34b7b3da326b4346a0ca9b90107e75b2.ppt

- Количество слайдов: 50

TES METHOD LIMITING INVASIVENESS DURING THE RETROFIT PROCESS Kimmo Lylykangas Architects ltd RENEWING THE CITY: RETROFITS & BROWNFIELD DEVELOPMENT Stockholm May the 8 th 2013

TES METHOD LIMITING INVASIVENESS DURING THE RETROFIT PROCESS Kimmo Lylykangas Architects ltd RENEWING THE CITY: RETROFITS & BROWNFIELD DEVELOPMENT Stockholm May the 8 th 2013

TES ENERGY FACADE

TES ENERGY FACADE

Forest Technology Platform Team-Up Award 2009 Wood. Wisdom-Net Best Project Awards “Prize for being the project with Best industrial involvement and relevance” 2011 Deutscher Holzbaupreis 2011 kategoriassa “Komponenten / Konzepte” Schweighofer Innovation Prize 2011 www. schweighofer-prize. org KUVA: Thomas Preiss, http: //www. apa-fotoservice. at/

Forest Technology Platform Team-Up Award 2009 Wood. Wisdom-Net Best Project Awards “Prize for being the project with Best industrial involvement and relevance” 2011 Deutscher Holzbaupreis 2011 kategoriassa “Komponenten / Konzepte” Schweighofer Innovation Prize 2011 www. schweighofer-prize. org KUVA: Thomas Preiss, http: //www. apa-fotoservice. at/

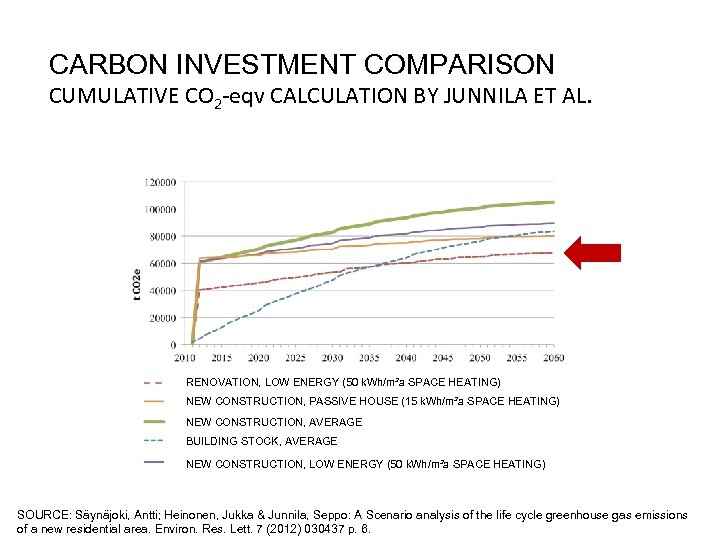

CARBON INVESTMENT COMPARISON CUMULATIVE CO 2 -eqv CALCULATION BY JUNNILA ET AL. RENOVATION, LOW ENERGY (50 k. Wh/m²a SPACE HEATING) NEW CONSTRUCTION, PASSIVE HOUSE (15 k. Wh/m²a SPACE HEATING) NEW CONSTRUCTION, AVERAGE BUILDING STOCK, AVERAGE NEW CONSTRUCTION, LOW ENERGY (50 k. Wh/m²a SPACE HEATING) SOURCE: Säynäjoki, Antti; Heinonen, Jukka & Junnila, Seppo: A Scenario analysis of the life cycle greenhouse gas emissions of a new residential area. Environ. Res. Lett. 7 (2012) 030437 p. 6.

CARBON INVESTMENT COMPARISON CUMULATIVE CO 2 -eqv CALCULATION BY JUNNILA ET AL. RENOVATION, LOW ENERGY (50 k. Wh/m²a SPACE HEATING) NEW CONSTRUCTION, PASSIVE HOUSE (15 k. Wh/m²a SPACE HEATING) NEW CONSTRUCTION, AVERAGE BUILDING STOCK, AVERAGE NEW CONSTRUCTION, LOW ENERGY (50 k. Wh/m²a SPACE HEATING) SOURCE: Säynäjoki, Antti; Heinonen, Jukka & Junnila, Seppo: A Scenario analysis of the life cycle greenhouse gas emissions of a new residential area. Environ. Res. Lett. 7 (2012) 030437 p. 6.

