ee5e47f9ee95bd5dc001305e82f818bd.ppt

- Количество слайдов: 42

Technology in Architecture Lecture 14 Upfeed Systems Pipe Sizing Procedure Pipe Sizing Example

Technology in Architecture Lecture 14 Upfeed Systems Pipe Sizing Procedure Pipe Sizing Example

Upfeed Systems

Upfeed Systems

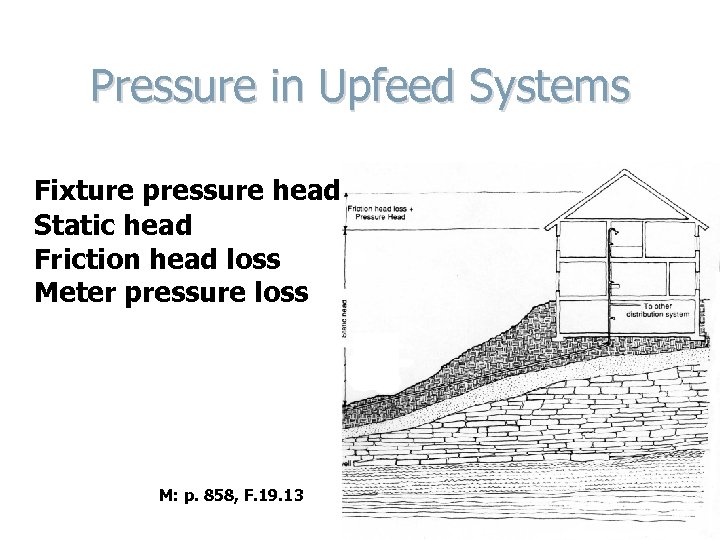

Pressure in Upfeed Systems Fixture pressure head Static head Friction head loss Meter pressure loss M: p. 858, F. 19. 13

Pressure in Upfeed Systems Fixture pressure head Static head Friction head loss Meter pressure loss M: p. 858, F. 19. 13

Pressure in Upfeed Systems Proper fixture flow pressure + Pressure lost due to height + Pressure lost due to friction + Pressure lost through meter Total street main pressure A B C D E

Pressure in Upfeed Systems Proper fixture flow pressure + Pressure lost due to height + Pressure lost due to friction + Pressure lost through meter Total street main pressure A B C D E

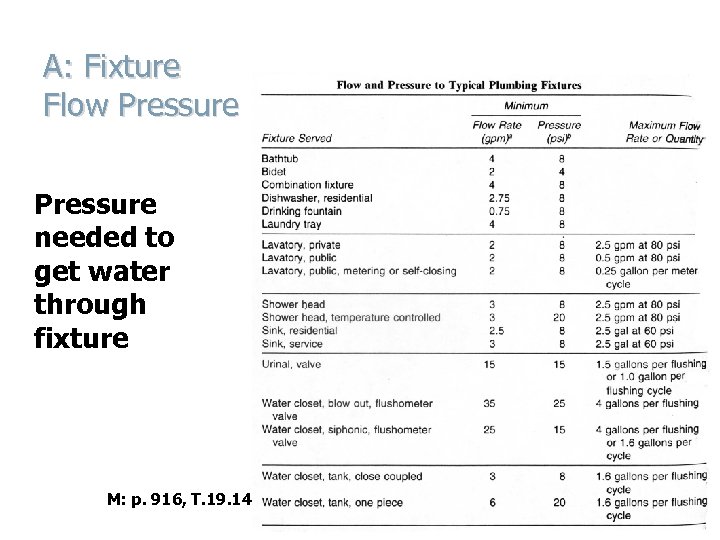

A: Fixture Flow Pressure needed to get water through fixture M: p. 916, T. 19. 14

A: Fixture Flow Pressure needed to get water through fixture M: p. 916, T. 19. 14

B: Pressure lost due to height Weight of water column M: p. 858, F. 19. 13

B: Pressure lost due to height Weight of water column M: p. 858, F. 19. 13

C: Pressure loss due to friction Initially unknown, must be calculated based on pressure remaining after accounting for the other factors

C: Pressure loss due to friction Initially unknown, must be calculated based on pressure remaining after accounting for the other factors

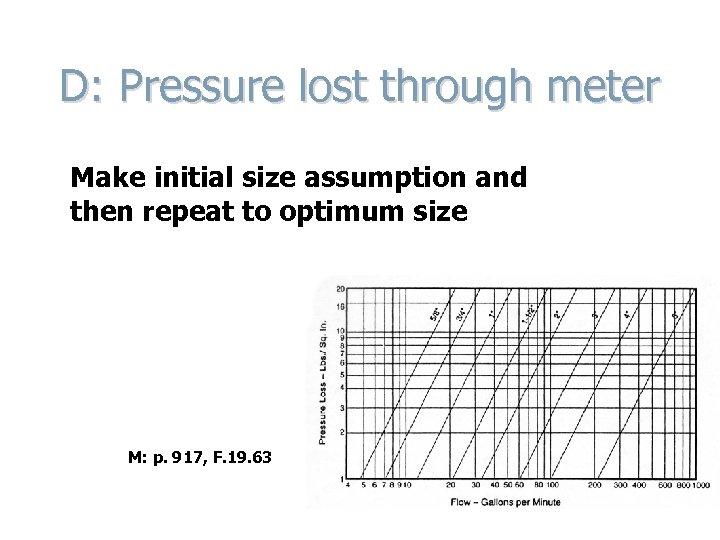

D: Pressure lost through meter Make initial size assumption and then repeat to optimum size M: p. 917, F. 19. 63

D: Pressure lost through meter Make initial size assumption and then repeat to optimum size M: p. 917, F. 19. 63

