d8300b05ac32f864112bc4658690830a.ppt

- Количество слайдов: 16

Talbor & Boralyn Materials for Nuclear Applications June, 2009

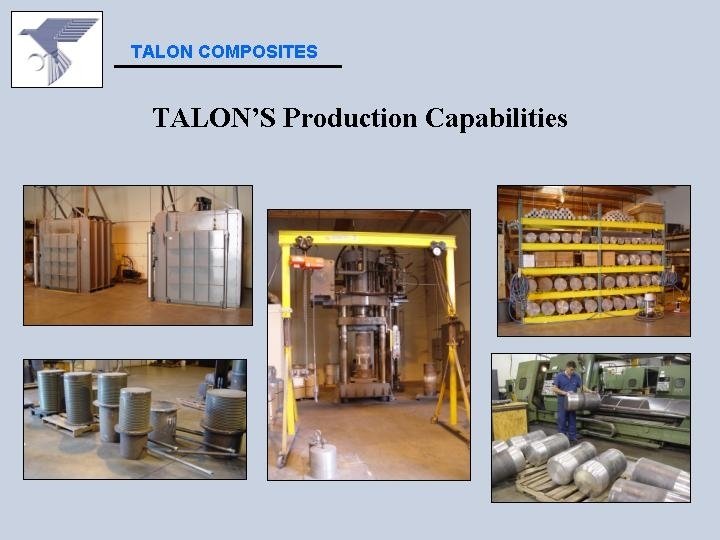

TALON’S PRODUCTION TECHNIQUES ARE SOPHISTICATED AND REQUIRE ADVANCED TECHNOLOGICAL PROCESSING

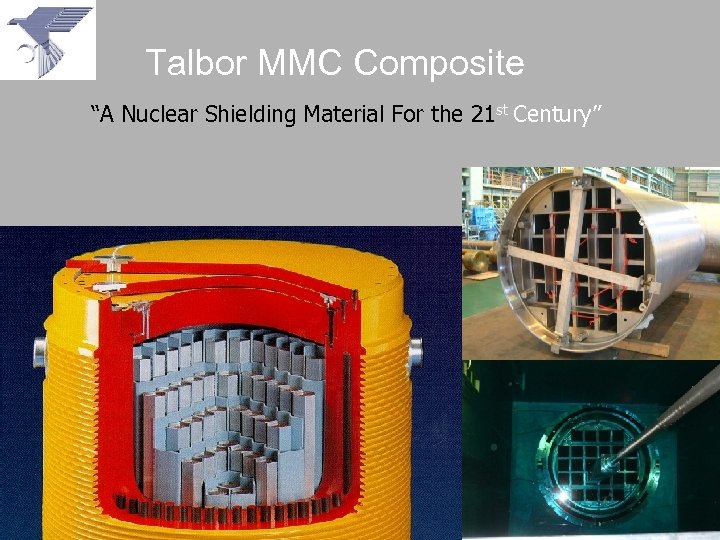

Talbor MMC Composite “A Nuclear Shielding Material For the 21 st Century”

