21b8d20adcde39afbfb005bcd54f69ab.ppt

- Количество слайдов: 17

TAIEX Workshop on the Pressure Equipment Directive Materials Bratislava 11/12/13 April 2005 Presented by Peter Hanmore For the benefit of business and people Taiex - Bratislava April 2005

TAIEX Workshop on the Pressure Equipment Directive Materials Bratislava 11/12/13 April 2005 Presented by Peter Hanmore For the benefit of business and people Taiex - Bratislava April 2005

Material Requirements SUMMARY 1 Suitability 2 Joining materials 3 Essential safety requirements 4 Material source 5 Certification 6 Guidelines 2

Material Requirements SUMMARY 1 Suitability 2 Joining materials 3 Essential safety requirements 4 Material source 5 Certification 6 Guidelines 2

1 General Materials Designer must select materials that are suitable for the expected application and intended lifetime Taiex - Bratislava April 2005 3

1 General Materials Designer must select materials that are suitable for the expected application and intended lifetime Taiex - Bratislava April 2005 3

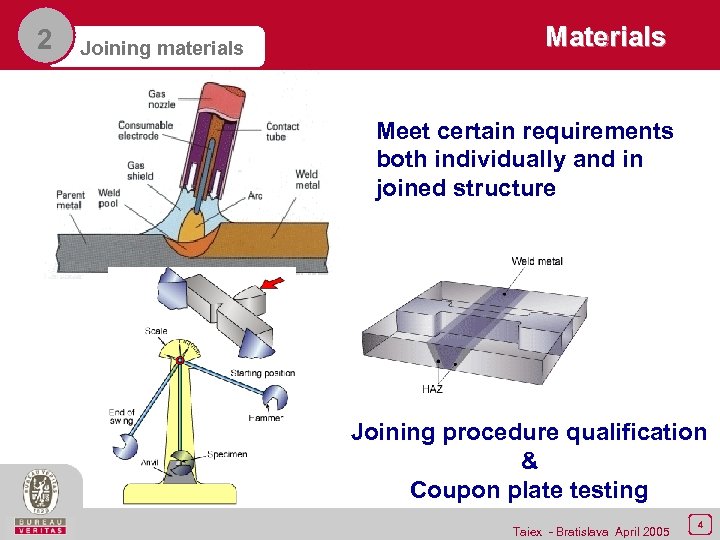

2 Joining materials Meet certain requirements both individually and in joined structure Joining procedure qualification & Coupon plate testing Taiex - Bratislava April 2005 4

2 Joining materials Meet certain requirements both individually and in joined structure Joining procedure qualification & Coupon plate testing Taiex - Bratislava April 2005 4

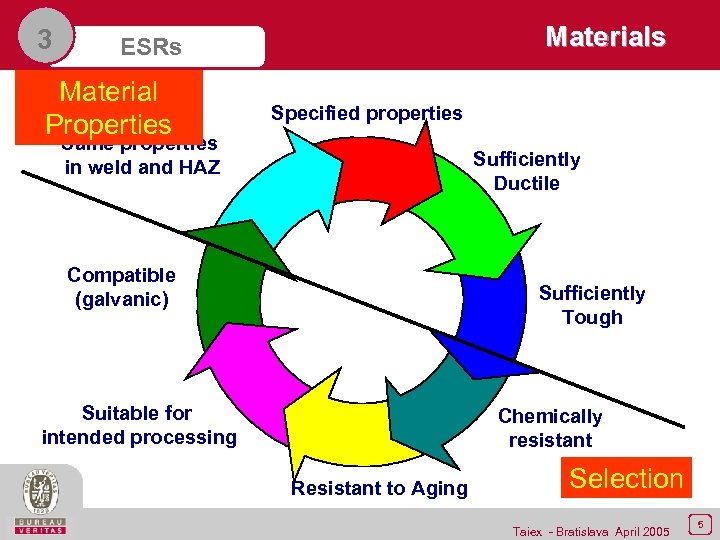

3 Materials ESRs Material Properties Specified properties Same properties in weld and HAZ Sufficiently Ductile Compatible (galvanic) Sufficiently Tough Suitable for intended processing Chemically resistant Resistant to Aging Selection Taiex - Bratislava April 2005 5

