321c7bab9a1118d1e03b527b6afff3e4.ppt

- Количество слайдов: 55

TEA Systems Products Critical Feature and Process Tuning Software Weir PW Weir PSFM Calibration Weir PSFM Fixed-Focus Weir TR Vector Raptor Weir DMA 65 Schlossburg St. Alburtis, PA 18011 (+1) 610 682 4146 tzavecz@TEAsystems. com http: //www. TEAsystems. com Ver: 1 -June-2007

TEA Systems Products Critical Feature and Process Tuning Software Weir PW Weir PSFM Calibration Weir PSFM Fixed-Focus Weir TR Vector Raptor Weir DMA 65 Schlossburg St. Alburtis, PA 18011 (+1) 610 682 4146 tzavecz@TEAsystems. com http: //www. TEAsystems. com Ver: 1 -June-2007

2 Outline • Products from TEA Systems – – – Vector Raptor Weir PW Weir TR Weir PSFM Calibration Weir PSFM Fixed Focus Weir DM and Weir DMA • Product Features • Applications – Addressed by each product • System Requirements • License Basis • Sample Wafer Plots 2007 TEA Systems Products TEA Systems

2 Outline • Products from TEA Systems – – – Vector Raptor Weir PW Weir TR Weir PSFM Calibration Weir PSFM Fixed Focus Weir DM and Weir DMA • Product Features • Applications – Addressed by each product • System Requirements • License Basis • Sample Wafer Plots 2007 TEA Systems Products TEA Systems

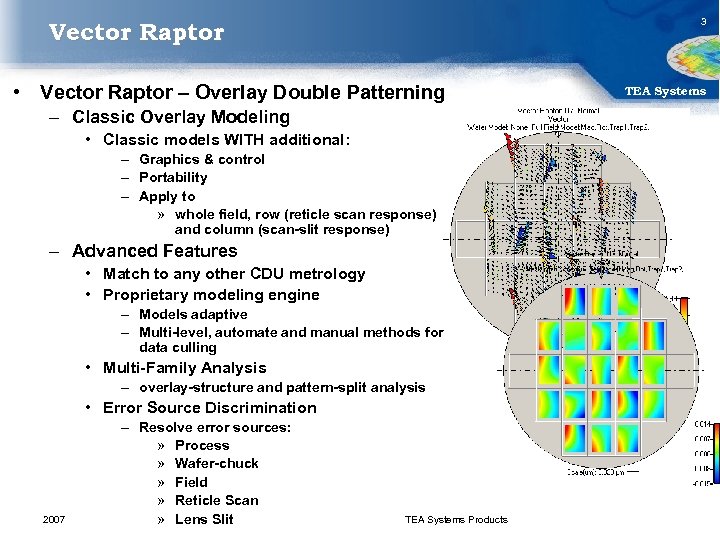

3 Vector Raptor • Vector Raptor – Overlay Double Patterning – Classic Overlay Modeling • Classic models WITH additional: – Graphics & control – Portability – Apply to » whole field, row (reticle scan response) and column (scan-slit response) – Advanced Features • Match to any other CDU metrology • Proprietary modeling engine – Models adaptive – Multi-level, automate and manual methods for data culling • Multi-Family Analysis – overlay-structure and pattern-split analysis • Error Source Discrimination 2007 – Resolve error sources: » Process » Wafer-chuck » Field » Reticle Scan » Lens Slit TEA Systems Products TEA Systems

3 Vector Raptor • Vector Raptor – Overlay Double Patterning – Classic Overlay Modeling • Classic models WITH additional: – Graphics & control – Portability – Apply to » whole field, row (reticle scan response) and column (scan-slit response) – Advanced Features • Match to any other CDU metrology • Proprietary modeling engine – Models adaptive – Multi-level, automate and manual methods for data culling • Multi-Family Analysis – overlay-structure and pattern-split analysis • Error Source Discrimination 2007 – Resolve error sources: » Process » Wafer-chuck » Field » Reticle Scan » Lens Slit TEA Systems Products TEA Systems

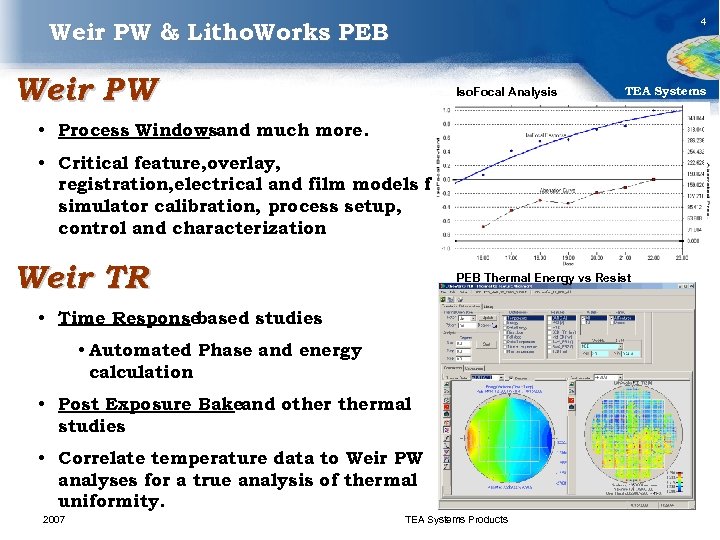

4 Weir PW & Litho. Works PEB Weir PW Iso. Focal Analysis TEA Systems • Process Windowsand much more. • Critical feature, overlay, registration, electrical and film models for simulator calibration, process setup, control and characterization Weir TR PEB Thermal Energy vs Resist • Time Response based studies • Automated Phase and energy calculation • Post Exposure Bakeand othermal studies • Correlate temperature data to Weir PW analyses for a true analysis of thermal uniformity. 2007 TEA Systems Products

4 Weir PW & Litho. Works PEB Weir PW Iso. Focal Analysis TEA Systems • Process Windowsand much more. • Critical feature, overlay, registration, electrical and film models for simulator calibration, process setup, control and characterization Weir TR PEB Thermal Energy vs Resist • Time Response based studies • Automated Phase and energy calculation • Post Exposure Bakeand othermal studies • Correlate temperature data to Weir PW analyses for a true analysis of thermal uniformity. 2007 TEA Systems Products

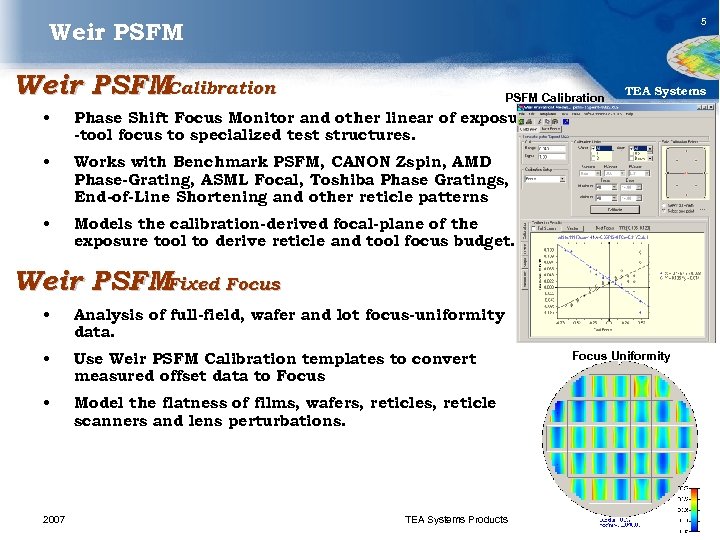

5 Weir PSFMCalibration PSFM Calibration • Phase Shift Focus Monitor and other linear of exposure -tool focus to specialized test structures. • Works with Benchmark PSFM, CANON Zspin, AMD Phase-Grating, ASML Focal, Toshiba Phase Gratings, End-of-Line Shortening and other reticle patterns • TEA Systems Models the calibration-derived focal-plane of the exposure tool to derive reticle and tool focus budget. Weir PSFMFixed Focus • Analysis of full-field, wafer and lot focus-uniformity data. • Use Weir PSFM Calibration templates to convert measured offset data to Focus • Model the flatness of films, wafers, reticle scanners and lens perturbations. 2007 TEA Systems Products Focus Uniformity

5 Weir PSFMCalibration PSFM Calibration • Phase Shift Focus Monitor and other linear of exposure -tool focus to specialized test structures. • Works with Benchmark PSFM, CANON Zspin, AMD Phase-Grating, ASML Focal, Toshiba Phase Gratings, End-of-Line Shortening and other reticle patterns • TEA Systems Models the calibration-derived focal-plane of the exposure tool to derive reticle and tool focus budget. Weir PSFMFixed Focus • Analysis of full-field, wafer and lot focus-uniformity data. • Use Weir PSFM Calibration templates to convert measured offset data to Focus • Model the flatness of films, wafers, reticle scanners and lens perturbations. 2007 TEA Systems Products Focus Uniformity

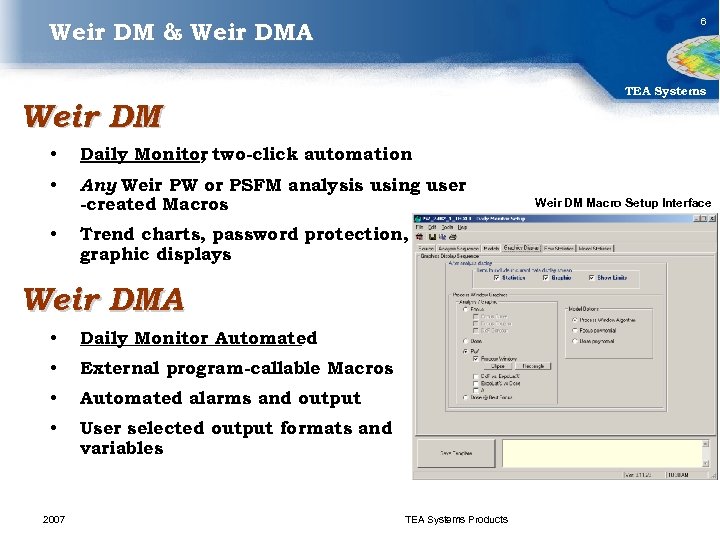

6 Weir DM & Weir DMA TEA Systems Weir DM • Daily Monitor two-click automation , • Any Weir PW or PSFM analysis using user -created Macros • Trend charts, password protection, graphic displays Weir DMA • Daily Monitor Automated • External program-callable Macros • Automated alarms and output • User selected output formats and variables 2007 TEA Systems Products Weir DM Macro Setup Interface

6 Weir DM & Weir DMA TEA Systems Weir DM • Daily Monitor two-click automation , • Any Weir PW or PSFM analysis using user -created Macros • Trend charts, password protection, graphic displays Weir DMA • Daily Monitor Automated • External program-callable Macros • Automated alarms and output • User selected output formats and variables 2007 TEA Systems Products Weir DM Macro Setup Interface

