c09c9eeffc3a5f1b06de731f524aed08.ppt

- Количество слайдов: 36

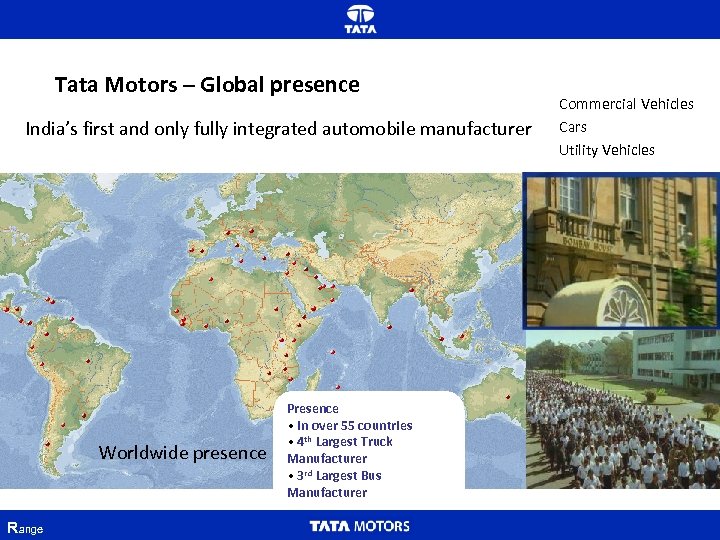

Tata Motors – Global presence India’s first and only fully integrated automobile manufacturer Worldwide presence Range Presence • In over 55 countries • 4 th Largest Truck Manufacturer • 3 rd Largest Bus Manufacturer Commercial Vehicles Cars Utility Vehicles

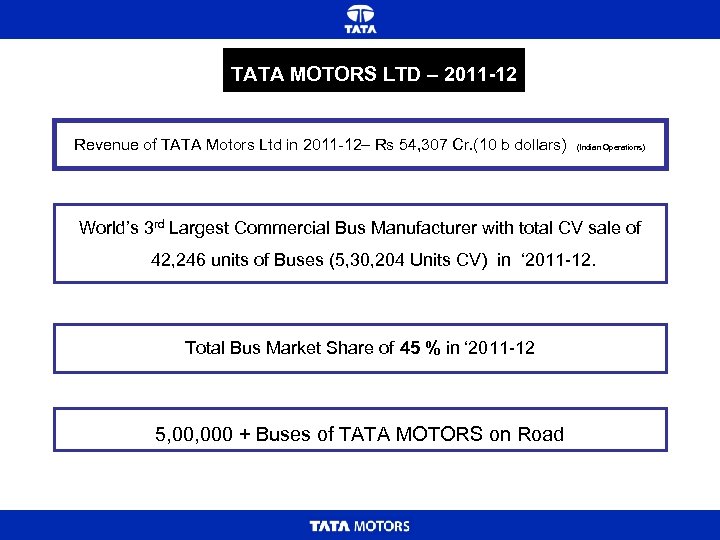

TATA MOTORS LTD – 2011 -12 Revenue of TATA Motors Ltd in 2011 -12– Rs 54, 307 Cr. (10 b dollars) (Indian Operations) World’s 3 rd Largest Commercial Bus Manufacturer with total CV sale of 42, 246 units of Buses (5, 30, 204 Units CV) in ‘ 2011 -12. Total Bus Market Share of 45 % in ‘ 2011 -12 5, 000 + Buses of TATA MOTORS on Road

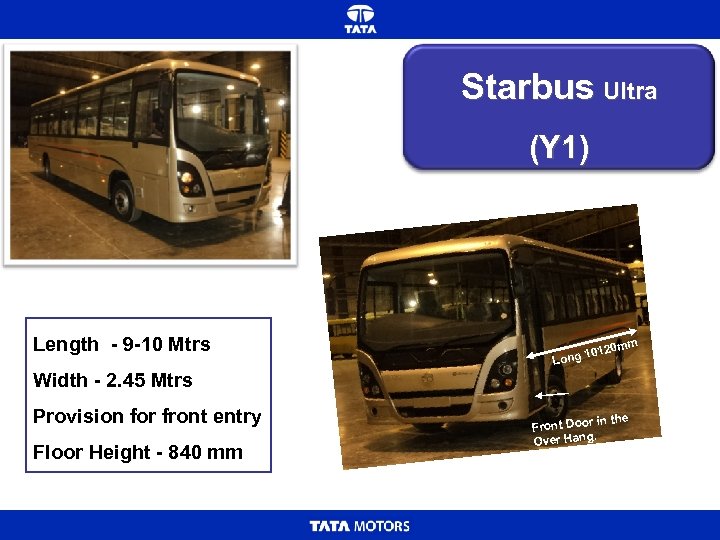

Starbus Ultra (Y 1) Length - 9 -10 Mtrs mm 0 1012 Long Width - 2. 45 Mtrs Provision for front entry Floor Height - 840 mm in the Front Door. Over Hang

