2b447657417ccfe8963daaf3cff534f0.ppt

- Количество слайдов: 17

System Simulation for Aftertreatment University Perspective Christopher J. Rutland Engine Research Center University of Wisconsin - Madison UW ERC – CLEERS April 21, 2010 1

System Simulation for Aftertreatment University Perspective Christopher J. Rutland Engine Research Center University of Wisconsin - Madison UW ERC – CLEERS April 21, 2010 1

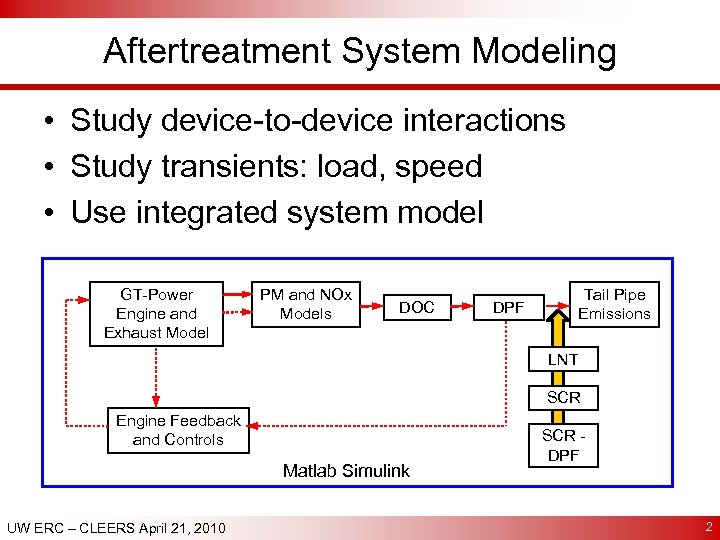

Aftertreatment System Modeling • Study device-to-device interactions • Study transients: load, speed • Use integrated system model GT-Power Engine and Exhaust Model PM and NOx Models DOC DPF Tail Pipe Emissions LNT SCR Engine Feedback and Controls Matlab Simulink UW ERC – CLEERS April 21, 2010 SCR DPF 2

Aftertreatment System Modeling • Study device-to-device interactions • Study transients: load, speed • Use integrated system model GT-Power Engine and Exhaust Model PM and NOx Models DOC DPF Tail Pipe Emissions LNT SCR Engine Feedback and Controls Matlab Simulink UW ERC – CLEERS April 21, 2010 SCR DPF 2

System Integration Development • Collect device models – Develop some in house – Obtain others from partners (primarily GM) • Use appropriate level of model fidelity • Individually tested and calibrated • Emphasis on integrating models – Device interaction – Transient simulation – Simple controls for operating system UW ERC – CLEERS April 21, 2010 3

System Integration Development • Collect device models – Develop some in house – Obtain others from partners (primarily GM) • Use appropriate level of model fidelity • Individually tested and calibrated • Emphasis on integrating models – Device interaction – Transient simulation – Simple controls for operating system UW ERC – CLEERS April 21, 2010 3

Funding University Research • Government – Supports longer term, more basic research • National priorities to support research communities – Does not expect immediate payoff • High risk research is OK – May solicit industry input (e. g. DOE) – Good match for university objectives and time scales • Industry – Provides real world problems: Relevance – Different priorities than universities UW ERC – CLEERS April 21, 2010 4

Funding University Research • Government – Supports longer term, more basic research • National priorities to support research communities – Does not expect immediate payoff • High risk research is OK – May solicit industry input (e. g. DOE) – Good match for university objectives and time scales • Industry – Provides real world problems: Relevance – Different priorities than universities UW ERC – CLEERS April 21, 2010 4

