293acea34d1af7cdcc70b8873a6a3ad6.ppt

- Количество слайдов: 30

Technical Presentation November 2006

Who Are We? We are the leading provider of Next Generation Water Disinfection Solutions We bring a revolutionary disinfection technology Hydro-Optic Disinfection (HOD): n Environmentally friendly Simple to use and maintain At a low cost of ownership n Really does the job… n n 2

Company Profile n Founded in March 2003 n Raised $30 M to date from leading investors n HQ in Israel – home to renowned innovation in high-tech and water technologies n 50 employees and growing n Seasoned water sector management n Interdisciplinary team of top scientists and engineers n Comprehensive Intellectual Property Portfolio n Proven the technology in industrial installations 3

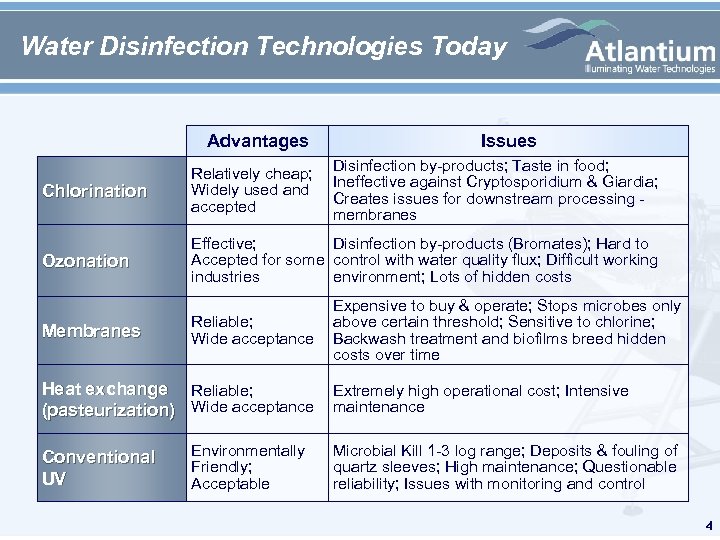

Water Disinfection Technologies Today Advantages Issues Disinfection by-products; Taste in food; Ineffective against Cryptosporidium & Giardia; Creates issues for downstream processing membranes Chlorination Relatively cheap; Widely used and accepted Ozonation Effective; Disinfection by-products (Bromates); Hard to Accepted for some control with water quality flux; Difficult working industries environment; Lots of hidden costs Membranes Reliable; Wide acceptance Heat exchange Reliable; (pasteurization) Wide acceptance Conventional UV Environmentally Friendly; Acceptable Expensive to buy & operate; Stops microbes only above certain threshold; Sensitive to chlorine; Backwash treatment and biofilms breed hidden costs over time Extremely high operational cost; Intensive maintenance Microbial Kill 1 -3 log range; Deposits & fouling of quartz sleeves; High maintenance; Questionable reliability; Issues with monitoring and control 4

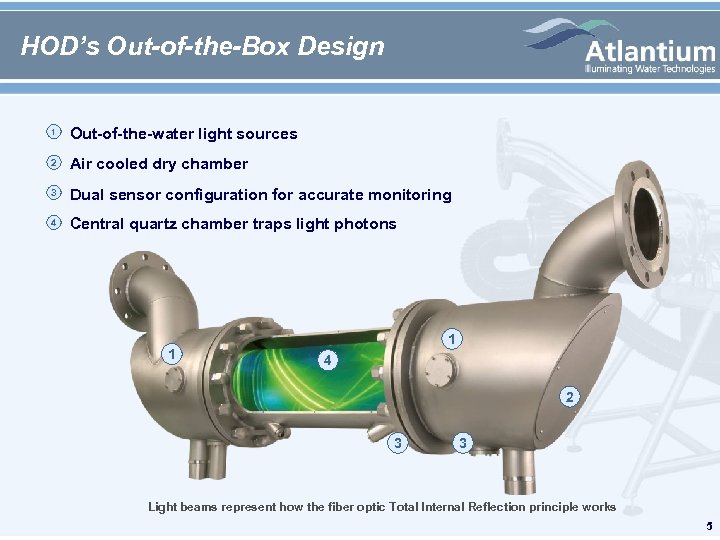

HOD’s Out-of-the-Box Design 1 Out-of-the-water light sources 2 Air cooled dry chamber 3 Dual sensor configuration for accurate monitoring 4 Central quartz chamber traps light photons 1 1 4 2 3 3 Light beams represent how the fiber optic Total Internal Reflection principle works 5