E: Total Street Main Pressure Check with water company or fire department

E: Total Street Main Pressure Check with water company or fire department

Pipe Sizing Procedure

Pipe Sizing Procedure

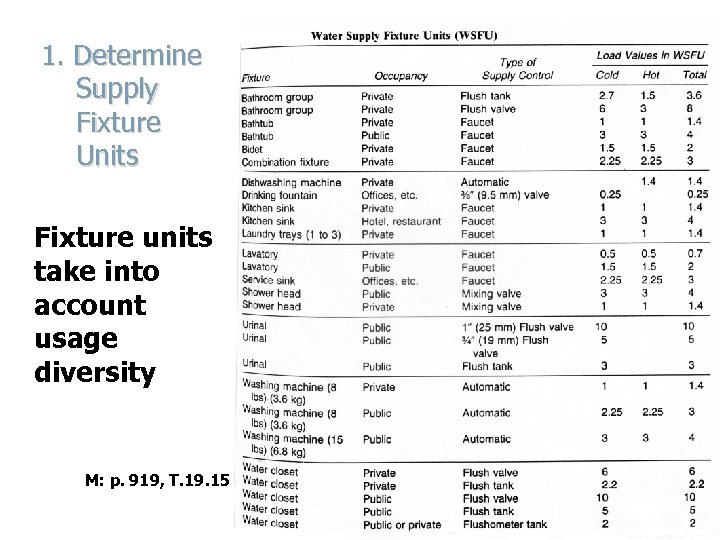

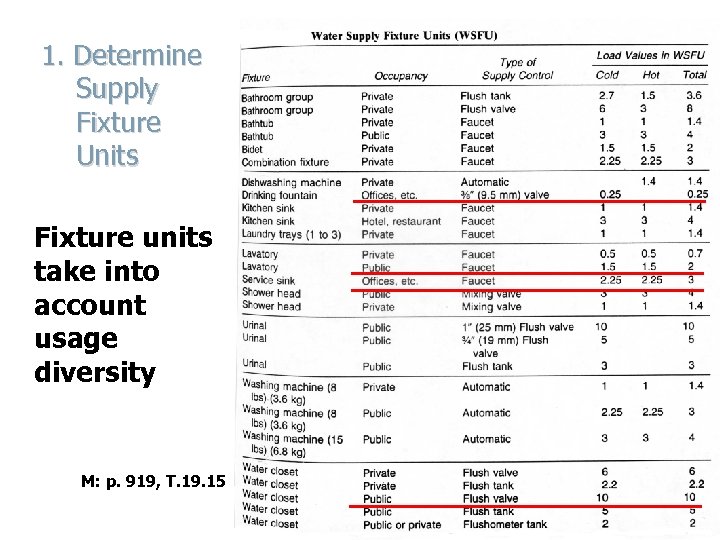

1. Determine Supply Fixture Units Fixture units take into account usage diversity M: p. 919, T. 19. 15

1. Determine Supply Fixture Units Fixture units take into account usage diversity M: p. 919, T. 19. 15

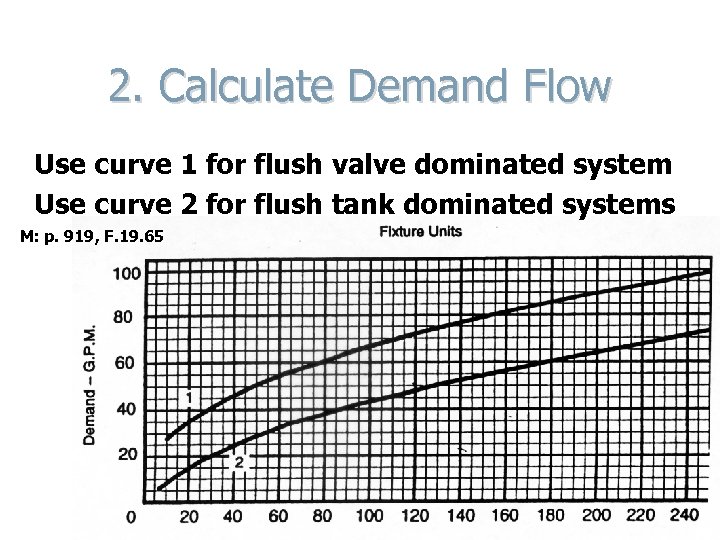

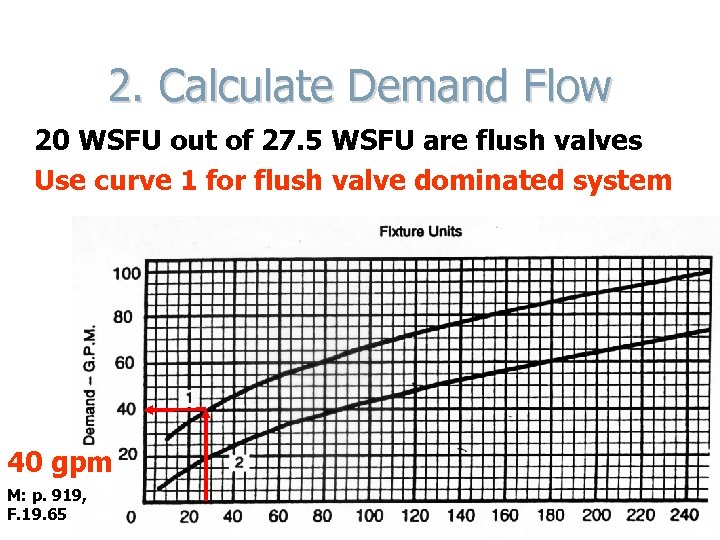

2. Calculate Demand Flow Use curve 1 for flush valve dominated system Use curve 2 for flush tank dominated systems M: p. 919, F. 19. 65