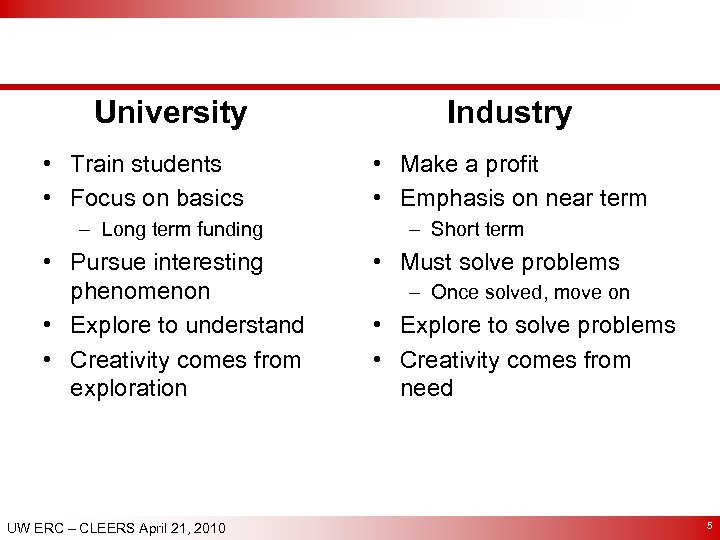

University • Train students • Focus on basics – Long term funding • Pursue interesting phenomenon • Explore to understand • Creativity comes from exploration UW ERC – CLEERS April 21, 2010 Industry • Make a profit • Emphasis on near term – Short term • Must solve problems – Once solved, move on • Explore to solve problems • Creativity comes from need 5

University • Train students • Focus on basics – Long term funding • Pursue interesting phenomenon • Explore to understand • Creativity comes from exploration UW ERC – CLEERS April 21, 2010 Industry • Make a profit • Emphasis on near term – Short term • Must solve problems – Once solved, move on • Explore to solve problems • Creativity comes from need 5

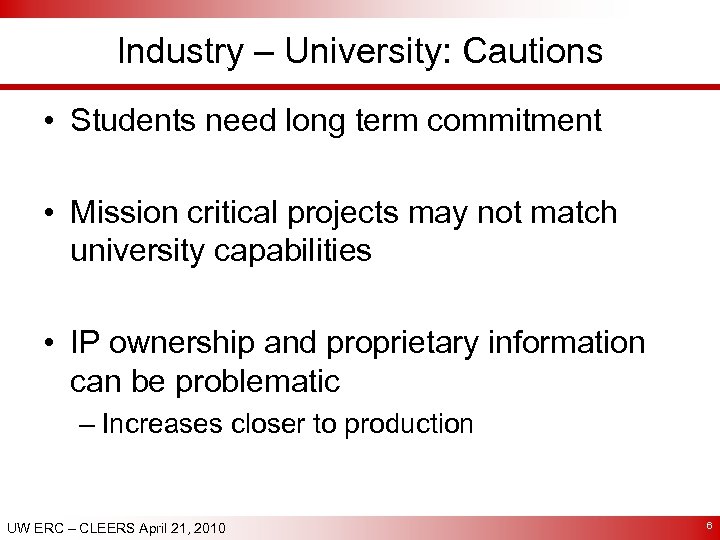

Industry – University: Cautions • Students need long term commitment • Mission critical projects may not match university capabilities • IP ownership and proprietary information can be problematic – Increases closer to production UW ERC – CLEERS April 21, 2010 6

Industry – University: Cautions • Students need long term commitment • Mission critical projects may not match university capabilities • IP ownership and proprietary information can be problematic – Increases closer to production UW ERC – CLEERS April 21, 2010 6

