Cup_Moscow_2012_the_newcomers.pptx

- Количество слайдов: 11

• Team “The Newcomers” • Ice-cream factory ecological footprint reduction strategy • • Alla Eremeyeva Rinat Akhmadishin Liliya Mingalieva Nikita Petelin

• Team “The Newcomers” • Ice-cream factory ecological footprint reduction strategy • • Alla Eremeyeva Rinat Akhmadishin Liliya Mingalieva Nikita Petelin

Liliya Mingalieva HSE’ 15 Bachelor Degree, Management Department Alla Eremeeva HSE’ 13 Bachelor Degree, Management Department Exchange Program in EBS, Germany Rinat Akhmadishin REU (Plekhanov University) Financial dept. Nikita Petelin HSE’ 15 Bachelor Degree, Management Department

Liliya Mingalieva HSE’ 15 Bachelor Degree, Management Department Alla Eremeeva HSE’ 13 Bachelor Degree, Management Department Exchange Program in EBS, Germany Rinat Akhmadishin REU (Plekhanov University) Financial dept. Nikita Petelin HSE’ 15 Bachelor Degree, Management Department

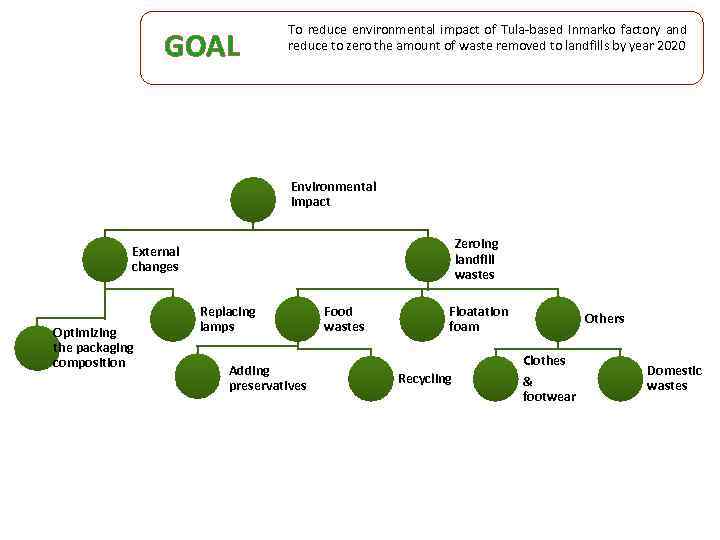

GOAL To reduce environmental impact of Tula-based Inmarko factory and reduce to zero the amount of waste removed to landfills by year 2020 Environmental impact Zeroing landfill wastes External changes Optimizing the packaging composition Replacing lamps Adding preservatives Food wastes Floatation foam Others Clothes Recycling & footwear Domestic wastes

GOAL To reduce environmental impact of Tula-based Inmarko factory and reduce to zero the amount of waste removed to landfills by year 2020 Environmental impact Zeroing landfill wastes External changes Optimizing the packaging composition Replacing lamps Adding preservatives Food wastes Floatation foam Others Clothes Recycling & footwear Domestic wastes