3 Materials ESRs Material Properties Specified properties Same properties in weld and HAZ Sufficiently Ductile Compatible (galvanic) Sufficiently Tough Suitable for intended processing Chemically resistant Resistant to Aging Selection Taiex - Bratislava April 2005 5

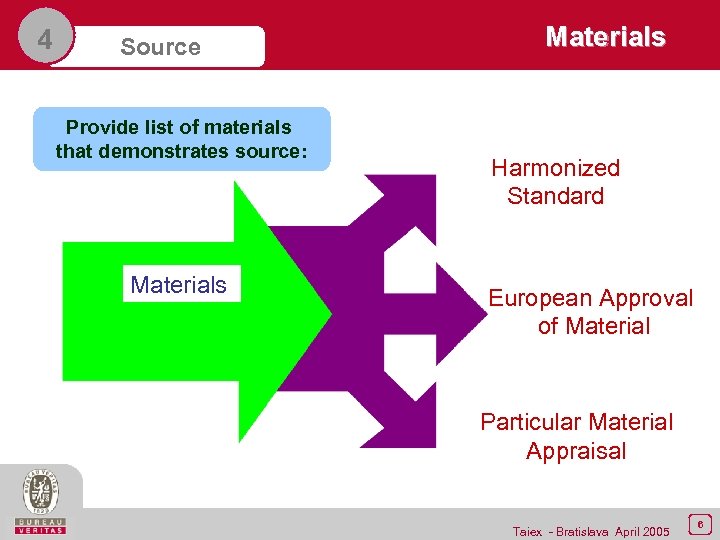

4 Source Provide list of materials that demonstrates source: Materials Harmonized Standard European Approval of Material Particular Material Appraisal Taiex - Bratislava April 2005 6

4 Source Provide list of materials that demonstrates source: Materials Harmonized Standard European Approval of Material Particular Material Appraisal Taiex - Bratislava April 2005 6

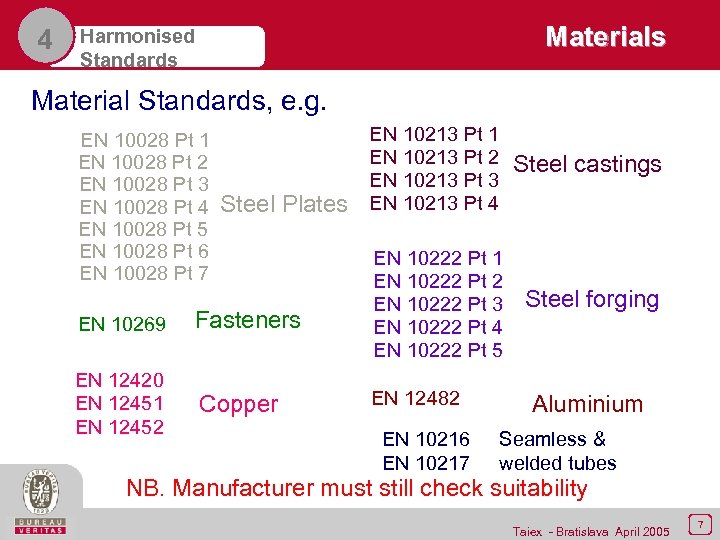

4 Materials Harmonised Standards Material Standards, e. g. EN 10028 Pt 1 EN 10028 Pt 2 EN 10028 Pt 3 EN 10028 Pt 4 EN 10028 Pt 5 EN 10028 Pt 6 EN 10028 Pt 7 Steel Plates EN 10269 Fasteners EN 12420 EN 12451 EN 12452 Copper EN 10213 Pt 1 EN 10213 Pt 2 EN 10213 Pt 3 EN 10213 Pt 4 Steel castings EN 10222 Pt 1 EN 10222 Pt 2 EN 10222 Pt 3 EN 10222 Pt 4 EN 10222 Pt 5 Steel forging EN 12482 EN 10216 EN 10217 Aluminium Seamless & welded tubes NB. Manufacturer must still check suitability Taiex - Bratislava April 2005 7

