6b1aa20c8aed64eb821fd35bac5ae910.ppt

- Количество слайдов: 24

Teer Coatings Ltd Hydrogen Energy Teer Coatings Limited Coatings for Fuel Cells & Hydrogen Applications Kevin Cooke Teer Coatings Ltd, West Stone House, Berry Hill Industrial Estate, Droitwich, Worcestershire, WR 9 9 AS, UK www. teercoatings. co. uk Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy Teer Coatings Limited Coatings for Fuel Cells & Hydrogen Applications Kevin Cooke Teer Coatings Ltd, West Stone House, Berry Hill Industrial Estate, Droitwich, Worcestershire, WR 9 9 AS, UK www. teercoatings. co. uk Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy Outline of Presentation • Introduction to Teer Coatings Ltd: Ø TCL’s proprietary technology: Closed Field Unbalanced Magnetron Sputter Ion Plating (CFUBMSIP) • Applications in Fuel Cells and Hydrogen Ø Example: coatings for PEM cell electrodes Ø TCL’s Low Carbon related Collaborative Research • Summary & Conclusions • Acknowledgements Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy Outline of Presentation • Introduction to Teer Coatings Ltd: Ø TCL’s proprietary technology: Closed Field Unbalanced Magnetron Sputter Ion Plating (CFUBMSIP) • Applications in Fuel Cells and Hydrogen Ø Example: coatings for PEM cell electrodes Ø TCL’s Low Carbon related Collaborative Research • Summary & Conclusions • Acknowledgements Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

