696bc7b724e1a57064a3291fece458fb.ppt

- Количество слайдов: 16

TCO Dennis Bertolucci

Two Worlds… • “Sure, we do the analysis…” • Based on my thirty years in this business, everyone talks about TCO, but few really look at it in any true detail. John Sparra, Sparra Packaging Machinery, Thorndale, PA

What is TCO* ? • • Tool to analyze new machine or line Compare existing v new, 2 - suppliers ‘Apples-to-apples’ ‘Opportunity costs’ – Lost production, setup, changeover – Training, operator, maintenance costs *Total Cost of Ownership

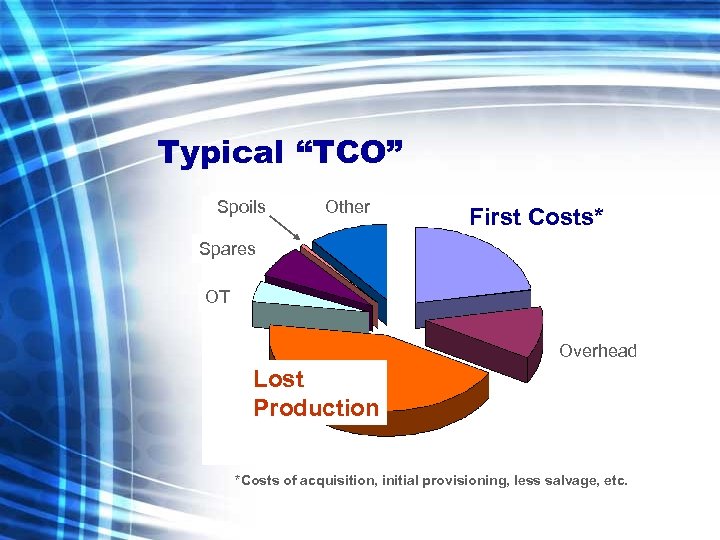

Typical “TCO” Spoils Other First Costs* Spares OT Overhead Lost Production *Costs of acquisition, initial provisioning, less salvage, etc.

More Good Reasons… 1. Justify the investment… don’t want headache of keeping inferior equipment running 2. Too many options, narrow down some of the operating assumptions 3. Vendor/supplier quotes are different… how to compare “apples-to-apples”

Reasons NOT to do TCO… “I’ve got all the money I need” “We’ve standardized on XYZ…” “We’ll need a cost-accountant” “Can’t predict the future!” Credit: EC Publications' Mad Magazine

Trends • Relentless drive towards…reliability, accuracy, speed, simple changeover and operation, package innovation, just-in-time batch runs and package size flexibility • Complex decisions: Manual, semi-auto or fully automated? Servo or PLC? Rotary or Inline? Offshore manufacturer or domestic supplier? • Like autos, aircraft, consumer appliances… these new technologies have a “learning curve”

VIDEO

TCO Best Practices

The ‘Right’ Questions • When do I need it? • What information will I need? • Keep it simple • Don’t put it on the shelf!

When do I need it? • After you have a handle on the capacity you need and the specs of the job(s) • Before you get too far down the road in negotiations or final selection • A very good idea to establish up-front with your supplier(s), anyone who must approve… what are the most important assumptions

What Information? • Obvious perhaps… capacity, sizes, materials, changeover, maintenance schedules, operator skills • Harder to get… MTBF’s, references to similar applications, training & support, parts & documentation, shipping, setup and typical contract terms • Your production assumptions… how you calculate the $ value of lost-production, interest rates for capital investments, depreciation schedules, lease-v-buy etc.

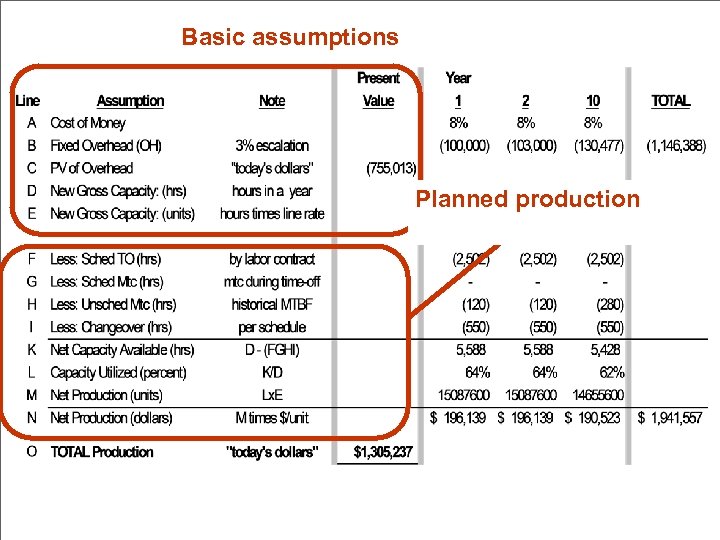

Basic assumptions Planned production

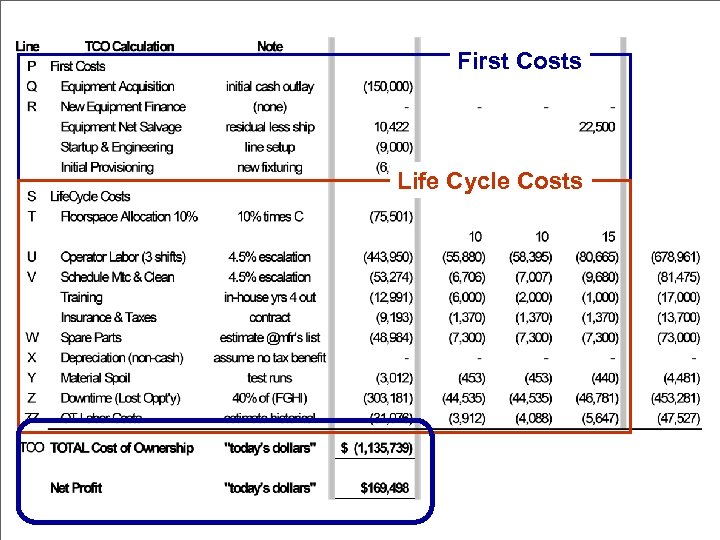

First Costs Life Cycle Costs

Other ‘Tips’ • Consider ‘optimistic’, ‘pessimistic’, most-likely scenarios • Ask associates, suppliers, those experienced for their ‘rule-of-thumb’ • Look at the TCO numbers—when cumulative annual expenses equal cumulative annual production—you have ‘payback’ • When things change, consider re-running the numbers (what spreadsheets are for!)

Q&A … dennis. bertolucci@simplexfiller. com Simplex Filler Company 640 -A Airpark Rd. Napa, California 94558 800 -796 -7539 PH: 707 -265 -6801 FX: 707 -265 -6868

696bc7b724e1a57064a3291fece458fb.ppt