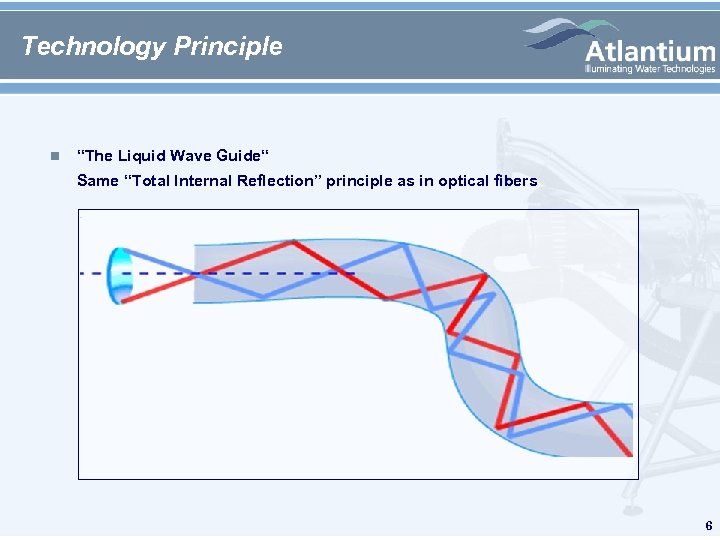

Technology Principle n “The Liquid Wave Guide“ Same “Total Internal Reflection” principle as in optical fibers 6

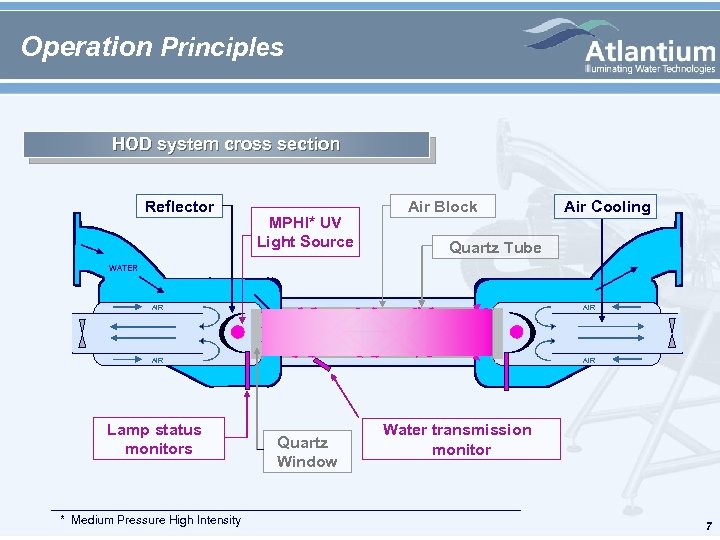

Operation Principles HOD system cross section Reflector MPHI* UV Light Source Air Block Air Cooling Quartz Tube WATER AIR AIR Lamp status monitors * Medium Pressure High Intensity Quartz Window Water transmission monitor 7

