16d36c73b5de84013e995ce150946686.ppt

- Количество слайдов: 11

Tex. Manage Manufacturing Solutions- Fabric Processing

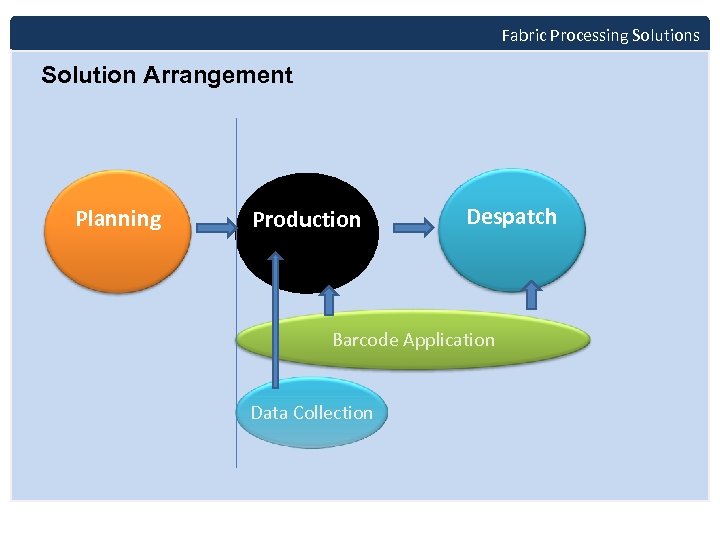

Fabric Processing Solutions Solution Arrangement Planning Production Despatch Barcode Application Data Collection

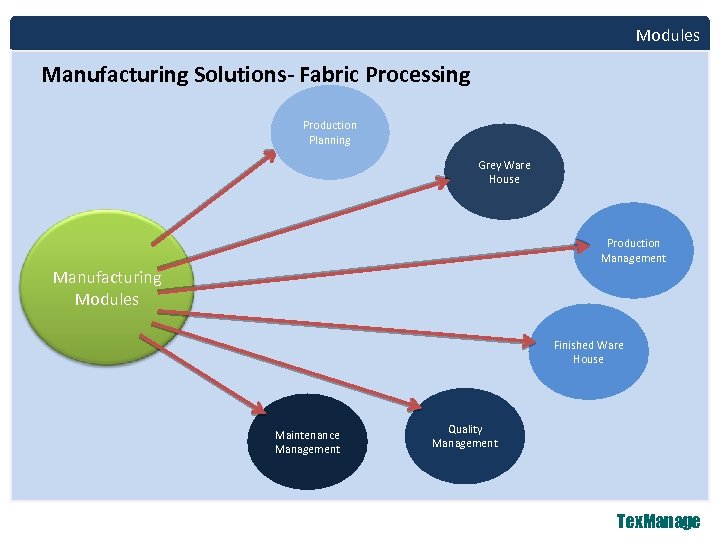

Modules Manufacturing Solutions- Fabric Processing Production Planning Grey Ware House Production Management Manufacturing Modules Finished Ware House Maintenance Management Quality Management Tex. Manage

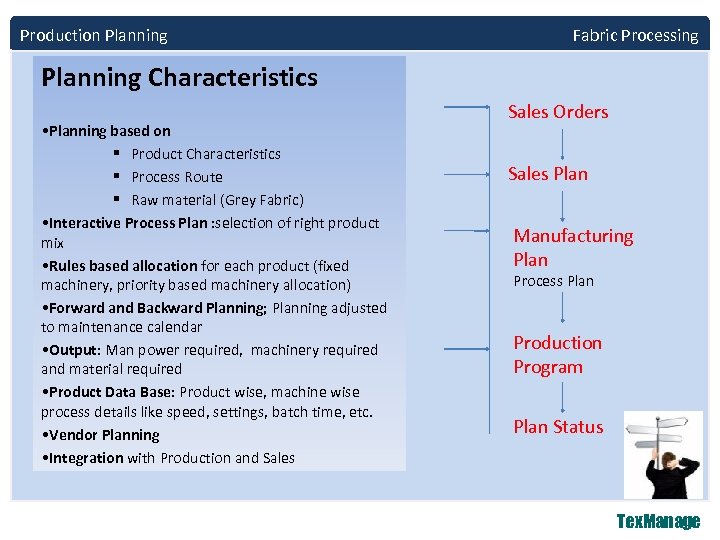

Production Planning Fabric Processing Planning Characteristics • Planning based on § Product Characteristics § Process Route § Raw material (Grey Fabric) • Interactive Process Plan : selection of right product mix • Rules based allocation for each product (fixed machinery, priority based machinery allocation) • Forward and Backward Planning; Planning adjusted to maintenance calendar • Output: Man power required, machinery required and material required • Product Data Base: Product wise, machine wise process details like speed, settings, batch time, etc. • Vendor Planning • Integration with Production and Sales Orders Sales Plan Manufacturing Plan Process Plan Production Program Plan Status Tex. Manage

