Technology of vegetable feedstock

Technology of vegetable feedstock gasification Prof. M. Sosna

Элементный состав бытового мусора Состав % (масс. ) Фракцион- Насып-ная Влажность, Вид сырья ный состав, масса, С Н N О S Зола % масс. мм г/см 3 Трава типа 44. 3 6. 2 0. 5 46. 8 отсут. 2. 2 3. 1 0. 1 1. 5 0. 25 “Камыш” Трава типа 43. 7 6. 1 0. 6 46. 3 отсут. 3. 3 35 0. 5 10 0. 3 “Бамбук” 0. 2 гранулы Бытовой мусор 39. 0 6. 0 0. 7 55 11. 0 - Cl-0. 5 15 х15 Промышленный ил 34. 8 5. 7 5. 8 30. 4 0. 6 22. 7 - 0. 5 3. 0 0. 71 (высушенный) Элементный состав углей Теплота Состав горючей массы, % Выход сгорания Топливо летучих (низшая), СГ SГ HГ ОГ NГ веществ, % МДж/кг Бурый уголь 64 -78 0, 3 -6 3, 8 -6, 3 15 -26 0, 6 -1, 6 40 -60 25 -29 Каменный уголь 75 -90 0, 5 -6 4 -6 2 -13 1 -2, 7 9 -50 31 -35

