333671edf68671e92ce91ddf7cde98b2.ppt

- Количество слайдов: 27

Sustainable Hotel Design Group 5 Presentation 4 Demand/Supply Matching

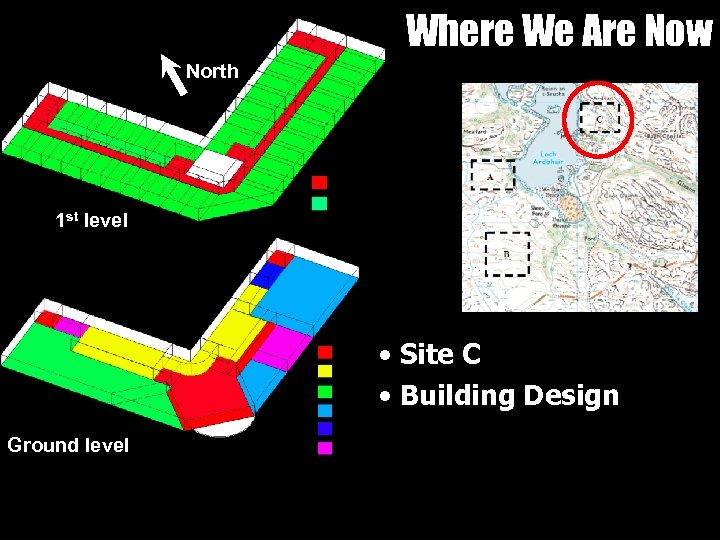

Where We Are Now North 1 st level • Site C • Building Design Ground level

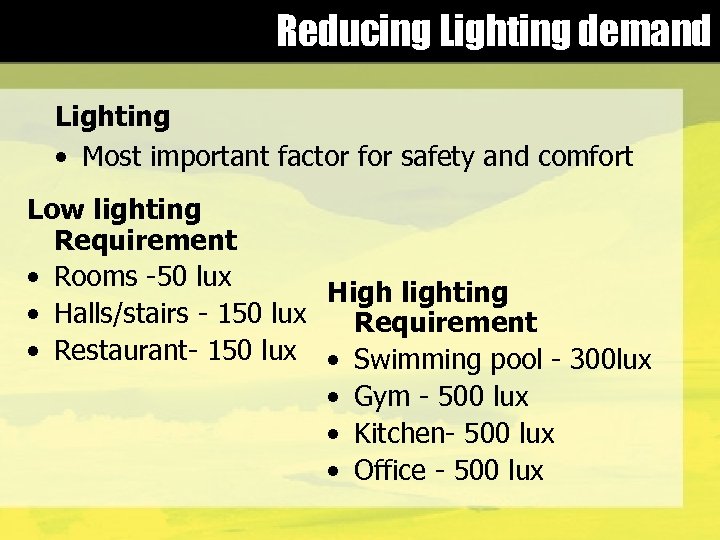

Reducing Lighting demand Lighting • Most important factor for safety and comfort Low lighting Requirement • Rooms -50 lux High lighting • Halls/stairs - 150 lux Requirement • Restaurant- 150 lux • Swimming pool - 300 lux • Gym - 500 lux • Kitchen- 500 lux • Office - 500 lux

