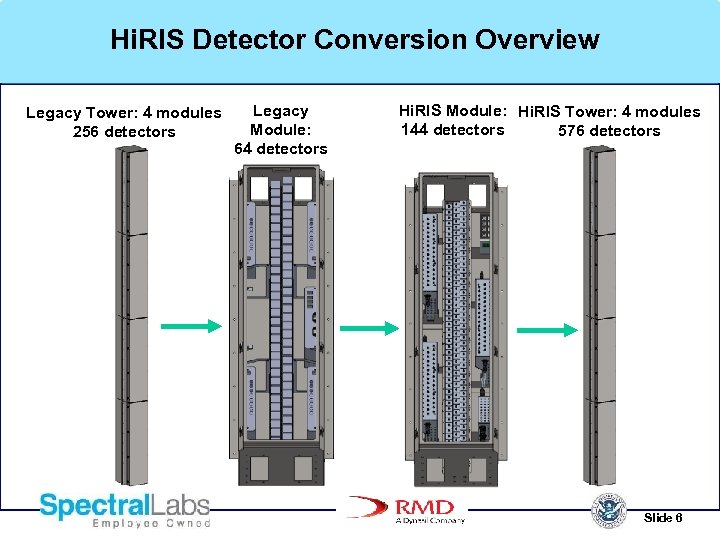

Hi. RIS Detector Conversion Overview Legacy Tower: 4 modules 256 detectors Legacy Module: 64 detectors Hi. RIS Module: Hi. RIS Tower: 4 modules 144 detectors 576 detectors Slide 6

Hi. RIS Detector Conversion Overview Legacy Tower: 4 modules 256 detectors Legacy Module: 64 detectors Hi. RIS Module: Hi. RIS Tower: 4 modules 144 detectors 576 detectors Slide 6

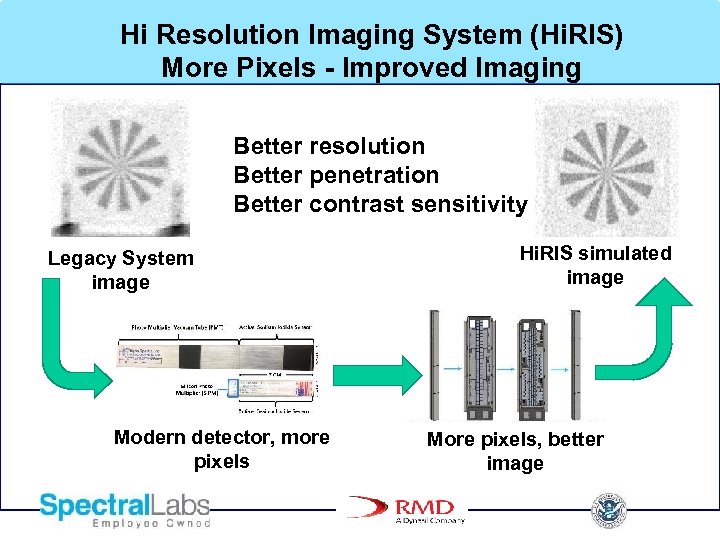

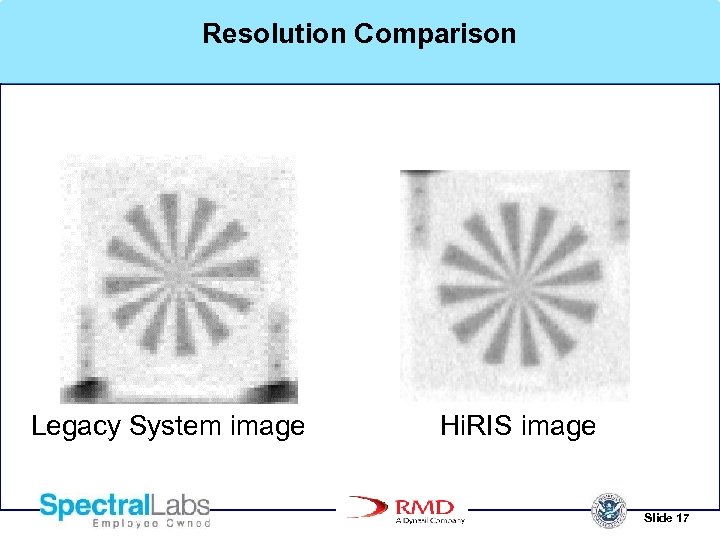

Hi Resolution Imaging System (Hi. RIS) More Pixels - Improved Imaging Better resolution Better penetration Better contrast sensitivity Legacy System image Modern detector, more pixels Hi. RIS simulated image More pixels, better image