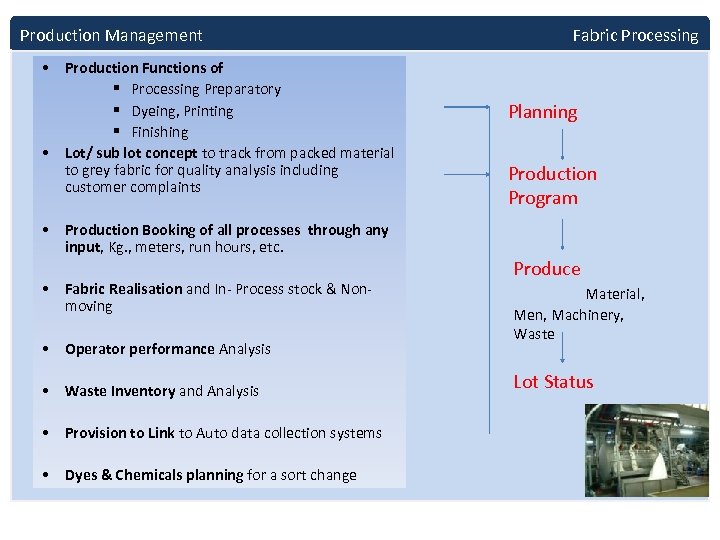

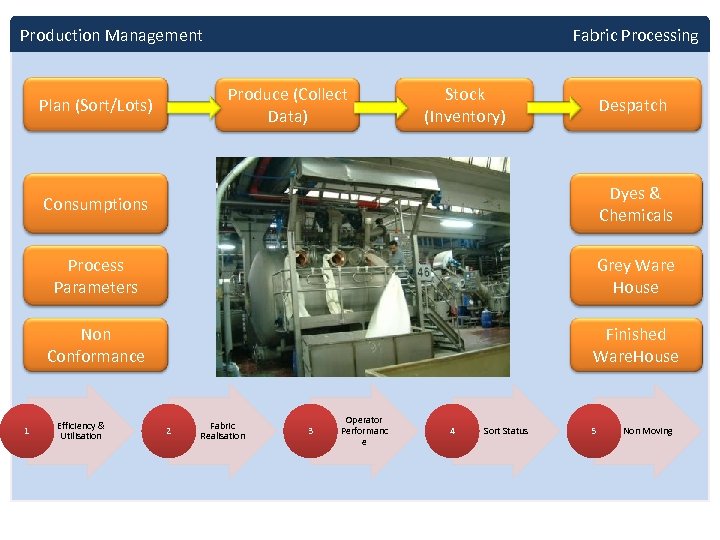

Production Management • Production Functions of § Processing Preparatory § Dyeing, Printing § Finishing • Lot/ sub lot concept to track from packed material to grey fabric for quality analysis including customer complaints Fabric Processing Planning Production Program • Production Booking of all processes through any input, Kg. , meters, run hours, etc. • Fabric Realisation and In- Process stock & Nonmoving • Operator performance Analysis • Waste Inventory and Analysis • Provision to Link to Auto data collection systems • Dyes & Chemicals planning for a sort change Produce Material, Men, Machinery, Waste Lot Status

Production Management Fabric Processing Produce (Collect Data) Plan (Sort/Lots) Stock (Inventory) Despatch Consumptions Process Parameters Grey Ware House Non Conformance 1 Dyes & Chemicals Finished Ware. House Efficiency & Utilisation 2 Fabric Realisation 3 Operator Performanc e 4 Sort Status 5 Non Moving

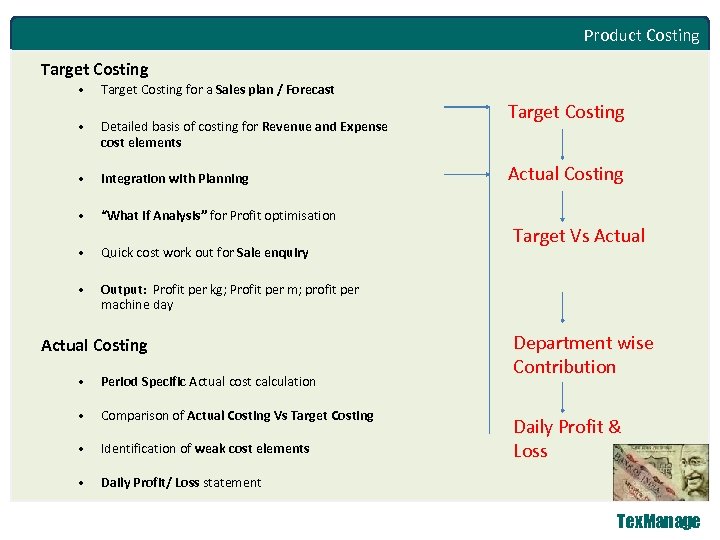

Product Costing Target Costing • Target Costing for a Sales plan / Forecast • Detailed basis of costing for Revenue and Expense cost elements • Integration with Planning • “What if Analysis” for Profit optimisation • Quick cost work out for Sale enquiry • Output: Profit per kg; Profit per m; profit per machine day Actual Costing • Period Specific Actual cost calculation • Comparison of Actual Costing Vs Target Costing • Identification of weak cost elements • Target Costing Actual Costing Target Vs Actual Department wise Contribution Daily Profit/ Loss statement Daily Profit & Loss Tex. Manage

