af4f1742034aa121ba4bf4e5744648c1.ppt

- Количество слайдов: 34

Team #1 Remote Controlled Motor Vehicle

Team #1 Remote Controlled Motor Vehicle

Team #1 Group Members l l l Ahmed Omar Muhammad Imran Apratim Kar Chang Jung Gurpreet Singh Thomas Murray l l l BSEE BSEE / CS

Team #1 Group Members l l l Ahmed Omar Muhammad Imran Apratim Kar Chang Jung Gurpreet Singh Thomas Murray l l l BSEE BSEE / CS

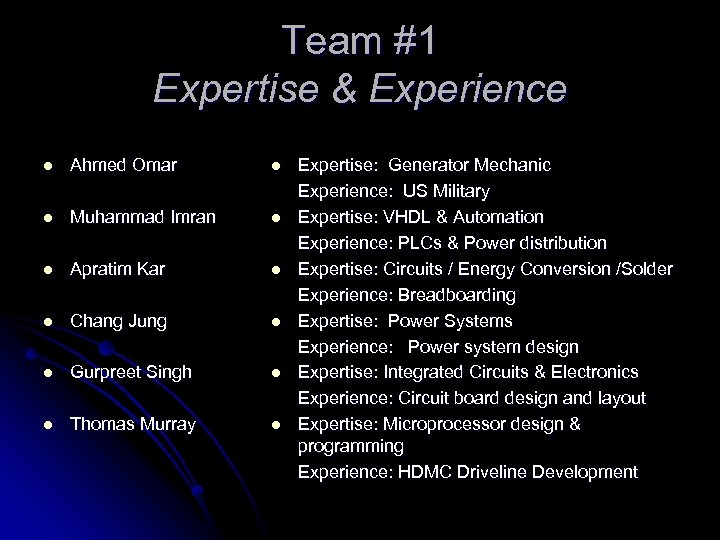

Team #1 Expertise & Experience l Ahmed Omar l l Muhammad Imran l l Apratim Kar l l Chang Jung l l Gurpreet Singh l l Thomas Murray l Expertise: Generator Mechanic Experience: US Military Expertise: VHDL & Automation Experience: PLCs & Power distribution Expertise: Circuits / Energy Conversion /Solder Experience: Breadboarding Expertise: Power Systems Experience: Power system design Expertise: Integrated Circuits & Electronics Experience: Circuit board design and layout Expertise: Microprocessor design & programming Experience: HDMC Driveline Development

Team #1 Expertise & Experience l Ahmed Omar l l Muhammad Imran l l Apratim Kar l l Chang Jung l l Gurpreet Singh l l Thomas Murray l Expertise: Generator Mechanic Experience: US Military Expertise: VHDL & Automation Experience: PLCs & Power distribution Expertise: Circuits / Energy Conversion /Solder Experience: Breadboarding Expertise: Power Systems Experience: Power system design Expertise: Integrated Circuits & Electronics Experience: Circuit board design and layout Expertise: Microprocessor design & programming Experience: HDMC Driveline Development

Team #1 Total Resources l l 35/Wk Man-hours $1000 UWM sponsorship for project

Team #1 Total Resources l l 35/Wk Man-hours $1000 UWM sponsorship for project

Team #1 Decision Making l l l Through much consideration, we decided that the best approach to decision making for our group is the majority vote strategy. If a decision can not be effectively reached by our group, our TA will be employed to help us reach a decision The Prof/Lecturer has the final call on any team decision

Team #1 Decision Making l l l Through much consideration, we decided that the best approach to decision making for our group is the majority vote strategy. If a decision can not be effectively reached by our group, our TA will be employed to help us reach a decision The Prof/Lecturer has the final call on any team decision

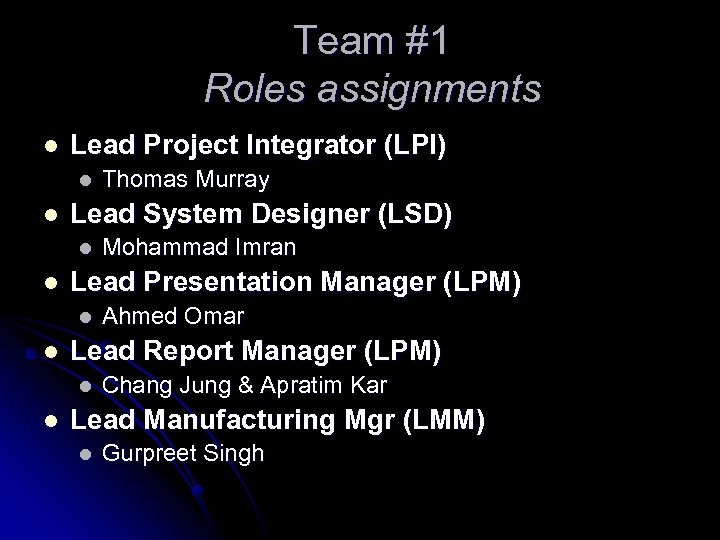

Team #1 Roles assignments l Lead Project Integrator (LPI) l l Lead System Designer (LSD) l l Ahmed Omar Lead Report Manager (LPM) l l Mohammad Imran Lead Presentation Manager (LPM) l l Thomas Murray Chang Jung & Apratim Kar Lead Manufacturing Mgr (LMM) l Gurpreet Singh

