surfaceacousticwavesawbasedsensors-130307092419-phpapp02.pptx

- Количество слайдов: 52

SURFACE ACOUSTIC WAVE (SAW) BASED SENSOR Shreesh Mohan Verma Tanuj Agarwal

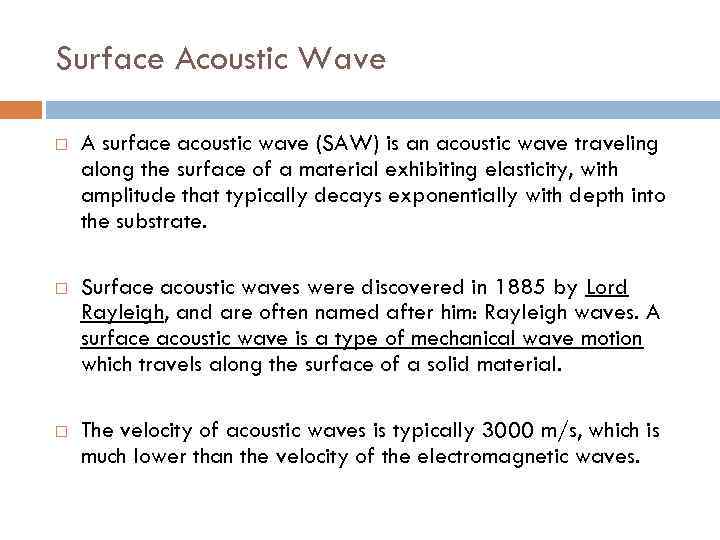

Surface Acoustic Wave A surface acoustic wave (SAW) is an acoustic wave traveling along the surface of a material exhibiting elasticity, with amplitude that typically decays exponentially with depth into the substrate. Surface acoustic waves were discovered in 1885 by Lord Rayleigh, and are often named after him: Rayleigh waves. A surface acoustic wave is a type of mechanical wave motion which travels along the surface of a solid material. The velocity of acoustic waves is typically 3000 m/s, which is much lower than the velocity of the electromagnetic waves.

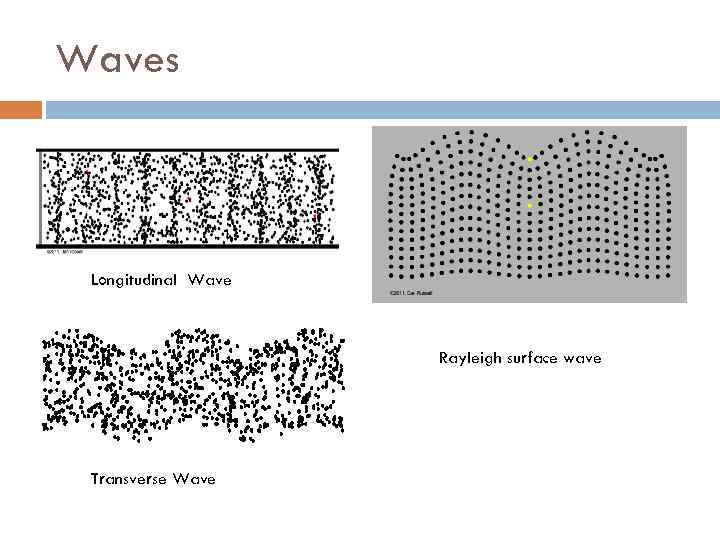

Waves Longitudinal Wave Rayleigh surface wave Transverse Wave

Surface Acoustic Wave Sensors Surface acoustic wave sensors are a class of microelectromechanical systems (MEMS) which rely on the modulation of surface acoustic waves to sense a physical phenomenon. The sensor transduces an input electrical signal into a mechanical wave which, unlike an electrical signal, can be easily influenced by physical phenomena. The device then transduces this wave back into an electrical signal. Changes in amplitude, phase, frequency, or time-delay between the input and output electrical signals can be used to measure the presence of the desired phenomenon.

Conventional fields of application – communications and signal processing Other application - as identification tags, chemical and biosensors, and as sensors of different physical quantities. The SAW sensors are passive elements (they do not need power supply) and can be accessed wirelessly, enabling remote monitoring in harsh environment. They work in the frequency range of 10 MHz to several GHz. They have the rugged compact structure, outstanding stability, high sensitivity, low cost, fast real time response, extremely small size (lightweight).

BASIC PRINCIPLE OF OPERATION OF SAW DEVICES The operation of the SAW device is based on acoustic wave propagation near the surface of a piezoelectric solid. This implies that the wave can be trapped or otherwise modified while propagating. The displacements decay exponentially away from the surface, so that the most of the wave energy (usually more than 95 %) is confined within a depth equal to one wavelength. The surface wave can be excited electrically by means of an interdigital transducer (IDT).