Hi Resolution Imaging System (Hi. RIS) More Pixels - Improved Imaging Better resolution Better penetration Better contrast sensitivity Legacy System image Modern detector, more pixels Hi. RIS simulated image More pixels, better image

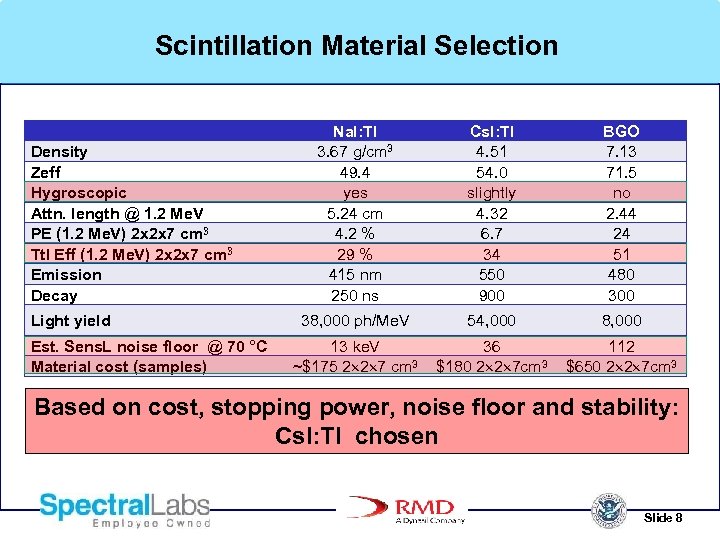

Scintillation Material Selection Density Zeff Hygroscopic Attn. length @ 1. 2 Me. V PE (1. 2 Me. V) 2 x 2 x 7 cm 3 Ttl Eff (1. 2 Me. V) 2 x 2 x 7 cm 3 Emission Decay Light yield Est. Sens. L noise floor @ 70 °C Material cost (samples) Na. I: Tl 3. 67 g/cm 3 49. 4 yes 5. 24 cm 4. 2 % 29 % 415 nm 250 ns Cs. I: Tl 4. 51 54. 0 slightly 4. 32 6. 7 34 550 900 BGO 7. 13 71. 5 no 2. 44 24 51 480 300 38, 000 ph/Me. V 54, 000 8, 000 13 ke. V ~$175 2 2 7 cm 3 36 $180 2 2 7 cm 3 112 $650 2 2 7 cm 3 Based on cost, stopping power, noise floor and stability: Cs. I: Tl chosen Slide 8

Scintillation Material Selection Density Zeff Hygroscopic Attn. length @ 1. 2 Me. V PE (1. 2 Me. V) 2 x 2 x 7 cm 3 Ttl Eff (1. 2 Me. V) 2 x 2 x 7 cm 3 Emission Decay Light yield Est. Sens. L noise floor @ 70 °C Material cost (samples) Na. I: Tl 3. 67 g/cm 3 49. 4 yes 5. 24 cm 4. 2 % 29 % 415 nm 250 ns Cs. I: Tl 4. 51 54. 0 slightly 4. 32 6. 7 34 550 900 BGO 7. 13 71. 5 no 2. 44 24 51 480 300 38, 000 ph/Me. V 54, 000 8, 000 13 ke. V ~$175 2 2 7 cm 3 36 $180 2 2 7 cm 3 112 $650 2 2 7 cm 3 Based on cost, stopping power, noise floor and stability: Cs. I: Tl chosen Slide 8