2. Calculate Demand Flow Use curve 1 for flush valve dominated system Use curve 2 for flush tank dominated systems M: p. 919, F. 19. 65

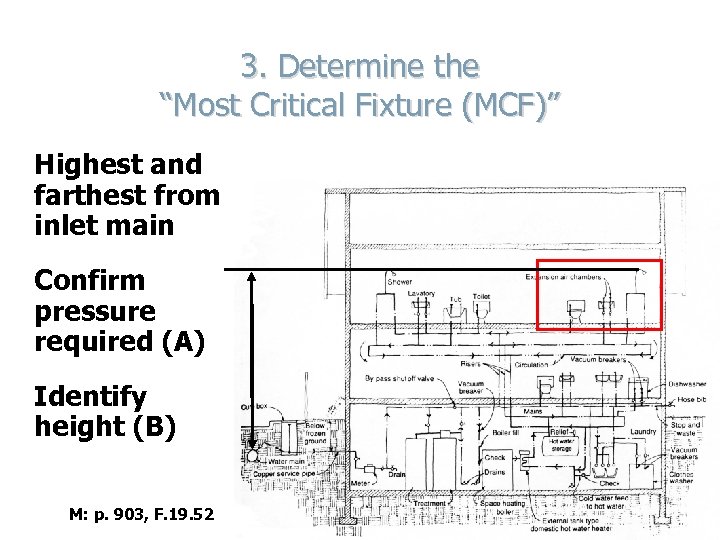

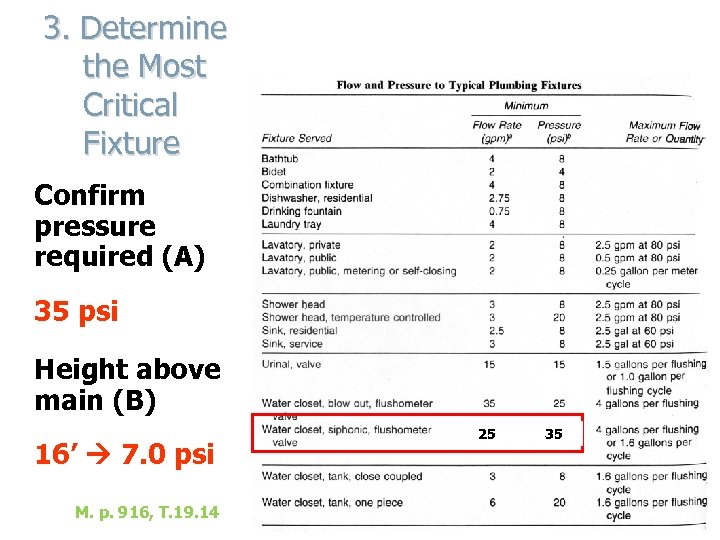

3. Determine the “Most Critical Fixture (MCF)” Highest and farthest from inlet main Confirm pressure required (A) Identify height (B) M: p. 903, F. 19. 52

3. Determine the “Most Critical Fixture (MCF)” Highest and farthest from inlet main Confirm pressure required (A) Identify height (B) M: p. 903, F. 19. 52

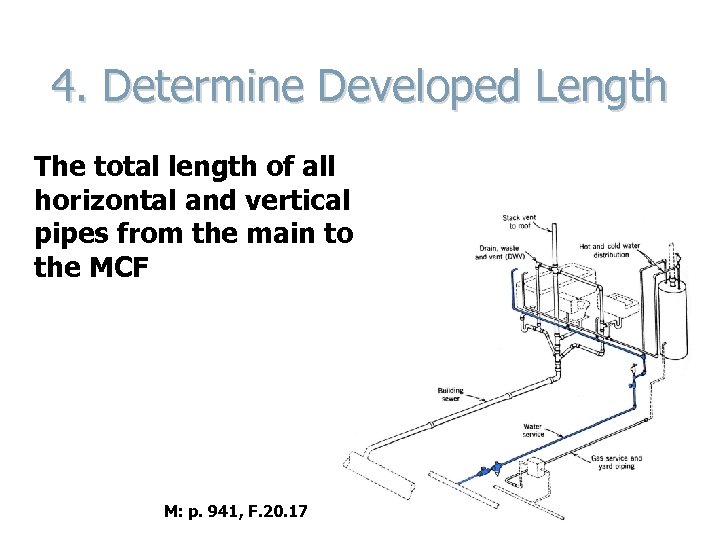

4. Determine Developed Length The total length of all horizontal and vertical pipes from the main to the MCF M: p. 941, F. 20. 17

4. Determine Developed Length The total length of all horizontal and vertical pipes from the main to the MCF M: p. 941, F. 20. 17

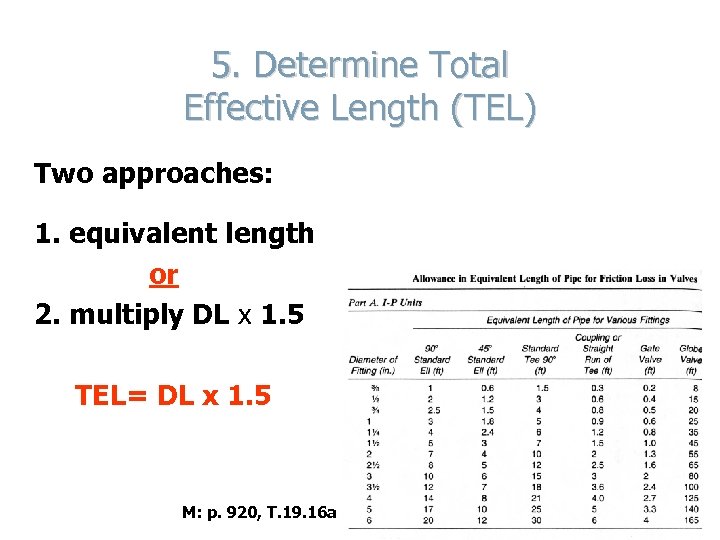

5. Determine Total Effective Length (TEL) Two approaches: 1. equivalent length or 2. multiply DL x 1. 5 TEL= DL x 1. 5 M: p. 920, T. 19. 16 a