Team #1 Roles assignments l Lead Project Integrator (LPI) l l Lead System Designer (LSD) l l Ahmed Omar Lead Report Manager (LPM) l l Mohammad Imran Lead Presentation Manager (LPM) l l Thomas Murray Chang Jung & Apratim Kar Lead Manufacturing Mgr (LMM) l Gurpreet Singh

Project Idea #1 l Mobile Automated Solar Power l l l It will provide power to RVs, campers and remote weather stations. Power will be accessible through outlets to where equipment i. e. computers can be connected. Will contain solar panels with an electrical interface, and will power up small household appliances. Project seems to intrigue group members.

Project Idea #1 l Mobile Automated Solar Power l l l It will provide power to RVs, campers and remote weather stations. Power will be accessible through outlets to where equipment i. e. computers can be connected. Will contain solar panels with an electrical interface, and will power up small household appliances. Project seems to intrigue group members.

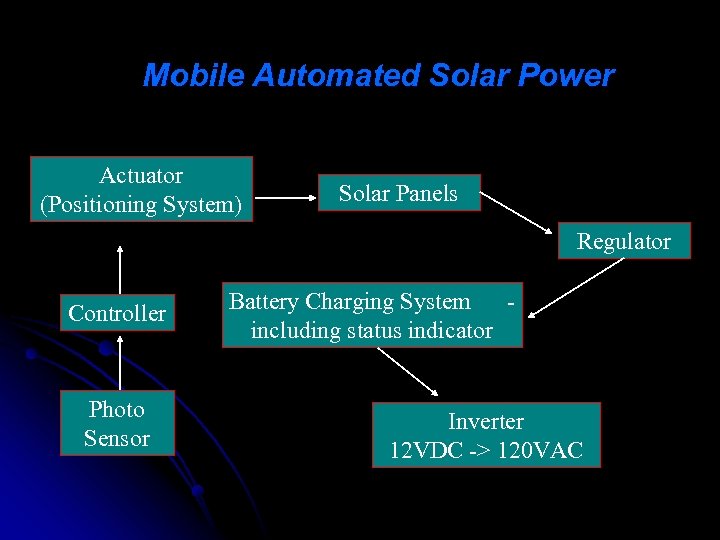

Mobile Automated Solar Power Actuator (Positioning System) Solar Panels Regulator Controller Photo Sensor Battery Charging System including status indicator Inverter 12 VDC -> 120 VAC

Mobile Automated Solar Power Actuator (Positioning System) Solar Panels Regulator Controller Photo Sensor Battery Charging System including status indicator Inverter 12 VDC -> 120 VAC

Project Idea #2 l Remote Accessed Pet Tender l l System will be accessed via the internet and through this, the owner will be able to monitor pets and also dispense food and water as needed AC/DC, internet software, access via internet Owners will be able to monitor their pets while away from home and dispense food/water as needed Considerable interest from group members who are pet owners

Project Idea #2 l Remote Accessed Pet Tender l l System will be accessed via the internet and through this, the owner will be able to monitor pets and also dispense food and water as needed AC/DC, internet software, access via internet Owners will be able to monitor their pets while away from home and dispense food/water as needed Considerable interest from group members who are pet owners

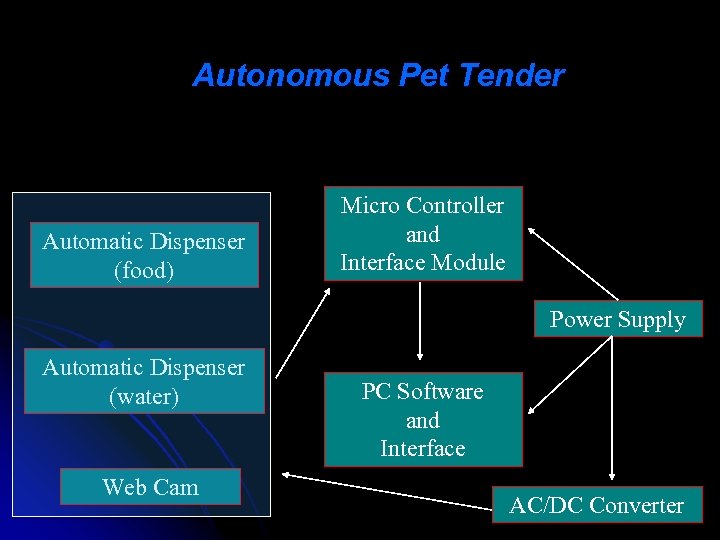

Autonomous Pet Tender Automatic Dispenser (food) Micro Controller and Interface Module Power Supply Automatic Dispenser (water) Web Cam PC Software and Interface AC/DC Converter