PASSIVE HOUSE RETROFIT Saturnuksenkatu 2 KOTIKULMA OY, BUILDING 10 • A 4 -storey residential building, first constructed in 1975 • 37 rental apartments and a day-care center ”Saturnus” • A relatively typical 1970’s multi-storey apartment building in Finland load-bearing concrete element frame, exterior walls constructed of sandwich elements the facades need to be renovated for technical reasons • Located in Peltosaari area, town of Riihimäki An area with multiple socio-economic problems typical to suburban areas in Finland

PASSIVE HOUSE RETROFIT Saturnuksenkatu 2 KOTIKULMA OY, BUILDING 10 • A 4 -storey residential building, first constructed in 1975 • 37 rental apartments and a day-care center ”Saturnus” • A relatively typical 1970’s multi-storey apartment building in Finland load-bearing concrete element frame, exterior walls constructed of sandwich elements the facades need to be renovated for technical reasons • Located in Peltosaari area, town of Riihimäki An area with multiple socio-economic problems typical to suburban areas in Finland

PASSIVE HOUSE RETROFIT Saturnuksenkatu 2 FACADE RENOVATION • Additional thermal insulation • New doors and windows • New entrance canopies • New balconies • New facade materials NEW ROOF • New technical space and the assembly space for ventilation ducts in the attic NEW VENTILATION SYSTEM • Centralized mechanical ventilation system with effective heat recovery [regerative heat exchanger] • New spaces for ventilation units in the attic and in a former storageroom on the 4 th storey

PASSIVE HOUSE RETROFIT Saturnuksenkatu 2 FACADE RENOVATION • Additional thermal insulation • New doors and windows • New entrance canopies • New balconies • New facade materials NEW ROOF • New technical space and the assembly space for ventilation ducts in the attic NEW VENTILATION SYSTEM • Centralized mechanical ventilation system with effective heat recovery [regerative heat exchanger] • New spaces for ventilation units in the attic and in a former storageroom on the 4 th storey

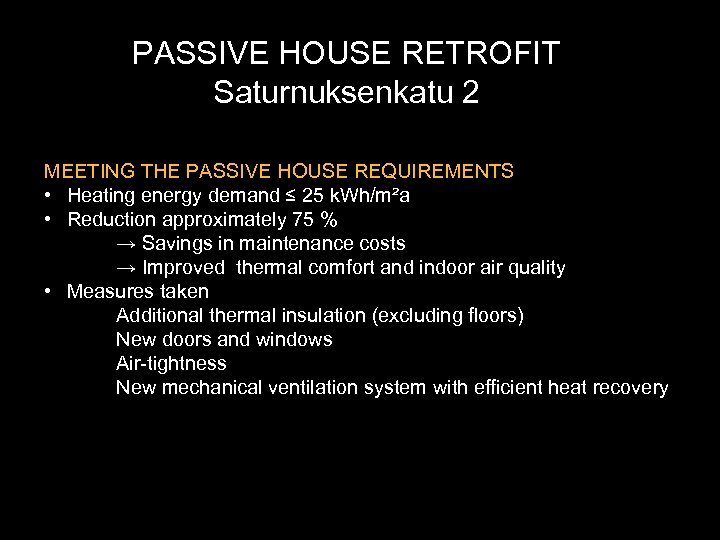

PASSIVE HOUSE RETROFIT Saturnuksenkatu 2 MEETING THE PASSIVE HOUSE REQUIREMENTS • Heating energy demand ≤ 25 k. Wh/m²a • Reduction approximately 75 % → Savings in maintenance costs → Improved thermal comfort and indoor air quality • Measures taken Additional thermal insulation (excluding floors) New doors and windows Air-tightness New mechanical ventilation system with efficient heat recovery

PASSIVE HOUSE RETROFIT Saturnuksenkatu 2 MEETING THE PASSIVE HOUSE REQUIREMENTS • Heating energy demand ≤ 25 k. Wh/m²a • Reduction approximately 75 % → Savings in maintenance costs → Improved thermal comfort and indoor air quality • Measures taken Additional thermal insulation (excluding floors) New doors and windows Air-tightness New mechanical ventilation system with efficient heat recovery