5. Determine Total Effective Length (TEL) Two approaches: 1. equivalent length or 2. multiply DL x 1. 5 TEL= DL x 1. 5 M: p. 920, T. 19. 16 a

6. Determine Street Main Pressure (E) Contact utility company or fire department

6. Determine Street Main Pressure (E) Contact utility company or fire department

7. Determine Pressure Available for Friction Loss Proper fixture flow pressure + Pressure lost due to height + Pressure lost due to friction + Pressure lost through meter Total street main pressure or C=E-A-B-D A B C D E

7. Determine Pressure Available for Friction Loss Proper fixture flow pressure + Pressure lost due to height + Pressure lost due to friction + Pressure lost through meter Total street main pressure or C=E-A-B-D A B C D E

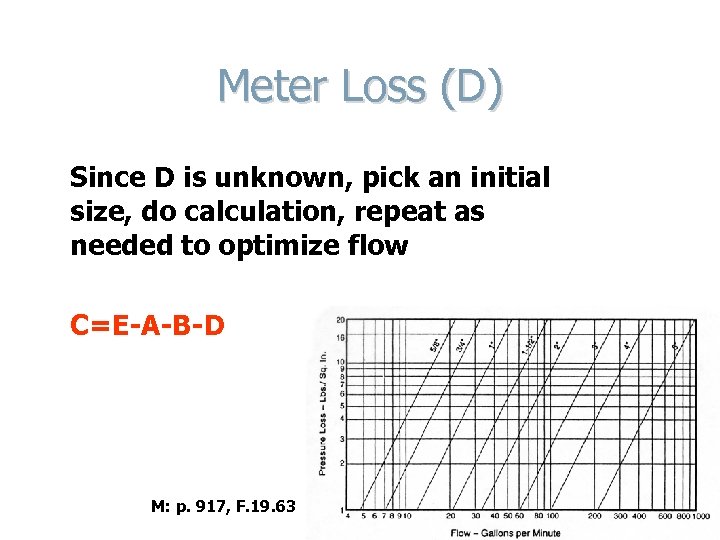

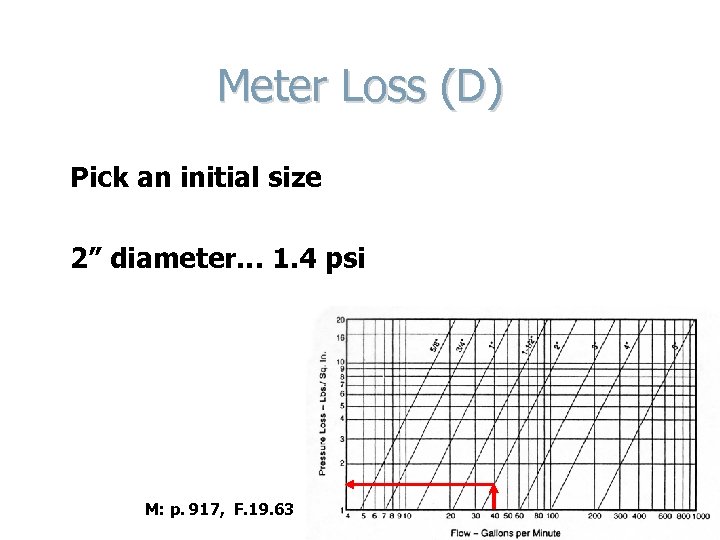

Meter Loss (D) Since D is unknown, pick an initial size, do calculation, repeat as needed to optimize flow C=E-A-B-D M: p. 917, F. 19. 63

Meter Loss (D) Since D is unknown, pick an initial size, do calculation, repeat as needed to optimize flow C=E-A-B-D M: p. 917, F. 19. 63

