fcfcd9bc8f6b7a9836d42b51ea6c81cb.ppt

- Количество слайдов: 85

Surface Acoustic Wave (SAW) Wireless Passive RF Sensor System Tutorial Donald C. Malocha Department of Electrical Engineering & Computer Science University of Central Florida Orlando, Fl. 32816 -2450 donald. malocha@ucf. edu 1

Surface Acoustic Wave (SAW) Wireless Passive RF Sensor System Tutorial Donald C. Malocha Department of Electrical Engineering & Computer Science University of Central Florida Orlando, Fl. 32816 -2450 donald. malocha@ucf. edu 1

Don Malocha University of Central Florida • • • Don Malocha, Professor, University of Central Florida BS, MS and Ph. D, Univ. of Illinois, UIUC Texas Instruments, Corporate Research Laboratory, Dallas, MTS Sawtek, Orlando, Mgr. of Advanced Product Development Motorola, Visiting/Member of the Technical Staff, Phoenix and Ft. Lauderdale • Visiting Faculty, ETH, Switzerland, and Univ. of Linz, Austria • Past President, IEEE Ultrasonics, Ferroelectrics and Frequency Control Society • WEB site: http: //caat. engr. ucf. edu/ UCF – nations 2 nd largest university 2

Don Malocha University of Central Florida • • • Don Malocha, Professor, University of Central Florida BS, MS and Ph. D, Univ. of Illinois, UIUC Texas Instruments, Corporate Research Laboratory, Dallas, MTS Sawtek, Orlando, Mgr. of Advanced Product Development Motorola, Visiting/Member of the Technical Staff, Phoenix and Ft. Lauderdale • Visiting Faculty, ETH, Switzerland, and Univ. of Linz, Austria • Past President, IEEE Ultrasonics, Ferroelectrics and Frequency Control Society • WEB site: http: //caat. engr. ucf. edu/ UCF – nations 2 nd largest university 2

Acknowledgment • The author wishes to thank continuing support from everyone who has aided us at NASA, and especially Dr. Robert Youngquist, NASA-KSC. • The foundation of this work was funded through NASA Graduate Student Research Program Fellowships, the University of Central Florida – Florida Space Grant Consortium, and NASA STTR and SBIR contracts. • Continuing research is funded through NASA STTR/SBIR contracts and industrial collaboration with our industrial partner Mnemonics Inc. (MNI), Melbourne, Fl. 3

Acknowledgment • The author wishes to thank continuing support from everyone who has aided us at NASA, and especially Dr. Robert Youngquist, NASA-KSC. • The foundation of this work was funded through NASA Graduate Student Research Program Fellowships, the University of Central Florida – Florida Space Grant Consortium, and NASA STTR and SBIR contracts. • Continuing research is funded through NASA STTR/SBIR contracts and industrial collaboration with our industrial partner Mnemonics Inc. (MNI), Melbourne, Fl. 3

General Background 4

General Background 4

Multi-Sensor TAG Approaches • Silicon RFID – integrated or external sensors – Requires battery, energy scavenging, or transmit power – Radiation sensitive – Limited operating temperature & environments • SAW RFID Tags - integrated or external sensors – Passive – powered by interrogation signal – Radiation hard – Operational temperatures ~ 0 - 500+ K • Resonator – coding in frequency • CDMA- time coding, 40 -60 d. B loss, wideband • OFC - time & frequency coding, 6 -20 d. B loss, ultra wide band 5

Multi-Sensor TAG Approaches • Silicon RFID – integrated or external sensors – Requires battery, energy scavenging, or transmit power – Radiation sensitive – Limited operating temperature & environments • SAW RFID Tags - integrated or external sensors – Passive – powered by interrogation signal – Radiation hard – Operational temperatures ~ 0 - 500+ K • Resonator – coding in frequency • CDMA- time coding, 40 -60 d. B loss, wideband • OFC - time & frequency coding, 6 -20 d. B loss, ultra wide band 5

Why Use SAW Sensors and Tags? • Frequency/time are measured with greatest accuracy compared to any other physical measurement (10 -10 - 10 -14). • External stimuli affects device parameters (frequency, phase, amplitude, delay) • Operate from cryogenic to >1000 o. C • Ability to both measure a stimuli and to wirelessly, passively transmit information • Frequency range (practical) ~100 MHz – 3 GHz • Monolithic structure fabricated with current IC photolithography techniques, small, rugged 6

Why Use SAW Sensors and Tags? • Frequency/time are measured with greatest accuracy compared to any other physical measurement (10 -10 - 10 -14). • External stimuli affects device parameters (frequency, phase, amplitude, delay) • Operate from cryogenic to >1000 o. C • Ability to both measure a stimuli and to wirelessly, passively transmit information • Frequency range (practical) ~100 MHz – 3 GHz • Monolithic structure fabricated with current IC photolithography techniques, small, rugged 6

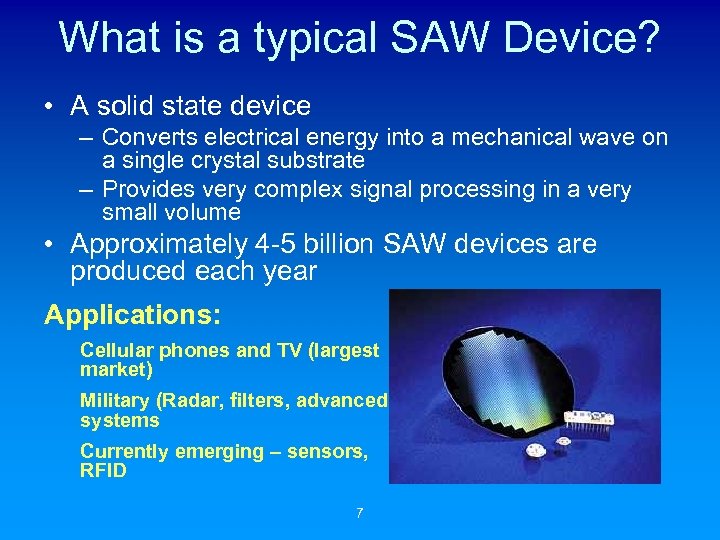

What is a typical SAW Device? • A solid state device – Converts electrical energy into a mechanical wave on a single crystal substrate – Provides very complex signal processing in a very small volume • Approximately 4 -5 billion SAW devices are produced each year Applications: Cellular phones and TV (largest market) Military (Radar, filters, advanced systems Currently emerging – sensors, RFID 7

What is a typical SAW Device? • A solid state device – Converts electrical energy into a mechanical wave on a single crystal substrate – Provides very complex signal processing in a very small volume • Approximately 4 -5 billion SAW devices are produced each year Applications: Cellular phones and TV (largest market) Military (Radar, filters, advanced systems Currently emerging – sensors, RFID 7

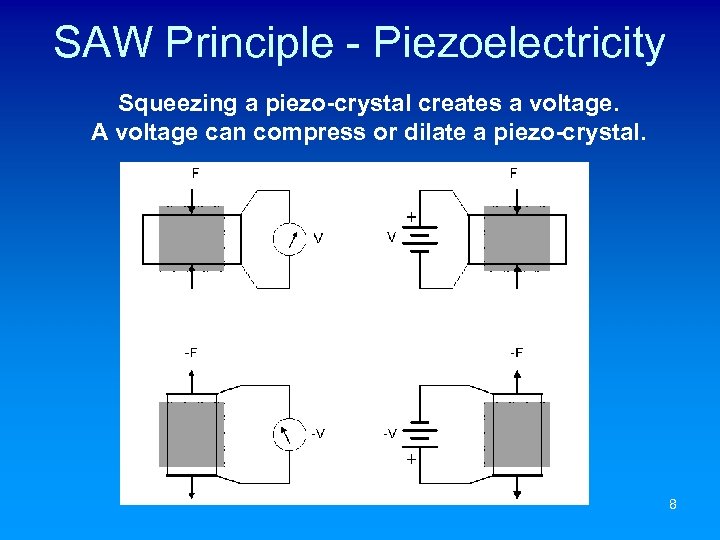

SAW Principle - Piezoelectricity Squeezing a piezo-crystal creates a voltage. A voltage can compress or dilate a piezo-crystal. 8

SAW Principle - Piezoelectricity Squeezing a piezo-crystal creates a voltage. A voltage can compress or dilate a piezo-crystal. 8

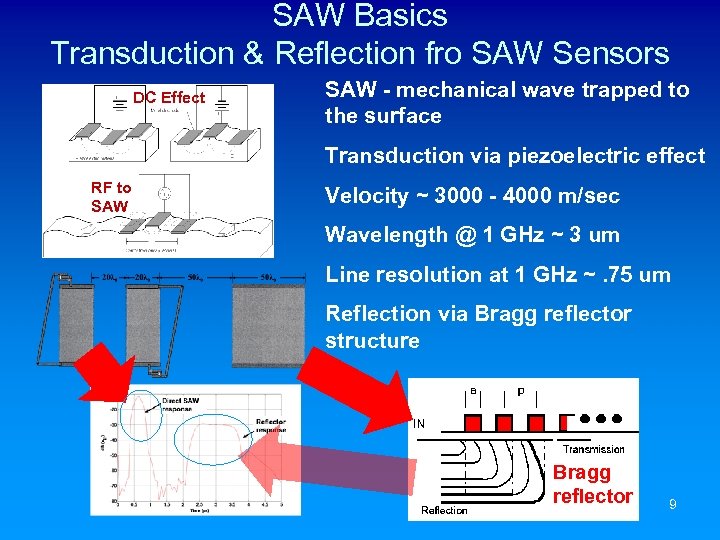

SAW Basics Transduction & Reflection fro SAW Sensors DC Effect SAW - mechanical wave trapped to the surface Transduction via piezoelectric effect RF to SAW Velocity ~ 3000 - 4000 m/sec Wavelength @ 1 GHz ~ 3 um Line resolution at 1 GHz ~. 75 um Reflection via Bragg reflector structure Bragg reflector 9

SAW Basics Transduction & Reflection fro SAW Sensors DC Effect SAW - mechanical wave trapped to the surface Transduction via piezoelectric effect RF to SAW Velocity ~ 3000 - 4000 m/sec Wavelength @ 1 GHz ~ 3 um Line resolution at 1 GHz ~. 75 um Reflection via Bragg reflector structure Bragg reflector 9

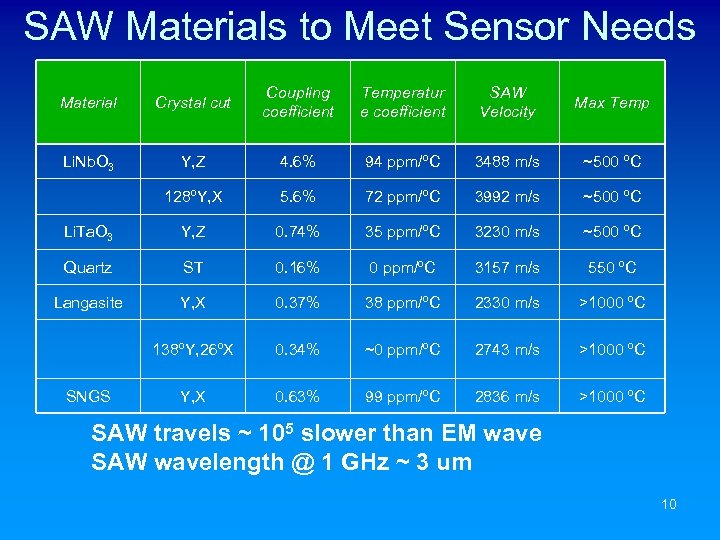

SAW Materials to Meet Sensor Needs Material Crystal cut Coupling coefficient Temperatur e coefficient SAW Velocity Max Temp Li. Nb. O 3 Y, Z 4. 6% 94 ppm/ºC 3488 m/s ~500 ºC 128ºY, X 5. 6% 72 ppm/ºC 3992 m/s ~500 ºC Li. Ta. O 3 Y, Z 0. 74% 35 ppm/ºC 3230 m/s ~500 ºC Quartz ST 0. 16% 0 ppm/ºC 3157 m/s 550 ºC Langasite Y, X 0. 37% 38 ppm/ºC 2330 m/s >1000 ºC 138ºY, 26ºX 0. 34% ~0 ppm/ºC 2743 m/s >1000 ºC Y, X 0. 63% 99 ppm/ºC 2836 m/s >1000 ºC SNGS SAW travels ~ 105 slower than EM wave SAW wavelength @ 1 GHz ~ 3 um 10

SAW Materials to Meet Sensor Needs Material Crystal cut Coupling coefficient Temperatur e coefficient SAW Velocity Max Temp Li. Nb. O 3 Y, Z 4. 6% 94 ppm/ºC 3488 m/s ~500 ºC 128ºY, X 5. 6% 72 ppm/ºC 3992 m/s ~500 ºC Li. Ta. O 3 Y, Z 0. 74% 35 ppm/ºC 3230 m/s ~500 ºC Quartz ST 0. 16% 0 ppm/ºC 3157 m/s 550 ºC Langasite Y, X 0. 37% 38 ppm/ºC 2330 m/s >1000 ºC 138ºY, 26ºX 0. 34% ~0 ppm/ºC 2743 m/s >1000 ºC Y, X 0. 63% 99 ppm/ºC 2836 m/s >1000 ºC SNGS SAW travels ~ 105 slower than EM wave SAW wavelength @ 1 GHz ~ 3 um 10

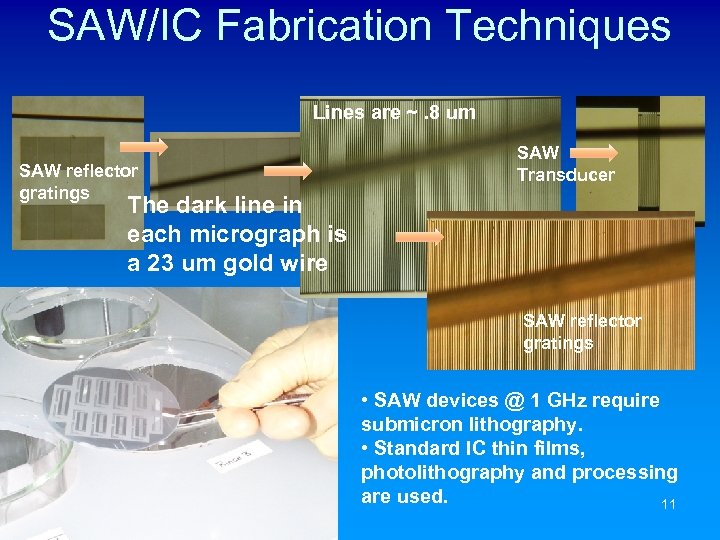

SAW/IC Fabrication Techniques Lines are ~. 8 um SAW reflector gratings SAW Transducer The dark line in each micrograph is a 23 um gold wire SAW reflector gratings • SAW devices @ 1 GHz require submicron lithography. • Standard IC thin films, photolithography and processing are used. 11

SAW/IC Fabrication Techniques Lines are ~. 8 um SAW reflector gratings SAW Transducer The dark line in each micrograph is a 23 um gold wire SAW reflector gratings • SAW devices @ 1 GHz require submicron lithography. • Standard IC thin films, photolithography and processing are used. 11