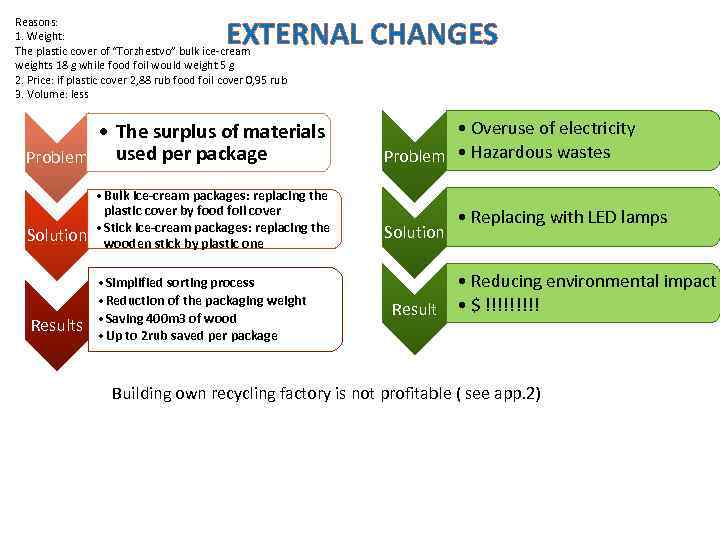

EXTERNAL CHANGES Reasons: 1. Weight: The plastic cover of “Torzhestvo” bulk ice-cream weights 18 g while food foil would weight 5 g 2. Price: if plastic cover 2, 88 rub food foil cover 0, 95 rub 3. Volume: less • The surplus of materials used per package Problem Solution Results • Bulk ice-cream packages: replacing the plastic cover by food foil cover • Stick ice-cream packages: replacing the wooden stick by plastic one • Simplified sorting process • Reduction of the packaging weight • Saving 400 m 3 of wood • Up to 2 rub saved per package • Overuse of electricity Problem • Hazardous wastes Solution Result • Replacing with LED lamps • Reducing environmental impact • $ !!!!! Building own recycling factory is not profitable ( see app. 2)

EXTERNAL CHANGES Reasons: 1. Weight: The plastic cover of “Torzhestvo” bulk ice-cream weights 18 g while food foil would weight 5 g 2. Price: if plastic cover 2, 88 rub food foil cover 0, 95 rub 3. Volume: less • The surplus of materials used per package Problem Solution Results • Bulk ice-cream packages: replacing the plastic cover by food foil cover • Stick ice-cream packages: replacing the wooden stick by plastic one • Simplified sorting process • Reduction of the packaging weight • Saving 400 m 3 of wood • Up to 2 rub saved per package • Overuse of electricity Problem • Hazardous wastes Solution Result • Replacing with LED lamps • Reducing environmental impact • $ !!!!! Building own recycling factory is not profitable ( see app. 2)

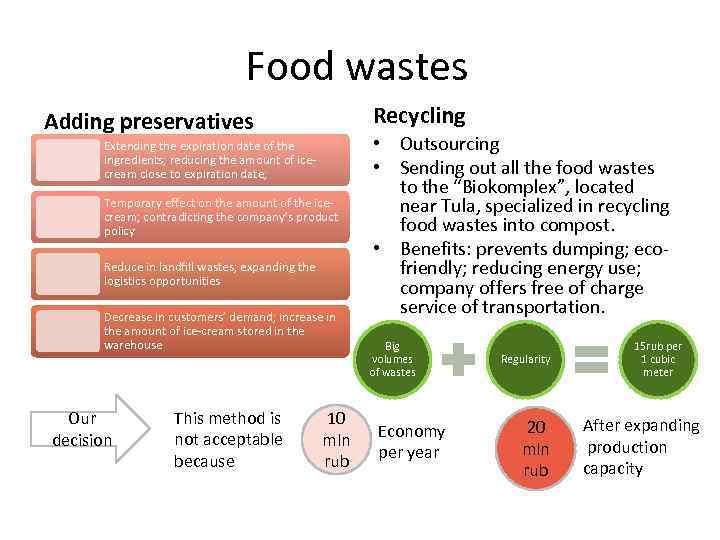

Food wastes Recycling Adding preservatives Extending the expiration date of the ingredients; reducing the amount of icecream close to expiration date; Temporary effect on the amount of the icecream; contradicting the company’s product policy Reduce in landfill wastes; expanding the logistics opportunities Decrease in customers’ demand; increase in the amount of ice-cream stored in the warehouse Our decision This method is not acceptable because 10 mln rub • Outsourcing • Sending out all the food wastes to the “Biokomplex”, located near Tula, specialized in recycling food wastes into compost. • Benefits: prevents dumping; ecofriendly; reducing energy use; company offers free of charge service of transportation. Big volumes of wastes Economy per year Regularity 20 mln rub 15 rub per 1 cubic meter After expanding production capacity