4 Materials Harmonised Standards Material Standards, e. g. EN 10028 Pt 1 EN 10028 Pt 2 EN 10028 Pt 3 EN 10028 Pt 4 EN 10028 Pt 5 EN 10028 Pt 6 EN 10028 Pt 7 Steel Plates EN 10269 Fasteners EN 12420 EN 12451 EN 12452 Copper EN 10213 Pt 1 EN 10213 Pt 2 EN 10213 Pt 3 EN 10213 Pt 4 Steel castings EN 10222 Pt 1 EN 10222 Pt 2 EN 10222 Pt 3 EN 10222 Pt 4 EN 10222 Pt 5 Steel forging EN 12482 EN 10216 EN 10217 Aluminium Seamless & welded tubes NB. Manufacturer must still check suitability Taiex - Bratislava April 2005 7

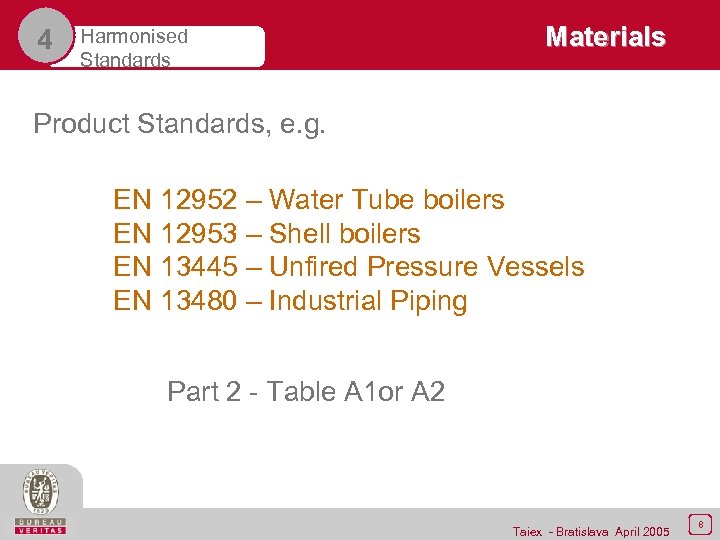

4 Harmonised Standards Materials Product Standards, e. g. EN 12952 – Water Tube boilers EN 12953 – Shell boilers EN 13445 – Unfired Pressure Vessels EN 13480 – Industrial Piping Part 2 - Table A 1 or A 2 Taiex - Bratislava April 2005 8

4 Harmonised Standards Materials Product Standards, e. g. EN 12952 – Water Tube boilers EN 12953 – Shell boilers EN 13445 – Unfired Pressure Vessels EN 13480 – Industrial Piping Part 2 - Table A 1 or A 2 Taiex - Bratislava April 2005 8

