cf3b64352efc191ce4d0505c2f89279b.ppt

- Количество слайдов: 53

Teseq — ESD Simulator Verification

Background Greg Senko, President Teseq Inc. – North American division of Teseq Laboratory Technical Manager – Edison NJ This presentation was first given in 2003 when lab was Schaffner Co-authored with Ken Wyatt, Lab Manager Agilent Technologies Teseq first ISO 17025 accredited by A 2 LA March 2006. Audited for re-accreditation in 2008 and 2010. Teseq scope of accreditation now includes IEC 61000 -4 -2: 2008 -12 as well as many other industry standards: EN 61000 -4 -2, IEC 801 -2, ISO TR 10605, ISO 10605, SAE J 1113 -13, ANSI C 63. 16, FORD ES-XW 7 T-1 A 278 -AC, GMW 3097, DC-10614, DC-11224 Presentation includes these updates and experiences 2

Outline Virtually every EMC laboratory has one or more ESD simulator. Many are equipped to verify the ESD simulators’ performance but few to the latest requirements. Topics: Verification techniques, including ISO, SAE, ANSI and IEC standards Latest changes to verification requirements How the new systems compare to older systems Practical aspects of measurement setup and performance Conflicts between specifications Recommendation for air-discharge verification 3

ESD Simulator Verification What parameters must be measured? Tip voltage – continuous, not discharge Current waveform – contact discharge Peak Rise time Current at 30 ns (for IEC network) Current at 60 ns (for IEC network) Current waveform – air discharge (automotive only) Rise time Time Constant 4

ESD Simulator Verification Measuring tip voltage Measured at standard test levels: ± 2 k. V, ± 4 k. V, ± 6 k. V, ± 8 k. V, ± 15 k. V and ± 25 k. V Measured using Electrometer or Giga-ohm meter Most standards don’t specify requirements ISO 10605 specifies 100 GOhm minimum input impedance The simulator’s tip voltage not affected by the measurement If a Giga-ohm meter is used, the simulator must continuously charge the high-voltage capacitor 5

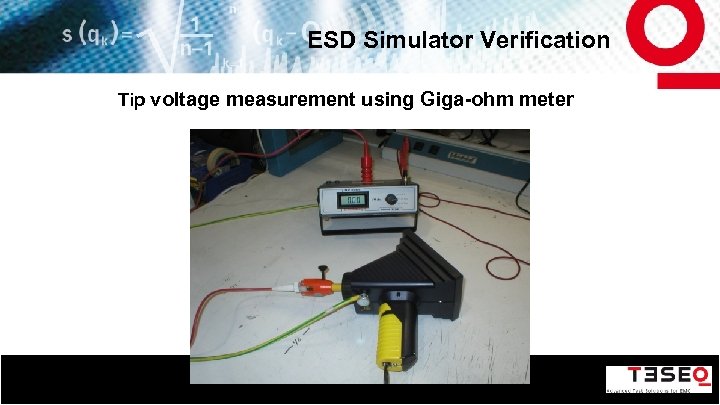

ESD Simulator Verification Tip voltage measurement using Giga-ohm meter 6

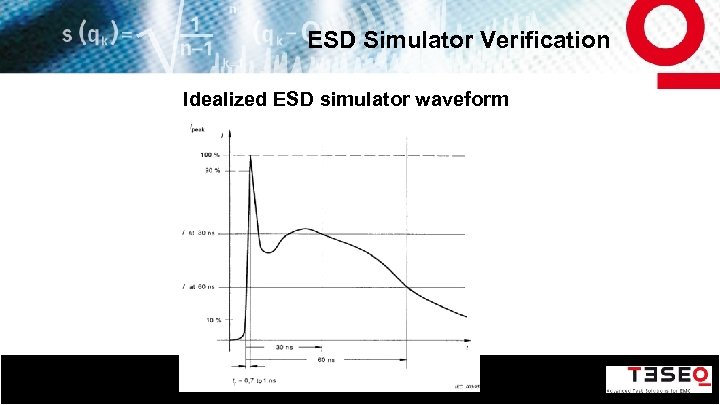

ESD Simulator Verification Idealized ESD simulator waveform 7

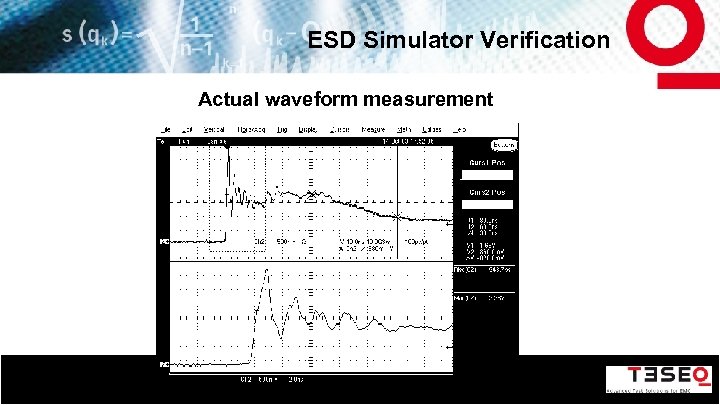

ESD Simulator Verification Actual waveform measurement 8

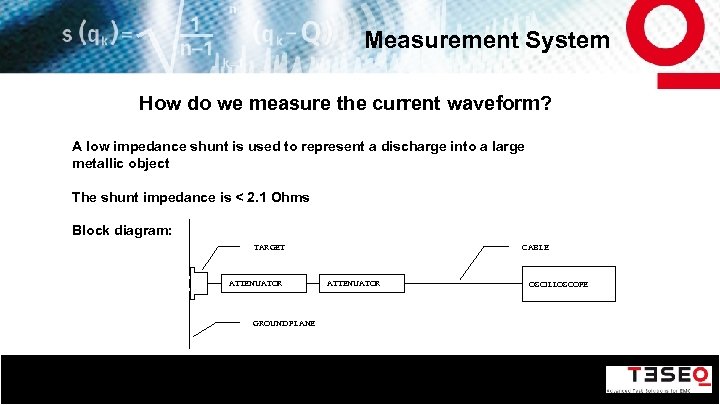

Measurement System How do we measure the current waveform? A low impedance shunt is used to represent a discharge into a large metallic object The shunt impedance is < 2. 1 Ohms Block diagram: TARGET ATTENUATOR GROUND PLANE 9 CABLE ATTENUATOR OSCILLOSCOPE