What is a typical SAW Device? A solid state device Converts electrical energy into a mechanical wave on a single crystal substrate Provides very complex signal processing in a very small volume Approximately 4 -5 billion SAW devices are produced each year Applications: Cellular phones and TV (largest market) Military (Radar, filters, advanced systems Currently emerging – sensors, RFID 7

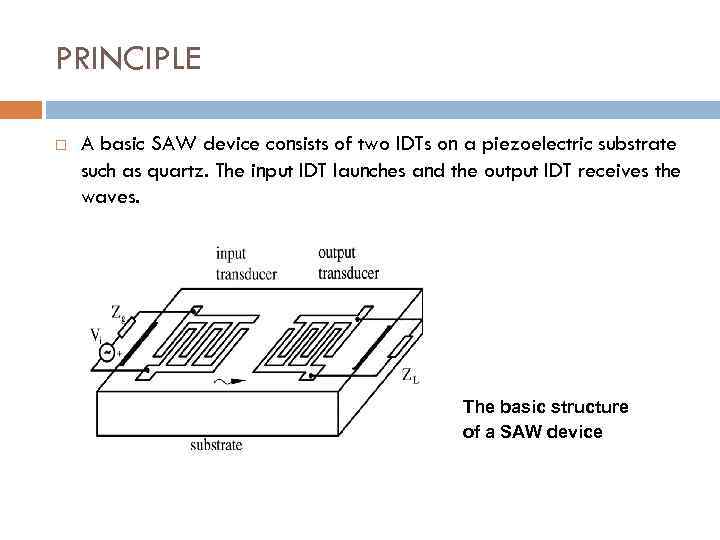

PRINCIPLE A basic SAW device consists of two IDTs on a piezoelectric substrate such as quartz. The input IDT launches and the output IDT receives the waves. The basic structure of a SAW device

PRINCIPLE The interdigital transducer consists of a series of interleaved electrodes made of a metal film deposited on a piezoelectric substrate as shown above. The width of the electrodes usually equals the width of the interelectrode gaps giving the maximal conversion of electrical to mechanical signal, and vice versa. The minimal electrode width which is obtained in industry is around 0. 3 μm, which determines the highest frequency of around 3 GHz.

PRINCIPLE The commonly used substrate crystals are: quartz, lithium niobate, lithium tantalate, zinc oxide and bismuth germanium oxide. They have different piezoelectric coupling coefficients and temperature sensitivities. The ST quartz is used for the most temperature stable devices. The wave velocity is a function of the substrate material and is in the range of 1500 m/s to 4800 m/s, which is 105 times lower than the electromagnetic wave velocity. This enables the construction of a small size delay line of a considerable delay. The input and output transducers may be equal or different. It depends upon the function which the SAW device has to perform. Usually, they differ in electrode’s overlaps, number and sometimes positioning.

If the electrodes are uniformly spaced, the phase characteristic is a linear function of frequency, e. g. , the phase delay is constant in the appropriate frequency range. This type of the SAW device is than called delay line. In the second type of SAW devices – SAW resonators , IDTs are only used as converters of electrical to mechanical signals, and vice versa, but the amplitude and phase characteristics are obtained in different ways.

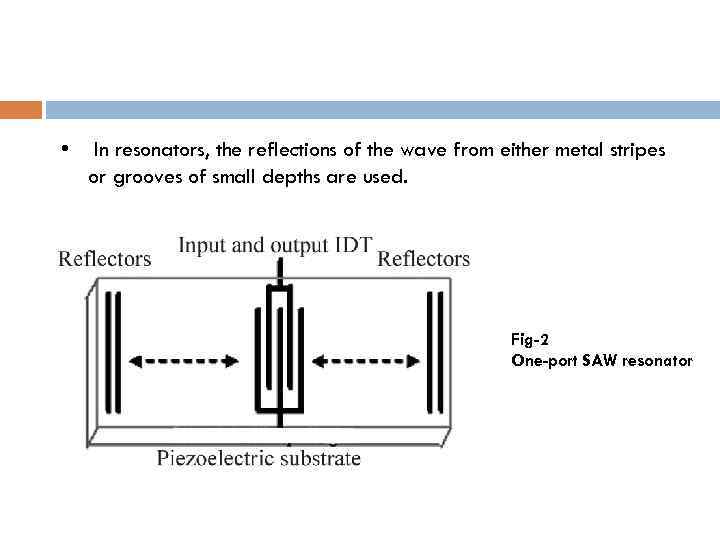

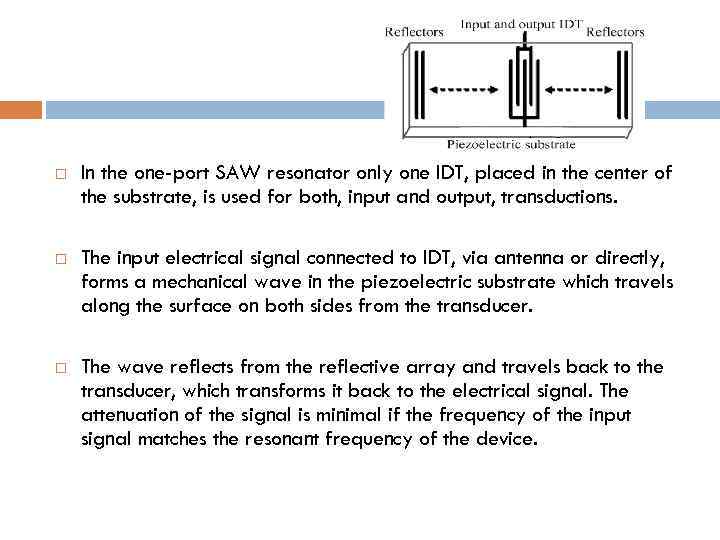

• In resonators, the reflections of the wave from either metal stripes or grooves of small depths are used. Fig-2 One-port SAW resonator

In the one-port SAW resonator only one IDT, placed in the center of the substrate, is used for both, input and output, transductions. The input electrical signal connected to IDT, via antenna or directly, forms a mechanical wave in the piezoelectric substrate which travels along the surface on both sides from the transducer. The wave reflects from the reflective array and travels back to the transducer, which transforms it back to the electrical signal. The attenuation of the signal is minimal if the frequency of the input signal matches the resonant frequency of the device.