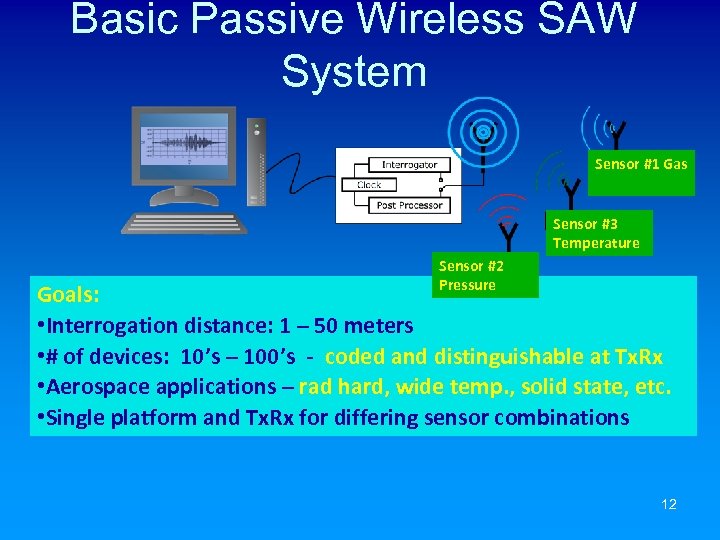

Basic Passive Wireless SAW System Sensor #1 Gas Sensor #3 Temperature Sensor #2 Pressure Goals: • Interrogation distance: 1 – 50 meters • # of devices: 10’s – 100’s - coded and distinguishable at Tx. Rx • Aerospace applications – rad hard, wide temp. , solid state, etc. • Single platform and Tx. Rx for differing sensor combinations 12

Basic Passive Wireless SAW System Sensor #1 Gas Sensor #3 Temperature Sensor #2 Pressure Goals: • Interrogation distance: 1 – 50 meters • # of devices: 10’s – 100’s - coded and distinguishable at Tx. Rx • Aerospace applications – rad hard, wide temp. , solid state, etc. • Single platform and Tx. Rx for differing sensor combinations 12

RFID and SAW Introduction 13

RFID and SAW Introduction 13

RFID Sensor Two primary system functions: RFID and extraction of the measurand. The RFID must first be acquired and then the measurand extracted. The presentation will address these issues for a temperature sensor system. • RFID Acquisition – Priority for system – Coding approach – Demodulation approach – System Parameters • Measurand Extraction – RFID is acquired – S/N ratio – Accuracy – Acquisition rate 14

RFID Sensor Two primary system functions: RFID and extraction of the measurand. The RFID must first be acquired and then the measurand extracted. The presentation will address these issues for a temperature sensor system. • RFID Acquisition – Priority for system – Coding approach – Demodulation approach – System Parameters • Measurand Extraction – RFID is acquired – S/N ratio – Accuracy – Acquisition rate 14

Diversity for Identification • Frequency Spectrum Diversity per Device – Coding – Divide into frequency bands • Time Delay per Device – Different offset delays per device – Pulse position modulation – Time allocations minimize code collisions • Spatial Diversity – device placement • Sensor & Tx-Rx Antenna Polarization • Use combinations of all to optimize system 15

Diversity for Identification • Frequency Spectrum Diversity per Device – Coding – Divide into frequency bands • Time Delay per Device – Different offset delays per device – Pulse position modulation – Time allocations minimize code collisions • Spatial Diversity – device placement • Sensor & Tx-Rx Antenna Polarization • Use combinations of all to optimize system 15

Brief Introduction to Wireless SAW Sensors • One port devices return the altered interrogation signal • Range depends on embodiment • Range increased using coherent integration of multiple responses • Interrogator used to excite devices • Several embodiments are shown next 16

Brief Introduction to Wireless SAW Sensors • One port devices return the altered interrogation signal • Range depends on embodiment • Range increased using coherent integration of multiple responses • Interrogator used to excite devices • Several embodiments are shown next 16

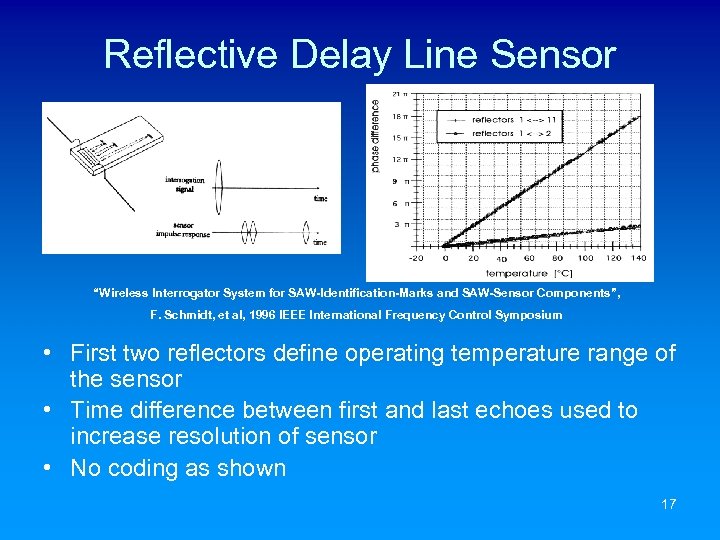

Reflective Delay Line Sensor “Wireless Interrogator System for SAW-Identification-Marks and SAW-Sensor Components”, F. Schmidt, et al, 1996 IEEE International Frequency Control Symposium • First two reflectors define operating temperature range of the sensor • Time difference between first and last echoes used to increase resolution of sensor • No coding as shown 17

Reflective Delay Line Sensor “Wireless Interrogator System for SAW-Identification-Marks and SAW-Sensor Components”, F. Schmidt, et al, 1996 IEEE International Frequency Control Symposium • First two reflectors define operating temperature range of the sensor • Time difference between first and last echoes used to increase resolution of sensor • No coding as shown 17

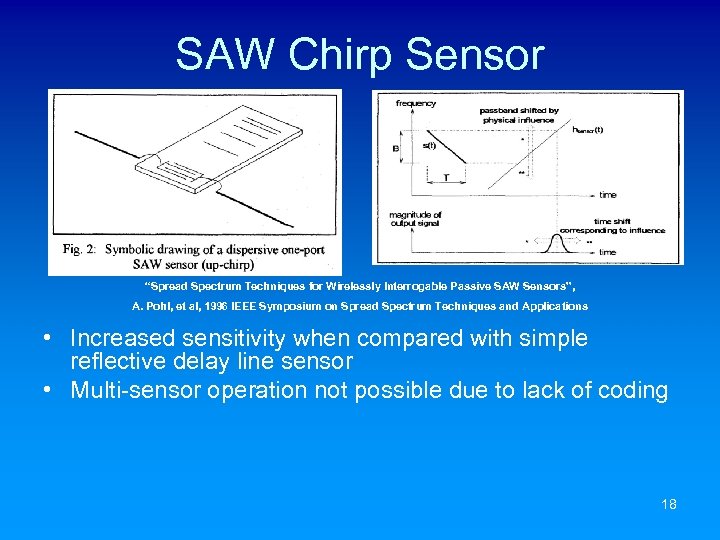

SAW Chirp Sensor “Spread Spectrum Techniques for Wirelessly Interrogable Passive SAW Sensors”, A. Pohl, et al, 1996 IEEE Symposium on Spread Spectrum Techniques and Applications • Increased sensitivity when compared with simple reflective delay line sensor • Multi-sensor operation not possible due to lack of coding 18

SAW Chirp Sensor “Spread Spectrum Techniques for Wirelessly Interrogable Passive SAW Sensors”, A. Pohl, et al, 1996 IEEE Symposium on Spread Spectrum Techniques and Applications • Increased sensitivity when compared with simple reflective delay line sensor • Multi-sensor operation not possible due to lack of coding 18

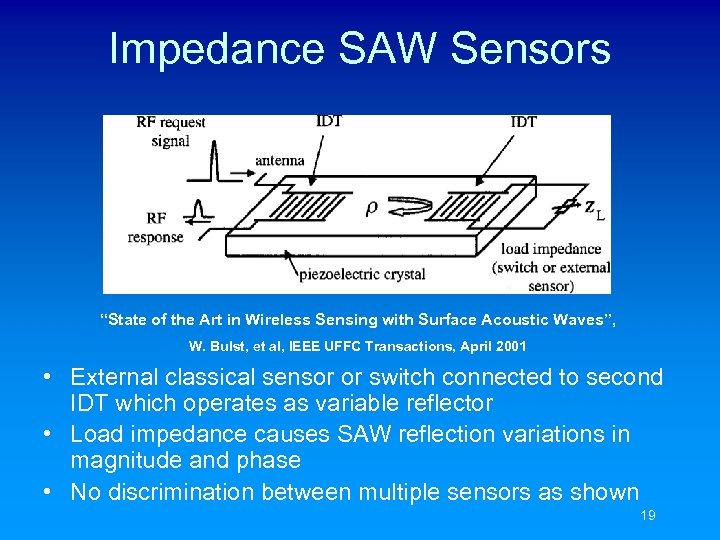

Impedance SAW Sensors “State of the Art in Wireless Sensing with Surface Acoustic Waves”, W. Bulst, et al, IEEE UFFC Transactions, April 2001 • External classical sensor or switch connected to second IDT which operates as variable reflector • Load impedance causes SAW reflection variations in magnitude and phase • No discrimination between multiple sensors as shown 19

Impedance SAW Sensors “State of the Art in Wireless Sensing with Surface Acoustic Waves”, W. Bulst, et al, IEEE UFFC Transactions, April 2001 • External classical sensor or switch connected to second IDT which operates as variable reflector • Load impedance causes SAW reflection variations in magnitude and phase • No discrimination between multiple sensors as shown 19

SAW RFID Practical Approaches • Resonator – Fabry-Perot Cavity – Frequency selective, SAW device Q~10, 000 • Code Division Multiple Access (CDMA) – Delay line – single frequency Bragg reflectors – Pulse position encoding • Orthogonal Frequency Coding (OFC) – Delay line, multi-frequency Bragg reflectors – Pulse position encoding – Frequency coupled with time diversity 20

SAW RFID Practical Approaches • Resonator – Fabry-Perot Cavity – Frequency selective, SAW device Q~10, 000 • Code Division Multiple Access (CDMA) – Delay line – single frequency Bragg reflectors – Pulse position encoding • Orthogonal Frequency Coding (OFC) – Delay line, multi-frequency Bragg reflectors – Pulse position encoding – Frequency coupled with time diversity 20

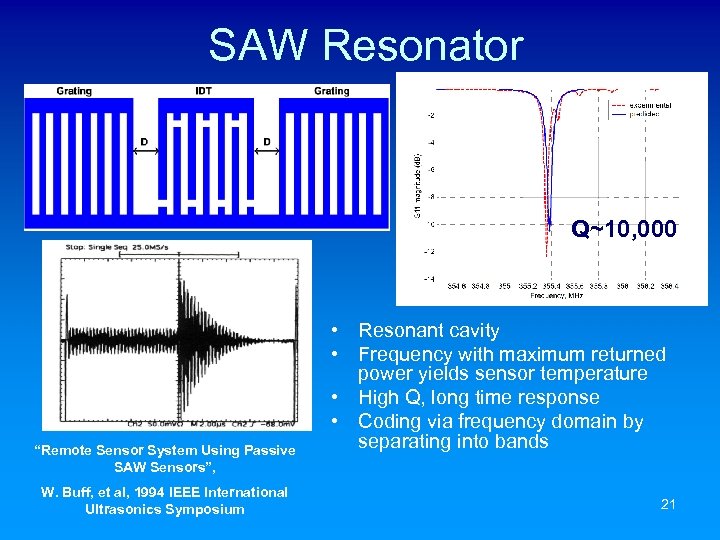

SAW Resonator Q~10, 000 “Remote Sensor System Using Passive SAW Sensors”, W. Buff, et al, 1994 IEEE International Ultrasonics Symposium • Resonant cavity • Frequency with maximum returned power yields sensor temperature • High Q, long time response • Coding via frequency domain by separating into bands 21

SAW Resonator Q~10, 000 “Remote Sensor System Using Passive SAW Sensors”, W. Buff, et al, 1994 IEEE International Ultrasonics Symposium • Resonant cavity • Frequency with maximum returned power yields sensor temperature • High Q, long time response • Coding via frequency domain by separating into bands 21

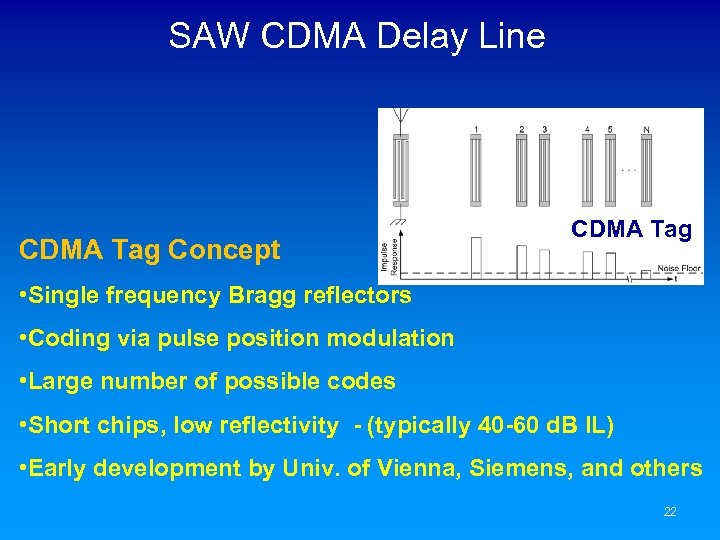

SAW CDMA Delay Line CDMA Tag Concept CDMA Tag • Single frequency Bragg reflectors • Coding via pulse position modulation • Large number of possible codes • Short chips, low reflectivity - (typically 40 -60 d. B IL) • Early development by Univ. of Vienna, Siemens, and others 22

SAW CDMA Delay Line CDMA Tag Concept CDMA Tag • Single frequency Bragg reflectors • Coding via pulse position modulation • Large number of possible codes • Short chips, low reflectivity - (typically 40 -60 d. B IL) • Early development by Univ. of Vienna, Siemens, and others 22