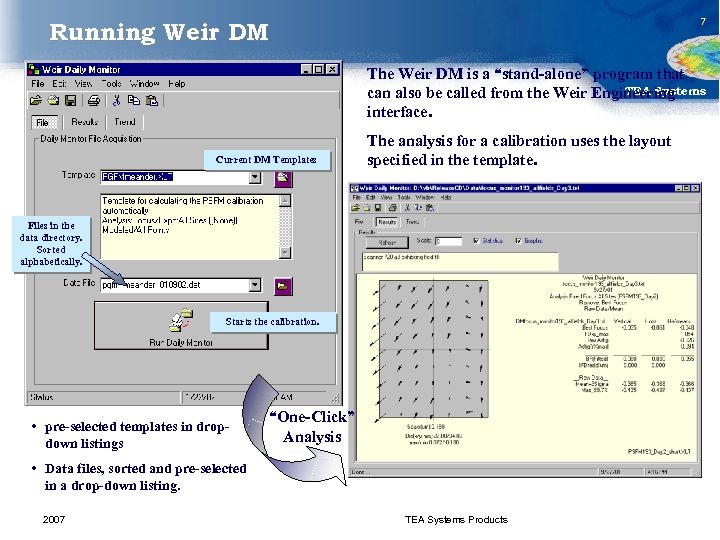

7 Running Weir DM The Weir DM is a “stand-alone” program that TEA Systems can also be called from the Weir Engineering interface. Current DM Templates The analysis for a calibration uses the layout specified in the template. Files in the data directory. Sorted alphabetically. Starts the calibration. • pre-selected templates in dropdown listings “One-Click” Analysis • Data files, sorted and pre-selected in a drop-down listing. 2007 TEA Systems Products

7 Running Weir DM The Weir DM is a “stand-alone” program that TEA Systems can also be called from the Weir Engineering interface. Current DM Templates The analysis for a calibration uses the layout specified in the template. Files in the data directory. Sorted alphabetically. Starts the calibration. • pre-selected templates in dropdown listings “One-Click” Analysis • Data files, sorted and pre-selected in a drop-down listing. 2007 TEA Systems Products

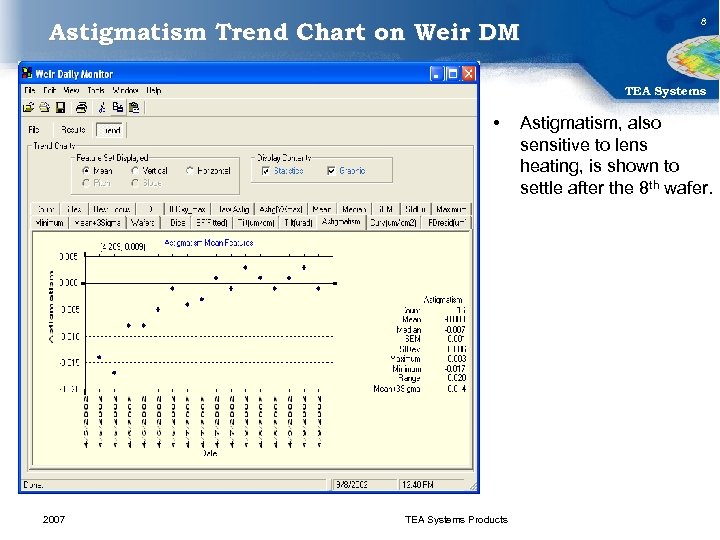

Astigmatism Trend Chart on Weir DM 8 TEA Systems • 2007 TEA Systems Products Astigmatism, also sensitive to lens heating, is shown to settle after the 8 th wafer.

Astigmatism Trend Chart on Weir DM 8 TEA Systems • 2007 TEA Systems Products Astigmatism, also sensitive to lens heating, is shown to settle after the 8 th wafer.

9 Outline: Product Features • Products from TEA Systems • General Product Features – – – – Data Import Graphics Features 2 D Graphics 3 D Graphics General Analyses Data Tools Retention & Reporting • Applications – As addressed by each product • System Requirements • License Basis 2007 TEA Systems Products TEA Systems

9 Outline: Product Features • Products from TEA Systems • General Product Features – – – – Data Import Graphics Features 2 D Graphics 3 D Graphics General Analyses Data Tools Retention & Reporting • Applications – As addressed by each product • System Requirements • License Basis 2007 TEA Systems Products TEA Systems

10 Data Import Features TEA Systems • Import ANY metrology – If we don’t have the import now, we will create it • Focus-Exposure excel spreadsheets • Overlay, film-thickness, profile, Cdsem, electrical test, etc. • Open data format – Microsoft Excel Workbooks • A unique Weir Workbook is created for each dataset • Any number of variables • Any size dataset 2007 • Weir imports data from any ASCII, Binary or database. • After import, data is converted into a standard Weir format Excel Workbook. • Workbook Stores – – Intermediate analysis data, analysis reports, Graphics Derived datasets • HTML delivery – Weir Worksheets can be saved as HTM or HTML files for internet display TEA Systems Products

10 Data Import Features TEA Systems • Import ANY metrology – If we don’t have the import now, we will create it • Focus-Exposure excel spreadsheets • Overlay, film-thickness, profile, Cdsem, electrical test, etc. • Open data format – Microsoft Excel Workbooks • A unique Weir Workbook is created for each dataset • Any number of variables • Any size dataset 2007 • Weir imports data from any ASCII, Binary or database. • After import, data is converted into a standard Weir format Excel Workbook. • Workbook Stores – – Intermediate analysis data, analysis reports, Graphics Derived datasets • HTML delivery – Weir Worksheets can be saved as HTM or HTML files for internet display TEA Systems Products

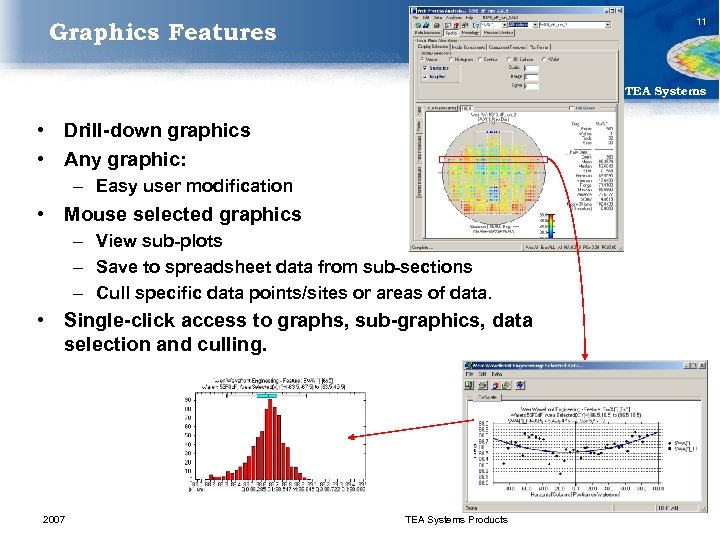

11 Graphics Features TEA Systems • Drill-down graphics • Any graphic: – Easy user modification • Mouse selected graphics – View sub-plots – Save to spreadsheet data from sub-sections – Cull specific data points/sites or areas of data. • Single-click access to graphs, sub-graphics, data selection and culling. 2007 TEA Systems Products

11 Graphics Features TEA Systems • Drill-down graphics • Any graphic: – Easy user modification • Mouse selected graphics – View sub-plots – Save to spreadsheet data from sub-sections – Cull specific data points/sites or areas of data. • Single-click access to graphs, sub-graphics, data selection and culling. 2007 TEA Systems Products

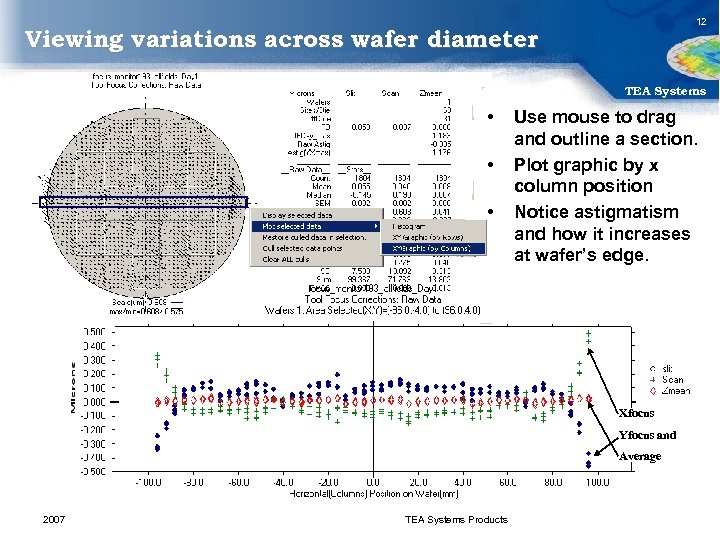

12 Viewing variations across wafer diameter TEA Systems • • • Use mouse to drag and outline a section. Plot graphic by x column position Notice astigmatism and how it increases at wafer’s edge. Xfocus Yfocus and Average 2007 TEA Systems Products

12 Viewing variations across wafer diameter TEA Systems • • • Use mouse to drag and outline a section. Plot graphic by x column position Notice astigmatism and how it increases at wafer’s edge. Xfocus Yfocus and Average 2007 TEA Systems Products

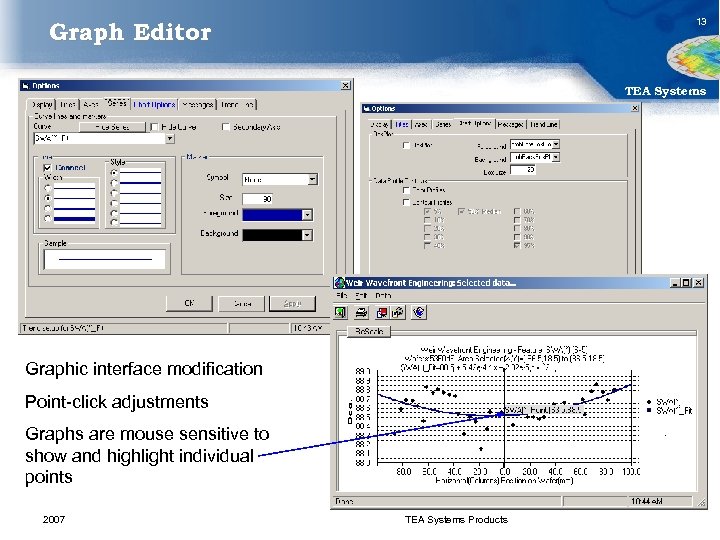

13 Graph Editor TEA Systems Graphic interface modification Point-click adjustments Graphs are mouse sensitive to show and highlight individual points 2007 TEA Systems Products

13 Graph Editor TEA Systems Graphic interface modification Point-click adjustments Graphs are mouse sensitive to show and highlight individual points 2007 TEA Systems Products

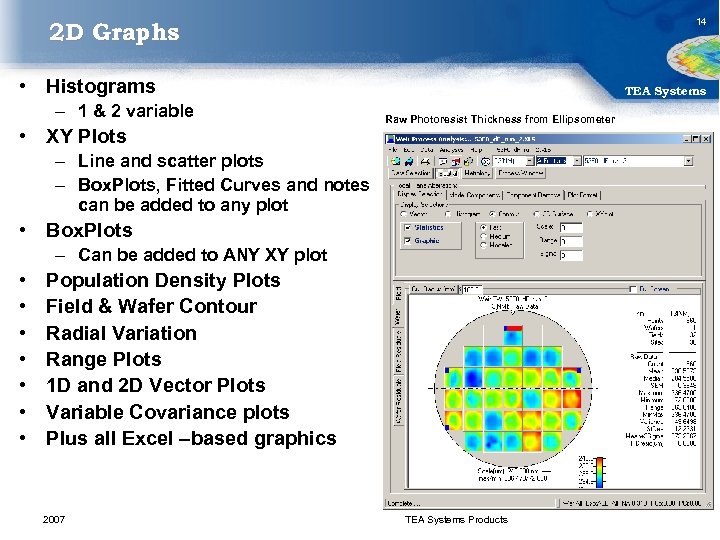

14 2 D Graphs • Histograms – 1 & 2 variable • XY Plots TEA Systems Raw Photoresist Thickness from Ellipsometer – Line and scatter plots – Box. Plots, Fitted Curves and notes can be added to any plot • Box. Plots – Can be added to ANY XY plot • • Population Density Plots Field & Wafer Contour Radial Variation Range Plots 1 D and 2 D Vector Plots Variable Covariance plots Plus all Excel –based graphics 2007 TEA Systems Products