New Air Conditioned Buses for Ahmedabad

AJL BRTS Bus on LPO 1613/55 CNG BS IV

PMPML BRTS Bus on LPO 1613/55 CNG BS IV

PMPML BRTS Bus on LPO 1613/55 CNG BS IV

AJL BRTS Bus on LPO 1613/55 CNG BS IV

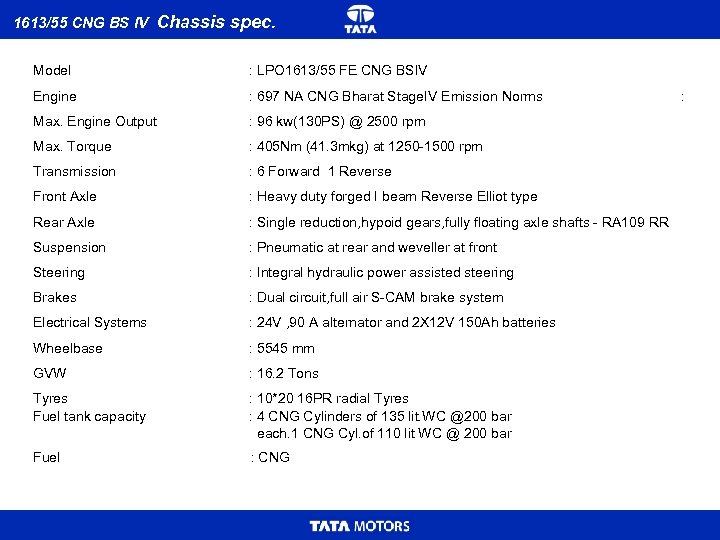

1613/55 CNG BS IV Chassis spec. Model : LPO 1613/55 FE CNG BSIV Engine : 697 NA CNG Bharat Stage. IV Emission Norms Max. Engine Output : 96 kw(130 PS) @ 2500 rpm Max. Torque : 405 Nm (41. 3 mkg) at 1250 -1500 rpm Transmission : 6 Forward 1 Reverse Front Axle : Heavy duty forged I beam Reverse Elliot type Rear Axle : Single reduction, hypoid gears, fully floating axle shafts - RA 109 RR Suspension : Pneumatic at rear and weveller at front Steering : Integral hydraulic power assisted steering Brakes : Dual circuit, full air S-CAM brake system Electrical Systems : 24 V , 90 A alternator and 2 X 12 V 150 Ah batteries Wheelbase : 5545 mm GVW : 16. 2 Tons Tyres Fuel tank capacity : 10*20 16 PR radial Tyres : 4 CNG Cylinders of 135 lit. WC @200 bar each. 1 CNG Cyl. of 110 lit WC @ 200 bar Fuel : CNG :