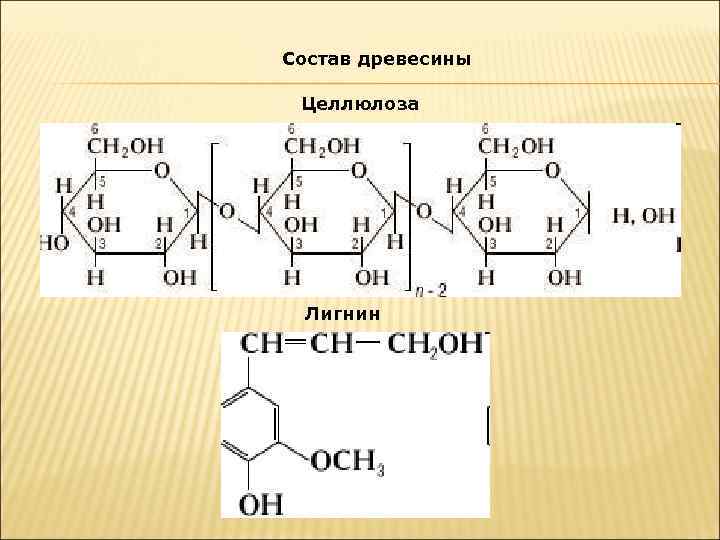

Состав древесины Целлюлоза Лигнин

Схема процесса газификации

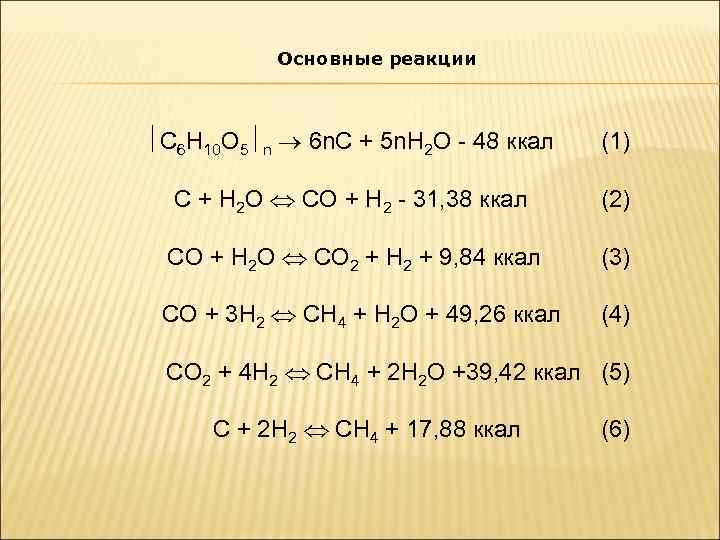

Основные реакции С 6 Н 10 О 5 n 6 n. С + 5 n. Н 2 О - 48 ккал (1) C + Н 2 О СО + Н 2 - 31, 38 ккал (2) СО + Н 2 О СО 2 + Н 2 + 9, 84 ккал (3) СО + 3 Н 2 СН 4 + Н 2 О + 49, 26 ккал (4) СО 2 + 4 Н 2 СН 4 + 2 Н 2 О +39, 42 ккал (5) С + 2 Н 2 СН 4 + 17, 88 ккал (6)

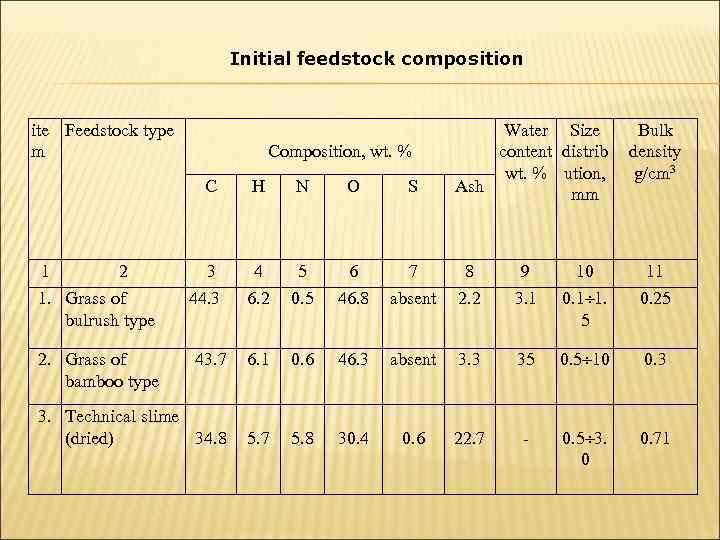

Initial feedstock composition ite Feedstock type Water Size Bulk m Composition, wt. % content distrib density wt. % ution, g/cm 3 С Н N О S Ash mm 1 2 3 4 5 6 7 8 9 10 11 1. Grass of 44. 3 6. 2 0. 5 46. 8 absent 2. 2 3. 1 0. 1 1. 0. 25 bulrush type 5 2. Grass of 43. 7 6. 1 0. 6 46. 3 absent 3. 3 35 0. 5 10 0. 3 bamboo type 3. Technical slime (dried) 34. 8 5. 7 5. 8 30. 4 0. 6 22. 7 - 0. 5 3. 0. 71 0