14 2 D Graphs • Histograms – 1 & 2 variable • XY Plots TEA Systems Raw Photoresist Thickness from Ellipsometer – Line and scatter plots – Box. Plots, Fitted Curves and notes can be added to any plot • Box. Plots – Can be added to ANY XY plot • • Population Density Plots Field & Wafer Contour Radial Variation Range Plots 1 D and 2 D Vector Plots Variable Covariance plots Plus all Excel –based graphics 2007 TEA Systems Products

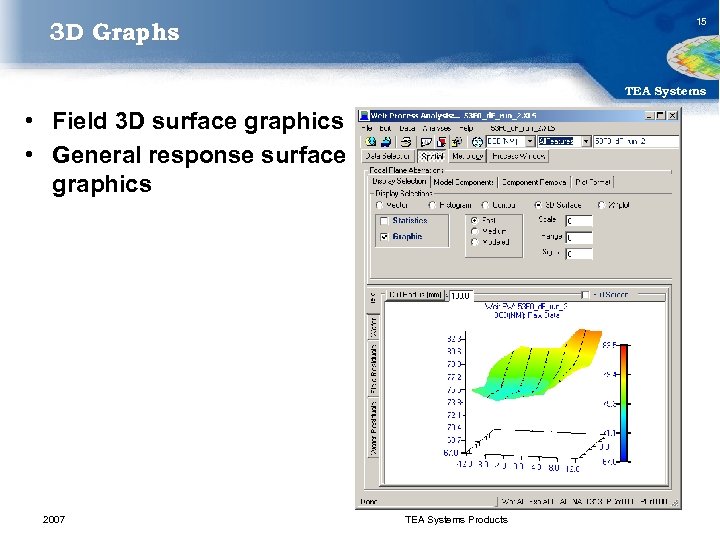

15 3 D Graphs TEA Systems • Field 3 D surface graphics • General response surface graphics 2007 TEA Systems Products

15 3 D Graphs TEA Systems • Field 3 D surface graphics • General response surface graphics 2007 TEA Systems Products

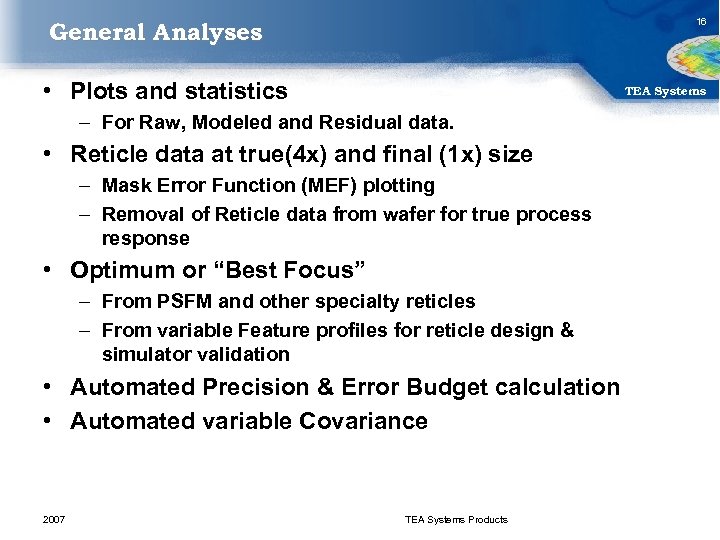

16 General Analyses • Plots and statistics TEA Systems – For Raw, Modeled and Residual data. • Reticle data at true(4 x) and final (1 x) size – Mask Error Function (MEF) plotting – Removal of Reticle data from wafer for true process response • Optimum or “Best Focus” – From PSFM and other specialty reticles – From variable Feature profiles for reticle design & simulator validation • Automated Precision & Error Budget calculation • Automated variable Covariance 2007 TEA Systems Products

16 General Analyses • Plots and statistics TEA Systems – For Raw, Modeled and Residual data. • Reticle data at true(4 x) and final (1 x) size – Mask Error Function (MEF) plotting – Removal of Reticle data from wafer for true process response • Optimum or “Best Focus” – From PSFM and other specialty reticles – From variable Feature profiles for reticle design & simulator validation • Automated Precision & Error Budget calculation • Automated variable Covariance 2007 TEA Systems Products

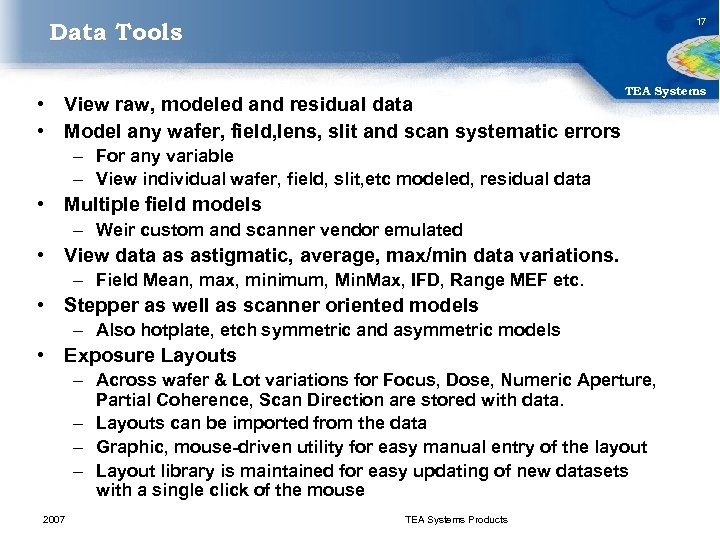

17 Data Tools • View raw, modeled and residual data • Model any wafer, field, lens, slit and scan systematic errors TEA Systems – For any variable – View individual wafer, field, slit, etc modeled, residual data • Multiple field models – Weir custom and scanner vendor emulated • View data as astigmatic, average, max/min data variations. – Field Mean, max, minimum, Min. Max, IFD, Range MEF etc. • Stepper as well as scanner oriented models – Also hotplate, etch symmetric and asymmetric models • Exposure Layouts – Across wafer & Lot variations for Focus, Dose, Numeric Aperture, Partial Coherence, Scan Direction are stored with data. – Layouts can be imported from the data – Graphic, mouse-driven utility for easy manual entry of the layout – Layout library is maintained for easy updating of new datasets with a single click of the mouse 2007 TEA Systems Products

17 Data Tools • View raw, modeled and residual data • Model any wafer, field, lens, slit and scan systematic errors TEA Systems – For any variable – View individual wafer, field, slit, etc modeled, residual data • Multiple field models – Weir custom and scanner vendor emulated • View data as astigmatic, average, max/min data variations. – Field Mean, max, minimum, Min. Max, IFD, Range MEF etc. • Stepper as well as scanner oriented models – Also hotplate, etch symmetric and asymmetric models • Exposure Layouts – Across wafer & Lot variations for Focus, Dose, Numeric Aperture, Partial Coherence, Scan Direction are stored with data. – Layouts can be imported from the data – Graphic, mouse-driven utility for easy manual entry of the layout – Layout library is maintained for easy updating of new datasets with a single click of the mouse 2007 TEA Systems Products

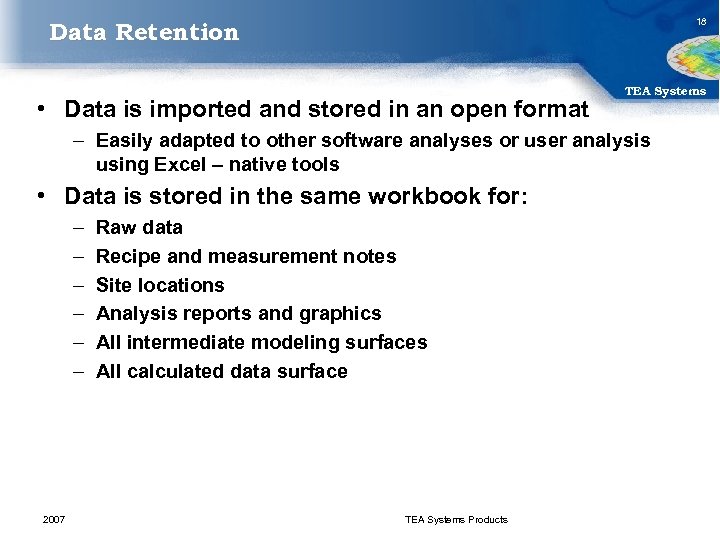

18 Data Retention • Data is imported and stored in an open format TEA Systems – Easily adapted to other software analyses or user analysis using Excel – native tools • Data is stored in the same workbook for: – – – 2007 Raw data Recipe and measurement notes Site locations Analysis reports and graphics All intermediate modeling surfaces All calculated data surface TEA Systems Products

18 Data Retention • Data is imported and stored in an open format TEA Systems – Easily adapted to other software analyses or user analysis using Excel – native tools • Data is stored in the same workbook for: – – – 2007 Raw data Recipe and measurement notes Site locations Analysis reports and graphics All intermediate modeling surfaces All calculated data surface TEA Systems Products

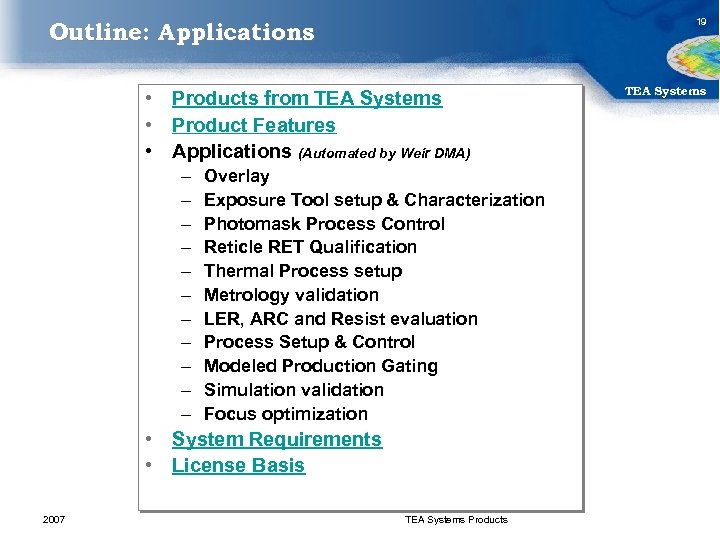

19 Outline: Applications • Products from TEA Systems • Product Features • Applications (Automated by Weir DMA) – – – Overlay Exposure Tool setup & Characterization Photomask Process Control Reticle RET Qualification Thermal Process setup Metrology validation LER, ARC and Resist evaluation Process Setup & Control Modeled Production Gating Simulation validation Focus optimization • System Requirements • License Basis 2007 TEA Systems Products TEA Systems

19 Outline: Applications • Products from TEA Systems • Product Features • Applications (Automated by Weir DMA) – – – Overlay Exposure Tool setup & Characterization Photomask Process Control Reticle RET Qualification Thermal Process setup Metrology validation LER, ARC and Resist evaluation Process Setup & Control Modeled Production Gating Simulation validation Focus optimization • System Requirements • License Basis 2007 TEA Systems Products TEA Systems