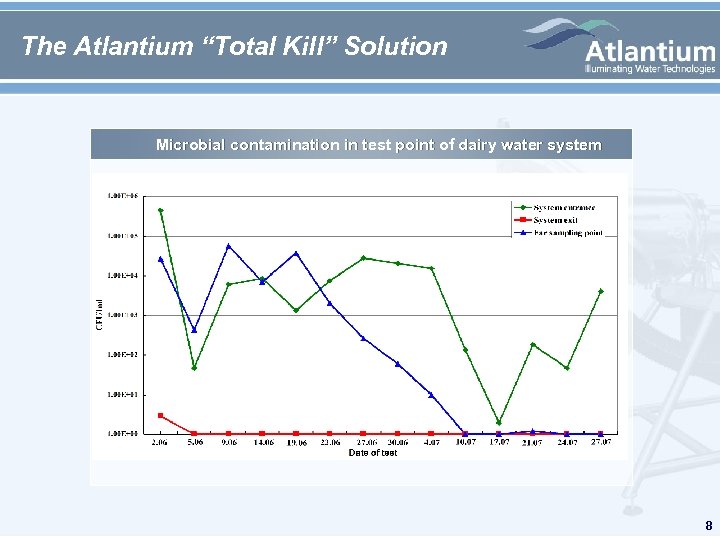

The Atlantium “Total Kill” Solution Microbial contamination in test point of dairy water system 8

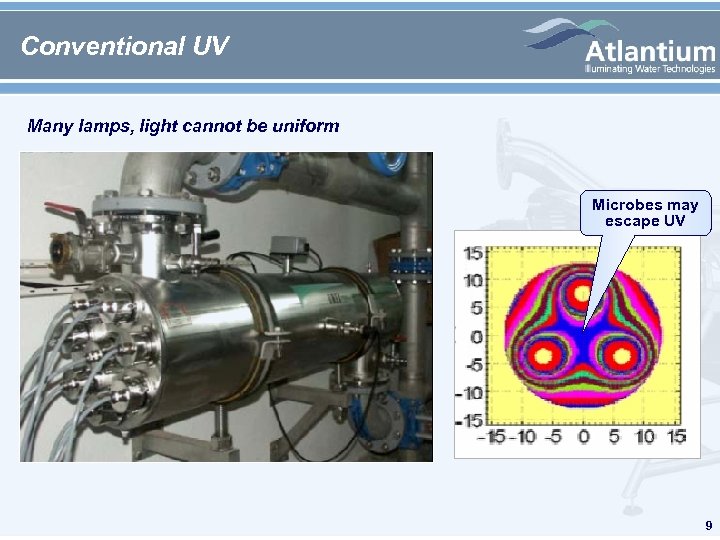

Conventional UV Many lamps, light cannot be uniform Microbes may escape UV 9

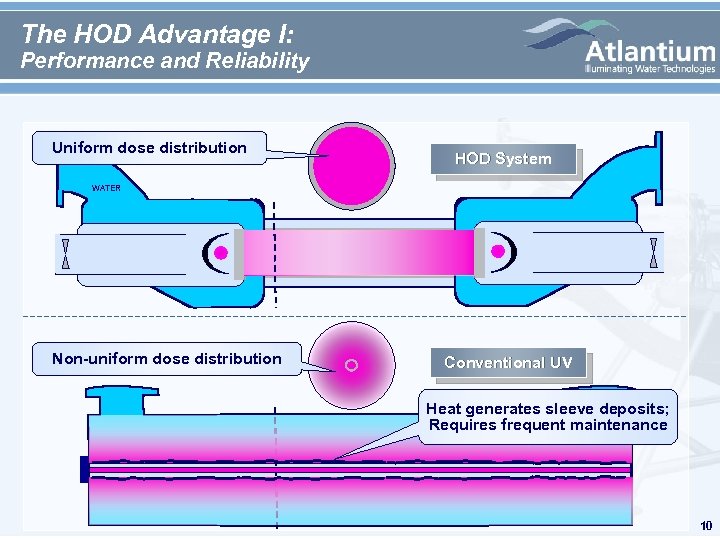

The HOD Advantage I: Performance and Reliability Uniform dose distribution HOD System WATER Non-uniform dose distribution Conventional UV Heat generates sleeve deposits; Requires frequent maintenance 10