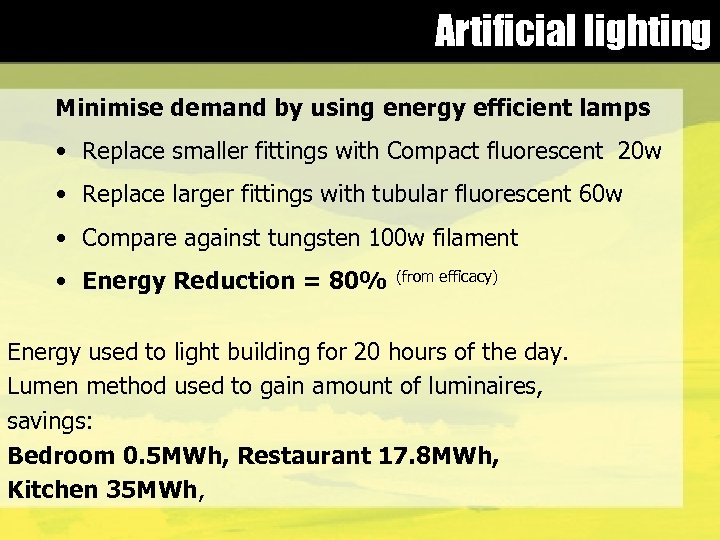

Artificial lighting Minimise demand by using energy efficient lamps • Replace smaller fittings with Compact fluorescent 20 w • Replace larger fittings with tubular fluorescent 60 w • Compare against tungsten 100 w filament • Energy Reduction = 80% (from efficacy) Energy used to light building for 20 hours of the day. Lumen method used to gain amount of luminaires, savings: Bedroom 0. 5 MWh, Restaurant 17. 8 MWh, Kitchen 35 MWh,

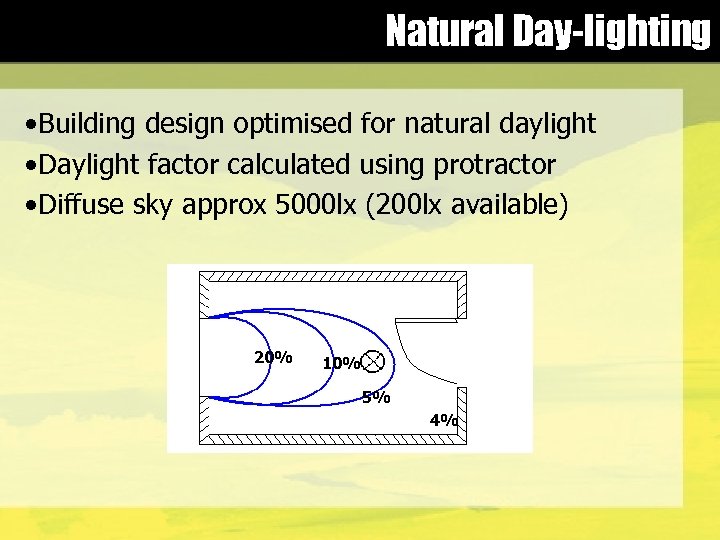

Natural Day-lighting • Building design optimised for natural daylight • Daylight factor calculated using protractor • Diffuse sky approx 5000 lx (200 lx available) 20% 10% 5% 4%

Control Lighting Control for bedrooms, (occupants) • Dimmer switch. • Internal removable shading. • Key card system. Control for restaurant, office (control systems) • Stepped PSALI and switch off zones • Would require light sensors • Master switch/timers

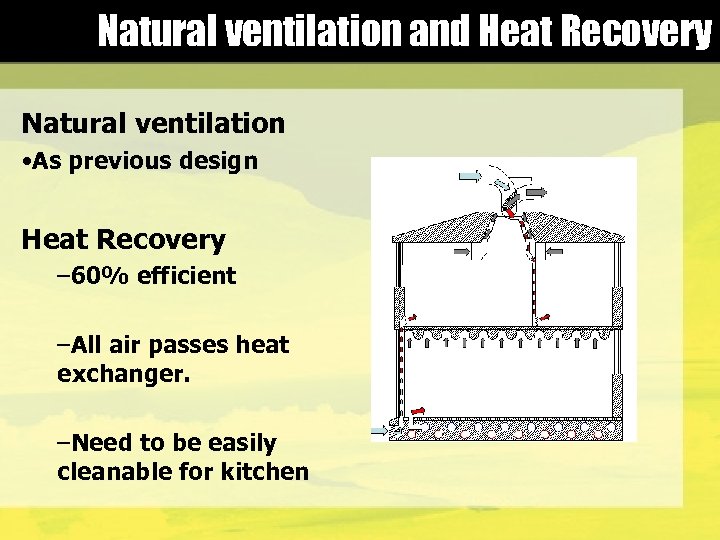

Natural ventilation and Heat Recovery Natural ventilation • As previous design Heat Recovery – 60% efficient –All air passes heat exchanger. –Need to be easily cleanable for kitchen

Mechanical Ventilation • Mechanical Ventilation • Using two Aerofoil bladed centrifugal pump (η 85%) • For outside 0 and inside 30 3 7290 m /s • Swimming pool load for fans= 1 k. W • Saving using heat recovery on heating load =35 k. W 3 11520 m /s fans=2 k. W • Kitchen load for • Required to remove contaminants from kitchen.