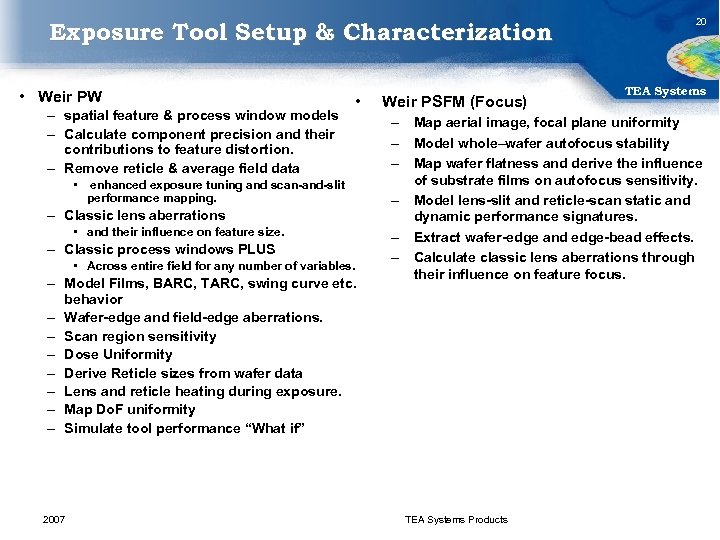

Exposure Tool Setup & Characterization • Weir PW – spatial feature & process window models – Calculate component precision and their contributions to feature distortion. – Remove reticle & average field data • • enhanced exposure tuning and scan-and-slit performance mapping. – Classic lens aberrations • and their influence on feature size. – Classic process windows PLUS • Across entire field for any number of variables. – Model Films, BARC, TARC, swing curve etc. behavior – Wafer-edge and field-edge aberrations. – Scan region sensitivity – Dose Uniformity – Derive Reticle sizes from wafer data – Lens and reticle heating during exposure. – Map Do. F uniformity – Simulate tool performance “What if” 2007 Weir PSFM (Focus) 20 TEA Systems – Map aerial image, focal plane uniformity – Model whole–wafer autofocus stability – Map wafer flatness and derive the influence of substrate films on autofocus sensitivity. – Model lens-slit and reticle-scan static and dynamic performance signatures. – Extract wafer-edge and edge-bead effects. – Calculate classic lens aberrations through their influence on feature focus. TEA Systems Products

Exposure Tool Setup & Characterization • Weir PW – spatial feature & process window models – Calculate component precision and their contributions to feature distortion. – Remove reticle & average field data • • enhanced exposure tuning and scan-and-slit performance mapping. – Classic lens aberrations • and their influence on feature size. – Classic process windows PLUS • Across entire field for any number of variables. – Model Films, BARC, TARC, swing curve etc. behavior – Wafer-edge and field-edge aberrations. – Scan region sensitivity – Dose Uniformity – Derive Reticle sizes from wafer data – Lens and reticle heating during exposure. – Map Do. F uniformity – Simulate tool performance “What if” 2007 Weir PSFM (Focus) 20 TEA Systems – Map aerial image, focal plane uniformity – Model whole–wafer autofocus stability – Map wafer flatness and derive the influence of substrate films on autofocus sensitivity. – Model lens-slit and reticle-scan static and dynamic performance signatures. – Extract wafer-edge and edge-bead effects. – Calculate classic lens aberrations through their influence on feature focus. TEA Systems Products

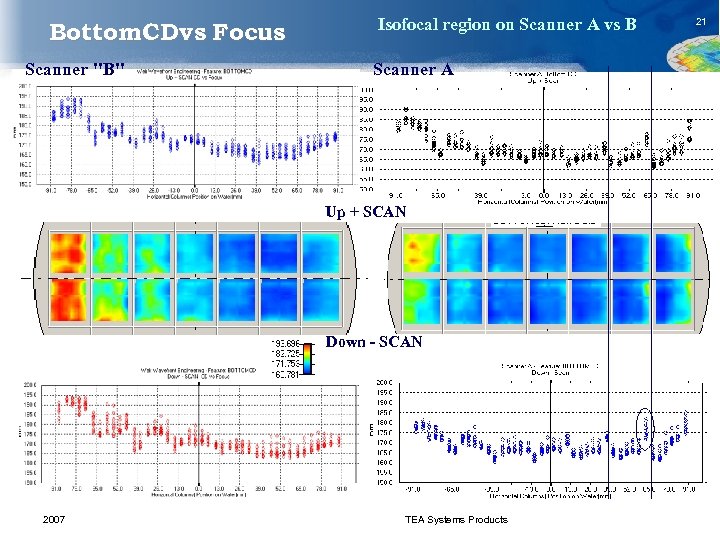

Bottom. CDvs Focus Scanner "B" Isofocal region on Scanner A vs B 21 Scanner A TEA Systems Up + SCAN Down - SCAN 2007 TEA Systems Products

Bottom. CDvs Focus Scanner "B" Isofocal region on Scanner A vs B 21 Scanner A TEA Systems Up + SCAN Down - SCAN 2007 TEA Systems Products

22 Photomask Process Control • Weir PW – – TEA Systems Metrology from any data source or manual entry Process Windows, Bossung Plots etc. Model etch uniformity from scatterometry Model feature profiles and etch depth • Correlate to wafer response across the process window – Encapsulate data • standard format for the wafer-fabrication engineer • Provides a valuable commodity by giving the wafer engineer a reticle signature library entry for: – – 2007 Reticle design qualification Reticle use re-validation Wafer process setup thru reticle signature removal Tool setup for thermal bake and exposure-tool reticle bending TEA Systems Products

22 Photomask Process Control • Weir PW – – TEA Systems Metrology from any data source or manual entry Process Windows, Bossung Plots etc. Model etch uniformity from scatterometry Model feature profiles and etch depth • Correlate to wafer response across the process window – Encapsulate data • standard format for the wafer-fabrication engineer • Provides a valuable commodity by giving the wafer engineer a reticle signature library entry for: – – 2007 Reticle design qualification Reticle use re-validation Wafer process setup thru reticle signature removal Tool setup for thermal bake and exposure-tool reticle bending TEA Systems Products

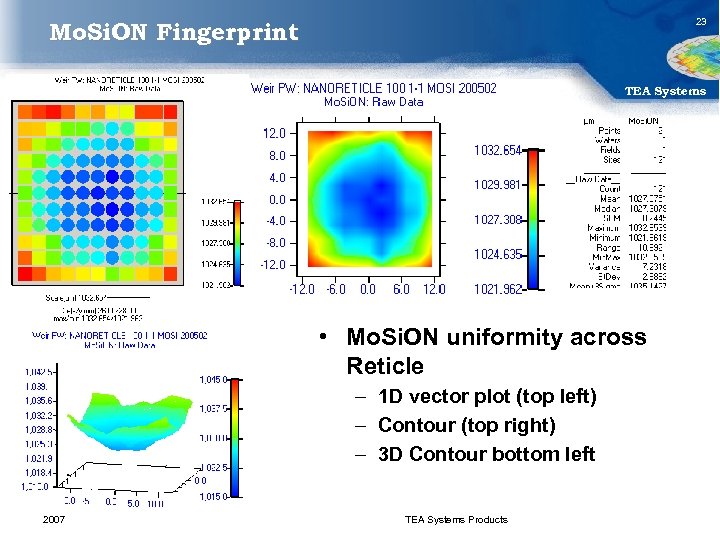

23 Mo. Si. ON Fingerprint TEA Systems • Mo. Si. ON uniformity across Reticle – 1 D vector plot (top left) – Contour (top right) – 3 D Contour bottom left 2007 TEA Systems Products

23 Mo. Si. ON Fingerprint TEA Systems • Mo. Si. ON uniformity across Reticle – 1 D vector plot (top left) – Contour (top right) – 3 D Contour bottom left 2007 TEA Systems Products

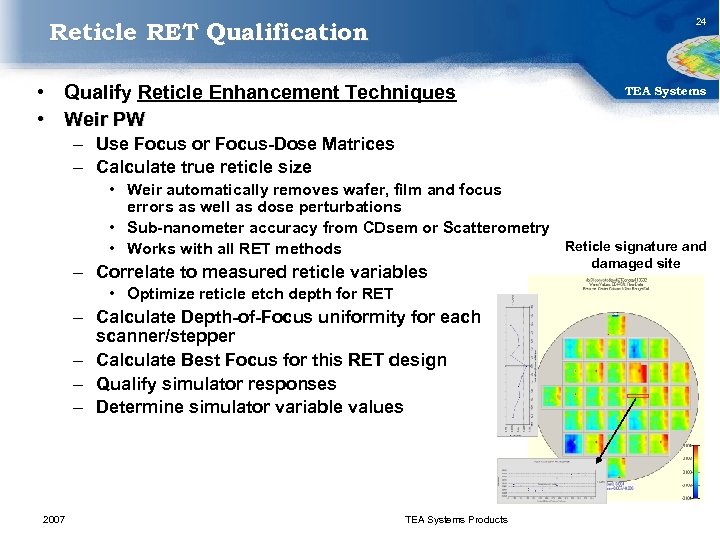

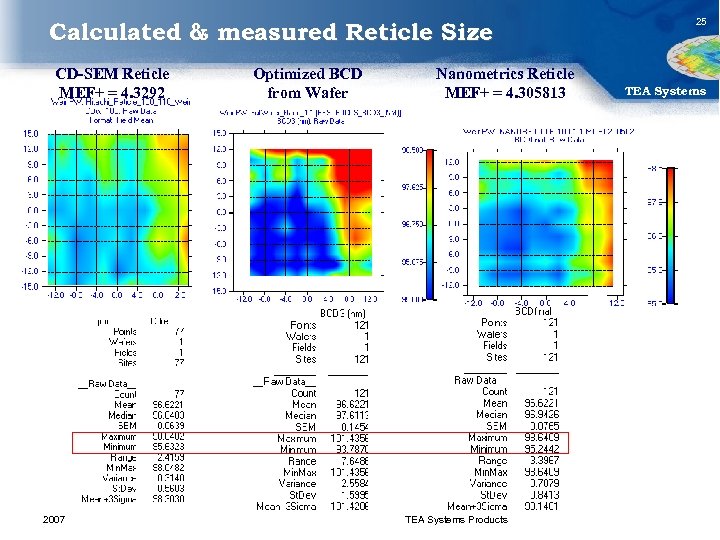

24 Reticle RET Qualification • Qualify Reticle Enhancement Techniques • Weir PW TEA Systems – Use Focus or Focus-Dose Matrices – Calculate true reticle size • Weir automatically removes wafer, film and focus errors as well as dose perturbations • Sub-nanometer accuracy from CDsem or Scatterometry Reticle signature and • Works with all RET methods – Correlate to measured reticle variables • Optimize reticle etch depth for RET – Calculate Depth-of-Focus uniformity for each scanner/stepper – Calculate Best Focus for this RET design – Qualify simulator responses – Determine simulator variable values 2007 TEA Systems Products damaged site

24 Reticle RET Qualification • Qualify Reticle Enhancement Techniques • Weir PW TEA Systems – Use Focus or Focus-Dose Matrices – Calculate true reticle size • Weir automatically removes wafer, film and focus errors as well as dose perturbations • Sub-nanometer accuracy from CDsem or Scatterometry Reticle signature and • Works with all RET methods – Correlate to measured reticle variables • Optimize reticle etch depth for RET – Calculate Depth-of-Focus uniformity for each scanner/stepper – Calculate Best Focus for this RET design – Qualify simulator responses – Determine simulator variable values 2007 TEA Systems Products damaged site

Calculated & measured Reticle Size CD-SEM Reticle MEF+ = 4. 3292 2007 Optimized BCD from Wafer Nanometrics Reticle MEF+ = 4. 305813 TEA Systems Products 25 TEA Systems