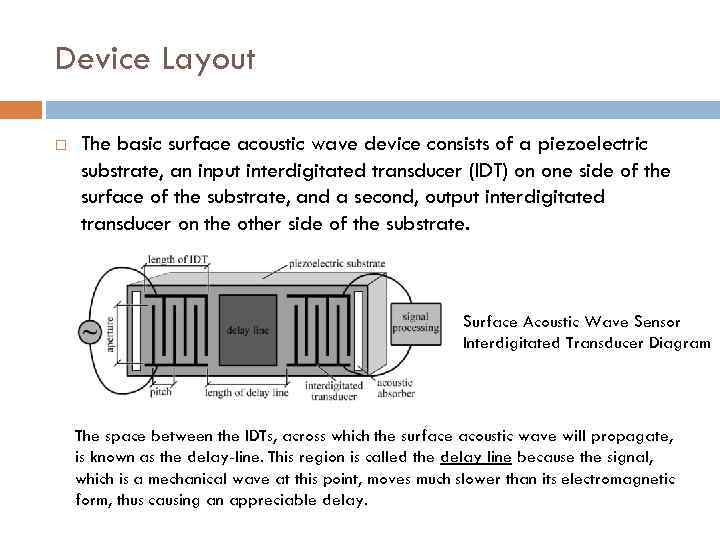

Device Layout The basic surface acoustic wave device consists of a piezoelectric substrate, an input interdigitated transducer (IDT) on one side of the surface of the substrate, and a second, output interdigitated transducer on the other side of the substrate. Surface Acoustic Wave Sensor Interdigitated Transducer Diagram The space between the IDTs, across which the surface acoustic wave will propagate, is known as the delay-line. This region is called the delay line because the signal, which is a mechanical wave at this point, moves much slower than its electromagnetic form, thus causing an appreciable delay.

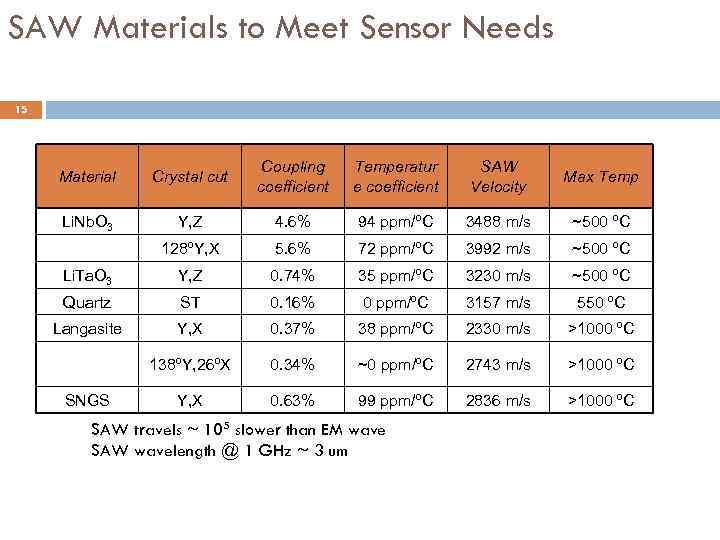

SAW Materials to Meet Sensor Needs 15 Material Crystal cut Coupling coefficient Temperatur e coefficient SAW Velocity Max Temp Li. Nb. O 3 Y, Z 4. 6% 94 ppm/ºC 3488 m/s ~500 ºC 128ºY, X 5. 6% 72 ppm/ºC 3992 m/s ~500 ºC Li. Ta. O 3 Y, Z 0. 74% 35 ppm/ºC 3230 m/s ~500 ºC Quartz ST 0. 16% 0 ppm/ºC 3157 m/s 550 ºC Langasite Y, X 0. 37% 38 ppm/ºC 2330 m/s >1000 ºC 138ºY, 26ºX 0. 34% ~0 ppm/ºC 2743 m/s >1000 ºC Y, X 0. 63% 99 ppm/ºC 2836 m/s >1000 ºC SNGS SAW travels ~ 105 slower than EM wave SAW wavelength @ 1 GHz ~ 3 um

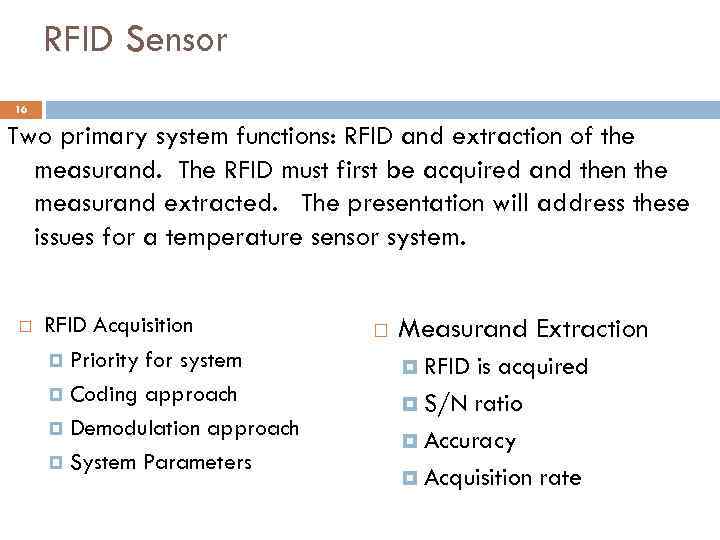

RFID Sensor 16 Two primary system functions: RFID and extraction of the measurand. The RFID must first be acquired and then the measurand extracted. The presentation will address these issues for a temperature sensor system. RFID Acquisition Priority for system Coding approach Demodulation approach System Parameters Measurand Extraction RFID is acquired S/N ratio Accuracy Acquisition rate