Food wastes Recycling Adding preservatives Extending the expiration date of the ingredients; reducing the amount of icecream close to expiration date; Temporary effect on the amount of the icecream; contradicting the company’s product policy Reduce in landfill wastes; expanding the logistics opportunities Decrease in customers’ demand; increase in the amount of ice-cream stored in the warehouse Our decision This method is not acceptable because 10 mln rub • Outsourcing • Sending out all the food wastes to the “Biokomplex”, located near Tula, specialized in recycling food wastes into compost. • Benefits: prevents dumping; ecofriendly; reducing energy use; company offers free of charge service of transportation. Big volumes of wastes Economy per year Regularity 20 mln rub 15 rub per 1 cubic meter After expanding production capacity

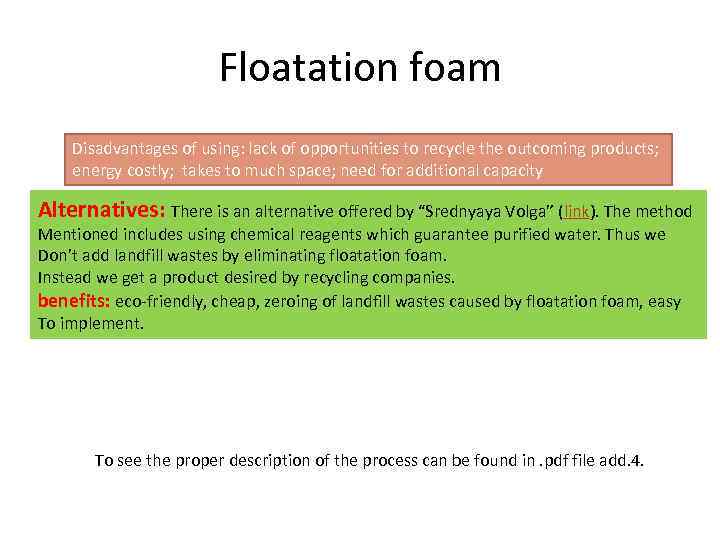

Floatation foam Disadvantages of using: lack of opportunities to recycle the outcoming products; energy costly; takes to much space; need for additional capacity Alternatives: There is an alternative offered by “Srednyaya Volga” (link). The method Mentioned includes using chemical reagents which guarantee purified water. Thus we Don’t add landfill wastes by eliminating floatation foam. Instead we get a product desired by recycling companies. benefits: eco-friendly, cheap, zeroing of landfill wastes caused by floatation foam, easy To implement. To see the proper description of the process can be found in. pdf file add. 4.

Floatation foam Disadvantages of using: lack of opportunities to recycle the outcoming products; energy costly; takes to much space; need for additional capacity Alternatives: There is an alternative offered by “Srednyaya Volga” (link). The method Mentioned includes using chemical reagents which guarantee purified water. Thus we Don’t add landfill wastes by eliminating floatation foam. Instead we get a product desired by recycling companies. benefits: eco-friendly, cheap, zeroing of landfill wastes caused by floatation foam, easy To implement. To see the proper description of the process can be found in. pdf file add. 4.