Calculated & measured Reticle Size CD-SEM Reticle MEF+ = 4. 3292 2007 Optimized BCD from Wafer Nanometrics Reticle MEF+ = 4. 305813 TEA Systems Products 25 TEA Systems

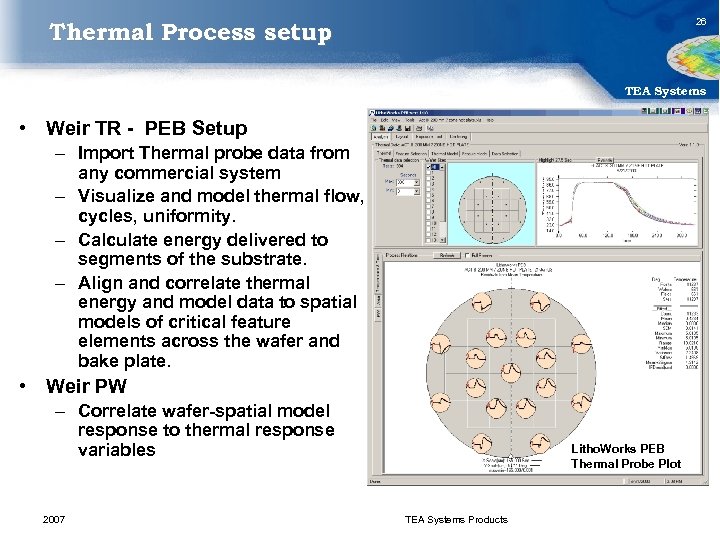

26 Thermal Process setup TEA Systems • Weir TR - PEB Setup – Import Thermal probe data from any commercial system – Visualize and model thermal flow, cycles, uniformity. – Calculate energy delivered to segments of the substrate. – Align and correlate thermal energy and model data to spatial models of critical feature elements across the wafer and bake plate. • Weir PW – Correlate wafer-spatial model response to thermal response variables 2007 Litho. Works PEB Thermal Probe Plot TEA Systems Products

26 Thermal Process setup TEA Systems • Weir TR - PEB Setup – Import Thermal probe data from any commercial system – Visualize and model thermal flow, cycles, uniformity. – Calculate energy delivered to segments of the substrate. – Align and correlate thermal energy and model data to spatial models of critical feature elements across the wafer and bake plate. • Weir PW – Correlate wafer-spatial model response to thermal response variables 2007 Litho. Works PEB Thermal Probe Plot TEA Systems Products

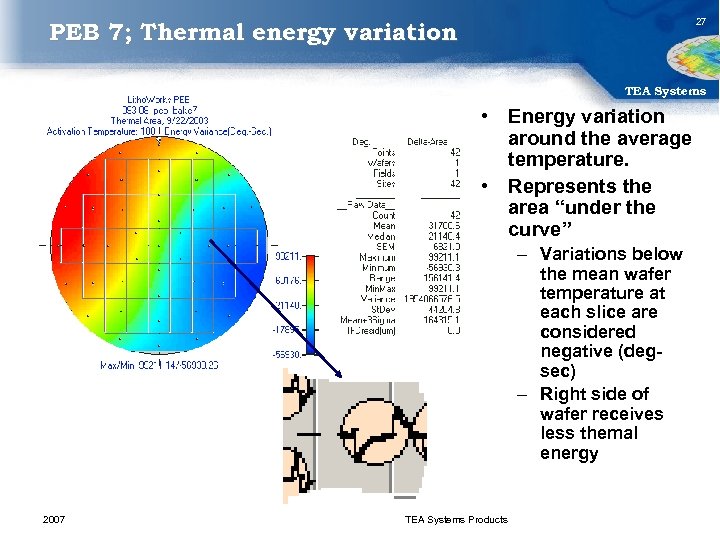

27 PEB 7; Thermal energy variation TEA Systems • Energy variation around the average temperature. • Represents the area “under the curve” – Variations below the mean wafer temperature at each slice are considered negative (degsec) – Right side of wafer receives less themal energy 2007 TEA Systems Products

27 PEB 7; Thermal energy variation TEA Systems • Energy variation around the average temperature. • Represents the area “under the curve” – Variations below the mean wafer temperature at each slice are considered negative (degsec) – Right side of wafer receives less themal energy 2007 TEA Systems Products

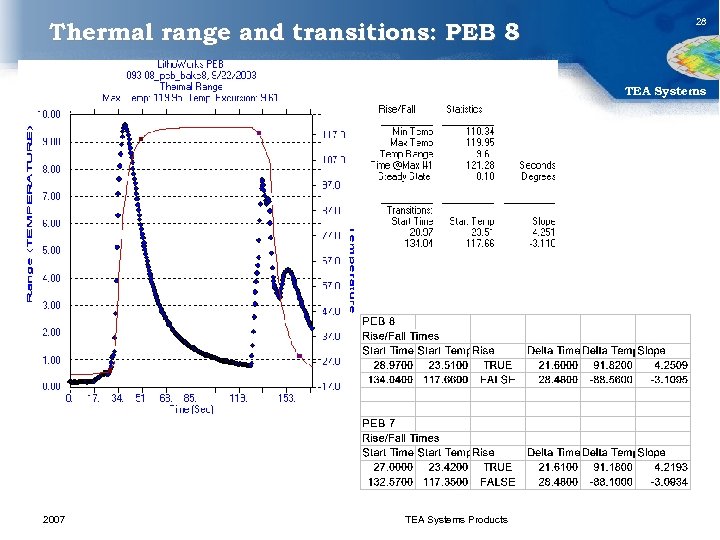

Thermal range and transitions: PEB 8 28 TEA Systems 2007 TEA Systems Products

Thermal range and transitions: PEB 8 28 TEA Systems 2007 TEA Systems Products

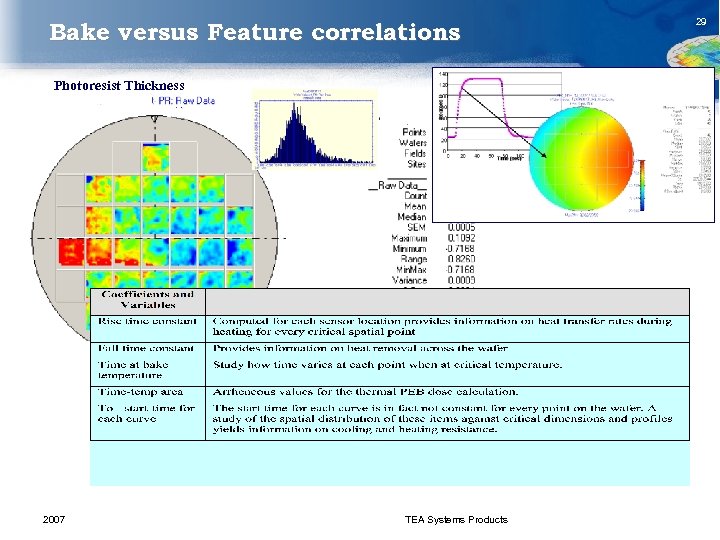

Bake versus Feature correlations Photoresist Thickness 2007 29 TEA Systems Products

Bake versus Feature correlations Photoresist Thickness 2007 29 TEA Systems Products

30 Metrology validation TEA Systems • Weir PW – Validate scatterometry model range and repeatability – Calculate metrology tool precision – Determine the limits of metrology tool variation 2007 TEA Systems Products

30 Metrology validation TEA Systems • Weir PW – Validate scatterometry model range and repeatability – Calculate metrology tool precision – Determine the limits of metrology tool variation 2007 TEA Systems Products

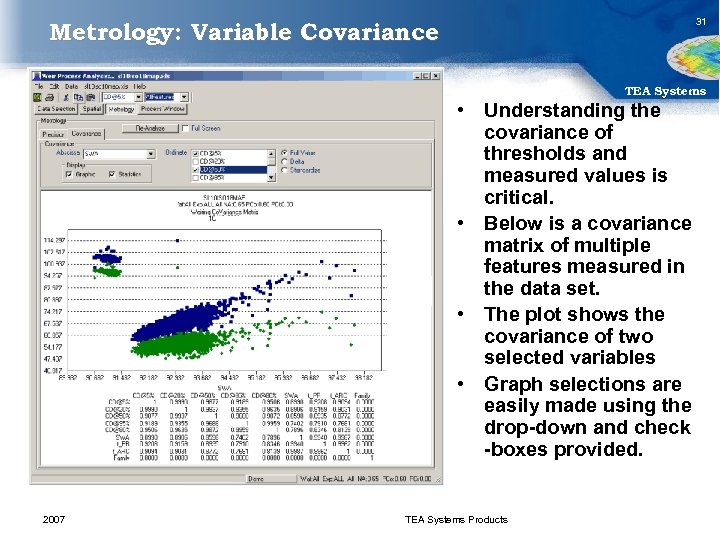

31 Metrology: Variable Covariance TEA Systems Top & bottom die sites 2007 • Understanding the covariance of thresholds and measured values is critical. • Below is a covariance matrix of multiple features measured in the data set. • The plot shows the covariance of two selected variables • Graph selections are easily made using the drop-down and check -boxes provided. TEA Systems Products

31 Metrology: Variable Covariance TEA Systems Top & bottom die sites 2007 • Understanding the covariance of thresholds and measured values is critical. • Below is a covariance matrix of multiple features measured in the data set. • The plot shows the covariance of two selected variables • Graph selections are easily made using the drop-down and check -boxes provided. TEA Systems Products

32 LER, ARC and Resist evaluation TEA Systems • Weir PW – Use with 4 -point probe, electrical or scatterometry data – Calculate swing curves from normal product data or focus –dose matrices – LER from any CDsem or other linewidth tool • mapped to wafer/field position • Calculate covariance with other metrology variables – ARC thickness and Photoresist optimization • • 2007 Bottom or Top ARC’s Determine thickness changes with focus/dose Calculate changes in optimum focus with ARC type and dose Compare to other brands for process window, influence on Do. F, optimum focus etc. TEA Systems Products

32 LER, ARC and Resist evaluation TEA Systems • Weir PW – Use with 4 -point probe, electrical or scatterometry data – Calculate swing curves from normal product data or focus –dose matrices – LER from any CDsem or other linewidth tool • mapped to wafer/field position • Calculate covariance with other metrology variables – ARC thickness and Photoresist optimization • • 2007 Bottom or Top ARC’s Determine thickness changes with focus/dose Calculate changes in optimum focus with ARC type and dose Compare to other brands for process window, influence on Do. F, optimum focus etc. TEA Systems Products

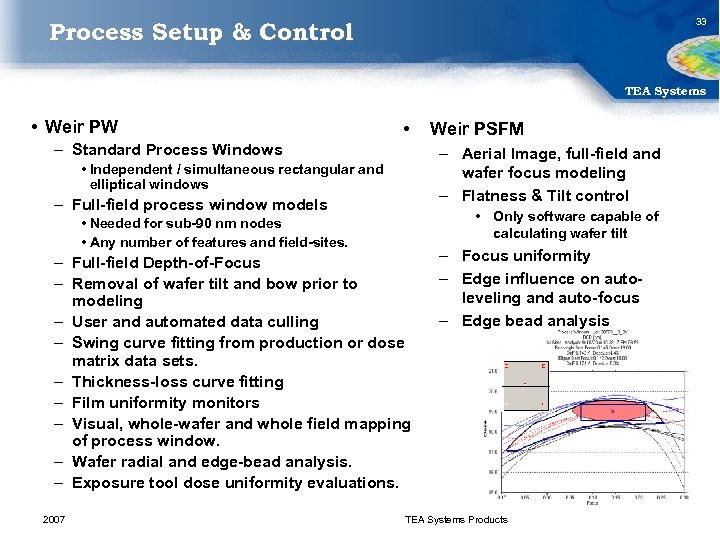

33 Process Setup & Control TEA Systems • Weir PW • – Standard Process Windows – Aerial Image, full-field and wafer focus modeling – Flatness & Tilt control • Independent / simultaneous rectangular and elliptical windows – Full-field process window models • Only software capable of calculating wafer tilt • Needed for sub-90 nm nodes • Any number of features and field-sites. – Full-field Depth-of-Focus – Removal of wafer tilt and bow prior to modeling – User and automated data culling – Swing curve fitting from production or dose matrix data sets. – Thickness-loss curve fitting – Film uniformity monitors – Visual, whole-wafer and whole field mapping of process window. – Wafer radial and edge-bead analysis. – Exposure tool dose uniformity evaluations. 2007 Weir PSFM – Focus uniformity – Edge influence on autoleveling and auto-focus – Edge bead analysis TEA Systems Products