Diversity for Identification 17 Frequency Spectrum Diversity per Device Coding Divide into frequency bands Time Delay per Device Different offset delays per device Pulse position modulation Time allocations minimize code collisions Spatial Diversity – device placement Sensor & Tx-Rx Antenna Polarization Use combinations of all to optimize system

Brief Introduction to Wireless SAW Sensors One port devices return the altered interrogation signal Range depends on embodiment Range increased using coherent integration of multiple responses Interrogator used to excite devices Several embodiments are shown next 18

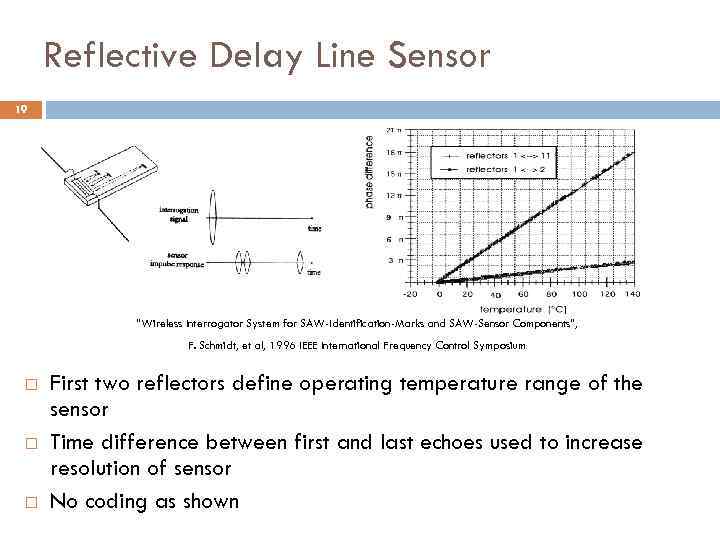

Reflective Delay Line Sensor 19 “Wireless Interrogator System for SAW-Identification-Marks and SAW-Sensor Components”, F. Schmidt, et al, 1996 IEEE International Frequency Control Symposium First two reflectors define operating temperature range of the sensor Time difference between first and last echoes used to increase resolution of sensor No coding as shown

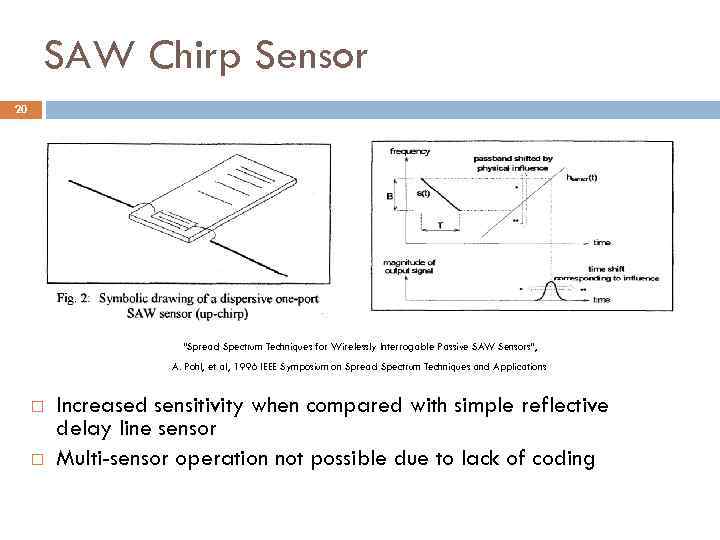

SAW Chirp Sensor 20 “Spread Spectrum Techniques for Wirelessly Interrogable Passive SAW Sensors”, A. Pohl, et al, 1996 IEEE Symposium on Spread Spectrum Techniques and Applications Increased sensitivity when compared with simple reflective delay line sensor Multi-sensor operation not possible due to lack of coding

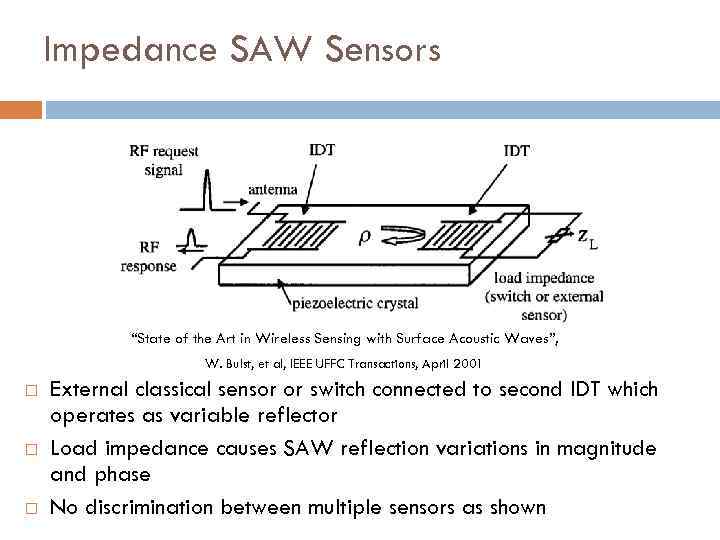

Impedance SAW Sensors “State of the Art in Wireless Sensing with Surface Acoustic Waves”, W. Bulst, et al, IEEE UFFC Transactions, April 2001 External classical sensor or switch connected to second IDT which operates as variable reflector Load impedance causes SAW reflection variations in magnitude and phase No discrimination between multiple sensors as shown 21