Hybrid Bus

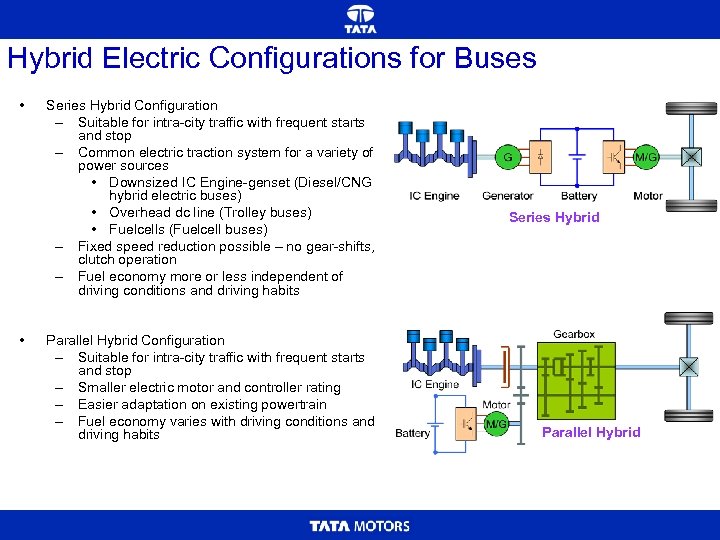

Hybrid Electric Configurations for Buses • • Series Hybrid Configuration – Suitable for intra-city traffic with frequent starts and stop – Common electric traction system for a variety of power sources • Downsized IC Engine-genset (Diesel/CNG hybrid electric buses) • Overhead dc line (Trolley buses) • Fuelcells (Fuelcell buses) – Fixed speed reduction possible – no gear-shifts, clutch operation – Fuel economy more or less independent of driving conditions and driving habits Parallel Hybrid Configuration – Suitable for intra-city traffic with frequent starts and stop – Smaller electric motor and controller rating – Easier adaptation on existing powertrain – Fuel economy varies with driving conditions and driving habits Series Hybrid Parallel Hybrid

BUS PHOTOS UPSRTC 400 mm Diesel NAC

BUS PHOTOS

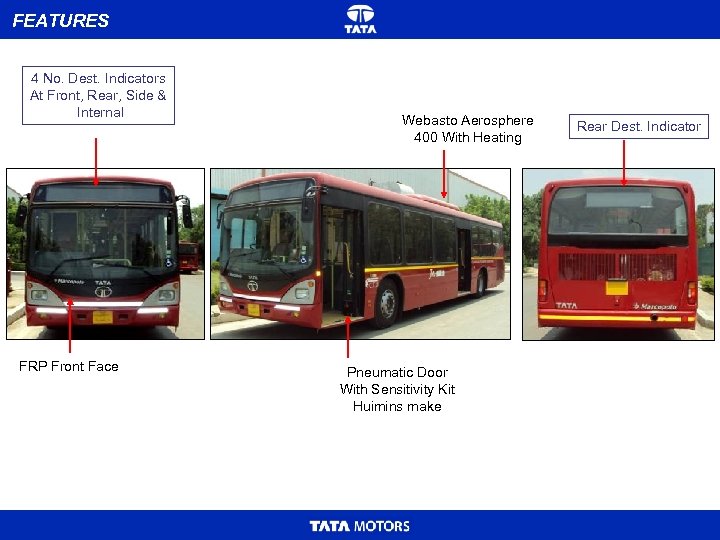

FEATURES 4 No. Dest. Indicators At Front, Rear, Side & Internal FRP Front Face Webasto Aerosphere 400 With Heating Pneumatic Door With Sensitivity Kit Huimins make Rear Dest. Indicator

New Technology for Urban Buses v Automatic Transmission for city bus application. v Multiplexing system for chassis and body level auto electrical. v Intelligent Transportation System with GPS tracking, Auto Ticketing etc features for city buses. v Fire detection and suppression system for city buses. v Introduction of front independent air suspension for intercity bus application and ECAS for city buses. v Introduction of ABS, disc brakes, NGT drum brakes, Retarder for brake related safety. v Tyre pressure monitoring system

Customer requirements Urban Bus specifications Few features: - Seating layout with type of seats and passenger area definition Wider pneumatic door for easy passenger embarking and disembarking Drivers work area with and ergonomics

Differentiating Features / External aesthetics Face uplift in terms of design feature as well as a boost to fuel efficiency Aerodynamic Design Improved styling for head lamps

Differentiating Features / Interior aesthetics Wider Reclining seats New Dashboard and Instrument Cluster Improvement in interior aesthetics. Also improves driver ergonomics and boost his efficiency Stylish Personal Controls