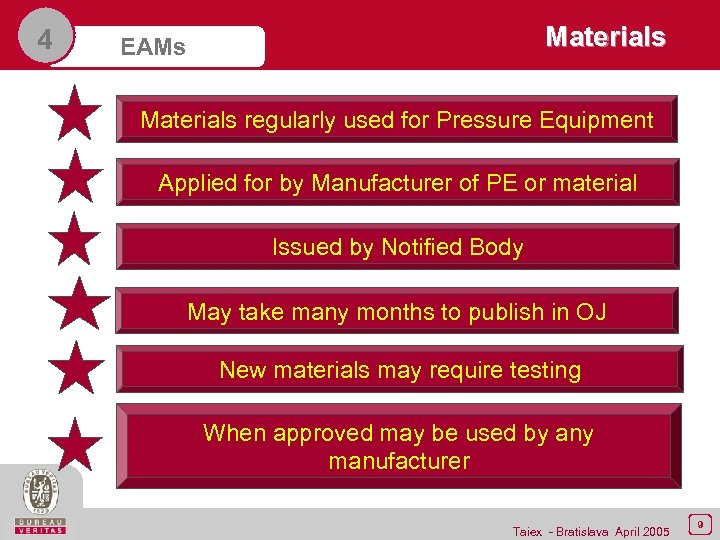

4 Materials EAMs Materials regularly used for Pressure Equipment Applied for by Manufacturer of PE or material Issued by Notified Body May take many months to publish in OJ New materials may require testing When approved may be used by any manufacturer Taiex - Bratislava April 2005 9

4 Materials EAMs Materials regularly used for Pressure Equipment Applied for by Manufacturer of PE or material Issued by Notified Body May take many months to publish in OJ New materials may require testing When approved may be used by any manufacturer Taiex - Bratislava April 2005 9

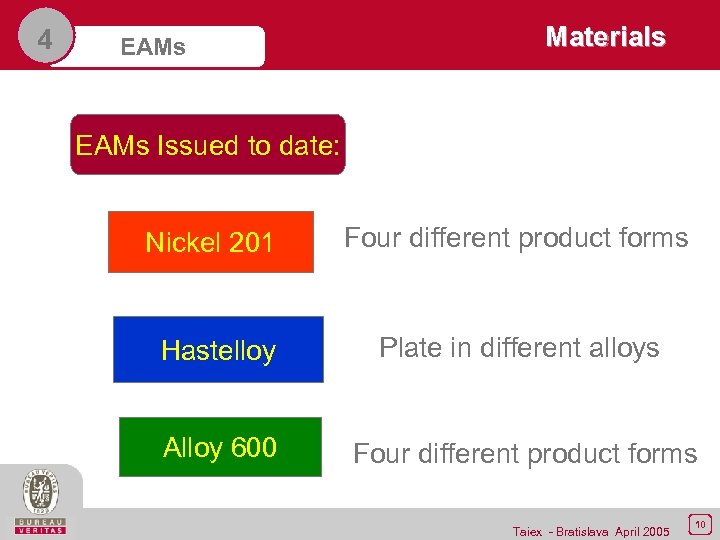

4 EAMs Materials EAMs Issued to date: Nickel 201 Four different product forms Hastelloy Plate in different alloys Alloy 600 Four different product forms Taiex - Bratislava April 2005 10

4 EAMs Materials EAMs Issued to date: Nickel 201 Four different product forms Hastelloy Plate in different alloys Alloy 600 Four different product forms Taiex - Bratislava April 2005 10

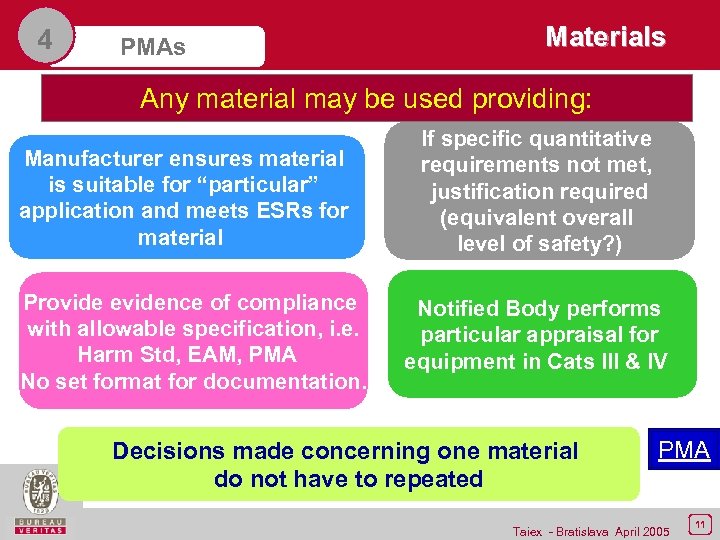

4 PMAs Materials Any material may be used providing: Manufacturer ensures material is suitable for “particular” application and meets ESRs for material Provide evidence of compliance with allowable specification, i. e. Harm Std, EAM, PMA No set format for documentation. If specific quantitative requirements not met, justification required (equivalent overall level of safety? ) Notified Body performs particular appraisal for equipment in Cats III & IV Decisions made concerning one material do not have to repeated PMA Taiex - Bratislava April 2005 11