SAW RFID Practical Approaches 22 Resonator Fabry-Perot Cavity Frequency selective, SAW device Q~10, 000 Code Division Multiple Access (CDMA) Delay line – single frequency Bragg reflectors Pulse position encoding Orthogonal Frequency Coding (OFC) Delay line, multi-frequency Bragg reflectors Pulse position encoding Frequency coupled with time diversity

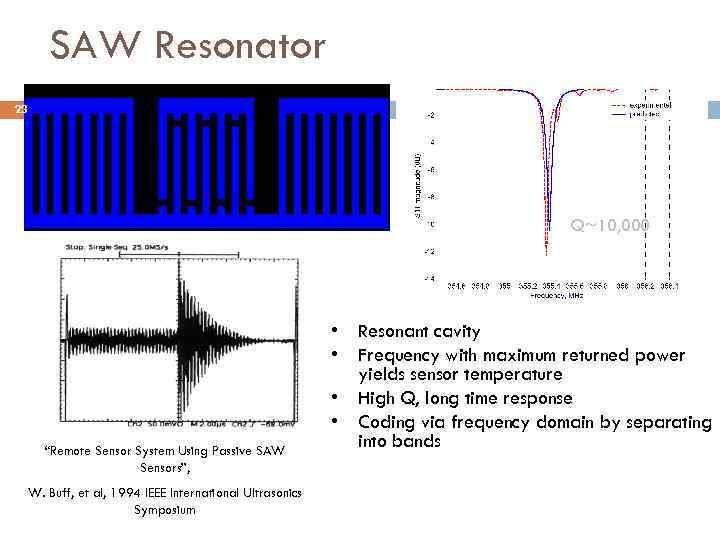

SAW Resonator 23 Q~10, 000 “Remote Sensor System Using Passive SAW Sensors”, W. Buff, et al, 1994 IEEE International Ultrasonics Symposium • Resonant cavity • Frequency with maximum returned power yields sensor temperature • High Q, long time response • Coding via frequency domain by separating into bands

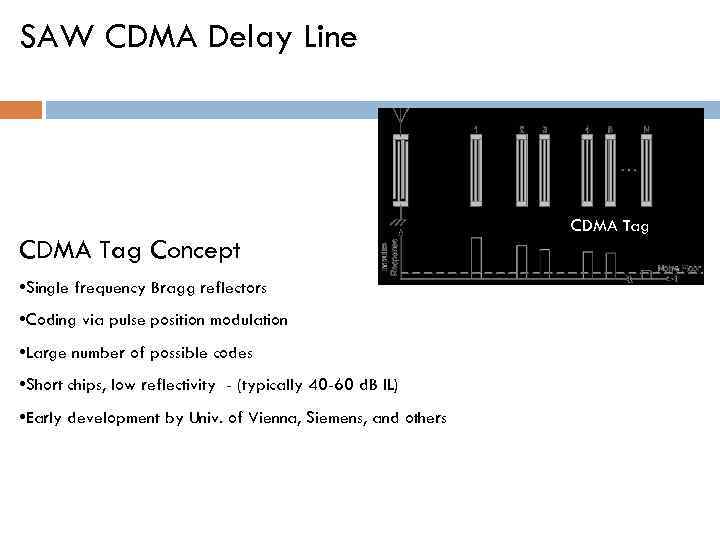

SAW CDMA Delay Line CDMA Tag Concept CDMA Tag • Single frequency Bragg reflectors • Coding via pulse position modulation • Large number of possible codes • Short chips, low reflectivity - (typically 40 -60 d. B IL) • Early development by Univ. of Vienna, Siemens, and others 24

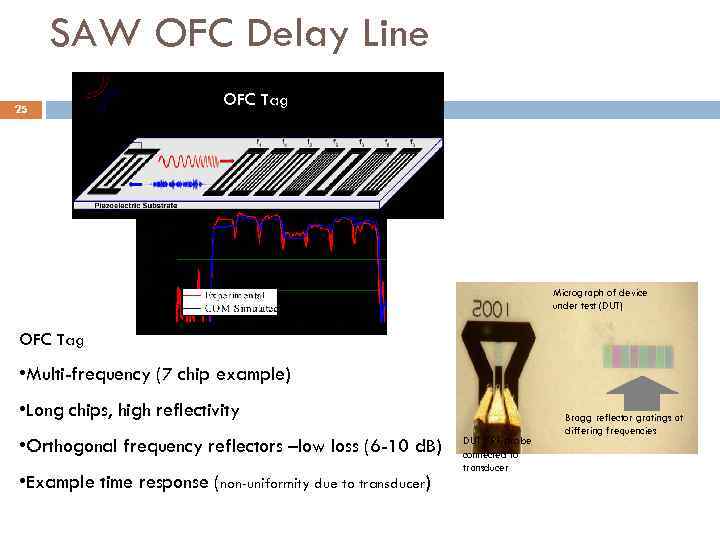

SAW OFC Delay Line 25 OFC Tag Micrograph of device under test (DUT) OFC Tag • Multi-frequency (7 chip example) • Long chips, high reflectivity • Orthogonal frequency reflectors –low loss (6 -10 d. B) • Example time response (non-uniformity due to transducer) DUT - RF probe connected to transducer Bragg reflector gratings at differing frequencies