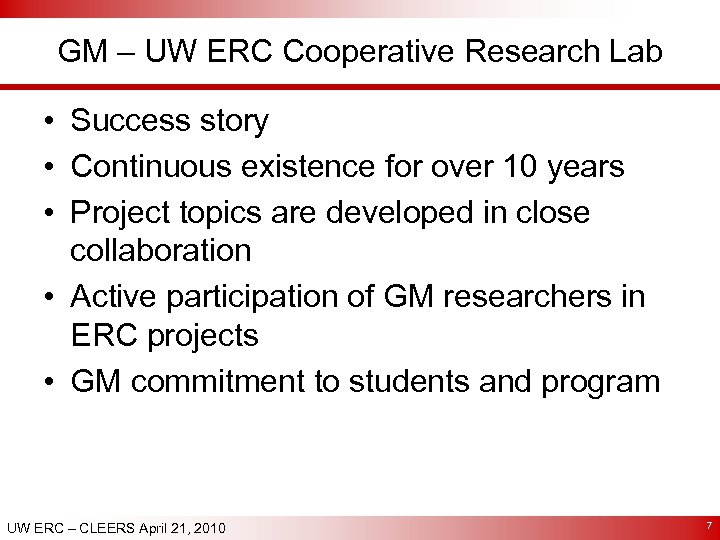

GM – UW ERC Cooperative Research Lab • Success story • Continuous existence for over 10 years • Project topics are developed in close collaboration • Active participation of GM researchers in ERC projects • GM commitment to students and program UW ERC – CLEERS April 21, 2010 7

GM – UW ERC Cooperative Research Lab • Success story • Continuous existence for over 10 years • Project topics are developed in close collaboration • Active participation of GM researchers in ERC projects • GM commitment to students and program UW ERC – CLEERS April 21, 2010 7

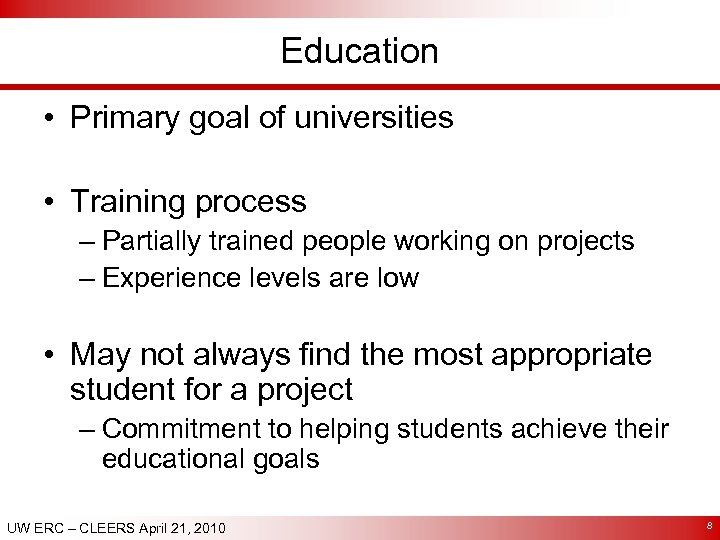

Education • Primary goal of universities • Training process – Partially trained people working on projects – Experience levels are low • May not always find the most appropriate student for a project – Commitment to helping students achieve their educational goals UW ERC – CLEERS April 21, 2010 8

Education • Primary goal of universities • Training process – Partially trained people working on projects – Experience levels are low • May not always find the most appropriate student for a project – Commitment to helping students achieve their educational goals UW ERC – CLEERS April 21, 2010 8

Examples • Using system simulations to explore aftertreatment issues 1. DPF loading vs. regeneration frequency • Impact on fuel economy 2. Using DPF thermal inertia • Both projects supported by UW-GM CRL UW ERC – CLEERS April 21, 2010 9

Examples • Using system simulations to explore aftertreatment issues 1. DPF loading vs. regeneration frequency • Impact on fuel economy 2. Using DPF thermal inertia • Both projects supported by UW-GM CRL UW ERC – CLEERS April 21, 2010 9