Autonomous Pet Tender Automatic Dispenser (food) Micro Controller and Interface Module Power Supply Automatic Dispenser (water) Web Cam PC Software and Interface AC/DC Converter

Project Idea #3 l Automated Lawn Mower l l l Mower will cut the loan with no human interference. The lawn mower and yard will have sensors that will ensure mower stays within the yard, ending in cutting the lawn automatically. DC powered. It will be a good solution for lawn care during extreme weather or for people who are unable to take care of their lawn themselves. Product already exists in market place

Project Idea #3 l Automated Lawn Mower l l l Mower will cut the loan with no human interference. The lawn mower and yard will have sensors that will ensure mower stays within the yard, ending in cutting the lawn automatically. DC powered. It will be a good solution for lawn care during extreme weather or for people who are unable to take care of their lawn themselves. Product already exists in market place

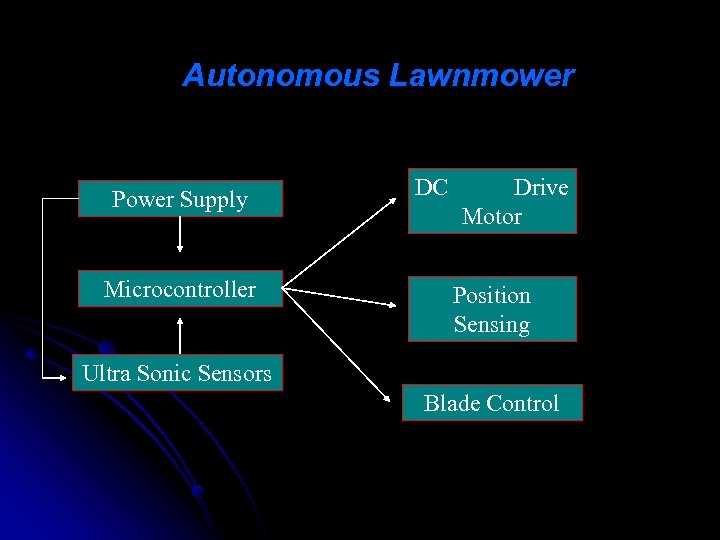

Autonomous Lawnmower Power Supply Microcontroller DC Drive Motor Position Sensing Ultra Sonic Sensors Blade Control

Autonomous Lawnmower Power Supply Microcontroller DC Drive Motor Position Sensing Ultra Sonic Sensors Blade Control

Project Idea #4 l Remote Controlled Vehicle l l l Vehicle will be used in UWM campus open house exhibitions to promote the engineering department. Vehicle will have a high power DC motor, controlled via pulse width modulation. DC power will be supplied via Pb-Acid batteries. No identical product exists in the market. Project is sponsored by UWM up to $1000. 00

Project Idea #4 l Remote Controlled Vehicle l l l Vehicle will be used in UWM campus open house exhibitions to promote the engineering department. Vehicle will have a high power DC motor, controlled via pulse width modulation. DC power will be supplied via Pb-Acid batteries. No identical product exists in the market. Project is sponsored by UWM up to $1000. 00

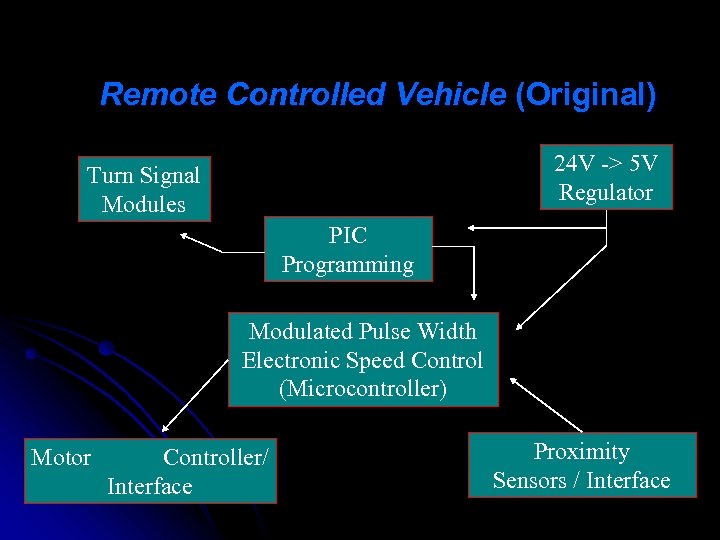

Remote Controlled Vehicle (Original) 24 V -> 5 V Regulator Turn Signal Modules PIC Programming Modulated Pulse Width Electronic Speed Control (Microcontroller) Motor Controller/ Interface Proximity Sensors / Interface

Remote Controlled Vehicle (Original) 24 V -> 5 V Regulator Turn Signal Modules PIC Programming Modulated Pulse Width Electronic Speed Control (Microcontroller) Motor Controller/ Interface Proximity Sensors / Interface