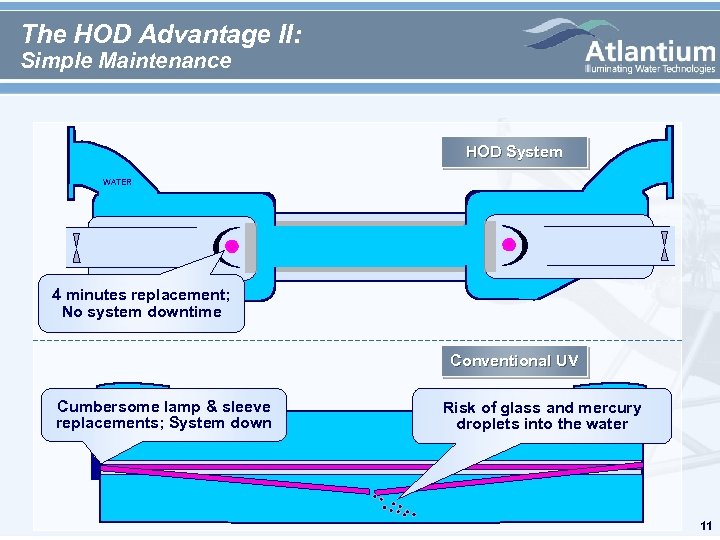

The HOD Advantage II: Simple Maintenance HOD System WATER 4 minutes replacement; No system downtime Conventional UV Cumbersome lamp & sleeve replacements; System down Risk of glass and mercury droplets into the water 11

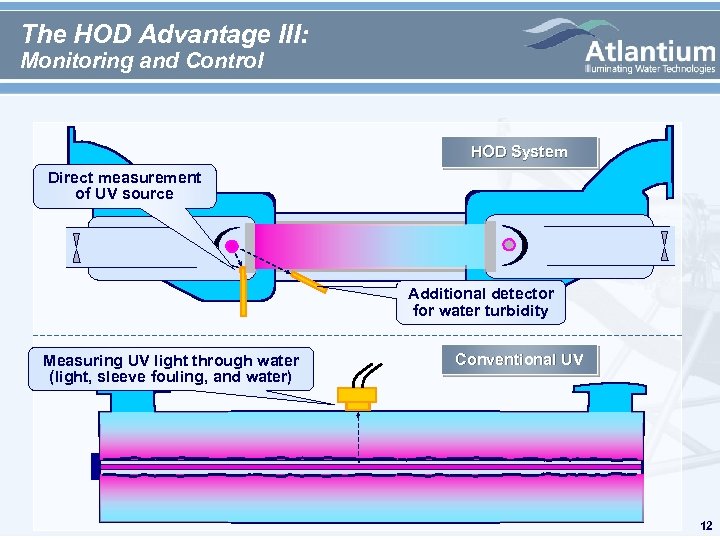

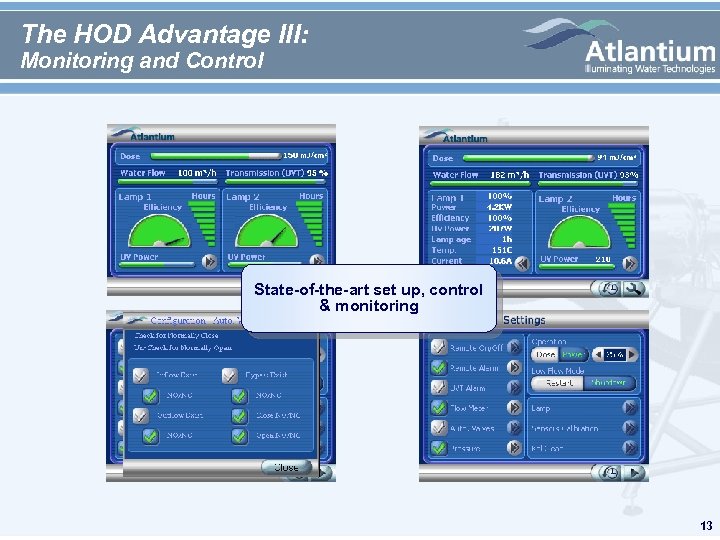

The HOD Advantage III: Monitoring and Control HOD System Direct measurement WATER of UV source Additional detector for water turbidity Measuring UV light through water (light, sleeve fouling, and water) Conventional UV 12

The HOD Advantage III: Monitoring and Control State-of-the-art set up, control & monitoring 13