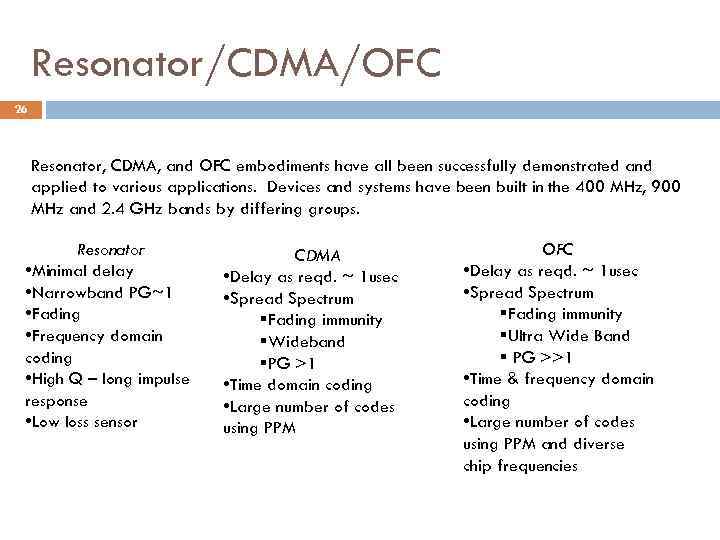

Resonator/CDMA/OFC 26 Resonator, CDMA, and OFC embodiments have all been successfully demonstrated and applied to various applications. Devices and systems have been built in the 400 MHz, 900 MHz and 2. 4 GHz bands by differing groups. Resonator • Minimal delay • Narrowband PG~1 • Fading • Frequency domain coding • High Q – long impulse response • Low loss sensor CDMA • Delay as reqd. ~ 1 usec • Spread Spectrum §Fading immunity §Wideband §PG >1 • Time domain coding • Large number of codes using PPM OFC • Delay as reqd. ~ 1 usec • Spread Spectrum §Fading immunity §Ultra Wide Band § PG >>1 • Time & frequency domain coding • Large number of codes using PPM and diverse chip frequencies

OFC Historical Development 27 Several different OFC sensors demonstrated Chose 1 st devices at 250 MHz for feasibility Demonstrated harmonic operated devices at 456, 915 MHz and 1. 6 GHz Fundamental device operation at 915 MHz Devices in the +1 GHz range in 2010 First OFC system at 250 MHz Current OFC system at 915 MHz First 4 device wireless operation in 2009 Mnemonics demonstrates first chirp OFC corelator receiver in 2010

Why OFC SAW Sensors? A game-changing approach All advatageous of SAW technology Wireless, passive and multicoded sensors Frequency & time offer greatest coding diversity Single communication platform for diverse sensor embodiments Radiation hard Wide operational temperature range 28

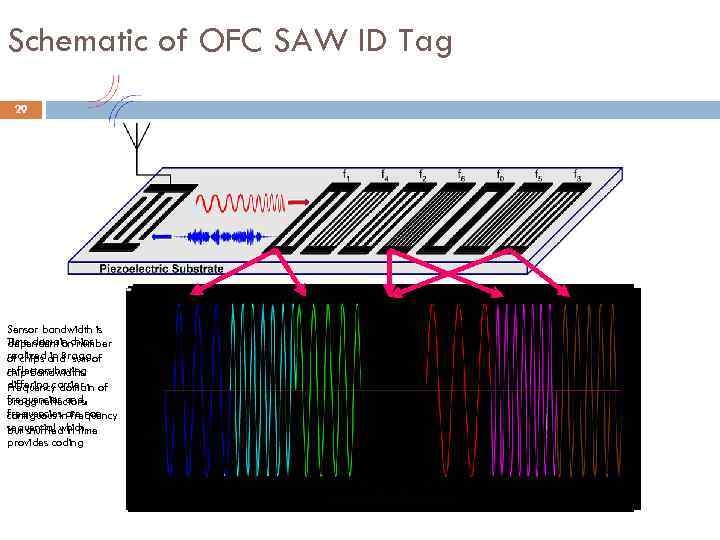

Schematic of OFC SAW ID Tag 29 Sensor bandwidth is Time domain chips dependent on number realizedand sum of of chips in Bragg reflectors having chip bandwidths. differing carrier of Frequency domain frequencies and Bragg reflectors: frequenciesinare noncontiguous frequency sequential which but shuffled in time provides coding