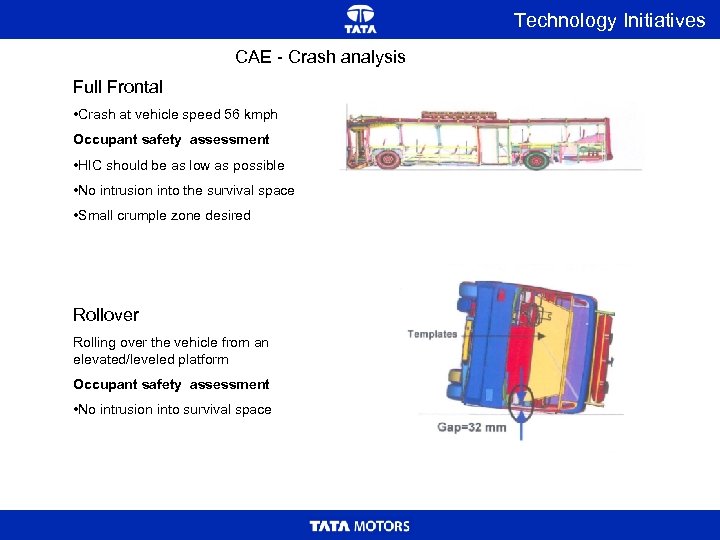

Technology Initiatives CAE - Crash analysis Full Frontal • Crash at vehicle speed 56 kmph Occupant safety assessment • HIC should be as low as possible • No intrusion into the survival space • Small crumple zone desired Rollover Rolling over the vehicle from an elevated/leveled platform Occupant safety assessment • No intrusion into survival space

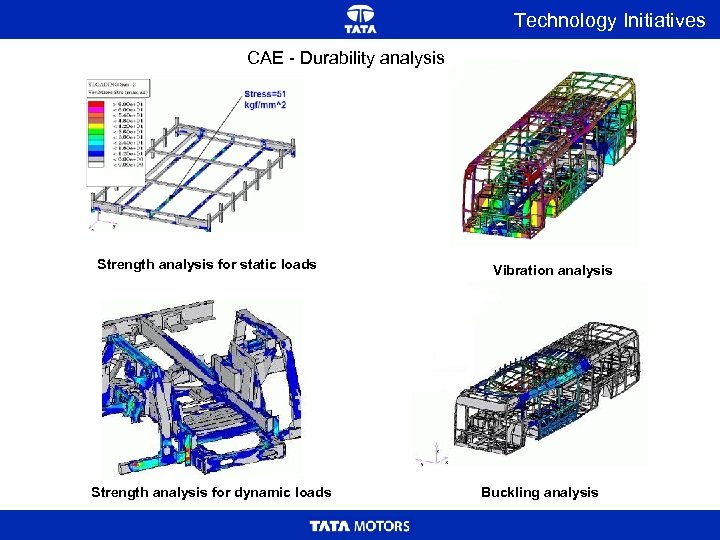

Technology Initiatives CAE - Durability analysis Strength analysis for static loads Strength analysis for dynamic loads Vibration analysis Buckling analysis

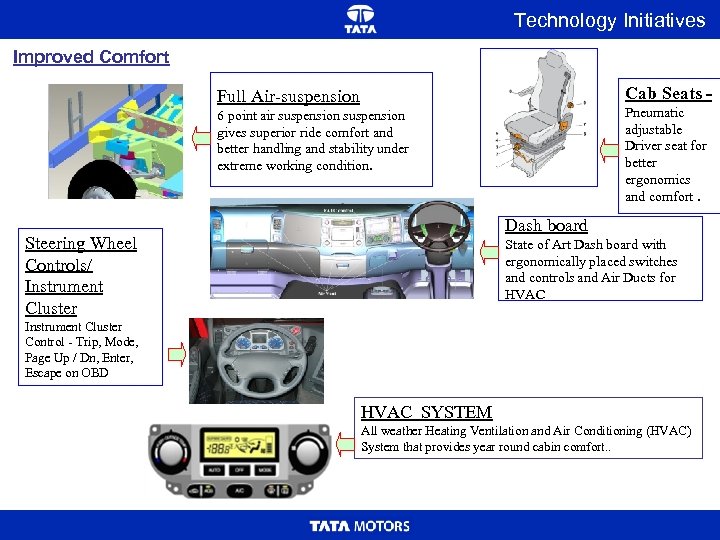

Technology Initiatives Improved Comfort Cab Seats - Full Air-suspension Pneumatic adjustable Driver seat for better ergonomics and comfort. 6 point air suspension gives superior ride comfort and better handling and stability under extreme working condition. Dash board Steering Wheel Controls/ Instrument Cluster State of Art Dash board with ergonomically placed switches and controls and Air Ducts for HVAC Instrument Cluster Control - Trip, Mode, Page Up / Dn, Enter, Escape on OBD HVAC SYSTEM All weather Heating Ventilation and Air Conditioning (HVAC) System that provides year round cabin comfort. .

