49beb9696dbc21b9a1129fcc63952c84.ppt

- Количество слайдов: 30

System Level Approach to Characterization and Radiometric Calibration of Space Based Electro-Optical Sensors Joe Tansock, Alan Thurgood, Mark Larsen Space Dynamics Laboratory Joe. Tansock@sdl. usu. edu 435 -797 -4369 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 1

Outline • Philosophy – What is meant by a complete calibration • Planning • Subsystem/Component Measurements • Sensor-Level Engineering Calibration • Sensor-Level Calibration – Facilities – Data Collection • On-Orbit Calibration 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 2

Calibration Philosophy – Complete Cal • A complete sensor calibration: – Provides a thorough understanding of sensor operation and performance – Verifies a sensor’s readiness for flight – Verifies requirements and quantifies radiometric and goniometric performance – Converts sensor output to engineering units that are compatible with measurement objectives – Provides traceability to appropriate standards – Estimates measurement uncertainties 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 3

Calibration Philosophy – Cal Domains • A complete calibration will address five responsivity domains: – Radiometric responsivity • • Radiance and irradiance traceable to NIST Response linearity and uniformity corrections Nominal/outlying pixel identification Transfer calibration to internal calibration units – Spectral responsivity • Sensor-level relative spectral response – Spatial responsivity • Point response function, effective field of view, optical distortion, and scatter – Temporal • Short, medium, and long-term repeatability, frequency response – Polarization • Polarization sensitivity 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 4

Calibration Philosophy – Cal Domains • The goal of calibration is to characterize each domain independently – Together, these individually characterized domains comprise a complete calibration of a radiometric sensor • Domains cannot always be characterized independently – Complicates and increases calibration effort – Example: Spectral spatial dependence caused by Stierwalt effect • Calibration parameters are grouped into two convenient categories: – Calibration equation • Converts sensor output (counts, volts, etc. ) to engineering units – Radiometric model • All parameters not included in calibration equation but required for complete calibration 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 5

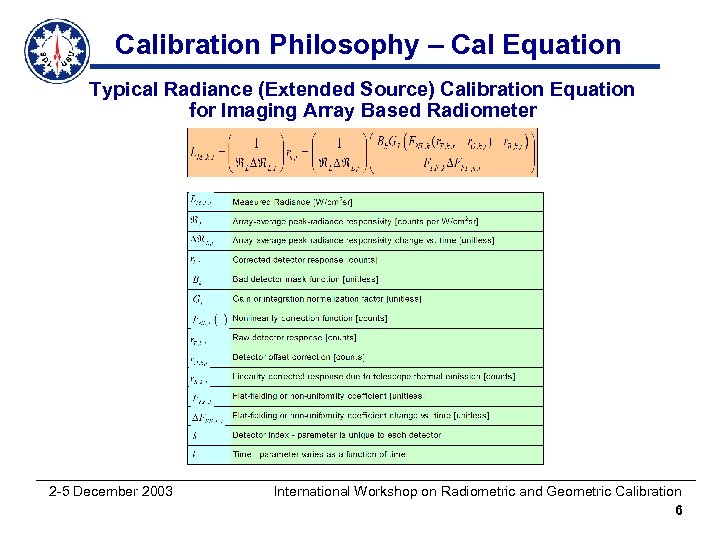

Calibration Philosophy – Cal Equation Typical Radiance (Extended Source) Calibration Equation for Imaging Array Based Radiometer 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 6

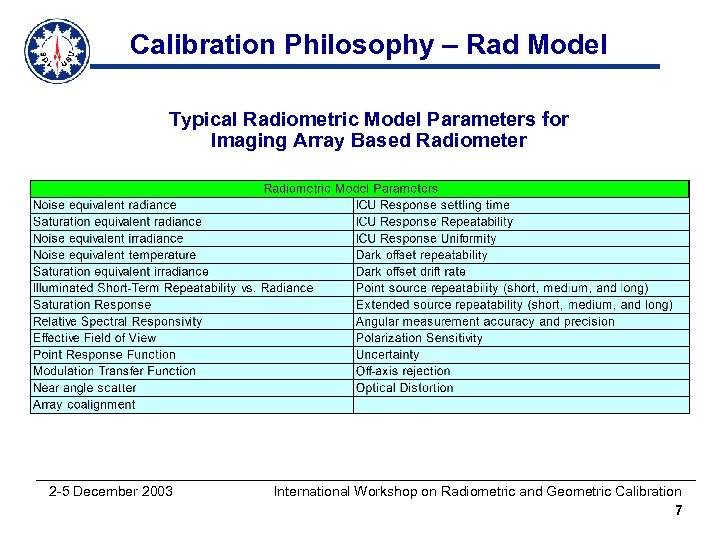

Calibration Philosophy – Rad Model Typical Radiometric Model Parameters for Imaging Array Based Radiometer 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 7