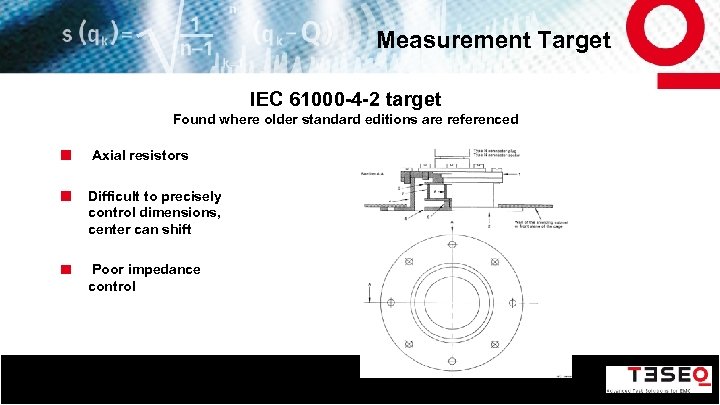

Measurement Target IEC 61000 -4 -2 target Found where older standard editions are referenced Axial resistors Difficult to precisely control dimensions, center can shift Poor impedance control 10

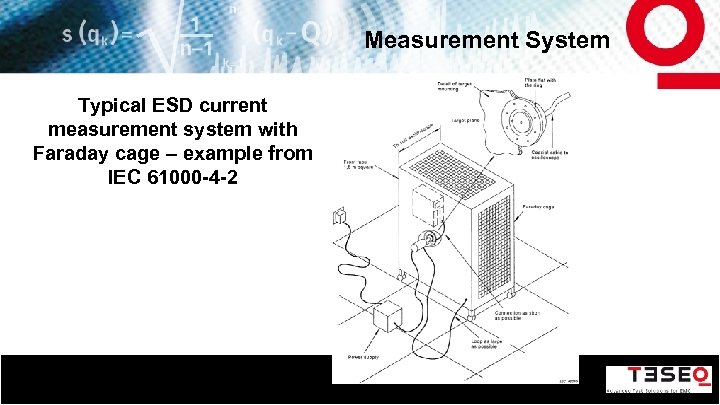

Measurement System Typical ESD current measurement system with Faraday cage – example from IEC 61000 -4 -2 11

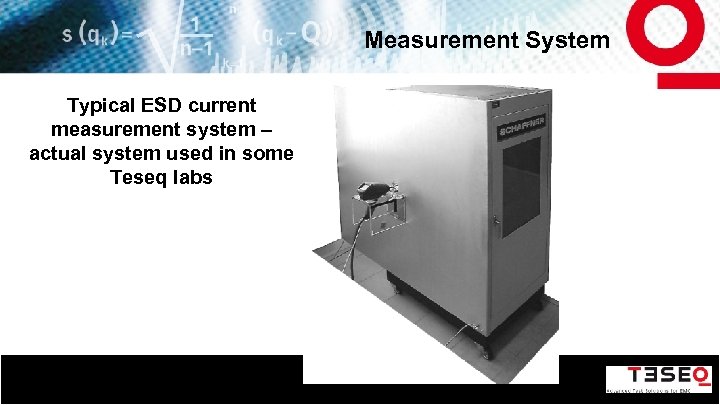

Measurement System Typical ESD current measurement system – actual system used in some Teseq labs 12

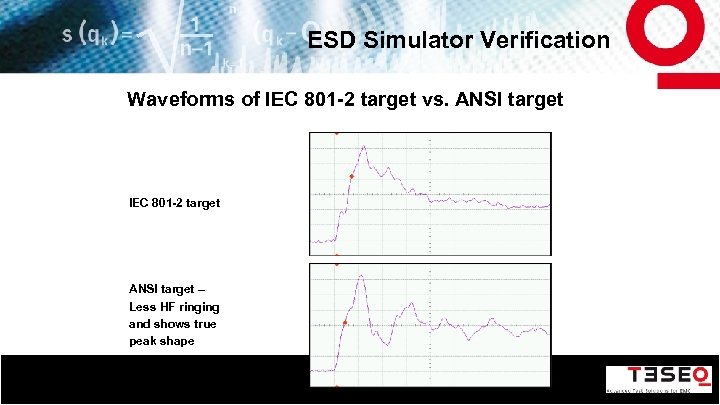

ESD Simulator Verification Waveforms of IEC 801 -2 target vs. ANSI target IEC 801 -2 target ANSI target – Less HF ringing and shows true peak shape 13

Attenuators Choosing attenuators Target transfer function is ~1 V/A when loaded by 50 Ohms Contact mode peak current at 8 k. V is ~30 A Input range of most oscilloscopes is < 10 V in 50 Ohm mode Attenuator is needed to reduce the signal level 20 d. B is typically chosen for 10: 1 ratio Contact mode to 25 k. V may require additional attenuation 14