4 PMAs Materials Any material may be used providing: Manufacturer ensures material is suitable for “particular” application and meets ESRs for material Provide evidence of compliance with allowable specification, i. e. Harm Std, EAM, PMA No set format for documentation. If specific quantitative requirements not met, justification required (equivalent overall level of safety? ) Notified Body performs particular appraisal for equipment in Cats III & IV Decisions made concerning one material do not have to repeated PMA Taiex - Bratislava April 2005 11

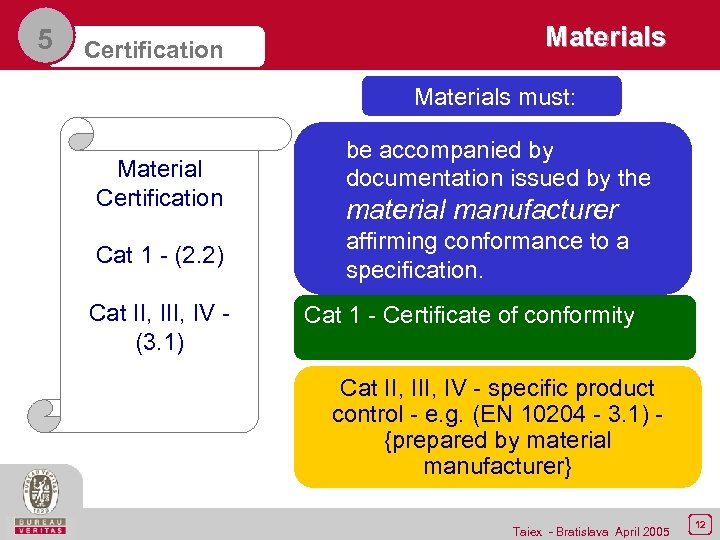

5 Certification Materials must: Material Certification Cat 1 - (2. 2) Cat II, IV (3. 1) be accompanied by documentation issued by the material manufacturer affirming conformance to a specification. Cat 1 - Certificate of conformity Cat II, IV - specific product control - e. g. (EN 10204 - 3. 1) {prepared by material manufacturer} Taiex - Bratislava April 2005 12

5 Certification Materials must: Material Certification Cat 1 - (2. 2) Cat II, IV (3. 1) be accompanied by documentation issued by the material manufacturer affirming conformance to a specification. Cat 1 - Certificate of conformity Cat II, IV - specific product control - e. g. (EN 10204 - 3. 1) {prepared by material manufacturer} Taiex - Bratislava April 2005 12