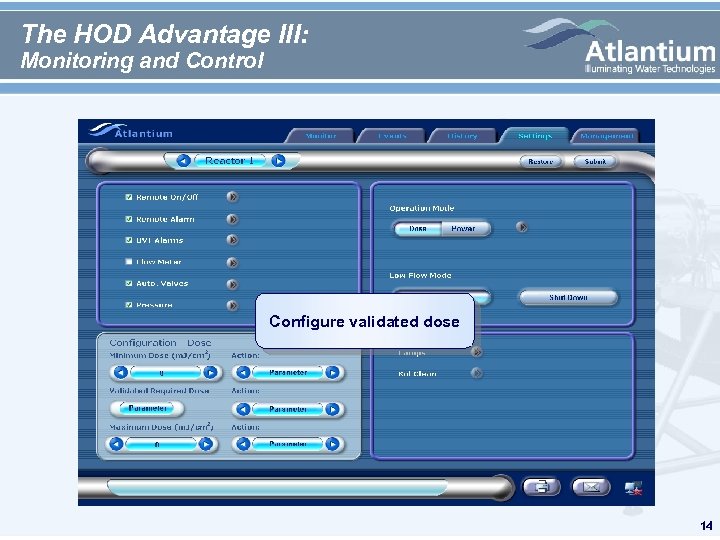

The HOD Advantage III: Monitoring and Control Configure validated dose 14

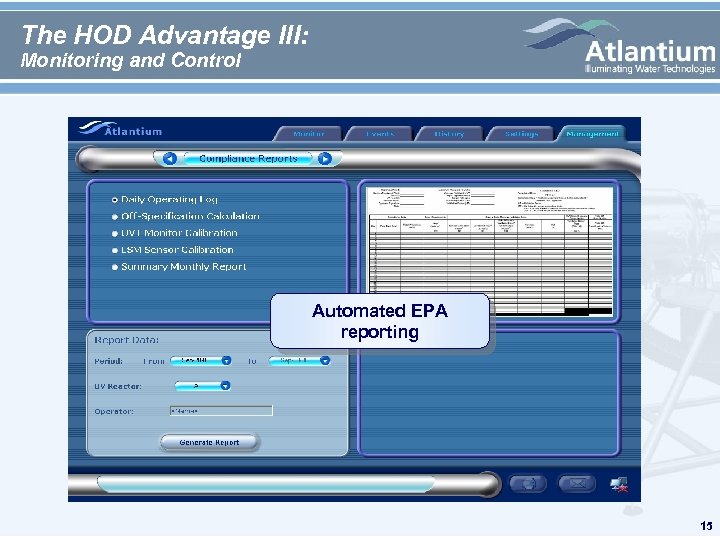

The HOD Advantage III: Monitoring and Control Automated EPA reporting 15

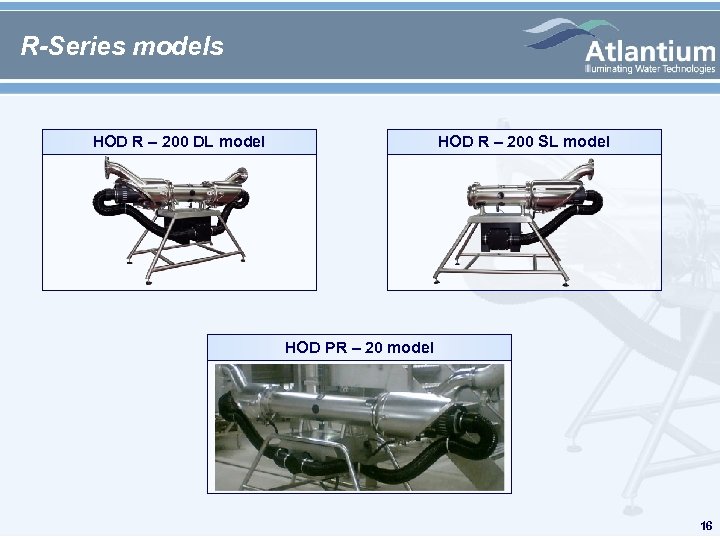

R-Series models HOD R – 200 DL model HOD R – 200 SL model HOD PR – 20 model 16

Overview: Markets & Products n R - models covering flow rates from 10 – 300 m 3/hr n Industrial and Municipal markets: n Industrial Food & Beverage Aquaculture Power plants Pharmaceuticals Other n Municipal Drinking water Water Re-use Desalination 17