Product Costing Target & Actual All approved plans is put through Target Costing estimation to see the profitability of the count pattern decided. Use the function also when you receive an enquiry and also forecast Estimation of Actual Cost Department wise Contribution Custom designed Cost Methodology Dynamically captures Target Cost estimation and provides Actual Costing Tex. Manage

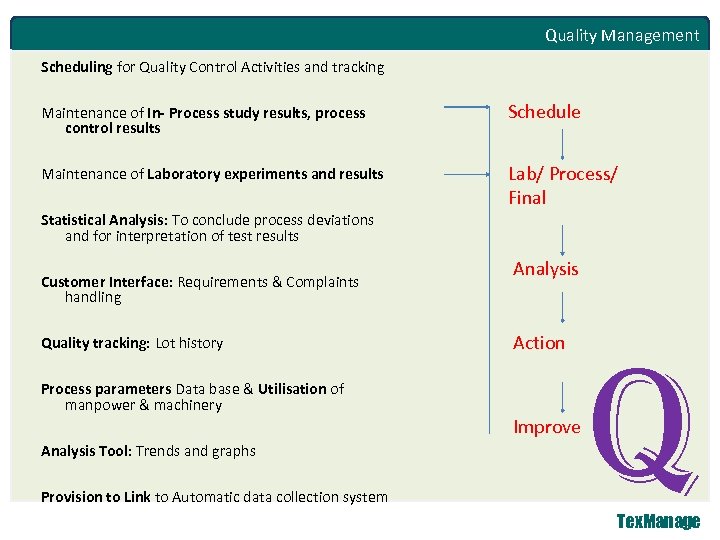

Quality Management Scheduling for Quality Control Activities and tracking Maintenance of In- Process study results, process control results Schedule Maintenance of Laboratory experiments and results Lab/ Process/ Final Statistical Analysis: To conclude process deviations and for interpretation of test results Customer Interface: Requirements & Complaints handling Quality tracking: Lot history Process parameters Data base & Utilisation of manpower & machinery Analysis Tool: Trends and graphs Provision to Link to Automatic data collection system Analysis Action Improve Q Tex. Manage

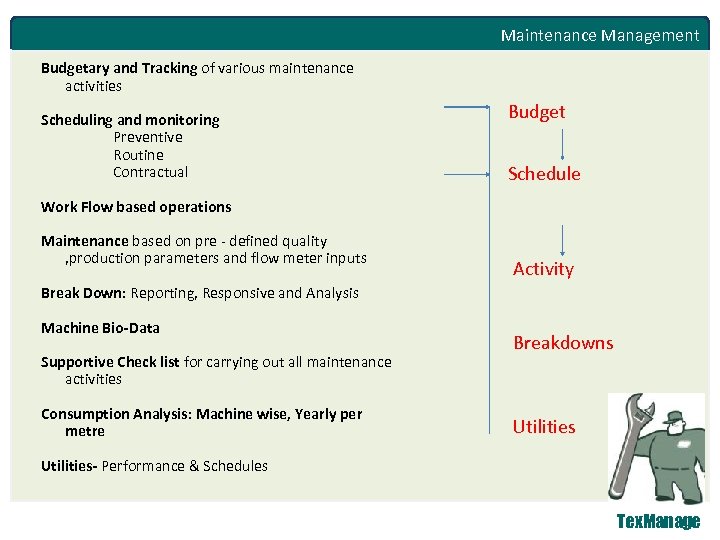

Maintenance Management Budgetary and Tracking of various maintenance activities Scheduling and monitoring Preventive Routine Contractual Budget Schedule Work Flow based operations Maintenance based on pre - defined quality , production parameters and flow meter inputs Activity Break Down: Reporting, Responsive and Analysis Machine Bio-Data Supportive Check list for carrying out all maintenance activities Consumption Analysis: Machine wise, Yearly per metre Breakdowns Utilities- Performance & Schedules Tex. Manage

Thank you 40, Thasami Park, Singanallur, Coimbatore -641 005 Ph: +91 422 3233345 Fax: +91 422 4348479 Email: info@indotexnology. com, Thirupathi@indotexnology. com Also: texmanage@indotexnology. com

16d36c73b5de84013e995ce150946686.ppt