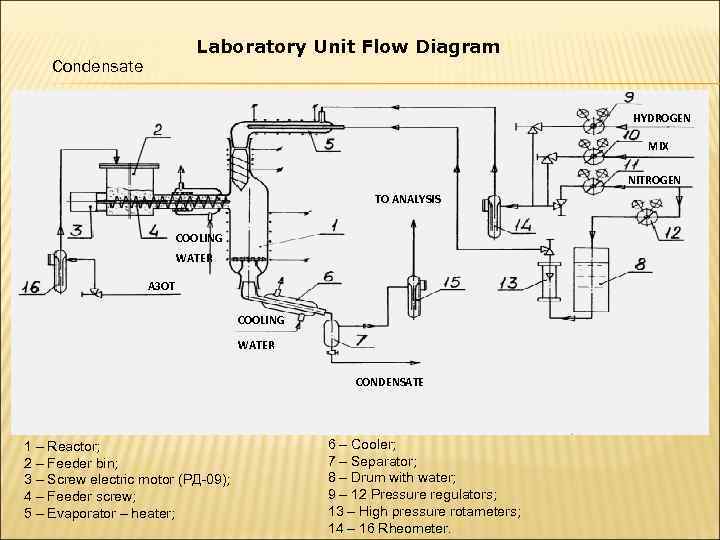

Laboratory Unit Flow Diagram Condensate HYDROGEN MIX NITROGEN TO ANALYSIS COOLING WATER АЗОТ COOLING WATER CONDENSATE 1 – Reactor; 6 – Cooler; 2 – Feeder bin; 7 – Separator; 3 – Screw electric motor (РД-09); 8 – Drum with water; 4 – Feeder screw; 9 – 12 Pressure regulators; 5 – Evaporator – heater; 13 – High pressure rotameters; 14 – 16 Rheometer.

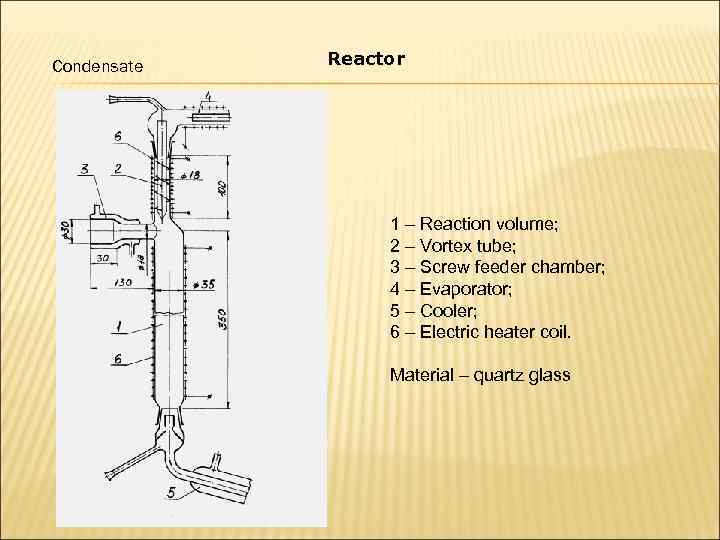

Condensate Reactor 1 – Reaction volume; 2 – Vortex tube; 3 – Screw feeder chamber; 4 – Evaporator; 5 – Cooler; 6 – Electric heater coil. Material – quartz glass

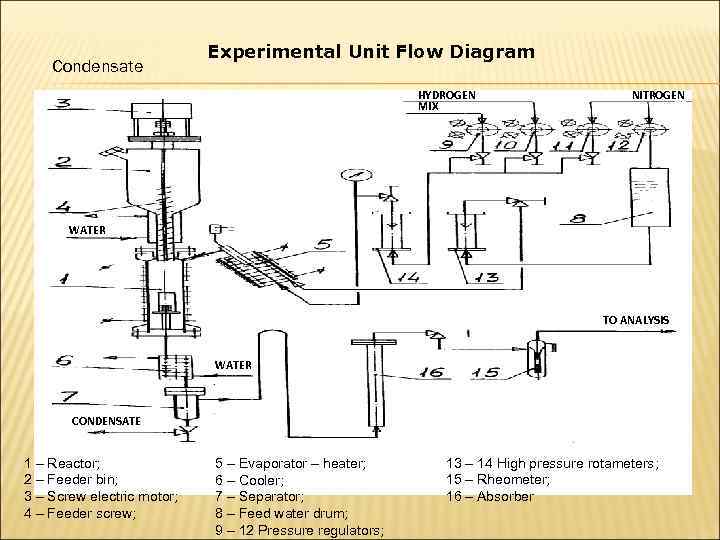

Experimental Unit Flow Diagram Condensate HYDROGEN NITROGEN MIX WATER TO ANALYSIS WATER CONDENSATE 1 – Reactor; 5 – Evaporator – heater; 13 – 14 High pressure rotameters; 2 – Feeder bin; 6 – Cooler; 15 – Rheometer; 3 – Screw electric motor; 7 – Separator; 16 – Absorber 4 – Feeder screw; 8 – Feed water drum; 9 – 12 Pressure regulators;