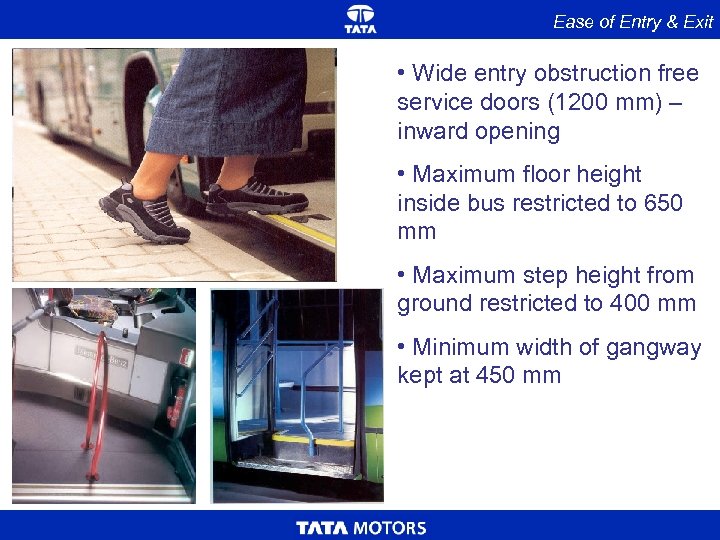

Ease of Entry & Exit • Wide entry obstruction free service doors (1200 mm) – inward opening • Maximum floor height inside bus restricted to 650 mm • Maximum step height from ground restricted to 400 mm • Minimum width of gangway kept at 450 mm

Comfortable Seating • Anti-Vandalism seats • Less tampering possible by passengers – More durable • Fabric inserts replaceable easily • 2 X 2 seating layout for better comfort

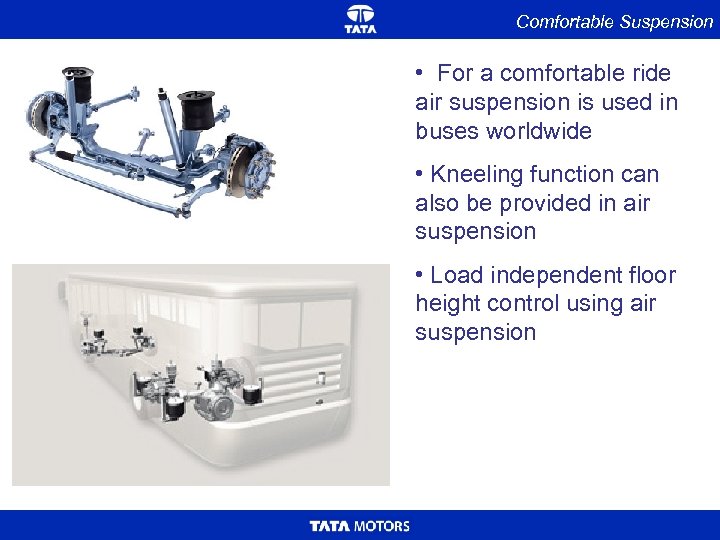

Comfortable Suspension • For a comfortable ride air suspension is used in buses worldwide • Kneeling function can also be provided in air suspension • Load independent floor height control using air suspension