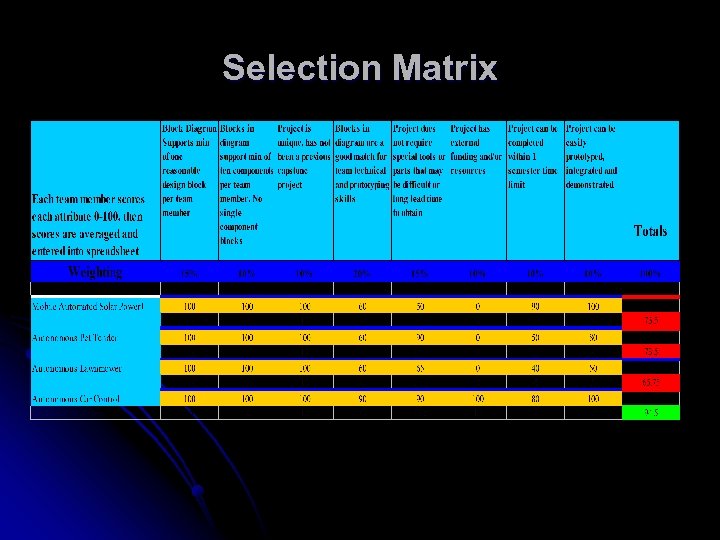

Selection Matrix

Selection Matrix

Project Selection l Overall Selection Process Ø l l l Our project selection process was conducted as follows First stage was brainstorming in which team members proposed several project ideas. Second stage was drawing the expected block diagrams for each proposal. Third stage was evaluating each project and assigning them score according to the provided selection matrix, which lead to our chosen project. Ø l Project was chosen for the following reason: It is funded, meets the requirements of 1 block person and it can be prototyped and demonstrated easily. Ø l The major risks in the project: Time constraints, possible design challenges Ø l Reason for rejecting other proposals: Other projects had no external funding and were not a good match for team skills Ø Project selection was achieved through unanimous decision

Project Selection l Overall Selection Process Ø l l l Our project selection process was conducted as follows First stage was brainstorming in which team members proposed several project ideas. Second stage was drawing the expected block diagrams for each proposal. Third stage was evaluating each project and assigning them score according to the provided selection matrix, which lead to our chosen project. Ø l Project was chosen for the following reason: It is funded, meets the requirements of 1 block person and it can be prototyped and demonstrated easily. Ø l The major risks in the project: Time constraints, possible design challenges Ø l Reason for rejecting other proposals: Other projects had no external funding and were not a good match for team skills Ø Project selection was achieved through unanimous decision

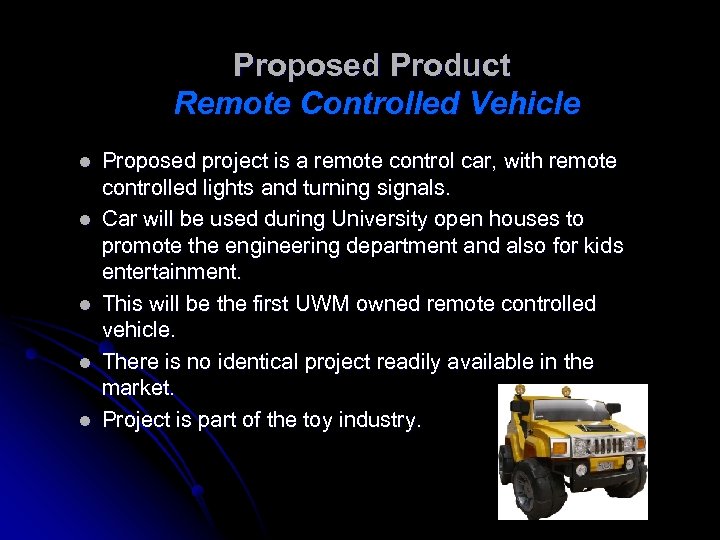

Proposed Product Remote Controlled Vehicle l l l Proposed project is a remote control car, with remote controlled lights and turning signals. Car will be used during University open houses to promote the engineering department and also for kids entertainment. This will be the first UWM owned remote controlled vehicle. There is no identical project readily available in the market. Project is part of the toy industry.

Proposed Product Remote Controlled Vehicle l l l Proposed project is a remote control car, with remote controlled lights and turning signals. Car will be used during University open houses to promote the engineering department and also for kids entertainment. This will be the first UWM owned remote controlled vehicle. There is no identical project readily available in the market. Project is part of the toy industry.