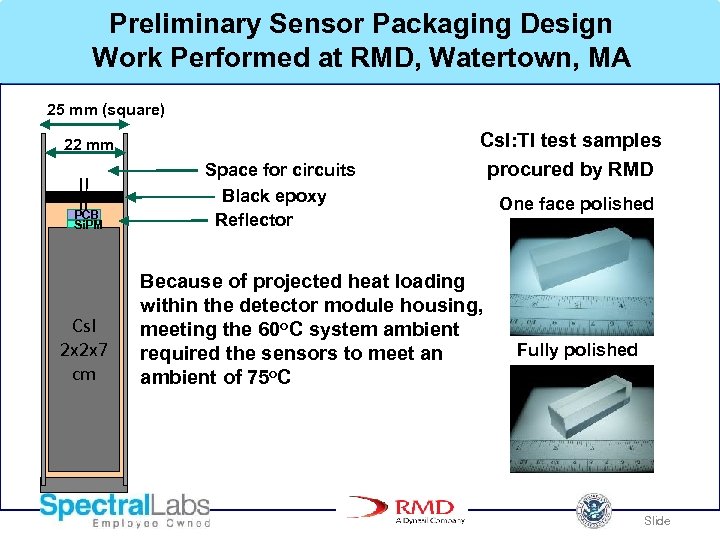

Preliminary Sensor Packaging Design Work Performed at RMD, Watertown, MA 25 mm (square) 22 mm PCB Si. PM Cs. I 2 x 2 x 7 cm Space for circuits Black epoxy Reflector Cs. I: Tl test samples procured by RMD Because of projected heat loading within the detector module housing, meeting the 60 o. C system ambient required the sensors to meet an ambient of 75 o. C One face polished Fully polished Slide

Preliminary Sensor Packaging Design Work Performed at RMD, Watertown, MA 25 mm (square) 22 mm PCB Si. PM Cs. I 2 x 2 x 7 cm Space for circuits Black epoxy Reflector Cs. I: Tl test samples procured by RMD Because of projected heat loading within the detector module housing, meeting the 60 o. C system ambient required the sensors to meet an ambient of 75 o. C One face polished Fully polished Slide

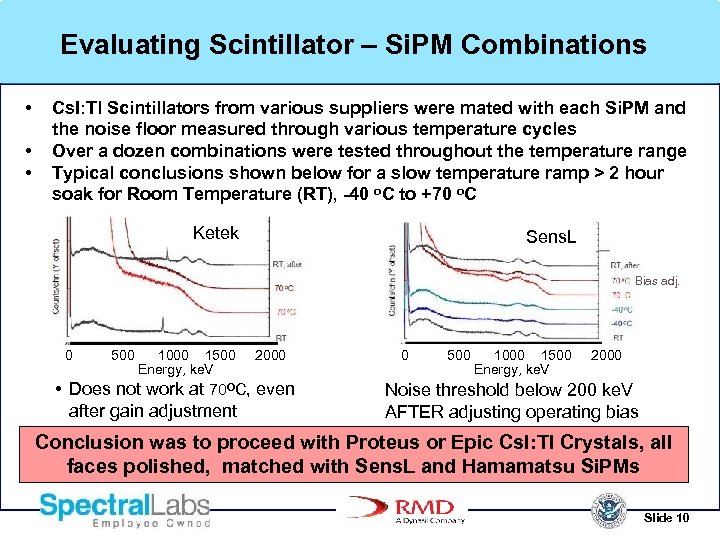

Evaluating Scintillator – Si. PM Combinations • • • Cs. I: Tl Scintillators from various suppliers were mated with each Si. PM and the noise floor measured through various temperature cycles Over a dozen combinations were tested throughout the temperature range Typical conclusions shown below for a slow temperature ramp > 2 hour soak for Room Temperature (RT), -40 o. C to +70 o. C Ketek Sens. L Bias adj. 0 500 1000 1500 Energy, ke. V 2000 • Does not work at 70 OC, even after gain adjustment 0 500 1000 1500 Energy, ke. V 2000 Noise threshold below 200 ke. V AFTER adjusting operating bias Conclusion was to proceed with Proteus or Epic Cs. I: Tl Crystals, all faces polished, matched with Sens. L and Hamamatsu Si. PMs Slide 10