Industrial Markets: F&B Applications Product Water Pasteurization Fire. Wall Process Water 18

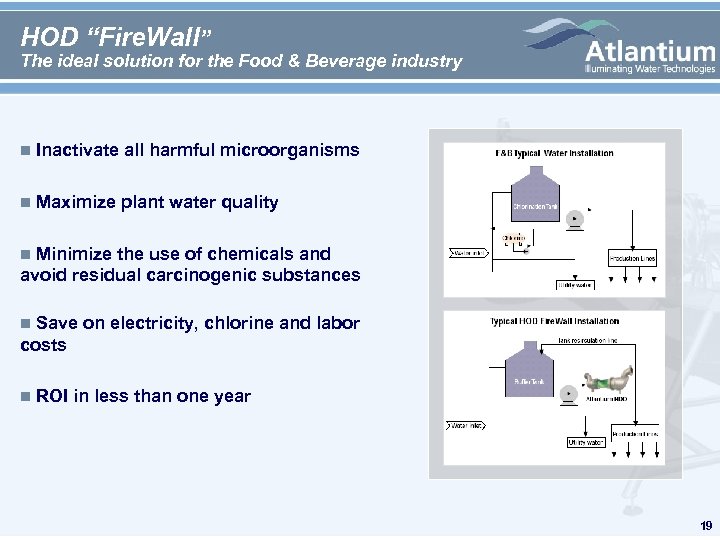

HOD “Fire. Wall” The ideal solution for the Food & Beverage industry n Inactivate all harmful microorganisms n Maximize plant water quality Minimize the use of chemicals and avoid residual carcinogenic substances n Save on electricity, chlorine and labor costs n n ROI in less than one year 19

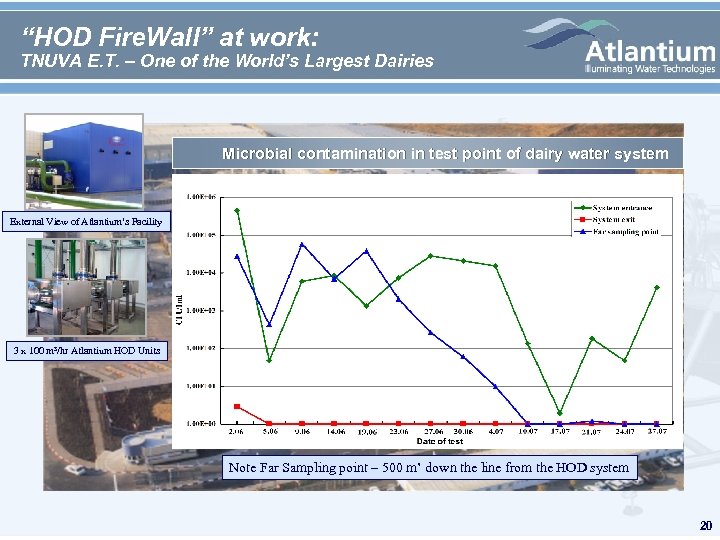

“HOD Fire. Wall” at work: TNUVA E. T. – One of the World’s Largest Dairies Microbial contamination in test point of dairy water system External View of Atlantium’s Facility 3 x 100 m 3/hr Atlantium HOD Units Note Far Sampling point – 500 m’ down the line from the HOD system 20