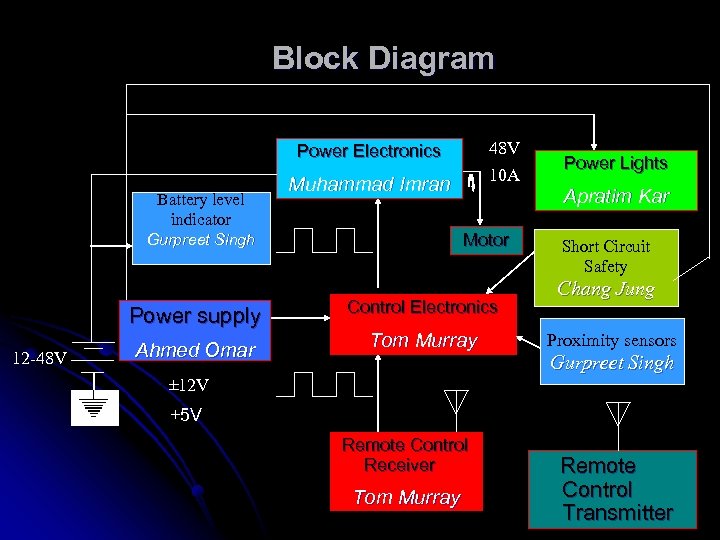

Block Diagram 48 V 10 A Power Electronics Battery level indicator Muhammad Imran Motor Gurpreet Singh Power supply 12 -48 V Ahmed Omar Control Electronics Tom Murray Power Lights Apratim Kar Short Circuit Safety Chang Jung Proximity sensors Gurpreet Singh ± 12 V +5 V Remote Control Receiver Tom Murray Remote Control Transmitter

Block Diagram 48 V 10 A Power Electronics Battery level indicator Muhammad Imran Motor Gurpreet Singh Power supply 12 -48 V Ahmed Omar Control Electronics Tom Murray Power Lights Apratim Kar Short Circuit Safety Chang Jung Proximity sensors Gurpreet Singh ± 12 V +5 V Remote Control Receiver Tom Murray Remote Control Transmitter

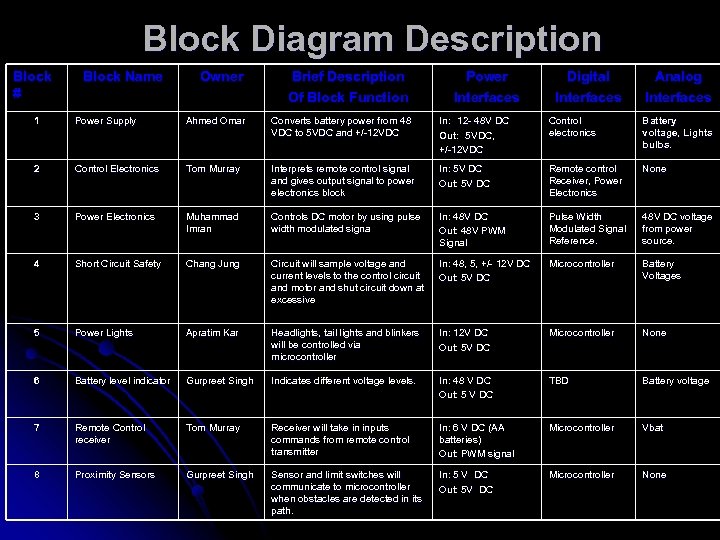

Block Diagram Description Block # Block Name Owner Brief Description Of Block Function Power Interfaces Digital Interfaces Analog Interfaces 1 Power Supply Ahmed Omar Converts battery power from 48 VDC to 5 VDC and +/-12 VDC In: 12 - 48 V DC Out: 5 VDC, +/-12 VDC Control electronics Battery voltage, Lights bulbs. 2 Control Electronics Tom Murray Interprets remote control signal and gives output signal to power electronics block In: 5 V DC Out: 5 V DC Remote control Receiver, Power Electronics None 3 Power Electronics Muhammad Imran Controls DC motor by using pulse width modulated signa In: 48 V DC Out: 48 V PWM Signal Pulse Width Modulated Signal Reference. 48 V DC voltage from power source. 4 Short Circuit Safety Chang Jung Circuit will sample voltage and current levels to the control circuit and motor and shut circuit down at excessive In: 48, 5, +/- 12 V DC Out: 5 V DC Microcontroller Battery Voltages 5 Power Lights Apratim Kar Headlights, tail lights and blinkers will be controlled via microcontroller In: 12 V DC Out: 5 V DC Microcontroller None 6 Battery level indicator Gurpreet Singh Indicates different voltage levels. In: 48 V DC Out: 5 V DC TBD Battery voltage 7 Remote Control receiver Tom Murray Receiver will take in inputs commands from remote control transmitter In: 6 V DC (AA batteries) Out: PWM signal Microcontroller Vbat 8 Proximity Sensors Gurpreet Singh Sensor and limit switches will communicate to microcontroller when obstacles are detected in its path. In: 5 V DC Out: 5 V DC Microcontroller None