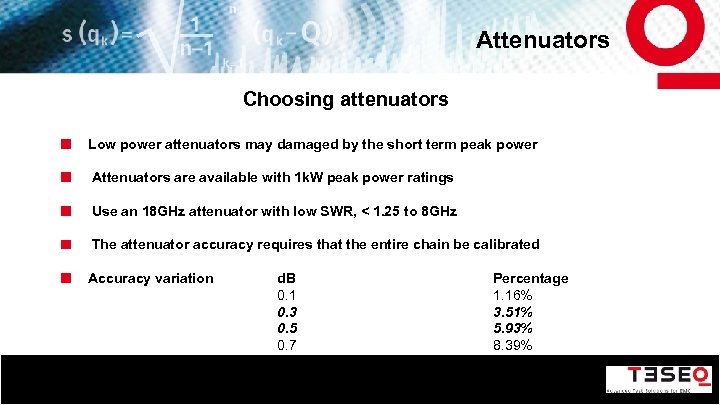

Attenuators Choosing attenuators Low power attenuators may damaged by the short term peak power Attenuators are available with 1 k. W peak power ratings Use an 18 GHz attenuator with low SWR, < 1. 25 to 8 GHz The attenuator accuracy requires that the entire chain be calibrated Accuracy variation 15 d. B 0. 1 0. 3 0. 5 0. 7 0. 9 Percentage 1. 16% 3. 51% 5. 93% 8. 39% 10. 92%

Cables Choosing cables A low loss cable is required Cable length < 1 m is required by most standards Double shielding is required by most standards The ANSI standard recommends RG 400 RG 214 is twice the diameter, 1/2 the loss and is commonly available 16

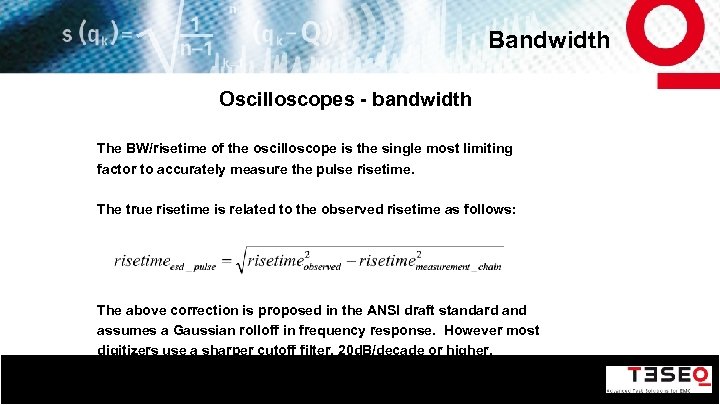

Bandwidth Oscilloscopes - bandwidth The BW/risetime of the oscilloscope is the single most limiting factor to accurately measure the pulse risetime. The true risetime is related to the observed risetime as follows: The above correction is proposed in the ANSI draft standard and assumes a Gaussian rolloff in frequency response. However most digitizers use a sharper cutoff filter, 20 d. B/decade or higher. 17

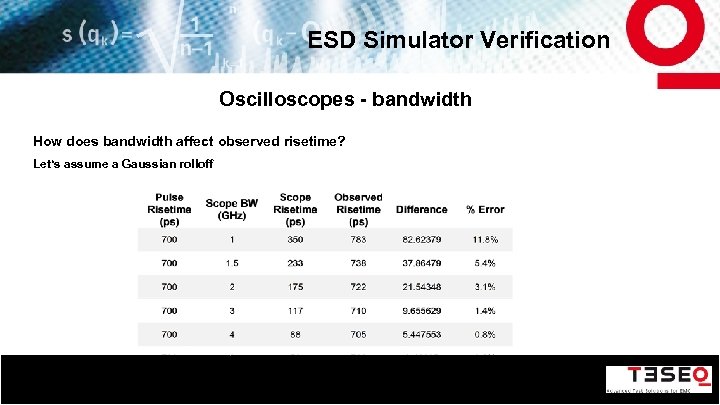

ESD Simulator Verification Oscilloscopes - bandwidth How does bandwidth affect observed risetime? Let‘s assume a Gaussian rolloff 18

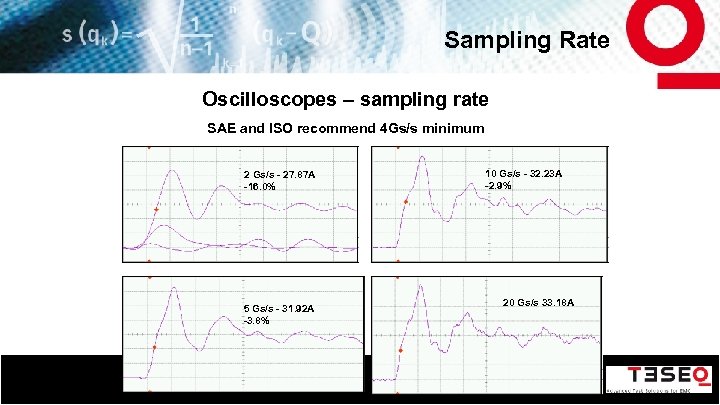

ESD Simulator Verification Oscilloscopes – sampling rate Single-shot sampling rate is the key Sharp/traingular peak requires fast sample rate Risetime of 800 ps from 10%-90% is 80% of waveform 10 Gs/s = 100 ps/sample 8 samples in 800 ps or 10%/sample! Since peak is symmetrical and somewhat rounded actual error is < 5% Effective sampling rate increased by capturing multiple shots Must have stable waveform Contact mode only - never for air discharge Shot to shot variation is low for most simulators Should be used for verification - not for calibration 19

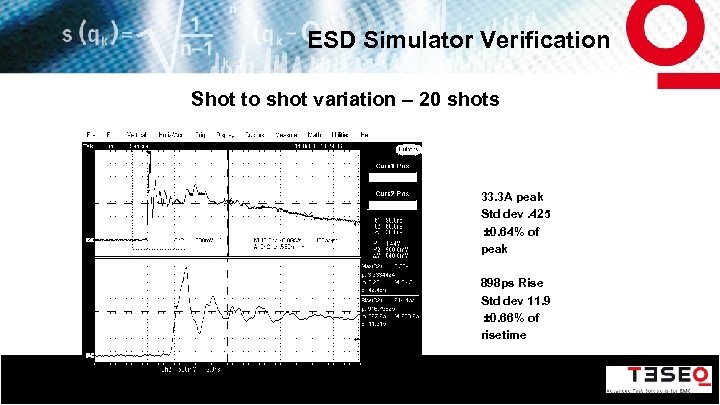

ESD Simulator Verification Shot to shot variation – 20 shots 33. 3 A peak Std dev. 425 ± 0. 64% of peak 898 ps Rise Std dev 11. 9 ± 0. 66% of risetime 20