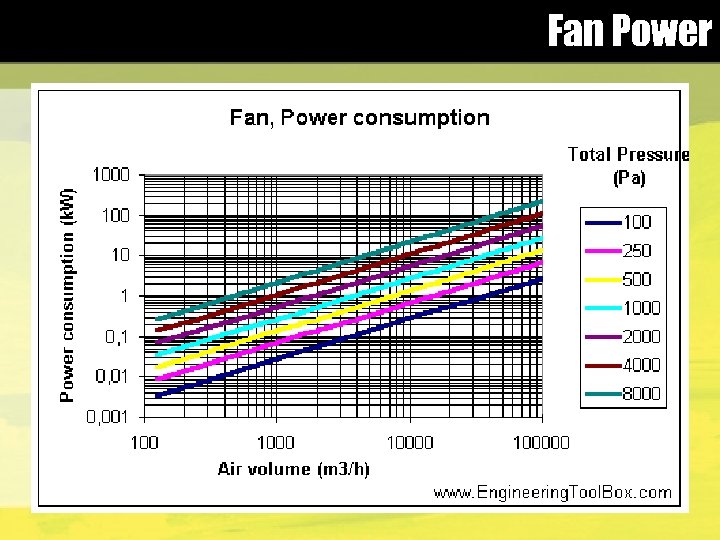

Fan Power

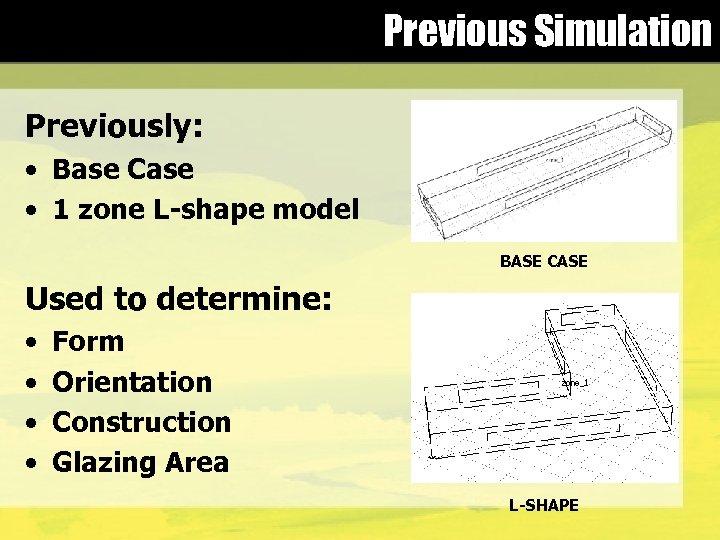

Previous Simulation Previously: • Base Case • 1 zone L-shape model BASE CASE Used to determine: • • Form Orientation Construction Glazing Area L-SHAPE