Block Diagram Description Block # Block Name Owner Brief Description Of Block Function Power Interfaces Digital Interfaces Analog Interfaces 1 Power Supply Ahmed Omar Converts battery power from 48 VDC to 5 VDC and +/-12 VDC In: 12 - 48 V DC Out: 5 VDC, +/-12 VDC Control electronics Battery voltage, Lights bulbs. 2 Control Electronics Tom Murray Interprets remote control signal and gives output signal to power electronics block In: 5 V DC Out: 5 V DC Remote control Receiver, Power Electronics None 3 Power Electronics Muhammad Imran Controls DC motor by using pulse width modulated signa In: 48 V DC Out: 48 V PWM Signal Pulse Width Modulated Signal Reference. 48 V DC voltage from power source. 4 Short Circuit Safety Chang Jung Circuit will sample voltage and current levels to the control circuit and motor and shut circuit down at excessive In: 48, 5, +/- 12 V DC Out: 5 V DC Microcontroller Battery Voltages 5 Power Lights Apratim Kar Headlights, tail lights and blinkers will be controlled via microcontroller In: 12 V DC Out: 5 V DC Microcontroller None 6 Battery level indicator Gurpreet Singh Indicates different voltage levels. In: 48 V DC Out: 5 V DC TBD Battery voltage 7 Remote Control receiver Tom Murray Receiver will take in inputs commands from remote control transmitter In: 6 V DC (AA batteries) Out: PWM signal Microcontroller Vbat 8 Proximity Sensors Gurpreet Singh Sensor and limit switches will communicate to microcontroller when obstacles are detected in its path. In: 5 V DC Out: 5 V DC Microcontroller None

Key Considerations l Market and Business l Environmental and Safety l Power / Electrical Interface l Mechanical Specifications l Manufacturing and Life Cycle l Risk Areas l Existing Patents

Key Considerations l Market and Business l Environmental and Safety l Power / Electrical Interface l Mechanical Specifications l Manufacturing and Life Cycle l Risk Areas l Existing Patents

Market and Business l l l l l Competitor: TYCO, R 2100 Market size: $69. 5 Million Average list price: $1899. 99 Market geography: North America Market demography: for age 12 and above, m/f, no restrictions. Intended application: Used in campus open house to promote the EE department, as well as common consumer entertainment. Material Cost: $429. 99 Manufacturing cost: $160. 00 Annual Volume: 7300

Market and Business l l l l l Competitor: TYCO, R 2100 Market size: $69. 5 Million Average list price: $1899. 99 Market geography: North America Market demography: for age 12 and above, m/f, no restrictions. Intended application: Used in campus open house to promote the EE department, as well as common consumer entertainment. Material Cost: $429. 99 Manufacturing cost: $160. 00 Annual Volume: 7300

Environmental and Safety l l l l Oper Temp Range: -24. 44 to 60 ° C Oper Humidity Range: 5 – 90% Oper Alt or Press Range: N/A Storage Temp Range: -24. 44 to 60 ° C Storage Humidity Range: 5 – 90% Storage Alt or Press Range: N/A Max Storage Duration: 2 Years Primary EMC Standards: l l EN 61204 -3: 2001—Low-voltage power supplies, dc output—Part 3: Electromagnetic compatibility (EMC). Primary Safety Standards: l ANSI/ISA S 82. 01: 1994—Safety standard for electrical and electronic test, measuring, controlling, and related equipment—General requirements.

Environmental and Safety l l l l Oper Temp Range: -24. 44 to 60 ° C Oper Humidity Range: 5 – 90% Oper Alt or Press Range: N/A Storage Temp Range: -24. 44 to 60 ° C Storage Humidity Range: 5 – 90% Storage Alt or Press Range: N/A Max Storage Duration: 2 Years Primary EMC Standards: l l EN 61204 -3: 2001—Low-voltage power supplies, dc output—Part 3: Electromagnetic compatibility (EMC). Primary Safety Standards: l ANSI/ISA S 82. 01: 1994—Safety standard for electrical and electronic test, measuring, controlling, and related equipment—General requirements.

Power Interfaces l l l Energy Source List: 4 x 12 V Rechargeable Lead Acid Batteries. Source Connection List: Permanent Min Oper Voltage Range: 40 -48 V Max Power Consumption: 500 W Max Energy 100 KW Hours/ Year

Power Interfaces l l l Energy Source List: 4 x 12 V Rechargeable Lead Acid Batteries. Source Connection List: Permanent Min Oper Voltage Range: 40 -48 V Max Power Consumption: 500 W Max Energy 100 KW Hours/ Year

Mechanical Specifications l l Shipping Container Size l 1. 13 m x 0. 845 m x 0. 467 m Max Volume l 0. 446 M 3 Max Mass l 40 Kg Elec I/F connectors l l l 4 - Way Flat Trailer Connector Max # of PCBs : 6 Max PCB Circuit Area : 929 cm 2

Mechanical Specifications l l Shipping Container Size l 1. 13 m x 0. 845 m x 0. 467 m Max Volume l 0. 446 M 3 Max Mass l 40 Kg Elec I/F connectors l l l 4 - Way Flat Trailer Connector Max # of PCBs : 6 Max PCB Circuit Area : 929 cm 2