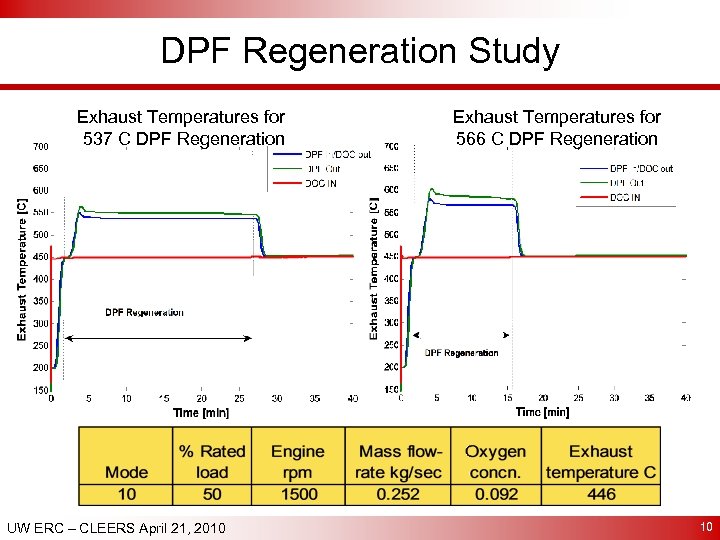

DPF Regeneration Study Exhaust Temperatures for 537 C DPF Regeneration UW ERC – CLEERS April 21, 2010 Exhaust Temperatures for 566 C DPF Regeneration 10

DPF Regeneration Study Exhaust Temperatures for 537 C DPF Regeneration UW ERC – CLEERS April 21, 2010 Exhaust Temperatures for 566 C DPF Regeneration 10

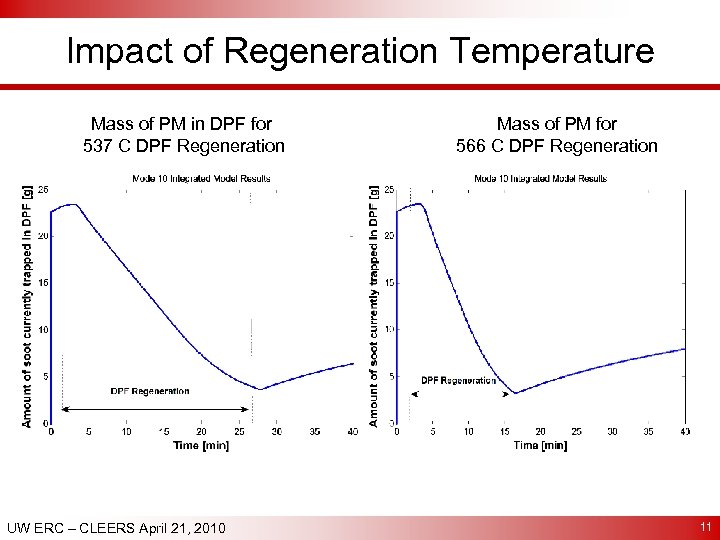

Impact of Regeneration Temperature Mass of PM in DPF for 537 C DPF Regeneration UW ERC – CLEERS April 21, 2010 Mass of PM for 566 C DPF Regeneration 11

Impact of Regeneration Temperature Mass of PM in DPF for 537 C DPF Regeneration UW ERC – CLEERS April 21, 2010 Mass of PM for 566 C DPF Regeneration 11

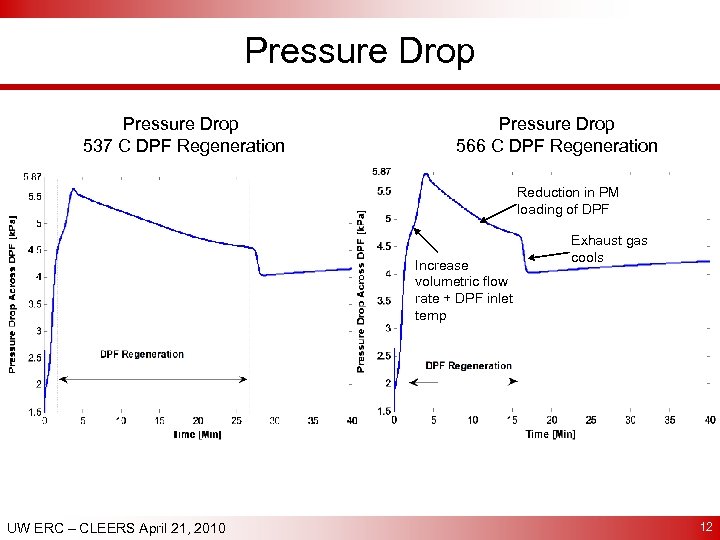

Pressure Drop 537 C DPF Regeneration Pressure Drop 566 C DPF Regeneration Reduction in PM loading of DPF Increase volumetric flow rate + DPF inlet temp UW ERC – CLEERS April 21, 2010 Exhaust gas cools 12