Calibration Philosophy – SI Units • Express calibration results in SI units – Standards maintained by national measurement institutes – Recommended Practice: Symbols, Terms, Units and Uncertainty Analysis for Radiometric Sensor Calibration, NIST Handbook 152, Clair Wyatt, et. al. – http: //ts. nist. gov/ts/htdocs/230/233/calibration/uncert/index. ht m • Contains Links for – Guidelines for Evaluating and Expressing the Uncertainty of NIST Measurement Results, 1994 – Guide to the Expression of Uncertainty in Measurement, International Standards Organization (ISO), 1993 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 8

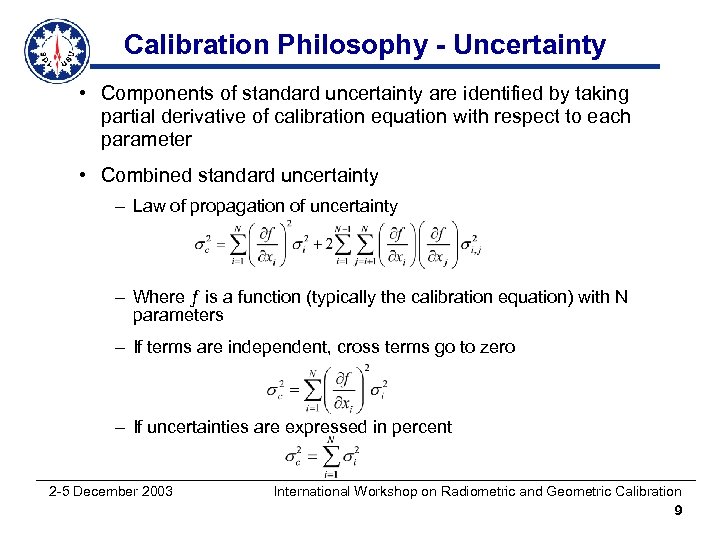

Calibration Philosophy - Uncertainty • Components of standard uncertainty are identified by taking partial derivative of calibration equation with respect to each parameter • Combined standard uncertainty – Law of propagation of uncertainty – Where ƒ is a function (typically the calibration equation) with N parameters – If terms are independent, cross terms go to zero – If uncertainties are expressed in percent 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 9

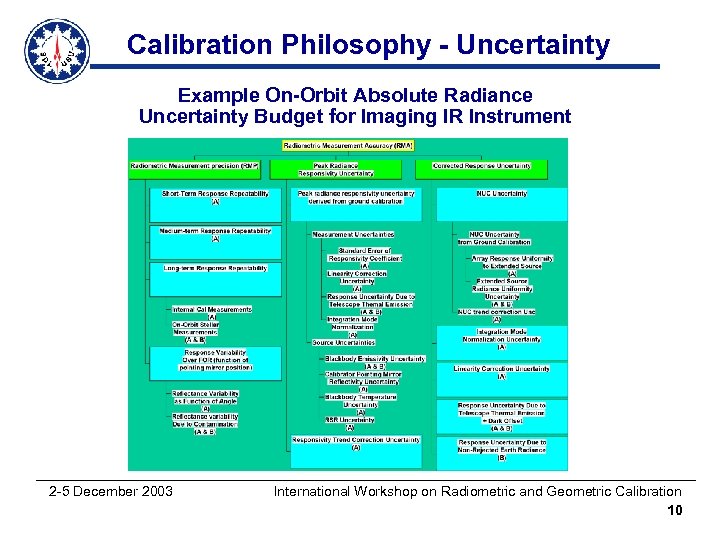

Calibration Philosophy - Uncertainty Example On-Orbit Absolute Radiance Uncertainty Budget for Imaging IR Instrument 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 10