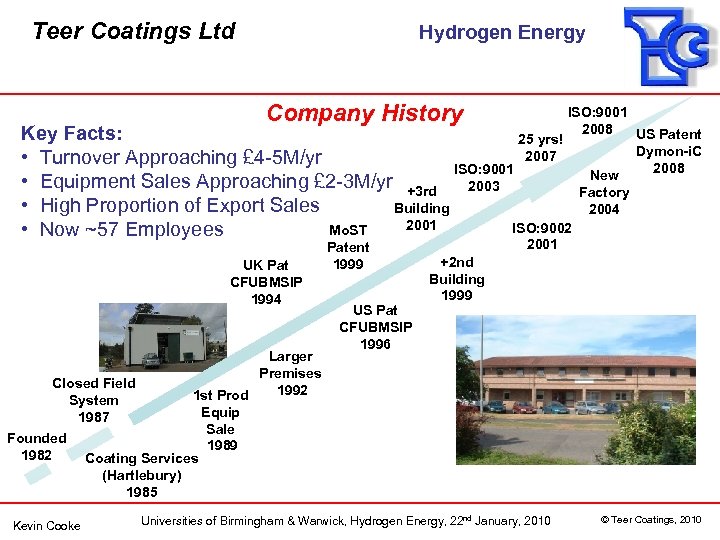

Teer Coatings Ltd Hydrogen Energy Company History ISO: 9001 2008 US Patent Key Facts: 25 yrs! Dymon-i. C 2007 • Turnover Approaching £ 4 -5 M/yr 2008 ISO: 9001 New • Equipment Sales Approaching £ 2 -3 M/yr +3 rd 2003 Factory • High Proportion of Export Sales Building 2004 2001 ISO: 9002 Mo. ST • Now ~57 Employees 2001 Patent +2 nd 1999 UK Pat Building CFUBMSIP 1999 1994 US Pat CFUBMSIP 1996 Larger Premises Closed Field 1992 1 st Prod System Equip 1987 Sale Founded 1989 1982 Coating Services (Hartlebury) 1985 Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy Company History ISO: 9001 2008 US Patent Key Facts: 25 yrs! Dymon-i. C 2007 • Turnover Approaching £ 4 -5 M/yr 2008 ISO: 9001 New • Equipment Sales Approaching £ 2 -3 M/yr +3 rd 2003 Factory • High Proportion of Export Sales Building 2004 2001 ISO: 9002 Mo. ST • Now ~57 Employees 2001 Patent +2 nd 1999 UK Pat Building CFUBMSIP 1999 1994 US Pat CFUBMSIP 1996 Larger Premises Closed Field 1992 1 st Prod System Equip 1987 Sale Founded 1989 1982 Coating Services (Hartlebury) 1985 Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy Company Structure PRODUCTION COATINGS • 15 Coating Systems • Automated cleaning, etc. • Single items to 10, 000’s/wk 3 PRIMARY DIVISIONS: • Design & Manufacture • Coating & Test Equipment • Inc. “bespoke” designs EQUIPMENT BUILDING Kevin Cooke • ~17 Coating Systems • plus, range of Testing & Analysis Equipment RESEARCH & DEVELOPMENT Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy Company Structure PRODUCTION COATINGS • 15 Coating Systems • Automated cleaning, etc. • Single items to 10, 000’s/wk 3 PRIMARY DIVISIONS: • Design & Manufacture • Coating & Test Equipment • Inc. “bespoke” designs EQUIPMENT BUILDING Kevin Cooke • ~17 Coating Systems • plus, range of Testing & Analysis Equipment RESEARCH & DEVELOPMENT Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • July 2009: Miba AG took a minority share (24. 9%) of TCL Ø full ownership is expected by the end of 2010. Ø until then TCL remains a SME! • The Miba Group is a leading international company, of ~2600 employees, headquartered in Austria. • Miba is a leading strategic partner of the international engine and automotive industry. Ø Miba’s product portfolio includes sintered components, engine bearings, friction and coated materials. • TCL & HTC (Miba’s Coatings Competence Centre, with ~40 employees) will collaborate closely. Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • July 2009: Miba AG took a minority share (24. 9%) of TCL Ø full ownership is expected by the end of 2010. Ø until then TCL remains a SME! • The Miba Group is a leading international company, of ~2600 employees, headquartered in Austria. • Miba is a leading strategic partner of the international engine and automotive industry. Ø Miba’s product portfolio includes sintered components, engine bearings, friction and coated materials. • TCL & HTC (Miba’s Coatings Competence Centre, with ~40 employees) will collaborate closely. Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy Routine Production Coatings: • Hard coatings, e. g. for cutting tools, etc. – e. g. single nitrides Ti. N, Cr. N… & alloy nitrides Ti. Al. N, Cr. Ti. Al. N…, oxides, multilayers, etc. • Self lubricating, low friction coatings for wear resistance – e. g. carbon based: TCL Graphit-i. C™& Dymon-i. C; and Mo. S 2 based: TCL Mo. ST™ • Plus, coatings for corrosion resistance, electrical conductivity, optical properties, etc. • Coatings typically 1 -3µm thick, but… – nm to mm thickness possible for special applications Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy Routine Production Coatings: • Hard coatings, e. g. for cutting tools, etc. – e. g. single nitrides Ti. N, Cr. N… & alloy nitrides Ti. Al. N, Cr. Ti. Al. N…, oxides, multilayers, etc. • Self lubricating, low friction coatings for wear resistance – e. g. carbon based: TCL Graphit-i. C™& Dymon-i. C; and Mo. S 2 based: TCL Mo. ST™ • Plus, coatings for corrosion resistance, electrical conductivity, optical properties, etc. • Coatings typically 1 -3µm thick, but… – nm to mm thickness possible for special applications Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

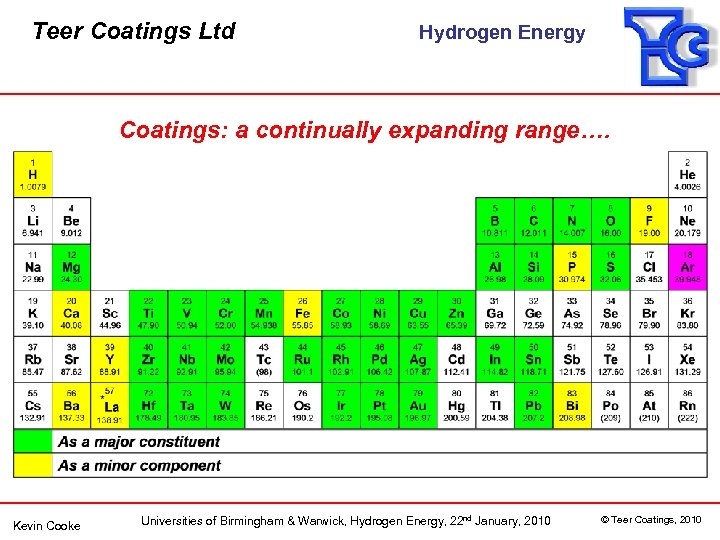

Teer Coatings Ltd Hydrogen Energy Coatings: a continually expanding range…. Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy Coatings: a continually expanding range…. Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