Evaluating Scintillator – Si. PM Combinations • • • Cs. I: Tl Scintillators from various suppliers were mated with each Si. PM and the noise floor measured through various temperature cycles Over a dozen combinations were tested throughout the temperature range Typical conclusions shown below for a slow temperature ramp > 2 hour soak for Room Temperature (RT), -40 o. C to +70 o. C Ketek Sens. L Bias adj. 0 500 1000 1500 Energy, ke. V 2000 • Does not work at 70 OC, even after gain adjustment 0 500 1000 1500 Energy, ke. V 2000 Noise threshold below 200 ke. V AFTER adjusting operating bias Conclusion was to proceed with Proteus or Epic Cs. I: Tl Crystals, all faces polished, matched with Sens. L and Hamamatsu Si. PMs Slide 10

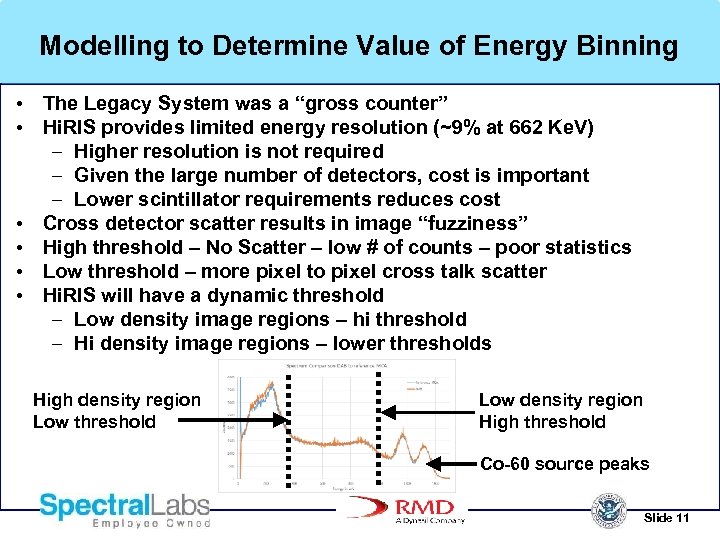

Modelling to Determine Value of Energy Binning • The Legacy System was a “gross counter” • Hi. RIS provides limited energy resolution (~9% at 662 Ke. V) – Higher resolution is not required – Given the large number of detectors, cost is important – Lower scintillator requirements reduces cost • Cross detector scatter results in image “fuzziness” • High threshold – No Scatter – low # of counts – poor statistics • Low threshold – more pixel to pixel cross talk scatter • Hi. RIS will have a dynamic threshold – Low density image regions – hi threshold – Hi density image regions – lower thresholds High density region Low threshold Low density region High threshold Co-60 source peaks Slide 11

Modelling to Determine Value of Energy Binning • The Legacy System was a “gross counter” • Hi. RIS provides limited energy resolution (~9% at 662 Ke. V) – Higher resolution is not required – Given the large number of detectors, cost is important – Lower scintillator requirements reduces cost • Cross detector scatter results in image “fuzziness” • High threshold – No Scatter – low # of counts – poor statistics • Low threshold – more pixel to pixel cross talk scatter • Hi. RIS will have a dynamic threshold – Low density image regions – hi threshold – Hi density image regions – lower thresholds High density region Low threshold Low density region High threshold Co-60 source peaks Slide 11

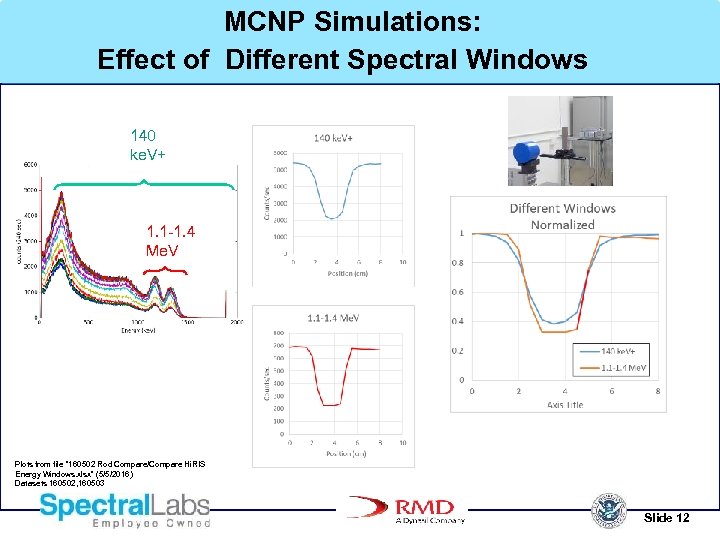

MCNP Simulations: Effect of Different Spectral Windows 140 ke. V+ 1. 1 -1. 4 Me. V Plots from file “ 160502 Rod Compare/Compare Hi. RIS Energy Windows. xlsx” (5/5/2016) Datasets 160502, 160503 Slide 12

