fcdbe4fc062be8d94e37cfec0e2d05ac.ppt

- Количество слайдов: 31

Sustainability in Practice How Canon can play a part in a sustainable procurement programme Reading University 2007

Canon Environment Ecology DVD Reading University 2007

Canon Philosophy Kyosei – ‘living and working together for the common good’ ¾ Establish a Truly Global Corporation Transcend borders to actively fulfill our social responsibility to all humankind, in every region of the world Accept the Responsibility of Being a Pioneer Create products without rival in quality and service, and which contribute to the improvement of societies around the world Reading University 2007 Ensure the Happiness of All the Canon Group Contribute to continuing prosperity by building an ideal firm

Reading University 2007

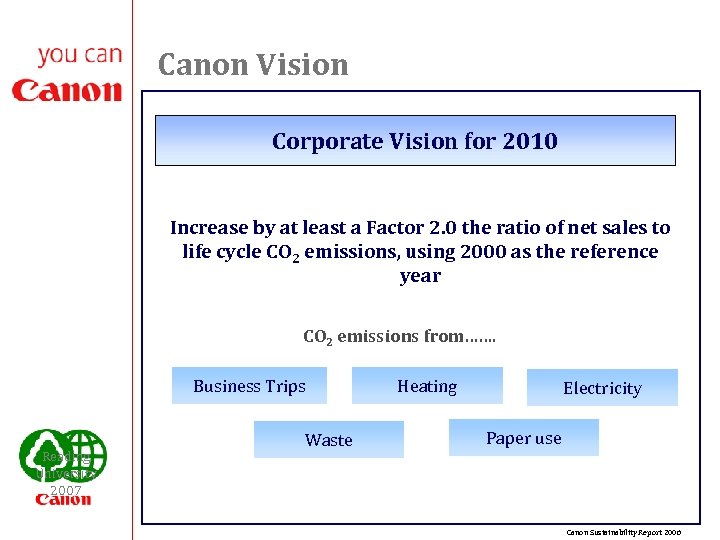

Canon Vision Corporate Vision for 2010 Increase by at least a Factor 2. 0 the ratio of net sales to life cycle CO 2 emissions, using 2000 as the reference year CO 2 emissions from……. Business Trips Reading University 2007 Waste Heating Electricity Paper use Canon Sustainability Report 2006

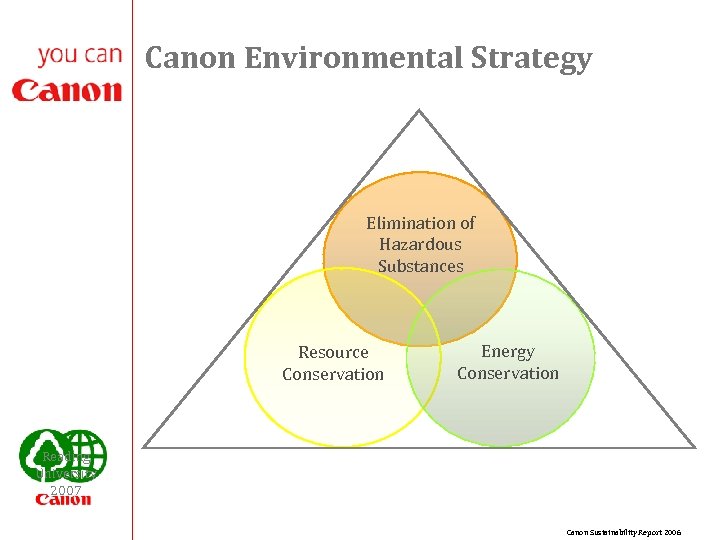

Canon Environmental Strategy Elimination of Hazardous Substances Resource Conservation Energy Conservation Reading University 2007 Canon Sustainability Report 2006

We are taking action in all these areas ¾ Production and manufacture including life cycle ¾ ¾ Social Responsibility ¾ Reading University 2007 Design Use of our products

Production and Manufacture Reading University 2007

Reading University 2007

Life Cycle Management Reading University 2007

Reading University 2007

Product Design Reading University 2007

Reading University 2007

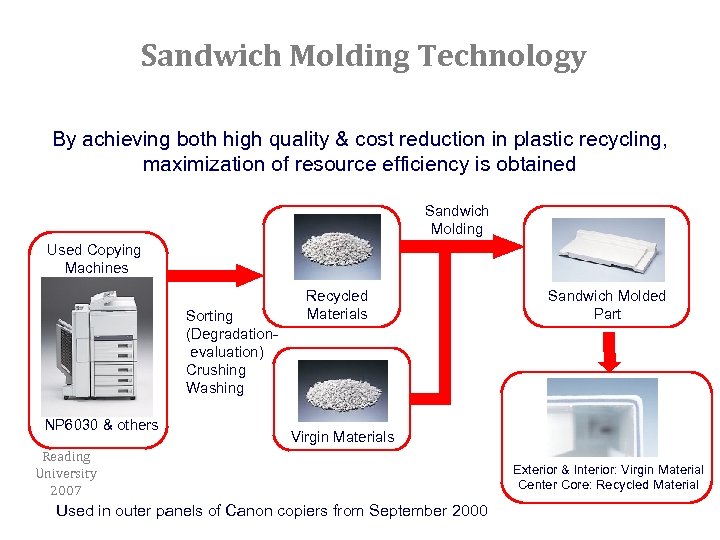

Sandwich Molding Technology By achieving both high quality & cost reduction in plastic recycling, maximization of resource efficiency is obtained Sandwich Molding Used Copying Machines Sorting (Degradationevaluation) Crushing Washing NP 6030 & others Recycled Materials Sandwich Molded Part Virgin Materials Reading University 2007 Used in outer panels of Canon copiers from September 2000 Exterior & Interior: Virgin Material Center Core: Recycled Material