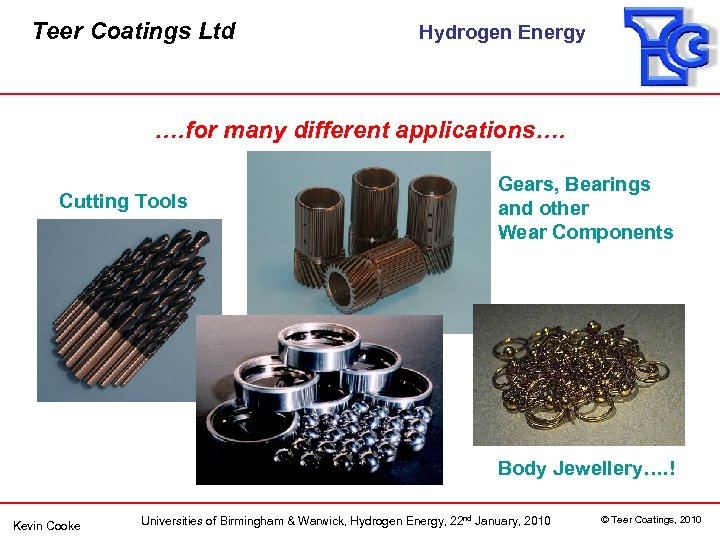

Teer Coatings Ltd Hydrogen Energy …. for many different applications…. Cutting Tools Gears, Bearings and other Wear Components Body Jewellery…. ! Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy …. for many different applications…. Cutting Tools Gears, Bearings and other Wear Components Body Jewellery…. ! Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

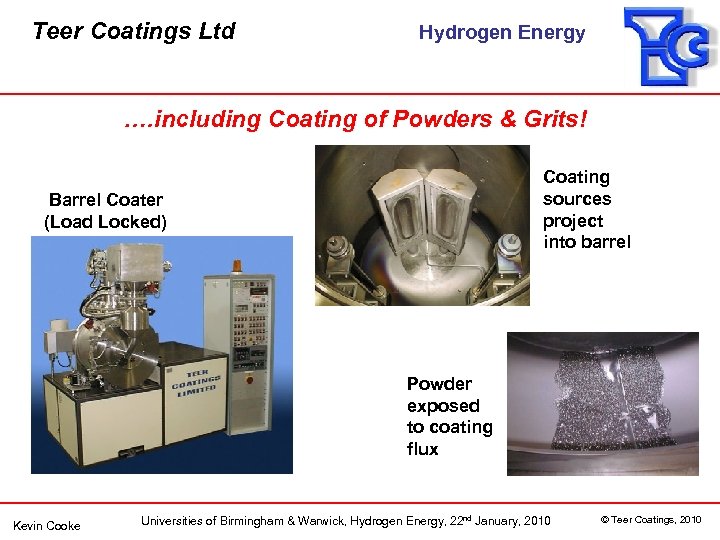

Teer Coatings Ltd Hydrogen Energy …. including Coating of Powders & Grits! Coating sources project into barrel Barrel Coater (Load Locked) Powder exposed to coating flux Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy …. including Coating of Powders & Grits! Coating sources project into barrel Barrel Coater (Load Locked) Powder exposed to coating flux Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