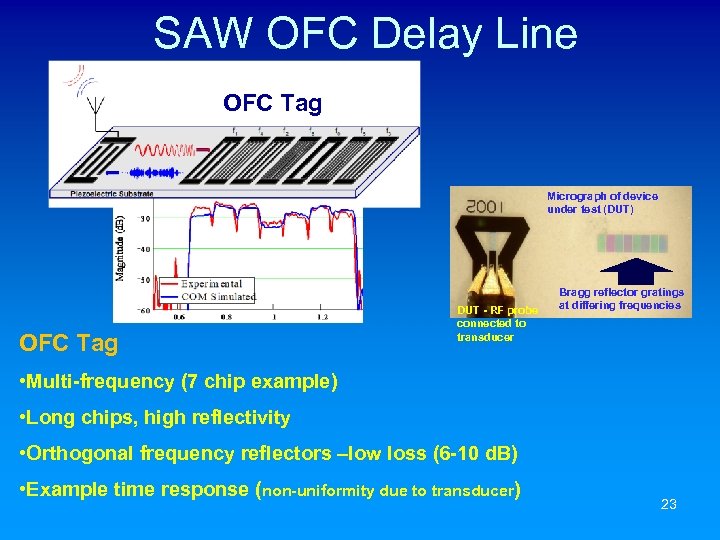

SAW OFC Delay Line OFC Tag Micrograph of device under test (DUT) OFC Tag DUT - RF probe connected to transducer Bragg reflector gratings at differing frequencies • Multi-frequency (7 chip example) • Long chips, high reflectivity • Orthogonal frequency reflectors –low loss (6 -10 d. B) • Example time response (non-uniformity due to transducer) 23

SAW OFC Delay Line OFC Tag Micrograph of device under test (DUT) OFC Tag DUT - RF probe connected to transducer Bragg reflector gratings at differing frequencies • Multi-frequency (7 chip example) • Long chips, high reflectivity • Orthogonal frequency reflectors –low loss (6 -10 d. B) • Example time response (non-uniformity due to transducer) 23

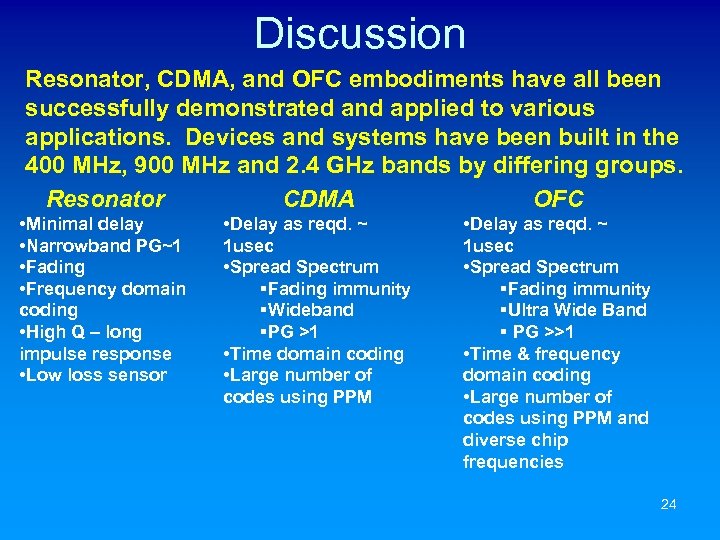

Discussion Resonator, CDMA, and OFC embodiments have all been successfully demonstrated and applied to various applications. Devices and systems have been built in the 400 MHz, 900 MHz and 2. 4 GHz bands by differing groups. Resonator CDMA OFC • Minimal delay • Narrowband PG~1 • Fading • Frequency domain coding • High Q – long impulse response • Low loss sensor • Delay as reqd. ~ 1 usec • Spread Spectrum §Fading immunity §Wideband §PG >1 • Time domain coding • Large number of codes using PPM • Delay as reqd. ~ 1 usec • Spread Spectrum §Fading immunity §Ultra Wide Band § PG >>1 • Time & frequency domain coding • Large number of codes using PPM and diverse chip frequencies 24

Discussion Resonator, CDMA, and OFC embodiments have all been successfully demonstrated and applied to various applications. Devices and systems have been built in the 400 MHz, 900 MHz and 2. 4 GHz bands by differing groups. Resonator CDMA OFC • Minimal delay • Narrowband PG~1 • Fading • Frequency domain coding • High Q – long impulse response • Low loss sensor • Delay as reqd. ~ 1 usec • Spread Spectrum §Fading immunity §Wideband §PG >1 • Time domain coding • Large number of codes using PPM • Delay as reqd. ~ 1 usec • Spread Spectrum §Fading immunity §Ultra Wide Band § PG >>1 • Time & frequency domain coding • Large number of codes using PPM and diverse chip frequencies 24

OFC Sensor Embodiment 25

OFC Sensor Embodiment 25

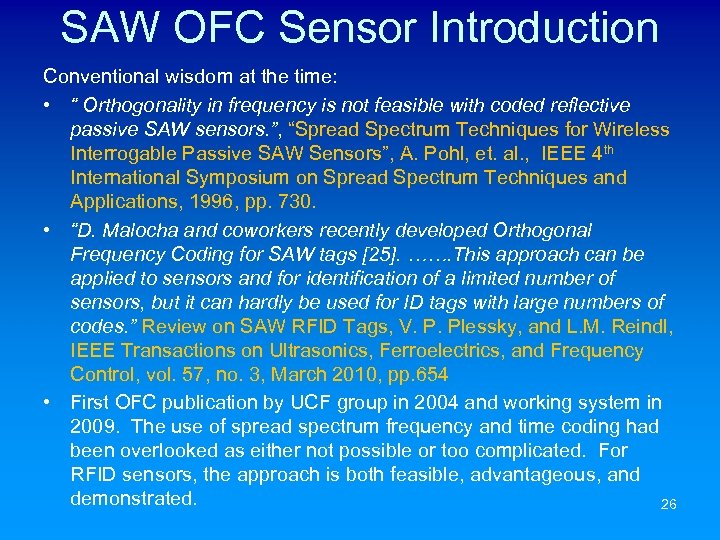

SAW OFC Sensor Introduction Conventional wisdom at the time: • “ Orthogonality in frequency is not feasible with coded reflective passive SAW sensors. ”, “Spread Spectrum Techniques for Wireless Interrogable Passive SAW Sensors”, A. Pohl, et. al. , IEEE 4 th International Symposium on Spread Spectrum Techniques and Applications, 1996, pp. 730. • “D. Malocha and coworkers recently developed Orthogonal Frequency Coding for SAW tags [25]. ……. This approach can be applied to sensors and for identification of a limited number of sensors, but it can hardly be used for ID tags with large numbers of codes. ” Review on SAW RFID Tags, V. P. Plessky, and L. M. Reindl, IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, vol. 57, no. 3, March 2010, pp. 654 • First OFC publication by UCF group in 2004 and working system in 2009. The use of spread spectrum frequency and time coding had been overlooked as either not possible or too complicated. For RFID sensors, the approach is both feasible, advantageous, and demonstrated. 26

SAW OFC Sensor Introduction Conventional wisdom at the time: • “ Orthogonality in frequency is not feasible with coded reflective passive SAW sensors. ”, “Spread Spectrum Techniques for Wireless Interrogable Passive SAW Sensors”, A. Pohl, et. al. , IEEE 4 th International Symposium on Spread Spectrum Techniques and Applications, 1996, pp. 730. • “D. Malocha and coworkers recently developed Orthogonal Frequency Coding for SAW tags [25]. ……. This approach can be applied to sensors and for identification of a limited number of sensors, but it can hardly be used for ID tags with large numbers of codes. ” Review on SAW RFID Tags, V. P. Plessky, and L. M. Reindl, IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, vol. 57, no. 3, March 2010, pp. 654 • First OFC publication by UCF group in 2004 and working system in 2009. The use of spread spectrum frequency and time coding had been overlooked as either not possible or too complicated. For RFID sensors, the approach is both feasible, advantageous, and demonstrated. 26

OFC Historical Development • Chose 1 st devices at 250 MHz for feasibility • Several different OFC sensors demonstrated • Demonstrated harmonic operated devices at 456, 915 MHz and 1. 6 GHz • Fundamental device operation at 915 MHz • Devices in the +1 GHz range in 2010 • First OFC system at 250 MHz • Current OFC system at 915 MHz • First 4 device wireless operation in 2009 • Mnemonics demonstrates first chirp OFC correlator receiver in 2010 27

OFC Historical Development • Chose 1 st devices at 250 MHz for feasibility • Several different OFC sensors demonstrated • Demonstrated harmonic operated devices at 456, 915 MHz and 1. 6 GHz • Fundamental device operation at 915 MHz • Devices in the +1 GHz range in 2010 • First OFC system at 250 MHz • Current OFC system at 915 MHz • First 4 device wireless operation in 2009 • Mnemonics demonstrates first chirp OFC correlator receiver in 2010 27

Why OFC SAW Sensors? • A game-changing approach • All advatageous of SAW technology • Wireless, passive and multi-coded sensors • Frequency & time offer greatest coding diversity • Single communication platform for diverse sensor embodiments • Radiation hard • Wide operational temperature range 28

Why OFC SAW Sensors? • A game-changing approach • All advatageous of SAW technology • Wireless, passive and multi-coded sensors • Frequency & time offer greatest coding diversity • Single communication platform for diverse sensor embodiments • Radiation hard • Wide operational temperature range 28

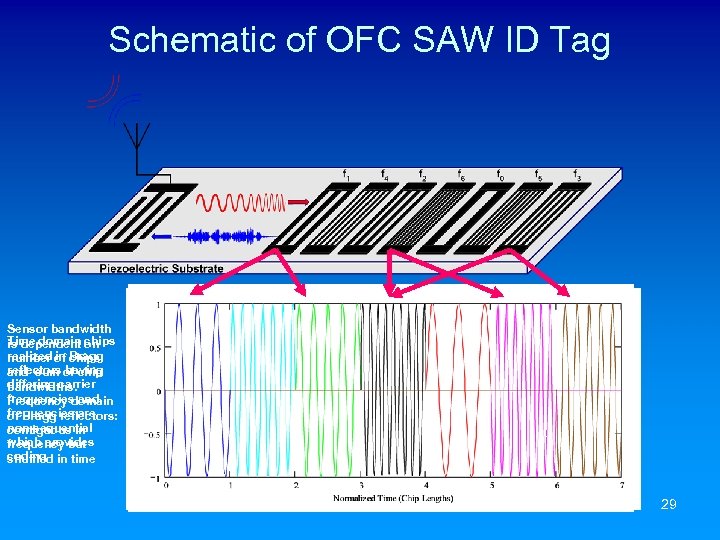

Schematic of OFC SAW ID Tag Sensor bandwidth Time domain chips is dependent on realized in Bragg number of chips reflectors having and sum of chip differing carrier bandwidths. frequencies and Frequency domain frequencies are of Bragg reflectors: non-sequential contiguous in which provides frequency but coding shuffled in time 29

Schematic of OFC SAW ID Tag Sensor bandwidth Time domain chips is dependent on realized in Bragg number of chips reflectors having and sum of chip differing carrier bandwidths. frequencies and Frequency domain frequencies are of Bragg reflectors: non-sequential contiguous in which provides frequency but coding shuffled in time 29

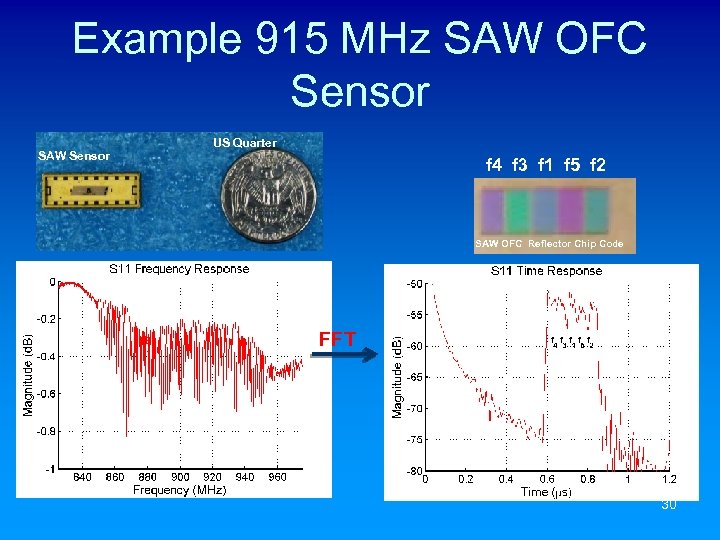

Example 915 MHz SAW OFC Sensor SAW Sensor US Quarter f 4 f 3 f 1 f 5 f 2 SAW OFC Reflector Chip Code FFT 30

Example 915 MHz SAW OFC Sensor SAW Sensor US Quarter f 4 f 3 f 1 f 5 f 2 SAW OFC Reflector Chip Code FFT 30

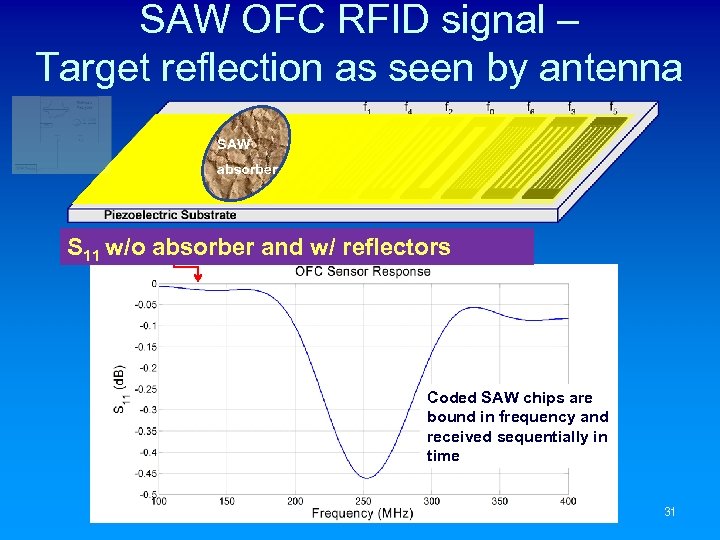

SAW OFC RFID signal – Target reflection as seen by antenna SAW absorber S 11 w/ absorber and w/o reflectors w/o absorber and w/ reflectors Coded SAW chips are bound in frequency and received sequentially in time 31

SAW OFC RFID signal – Target reflection as seen by antenna SAW absorber S 11 w/ absorber and w/o reflectors w/o absorber and w/ reflectors Coded SAW chips are bound in frequency and received sequentially in time 31

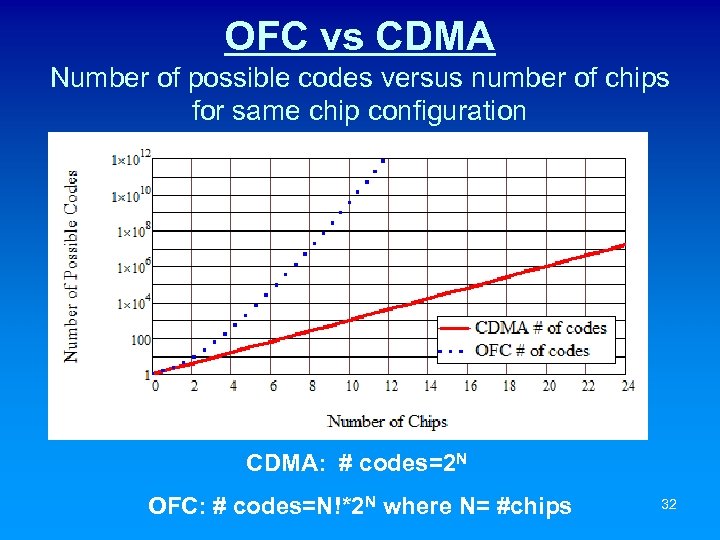

OFC vs CDMA Number of possible codes versus number of chips for same chip configuration CDMA: # codes=2 N OFC: # codes=N!*2 N where N= #chips 32