Sampling Rate Oscilloscopes – sampling rate SAE and ISO recommend 4 Gs/s minimum 2 Gs/s - 27. 87 A -16. 0% 5 Gs/s - 31. 92 A -3. 8% 21 10 Gs/s - 32. 23 A -2. 9% 20 Gs/s 33. 18 A

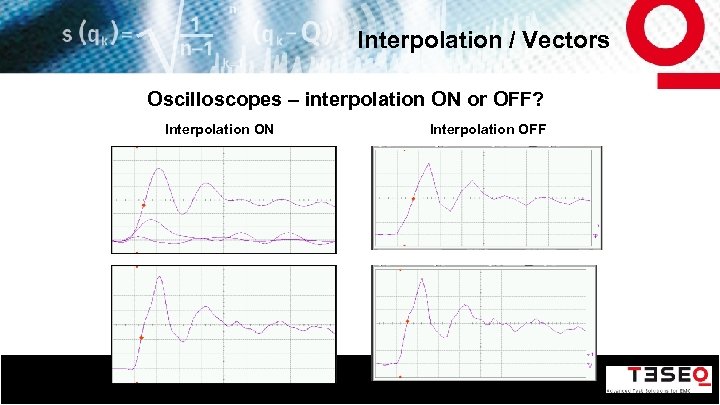

Interpolation / Vectors Oscilloscopes – interpolation ON or OFF? Interpolation ON 22 Interpolation OFF

ESD Simulator Verification Other factors – Dos and don’ts Shielding Do we need it? Position of ground cable Will it affect waveform? Orientation of simulator Will it affect waveform? Automatic Measurements Must use Min and Max values to calculate 10% and 90% points Other cables Keep them well separated 23

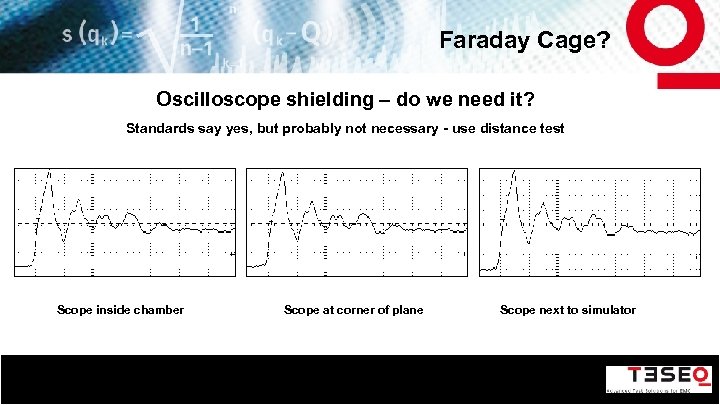

Faraday Cage? Oscilloscope shielding – do we need it? Standards say yes, but probably not necessary - use distance test Scope inside chamber 24 Scope at corner of plane Scope next to simulator

Measurement System Working ESD current measurement system without Faraday cage 25

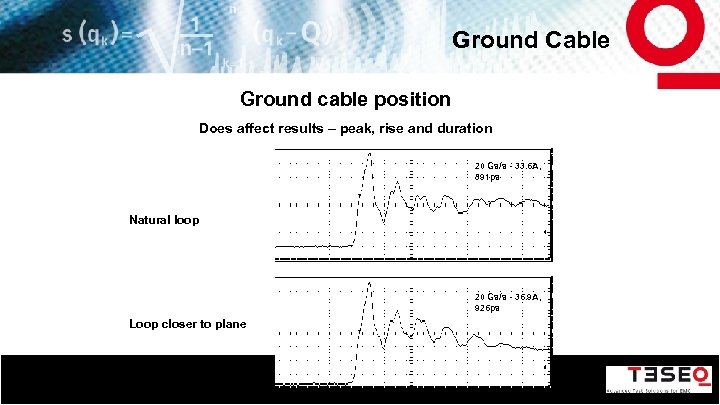

Ground Cable Ground cable position Does affect results – peak, rise and duration 20 Gs/s - 33. 6 A, 891 ps Natural loop 20 Gs/s - 36. 9 A, 926 ps Loop closer to plane 26

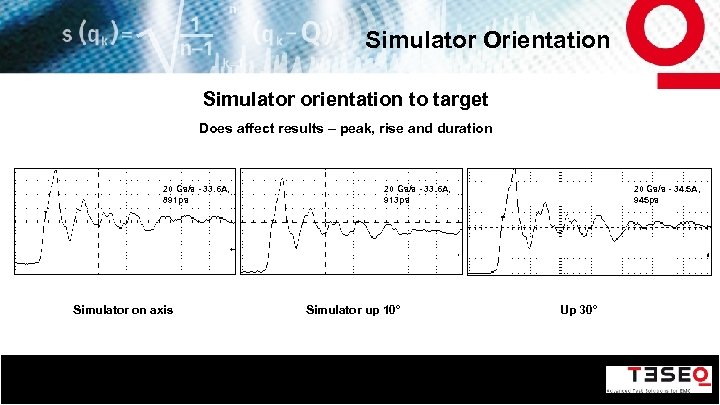

Simulator Orientation Simulator orientation to target Does affect results – peak, rise and duration 20 Gs/s - 33. 6 A, 891 ps Simulator on axis 27 20 Gs/s - 33. 6 A, 913 ps Simulator up 10° 20 Gs/s - 34. 5 A, 945 ps Up 30°