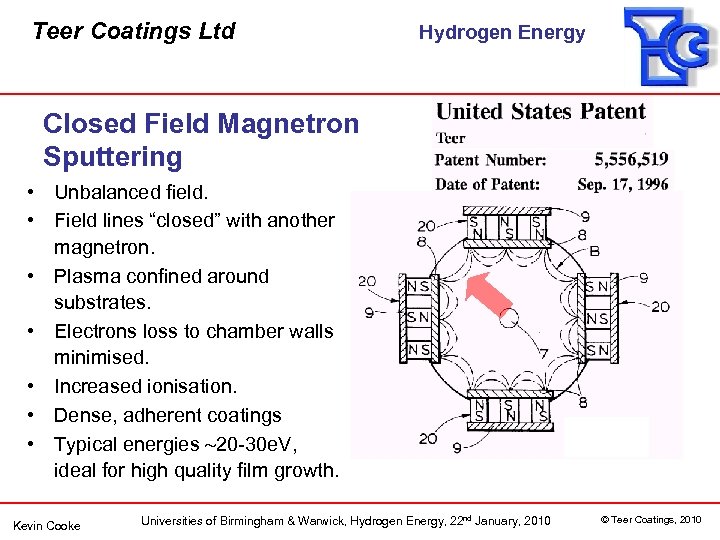

Teer Coatings Ltd Hydrogen Energy Closed Field Magnetron Sputtering • Unbalanced field. • Field lines “closed” with another magnetron. • Plasma confined around substrates. • Electrons loss to chamber walls minimised. • Increased ionisation. • Dense, adherent coatings • Typical energies 20 -30 e. V, ideal for high quality film growth. Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy Closed Field Magnetron Sputtering • Unbalanced field. • Field lines “closed” with another magnetron. • Plasma confined around substrates. • Electrons loss to chamber walls minimised. • Increased ionisation. • Dense, adherent coatings • Typical energies 20 -30 e. V, ideal for high quality film growth. Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • FC&H 2 Example - coatings for bipolar plates: – TCL’s magnetron sputtering technology is • industrially qualified • ideal for the deposition of thin, dense, well adhered, high quality coatings on a wide range of substrates (including metals and vacuum-stable polymers). – Product-specific results of TCL’s previous work in this field are obviously confidential to the customers concerned! [V Fox: presented at - Manufacturing of Bipolar Plates event, Swerea IVF, Stockholm, 29 th January 2008] Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • FC&H 2 Example - coatings for bipolar plates: – TCL’s magnetron sputtering technology is • industrially qualified • ideal for the deposition of thin, dense, well adhered, high quality coatings on a wide range of substrates (including metals and vacuum-stable polymers). – Product-specific results of TCL’s previous work in this field are obviously confidential to the customers concerned! [V Fox: presented at - Manufacturing of Bipolar Plates event, Swerea IVF, Stockholm, 29 th January 2008] Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • “Metallic” thin film coatings for bipolar plates: – dense, homogeneous coatings of metals are deposited at high rates – multiple elemental targets (typically 4 or 6) • alloys and/or graded compositions easily created – compounds (nitrides, oxides, etc. ) can be synthesised by reactive deposition • reactive gas (e. g. N 2) introduced during the deposition process • compound (e. g metal + nitrogen = Me. N) formed in situ • automatic feed back control (reactive gas flow slaved to metal content of the plasma) Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • “Metallic” thin film coatings for bipolar plates: – dense, homogeneous coatings of metals are deposited at high rates – multiple elemental targets (typically 4 or 6) • alloys and/or graded compositions easily created – compounds (nitrides, oxides, etc. ) can be synthesised by reactive deposition • reactive gas (e. g. N 2) introduced during the deposition process • compound (e. g metal + nitrogen = Me. N) formed in situ • automatic feed back control (reactive gas flow slaved to metal content of the plasma) Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