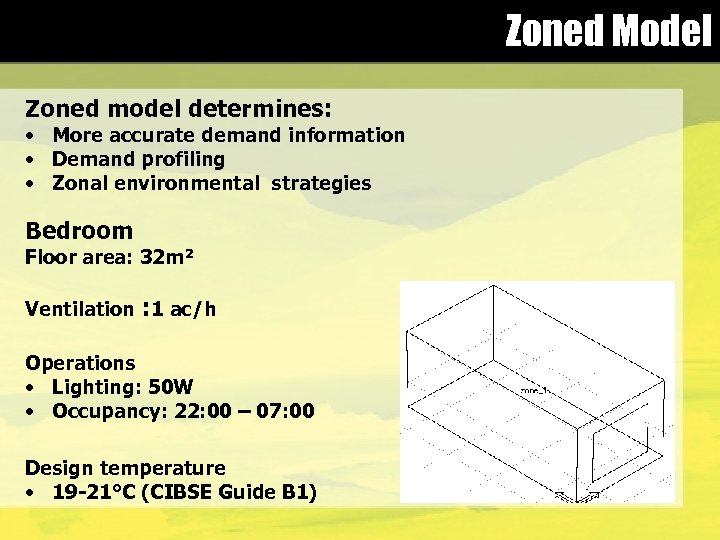

Zoned Model Zoned model determines: • More accurate demand information • Demand profiling • Zonal environmental strategies Bedroom Floor area: 32 m² Ventilation : 1 ac/h Operations • Lighting: 50 W • Occupancy: 22: 00 – 07: 00 Design temperature • 19 -21°C (CIBSE Guide B 1)

Tweaking the Design Glazing Area: 30% • Minimise overheating in summer • Reduce heat loss in winter Ventilation rate • Summer: 3 ac/h 10: 00 – 18: 00 1 ac/h 18: 00 – 10: 00 (following day) • Winter / Transition: 1 ac/h 00: 00 - 24: 00 Construction • Varied load bearing block work to timber construction

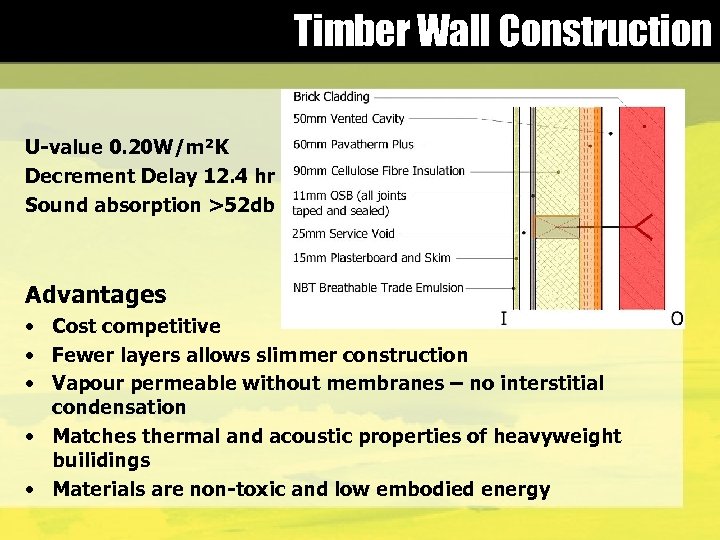

Timber Wall Construction U-value 0. 20 W/m²K Decrement Delay 12. 4 hr Sound absorption >52 db Advantages • Cost competitive • Fewer layers allows slimmer construction • Vapour permeable without membranes – no interstitial condensation • Matches thermal and acoustic properties of heavyweight builidings • Materials are non-toxic and low embodied energy

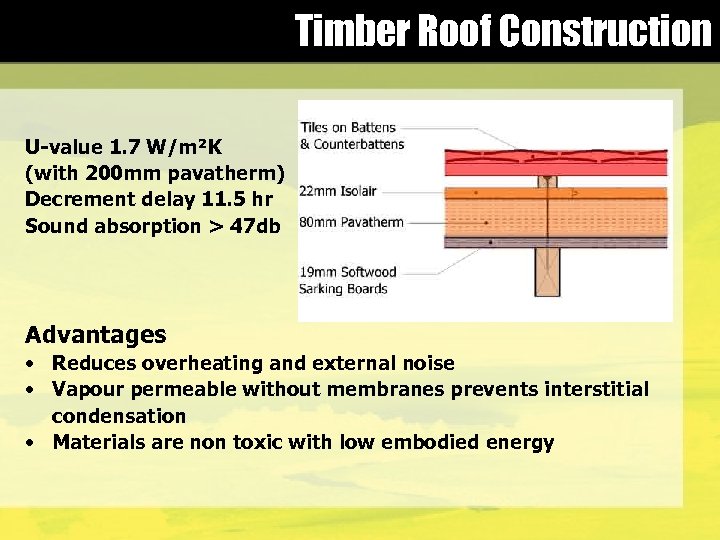

Timber Roof Construction U-value 1. 7 W/m²K (with 200 mm pavatherm) Decrement delay 11. 5 hr Sound absorption > 47 db Advantages • Reduces overheating and external noise • Vapour permeable without membranes prevents interstitial condensation • Materials are non toxic with low embodied energy