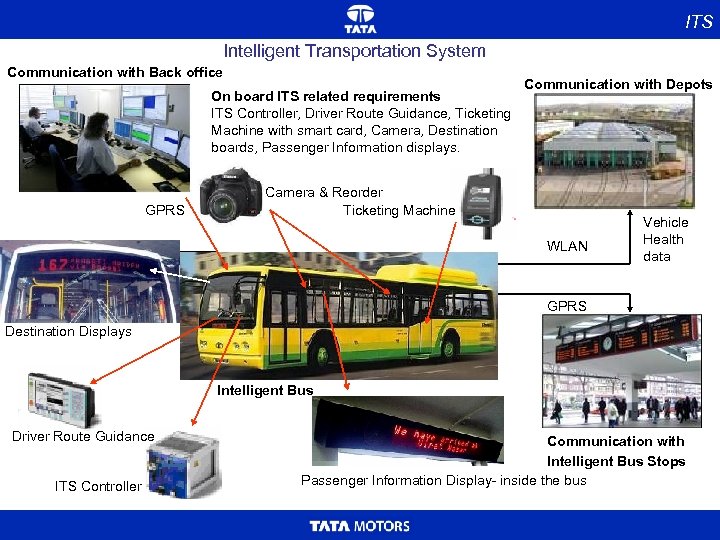

ITS Intelligent Transportation System Communication with Back office On board ITS related requirements ITS Controller, Driver Route Guidance, Ticketing Machine with smart card, Camera, Destination boards, Passenger Information displays. GPRS Communication with Depots Camera & Reorder Ticketing Machine WLAN Ethernet, RS 485, CAN Vehicle Health data GPRS Destination Displays GPRS Intelligent Bus Driver Route Guidance ITS Controller Communication with Intelligent Bus Stops Passenger Information Display- inside the bus

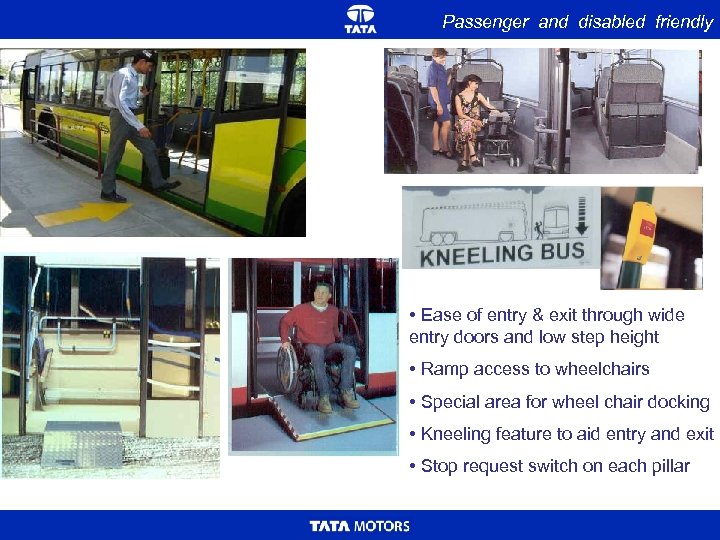

Passenger and disabled friendly • Ease of entry & exit through wide entry doors and low step height • Ramp access to wheelchairs • Special area for wheel chair docking • Kneeling feature to aid entry and exit • Stop request switch on each pillar

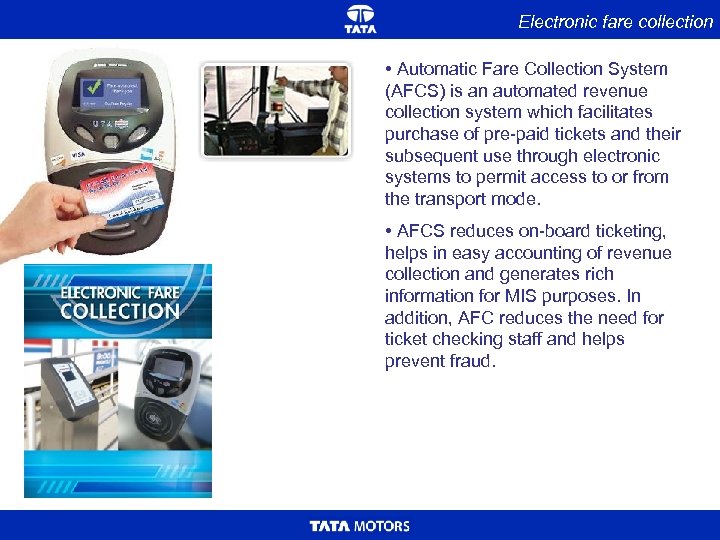

Electronic fare collection • Automatic Fare Collection System (AFCS) is an automated revenue collection system which facilitates purchase of pre-paid tickets and their subsequent use through electronic systems to permit access to or from the transport mode. • AFCS reduces on-board ticketing, helps in easy accounting of revenue collection and generates rich information for MIS purposes. In addition, AFC reduces the need for ticket checking staff and helps prevent fraud.