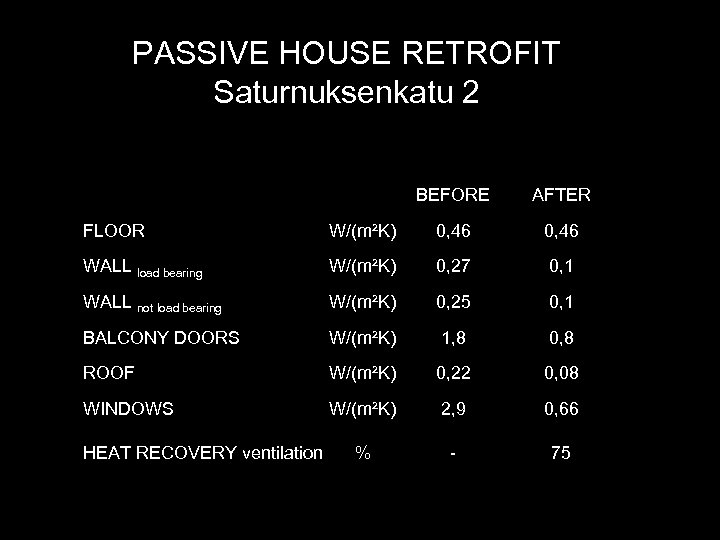

PASSIVE HOUSE RETROFIT Saturnuksenkatu 2 BEFORE AFTER FLOOR W/(m²K) 0, 46 WALL load bearing W/(m²K) 0, 27 0, 1 WALL not load bearing W/(m²K) 0, 25 0, 1 BALCONY DOORS W/(m²K) 1, 8 0, 8 ROOF W/(m²K) 0, 22 0, 08 WINDOWS W/(m²K) 2, 9 0, 66 % - 75 HEAT RECOVERY ventilation

PASSIVE HOUSE RETROFIT Saturnuksenkatu 2 BEFORE AFTER FLOOR W/(m²K) 0, 46 WALL load bearing W/(m²K) 0, 27 0, 1 WALL not load bearing W/(m²K) 0, 25 0, 1 BALCONY DOORS W/(m²K) 1, 8 0, 8 ROOF W/(m²K) 0, 22 0, 08 WINDOWS W/(m²K) 2, 9 0, 66 % - 75 HEAT RECOVERY ventilation