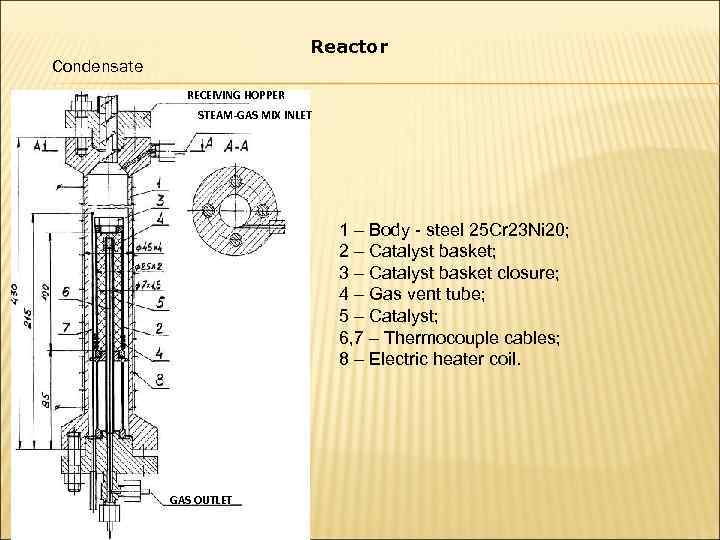

Reactor Condensate RECEIVING HOPPER STEAM-GAS MIX INLET 1 – Body - steel 25 Cr 23 Ni 20; 2 – Catalyst basket; 3 – Catalyst basket closure; 4 – Gas vent tube; 5 – Catalyst; 6, 7 – Thermocouple cables; 8 – Electric heater coil. GAS OUTLET