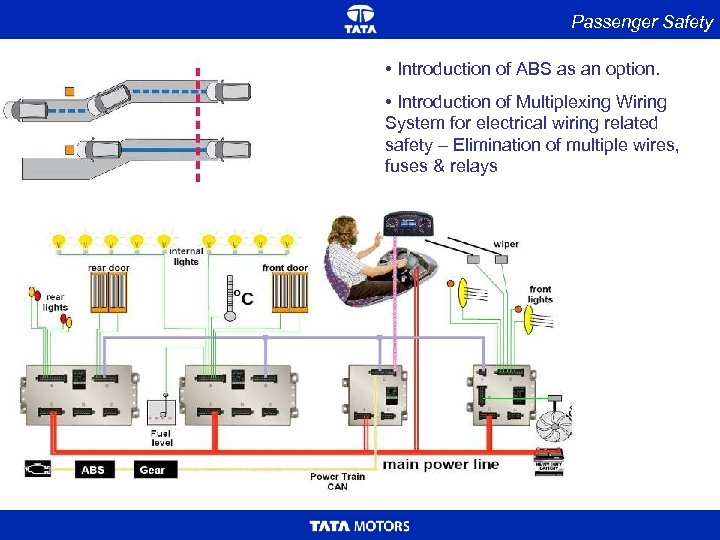

Passenger Safety • Introduction of ABS as an option. • Introduction of Multiplexing Wiring System for electrical wiring related safety – Elimination of multiple wires, fuses & relays

o n i t o r i n g S y s t e m • Monitor tire pressure and alert driver via display and audible alarms when tire pressures reach varying levels • Can also monitor temperatures and provide warnings when specified temperature thresholds are reached

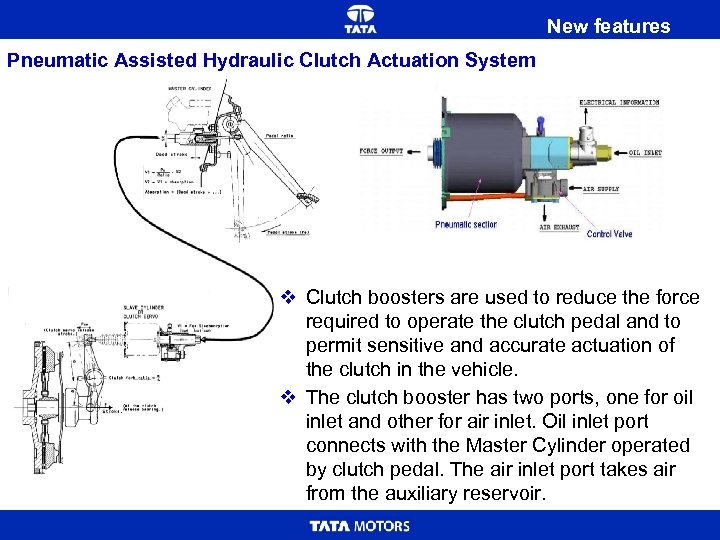

New features Pneumatic Assisted Hydraulic Clutch Actuation System v Clutch boosters are used to reduce the force required to operate the clutch pedal and to permit sensitive and accurate actuation of the clutch in the vehicle. v The clutch booster has two ports, one for oil inlet and other for air inlet. Oil inlet port connects with the Master Cylinder operated by clutch pedal. The air inlet port takes air from the auxiliary reservoir.