33 Process Setup & Control TEA Systems • Weir PW • – Standard Process Windows – Aerial Image, full-field and wafer focus modeling – Flatness & Tilt control • Independent / simultaneous rectangular and elliptical windows – Full-field process window models • Only software capable of calculating wafer tilt • Needed for sub-90 nm nodes • Any number of features and field-sites. – Full-field Depth-of-Focus – Removal of wafer tilt and bow prior to modeling – User and automated data culling – Swing curve fitting from production or dose matrix data sets. – Thickness-loss curve fitting – Film uniformity monitors – Visual, whole-wafer and whole field mapping of process window. – Wafer radial and edge-bead analysis. – Exposure tool dose uniformity evaluations. 2007 Weir PSFM – Focus uniformity – Edge influence on autoleveling and auto-focus – Edge bead analysis TEA Systems Products

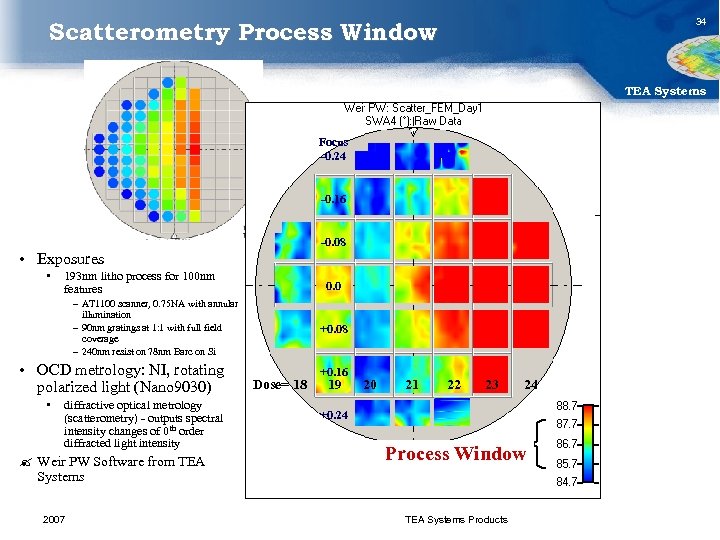

34 Scatterometry Process Window TEA Systems Focus -0. 24 -0. 16 -0. 08 • Exposures • 193 nm litho process for 100 nm features 0. 0 – AT 1100 scanner, 0. 75 NA with annular illumination – 90 nm gratings at 1: 1 with full field coverage – 240 nm resist on 78 nm Barc on Si • OCD metrology: NI, rotating polarized light (Nano 9030) • diffractive optical metrology (scatterometry) - outputs spectral intensity changes of 0 th order diffracted light intensity ? Weir PW Software from TEA Systems 2007 +0. 08 Dose= 18 +0. 16 19 20 21 22 23 24 +0. 24 Process Window TEA Systems Products

34 Scatterometry Process Window TEA Systems Focus -0. 24 -0. 16 -0. 08 • Exposures • 193 nm litho process for 100 nm features 0. 0 – AT 1100 scanner, 0. 75 NA with annular illumination – 90 nm gratings at 1: 1 with full field coverage – 240 nm resist on 78 nm Barc on Si • OCD metrology: NI, rotating polarized light (Nano 9030) • diffractive optical metrology (scatterometry) - outputs spectral intensity changes of 0 th order diffracted light intensity ? Weir PW Software from TEA Systems 2007 +0. 08 Dose= 18 +0. 16 19 20 21 22 23 24 +0. 24 Process Window TEA Systems Products

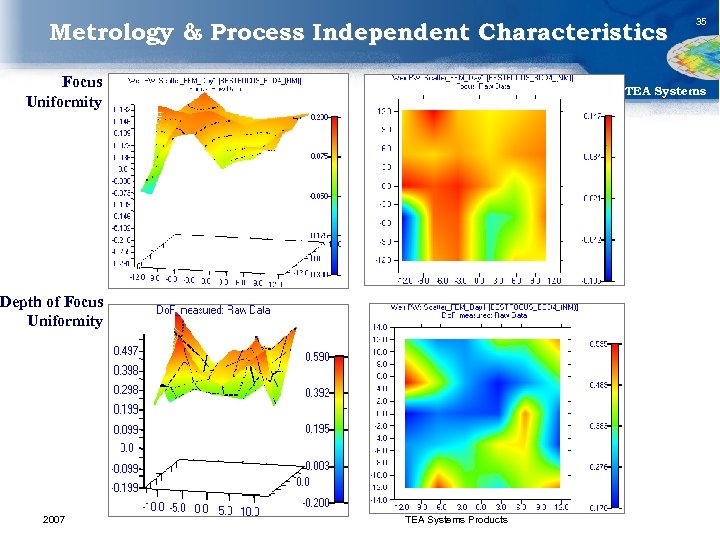

Metrology & Process Independent Characteristics Focus Uniformity TEA Systems Depth of Focus Uniformity 2007 35 TEA Systems Products

Metrology & Process Independent Characteristics Focus Uniformity TEA Systems Depth of Focus Uniformity 2007 35 TEA Systems Products

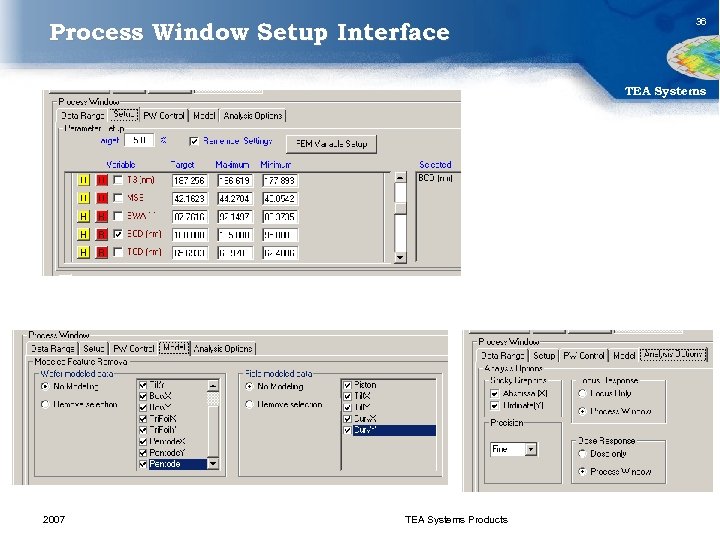

Process Window Setup Interface 36 TEA Systems 2007 TEA Systems Products

Process Window Setup Interface 36 TEA Systems 2007 TEA Systems Products

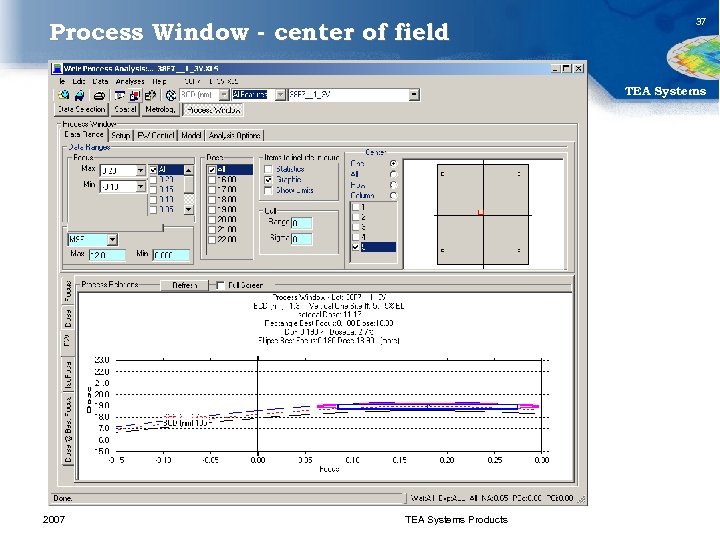

Process Window - center of field 37 TEA Systems 2007 TEA Systems Products

Process Window - center of field 37 TEA Systems 2007 TEA Systems Products

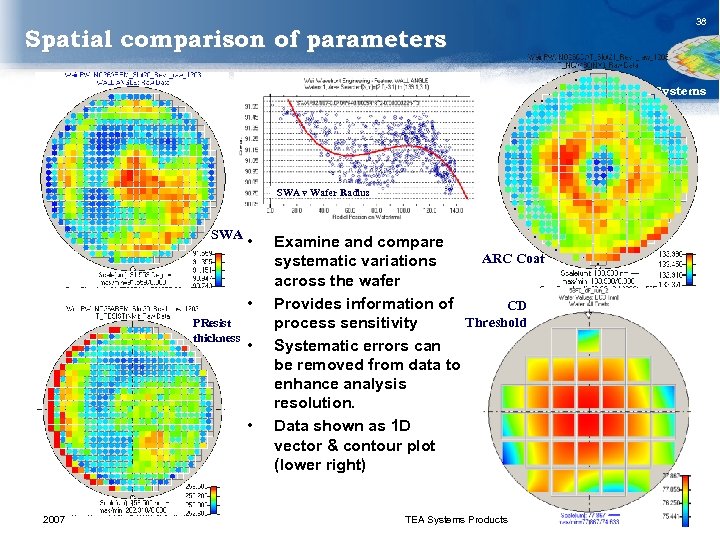

Spatial comparison of parameters 38 TEA Systems SWA v Wafer Radius SWA • • PResist thickness • • 2007 Examine and compare ARC Coat systematic variations across the wafer Provides information of CD Threshold process sensitivity Systematic errors can be removed from data to enhance analysis resolution. Data shown as 1 D vector & contour plot (lower right) TEA Systems Products

Spatial comparison of parameters 38 TEA Systems SWA v Wafer Radius SWA • • PResist thickness • • 2007 Examine and compare ARC Coat systematic variations across the wafer Provides information of CD Threshold process sensitivity Systematic errors can be removed from data to enhance analysis resolution. Data shown as 1 D vector & contour plot (lower right) TEA Systems Products