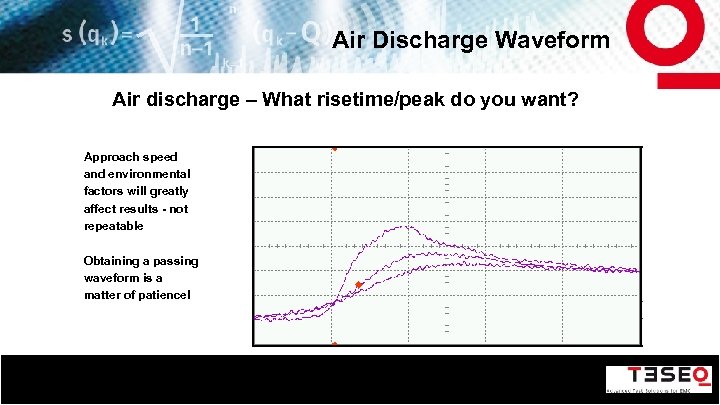

Air Discharge Waveform Air discharge – What risetime/peak do you want? Approach speed and environmental factors will greatly affect results - not repeatable Obtaining a passing waveform is a matter of patience! 28

ESD Simulator Verification Measurement uncertainty The estimated bounds of the deviation of a measured quantity from its true value List all the possible error sources and compute the uncertainty Uncertainty budget for each measured parameter Statement of confidence that can be placed in the value of uncertainty Does measured result truly fall within acceptable limits? National Association for Measurement and Sampling publication NIS 81, The Treatment of Uncertainty in EMC Measurements Extensive reference information with examples in IEC 61000 -4 -2: 2008 Appendix E 29

The New IEC -4 -2 Changes to Simulator Verification in IEC 61000 -4 -2: 2008 Method for measuring low frequency system transfer impedance Improved measurement target with RF specifications to 4 GHz Target calibration adapter defined Minimum 2 GHz oscilloscope bandwidth Faraday cage may not be required Peak current tolerance relaxed from ± 10% to ± 15% Minimum rise time reduced from 700 ps to 600 ps Ground cable position defined Uncertainty calculation examples in Appendix E 30

Target Evolution Target design history IEC 801 -2: 1991 No longer referenced by any current standard No performance specifications Poor design - lots of ringing Small ground plane IEC 61000 -4 -2: 1995, 2001 Referenced by virtually all current standards No performance specifications Transfer function “zero” at 5 -6 GHz IEC 61000 -4 -2: 2008 -12 New design with flatness specified to 4 GHz ≥ 2 GHz Oscilloscope required Adapter to evaluate high frequency performance 31

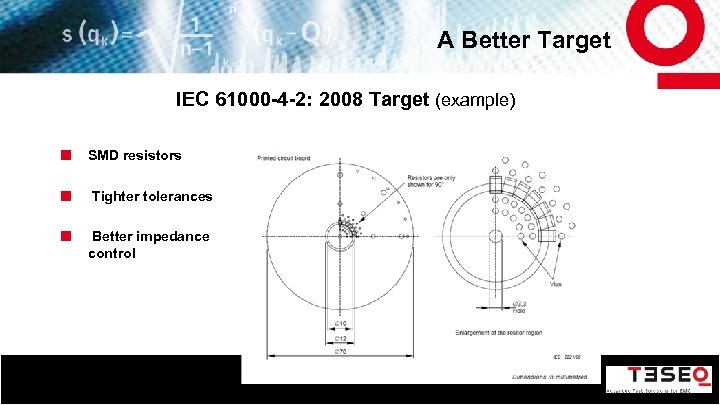

A Better Target IEC 61000 -4 -2: 2008 Target (example) SMD resistors Tighter tolerances Better impedance control 32

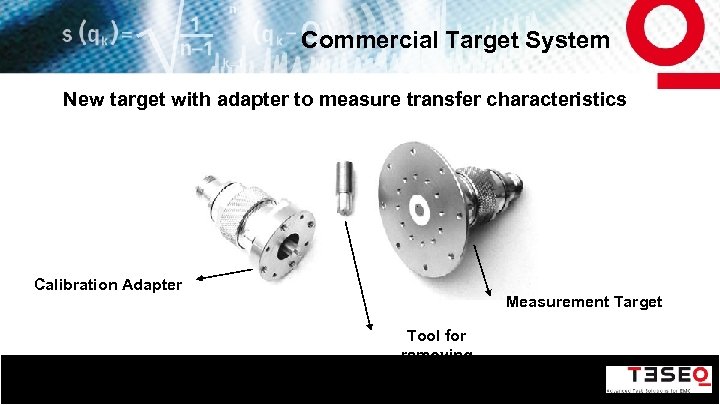

Commercial Target System New target with adapter to measure transfer characteristics Calibration Adapter 33 Measurement Target Tool for removing center

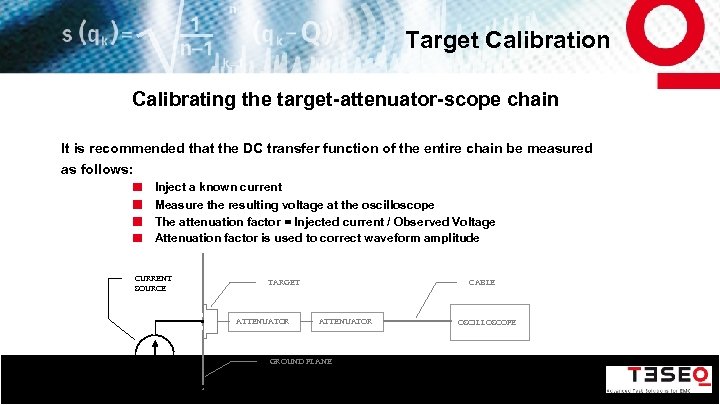

Target Calibration Calibrating the target-attenuator-scope chain It is recommended that the DC transfer function of the entire chain be measured as follows: Inject a known current Measure the resulting voltage at the oscilloscope The attenuation factor = Injected current / Observed Voltage Attenuation factor is used to correct waveform amplitude CURRENT SOURCE TARGET ATTENUATOR CABLE ATTENUATOR GROUND PLANE 34 OSCILLOSCOPE