Manufacturing and Life Cycle l l l l l Max parts count : TBD Max unique parts count: 1 Parts/Mat $ Allocation: $429. 99 Asm/Test $ Allocation: $160. 00 Product Life, Reliability: TBD Full Warranty Period: TBD Product Disposition: TBD Production Life Support: TBD Service Strategy: Factory Repair

Manufacturing and Life Cycle l l l l l Max parts count : TBD Max unique parts count: 1 Parts/Mat $ Allocation: $429. 99 Asm/Test $ Allocation: $160. 00 Product Life, Reliability: TBD Full Warranty Period: TBD Product Disposition: TBD Production Life Support: TBD Service Strategy: Factory Repair

System – Perf Reqs: Modes of Operation l Requirement Power Modes l Definition ON/OFF, ON/AC, ON/Battery

System – Perf Reqs: Modes of Operation l Requirement Power Modes l Definition ON/OFF, ON/AC, ON/Battery

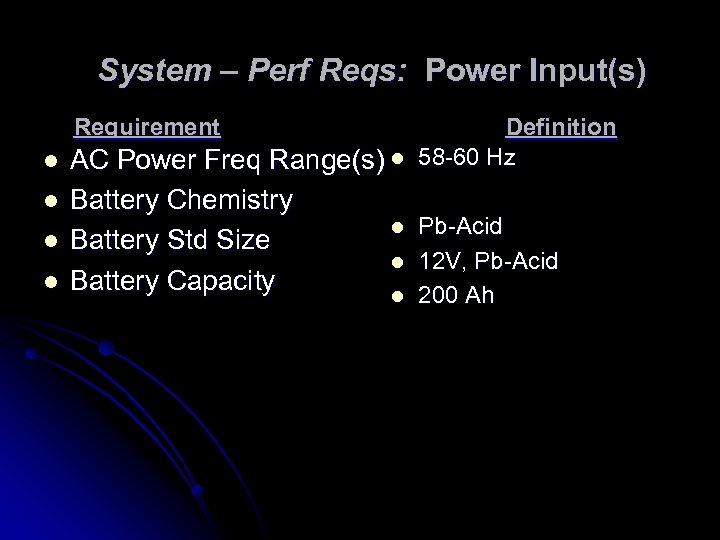

System – Perf Reqs: Power Input(s) Requirement l l AC Power Freq Range(s) l Battery Chemistry l Battery Std Size l Battery Capacity l Definition 58 -60 Hz Pb-Acid 12 V, Pb-Acid 200 Ah

System – Perf Reqs: Power Input(s) Requirement l l AC Power Freq Range(s) l Battery Chemistry l Battery Std Size l Battery Capacity l Definition 58 -60 Hz Pb-Acid 12 V, Pb-Acid 200 Ah

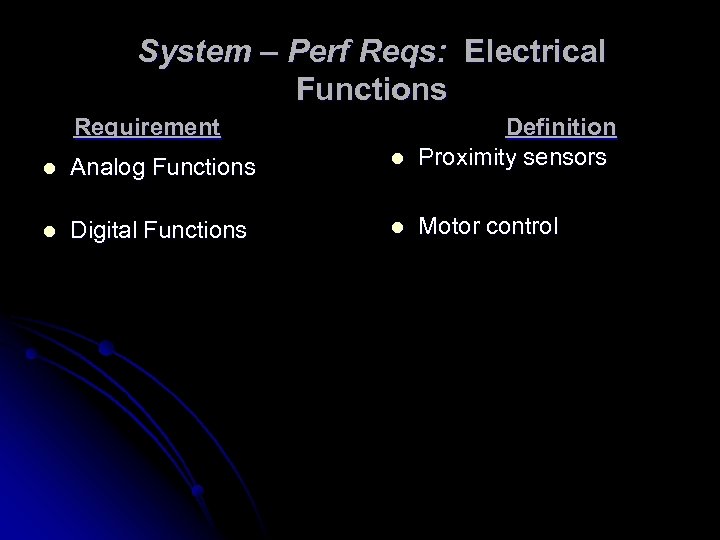

System – Perf Reqs: Electrical Functions Requirement l Analog Functions l Definition Proximity sensors l Digital Functions l Motor control

System – Perf Reqs: Electrical Functions Requirement l Analog Functions l Definition Proximity sensors l Digital Functions l Motor control