OFC vs CDMA Number of possible codes versus number of chips for same chip configuration CDMA: # codes=2 N OFC: # codes=N!*2 N where N= #chips 32

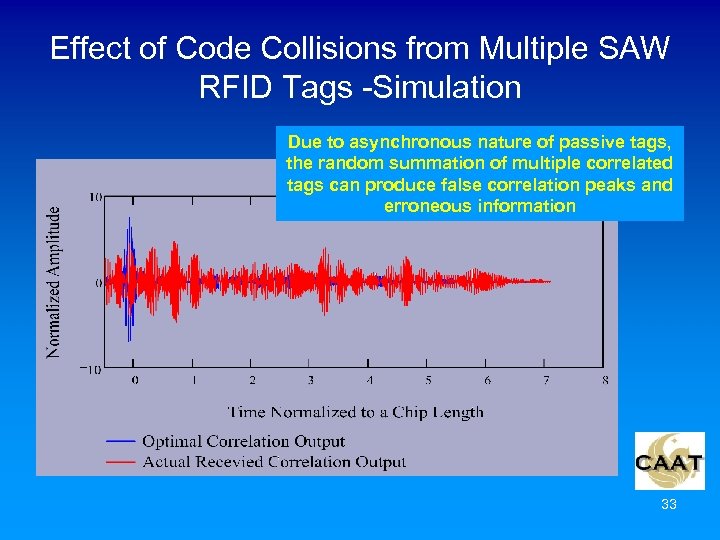

Effect of Code Collisions from Multiple SAW RFID Tags -Simulation Due to asynchronous nature of passive tags, the random summation of multiple correlated tags can produce false correlation peaks and erroneous information 33

Effect of Code Collisions from Multiple SAW RFID Tags -Simulation Due to asynchronous nature of passive tags, the random summation of multiple correlated tags can produce false correlation peaks and erroneous information 33

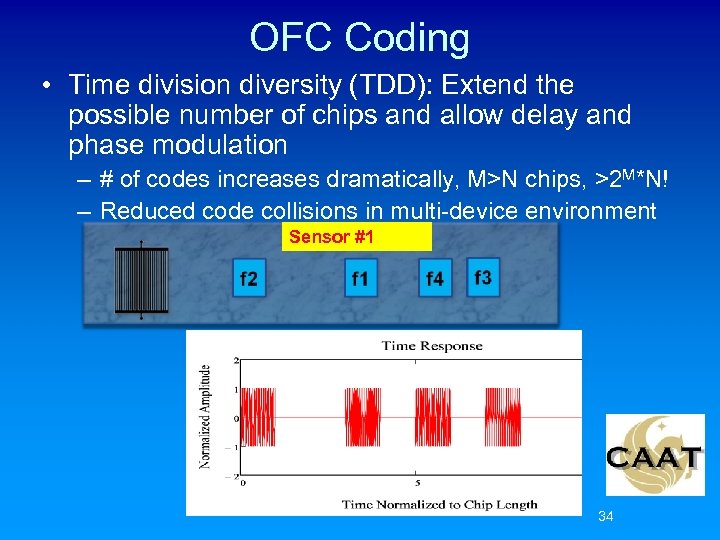

OFC Coding • Time division diversity (TDD): Extend the possible number of chips and allow delay and phase modulation – # of codes increases dramatically, M>N chips, >2 M*N! – Reduced code collisions in multi-device environment Sensor #1 34

OFC Coding • Time division diversity (TDD): Extend the possible number of chips and allow delay and phase modulation – # of codes increases dramatically, M>N chips, >2 M*N! – Reduced code collisions in multi-device environment Sensor #1 34

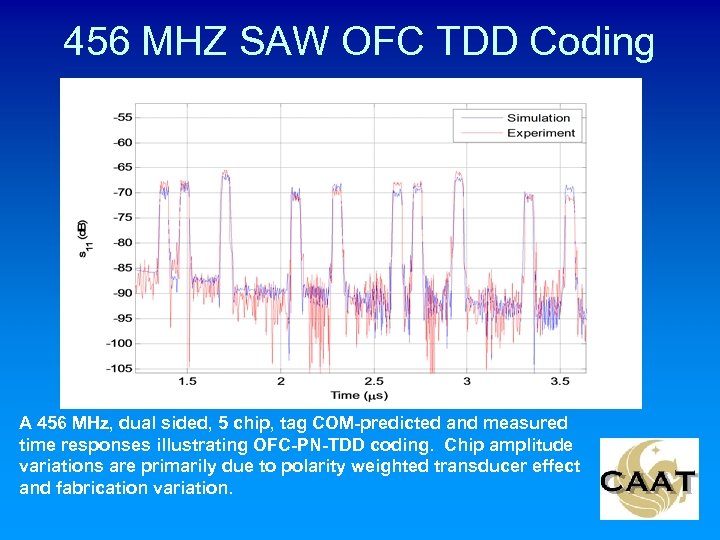

456 MHZ SAW OFC TDD Coding A 456 MHz, dual sided, 5 chip, tag COM-predicted and measured time responses illustrating OFC-PN-TDD coding. Chip amplitude variations are primarily due to polarity weighted transducer effect and fabrication variation. 35

456 MHZ SAW OFC TDD Coding A 456 MHz, dual sided, 5 chip, tag COM-predicted and measured time responses illustrating OFC-PN-TDD coding. Chip amplitude variations are primarily due to polarity weighted transducer effect and fabrication variation. 35

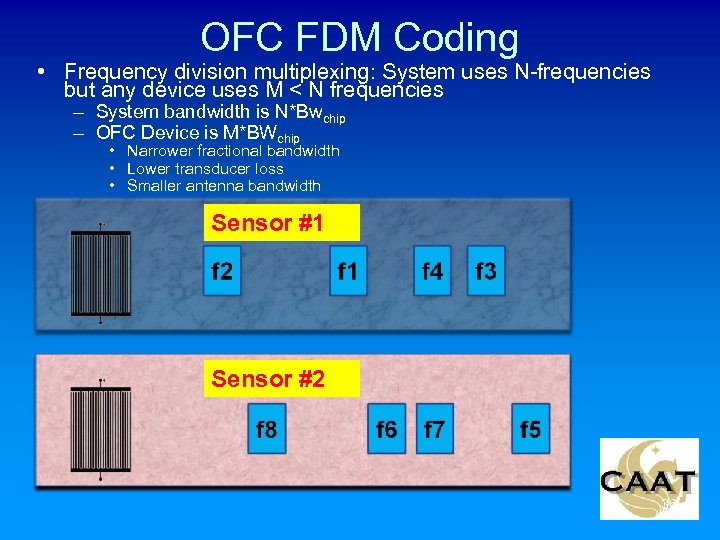

OFC FDM Coding • Frequency division multiplexing: System uses N-frequencies but any device uses M < N frequencies – System bandwidth is N*Bwchip – OFC Device is M*BWchip • Narrower fractional bandwidth • Lower transducer loss • Smaller antenna bandwidth Sensor #1 Sensor #2 36 36

OFC FDM Coding • Frequency division multiplexing: System uses N-frequencies but any device uses M < N frequencies – System bandwidth is N*Bwchip – OFC Device is M*BWchip • Narrower fractional bandwidth • Lower transducer loss • Smaller antenna bandwidth Sensor #1 Sensor #2 36 36

Antenna and SAW Sensor Design Considerations 37

Antenna and SAW Sensor Design Considerations 37

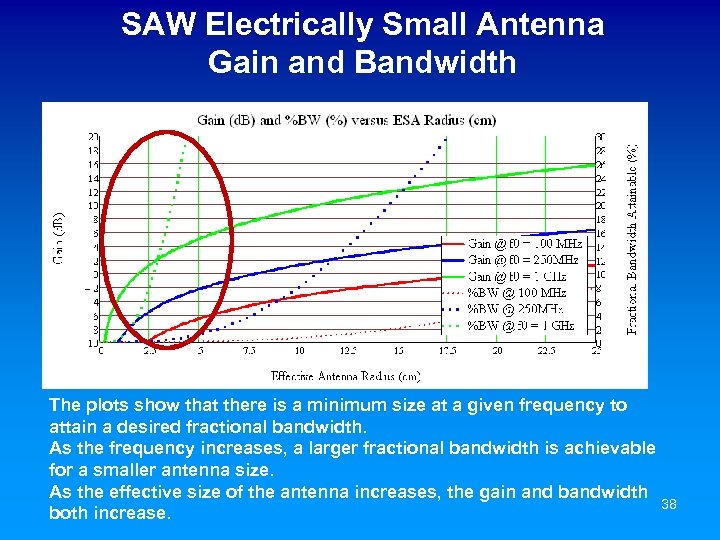

SAW Electrically Small Antenna Gain and Bandwidth The plots show that there is a minimum size at a given frequency to attain a desired fractional bandwidth. As the frequency increases, a larger fractional bandwidth is achievable for a smaller antenna size. As the effective size of the antenna increases, the gain and bandwidth 38 both increase.

SAW Electrically Small Antenna Gain and Bandwidth The plots show that there is a minimum size at a given frequency to attain a desired fractional bandwidth. As the frequency increases, a larger fractional bandwidth is achievable for a smaller antenna size. As the effective size of the antenna increases, the gain and bandwidth 38 both increase.

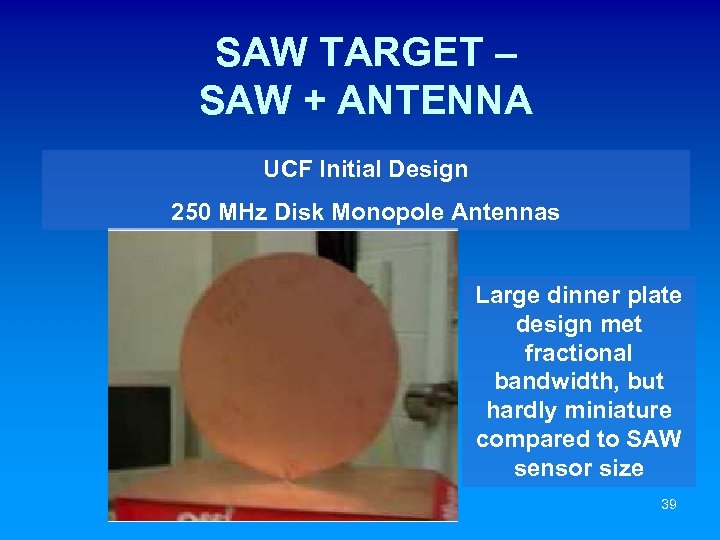

SAW TARGET – SAW + ANTENNA UCF Initial Design 250 MHz Disk Monopole Antennas Large dinner plate design met fractional bandwidth, but hardly miniature compared to SAW sensor size 39

SAW TARGET – SAW + ANTENNA UCF Initial Design 250 MHz Disk Monopole Antennas Large dinner plate design met fractional bandwidth, but hardly miniature compared to SAW sensor size 39

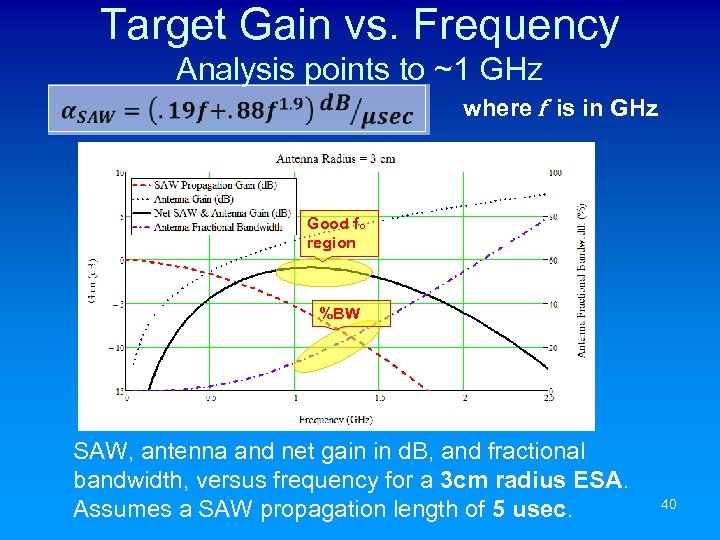

Target Gain vs. Frequency Analysis points to ~1 GHz where f is in GHz Good fo region %BW SAW, antenna and net gain in d. B, and fractional bandwidth, versus frequency for a 3 cm radius ESA. Assumes a SAW propagation length of 5 usec. 40

Target Gain vs. Frequency Analysis points to ~1 GHz where f is in GHz Good fo region %BW SAW, antenna and net gain in d. B, and fractional bandwidth, versus frequency for a 3 cm radius ESA. Assumes a SAW propagation length of 5 usec. 40

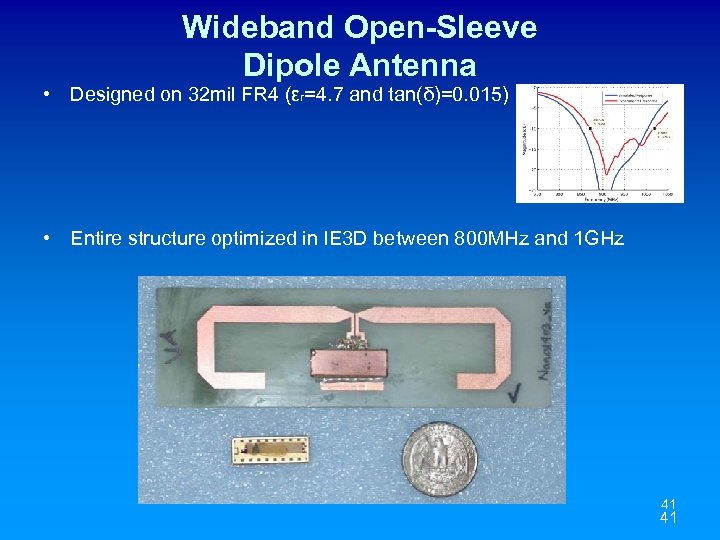

Wideband Open-Sleeve Dipole Antenna • Designed on 32 mil FR 4 (εr=4. 7 and tan(δ)=0. 015) • Entire structure optimized in IE 3 D between 800 MHz and 1 GHz 41 41

Wideband Open-Sleeve Dipole Antenna • Designed on 32 mil FR 4 (εr=4. 7 and tan(δ)=0. 015) • Entire structure optimized in IE 3 D between 800 MHz and 1 GHz 41 41