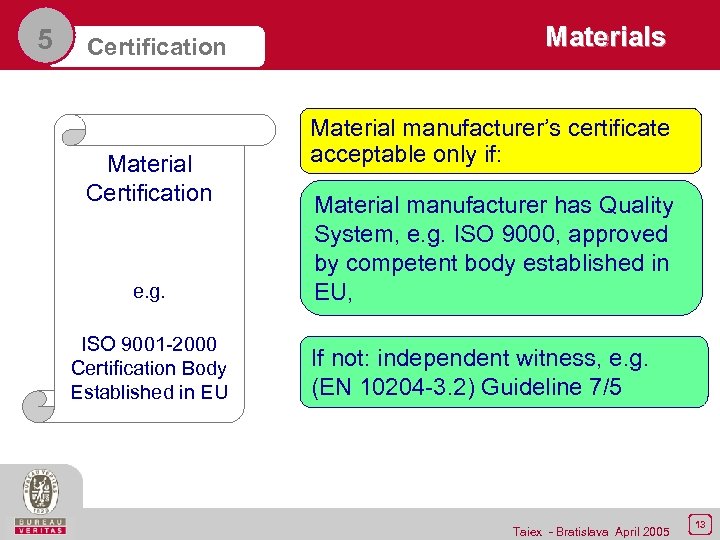

5 Certification Material Certification e. g. ISO 9001 -2000 Certification Body Established in EU Materials Material manufacturer’s certificate acceptable only if: Material manufacturer has Quality System, e. g. ISO 9000, approved by competent body established in EU, If not: independent witness, e. g. (EN 10204 -3. 2) Guideline 7/5 Taiex - Bratislava April 2005 13

5 Certification Material Certification e. g. ISO 9001 -2000 Certification Body Established in EU Materials Material manufacturer’s certificate acceptable only if: Material manufacturer has Quality System, e. g. ISO 9000, approved by competent body established in EU, If not: independent witness, e. g. (EN 10204 -3. 2) Guideline 7/5 Taiex - Bratislava April 2005 13

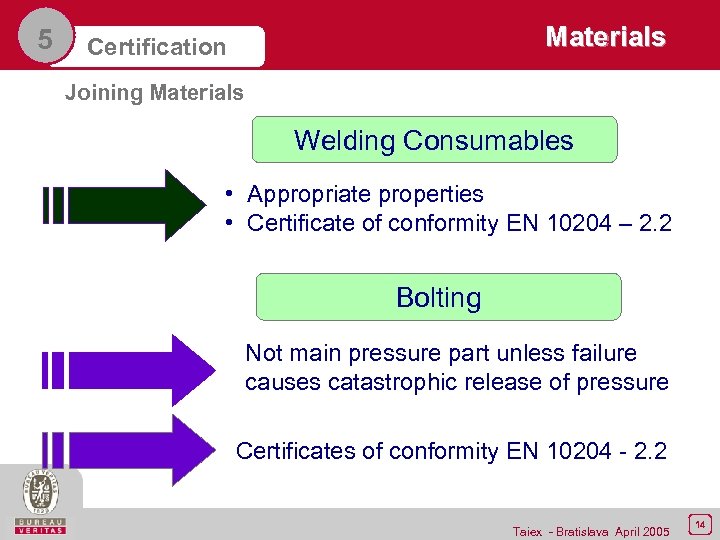

5 Materials Certification Joining Materials Welding Consumables • Appropriate properties • Certificate of conformity EN 10204 – 2. 2 Bolting Not main pressure part unless failure causes catastrophic release of pressure Certificates of conformity EN 10204 - 2. 2 Taiex - Bratislava April 2005 14

5 Materials Certification Joining Materials Welding Consumables • Appropriate properties • Certificate of conformity EN 10204 – 2. 2 Bolting Not main pressure part unless failure causes catastrophic release of pressure Certificates of conformity EN 10204 - 2. 2 Taiex - Bratislava April 2005 14

6 WGP Guidelines Materials http: //ped. eurodyn. com/ 8 Section 7 - Materials • 7/5 - Inspection documents when manufacturer does not hold appropriate QS approval • 7/17 – Impact testing • 7/19 - Components • 7/24 – Assured properties • 7/25 – Welded pipe Taiex - Bratislava April 2005 17

6 WGP Guidelines Materials http: //ped. eurodyn. com/ 8 Section 7 - Materials • 7/5 - Inspection documents when manufacturer does not hold appropriate QS approval • 7/17 – Impact testing • 7/19 - Components • 7/24 – Assured properties • 7/25 – Welded pipe Taiex - Bratislava April 2005 17

Taiex - Bratislava April 2005 18

Taiex - Bratislava April 2005 18

For further information, please contact: Peter Hanmore Technical Manager Bureau Veritas - + 44 161 446 4600 peter. hanmore@uk. bureauveritas. com 19

For further information, please contact: Peter Hanmore Technical Manager Bureau Veritas - + 44 161 446 4600 peter. hanmore@uk. bureauveritas. com 19