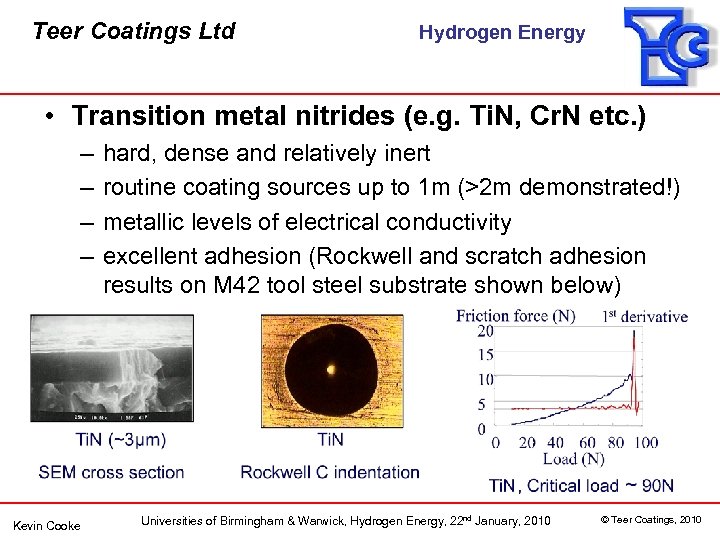

Teer Coatings Ltd Hydrogen Energy • Transition metal nitrides (e. g. Ti. N, Cr. N etc. ) – – Kevin Cooke hard, dense and relatively inert routine coating sources up to 1 m (>2 m demonstrated!) metallic levels of electrical conductivity excellent adhesion (Rockwell and scratch adhesion results on M 42 tool steel substrate shown below) Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • Transition metal nitrides (e. g. Ti. N, Cr. N etc. ) – – Kevin Cooke hard, dense and relatively inert routine coating sources up to 1 m (>2 m demonstrated!) metallic levels of electrical conductivity excellent adhesion (Rockwell and scratch adhesion results on M 42 tool steel substrate shown below) Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • New high rate magnetron deposition of Ti. N: – 2 magnetrons (12. 5 k. W each) – 50 mins deposition: total thickness 3. 36 μm – deposition rate 4 μm/hr 4 x higher than from conventional magnetrons – hardness: 33 GPa – scratch adhesion – Lc>60 N (i. e. very good) • So, achieved 4 x increase in rate with no obvious deterioration in coating quality Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • New high rate magnetron deposition of Ti. N: – 2 magnetrons (12. 5 k. W each) – 50 mins deposition: total thickness 3. 36 μm – deposition rate 4 μm/hr 4 x higher than from conventional magnetrons – hardness: 33 GPa – scratch adhesion – Lc>60 N (i. e. very good) • So, achieved 4 x increase in rate with no obvious deterioration in coating quality Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • Graphit-i. C™ coatings – originally developed for demanding, high load bearing, tribological applications • • • contains ~5 at. % chromium hardness H = 10 to 40 GPa (selectable); Young’s modulus E* ~ 155 GPa low coefficient of friction (<0. 1) very low specific wear rate (~ 10 -17 m 3 N-1 m-1) electrically conducting (like graphite) – high sp 2 content – conventional process, ~2µm takes several hrs Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • Graphit-i. C™ coatings – originally developed for demanding, high load bearing, tribological applications • • • contains ~5 at. % chromium hardness H = 10 to 40 GPa (selectable); Young’s modulus E* ~ 155 GPa low coefficient of friction (<0. 1) very low specific wear rate (~ 10 -17 m 3 N-1 m-1) electrically conducting (like graphite) – high sp 2 content – conventional process, ~2µm takes several hrs Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