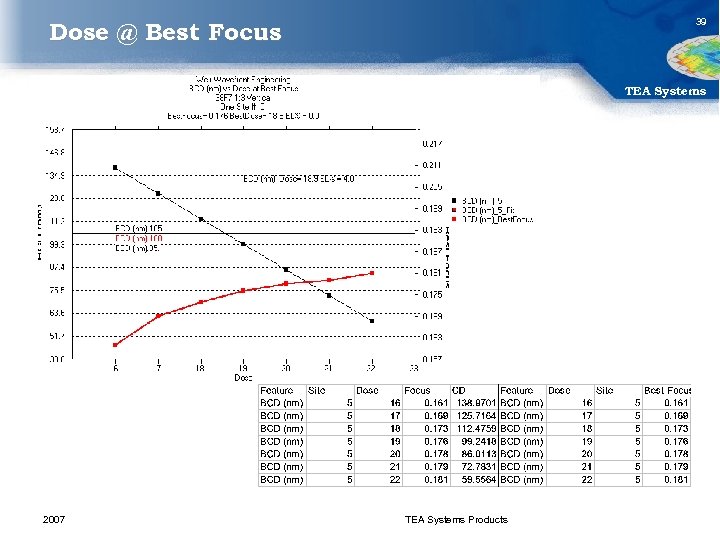

39 Dose @ Best Focus TEA Systems 2007 TEA Systems Products

39 Dose @ Best Focus TEA Systems 2007 TEA Systems Products

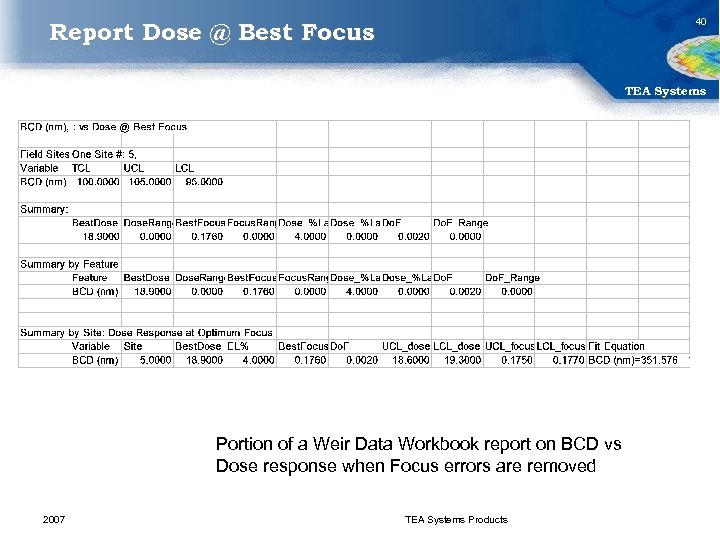

40 Report Dose @ Best Focus TEA Systems Portion of a Weir Data Workbook report on BCD vs Dose response when Focus errors are removed 2007 TEA Systems Products

40 Report Dose @ Best Focus TEA Systems Portion of a Weir Data Workbook report on BCD vs Dose response when Focus errors are removed 2007 TEA Systems Products

41 Modeled Production Gating TEA Systems • Weir PW – Model profile variation across the field and wafer – Pass/fail wafers for redo loops or control based on modeled results • Results in fewer wafers rejected when compared to “mean+3 sigma” gating tests – Model film thickness, profiles, Side-wall-angle (SWA), CD size, etc. 2007 TEA Systems Products

41 Modeled Production Gating TEA Systems • Weir PW – Model profile variation across the field and wafer – Pass/fail wafers for redo loops or control based on modeled results • Results in fewer wafers rejected when compared to “mean+3 sigma” gating tests – Model film thickness, profiles, Side-wall-angle (SWA), CD size, etc. 2007 TEA Systems Products

42 Simulation validation TEA Systems • Weir PW – – 2007 Evaluate film thickness and feature profiles Correlate data with outputs from Prolith, Sigma C etc. Calculate simulator variables to improve simulations Determine influence of the full process window on simulators TEA Systems Products

42 Simulation validation TEA Systems • Weir PW – – 2007 Evaluate film thickness and feature profiles Correlate data with outputs from Prolith, Sigma C etc. Calculate simulator variables to improve simulations Determine influence of the full process window on simulators TEA Systems Products

43 Focus optimization • Weir PW TEA Systems – Derive focus and dose uniformity • from feature focus-matrices and line-end-shortening. – Calculate "Best Focus" across field (IFD) and Focal-plane uniformity • from any Critical Feature metrology set, Line-End-Shortening – Determine Dose response from focus-error-free data • Weir PSFM – Calibrate Phase Shift Focus Monitor (PSFM), Phase Grating( PGM), End-of-Line, and Z-spin Reticles. – Apply reticle calibrations to whole-wafer focus uniformity analyses. – Calculate both wafer and field tilt, bow and random errors – Calculate the effects of thermal heating during exposure – Effects of film, trench-etch, wafer and scanner stage – Wafer edge-bead and edge-die influence – Measure wafer flatness. – Analyze ASML FOCAL focus data • with raw or modeled full-field analyses 2007 TEA Systems Products

43 Focus optimization • Weir PW TEA Systems – Derive focus and dose uniformity • from feature focus-matrices and line-end-shortening. – Calculate "Best Focus" across field (IFD) and Focal-plane uniformity • from any Critical Feature metrology set, Line-End-Shortening – Determine Dose response from focus-error-free data • Weir PSFM – Calibrate Phase Shift Focus Monitor (PSFM), Phase Grating( PGM), End-of-Line, and Z-spin Reticles. – Apply reticle calibrations to whole-wafer focus uniformity analyses. – Calculate both wafer and field tilt, bow and random errors – Calculate the effects of thermal heating during exposure – Effects of film, trench-etch, wafer and scanner stage – Wafer edge-bead and edge-die influence – Measure wafer flatness. – Analyze ASML FOCAL focus data • with raw or modeled full-field analyses 2007 TEA Systems Products

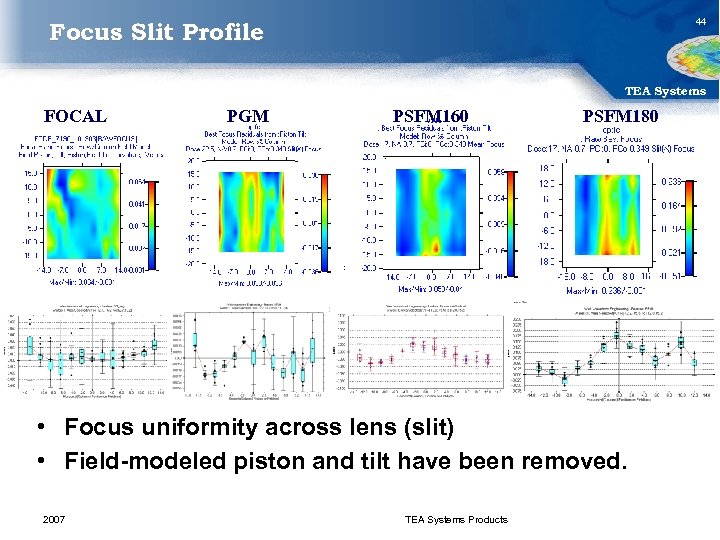

44 Focus Slit Profile TEA Systems FOCAL PGM PSFM 160 PSFM 180 • Focus uniformity across lens (slit) • Field-modeled piston and tilt have been removed. 2007 TEA Systems Products

44 Focus Slit Profile TEA Systems FOCAL PGM PSFM 160 PSFM 180 • Focus uniformity across lens (slit) • Field-modeled piston and tilt have been removed. 2007 TEA Systems Products

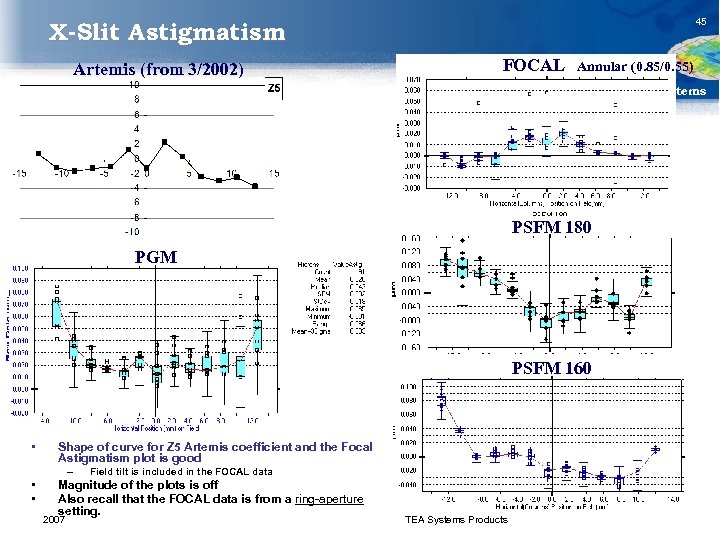

45 X-Slit Astigmatism Artemis (from 3/2002) FOCAL Annular (0. 85/0. 55) TEA Systems PSFM 180 PGM PSFM 160 • Shape of curve for Z 5 Artemis coefficient and the Focal Astigmatism plot is good – • • Field tilt is included in the FOCAL data Magnitude of the plots is off Also recall that the FOCAL data is from a ring-aperture setting. 2007 TEA Systems Products

45 X-Slit Astigmatism Artemis (from 3/2002) FOCAL Annular (0. 85/0. 55) TEA Systems PSFM 180 PGM PSFM 160 • Shape of curve for Z 5 Artemis coefficient and the Focal Astigmatism plot is good – • • Field tilt is included in the FOCAL data Magnitude of the plots is off Also recall that the FOCAL data is from a ring-aperture setting. 2007 TEA Systems Products

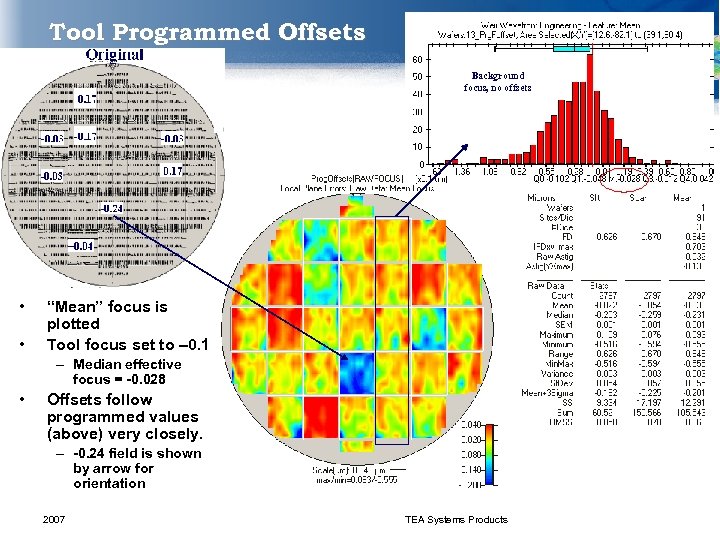

46 Tool Programmed Offsets Background focus, no offsets • • “Mean” focus is plotted Tool focus set to – 0. 1 – Median effective focus = -0. 028 • Offsets follow programmed values (above) very closely. – -0. 24 field is shown by arrow for orientation 2007 TEA Systems Products TEA Systems

46 Tool Programmed Offsets Background focus, no offsets • • “Mean” focus is plotted Tool focus set to – 0. 1 – Median effective focus = -0. 028 • Offsets follow programmed values (above) very closely. – -0. 24 field is shown by arrow for orientation 2007 TEA Systems Products TEA Systems