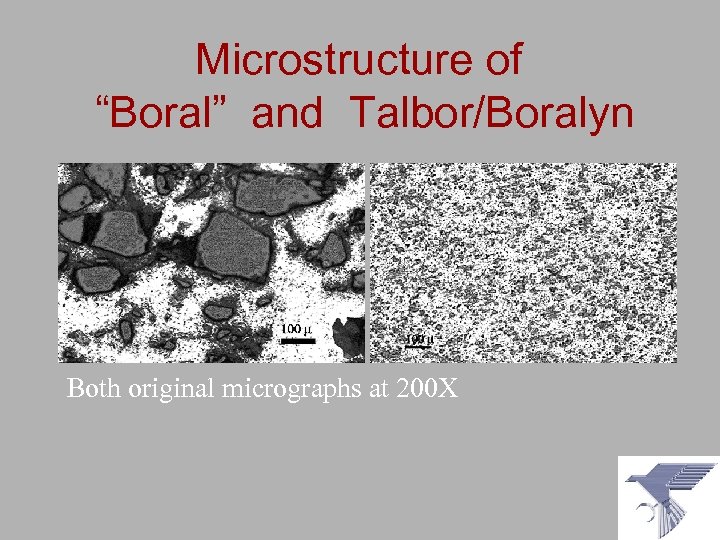

Microstructure of “Boral” and Talbor/Boralyn Both original micrographs at 200 X

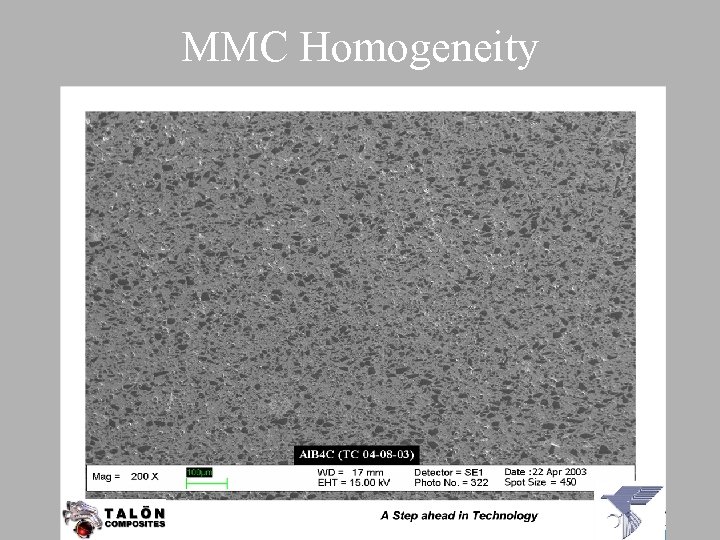

MMC Homogeneity

ADVANTAGES of Talon’s MMC® • Uniform Fine Microstructure – Uniform Shielding-No Channeling • High Ductility – Fracture Resistance – Formability • Structural Property Capability – 6092 and 7093 Matrix Alloy Available • 55 ksi and 90 ksi yield strength

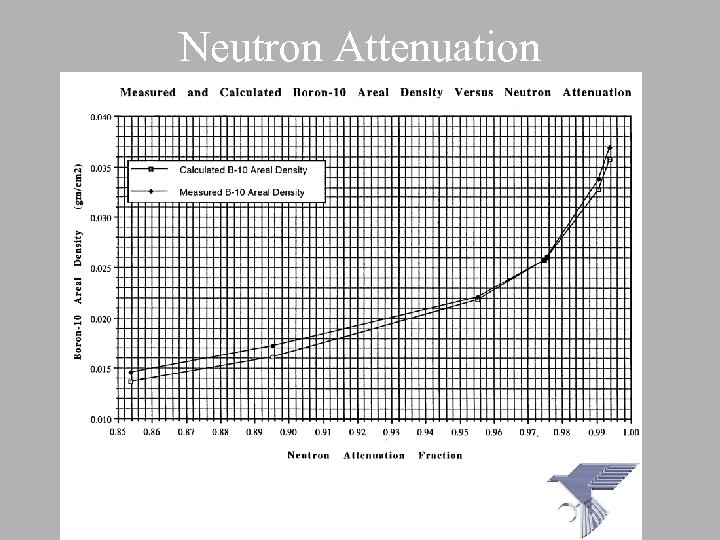

Neutron Attenuation

Nuclear Traceable Verification

Established Quality Assurance Program ISO-9002 Compliant

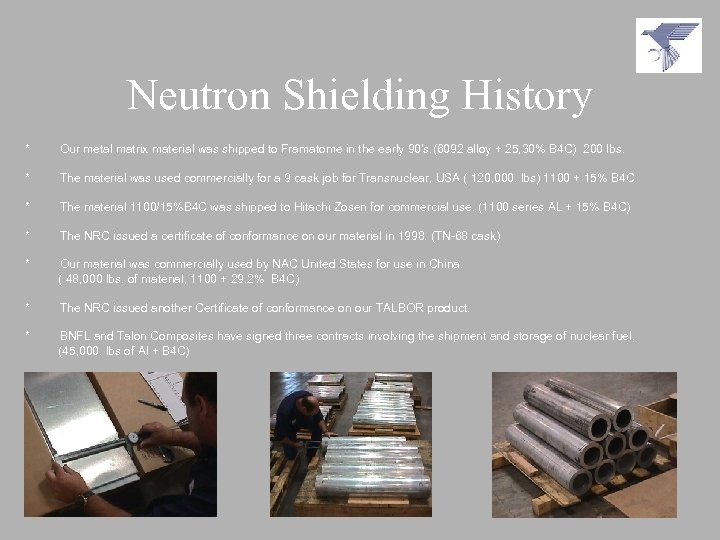

Neutron Shielding History * Our metal matrix material was shipped to Framatome in the early 90's. (6092 alloy + 25, 30% B 4 C) 200 lbs. * The material was used commercially for a 9 cask job for Transnuclear, USA ( 120, 000. lbs) 1100 + 15% B 4 C * The material 1100/15%B 4 C was shipped to Hitachi Zosen for commercial use. (1100 series AL + 15% B 4 C) * The NRC issued a certificate of conformance on our material in 1998. (TN-68 cask) * Our material was commercially used by NAC United States for use in China. ( 48, 000 lbs. of material, 1100 + 29. 2% B 4 C) * The NRC issued another Certificate of conformance on our TALBOR product. * BNFL and Talon Composites have signed three contracts involving the shipment and storage of nuclear fuel. (45, 000. lbs of Al + B 4 C)

Hitachi Japan- Transnuclear US - 1997 -1999

NAC – CHINA Casks 1999 -2006

BNFL – 2001 - 2006

Research & Development Instron Tensile and X-ray testing on Titanium and MMC Composites

d8300b05ac32f864112bc4658690830a.ppt