Target Calibration IEC 61000 -4 -2 target and adapter specifications Variation of attenuation of the adapter-target-attenuator-cable chain < ± 0. 5 d. B from DC to 1 GHz (< ± 5. 9%) < ± 1. 2 d. B from 1 GHz to 4 GHz (< ± 14. 8%) Adapters must be tested too! Return loss of two adapters face-to-face > 30 d. B from DC to 1 GHz > 20 d. B from 1 GHz to 4 GHz Insertion loss of two adapters face-to-face < 0. 3 d. B up to 4 GHz 35

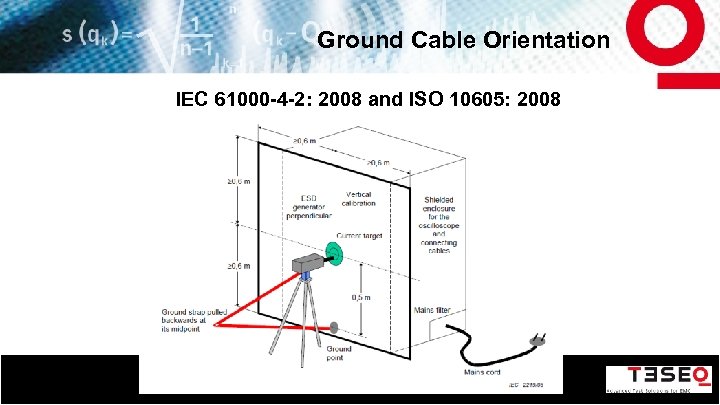

Ground Cable Orientation IEC 61000 -4 -2: 2008 and ISO 10605: 2008 36

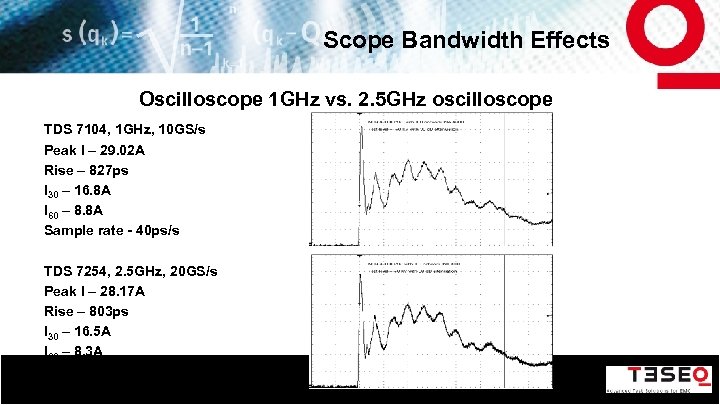

Scope Bandwidth Effects Oscilloscope 1 GHz vs. 2. 5 GHz oscilloscope TDS 7104, 1 GHz, 10 GS/s Peak I – 29. 02 A Rise – 827 ps I 30 – 16. 8 A I 60 – 8. 8 A Sample rate - 40 ps/s TDS 7254, 2. 5 GHz, 20 GS/s Peak I – 28. 17 A Rise – 803 ps I 30 – 16. 5 A I 60 – 8. 3 A Sample rate – 10 ps/s 37

The New 10605 Changes to Simulator Verification in ISO 10605: 2008 New RC networks added to existing 150 p. F / 2 kΩ, 330 p. F / 2 kΩ 150 p. F/ 330Ω – same specs as IEC 61000 -4 -2 330 p. F/ 330Ω – DC 10614 New networks have IEC-like limits ± 10% peak vs. +30/-0% No air discharge verification – variability too high Voltage Approach speed Humidity Arc length Ionization 38

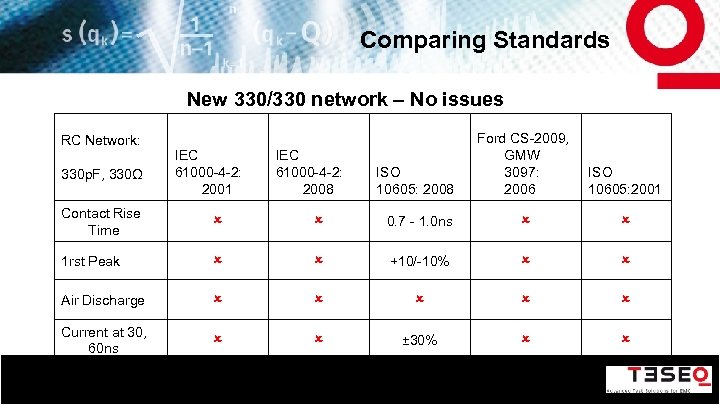

Comparing Standards New 330/330 network – No issues RC Network: 330 p. F, 330Ω IEC 61000 -4 -2: 2001 IEC 61000 -4 -2: 2008 ISO 10605: 2008 Ford CS-2009, GMW 3097: 2006 ISO 10605: 2001 Contact Rise Time O 0. 7 - 1. 0 ns O O 1 rst Peak O O +10/-10% O O Air Discharge O O O Current at 30, 60 ns 39 O O O ± 30% O O