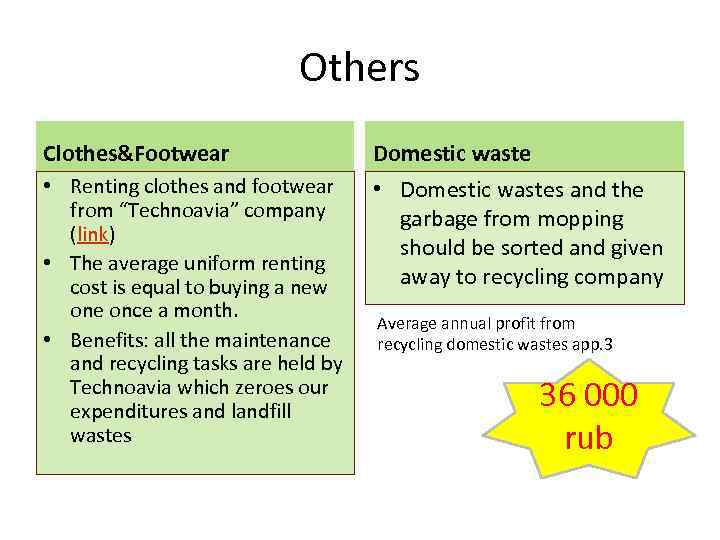

Others Clothes&Footwear Domestic waste • Renting clothes and footwear from “Technoavia” company (link) • The average uniform renting cost is equal to buying a new one once a month. • Benefits: all the maintenance and recycling tasks are held by Technoavia which zeroes our expenditures and landfill wastes • Domestic wastes and the garbage from mopping should be sorted and given away to recycling company Average annual profit from recycling domestic wastes app. 3 36 000 rub

Others Clothes&Footwear Domestic waste • Renting clothes and footwear from “Technoavia” company (link) • The average uniform renting cost is equal to buying a new one once a month. • Benefits: all the maintenance and recycling tasks are held by Technoavia which zeroes our expenditures and landfill wastes • Domestic wastes and the garbage from mopping should be sorted and given away to recycling company Average annual profit from recycling domestic wastes app. 3 36 000 rub

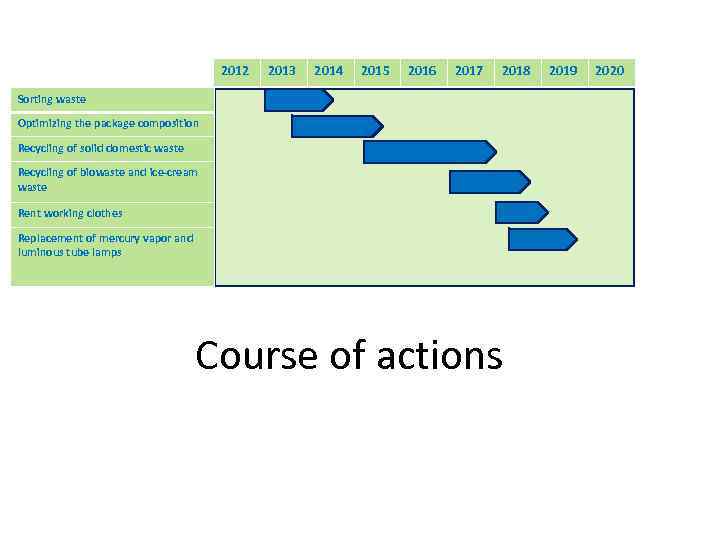

2012 2013 2014 2015 2016 2017 2018 Sorting waste Optimizing the package composition Recycling of solid domestic waste Recycling of biowaste and ice-cream waste Rent working clothes Replacement of mercury vapor and luminous tube lamps Course of actions 2019 2020

2012 2013 2014 2015 2016 2017 2018 Sorting waste Optimizing the package composition Recycling of solid domestic waste Recycling of biowaste and ice-cream waste Rent working clothes Replacement of mercury vapor and luminous tube lamps Course of actions 2019 2020