Pressure Drop 537 C DPF Regeneration Pressure Drop 566 C DPF Regeneration Reduction in PM loading of DPF Increase volumetric flow rate + DPF inlet temp UW ERC – CLEERS April 21, 2010 Exhaust gas cools 12

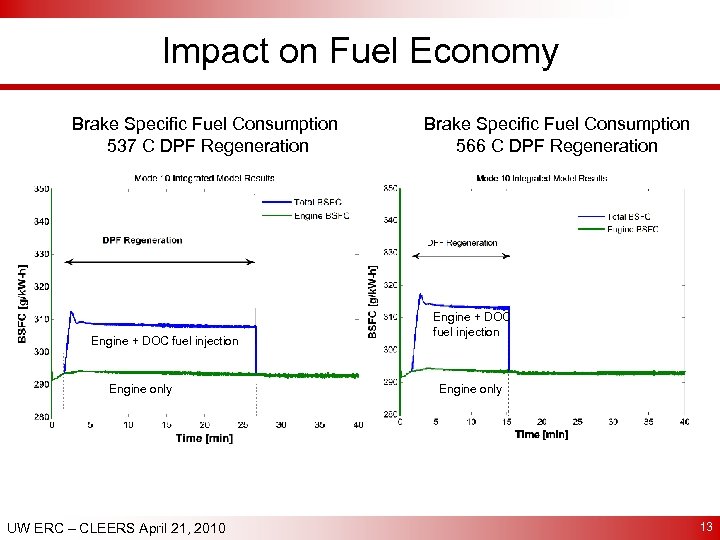

Impact on Fuel Economy Brake Specific Fuel Consumption 537 C DPF Regeneration Engine + DOC fuel injection Engine only UW ERC – CLEERS April 21, 2010 Brake Specific Fuel Consumption 566 C DPF Regeneration Engine + DOC fuel injection Engine only 13

Impact on Fuel Economy Brake Specific Fuel Consumption 537 C DPF Regeneration Engine + DOC fuel injection Engine only UW ERC – CLEERS April 21, 2010 Brake Specific Fuel Consumption 566 C DPF Regeneration Engine + DOC fuel injection Engine only 13

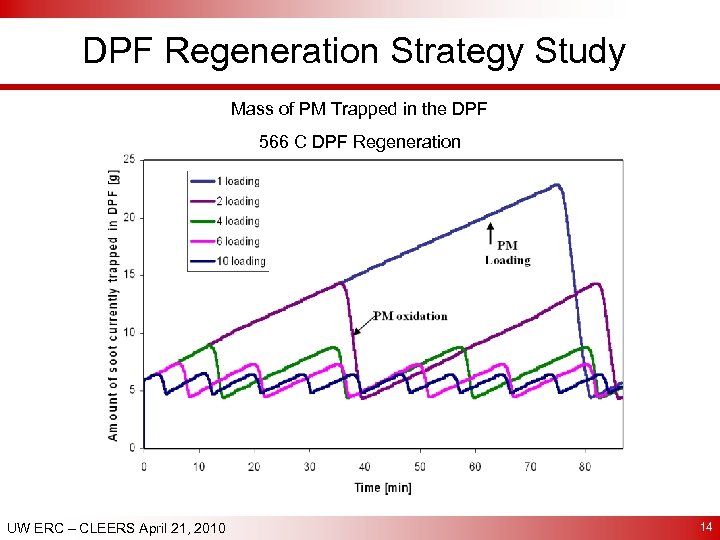

DPF Regeneration Strategy Study Mass of PM Trapped in the DPF 566 C DPF Regeneration UW ERC – CLEERS April 21, 2010 14

DPF Regeneration Strategy Study Mass of PM Trapped in the DPF 566 C DPF Regeneration UW ERC – CLEERS April 21, 2010 14