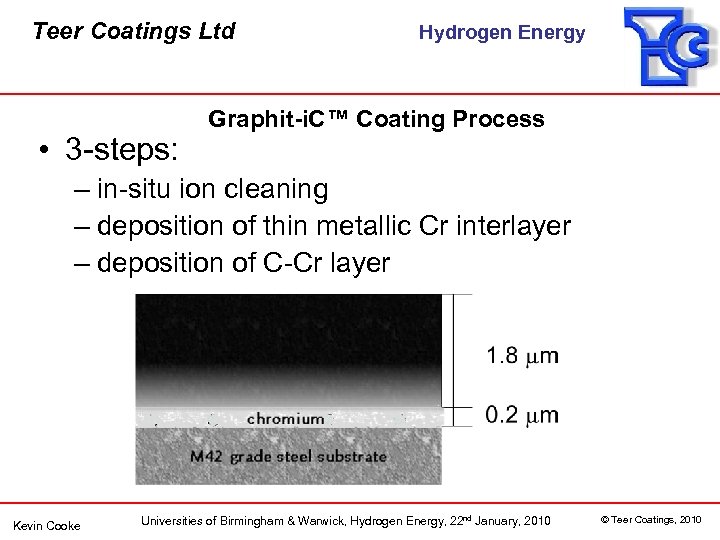

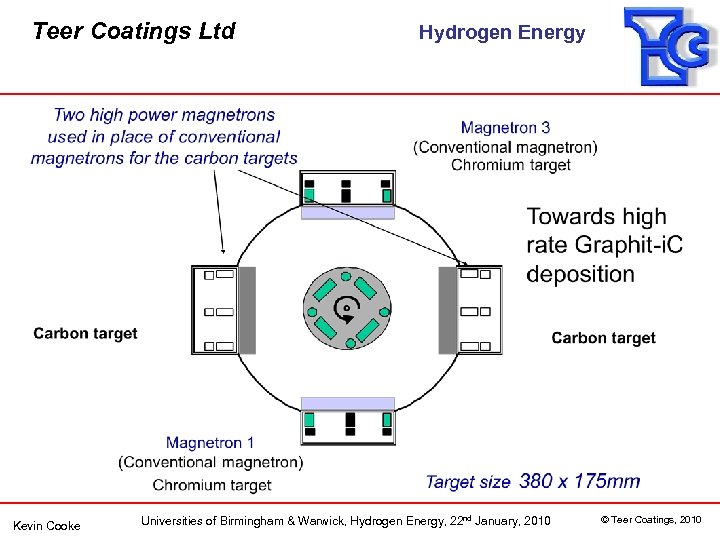

Teer Coatings Ltd • 3 -steps: Hydrogen Energy Graphit-i. C™ Coating Process – in-situ ion cleaning – deposition of thin metallic Cr interlayer – deposition of C-Cr layer Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd • 3 -steps: Hydrogen Energy Graphit-i. C™ Coating Process – in-situ ion cleaning – deposition of thin metallic Cr interlayer – deposition of C-Cr layer Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Kevin Cooke Hydrogen Energy Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Kevin Cooke Hydrogen Energy Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • Graphit-i. C™ coatings for bipolar plates: – power input can be increased by up to 3 x cf TCL’s “conventional” Graphit-i. C coating process – deposition rates improved by 2 to 2. 7 x, say – here, 2 -axis rotation improves coating uniformity. In-line systems with magnetrons sputtering simultaneously onto both sides of the plates could be used in a production process. – pure carbon or Graphit-i. C coatings can be deposited at thickness ranging from <100 nm to a few microns – coatings can be (have been) deposited with or without Cr adhesion layers – rates as high as ~5 µm/hour are already achievable for a stationary substrate (equivalent to 85 nm per min) Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • Graphit-i. C™ coatings for bipolar plates: – power input can be increased by up to 3 x cf TCL’s “conventional” Graphit-i. C coating process – deposition rates improved by 2 to 2. 7 x, say – here, 2 -axis rotation improves coating uniformity. In-line systems with magnetrons sputtering simultaneously onto both sides of the plates could be used in a production process. – pure carbon or Graphit-i. C coatings can be deposited at thickness ranging from <100 nm to a few microns – coatings can be (have been) deposited with or without Cr adhesion layers – rates as high as ~5 µm/hour are already achievable for a stationary substrate (equivalent to 85 nm per min) Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