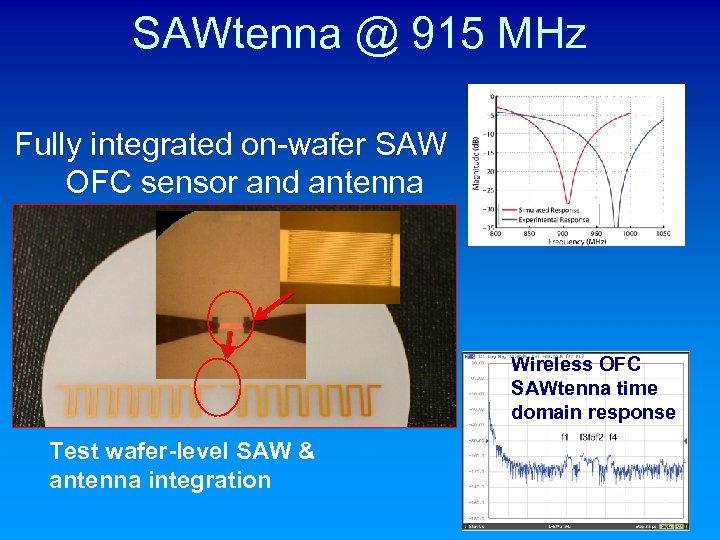

SAWtenna @ 915 MHz Fully integrated on-wafer SAW OFC sensor and antenna Wireless OFC SAWtenna time domain response Test wafer-level SAW & antenna integration 42

SAWtenna @ 915 MHz Fully integrated on-wafer SAW OFC sensor and antenna Wireless OFC SAWtenna time domain response Test wafer-level SAW & antenna integration 42

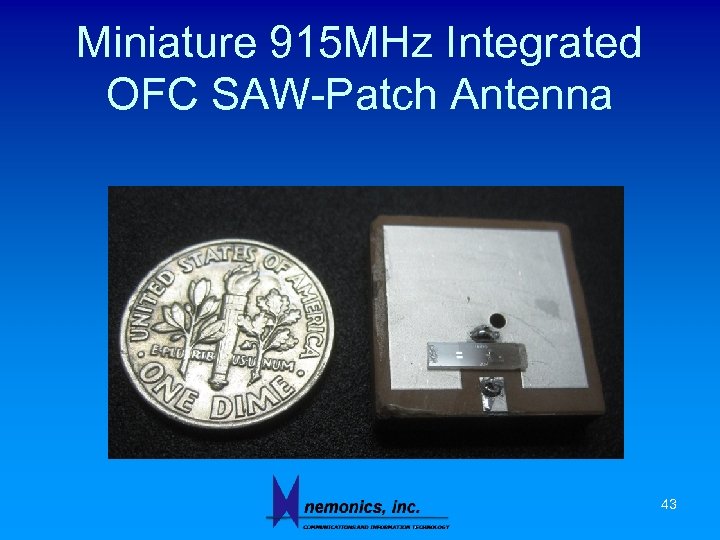

Miniature 915 MHz Integrated OFC SAW-Patch Antenna 43

Miniature 915 MHz Integrated OFC SAW-Patch Antenna 43

Synchronous Correlator Transceiver 44

Synchronous Correlator Transceiver 44

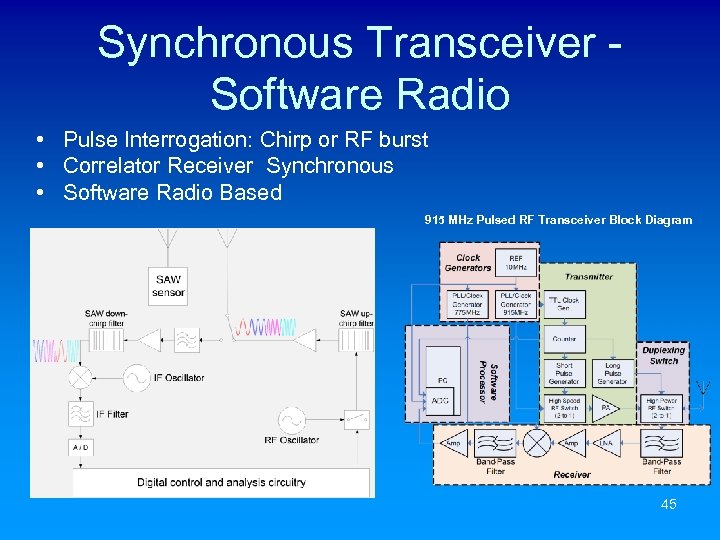

Synchronous Transceiver Software Radio • Pulse Interrogation: Chirp or RF burst • Correlator Receiver Synchronous • Software Radio Based 915 MHz Pulsed RF Transceiver Block Diagram 45

Synchronous Transceiver Software Radio • Pulse Interrogation: Chirp or RF burst • Correlator Receiver Synchronous • Software Radio Based 915 MHz Pulsed RF Transceiver Block Diagram 45

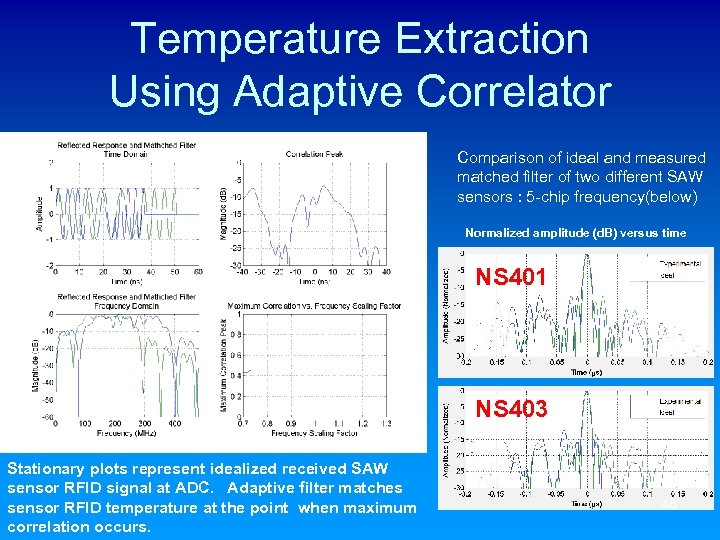

Temperature Extraction Using Adaptive Correlator Comparison of ideal and measured matched filter of two different SAW sensors : 5 -chip frequency(below) Normalized amplitude (d. B) versus time NS 401 NS 403 Stationary plots represent idealized received SAW sensor RFID signal at ADC. Adaptive filter matches sensor RFID temperature at the point when maximum correlation occurs. 46

Temperature Extraction Using Adaptive Correlator Comparison of ideal and measured matched filter of two different SAW sensors : 5 -chip frequency(below) Normalized amplitude (d. B) versus time NS 401 NS 403 Stationary plots represent idealized received SAW sensor RFID signal at ADC. Adaptive filter matches sensor RFID temperature at the point when maximum correlation occurs. 46

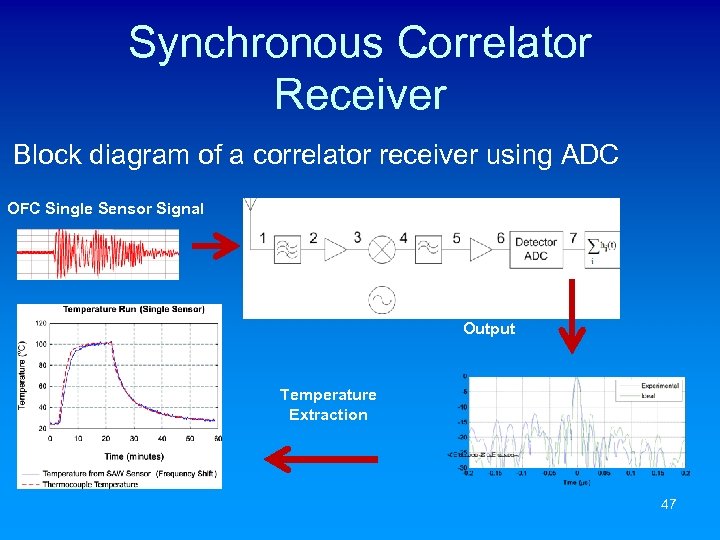

Synchronous Correlator Receiver Block diagram of a correlator receiver using ADC OFC Single Sensor Signal Correlation Output Temperature Extraction 47

Synchronous Correlator Receiver Block diagram of a correlator receiver using ADC OFC Single Sensor Signal Correlation Output Temperature Extraction 47

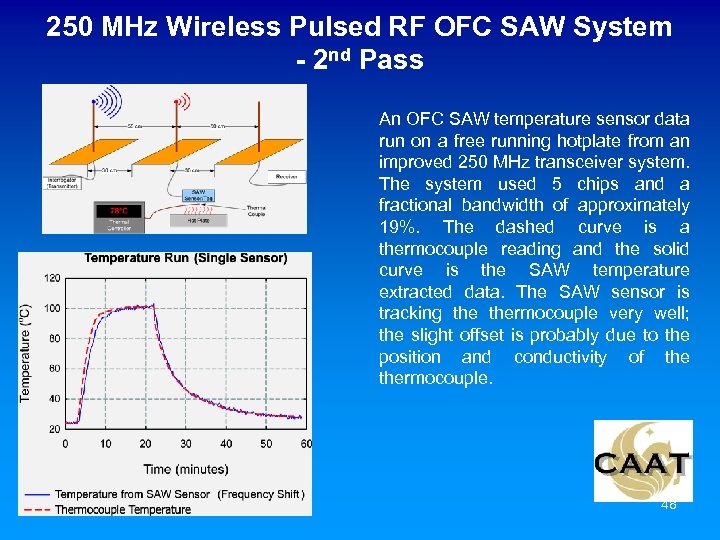

250 MHz Wireless Pulsed RF OFC SAW System - 2 nd Pass An OFC SAW temperature sensor data run on a free running hotplate from an improved 250 MHz transceiver system. The system used 5 chips and a fractional bandwidth of approximately 19%. The dashed curve is a thermocouple reading and the solid curve is the SAW temperature extracted data. The SAW sensor is tracking thermocouple very well; the slight offset is probably due to the position and conductivity of thermocouple. 48

250 MHz Wireless Pulsed RF OFC SAW System - 2 nd Pass An OFC SAW temperature sensor data run on a free running hotplate from an improved 250 MHz transceiver system. The system used 5 chips and a fractional bandwidth of approximately 19%. The dashed curve is a thermocouple reading and the solid curve is the SAW temperature extracted data. The SAW sensor is tracking thermocouple very well; the slight offset is probably due to the position and conductivity of thermocouple. 48

SAW 915 MHz Correlator Transceiver 49

SAW 915 MHz Correlator Transceiver 49

MNI Transceiver Design • Pulsed RF Chirp • Correlator Receiver – Synchronous operation – Integration of multiple “pings” – OFC processing gain • Adaptive filter temperature extraction • Software radio based approach for versatility 50

MNI Transceiver Design • Pulsed RF Chirp • Correlator Receiver – Synchronous operation – Integration of multiple “pings” – OFC processing gain • Adaptive filter temperature extraction • Software radio based approach for versatility 50

Current Sensor System Results • 915 MHz transceiver developed by Mnemonics, Inc. (MNI), Melbourne, Fl – RF Chirp 700 nsec, 28 d. Bm peak power – Synchronous receiver • OFC SAW temperature sensors developed by UCF – YZ Li. Nb. O 3, 5 chip OFC delay line sensor – 915 MHz fundamental, 0. 8 um electrodes • Correlator software developed at UCF 51

Current Sensor System Results • 915 MHz transceiver developed by Mnemonics, Inc. (MNI), Melbourne, Fl – RF Chirp 700 nsec, 28 d. Bm peak power – Synchronous receiver • OFC SAW temperature sensors developed by UCF – YZ Li. Nb. O 3, 5 chip OFC delay line sensor – 915 MHz fundamental, 0. 8 um electrodes • Correlator software developed at UCF 51

Critical Transceiver Operational Parameters • • • EM Path Loss Considerations Electrically Small Antennas (ESA) SAW Device Propagation Loss Target Gain versus Center Frequency Integrated SAW and Antenna 52

Critical Transceiver Operational Parameters • • • EM Path Loss Considerations Electrically Small Antennas (ESA) SAW Device Propagation Loss Target Gain versus Center Frequency Integrated SAW and Antenna 52

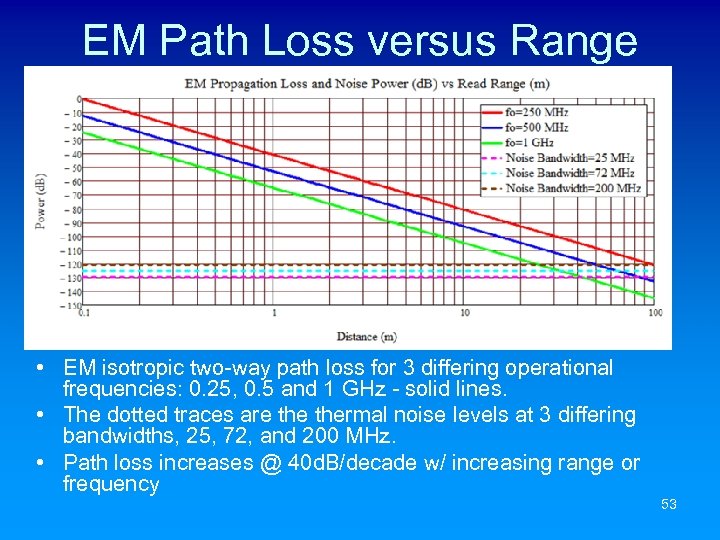

EM Path Loss versus Range • EM isotropic two-way path loss for 3 differing operational frequencies: 0. 25, 0. 5 and 1 GHz - solid lines. • The dotted traces are thermal noise levels at 3 differing bandwidths, 25, 72, and 200 MHz. • Path loss increases @ 40 d. B/decade w/ increasing range or frequency 53

EM Path Loss versus Range • EM isotropic two-way path loss for 3 differing operational frequencies: 0. 25, 0. 5 and 1 GHz - solid lines. • The dotted traces are thermal noise levels at 3 differing bandwidths, 25, 72, and 200 MHz. • Path loss increases @ 40 d. B/decade w/ increasing range or frequency 53

RF Transceiver: Sensor Overview • • • OFC with single wideband transducer Center Frequency: 915 MHz Bandwidth: Chirp - ~78 MHz Number of Chips: 5 Chip length 54 ns/each, total reflector length 270 ns • Substrate: YZ Li. Nb. O 3 54

RF Transceiver: Sensor Overview • • • OFC with single wideband transducer Center Frequency: 915 MHz Bandwidth: Chirp - ~78 MHz Number of Chips: 5 Chip length 54 ns/each, total reflector length 270 ns • Substrate: YZ Li. Nb. O 3 54

SAW 915 MHz OFC Sensor • SAW sensor acts as RFID and sensor • All antenna & transducer effects are doubled • Antenna gain and bandwidth are dependent on size scaled to frequency • SAW propagation loss is frequency dependent 55

SAW 915 MHz OFC Sensor • SAW sensor acts as RFID and sensor • All antenna & transducer effects are doubled • Antenna gain and bandwidth are dependent on size scaled to frequency • SAW propagation loss is frequency dependent 55