MCNP Simulations: Effect of Different Spectral Windows 140 ke. V+ 1. 1 -1. 4 Me. V Plots from file “ 160502 Rod Compare/Compare Hi. RIS Energy Windows. xlsx” (5/5/2016) Datasets 160502, 160503 Slide 12

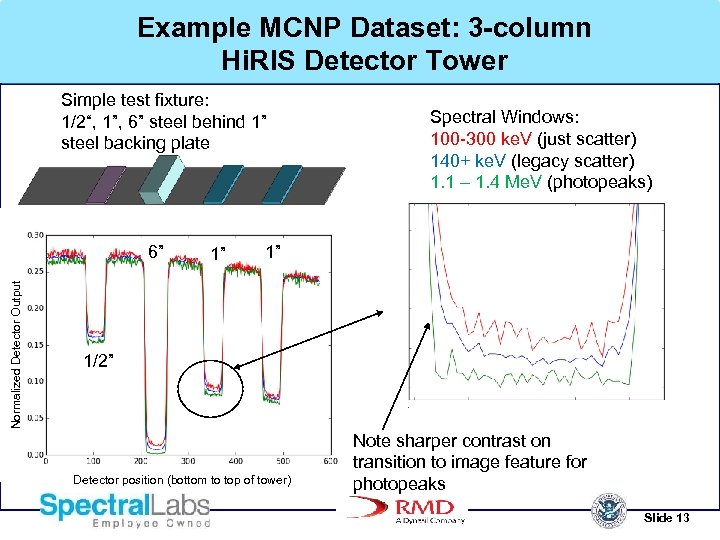

Example MCNP Dataset: 3 -column Hi. RIS Detector Tower Simple test fixture: 1/2“, 1”, 6” steel behind 1” steel backing plate Normalized Detector Output 6” 1” Spectral Windows: 100 -300 ke. V (just scatter) 140+ ke. V (legacy scatter) 1. 1 – 1. 4 Me. V (photopeaks) 1” 1/2” Detector position (bottom to top of tower) Note sharper contrast on transition to image feature for photopeaks Slide 13

Example MCNP Dataset: 3 -column Hi. RIS Detector Tower Simple test fixture: 1/2“, 1”, 6” steel behind 1” steel backing plate Normalized Detector Output 6” 1” Spectral Windows: 100 -300 ke. V (just scatter) 140+ ke. V (legacy scatter) 1. 1 – 1. 4 Me. V (photopeaks) 1” 1/2” Detector position (bottom to top of tower) Note sharper contrast on transition to image feature for photopeaks Slide 13

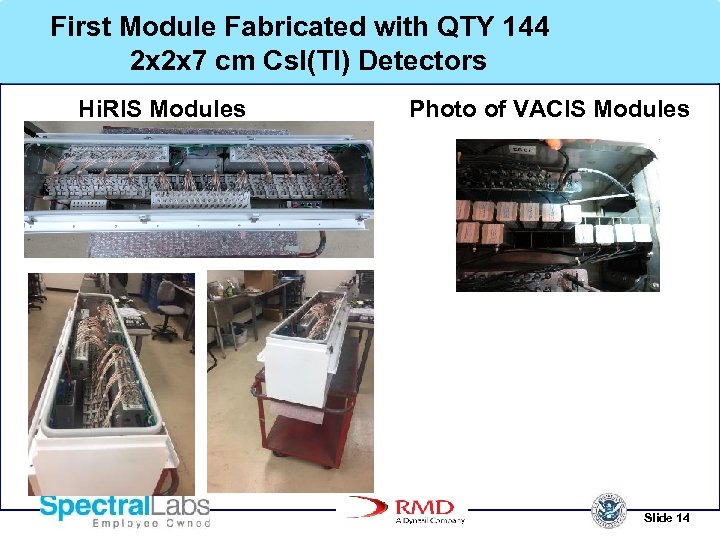

First Module Fabricated with QTY 144 2 x 2 x 7 cm Cs. I(Tl) Detectors Hi. RIS Modules Photo of VACIS Modules Slide 14