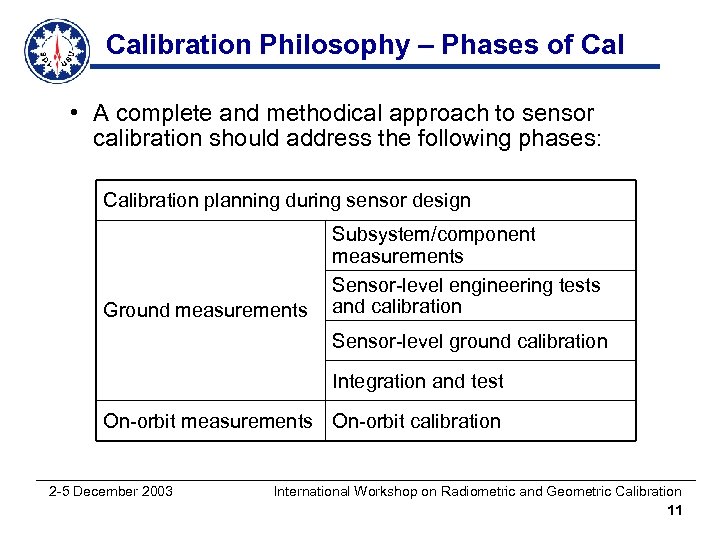

Calibration Philosophy – Phases of Cal • A complete and methodical approach to sensor calibration should address the following phases: Calibration planning during sensor design Ground measurements Subsystem/component measurements Sensor-level engineering tests and calibration Sensor-level ground calibration Integration and test On-orbit measurements On-orbit calibration 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 11

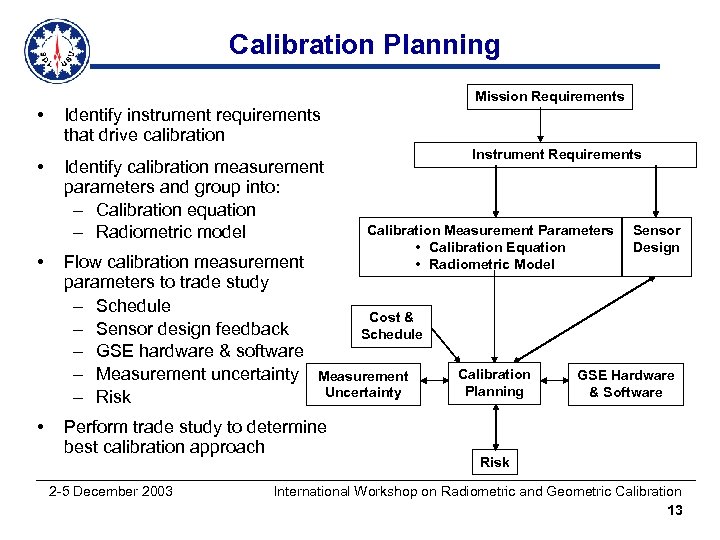

Calibration Planning • Perform calibration planning during sensor design – Sensor design should allow for efficient and complete calibration – Sensor design and calibration approach can be optimized to achieve performance requirements • Planning phase can help shake out problems – Schedule and cost risk is minimized by understanding what is required to perform a successful calibration early in the design phase 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 12

Calibration Planning Mission Requirements • • Identify instrument requirements that drive calibration Identify calibration measurement parameters and group into: – Calibration equation – Radiometric model Flow calibration measurement parameters to trade study – Schedule – Sensor design feedback – GSE hardware & software – Measurement uncertainty – Risk Calibration Measurement Parameters • Calibration Equation • Radiometric Model Sensor Design Cost & Schedule Measurement Uncertainty Perform trade study to determine best calibration approach 2 -5 December 2003 Instrument Requirements Calibration Planning GSE Hardware & Software Risk International Workshop on Radiometric and Geometric Calibration 13

Subsystem/Component Measurements • Subsystem and/or component level measurements – Help verify, understand, and predict performance – Minimize schedule risk during system assembly • Identifies problems at lowest level of assembly • Minimizes schedule impact by minimizing disassembly effort to fix a problem • System/Sensor level measurements – Allow for end-to-end measurements – Account for interactions between subsystems and components that are difficult to predict 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 14

Subsystem/Component Measurements • Merging component-level measurements to predict sensor level calibration parameters may increase system-level uncertainties A, B – SABER relative spectral responsivity (RSR) • 9 of 10 channels < 5% difference • 1 channel 24% difference (reason unknown) A. ) Component Level Prediction versus System Level Measurement of SABER Relative Spectral response, Scott Hansen, et. al. , Conference on Characterization and Radiometric Calibration for Remote Sensing, 1999 B. ) System Level Vs. Piece Parts Calibration: NIST Traceability – When Do You Have It and What Does It Mean? Steven Lorentz, L-1 Standards and Technology, Inc, Joseph Rice, NIST, CALCON, 2003 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 15