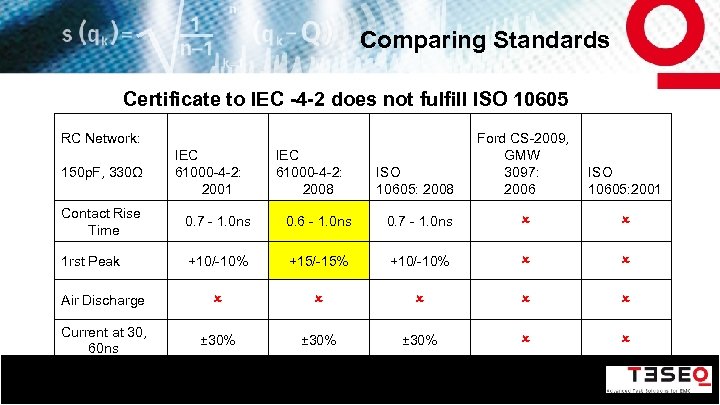

Comparing Standards Certificate to IEC -4 -2 does not fulfill ISO 10605 RC Network: 150 p. F, 330Ω IEC 61000 -4 -2: 2001 IEC 61000 -4 -2: 2008 ISO 10605: 2008 Ford CS-2009, GMW 3097: 2006 ISO 10605: 2001 Contact Rise Time 0. 6 - 1. 0 ns 0. 7 - 1. 0 ns O O 1 rst Peak +10/-10% +15/-15% +10/-10% O O Air Discharge O O O Current at 30, 60 ns 40 0. 7 - 1. 0 ns ± 30% O O

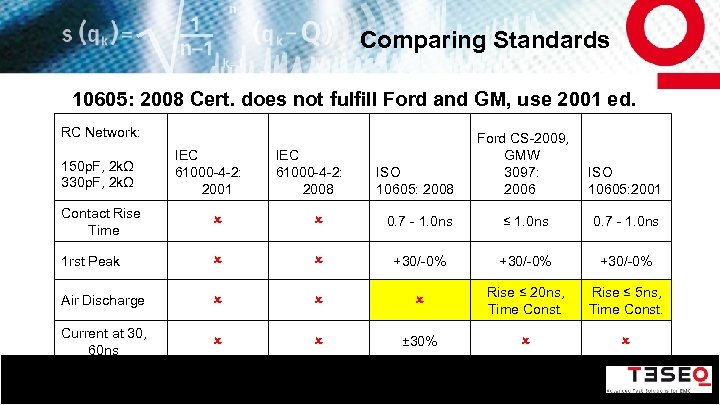

Comparing Standards 10605: 2008 Cert. does not fulfill Ford and GM, use 2001 ed. RC Network: 150 p. F, 2 kΩ 330 p. F, 2 kΩ IEC 61000 -4 -2: 2001 IEC 61000 -4 -2: 2008 ISO 10605: 2008 Ford CS-2009, GMW 3097: 2006 ISO 10605: 2001 Contact Rise Time O 0. 7 - 1. 0 ns ≤ 1. 0 ns 0. 7 - 1. 0 ns 1 rst Peak O O +30/-0% Air Discharge O O O Rise ≤ 20 ns, Time Const. Rise ≤ 5 ns, Time Const. Current at 30, 60 ns 41 O O O ± 30% O O

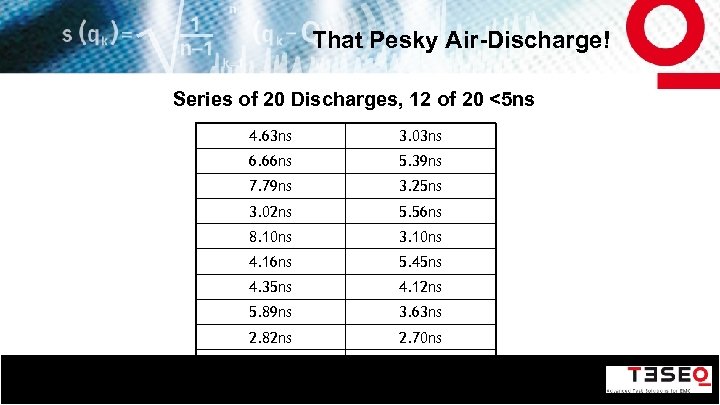

That Pesky Air-Discharge! Requirements from ISO 10605: 2001 Only single events are allowed Start at least 15 mm away from the target Approach slowly, 5 mm/s or less Levels are 4, 8 and 15 k. V both polarities Rise time must be less than 5 ns Acceptable waveforms must be repeatable at least 6 of 10 attempts Time constant is 300 ns ± 60 ns for 150 p. F network Time constant is 660 ns ± 130 ns for 150 p. F network Target from IEC 61000 -4 -2: 1995 referenced, no target plane req’s 42

That Pesky Air-Discharge! Series of 20 Discharges, 12 of 20 <5 ns 4. 63 ns 6. 66 ns 5. 39 ns 7. 79 ns 3. 25 ns 3. 02 ns 5. 56 ns 8. 10 ns 3. 10 ns 4. 16 ns 5. 45 ns 4. 35 ns 4. 12 ns 5. 89 ns 3. 63 ns 2. 82 ns 2. 70 ns 3. 35 ns 43 3. 03 ns 5. 14 ns

That Pesky Air-Discharge! Series of 20 Discharges, Event #1 44

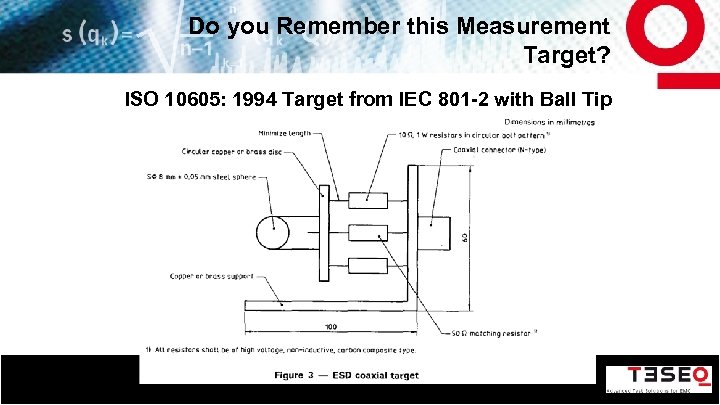

Do you Remember this Measurement Target? ISO 10605: 1994 Target from IEC 801 -2 with Ball Tip 45