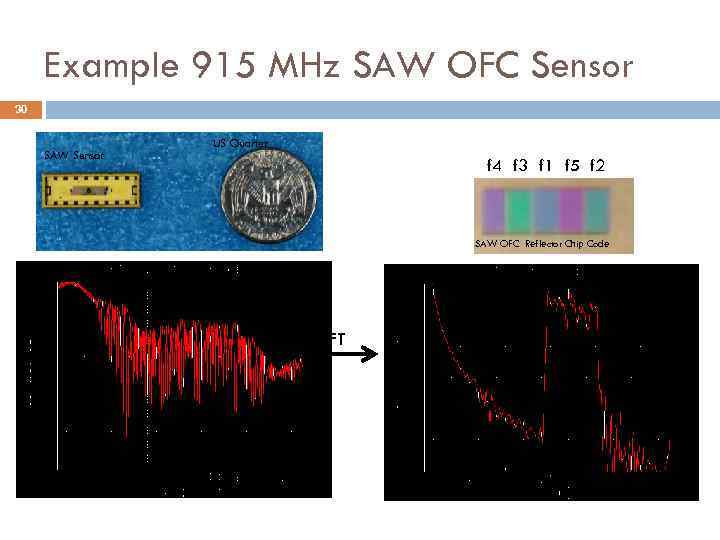

Example 915 MHz SAW OFC Sensor 30 SAW Sensor US Quarter f 4 f 3 f 1 f 5 f 2 SAW OFC Reflector Chip Code FFT

Synchronous Correlator Transceiver 31

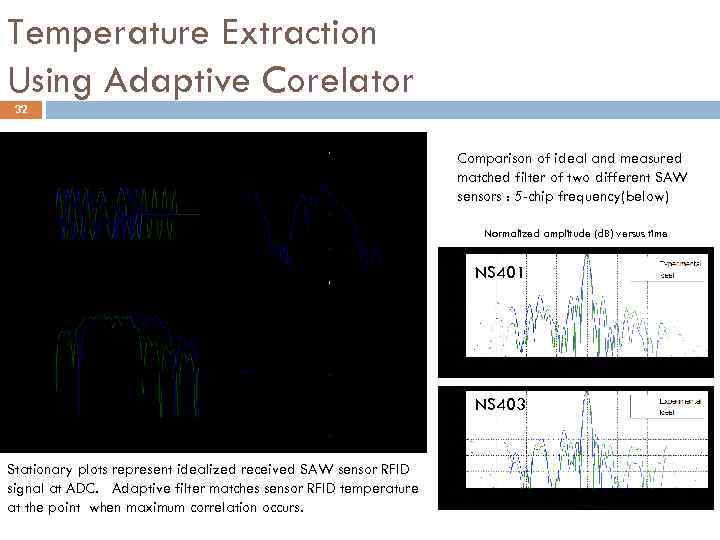

Temperature Extraction Using Adaptive Corelator 32 Comparison of ideal and measured matched filter of two different SAW sensors : 5 -chip frequency(below) Normalized amplitude (d. B) versus time NS 401 NS 403 Stationary plots represent idealized received SAW sensor RFID signal at ADC. Adaptive filter matches sensor RFID temperature at the point when maximum correlation occurs.

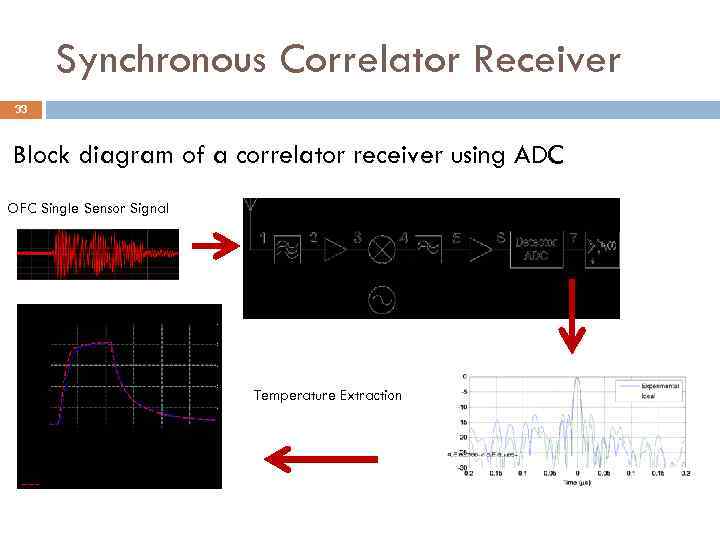

Synchronous Correlator Receiver 33 Block diagram of a correlator receiver using ADC OFC Single Sensor Signal Correlation Output Temperature Extraction

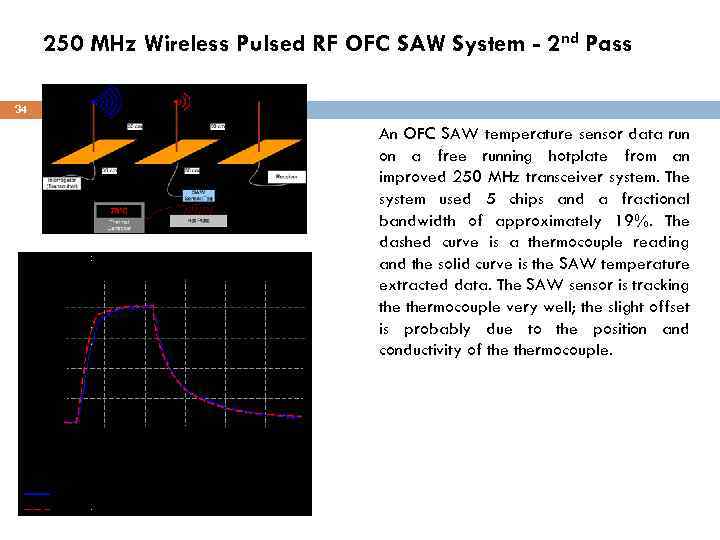

250 MHz Wireless Pulsed RF OFC SAW System - 2 nd Pass 34 An OFC SAW temperature sensor data run on a free running hotplate from an improved 250 MHz transceiver system. The system used 5 chips and a fractional bandwidth of approximately 19%. The dashed curve is a thermocouple reading and the solid curve is the SAW temperature extracted data. The SAW sensor is tracking thermocouple very well; the slight offset is probably due to the position and conductivity of thermocouple.