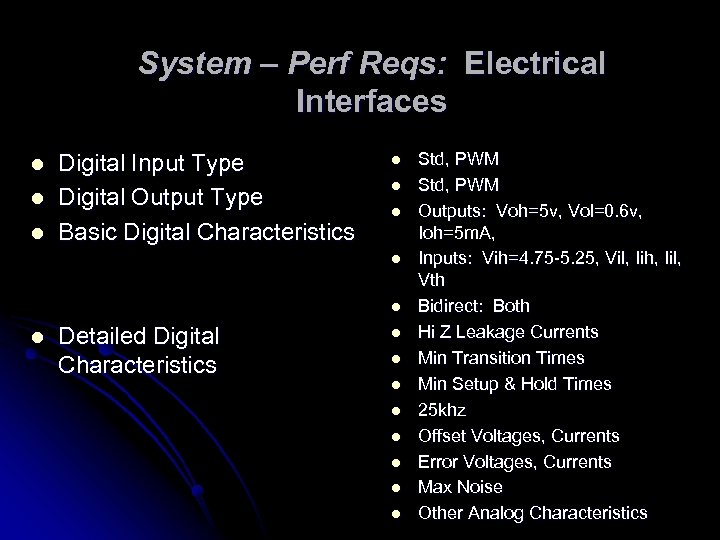

System – Perf Reqs: Electrical Interfaces l l l Digital Input Type Digital Output Type Basic Digital Characteristics l l l Detailed Digital Characteristics l l l l Std, PWM Outputs: Voh=5 v, Vol=0. 6 v, Ioh=5 m. A, Inputs: Vih=4. 75 -5. 25, Vil, Iih, Iil, Vth Bidirect: Both Hi Z Leakage Currents Min Transition Times Min Setup & Hold Times 25 khz Offset Voltages, Currents Error Voltages, Currents Max Noise Other Analog Characteristics

System – Perf Reqs: Electrical Interfaces l l l Digital Input Type Digital Output Type Basic Digital Characteristics l l l Detailed Digital Characteristics l l l l Std, PWM Outputs: Voh=5 v, Vol=0. 6 v, Ioh=5 m. A, Inputs: Vih=4. 75 -5. 25, Vil, Iih, Iil, Vth Bidirect: Both Hi Z Leakage Currents Min Transition Times Min Setup & Hold Times 25 khz Offset Voltages, Currents Error Voltages, Currents Max Noise Other Analog Characteristics

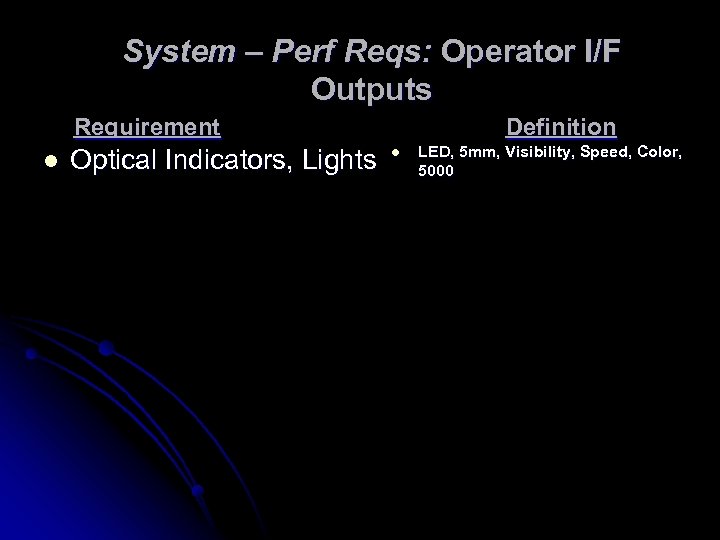

System – Perf Reqs: Operator I/F Outputs Requirement l Optical Indicators, Lights Definition l LED, 5 mm, Visibility, Speed, Color, 5000

System – Perf Reqs: Operator I/F Outputs Requirement l Optical Indicators, Lights Definition l LED, 5 mm, Visibility, Speed, Color, 5000

System – Perf Reqs: Operator I/F Inputs l Requirement RF controller Definition l Remote control, guides vehicle and lights.

System – Perf Reqs: Operator I/F Inputs l Requirement RF controller Definition l Remote control, guides vehicle and lights.

System – Perf Reqs: Mech Interfaces l Requirement Mounting l Definition Brackets, Clamps. l Carry Handles l None l Sensory l Distance l Connectors l AC Plug

System – Perf Reqs: Mech Interfaces l Requirement Mounting l Definition Brackets, Clamps. l Carry Handles l None l Sensory l Distance l Connectors l AC Plug

Key Risk Areas Electrical Shock l Pb-Acid spill/poisoning l Short Circuit Fire l Injury due to misuse l

Key Risk Areas Electrical Shock l Pb-Acid spill/poisoning l Short Circuit Fire l Injury due to misuse l

US Patents • • • Patent 7107075 Wireless Communications Methods & systems Using A Remote, Self Contained Antenna Unit. (Sep 12, 2006) Patent D 528673 LED light bulb (Sep 19, 2006) Patent D 528469 Automobile & Toy Replica (Sep 19, 2006)

US Patents • • • Patent 7107075 Wireless Communications Methods & systems Using A Remote, Self Contained Antenna Unit. (Sep 12, 2006) Patent D 528673 LED light bulb (Sep 19, 2006) Patent D 528469 Automobile & Toy Replica (Sep 19, 2006)