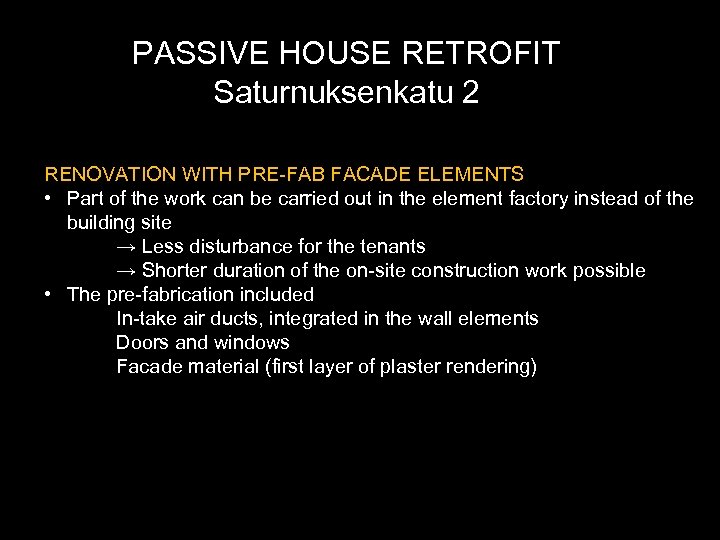

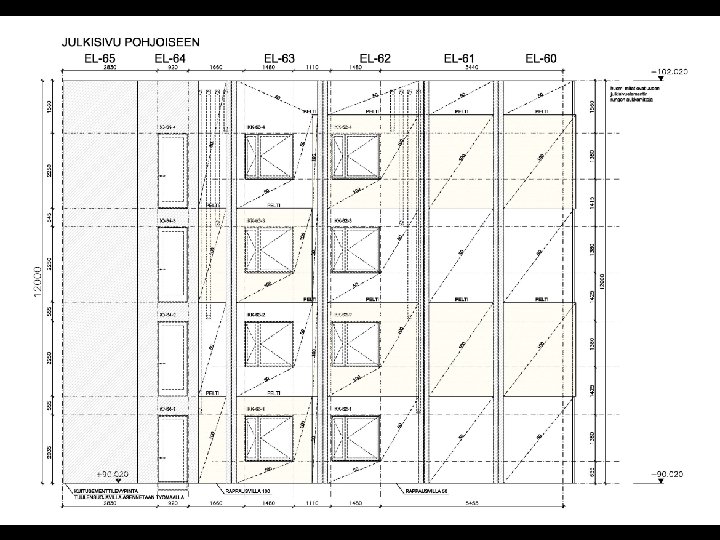

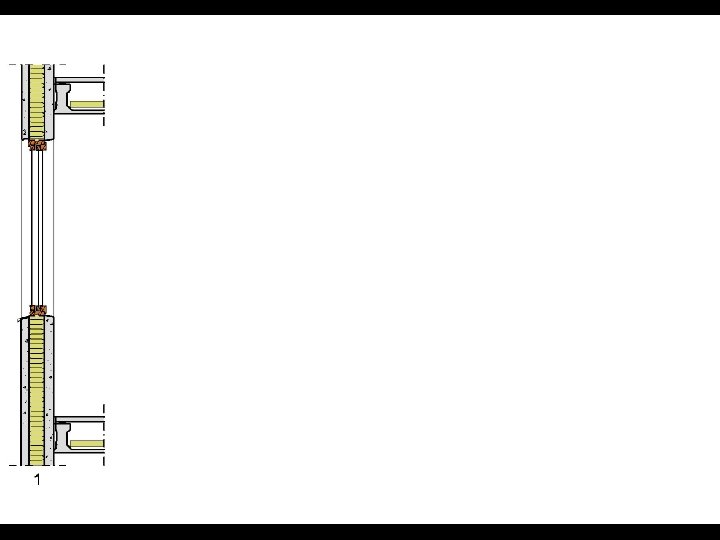

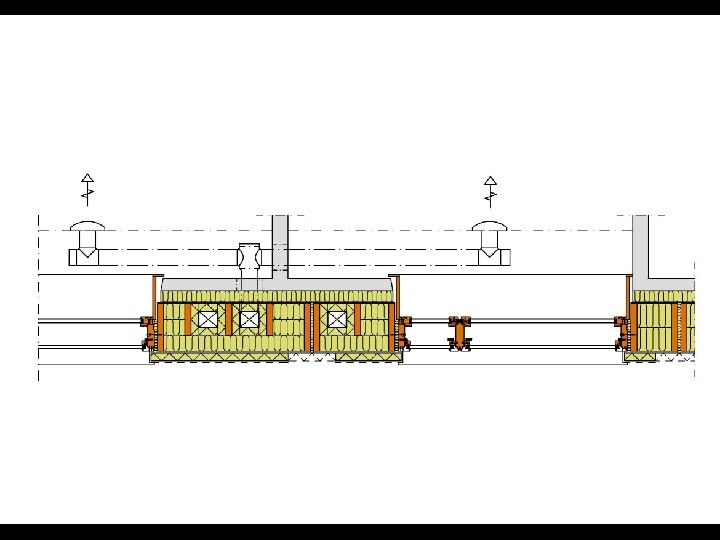

PASSIVE HOUSE RETROFIT Saturnuksenkatu 2 RENOVATION WITH PRE-FAB FACADE ELEMENTS • Part of the work can be carried out in the element factory instead of the building site → Less disturbance for the tenants → Shorter duration of the on-site construction work possible • The pre-fabrication included In-take air ducts, integrated in the wall elements Doors and windows Facade material (first layer of plaster rendering)

PASSIVE HOUSE RETROFIT Saturnuksenkatu 2 RENOVATION WITH PRE-FAB FACADE ELEMENTS • Part of the work can be carried out in the element factory instead of the building site → Less disturbance for the tenants → Shorter duration of the on-site construction work possible • The pre-fabrication included In-take air ducts, integrated in the wall elements Doors and windows Facade material (first layer of plaster rendering)