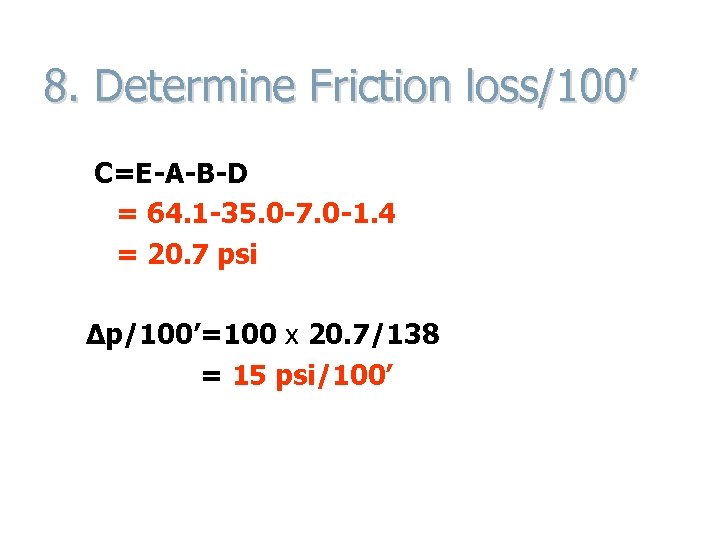

8. Determine Friction loss/100’ C=E-A-B-D Δp/100’ = 100 x C/TEL

8. Determine Friction loss/100’ C=E-A-B-D Δp/100’ = 100 x C/TEL

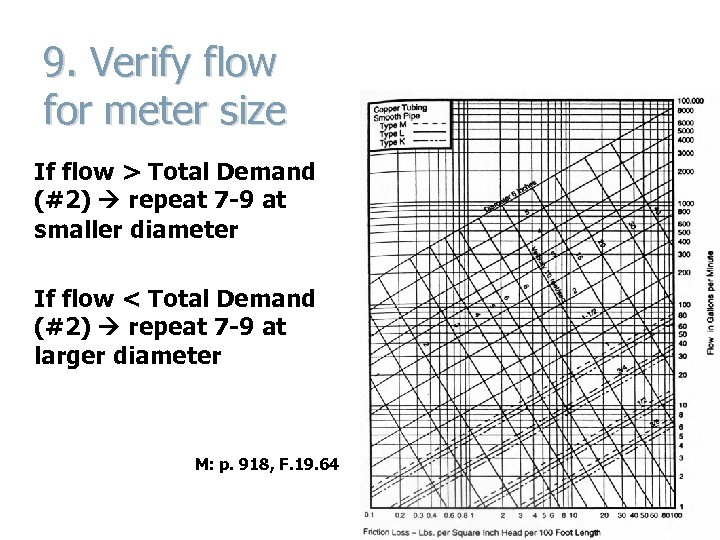

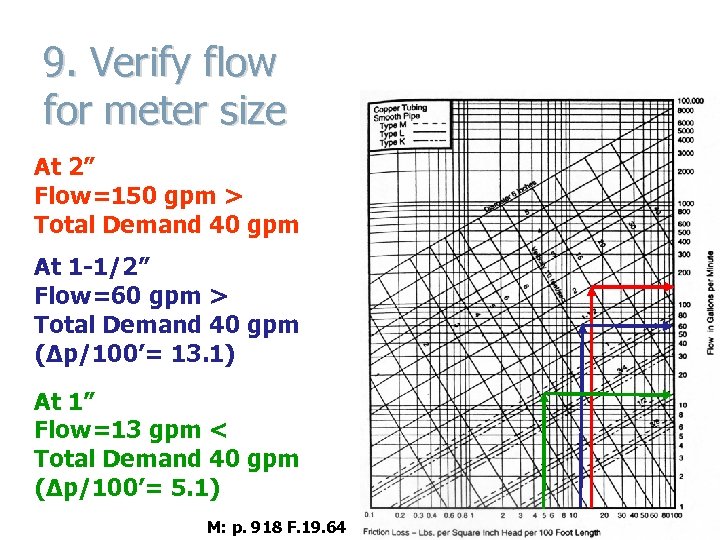

9. Verify flow for meter size If flow > Total Demand (#2) repeat 7 -9 at smaller diameter If flow < Total Demand (#2) repeat 7 -9 at larger diameter M: p. 918, F. 19. 64

9. Verify flow for meter size If flow > Total Demand (#2) repeat 7 -9 at smaller diameter If flow < Total Demand (#2) repeat 7 -9 at larger diameter M: p. 918, F. 19. 64