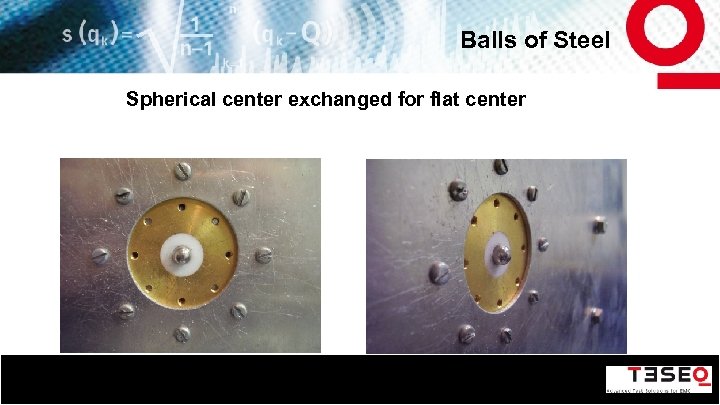

Balls of Steel Spherical center exchanged for flat center 46

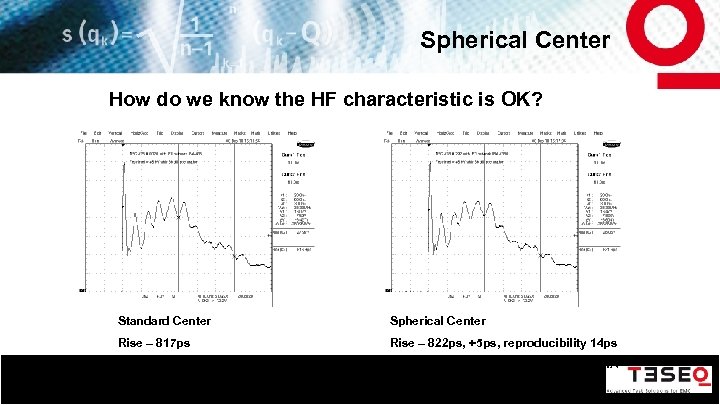

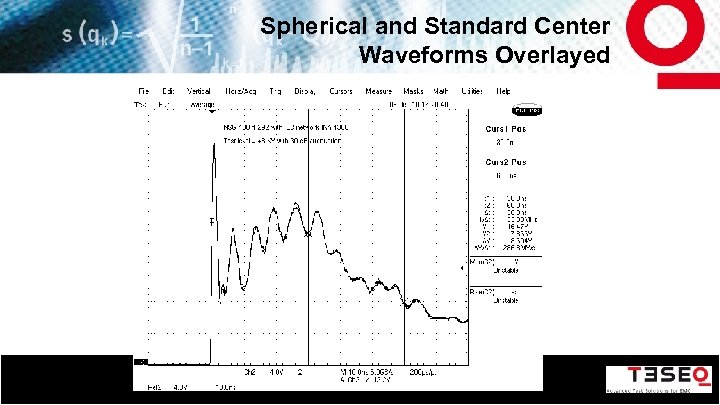

Spherical Center How do we know the HF characteristic is OK? Standard Center Rise – 817 ps Rise – 822 ps, +5 ps, reproducibility 14 ps Peak – 27. 9 A 47 Spherical Center Peak – 28. 0 A, +0. 1, reproducibility 0. 24 A

Spherical and Standard Center Waveforms Overlayed 48

That Pesky Air-Discharge! Summary Some checks should be applied There will be a high degree of variability shot-to-shot Internal contact discharge relays increase variability Environmental characteristics pay a big role Contact shape affects discharge waveform Flat targets perform worse than spherical centers Spherical center does not alter target characteristics 49

Multiples Are they really there? Very hard to capture A second and sometimes a third discharge occurs Typically >100 ms between discharges Fast sampling rate required to catch event, >1 Gs/s Long record length required – For 500 ms, 500 Mb! Peak detect sampling mode works well 50

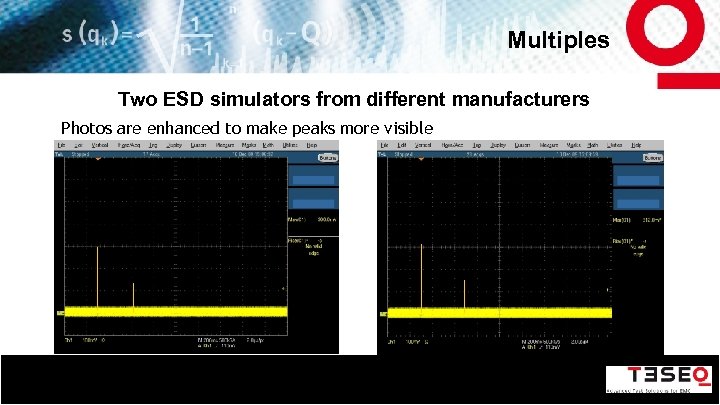

Multiples Two ESD simulators from different manufacturers Photos are enhanced to make peaks more visible 51

Multiples Why do they occur? At 15 k. V, the first discharge arc occurs well before the contacts touch Arc can be 5 to >10 mm At 5 mm/s, 1 – 2 seconds from first arc to contact The ESD discharge lasts for just 10’s of nanoseconds Arc extinguishes when current is low but before all energy discharged Additional discharge happens when tip gets close enough for new arc, approx. 200 – 400 ms after first event 52

ESD Simulator Verification Thank you for your attention Your feedback is welcome Gregory Senko, President Teseq, Inc. 978 -764 -7358 gregory. senko@teseq. com 53

cf3b64352efc191ce4d0505c2f89279b.ppt