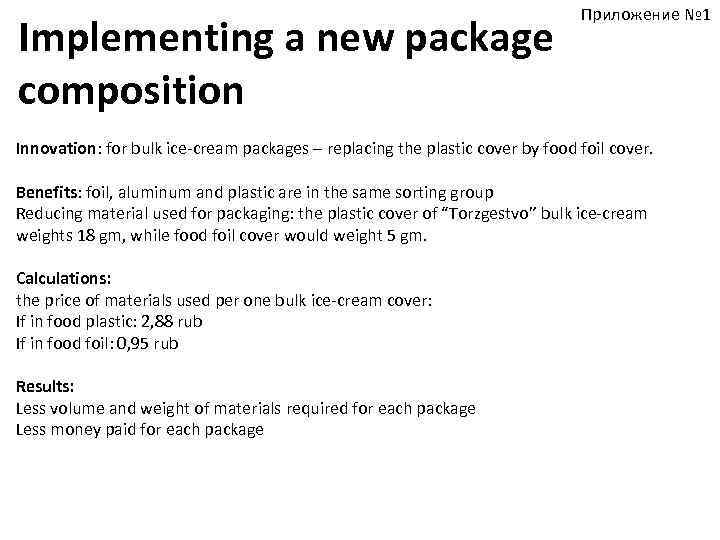

Implementing a new package composition Приложение № 1 Innovation: for bulk ice-cream packages – replacing the plastic cover by food foil cover. Benefits: foil, aluminum and plastic are in the same sorting group Reducing material used for packaging: the plastic cover of “Torzgestvo” bulk ice-cream weights 18 gm, while food foil cover would weight 5 gm. Calculations: the price of materials used per one bulk ice-cream cover: If in food plastic: 2, 88 rub If in food foil: 0, 95 rub Results: Less volume and weight of materials required for each package Less money paid for each package

Implementing a new package composition Приложение № 1 Innovation: for bulk ice-cream packages – replacing the plastic cover by food foil cover. Benefits: foil, aluminum and plastic are in the same sorting group Reducing material used for packaging: the plastic cover of “Torzgestvo” bulk ice-cream weights 18 gm, while food foil cover would weight 5 gm. Calculations: the price of materials used per one bulk ice-cream cover: If in food plastic: 2, 88 rub If in food foil: 0, 95 rub Results: Less volume and weight of materials required for each package Less money paid for each package

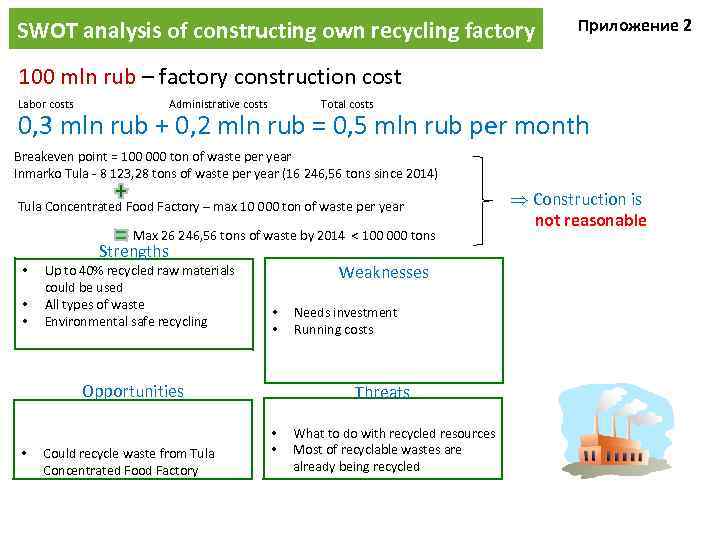

SWOT analysis of constructing own recycling factory Приложение 2 100 mln rub – factory construction cost Labor costs Administrative costs Total costs 0, 3 mln rub + 0, 2 mln rub = 0, 5 mln rub per month Breakeven point = 100 000 ton of waste per year Inmarko Tula - 8 123, 28 tons of waste per year (16 246, 56 tons since 2014) Tula Concentrated Food Factory – max 10 000 ton of waste per year Max 26 246, 56 tons of waste by 2014 < 100 000 tons • • • Strengths Up to 40% recycled raw materials could be used All types of waste Environmental safe recycling Weaknesses • • Opportunities • Could recycle waste from Tula Concentrated Food Factory Needs investment Running costs Threats • • What to do with recycled resources Most of recyclable wastes are already being recycled Þ Construction is not reasonable