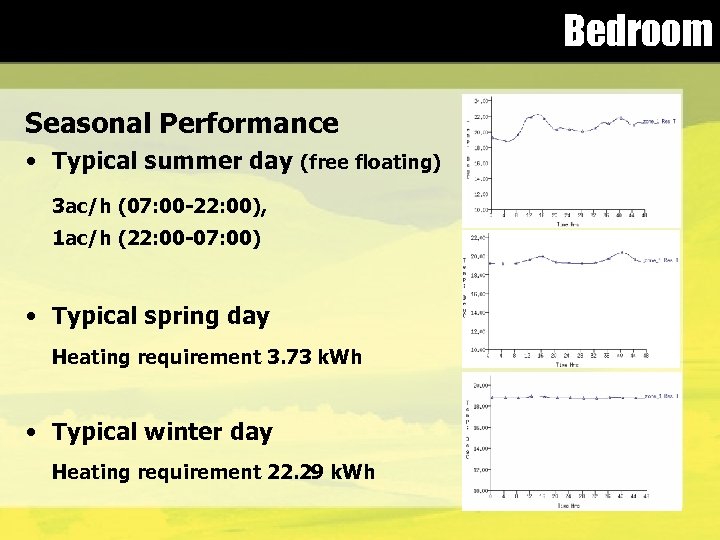

Bedroom Seasonal Performance • Typical summer day (free floating) 3 ac/h (07: 00 -22: 00), 1 ac/h (22: 00 -07: 00) • Typical spring day Heating requirement 3. 73 k. Wh • Typical winter day Heating requirement 22. 29 k. Wh

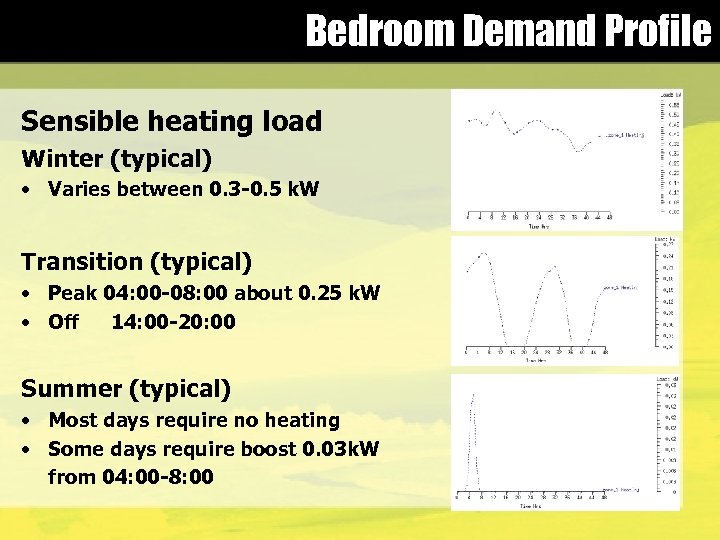

Bedroom Demand Profile Sensible heating load Winter (typical) • Varies between 0. 3 -0. 5 k. W Transition (typical) • Peak 04: 00 -08: 00 about 0. 25 k. W • Off 14: 00 -20: 00 Summer (typical) • Most days require no heating • Some days require boost 0. 03 k. W from 04: 00 -8: 00