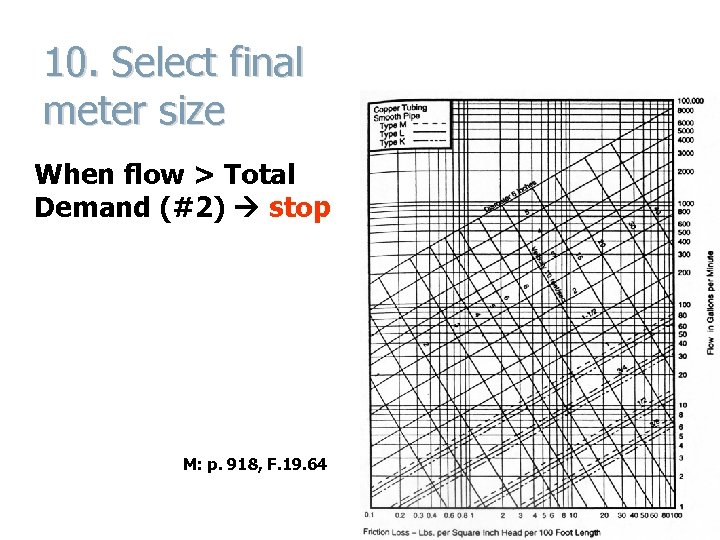

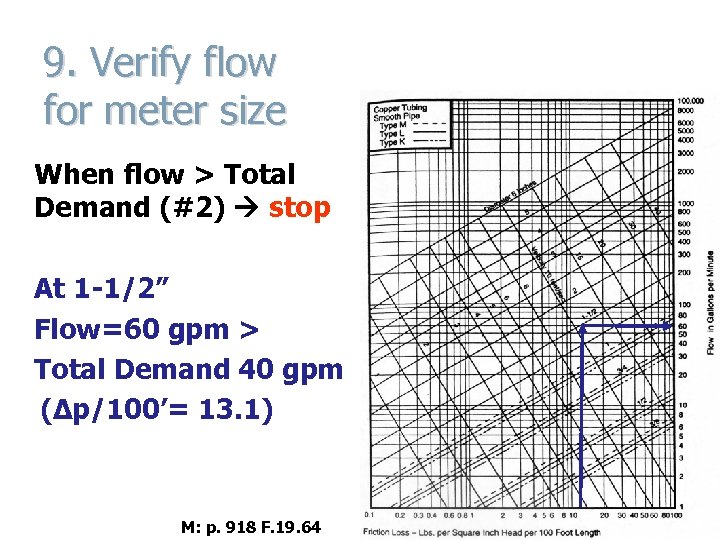

10. Select final meter size When flow > Total Demand (#2) stop M: p. 918, F. 19. 64

10. Select final meter size When flow > Total Demand (#2) stop M: p. 918, F. 19. 64

Pipe Sizing Example

Pipe Sizing Example

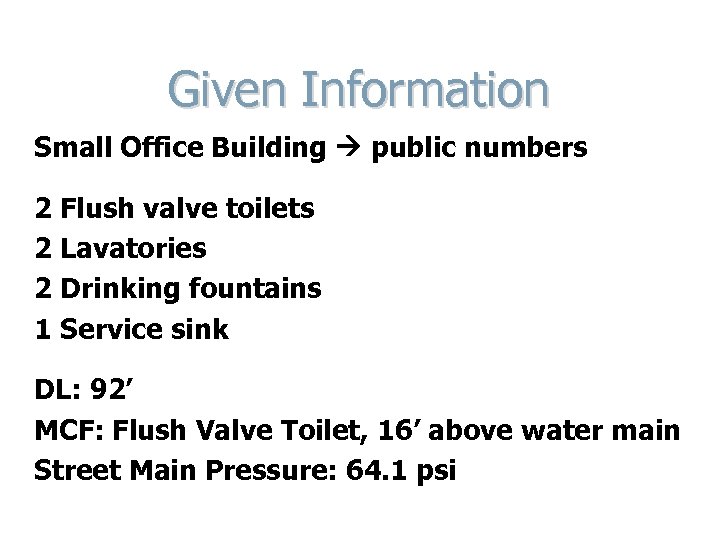

Given Information Small Office Building public numbers 2 Flush valve toilets 2 Lavatories 2 Drinking fountains 1 Service sink DL: 92’ MCF: Flush Valve Toilet, 16’ above water main Street Main Pressure: 64. 1 psi

Given Information Small Office Building public numbers 2 Flush valve toilets 2 Lavatories 2 Drinking fountains 1 Service sink DL: 92’ MCF: Flush Valve Toilet, 16’ above water main Street Main Pressure: 64. 1 psi

1. Determine Supply Fixture Units Fixture units take into account usage diversity M: p. 919, T. 19. 15

1. Determine Supply Fixture Units Fixture units take into account usage diversity M: p. 919, T. 19. 15

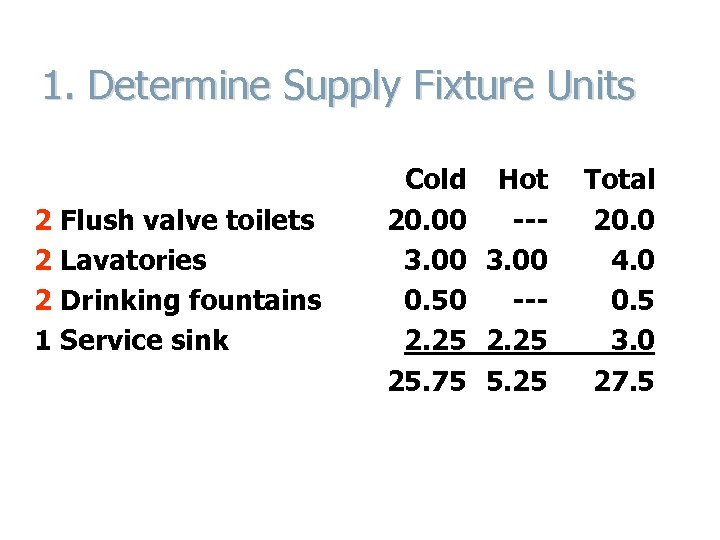

1. Determine Supply Fixture Units 2 Flush valve toilets 2 Lavatories 2 Drinking fountains 1 Service sink Cold Hot 20. 00 --3. 00 0. 50 --2. 25 25. 75 5. 25 Total 20. 0 4. 0 0. 5 3. 0 27. 5

1. Determine Supply Fixture Units 2 Flush valve toilets 2 Lavatories 2 Drinking fountains 1 Service sink Cold Hot 20. 00 --3. 00 0. 50 --2. 25 25. 75 5. 25 Total 20. 0 4. 0 0. 5 3. 0 27. 5

2. Calculate Demand Flow 20 WSFU out of 27. 5 WSFU are flush valves Use curve 1 for flush valve dominated system 40 gpm M: p. 919, F. 19. 65

2. Calculate Demand Flow 20 WSFU out of 27. 5 WSFU are flush valves Use curve 1 for flush valve dominated system 40 gpm M: p. 919, F. 19. 65

3. Determine the Most Critical Fixture Confirm pressure required (A) 35 psi Height above main (B) 16’ 7. 0 psi M. p. 916, T. 19. 14 25 35

3. Determine the Most Critical Fixture Confirm pressure required (A) 35 psi Height above main (B) 16’ 7. 0 psi M. p. 916, T. 19. 14 25 35

4. Determine Developed Length Developed length 92’ M: p. 941, F. 20. 17 Note: this figure for generic reference only and does not illustrate the example problem

4. Determine Developed Length Developed length 92’ M: p. 941, F. 20. 17 Note: this figure for generic reference only and does not illustrate the example problem

5. Determine Total Effective Length (TEL) TEL= DL x 1. 5 = 92 x 1. 5 = 138’

5. Determine Total Effective Length (TEL) TEL= DL x 1. 5 = 92 x 1. 5 = 138’

6. Determine Street Main Pressure (E) 64. 1 psi

6. Determine Street Main Pressure (E) 64. 1 psi

7. Determine Pressure Available for Friction Loss Proper fixture flow pressure + Pressure lost due to height + Pressure lost due to friction + Pressure lost through meter Total street main pressure A B C D E 35. 0 7. 0 ? ? 64. 1

7. Determine Pressure Available for Friction Loss Proper fixture flow pressure + Pressure lost due to height + Pressure lost due to friction + Pressure lost through meter Total street main pressure A B C D E 35. 0 7. 0 ? ? 64. 1