Sensor-Level Engineering Calibration • Engineering calibration – Performed before ground calibration (Lesson Learned) – Perform abbreviated set of all calibration measurements – Verifies GSE operation, test configurations, and test procedures – Checks out the sensor – Produces preliminary data to evaluate sensor performance – Feedbacks info to flight unit, calibration equipment, procedures, etc. • Engineering calibration data analysis – Evaluates sensor performance, test procedures, calibration hardware performance and test procedures • Based on results of engineering calibration, appropriate updates can be made to prepare for ground calibration data collection 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 16

Sensor-Level Ground Calibration • Provides complete calibration • Is performed under conditions that simulate operational conditions for intended application/measurement • Minimizes risk of not discovering a problem prior to launch • Promotes mission success during on-orbit operations • For many sensor applications – Detailed calibration is most efficiently performed during ground calibration – On-orbit calibration will not provide sufficient number of sources at needed flux levels – Operational time required for calibration is minimized • Best to perform ground calibration at highest level of assembly possible – Sensor-level at a minimum is recommended 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 17

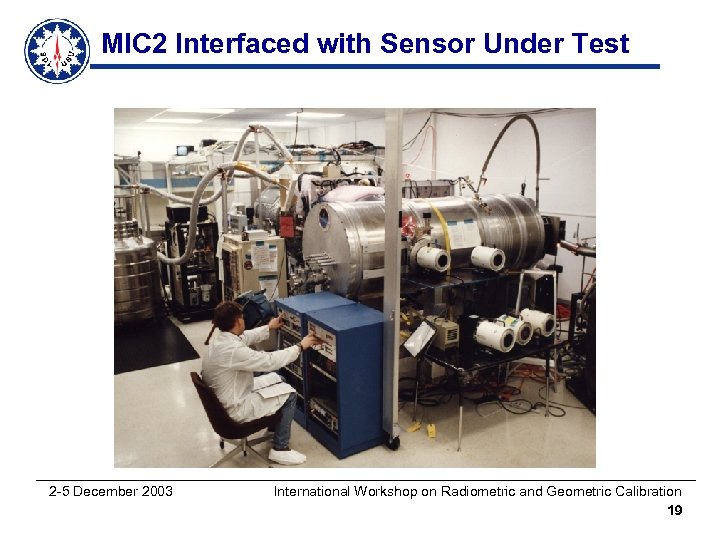

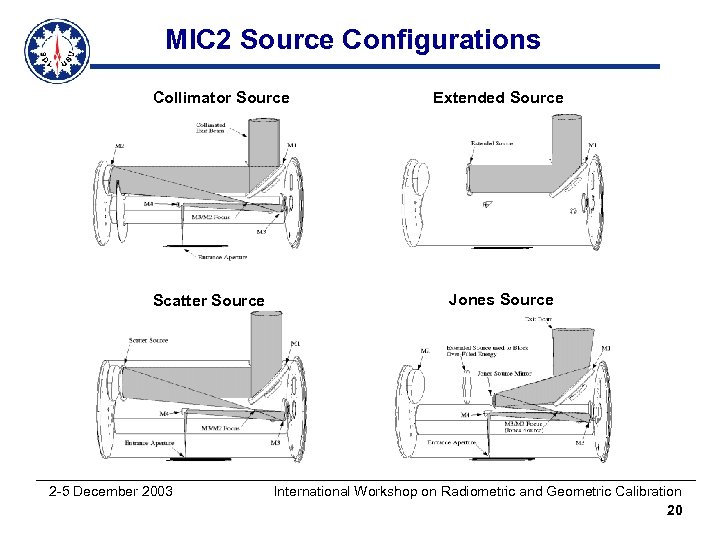

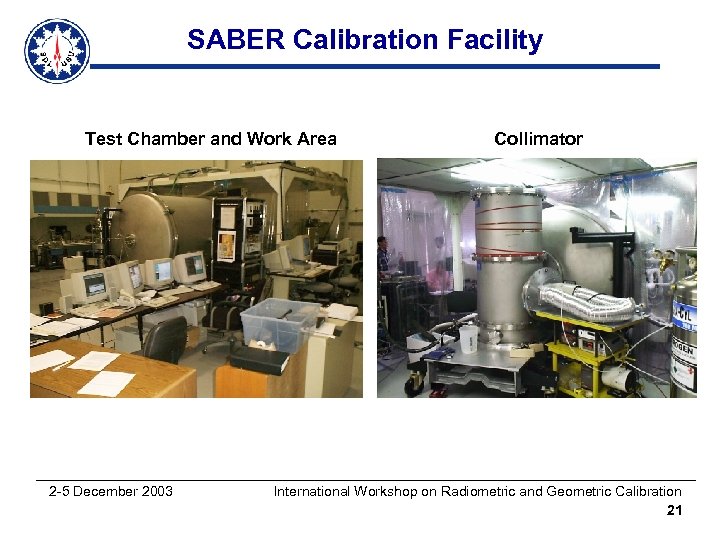

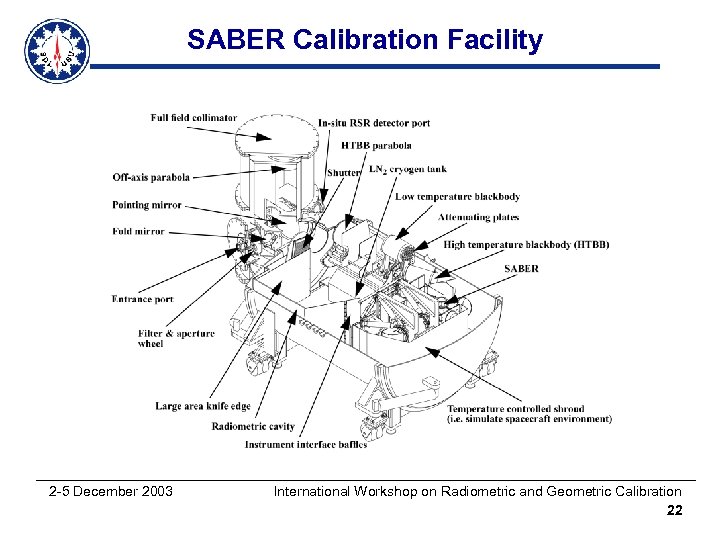

Calibration Facilities • Make sure calibration hardware has been tested and characterized (Lesson Learned) – Problems with calibration hardware may cause schedule delays and degraded calibration • If possible, integrate calibration measurements into single facility (Lesson Learned) – Minimizes