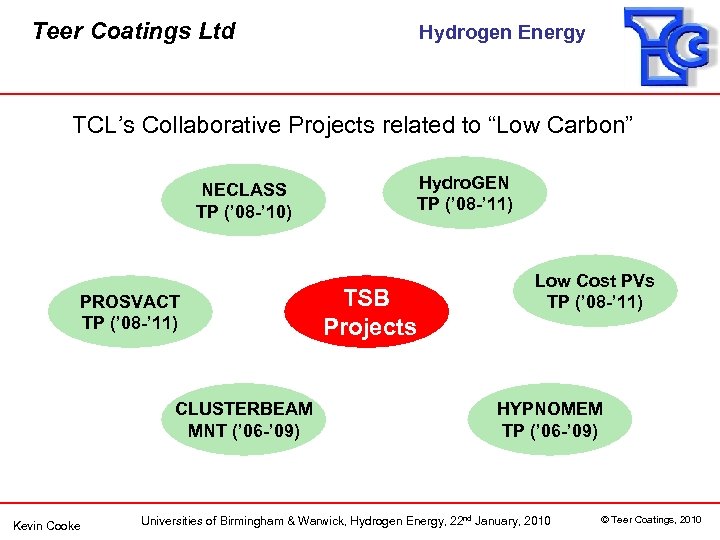

Teer Coatings Ltd Hydrogen Energy TCL’s Collaborative Projects related to “Low Carbon” NECLASS TP (’ 08 -’ 10) PROSVACT TP (’ 08 -’ 11) CLUSTERBEAM MNT (’ 06 -’ 09) Kevin Cooke Hydro. GEN TP (’ 08 -’ 11) TSB Projects Low Cost PVs TP (’ 08 -’ 11) HYPNOMEM TP (’ 06 -’ 09) Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy TCL’s Collaborative Projects related to “Low Carbon” NECLASS TP (’ 08 -’ 10) PROSVACT TP (’ 08 -’ 11) CLUSTERBEAM MNT (’ 06 -’ 09) Kevin Cooke Hydro. GEN TP (’ 08 -’ 11) TSB Projects Low Cost PVs TP (’ 08 -’ 11) HYPNOMEM TP (’ 06 -’ 09) Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • Technology Programme projects include: – – NECLASS: improving FC catalyst utilisation Hydro. GEN: coatings for electrolysis HYPNOMEM: thin film membranes for H 2 purification CLUSTERBEAM/PROSVACT: creating nano-clusters for model catalysts, etc. – Low cost Photovoltaics: cheap, PV materials by thin film, with improved spectral response & long life • TCL project leader – except for Hydro. GEN &NECLASS Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • Technology Programme projects include: – – NECLASS: improving FC catalyst utilisation Hydro. GEN: coatings for electrolysis HYPNOMEM: thin film membranes for H 2 purification CLUSTERBEAM/PROSVACT: creating nano-clusters for model catalysts, etc. – Low cost Photovoltaics: cheap, PV materials by thin film, with improved spectral response & long life • TCL project leader – except for Hydro. GEN &NECLASS Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy Summary & Conclusions • PVD coatings have multiple potential applications in Fuel Cells and the Hydrogen Economy • Teer Coatings Limited offers relevant, industriallyqualified, thin film coatings – e. g. environmentally resistant, electrically conductive thin film coatings for electrode plates • TCL can support partners’ process and equipment needs, from R&D through to full production • TCL’s research portfolio includes relevant collaborative projects Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy Summary & Conclusions • PVD coatings have multiple potential applications in Fuel Cells and the Hydrogen Economy • Teer Coatings Limited offers relevant, industriallyqualified, thin film coatings – e. g. environmentally resistant, electrically conductive thin film coatings for electrode plates • TCL can support partners’ process and equipment needs, from R&D through to full production • TCL’s research portfolio includes relevant collaborative projects Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy Acknowledgements • The collaborative projects described above have benefited from DTI/Technology Strategy Board (MNT and Technology Programme) support. • HYPNOMEM was a joint feasibility project by Univ B’ham’s Metallurgy & Materials Department (Rex Harris, John Speight, David Book, Vicky Mann, Sean Fletcher, Jo Grant) and TCL (Joanne Hampshire). • Other project collaborators are too numerous to mention, but are gratefully acknowledged! Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy Acknowledgements • The collaborative projects described above have benefited from DTI/Technology Strategy Board (MNT and Technology Programme) support. • HYPNOMEM was a joint feasibility project by Univ B’ham’s Metallurgy & Materials Department (Rex Harris, John Speight, David Book, Vicky Mann, Sean Fletcher, Jo Grant) and TCL (Joanne Hampshire). • Other project collaborators are too numerous to mention, but are gratefully acknowledged! Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • For more information please contact: Teer Coatings Limited, West Stone House, Berry Hill Industrial Estate, Droitwich, Worcs, WR 9 9 AS, UK. Tel: +44(0)870 220 3910; Fax: +44(0)870 220 3911 www. teercoatings. co. uk Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • For more information please contact: Teer Coatings Limited, West Stone House, Berry Hill Industrial Estate, Droitwich, Worcs, WR 9 9 AS, UK. Tel: +44(0)870 220 3910; Fax: +44(0)870 220 3911 www. teercoatings. co. uk Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • Key Contacts: Paul Teer – Managing Director Dennis Teer – Chairman/Technical Director Dr Kevin Cooke – Collaborative Research Coord Dr Glynn Dyson – Sales & Marketing Manager Wayne Southall – Production Coatings Manager Dr Joanne Hampshire – Special Coatings Manager Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010

Teer Coatings Ltd Hydrogen Energy • Key Contacts: Paul Teer – Managing Director Dennis Teer – Chairman/Technical Director Dr Kevin Cooke – Collaborative Research Coord Dr Glynn Dyson – Sales & Marketing Manager Wayne Southall – Production Coatings Manager Dr Joanne Hampshire – Special Coatings Manager Kevin Cooke Universities of Birmingham & Warwick, Hydrogen Energy, 22 nd January, 2010 © Teer Coatings, 2010