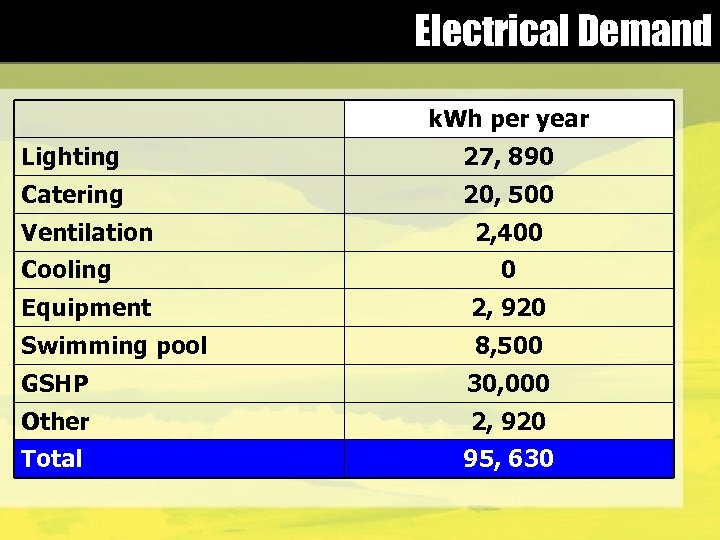

Electrical Demand k. Wh per year Lighting 27, 890 Catering 20, 500 Ventilation Cooling 2, 400 0 Equipment 2, 920 Swimming pool 8, 500 GSHP 30, 000 Other 2, 920 Total 95, 630

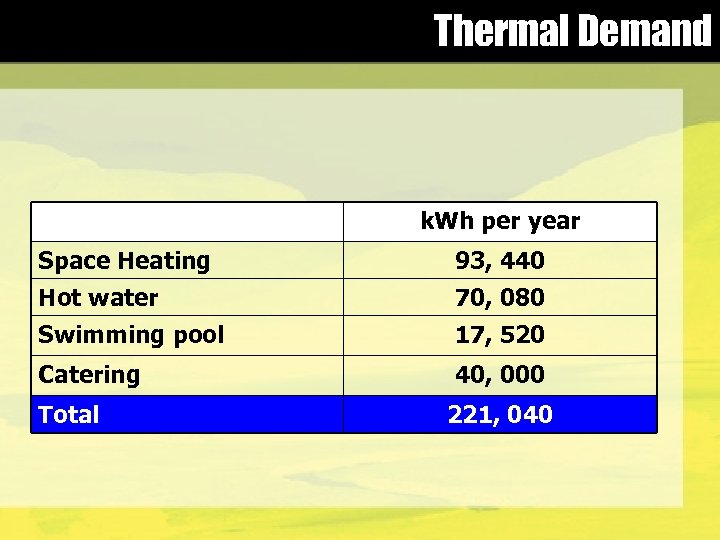

Thermal Demand k. Wh per year Space Heating 93, 440 Hot water 70, 080 Swimming pool 17, 520 Catering 40, 000 Total 221, 040

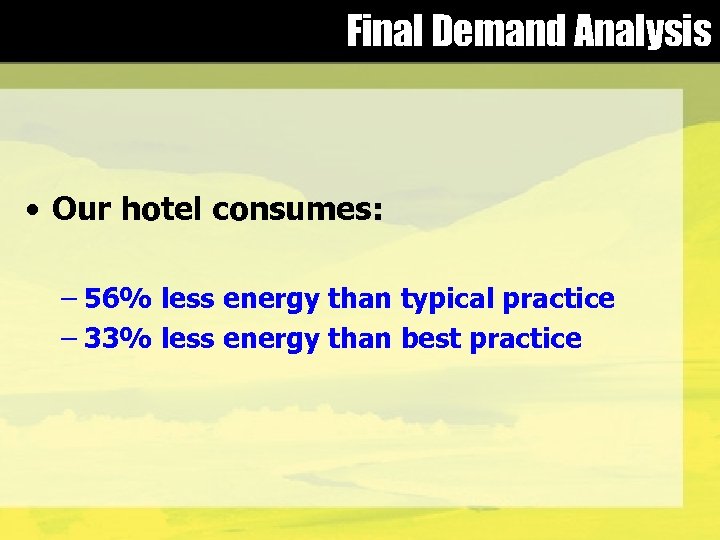

Final Demand Analysis • Our hotel consumes: – 56% less energy than typical practice – 33% less energy than best practice