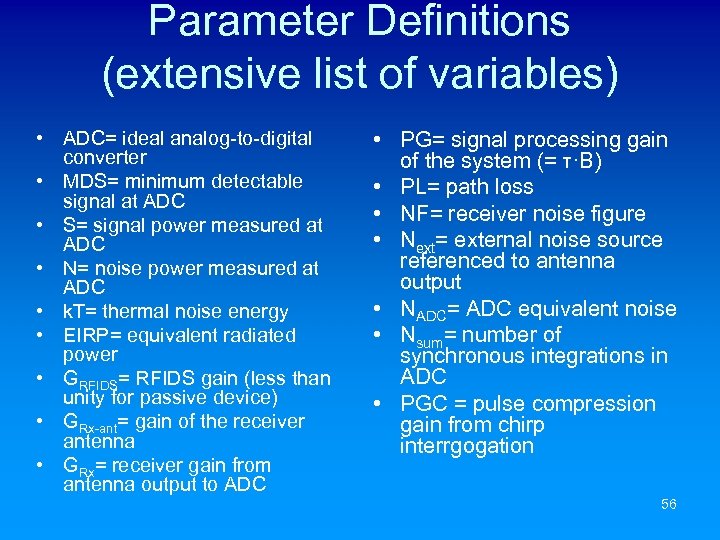

Parameter Definitions (extensive list of variables) • ADC= ideal analog-to-digital converter • MDS= minimum detectable signal at ADC • S= signal power measured at ADC • N= noise power measured at ADC • k. T= thermal noise energy • EIRP= equivalent radiated power • GRFIDS= RFIDS gain (less than unity for passive device) • GRx-ant= gain of the receiver antenna • GRx= receiver gain from antenna output to ADC • PG= signal processing gain of the system (= τ·B) • PL= path loss • NF= receiver noise figure • Next= external noise source referenced to antenna output • NADC= ADC equivalent noise • Nsum= number of synchronous integrations in ADC • PGC = pulse compression gain from chirp interrgogation 56

Parameter Definitions (extensive list of variables) • ADC= ideal analog-to-digital converter • MDS= minimum detectable signal at ADC • S= signal power measured at ADC • N= noise power measured at ADC • k. T= thermal noise energy • EIRP= equivalent radiated power • GRFIDS= RFIDS gain (less than unity for passive device) • GRx-ant= gain of the receiver antenna • GRx= receiver gain from antenna output to ADC • PG= signal processing gain of the system (= τ·B) • PL= path loss • NF= receiver noise figure • Next= external noise source referenced to antenna output • NADC= ADC equivalent noise • Nsum= number of synchronous integrations in ADC • PGC = pulse compression gain from chirp interrgogation 56

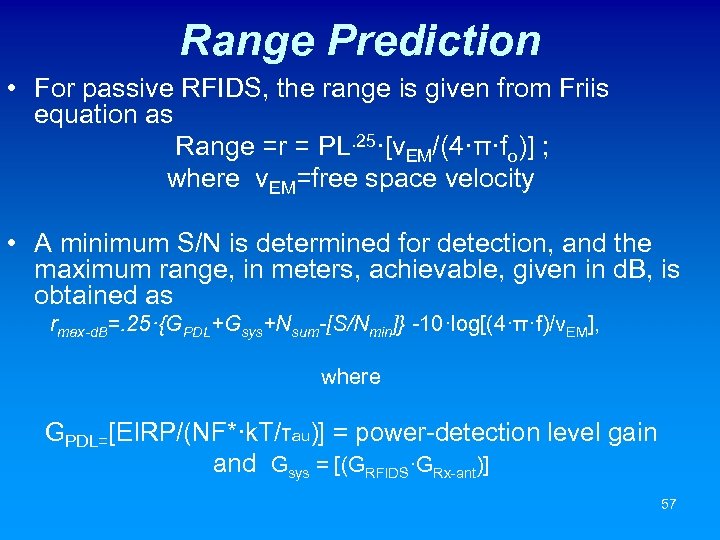

Range Prediction • For passive RFIDS, the range is given from Friis equation as Range =r = PL. 25·[v. EM/(4·π·fo)] ; where v. EM=free space velocity • A minimum S/N is determined for detection, and the maximum range, in meters, achievable, given in d. B, is obtained as rmax-d. B=. 25·{GPDL+Gsys+Nsum-[S/Nmin]} -10·log[(4·π·f)/v. EM], where GPDL=[EIRP/(NF*·k. T/τau)] = power-detection level gain and Gsys = [(GRFIDS·GRx-ant)] 57

Range Prediction • For passive RFIDS, the range is given from Friis equation as Range =r = PL. 25·[v. EM/(4·π·fo)] ; where v. EM=free space velocity • A minimum S/N is determined for detection, and the maximum range, in meters, achievable, given in d. B, is obtained as rmax-d. B=. 25·{GPDL+Gsys+Nsum-[S/Nmin]} -10·log[(4·π·f)/v. EM], where GPDL=[EIRP/(NF*·k. T/τau)] = power-detection level gain and Gsys = [(GRFIDS·GRx-ant)] 57

RF Chirp Transceiver Parameters • • Power to antenna = 30 d. Bm Pulse-length = 700 ns, 20 Vpp Antenna Gain = 9 d. B Bandwidth = 74 MHz Receiver Gain = 45 d. B NF = 15 d. B PGC= 49 = 17 d. B 58

RF Chirp Transceiver Parameters • • Power to antenna = 30 d. Bm Pulse-length = 700 ns, 20 Vpp Antenna Gain = 9 d. B Bandwidth = 74 MHz Receiver Gain = 45 d. B NF = 15 d. B PGC= 49 = 17 d. B 58

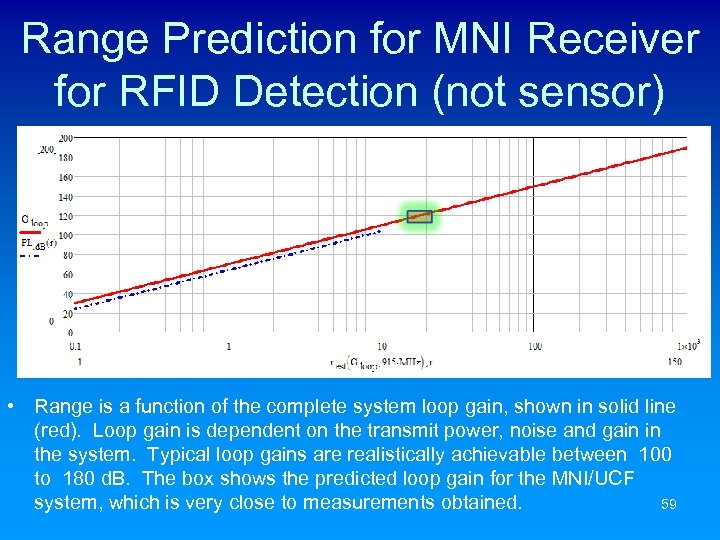

Range Prediction for MNI Receiver for RFID Detection (not sensor) • Range is a function of the complete system loop gain, shown in solid line (red). Loop gain is dependent on the transmit power, noise and gain in the system. Typical loop gains are realistically achievable between 100 to 180 d. B. The box shows the predicted loop gain for the MNI/UCF 59 system, which is very close to measurements obtained.

Range Prediction for MNI Receiver for RFID Detection (not sensor) • Range is a function of the complete system loop gain, shown in solid line (red). Loop gain is dependent on the transmit power, noise and gain in the system. Typical loop gains are realistically achievable between 100 to 180 d. B. The box shows the predicted loop gain for the MNI/UCF 59 system, which is very close to measurements obtained.

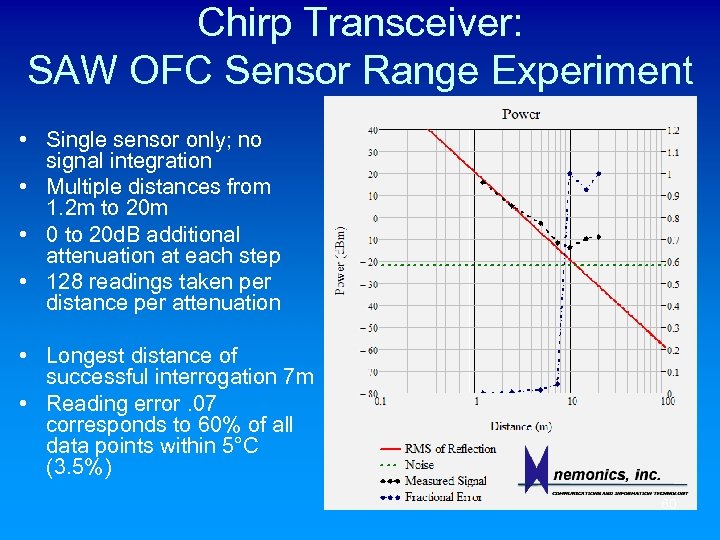

Chirp Transceiver: SAW OFC Sensor Range Experiment • Single sensor only; no signal integration • Multiple distances from 1. 2 m to 20 m • 0 to 20 d. B additional attenuation at each step • 128 readings taken per distance per attenuation • Longest distance of successful interrogation 7 m • Reading error. 07 corresponds to 60% of all data points within 5°C (3. 5%) 60

Chirp Transceiver: SAW OFC Sensor Range Experiment • Single sensor only; no signal integration • Multiple distances from 1. 2 m to 20 m • 0 to 20 d. B additional attenuation at each step • 128 readings taken per distance per attenuation • Longest distance of successful interrogation 7 m • Reading error. 07 corresponds to 60% of all data points within 5°C (3. 5%) 60

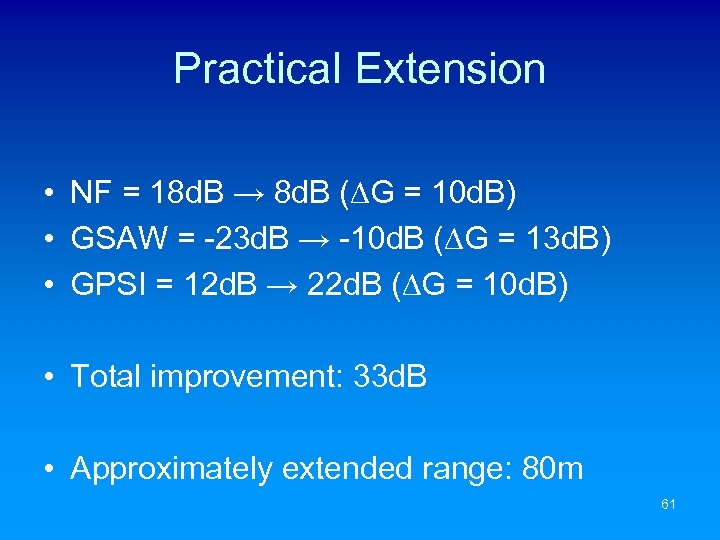

Practical Extension • NF = 18 d. B → 8 d. B (∆G = 10 d. B) • GSAW = -23 d. B → -10 d. B (∆G = 13 d. B) • GPSI = 12 d. B → 22 d. B (∆G = 10 d. B) • Total improvement: 33 d. B • Approximately extended range: 80 m 61

Practical Extension • NF = 18 d. B → 8 d. B (∆G = 10 d. B) • GSAW = -23 d. B → -10 d. B (∆G = 13 d. B) • GPSI = 12 d. B → 22 d. B (∆G = 10 d. B) • Total improvement: 33 d. B • Approximately extended range: 80 m 61

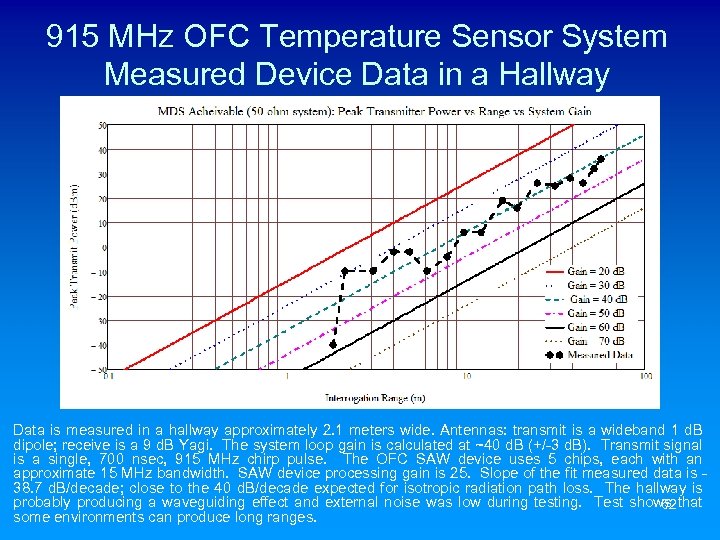

915 MHz OFC Temperature Sensor System Measured Device Data in a Hallway Data is measured in a hallway approximately 2. 1 meters wide. Antennas: transmit is a wideband 1 d. B dipole; receive is a 9 d. B Yagi. The system loop gain is calculated at ~40 d. B (+/-3 d. B). Transmit signal is a single, 700 nsec, 915 MHz chirp pulse. The OFC SAW device uses 5 chips, each with an approximate 15 MHz bandwidth. SAW device processing gain is 25. Slope of the fit measured data is 38. 7 d. B/decade; close to the 40 d. B/decade expected for isotropic radiation path loss. The hallway is probably producing a waveguiding effect and external noise was low during testing. Test shows that 62 some environments can produce long ranges.

915 MHz OFC Temperature Sensor System Measured Device Data in a Hallway Data is measured in a hallway approximately 2. 1 meters wide. Antennas: transmit is a wideband 1 d. B dipole; receive is a 9 d. B Yagi. The system loop gain is calculated at ~40 d. B (+/-3 d. B). Transmit signal is a single, 700 nsec, 915 MHz chirp pulse. The OFC SAW device uses 5 chips, each with an approximate 15 MHz bandwidth. SAW device processing gain is 25. Slope of the fit measured data is 38. 7 d. B/decade; close to the 40 d. B/decade expected for isotropic radiation path loss. The hallway is probably producing a waveguiding effect and external noise was low during testing. Test shows that 62 some environments can produce long ranges.