Meter Loss (D) Pick an initial size 2” diameter… 1. 4 psi M: p. 917, F. 19. 63

Meter Loss (D) Pick an initial size 2” diameter… 1. 4 psi M: p. 917, F. 19. 63

8. Determine Friction loss/100’ C=E-A-B-D = 64. 1 -35. 0 -7. 0 -1. 4 = 20. 7 psi Δp/100’=100 x 20. 7/138 = 15 psi/100’

8. Determine Friction loss/100’ C=E-A-B-D = 64. 1 -35. 0 -7. 0 -1. 4 = 20. 7 psi Δp/100’=100 x 20. 7/138 = 15 psi/100’

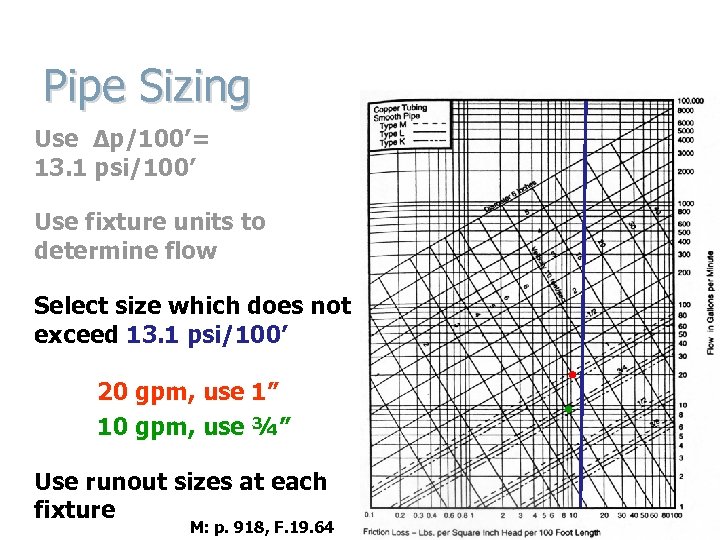

9. Verify flow for meter size At 2” Flow=150 gpm > Total Demand 40 gpm At 1 -1/2” Flow=60 gpm > Total Demand 40 gpm (Δp/100’= 13. 1) At 1” Flow=13 gpm < Total Demand 40 gpm (Δp/100’= 5. 1) M: p. 918 F. 19. 64

9. Verify flow for meter size At 2” Flow=150 gpm > Total Demand 40 gpm At 1 -1/2” Flow=60 gpm > Total Demand 40 gpm (Δp/100’= 13. 1) At 1” Flow=13 gpm < Total Demand 40 gpm (Δp/100’= 5. 1) M: p. 918 F. 19. 64

9. Verify flow for meter size When flow > Total Demand (#2) stop At 1 -1/2” Flow=60 gpm > Total Demand 40 gpm (Δp/100’= 13. 1) M: p. 918 F. 19. 64

9. Verify flow for meter size When flow > Total Demand (#2) stop At 1 -1/2” Flow=60 gpm > Total Demand 40 gpm (Δp/100’= 13. 1) M: p. 918 F. 19. 64

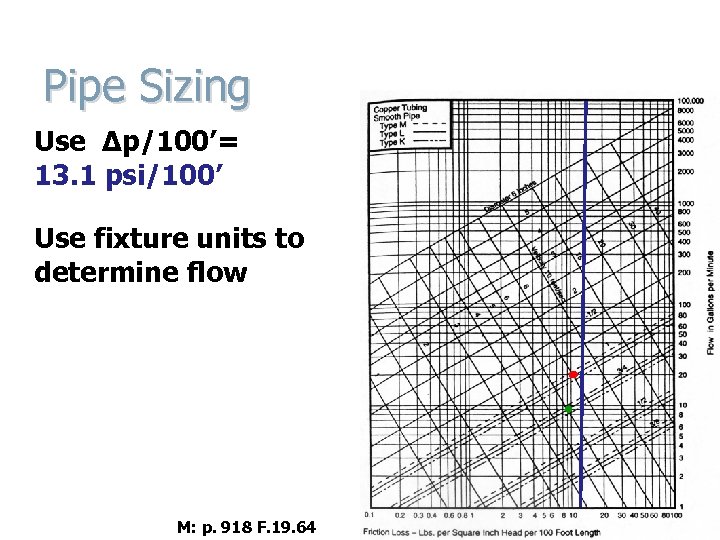

Pipe Sizing Use Δp/100’= 13. 1 psi/100’ Use fixture units to determine flow M: p. 918 F. 19. 64

Pipe Sizing Use Δp/100’= 13. 1 psi/100’ Use fixture units to determine flow M: p. 918 F. 19. 64

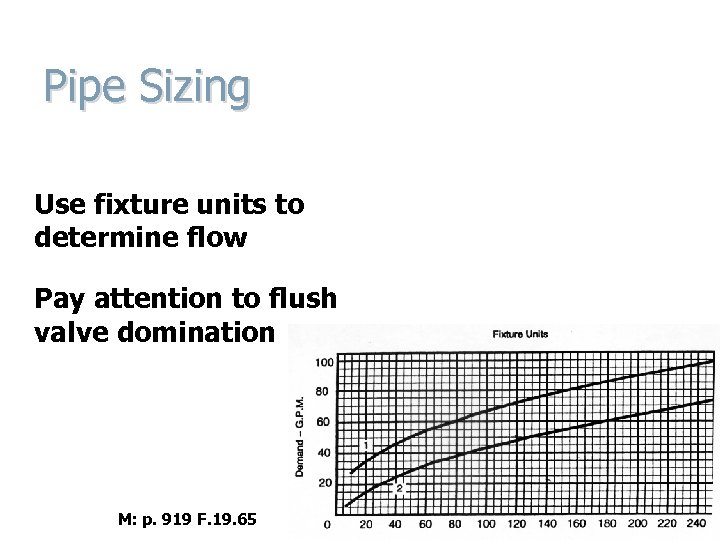

Pipe Sizing Use fixture units to determine flow Pay attention to flush valve domination M: p. 919 F. 19. 65