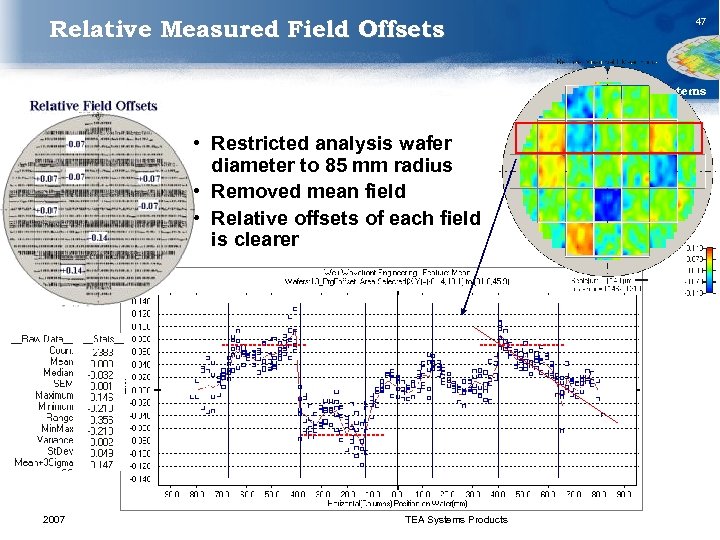

Relative Measured Field Offsets 47 TEA Systems • Restricted analysis wafer diameter to 85 mm radius • Removed mean field • Relative offsets of each field is clearer 2007 TEA Systems Products

Relative Measured Field Offsets 47 TEA Systems • Restricted analysis wafer diameter to 85 mm radius • Removed mean field • Relative offsets of each field is clearer 2007 TEA Systems Products

Recommended System Requirements 48 TEA Systems • Minimum recommended system: – – – 2007 Windows 2000 or XP Professional Microsoft Excel version 9 or later Pentium IV, 1. 2 Gigahertz CPU 256 Megabytes of RAM Monitor 1024 x 780 TEA Systems Products

Recommended System Requirements 48 TEA Systems • Minimum recommended system: – – – 2007 Windows 2000 or XP Professional Microsoft Excel version 9 or later Pentium IV, 1. 2 Gigahertz CPU 256 Megabytes of RAM Monitor 1024 x 780 TEA Systems Products

License Basis 49 • License formats TEA Systems – Licenses are software locks that are keyed to the hardware upon which it is installed. – Licenses can be input manually or delivered via email text files. – License periods can be set from 1 to 365 days or as a permanent license – Demonstration, lease and permanent licenses are available. • Single-user node-locked license – License is locked to a computer’s disk – Only one user, on the target computer may use the license • Floating node license – – License is locked to a computer’s disk Any user on the network can access and use the software Only one user at a time may use the software Software image shuts-down after 30 minutes of non-use • Thereby freeing the license for the next user. 2007 TEA Systems Products

License Basis 49 • License formats TEA Systems – Licenses are software locks that are keyed to the hardware upon which it is installed. – Licenses can be input manually or delivered via email text files. – License periods can be set from 1 to 365 days or as a permanent license – Demonstration, lease and permanent licenses are available. • Single-user node-locked license – License is locked to a computer’s disk – Only one user, on the target computer may use the license • Floating node license – – License is locked to a computer’s disk Any user on the network can access and use the software Only one user at a time may use the software Software image shuts-down after 30 minutes of non-use • Thereby freeing the license for the next user. 2007 TEA Systems Products

50 Summary of Weir PW • TEA Systems Any metrology data can be imported – Weir PW contains a layout optimizer and basic metrology analysis capabilities – Any user-defined variable names may be used – Data is stored in Microsoft Excel® worksheet and workbooks • Multiple data sets can be combined and data sub-sets selected for analysis – Point-and-click mouse interaction for data viewing and culling • “Metrology” analysis – Automated metrology covariance – Automated error-budget analysis. • • • Spatial analysis of variables – Provides information on variation with scan direction and film thickness variation – Point-and-click drill down capability for sub-field graphics, data viewing and analysis – Remove critical systematic components to see the true exposure performance Process Window analysis and more! – Extend beyond the single feature/family analysis. – Examine process window performance variation across the full field of exposure. Automation – Weir DM can be used to automate process-monitor points for any variable series. 2007 TEA Systems Products

50 Summary of Weir PW • TEA Systems Any metrology data can be imported – Weir PW contains a layout optimizer and basic metrology analysis capabilities – Any user-defined variable names may be used – Data is stored in Microsoft Excel® worksheet and workbooks • Multiple data sets can be combined and data sub-sets selected for analysis – Point-and-click mouse interaction for data viewing and culling • “Metrology” analysis – Automated metrology covariance – Automated error-budget analysis. • • • Spatial analysis of variables – Provides information on variation with scan direction and film thickness variation – Point-and-click drill down capability for sub-field graphics, data viewing and analysis – Remove critical systematic components to see the true exposure performance Process Window analysis and more! – Extend beyond the single feature/family analysis. – Examine process window performance variation across the full field of exposure. Automation – Weir DM can be used to automate process-monitor points for any variable series. 2007 TEA Systems Products

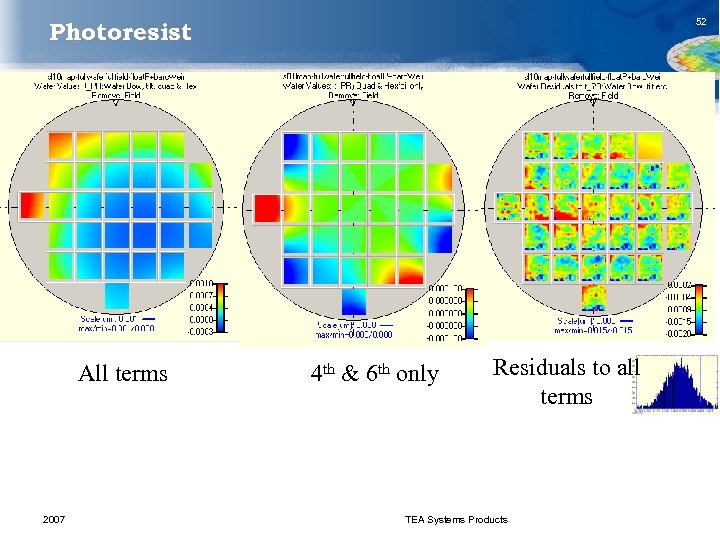

51 TEA Systems th Extra Wafer Maps of 6 order parameter variation (next section) These slides illustrate the variation of measured feature size across the wafer and field. More importantly, they illustrate that feature sizes can be modeled as systematic errors across each. Note that when these systematic errors are removed, the residuals track the variation of underlying film thickness (such as. anti-reflective coatings) and thermal-variation (Post Exposure Bake) across the wafer during processing. Slide 34 is a good example. Weir therefore provides a direct method of measuring both feature and filmvariation influence on feature size. 2007 TEA Systems Products

51 TEA Systems th Extra Wafer Maps of 6 order parameter variation (next section) These slides illustrate the variation of measured feature size across the wafer and field. More importantly, they illustrate that feature sizes can be modeled as systematic errors across each. Note that when these systematic errors are removed, the residuals track the variation of underlying film thickness (such as. anti-reflective coatings) and thermal-variation (Post Exposure Bake) across the wafer during processing. Slide 34 is a good example. Weir therefore provides a direct method of measuring both feature and filmvariation influence on feature size. 2007 TEA Systems Products

52 Photoresist TEA Systems All terms 2007 4 th & 6 th only Residuals to all terms TEA Systems Products

52 Photoresist TEA Systems All terms 2007 4 th & 6 th only Residuals to all terms TEA Systems Products

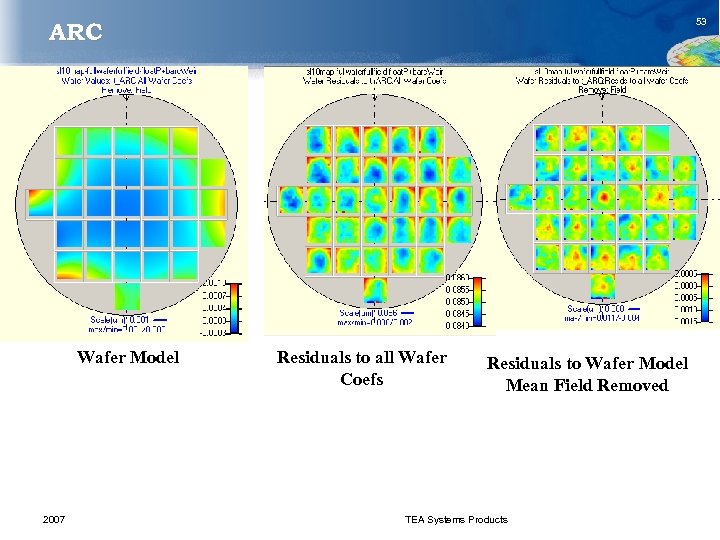

53 ARC TEA Systems Wafer Model 2007 Residuals to all Wafer Coefs Residuals to Wafer Model Mean Field Removed TEA Systems Products

53 ARC TEA Systems Wafer Model 2007 Residuals to all Wafer Coefs Residuals to Wafer Model Mean Field Removed TEA Systems Products

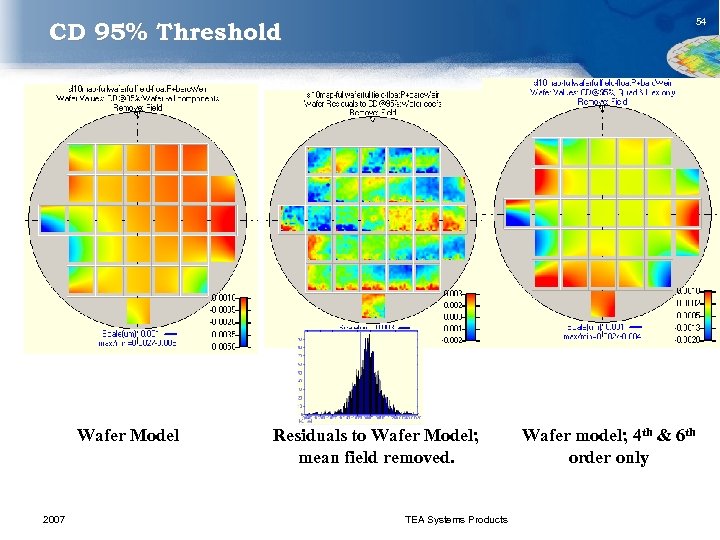

54 CD 95% Threshold TEA Systems Wafer Model 2007 Residuals to Wafer Model; mean field removed. TEA Systems Products Wafer model; 4 th & 6 th order only

54 CD 95% Threshold TEA Systems Wafer Model 2007 Residuals to Wafer Model; mean field removed. TEA Systems Products Wafer model; 4 th & 6 th order only

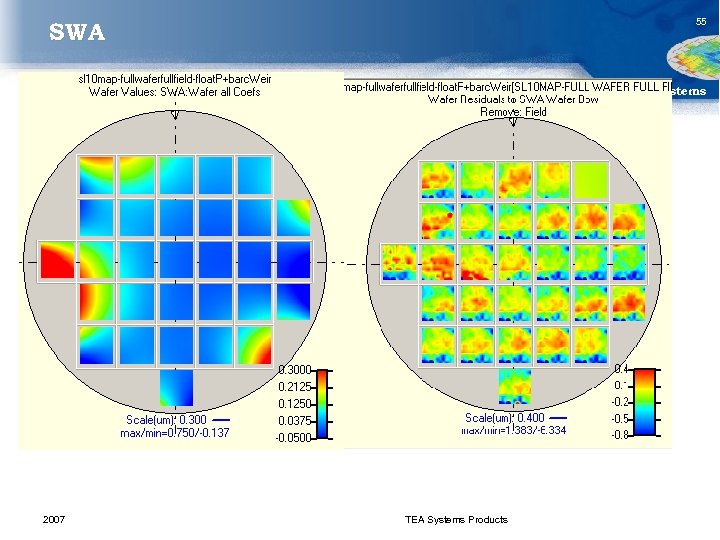

55 SWA TEA Systems 2007 TEA Systems Products

55 SWA TEA Systems 2007 TEA Systems Products