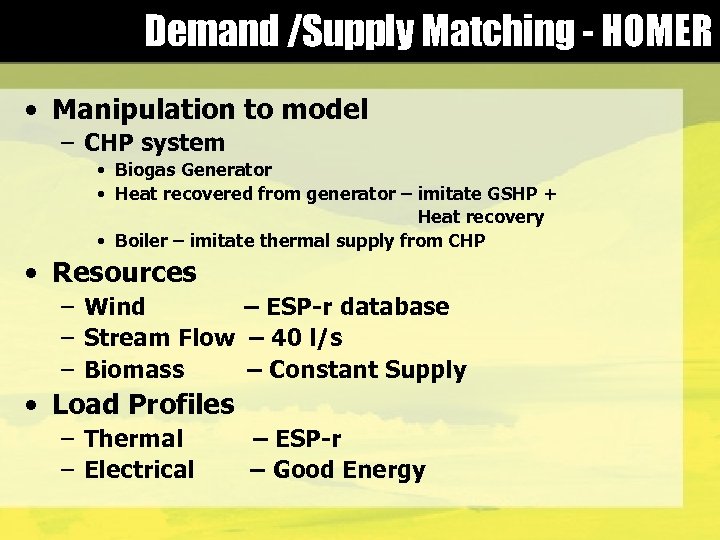

Demand /Supply Matching - HOMER • Manipulation to model – CHP system • Biogas Generator • Heat recovered from generator – imitate GSHP + Heat recovery • Boiler – imitate thermal supply from CHP • Resources – Wind – ESP-r database – Stream Flow – 40 l/s – Biomass – Constant Supply • Load Profiles – Thermal – Electrical – ESP-r – Good Energy

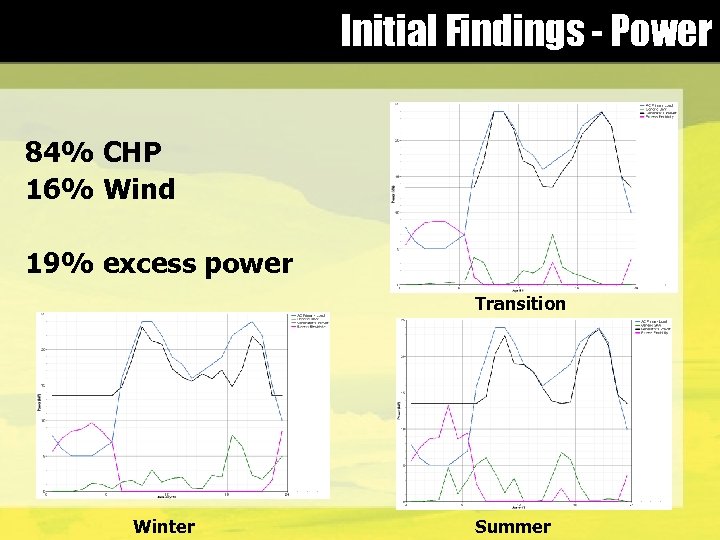

Initial Findings - Power 84% CHP 16% Wind 19% excess power Transition Winter Summer