calibration time by reducing or preventing repeated cycle (i. e. pump, cool-down, warm-up) and configuration times • Examples: – The multi function infrared calibrator (MIC 2) incorporates 4 source configurations in single package – SABER calibration facility • Test chamber interfaced with collimator provided calibration measurement configurations 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 18

MIC 2 Interfaced with Sensor Under Test 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 19

MIC 2 Source Configurations Collimator Source Scatter Source 2 -5 December 2003 Extended Source Jones Source International Workshop on Radiometric and Geometric Calibration 20

SABER Calibration Facility Test Chamber and Work Area 2 -5 December 2003 Collimator International Workshop on Radiometric and Geometric Calibration 21

SABER Calibration Facility 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 22

Calibration Data Collection • Develop and write calibration data collection procedures – Include: • • • Test procedures Time requirements Preparation and data collection steps Documentation of script files Data collection log sheets 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 23

Calibration Data Collection • Data collection should be automated when possible and practical – Automate with scripting language to make measurements efficient and repeatable • Data collection procedures should be detailed and mature • Sensor engineers and/or technicians may assist with data collection – Requires familiarity with sensor under test – Makes shift work possible to facilitate schedule • Data quality should be verified for its intended use with quicklook analyses • Contamination should be monitored using QCM and/or radiometric techniques – Quantify contamination levels – Determine when corrective action is required 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 24