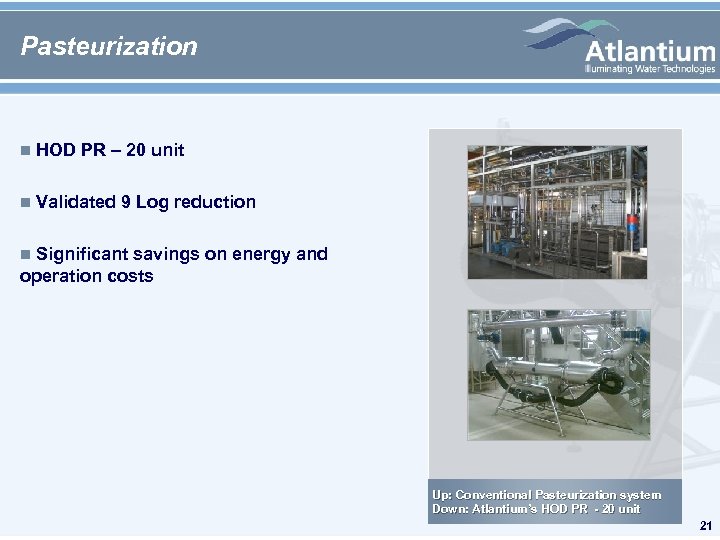

Pasteurization n HOD PR – 20 unit n Validated 9 Log reduction Significant savings on energy and operation costs n Up: Conventional Pasteurization system Down: Atlantium’s HOD PR - 20 unit 21

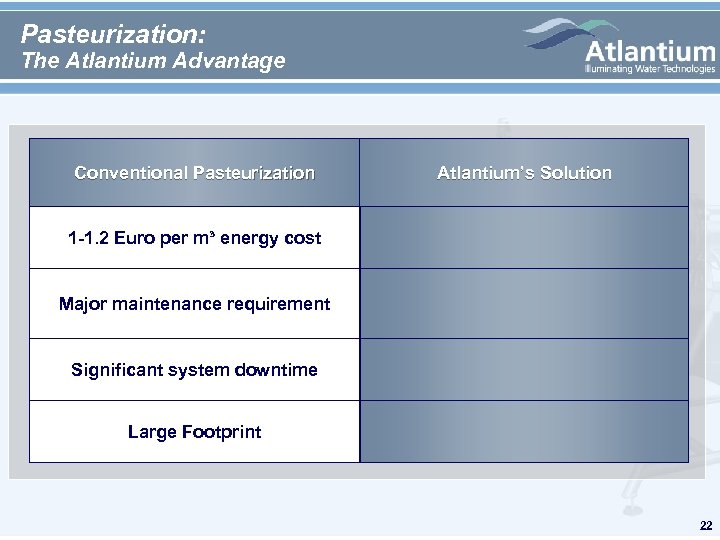

Pasteurization: The Atlantium Advantage Conventional Pasteurization Atlantium’s Solution 1 -1. 2 Euro per m³ energy cost 0. 05 Euro per m³ energy cost Major maintenance requirement Simple & easy maintenance Significant system downtime Almost no system downtime Large Footprint Small Footprint 22

TOC & THMs Reduction n Efficient way to reduce TOC & THMs: Creation of “radicals-saturated” zone All water are exposed to “radicals-saturated” zone Continuous generation of radicals Utilization of entire HOD reactor’s chamber for chemical reaction n Reduces chlorine usage to a minimum n Cost Effective: Eliminated the need for PAC and UF Membranes Reduces O&M costs 23

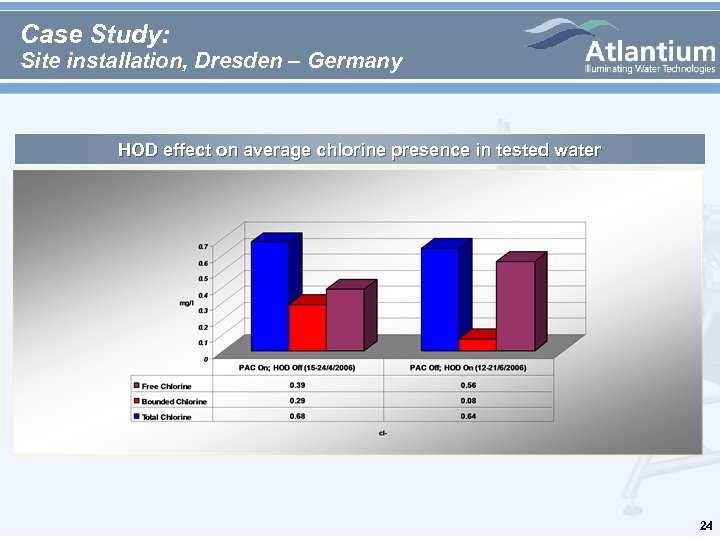

Case Study: Site installation, Dresden – Germany HOD effect on average chlorine presence in tested water 24