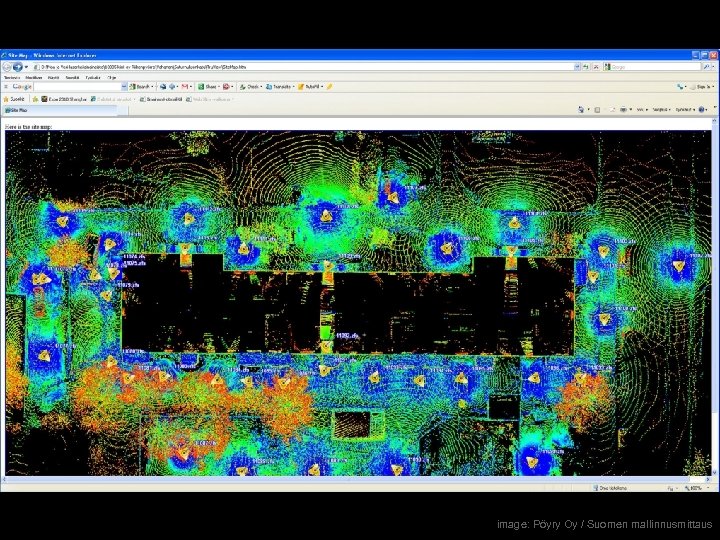

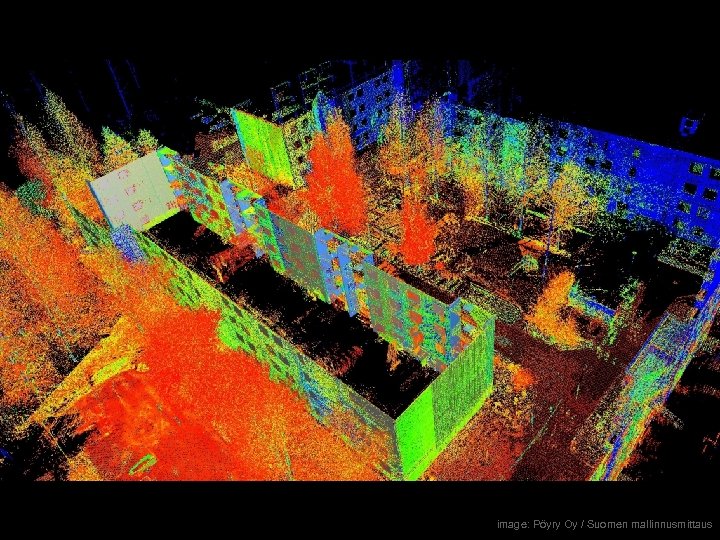

laser scanning 3 D modelling

laser scanning 3 D modelling

image: Aalto University / Wood Construction

image: Aalto University / Wood Construction

image: Pöyry Oy / Suomen mallinnusmittaus

image: Pöyry Oy / Suomen mallinnusmittaus

image: Pöyry Oy / Suomen mallinnusmittaus

image: Pöyry Oy / Suomen mallinnusmittaus

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

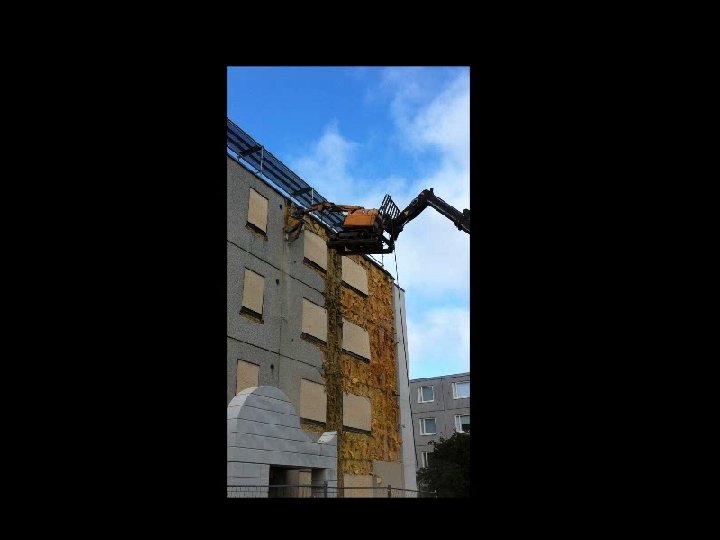

dismantling of the old facade

dismantling of the old facade

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

Image: Simon le Roux, Aalto University

Image: Simon le Roux, Aalto University

architectural design

architectural design

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

facade elements

facade elements

© Paroc Group 29 Image: Jukka Sevon, Paroc Oy Ab

© Paroc Group 29 Image: Jukka Sevon, Paroc Oy Ab

© Paroc Group 30 Image: Jukka Sevon, Paroc Oy Ab

© Paroc Group 30 Image: Jukka Sevon, Paroc Oy Ab

© Paroc Group 31 Image: Jukka Sevon, Paroc Oy Ab

© Paroc Group 31 Image: Jukka Sevon, Paroc Oy Ab

© Paroc Group 32 Image: Kimmo Lylykangas Architects ltd

© Paroc Group 32 Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

3/18/2018 © Paroc Group 35 Image: Jukka Sevón, Paroc Oy Ab

3/18/2018 © Paroc Group 35 Image: Jukka Sevón, Paroc Oy Ab

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

Image: Simon le Roux, Aalto University

Image: Simon le Roux, Aalto University

Roof elements on-site assembly Riihimäki Innova project photos: Simon le Roux 28. 9. 2011 Image: Simon le Roux, Aalto University