Pipe Sizing Use fixture units to determine flow Pay attention to flush valve domination M: p. 919 F. 19. 65

Pipe Sizing Use Δp/100’= 13. 1 psi/100’ Use fixture units to determine flow Select size which does not exceed 13. 1 psi/100’ 20 gpm, use 1” 10 gpm, use ¾” Use runout sizes at each fixture M: p. 918, F. 19. 64

Pipe Sizing Use Δp/100’= 13. 1 psi/100’ Use fixture units to determine flow Select size which does not exceed 13. 1 psi/100’ 20 gpm, use 1” 10 gpm, use ¾” Use runout sizes at each fixture M: p. 918, F. 19. 64

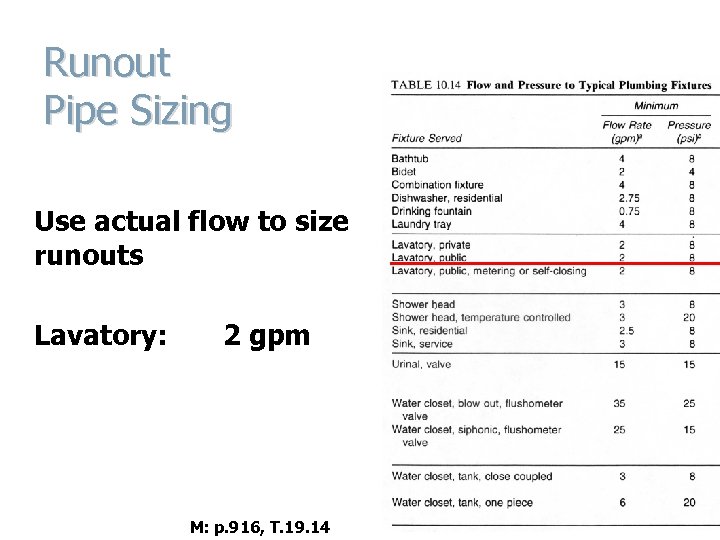

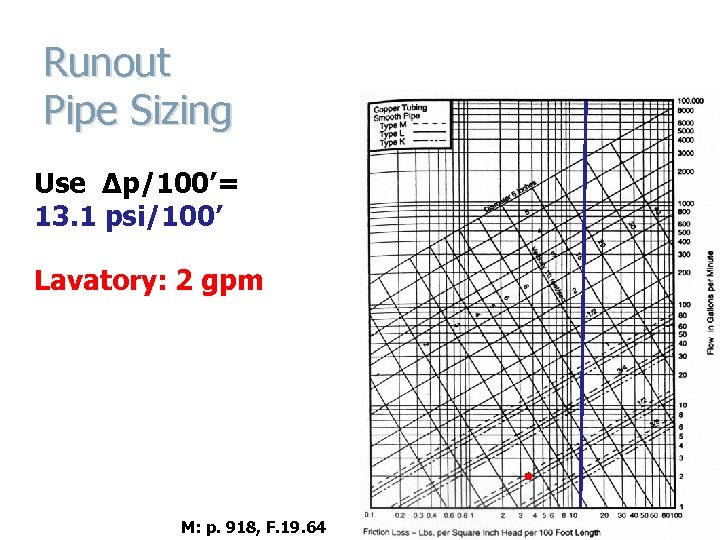

Runout Pipe Sizing Use actual flow to size runouts Lavatory: 2 gpm M: p. 916, T. 19. 14

Runout Pipe Sizing Use actual flow to size runouts Lavatory: 2 gpm M: p. 916, T. 19. 14

Runout Pipe Sizing Use Δp/100’= 13. 1 psi/100’ Lavatory: 2 gpm M: p. 918, F. 19. 64

Runout Pipe Sizing Use Δp/100’= 13. 1 psi/100’ Lavatory: 2 gpm M: p. 918, F. 19. 64

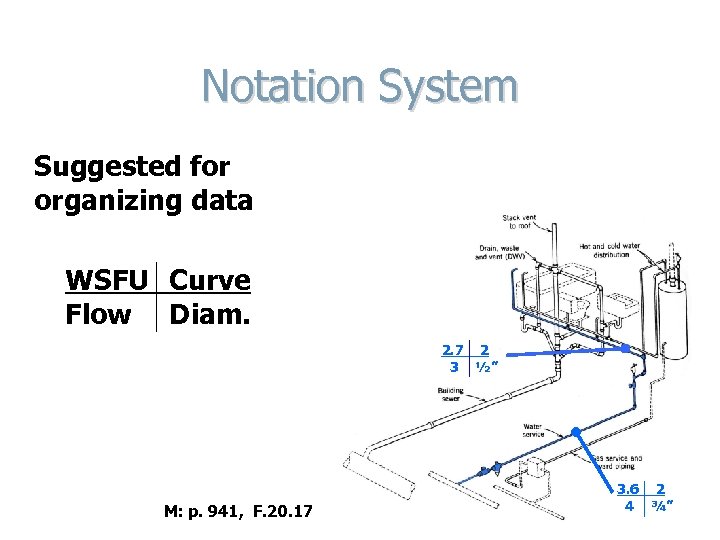

Notation System Suggested for organizing data WSFU Curve Flow Diam. 2. 7 2 3 ½” M: p. 941, F. 20. 17 3. 6 2 4 ¾”

Notation System Suggested for organizing data WSFU Curve Flow Diam. 2. 7 2 3 ½” M: p. 941, F. 20. 17 3. 6 2 4 ¾”