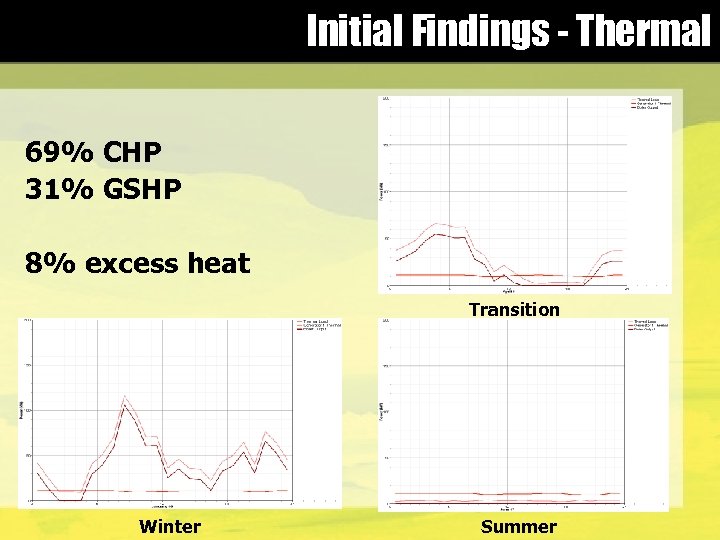

Initial Findings - Thermal 69% CHP 31% GSHP 8% excess heat Transition Winter Summer

Alterations to Model • Addition of Battery – 152 k. Wh – 304 k. Wh – 408 k. Wh • Subtraction of Hydro Power

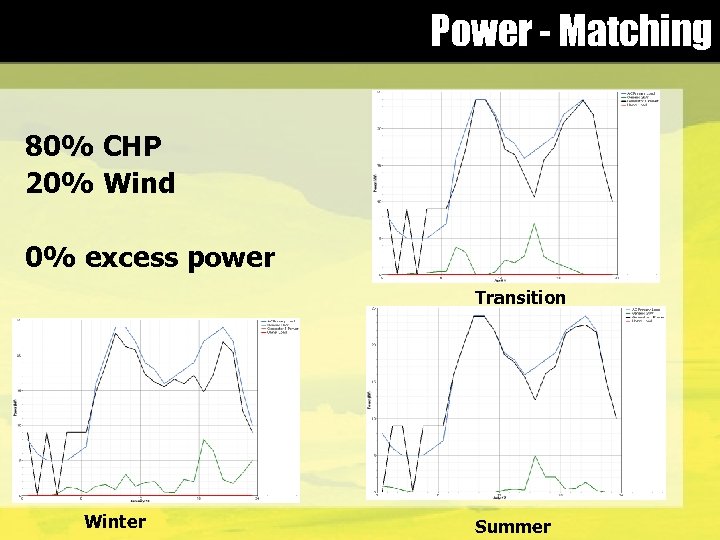

Power - Matching 80% CHP 20% Wind 0% excess power Transition Winter Summer

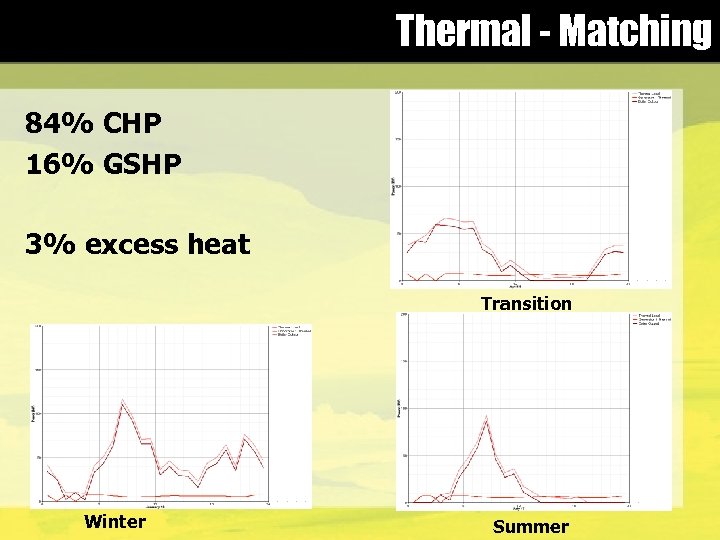

Thermal - Matching 84% CHP 16% GSHP 3% excess heat Transition Winter Summer

Conclusions • Final Supply Systems – Biomass CHP – Wind Energy – Ground Source Heat Pumps • Do without Hydro Power • Use of Batteries

Thank You For Listening Any Questions ?

333671edf68671e92ce91ddf7cde98b2.ppt