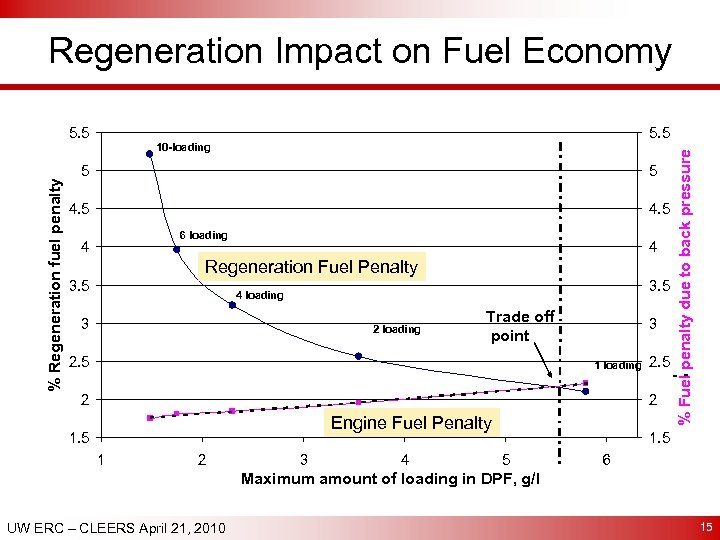

Regeneration Impact on Fuel Economy 5. 5 10 -loading 5 5 Regeneration fuel penalty 4. 5 6 loading 4 4 Regeneration Fuel Penalty 3. 5 4 loading 3 2 loading 3. 5 Trade off Point point 2. 5 3 1 loading 2 2. 5 2 Engine Fuel Penalty penalty Back pressure fuel 1. 5 1 2 3 4 5 % Fuel penalty due to back pressure % Regeneration fuel penalty 5. 5 1. 5 6 Maximum amount of loading in DPF, g/l UW ERC – CLEERS April 21, 2010 15

Regeneration Impact on Fuel Economy 5. 5 10 -loading 5 5 Regeneration fuel penalty 4. 5 6 loading 4 4 Regeneration Fuel Penalty 3. 5 4 loading 3 2 loading 3. 5 Trade off Point point 2. 5 3 1 loading 2 2. 5 2 Engine Fuel Penalty penalty Back pressure fuel 1. 5 1 2 3 4 5 % Fuel penalty due to back pressure % Regeneration fuel penalty 5. 5 1. 5 6 Maximum amount of loading in DPF, g/l UW ERC – CLEERS April 21, 2010 15

![Oxidation Rate and Thermal Inertia Mass of soot [g]/ Soot oxidation rate [mg/s] 40 Oxidation Rate and Thermal Inertia Mass of soot [g]/ Soot oxidation rate [mg/s] 40](https://present5.com/presentation/2b447657417ccfe8963daaf3cff534f0/image-16.jpg) Oxidation Rate and Thermal Inertia Mass of soot [g]/ Soot oxidation rate [mg/s] 40 Fuel rate 30 Soot oxidation rate 20 1. 5 1 Trapped soot 10 0. 5 -4 Exhaust fuel rate [kg/s] x 10 2 Minimum soot target 0 0 800 0 1600 Time [s] • Oxidation rate decreases • Constant temperature • Decreasing amount of soot UW ERC – CLEERS April 21, 2010 • Thermal inertia • Soot continues to be consumed after fuel injection stops • Opportunities for optimization 16

Oxidation Rate and Thermal Inertia Mass of soot [g]/ Soot oxidation rate [mg/s] 40 Fuel rate 30 Soot oxidation rate 20 1. 5 1 Trapped soot 10 0. 5 -4 Exhaust fuel rate [kg/s] x 10 2 Minimum soot target 0 0 800 0 1600 Time [s] • Oxidation rate decreases • Constant temperature • Decreasing amount of soot UW ERC – CLEERS April 21, 2010 • Thermal inertia • Soot continues to be consumed after fuel injection stops • Opportunities for optimization 16

Summary • University system simulation – Training students – Should focus on basics – Can greatly benefit from industry ties when done correctly • Integrated system useful for studying device interactions and transients UW ERC – CLEERS April 21, 2010 17

Summary • University system simulation – Training students – Should focus on basics – Can greatly benefit from industry ties when done correctly • Integrated system useful for studying device interactions and transients UW ERC – CLEERS April 21, 2010 17