Industrial Markets: Aquaculture Applications 25

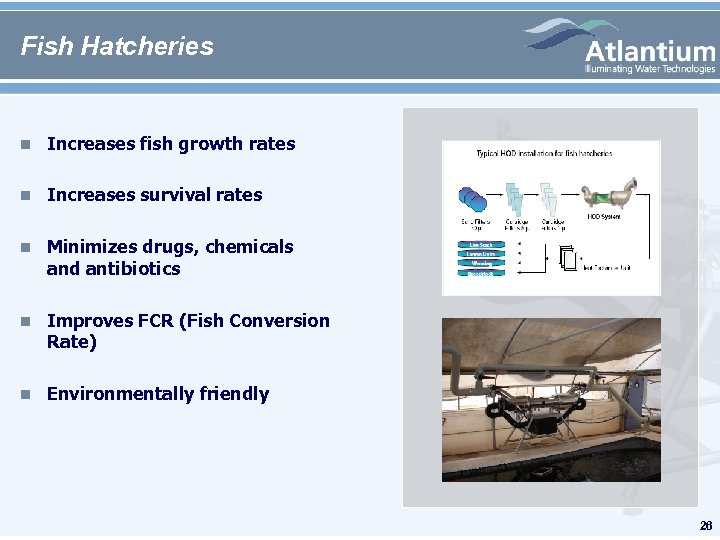

Fish Hatcheries n Increases fish growth rates n Increases survival rates n Minimizes drugs, chemicals and antibiotics n Improves FCR (Fish Conversion Rate) n Environmentally friendly 26

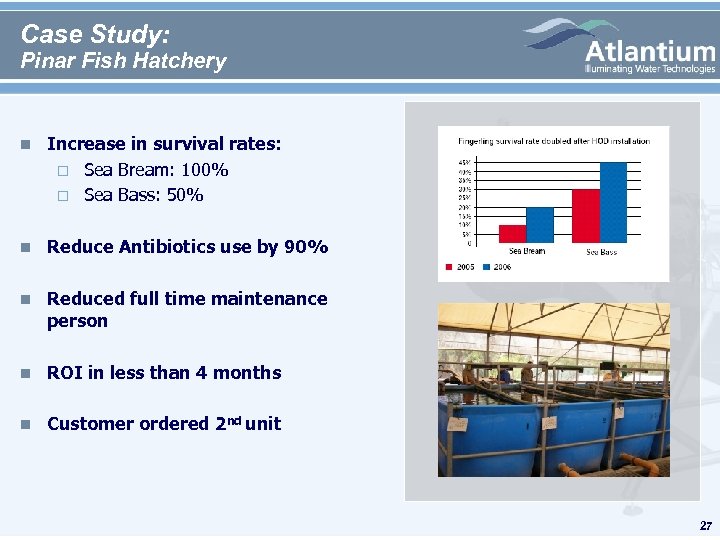

Case Study: Pinar Fish Hatchery n Increase in survival rates: Sea Bream: 100% Sea Bass: 50% n Reduce Antibiotics use by 90% n Reduced full time maintenance person n ROI in less than 4 months n Customer ordered 2 nd unit 27

Summary n Leader in innovative water disinfection solutions: Introducing Hydro-Optic Disinfection (HOD) technology A Revolutionary primary disinfection method n Dozens of successful industrial installations n Comprehensive Intellectual Property (IP) portfolio Seasoned management, academic and R&D staff Registered and pending patents worldwide n Operations in Europe, US and Asia – over 20 countries worldwide n Partnering with reps/ distributors and water companies for sales, installation, support, distribution, and R&D projects 28

Most important … The Sleep Well At Night (SWAN) Factor 29

THANK YOU! Atlantium Ltd. Har Tuv Industrial Park POB 11071, Bet Shemesh 99100, Israel Tel : + 972 2 992 5001 Fax : + 972 2 992 5005 info@atlantium. com www. atlantium. com

293acea34d1af7cdcc70b8873a6a3ad6.ppt