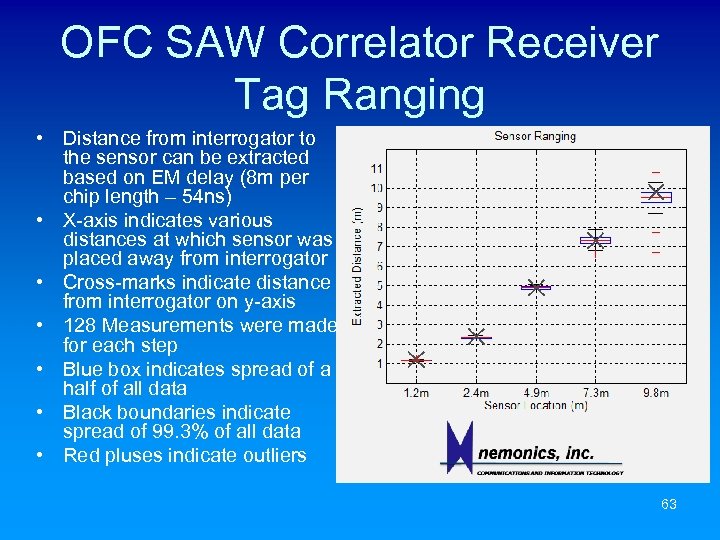

OFC SAW Correlator Receiver Tag Ranging • Distance from interrogator to the sensor can be extracted based on EM delay (8 m per chip length – 54 ns) • X-axis indicates various distances at which sensor was placed away from interrogator • Cross-marks indicate distance from interrogator on y-axis • 128 Measurements were made for each step • Blue box indicates spread of a half of all data • Black boundaries indicate spread of 99. 3% of all data • Red pluses indicate outliers 63

OFC SAW Correlator Receiver Tag Ranging • Distance from interrogator to the sensor can be extracted based on EM delay (8 m per chip length – 54 ns) • X-axis indicates various distances at which sensor was placed away from interrogator • Cross-marks indicate distance from interrogator on y-axis • 128 Measurements were made for each step • Blue box indicates spread of a half of all data • Black boundaries indicate spread of 99. 3% of all data • Red pluses indicate outliers 63

UCF Sensor Development • There is an extensive body of knowledge on sensing • Wired SAW sensing has quite an extensive body of knowledge and continues • Wireless SAW sensing has been most successfully demonstrated for single, or very few devices and in limited environments • The following are a few of the successful UCF sensor projects • The aim is to enable wireless acquisition of the sensors data • The further goal is to develop a multi-sensor system for aerospace applications • Successful wireless sensing has been demonstrated for temperature, liquid, closure, and range 64

UCF Sensor Development • There is an extensive body of knowledge on sensing • Wired SAW sensing has quite an extensive body of knowledge and continues • Wireless SAW sensing has been most successfully demonstrated for single, or very few devices and in limited environments • The following are a few of the successful UCF sensor projects • The aim is to enable wireless acquisition of the sensors data • The further goal is to develop a multi-sensor system for aerospace applications • Successful wireless sensing has been demonstrated for temperature, liquid, closure, and range 64

UCF OFC Sensor Successful Demonstrations • Temperature sensing – Cryogenic: liquid nitrogen – Room temperature to 250 o. C – Currently working on sensor for operation to 750 o. C • Cryogenic liquid level sensor: liquid nitrogen • Pressure/Strain sensor • Hydrogen gas sensor • Closure sensor with temperature 65

UCF OFC Sensor Successful Demonstrations • Temperature sensing – Cryogenic: liquid nitrogen – Room temperature to 250 o. C – Currently working on sensor for operation to 750 o. C • Cryogenic liquid level sensor: liquid nitrogen • Pressure/Strain sensor • Hydrogen gas sensor • Closure sensor with temperature 65

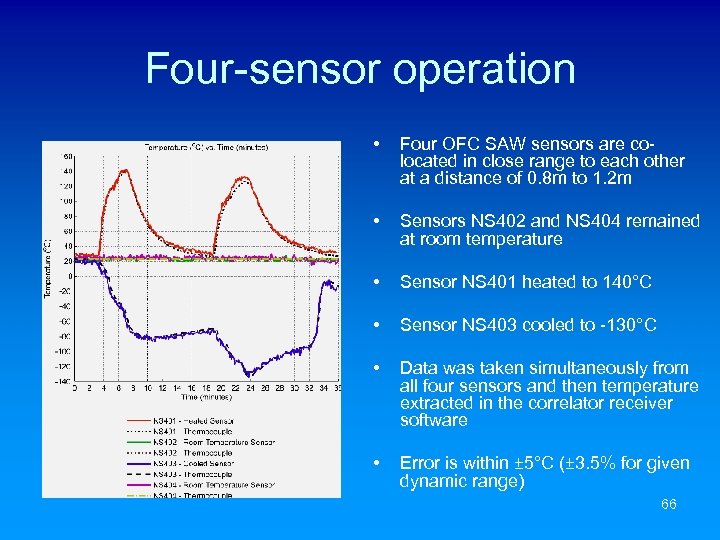

Four-sensor operation • Four OFC SAW sensors are colocated in close range to each other at a distance of 0. 8 m to 1. 2 m • Sensors NS 402 and NS 404 remained at room temperature • Sensor NS 401 heated to 140°C • Sensor NS 403 cooled to -130°C • Data was taken simultaneously from all four sensors and then temperature extracted in the correlator receiver software • Error is within ± 5°C (± 3. 5% for given dynamic range) 66

Four-sensor operation • Four OFC SAW sensors are colocated in close range to each other at a distance of 0. 8 m to 1. 2 m • Sensors NS 402 and NS 404 remained at room temperature • Sensor NS 401 heated to 140°C • Sensor NS 403 cooled to -130°C • Data was taken simultaneously from all four sensors and then temperature extracted in the correlator receiver software • Error is within ± 5°C (± 3. 5% for given dynamic range) 66

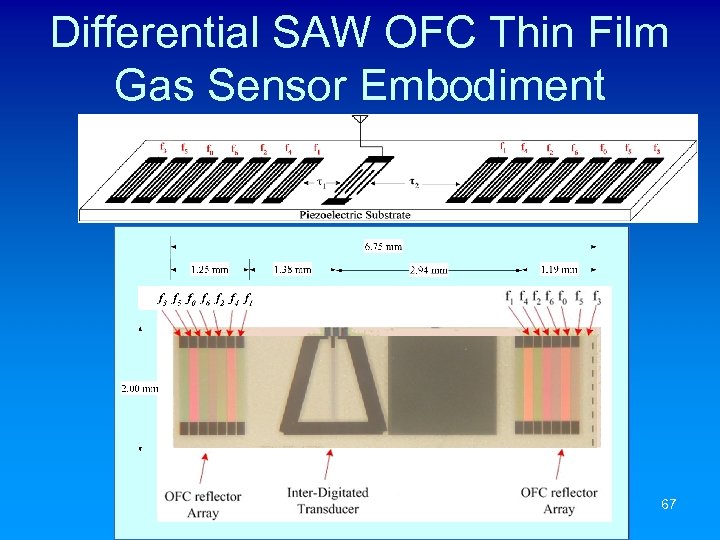

Differential SAW OFC Thin Film Gas Sensor Embodiment 67

Differential SAW OFC Thin Film Gas Sensor Embodiment 67

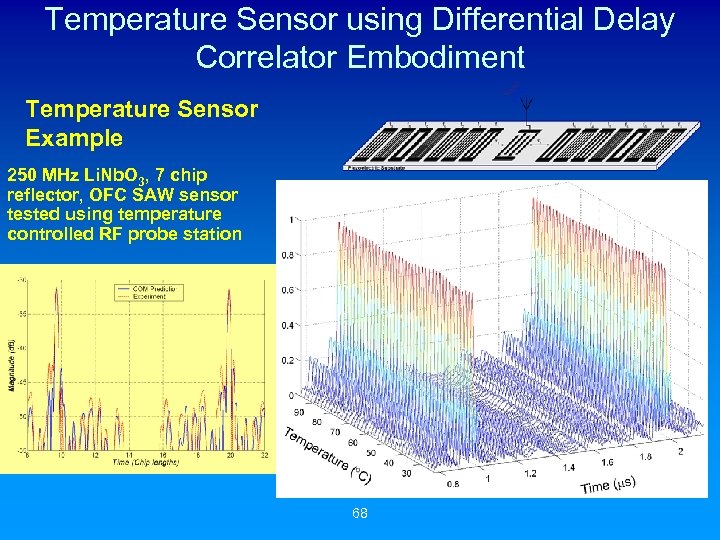

Temperature Sensor using Differential Delay Correlator Embodiment Temperature Sensor Example 250 MHz Li. Nb. O 3, 7 chip reflector, OFC SAW sensor tested using temperature controlled RF probe station 68

Temperature Sensor using Differential Delay Correlator Embodiment Temperature Sensor Example 250 MHz Li. Nb. O 3, 7 chip reflector, OFC SAW sensor tested using temperature controlled RF probe station 68

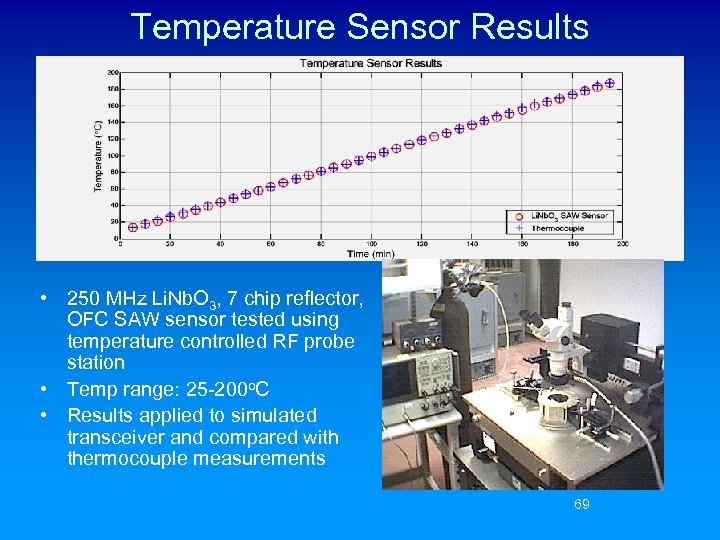

Temperature Sensor Results • 250 MHz Li. Nb. O 3, 7 chip reflector, OFC SAW sensor tested using temperature controlled RF probe station • Temp range: 25 -200 o. C • Results applied to simulated transceiver and compared with thermocouple measurements 69

Temperature Sensor Results • 250 MHz Li. Nb. O 3, 7 chip reflector, OFC SAW sensor tested using temperature controlled RF probe station • Temp range: 25 -200 o. C • Results applied to simulated transceiver and compared with thermocouple measurements 69

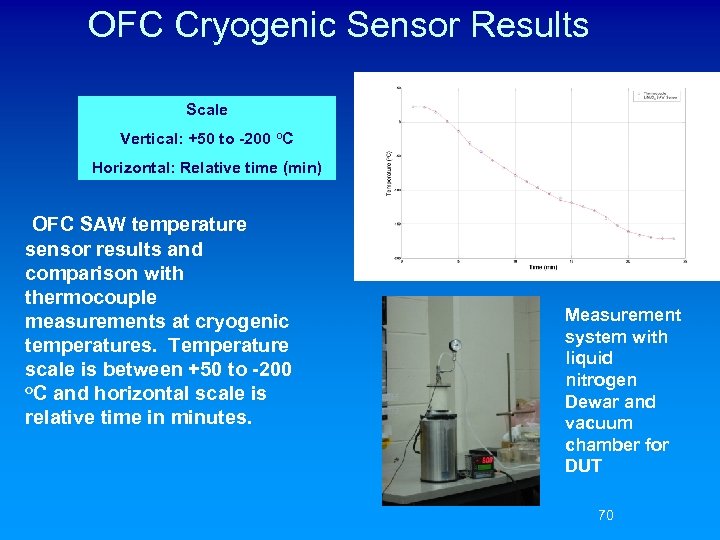

OFC Cryogenic Sensor Results Scale Vertical: +50 to -200 o. C Horizontal: Relative time (min) OFC SAW temperature sensor results and comparison with thermocouple measurements at cryogenic temperatures. Temperature scale is between +50 to -200 o. C and horizontal scale is relative time in minutes. Measurement system with liquid nitrogen Dewar and vacuum chamber for DUT 70

OFC Cryogenic Sensor Results Scale Vertical: +50 to -200 o. C Horizontal: Relative time (min) OFC SAW temperature sensor results and comparison with thermocouple measurements at cryogenic temperatures. Temperature scale is between +50 to -200 o. C and horizontal scale is relative time in minutes. Measurement system with liquid nitrogen Dewar and vacuum chamber for DUT 70

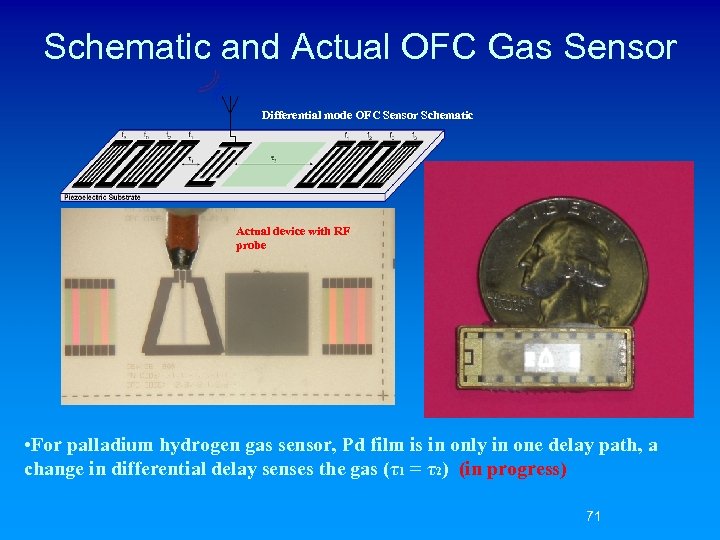

Schematic and Actual OFC Gas Sensor Differential mode OFC Sensor Schematic Actual device with RF probe • For palladium hydrogen gas sensor, Pd film is in only in one delay path, a change in differential delay senses the gas (τ1 = τ2) (in progress) 71

Schematic and Actual OFC Gas Sensor Differential mode OFC Sensor Schematic Actual device with RF probe • For palladium hydrogen gas sensor, Pd film is in only in one delay path, a change in differential delay senses the gas (τ1 = τ2) (in progress) 71

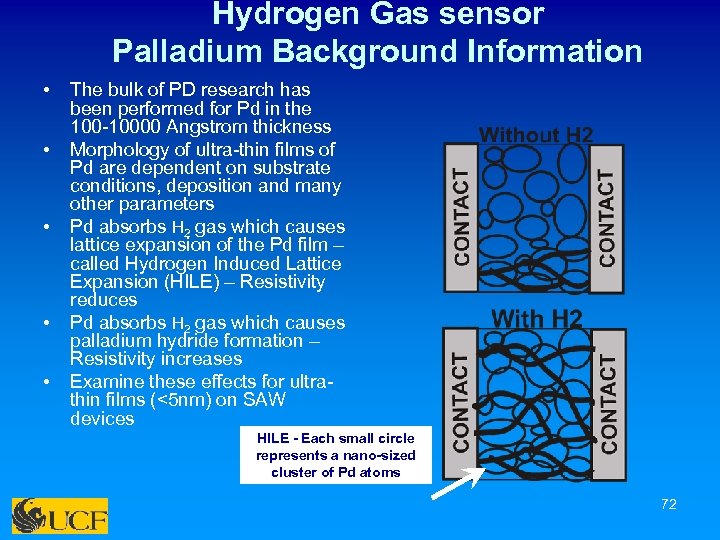

Hydrogen Gas sensor Palladium Background Information • • • The bulk of PD research has been performed for Pd in the 100 -10000 Angstrom thickness Morphology of ultra-thin films of Pd are dependent on substrate conditions, deposition and many other parameters Pd absorbs H 2 gas which causes lattice expansion of the Pd film – called Hydrogen Induced Lattice Expansion (HILE) – Resistivity reduces Pd absorbs H 2 gas which causes palladium hydride formation – Resistivity increases Examine these effects for ultrathin films (<5 nm) on SAW devices HILE - Each small circle represents a nano-sized cluster of Pd atoms 72