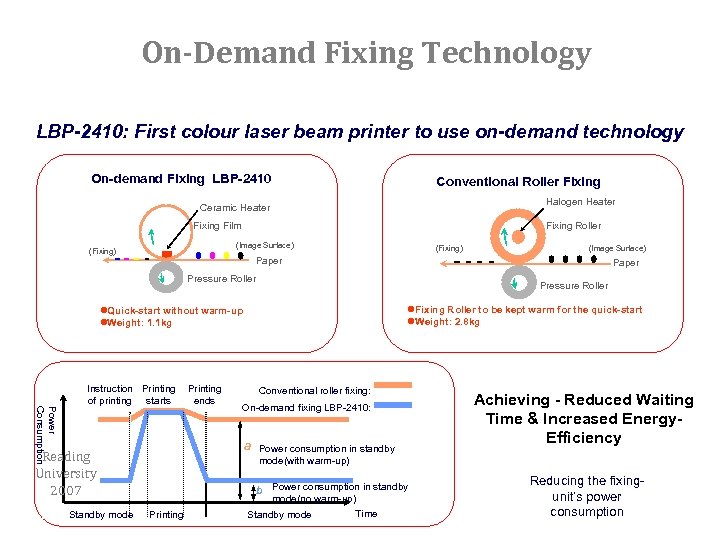

On-Demand Fixing Technology LBP-2410: First colour laser beam printer to use on-demand technology On-demand Fixing LBP-2410 Conventional Roller Fixing Halogen Heater Ceramic Heater Fixing Roller Fixing Film (Image Surface) (Fixing) Paper Pressure Roller 定着ローラ(熱容量大)への l. Fixing Roller to be kept warm for the quick-start l. Weight: 2. 8 kg l. Quick-start without warm-up l. Weight: 1. 1 kg Power Consumption Instruction Printing of printing starts Printing ends Conventional roller fixing: On-demand fixing LBP-2410: a Reading University 2007 Standby mode (Image Surface) Power consumption in standby mode(with warm-up) b Power consumption in standby Printing mode(no warm-up) Time Standby mode Achieving - Reduced Waiting Time & Increased Energy. Efficiency Reducing the fixingunit’s power consumption

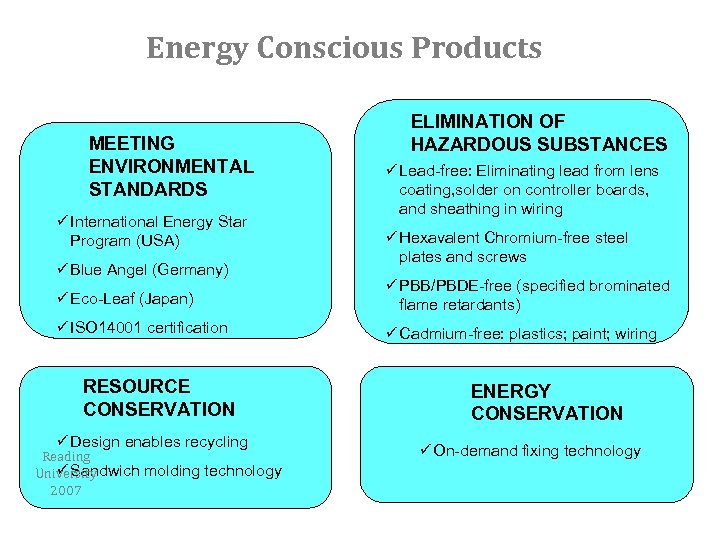

Energy Conscious Products MEETING ENVIRONMENTAL STANDARDS ü International Energy Star Program (USA) Program ü Blue Angel (Germany) ü Eco-Leaf (Japan) ü ISO 14001 certification RESOURCE CONSERVATION ü Design enables recycling Reading ü Sandwich molding technology University ü Sandwich molding technology 2007 ELIMINATION OF HAZARDOUS SUBSTANCES ü Lead-free: Eliminating lead from lens coating, solder on controller boards, and sheathing in wiring ü Hexavalent Chromium-free steel plates and screws ü PBB/PBDE-free (specified brominated flame retardants) ü Cadmium-free: plastics; paint; wiring ENERGY CONSERVATION ü On-demand fixing technology