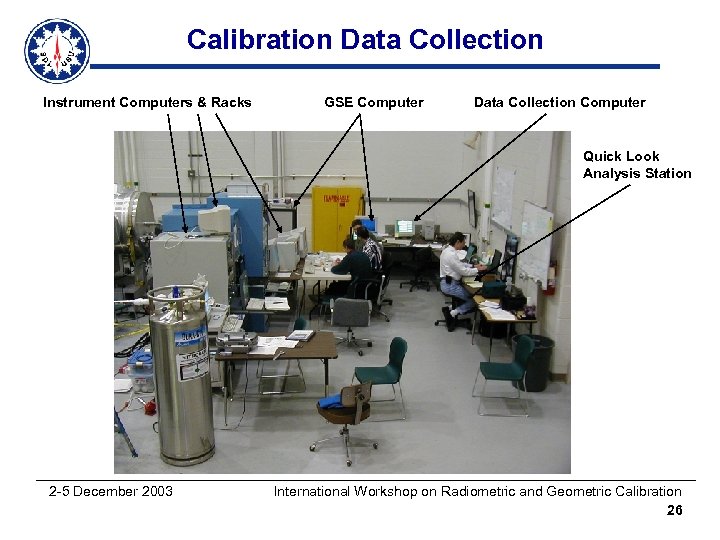

Calibration Data Collection • Data collection environment includes: – Test conductor and data collection station – Ground support equipment (GSE) computer • Controls and views status of GSE – Instrument computer • Controls and views status of instrument – Data collection computer • Initiates and executes data collection • Controls and monitors status – GSE – Instrument – Quick look analysis station 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 25

Calibration Data Collection Instrument Computers & Racks GSE Computer Data Collection Computer Quick Look Analysis Station 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 26

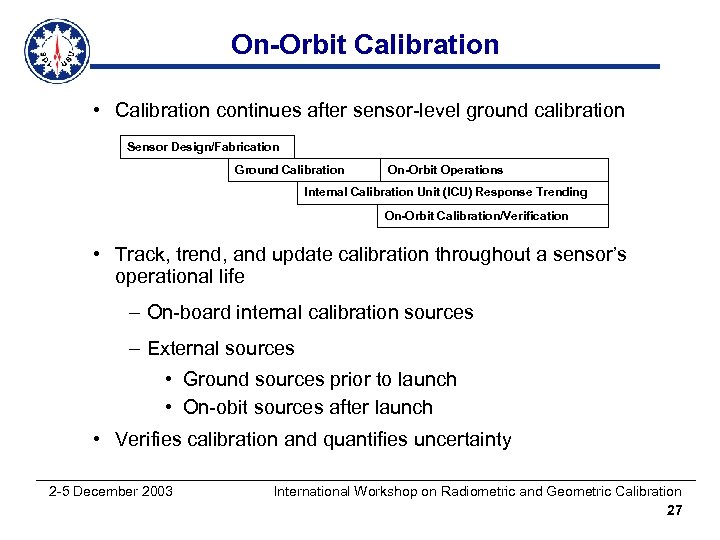

On-Orbit Calibration • Calibration continues after sensor-level ground calibration Sensor Design/Fabrication Ground Calibration On-Orbit Operations Internal Calibration Unit (ICU) Response Trending On-Orbit Calibration/Verification • Track, trend, and update calibration throughout a sensor’s operational life – On-board internal calibration sources – External sources • Ground sources prior to launch • On-obit sources after launch • Verifies calibration and quantifies uncertainty 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 27

On-Orbit Calibration • On-orbit sources – Standard IR stars • Stars a. Boo, a. Lyra, a. Tau, a. CMa, b. Gem, b. Peg • Catalogs include IRC, AFGL, IRAS, MSX, 2 MASS – Planetary objects • Planets provide bright variable sources • Asteroids, moon, etc. • Sometimes you have to be creative: – Off-axis scatter characterization using the moon – Reference spheres – Other techniques • View large area source located on surface of earth (remote sensing applications) 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 28

Summary • What is meant by a complete calibration • Calibration parameters are organized into two categories – Calibration equation and radiometric model • Overall calibration approach – Perform calibration planning in parallel with sensor design – Subsystem measurements are a good idea but don’t rely on these measurements to give system level calibration – Perform engineering calibration to verify GSE, test procedures, and estimate sensor performance – Obtain complete and thorough sensor level calibration – Verify and/or update calibration throughout operational life 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 29

The Annual Conference on Characterization & Radiometric Calibration for Remote Sensing addresses characterization, calibration, and radiometric issues within the IR, Visible and UV spectrums. Session Topics Include: § Concepts and Applications of Measurement Uncertainty § Solar, Lunar and Stellar Radiometric Measurements § Pre-launch to On-orbit Calibration Transfer: Approaches and On-orbit Monitoring Techniques § Developing National Calibration/Certification Standards for EO/IR Systems Join us at Utah State University September 13 -16, 2004! 2 -5 December 2003 International Workshop on Radiometric and Geometric Calibration 30

49beb9696dbc21b9a1129fcc63952c84.ppt