Hydrogen Gas sensor Palladium Background Information • • • The bulk of PD research has been performed for Pd in the 100 -10000 Angstrom thickness Morphology of ultra-thin films of Pd are dependent on substrate conditions, deposition and many other parameters Pd absorbs H 2 gas which causes lattice expansion of the Pd film – called Hydrogen Induced Lattice Expansion (HILE) – Resistivity reduces Pd absorbs H 2 gas which causes palladium hydride formation – Resistivity increases Examine these effects for ultrathin films (<5 nm) on SAW devices HILE - Each small circle represents a nano-sized cluster of Pd atoms 72

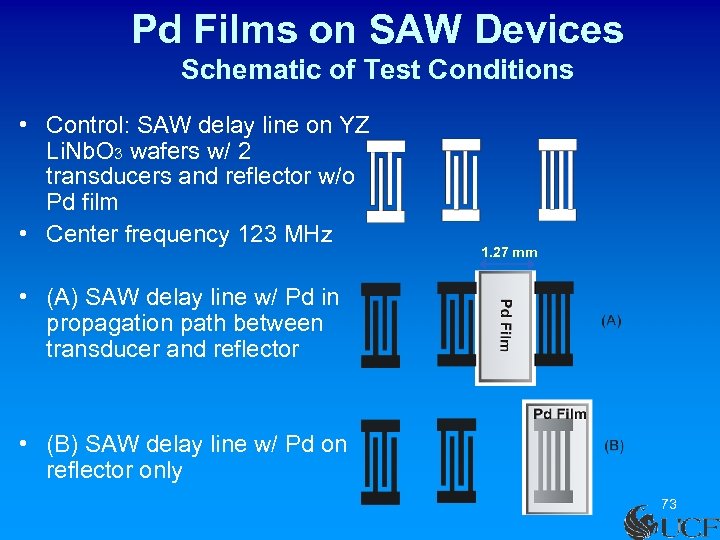

Pd Films on SAW Devices Schematic of Test Conditions • Control: SAW delay line on YZ Li. Nb. O 3 wafers w/ 2 transducers and reflector w/o Pd film • Center frequency 123 MHz 1. 27 mm • (A) SAW delay line w/ Pd in propagation path between transducer and reflector • (B) SAW delay line w/ Pd on reflector only 73

Pd Films on SAW Devices Schematic of Test Conditions • Control: SAW delay line on YZ Li. Nb. O 3 wafers w/ 2 transducers and reflector w/o Pd film • Center frequency 123 MHz 1. 27 mm • (A) SAW delay line w/ Pd in propagation path between transducer and reflector • (B) SAW delay line w/ Pd on reflector only 73

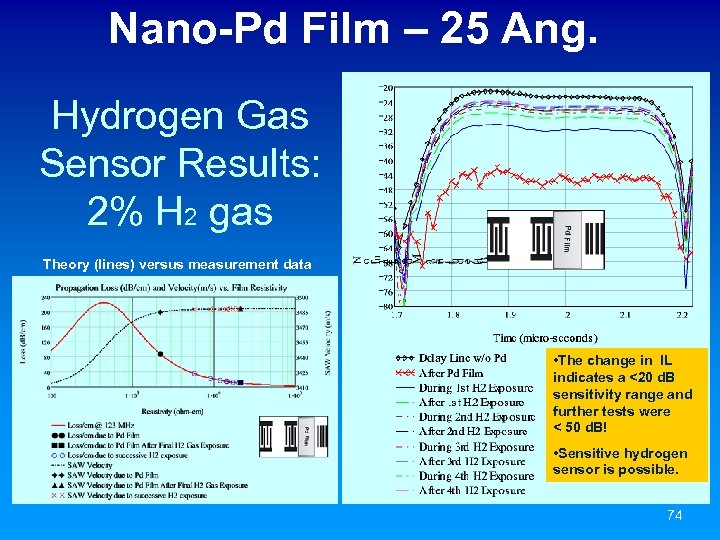

Nano-Pd Film – 25 Ang. Hydrogen Gas Sensor Results: 2% H 2 gas Theory (lines) versus measurement data • The change in IL indicates a <20 d. B sensitivity range and further tests were < 50 d. B! • Sensitive hydrogen sensor is possible. 74

Nano-Pd Film – 25 Ang. Hydrogen Gas Sensor Results: 2% H 2 gas Theory (lines) versus measurement data • The change in IL indicates a <20 d. B sensitivity range and further tests were < 50 d. B! • Sensitive hydrogen sensor is possible. 74

Cantilever Sensor Results • Initial cantilever sensor results • Apply results to strain and pressure sensors 75

Cantilever Sensor Results • Initial cantilever sensor results • Apply results to strain and pressure sensors 75

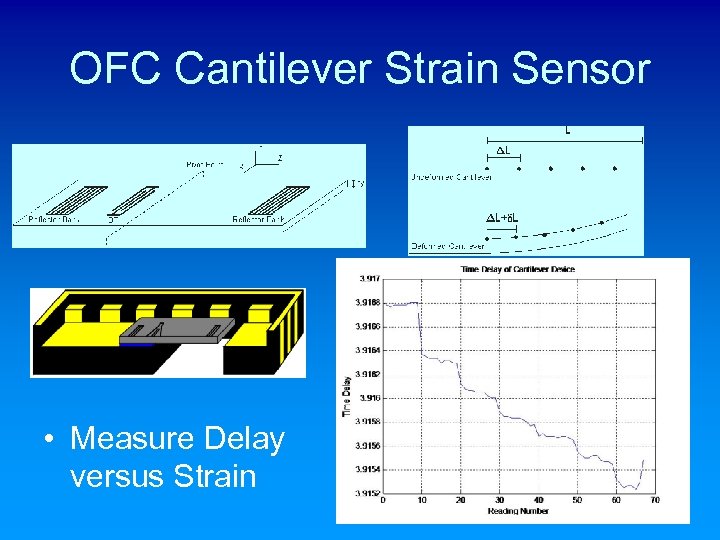

OFC Cantilever Strain Sensor • Measure Delay versus Strain 76

OFC Cantilever Strain Sensor • Measure Delay versus Strain 76

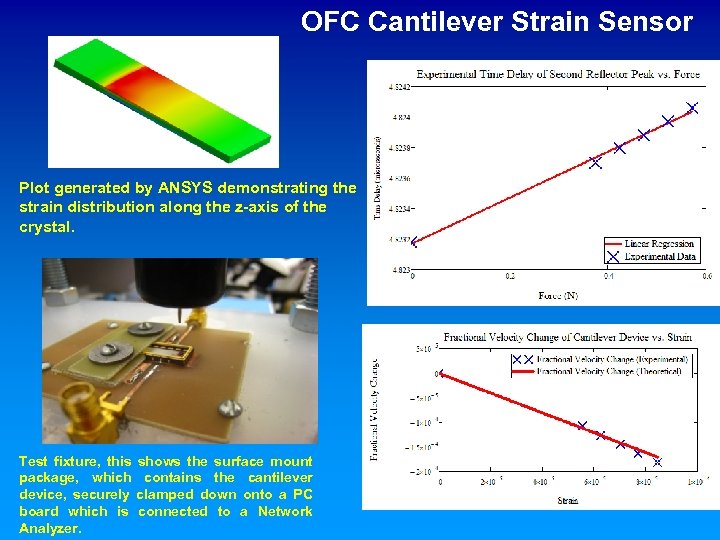

OFC Cantilever Strain Sensor Plot generated by ANSYS demonstrating the strain distribution along the z-axis of the crystal. Test fixture, this shows the surface mount package, which contains the cantilever device, securely clamped down onto a PC board which is connected to a Network Analyzer. 77

OFC Cantilever Strain Sensor Plot generated by ANSYS demonstrating the strain distribution along the z-axis of the crystal. Test fixture, this shows the surface mount package, which contains the cantilever device, securely clamped down onto a PC board which is connected to a Network Analyzer. 77

Applications • Current efforts include OFC SAW liquid level, hydrogen gas, pressure and temperature sensors • Multi-sensor spread spectrum systems • Cryogenic sensing • High temperature sensing • Space applications • Turbine generators • Harsh environments • Ultra Wide band (UWB) Communication – UWB OFC transducers • Potentially many others 78

Applications • Current efforts include OFC SAW liquid level, hydrogen gas, pressure and temperature sensors • Multi-sensor spread spectrum systems • Cryogenic sensing • High temperature sensing • Space applications • Turbine generators • Harsh environments • Ultra Wide band (UWB) Communication – UWB OFC transducers • Potentially many others 78

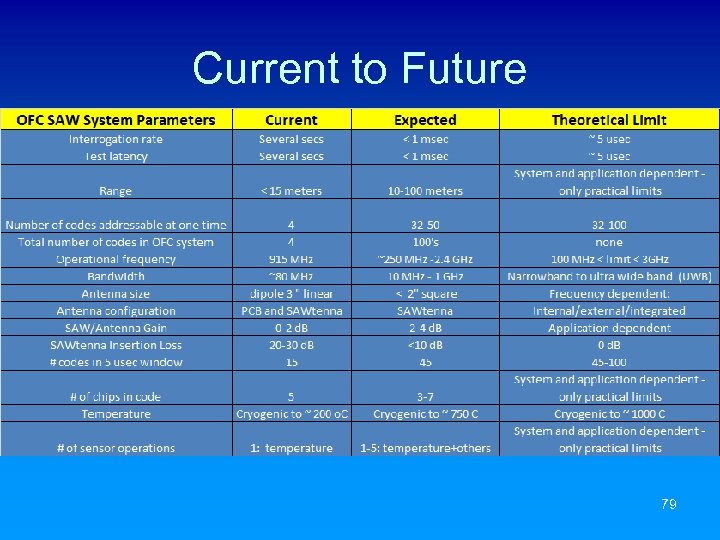

Current to Future 79

Current to Future 79

Vision for Future • Multiple access, SAW RFID sensors • SAW RFID sensor loss approaching 6 d. B – Unidirectional transducers – Low loss reflectors • New and novel coding • New and novel sensors • New materials for high temperature (1000 o. C) and harsh environments • SAW sensors in test space flight and support operations in 1 to 5 years 80

Vision for Future • Multiple access, SAW RFID sensors • SAW RFID sensor loss approaching 6 d. B – Unidirectional transducers – Low loss reflectors • New and novel coding • New and novel sensors • New materials for high temperature (1000 o. C) and harsh environments • SAW sensors in test space flight and support operations in 1 to 5 years 80

Ultra Wide Band • BW defined by chirp, not by individual sensors • Could use a frequency hopped chirp system • Frequency diversity is increased • Code coliision reduction • Multi-bands for multisensors • Subsets of sensors activated at any given time • Narrower band antennas, lower loss devices 81

Ultra Wide Band • BW defined by chirp, not by individual sensors • Could use a frequency hopped chirp system • Frequency diversity is increased • Code coliision reduction • Multi-bands for multisensors • Subsets of sensors activated at any given time • Narrower band antennas, lower loss devices 81

SAW Research at UCF • UCF Center for Acoustoelectronic Technology (CAAT) has been actively doing SAW and BAW research for over 25 years • Research includes communication devices and systems, new piezoelectric materials, & sensors • Capabilities include SAW/BAW analysis, design, mask generation, device fabrication, RF testing, and RF system development • Current group has 6 Ph. Ds & 1 Post-doc 82

SAW Research at UCF • UCF Center for Acoustoelectronic Technology (CAAT) has been actively doing SAW and BAW research for over 25 years • Research includes communication devices and systems, new piezoelectric materials, & sensors • Capabilities include SAW/BAW analysis, design, mask generation, device fabrication, RF testing, and RF system development • Current group has 6 Ph. Ds & 1 Post-doc 82

Capabilities • Proprietary software: COM analysis & design, parameter extraction, data acquisition and test • UCF device fabrication to <. 8 um resolution • In-house mask fab & thin film capabilities • Complete RF SAW characterization facility • Extensive RF laboratory for system development 83

Capabilities • Proprietary software: COM analysis & design, parameter extraction, data acquisition and test • UCF device fabrication to <. 8 um resolution • In-house mask fab & thin film capabilities • Complete RF SAW characterization facility • Extensive RF laboratory for system development 83

UCF SAW OFC Contracts & Intellectual Property A. 6 – Phase I and 4 –Phase II STTR/SBIRs on SAW OFC Sensors B. NASA KSC, Langley, and JSC contracts C. Fellowships from NASA, NSF, Motorola, NSDEG, UCF, Mc. Knight, and Florida Space Grant D. Patents on SAW OFC: #7, 642, 898 D. C. Malocha and Puccio, Orthogonal Frequency Coding for Surface Acoustic Wave Communications, Tag, and Sensors, Jan. 5, 2010. #7, 623, 037 D. C. Malocha, Multi-transducer/antenna surface acoustic wave device sensor and tag, November 24, 2009. #7, 825, 805, D. C. Malocha and D. Puccio, Delayed Offset Multi-Track OFC Sensors and Tags, Nov. 2, 2010. #7, 777, 625, D. C. Malocha and D. Puccio, Weighted Reflectors for OFC Coding, Aug. 17, 2010. #7, 791, 249, D. C. Malocha and N. Y. Kozlovski, SAW Coding for OFC Devices, Appl # 12, 618, 034, D. C. Malocha and N. Kozlovski, Coding for Surface Acoustic Wave Devices, Filed Nov. 13, 2009. Several in process 84

UCF SAW OFC Contracts & Intellectual Property A. 6 – Phase I and 4 –Phase II STTR/SBIRs on SAW OFC Sensors B. NASA KSC, Langley, and JSC contracts C. Fellowships from NASA, NSF, Motorola, NSDEG, UCF, Mc. Knight, and Florida Space Grant D. Patents on SAW OFC: #7, 642, 898 D. C. Malocha and Puccio, Orthogonal Frequency Coding for Surface Acoustic Wave Communications, Tag, and Sensors, Jan. 5, 2010. #7, 623, 037 D. C. Malocha, Multi-transducer/antenna surface acoustic wave device sensor and tag, November 24, 2009. #7, 825, 805, D. C. Malocha and D. Puccio, Delayed Offset Multi-Track OFC Sensors and Tags, Nov. 2, 2010. #7, 777, 625, D. C. Malocha and D. Puccio, Weighted Reflectors for OFC Coding, Aug. 17, 2010. #7, 791, 249, D. C. Malocha and N. Y. Kozlovski, SAW Coding for OFC Devices, Appl # 12, 618, 034, D. C. Malocha and N. Kozlovski, Coding for Surface Acoustic Wave Devices, Filed Nov. 13, 2009. Several in process 84

Conclusion • 915 MHz OFC SAW temperature sensor system has been demonstrated • Current tests show 10 meter open range • 4 sensors have been simultaneously interrogated and measured • Range predictions and measured data have been shown • Wireless passive SAW sensors are a “game-changing” technology 85

Conclusion • 915 MHz OFC SAW temperature sensor system has been demonstrated • Current tests show 10 meter open range • 4 sensors have been simultaneously interrogated and measured • Range predictions and measured data have been shown • Wireless passive SAW sensors are a “game-changing” technology 85