SWOT analysis of constructing own recycling factory Приложение 2 100 mln rub – factory construction cost Labor costs Administrative costs Total costs 0, 3 mln rub + 0, 2 mln rub = 0, 5 mln rub per month Breakeven point = 100 000 ton of waste per year Inmarko Tula - 8 123, 28 tons of waste per year (16 246, 56 tons since 2014) Tula Concentrated Food Factory – max 10 000 ton of waste per year Max 26 246, 56 tons of waste by 2014 < 100 000 tons • • • Strengths Up to 40% recycled raw materials could be used All types of waste Environmental safe recycling Weaknesses • • Opportunities • Could recycle waste from Tula Concentrated Food Factory Needs investment Running costs Threats • • What to do with recycled resources Most of recyclable wastes are already being recycled Þ Construction is not reasonable

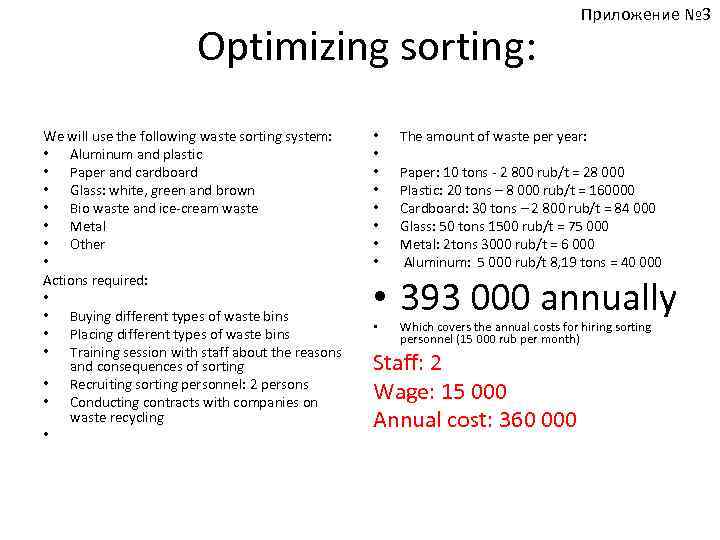

Optimizing sorting: We will use the following waste sorting system: • Aluminum and plastic • Paper and cardboard • Glass: white, green and brown • Bio waste and ice-cream waste • Metal • Other • Actions required: • • Buying different types of waste bins • Placing different types of waste bins • Training session with staff about the reasons and consequences of sorting • Recruiting sorting personnel: 2 persons • Conducting contracts with companies on waste recycling • • • Приложение № 3 The amount of waste per year: Paper: 10 tons - 2 800 rub/t = 28 000 Plastic: 20 tons – 8 000 rub/t = 160000 Cardboard: 30 tons – 2 800 rub/t = 84 000 Glass: 50 tons 1500 rub/t = 75 000 Metal: 2 tons 3000 rub/t = 6 000 Aluminum: 5 000 rub/t 8, 19 tons = 40 000 • 393 000 annually • Which covers the annual costs for hiring sorting personnel (15 000 rub per month) Staff: 2 Wage: 15 000 Annual cost: 360 000

Optimizing sorting: We will use the following waste sorting system: • Aluminum and plastic • Paper and cardboard • Glass: white, green and brown • Bio waste and ice-cream waste • Metal • Other • Actions required: • • Buying different types of waste bins • Placing different types of waste bins • Training session with staff about the reasons and consequences of sorting • Recruiting sorting personnel: 2 persons • Conducting contracts with companies on waste recycling • • • Приложение № 3 The amount of waste per year: Paper: 10 tons - 2 800 rub/t = 28 000 Plastic: 20 tons – 8 000 rub/t = 160000 Cardboard: 30 tons – 2 800 rub/t = 84 000 Glass: 50 tons 1500 rub/t = 75 000 Metal: 2 tons 3000 rub/t = 6 000 Aluminum: 5 000 rub/t 8, 19 tons = 40 000 • 393 000 annually • Which covers the annual costs for hiring sorting personnel (15 000 rub per month) Staff: 2 Wage: 15 000 Annual cost: 360 000