Reading University 2007

Use of Canon Products Reading University 2007

How green do you want your business to be? ¾ ¾ ¾ Reading University 2007 Workgroup print solution (fax, scanner, printer, copier) into one device reducing the total resource burden On-demand/induction heating cuts warm up time and reduces power consumption by as much as 78% User network log-on (single sign-on) reduces waste by only allowing registered users access to the device Secure Print option reduces the number of print jobs Set up Personal Mailboxes making each end user print to a folder on the device

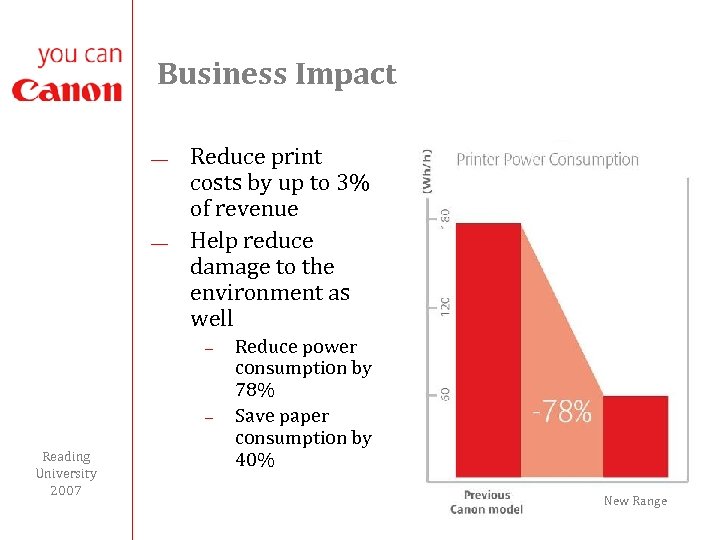

Business Impact ¾ ¾ Reduce print costs by up to 3% of revenue Help reduce damage to the environment as well - Reading University 2007 Reduce power consumption by 78% Save paper consumption by 40% New Range

Save Trees with double-sided print ¾ ¾ ¾ Reading University 2007 How could using double-sided print as standard help the environment? On average 1 tree makes 17 reams of copy paper(www. conservatree. com) With the double-sided function on Canon’s new i. RC 4580 i device this could save 9 trees per year (Average paper use by i. RC 4580 i device is 364 reams/yr (15, 184 sheets AMPV) Assumes 40% saving: 146, saves 9 trees)

How green do you want your business to be? ¾ ¾ Reading University 2007 How could using devices with low standby energy consumption help the environment? The new i. RC 4580 i device uses only 3 watts in standby mode. 687 watts less electricity than older devices* This is the equivalent energy saving needed to run a microwave oven Over a year this could equate to the energy needed for 17, 500 roast chickens *compared to standby mode of i. RC 2105: 690 watts Assumes running a 700 w microwave, 25 min per chicken at full power

What do our customers need? ¾ ¾ ¾ Reading University 2007 Information – - Websites: www. canon. com - www. canon. co. uk - www. canon-europe. com - www. eu-energystar. org Compliance - WEEE and ROHS Accreditation – ISO 14001

Case Study Reading University 2007

Background to Document Imaging Strategy - Photocopier contract renewal in 2004 - In 2004 the Customer: - Spent approx. £ 2. 6 M pa on Document Imaging - Reading University 2007 2, 585 stand alone devices Ratio of printing devices to staff of 1: 7

Opportunities - - - Reading University 2007 Industry standard ratio range from 1: 20 to 1: 50 Technology improving MFDs replacing the need for stand alone printers Reduction in environmental footprint Financial savings “Document Imaging Strategy” Project created

Aims and Anticipated Benefits ¾ ¾ Reading University 2007 To achieve a ratio of printing devices of 1: 20 To decrease the number of stand alone devices, leading to less: - Energy and Paper consumption - Consumable expenditure on printers, fax and copiers - Equipment purchases for scanners, printers, faxes and copiers - IT maintenance of a controlled and reduced fleet

Anticipated Risks ¾ ¾ ¾ Reading University 2007 User buy in - “I don’t want to walk to collect my printing” Management buy in Technical issues - do the machines work within the current environment? Fleet / contingency issues All of above can be managed by pro-active communication, thorough testing and establishing a working relationship with the supplier.

Model Implementation - Phase 1 ¾ ¾ Reading University 2007 Contract Award Full system testing of devices to identify: - How the MFDs fit within current environment - The range and suitability of different models - Any internal installation processes

Model Implementation – Phase 2 ¾ Site Surveys ¾ Staff communications ¾ Order & Installation ¾ “Think Before You Print” campaign ¾ Training ¾ ¾ Reading University 2007 Disposal / re-marketing of stand alone devices Ongoing managed policy of leasing new devices

The Customer today ¾ ¾ ¾ ¾ Reading University 2007 Devices reduced by 63% Ratio of 1: 15 Savings of £ 1. 4 M over 3 years (approx. . 20% pa). Additional savings on energy Savings will continue as MFDs are replaced by MFDs Easier fleet to manage User acceptance of the change Confident they are following a “Best Practice” model and working to make it even better

fcdbe4fc062be8d94e37cfec0e2d05ac.ppt