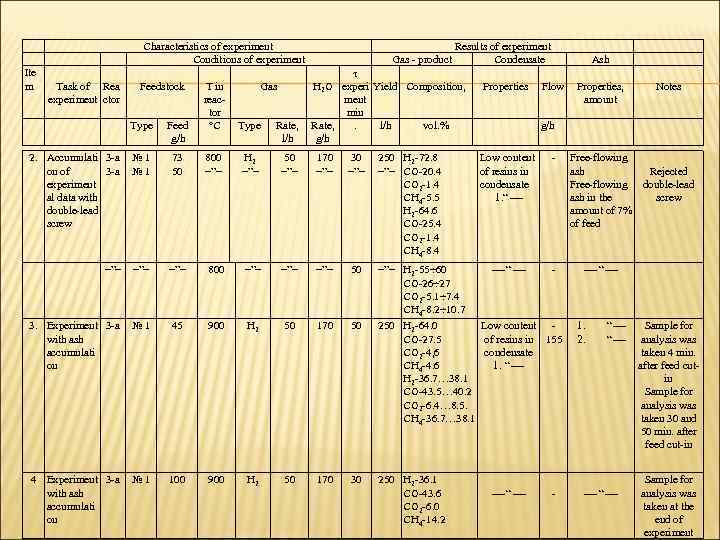

Characteristics of experiment Results of experiment Conditions of experiment Gas - product Condensate Ash Ite m Task of Rea Feedstock Т in Gas Н 2 О experi Yield Composition, Properties Flow Properties, Notes experiment ctor reac- ment amount tor min Type Feed С Type Rate, . l/h vol. % g/h l/h g/h 2. Accumulati 3 -а № 1 73 800 Н 2 50 170 30 250 Н 2 -72. 8 Low content - Free-flowing on of 3 -а № 1 50 ” ” ” ” СО-20. 4 of resins in ash Rejected experiment СО 2 -1. 4 condensate Free-flowing double-lead al data with СН 4 -5. 5 1. “ ash in the screw double-lead Н 2 -64. 6 amount of 7% screw СО-25. 4 of feed СО 2 -1. 4 СН 4 -8. 4 ” ” ” 800 ” ” 50 ” Н 2 -55 60 “ - “ СО-26 27 СО 2 -5. 1 7. 4 СН 4 -8. 2 10. 7 3. Experiment 3 -а № 1 45 900 Н 2 50 170 50 250 Н 2 -64. 0 Low content - 1. “ Sample for with ash СО-27. 5 of resins in 155 2. “ analysis was accumulati СО 2 -4, 6 condensate taken 4 min. on СН 4 -4. 6 1. “ after feed cut- Н 2 -36. 7 38. 1 in СО-43. 5 40. 2 Sample for СО 2 -6. 4 8. 5. analysis was СН 4 -36. 7 38. 1 taken 30 and 50 min. after feed cut-in 4 Experiment 3 -а № 1 100 900 Н 2 50 170 30 250 Н 2 -36. 1 Sample for with ash СО-43. 6 “ - “ analysis was accumulati СО 2 -6. 0 taken at the on СН 4 -14. 2 end of experiment

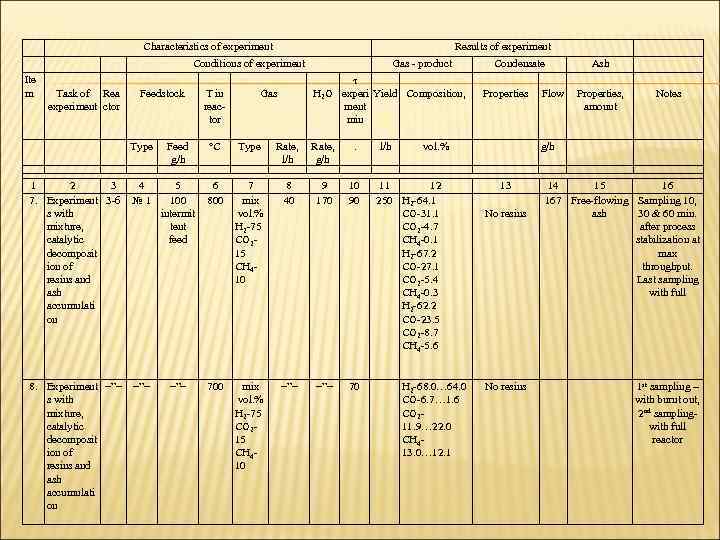

Characteristics of experiment Results of experiment Conditions of experiment Gas - product Condensate Ash Ite m Task of Rea Feedstock Т in Gas Н 2 О experi Yield Composition, Properties Flow Properties, Notes experiment ctor reac- ment amount tor min Type Feed С Type Rate, . l/h vol. % g/h l/h g/h 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 7. Experiment 3 -б № 1 100 800 mix 40 170 90 250 Н 2 -64. 1 167 Free-flowing Sampling 10, s with intermit vol. % СО-31. 1 No resins ash 30 & 60 min. mixture, tent Н 2 -75 СО 2 -4. 7 after process catalytic feed СО 2 - СН 4 -0. 1 stabilization at decomposit 15 Н 2 -67. 2 max ion of СН 4 - СО-27. 1 throughput. resins and 10 СО 2 -5. 4 Last sampling ash СН 4 -0. 3 with full accumulati Н 2 -62. 2 on СО-23. 5 СО 2 -8. 7 СН 4 -5. 6 8. Experiment ” ” ” 700 mix ” ” 70 Н 2 -68. 0 64. 0 No resins 1 st sampling – s with vol. % СО-6. 7 1. 6 with burnt out, mixture, Н 2 -75 СО 2 - 2 nd sampling- catalytic СО 2 - 11. 9 22. 0 with full decomposit 15 СН 4 - reactor ion of СН 4 - 13. 0 12. 1 resins and 10 ash accumulati on

Газификация растительного сырья-ENG-2.ppt

- Количество слайдов: 12