Roof elements on-site assembly Riihimäki Innova project photos: Simon le Roux 28. 9. 2011 Image: Simon le Roux, Aalto University

Images: Simon le Roux, Aalto University

Images: Simon le Roux, Aalto University

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

Image: Jukka Sevón, Paroc Oy Ab

Image: Jukka Sevón, Paroc Oy Ab

Image: Jukka Sevón, Paroc Oy Ab

Image: Jukka Sevón, Paroc Oy Ab

after renovation

after renovation

Image: Jukka Sevón, Paroc Oy Ab

Image: Jukka Sevón, Paroc Oy Ab

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

Image: Kimmo Lylykangas Architects ltd

PILOT PROJECT EXPERIENCES • Laser scanning and high precision in element manufacturing enable pre -fabrication in retrofitting • Vertical elementation and thick insulation layers enable the integration of ventilation ducts (in-take air ductwork) in facade elements • Pre-fabrication can make the duration of the on-site construction work shorter and reduce both the costs and the disturbance for tenants • We were expecting problems in. . . precision and element installation ductwork integration and joints • The problems were met in. . . moisture control building site arrangements ensuring the safety and the comfort of the tenants

PILOT PROJECT EXPERIENCES • Laser scanning and high precision in element manufacturing enable pre -fabrication in retrofitting • Vertical elementation and thick insulation layers enable the integration of ventilation ducts (in-take air ductwork) in facade elements • Pre-fabrication can make the duration of the on-site construction work shorter and reduce both the costs and the disturbance for tenants • We were expecting problems in. . . precision and element installation ductwork integration and joints • The problems were met in. . . moisture control building site arrangements ensuring the safety and the comfort of the tenants

HOW TO DEVELOP THE PROCESS • Better coordination and pacing of three work phases: dismantling straightening of surfaces element installation • Minimizing the on-site work and avoiding the need for storaging of materials • Creating guidelines for ”living in the building site” , for example moisture control maximum noise level impurities in the ventilation system during the construction work tenant safety during the construction work • Ensuring good indoor air quality and thermal comfort during every phase of the retrofit • Separation of the areas for construction work and for tenants

HOW TO DEVELOP THE PROCESS • Better coordination and pacing of three work phases: dismantling straightening of surfaces element installation • Minimizing the on-site work and avoiding the need for storaging of materials • Creating guidelines for ”living in the building site” , for example moisture control maximum noise level impurities in the ventilation system during the construction work tenant safety during the construction work • Ensuring good indoor air quality and thermal comfort during every phase of the retrofit • Separation of the areas for construction work and for tenants

![MORE INFORMATION ON PRE-FAB RETROFITS: www. paroc. fi/kampanjat/innova-projekti [in Finnish only] www. tesenergyfacade. com MORE INFORMATION ON PRE-FAB RETROFITS: www. paroc. fi/kampanjat/innova-projekti [in Finnish only] www. tesenergyfacade. com](https://present5.com/presentation/34b7b3da326b4346a0ca9b90107e75b2/image-50.jpg) MORE INFORMATION ON PRE-FAB RETROFITS: www. paroc. fi/kampanjat/innova-projekti [in Finnish only] www. tesenergyfacade. com www. e 2 rebuild. eu www. ecbcs. org/annexes/annex 50 www. empa-ren. ch/A 50 THANK YOU FOR YOUR ATTENTION kimmo. lylykangas@arklylykangas. com

MORE INFORMATION ON PRE-FAB RETROFITS: www. paroc. fi/kampanjat/innova-projekti [in Finnish only] www. tesenergyfacade. com www. e 2 rebuild. eu www. ecbcs. org/annexes/annex 50 www. empa-ren. ch/A 50 THANK YOU FOR YOUR ATTENTION kimmo. lylykangas@arklylykangas. com