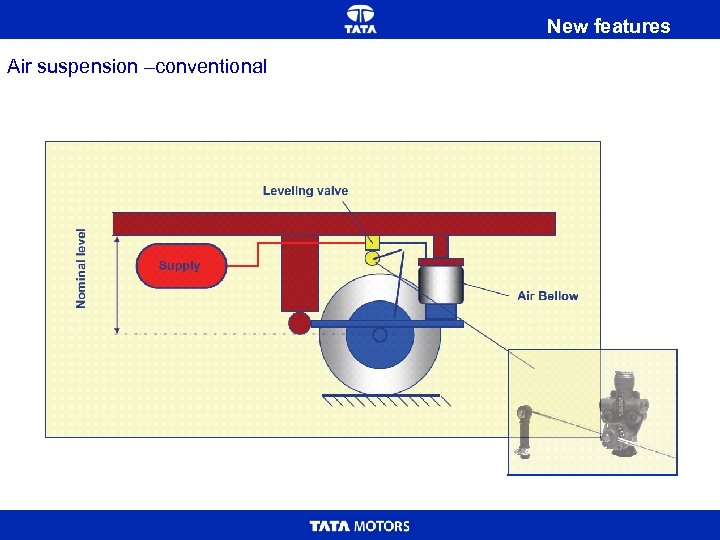

New features Air suspension –conventional

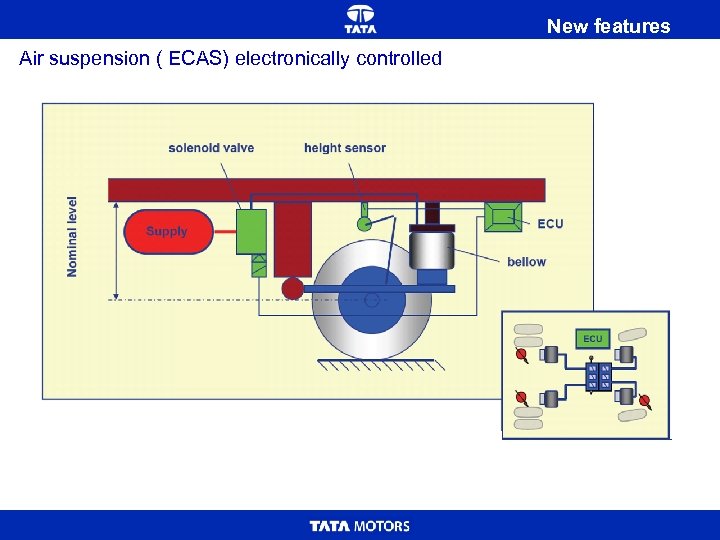

New features Air suspension ( ECAS) electronically controlled

New features New Generation Technology Brakes Definition: NGT is recent updated version of CGT Brake in which ; • Foundation brake is better in Lining life, reduced Brake Noise, provision of Wear and temperature monitoring sensors, High performance brake liner, etc. • Brake Actuation system is 9 bar with oil separator and 230 CC compressor for in un interrupted supply of clean air.

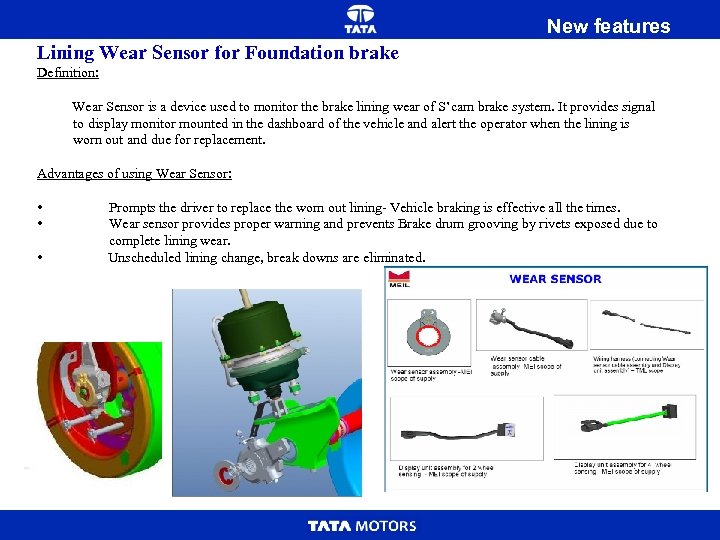

New features Lining Wear Sensor for Foundation brake Definition: Wear Sensor is a device used to monitor the brake lining wear of S’cam brake system. It provides signal to display monitor mounted in the dashboard of the vehicle and alert the operator when the lining is worn out and due for replacement. Advantages of using Wear Sensor: • • • Prompts the driver to replace the worn out lining- Vehicle braking is effective all the times. Wear sensor provides proper warning and prevents Brake drum grooving by rivets exposed due to complete lining wear. Unscheduled lining change, break downs are eliminated.

New features Low Noise and High lining Life Brake liner. Definition: New brake liner suitable for CGT and NGT brake for bus application. ; This liner proven its usefulness in severe duty cycles where brake liner temperatures are up to 200 to 250 degree Celsius. Advantages of using Masu brake lining. : • • Linear torque characteristics wrt to braking pressure @ low speed and low pressure; resulting in uniform torque. (Less Noise) In the Transfer Film Technology friction is produced by inter action of films rather than mechanical action between drum and lining which produces vibration. Therefore the reduction on brake Noise. This also reduces thermal effect on foundation brake and thus improves lining life. (Almost Double). Constant deceleration and stopping distance even when vehicle reaches to High speed up to 100 kmh.

Thank You

c09c9eeffc3a5f1b06de731f524aed08.ppt