First Module Fabricated with QTY 144 2 x 2 x 7 cm Cs. I(Tl) Detectors Hi. RIS Modules Photo of VACIS Modules Slide 14

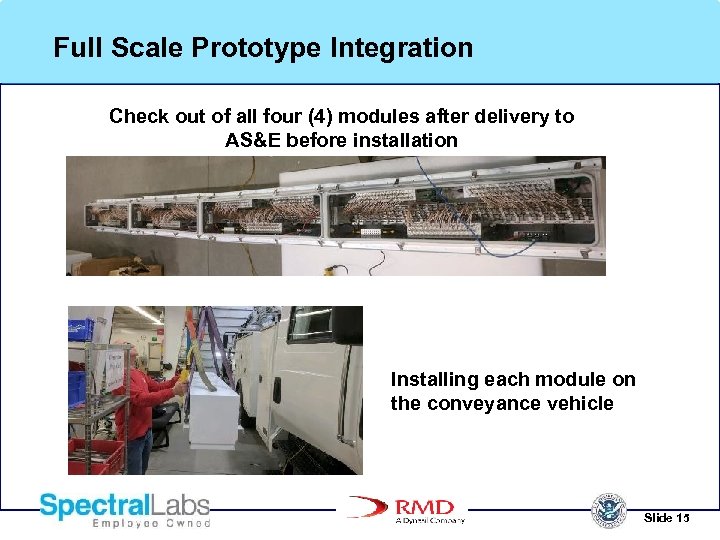

Full Scale Prototype Integration Check out of all four (4) modules after delivery to AS&E before installation Installing each module on the conveyance vehicle Slide 15

Full Scale Prototype Integration Check out of all four (4) modules after delivery to AS&E before installation Installing each module on the conveyance vehicle Slide 15

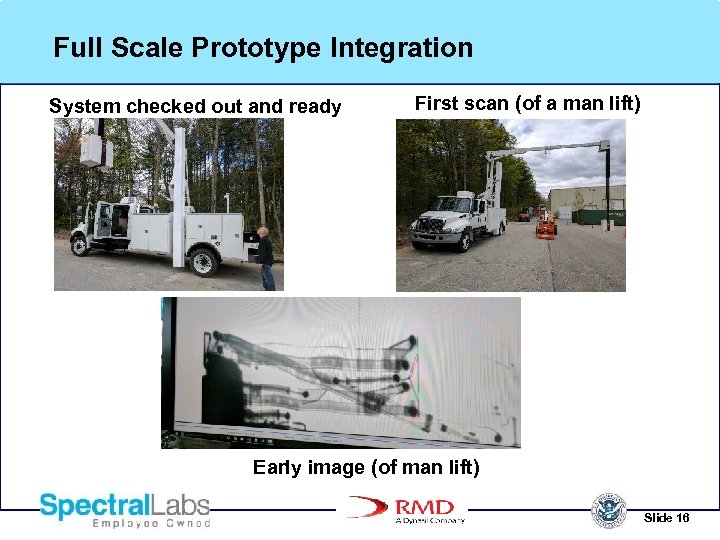

Full Scale Prototype Integration System checked out and ready First scan (of a man lift) Early image (of man lift) Slide 16

Full Scale Prototype Integration System checked out and ready First scan (of a man lift) Early image (of man lift) Slide 16

Resolution Comparison Legacy System image Hi. RIS image Slide 17

Resolution Comparison Legacy System image Hi. RIS image Slide 17

Conclusion Once the Hi. RIS Prototype has been successfully demonstrated at a Port of Entry, the Hi. RIS Technology will provide a cost-effective means of enhancing the performance and extend the life of hundreds of VACIS systems Slide 18

Conclusion Once the Hi. RIS Prototype has been successfully demonstrated at a Port of Entry, the Hi. RIS Technology will provide a cost-effective means of enhancing the performance and extend the life of hundreds of VACIS systems Slide 18