RF Transceiver: Sensor Overview 35 OFC with single wideband transducer Center Frequency: 915 MHz Bandwidth: Chirp - ~78 MHz Number of Chips: 5 Chip length 54 ns/each, total reflector length 270 ns Substrate: YZ Li. Nb. O 3

SAW 915 MHz OFC Sensor 36 SAW sensor acts as RFID and sensor All antenna & transducer effects are doubled Antenna gain and bandwidth are dependent on size scaled to frequency SAW propagation loss is frequency dependent

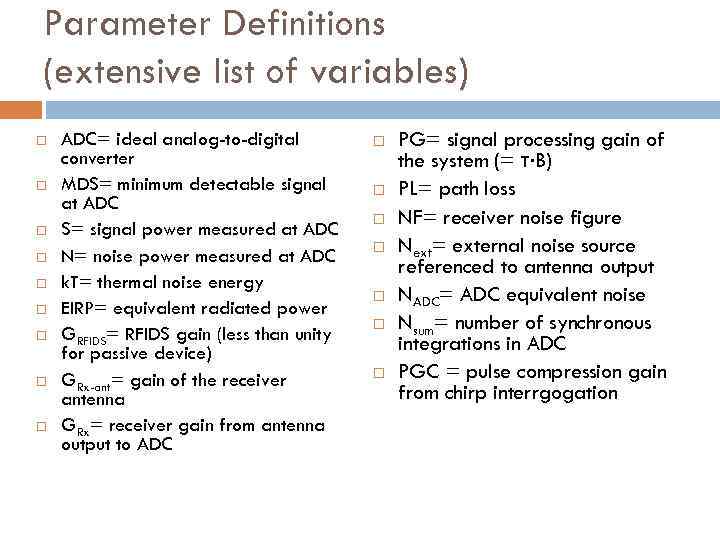

Parameter Definitions (extensive list of variables) ADC= ideal analog-to-digital converter MDS= minimum detectable signal at ADC S= signal power measured at ADC N= noise power measured at ADC k. T= thermal noise energy EIRP= equivalent radiated power GRFIDS= RFIDS gain (less than unity for passive device) GRx-ant= gain of the receiver antenna GRx= receiver gain from antenna output to ADC PG= signal processing gain of the system (= τ·B) PL= path loss NF= receiver noise figure Next= external noise source referenced to antenna output NADC= ADC equivalent noise Nsum= number of synchronous integrations in ADC PGC = pulse compression gain from chirp interrgogation 37

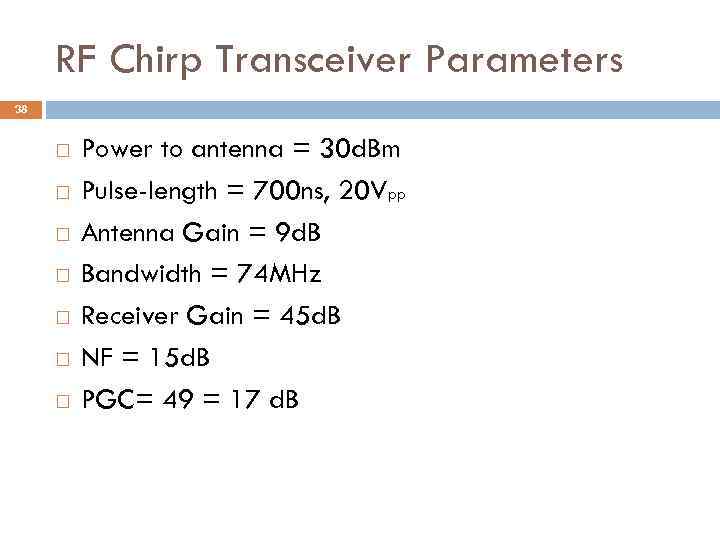

RF Chirp Transceiver Parameters 38 Power to antenna = 30 d. Bm Pulse-length = 700 ns, 20 Vpp Antenna Gain = 9 d. B Bandwidth = 74 MHz Receiver Gain = 45 d. B NF = 15 d. B PGC= 49 = 17 d. B

UCF Sensor Development There is an extensive body of knowledge on sensing The following are a few of the successful UCF sensor projects Wired SAW sensing has quite an extensive body of knowledge and continues The aim is to enable wireless acquisition of the sensors data The further goal is to develop a multi-sensor system for aerospace applications Successful wireless sensing has been demonstrated for temperature, liquid, closure, and range Wireless SAW sensing has been most successfully demonstrated for single, or very few devices and in limited environments 39

UCF OFC Sensor Successful Demonstrations 40 Temperature sensing Cryogenic: liquid nitrogen Room temperature to 250 o. C Currently working on sensor for operation to 750 o. C Cryogenic liquid level sensor: liquid nitrogen Pressure/Strain sensor Hydrogen gas sensor Closure sensor with temperature

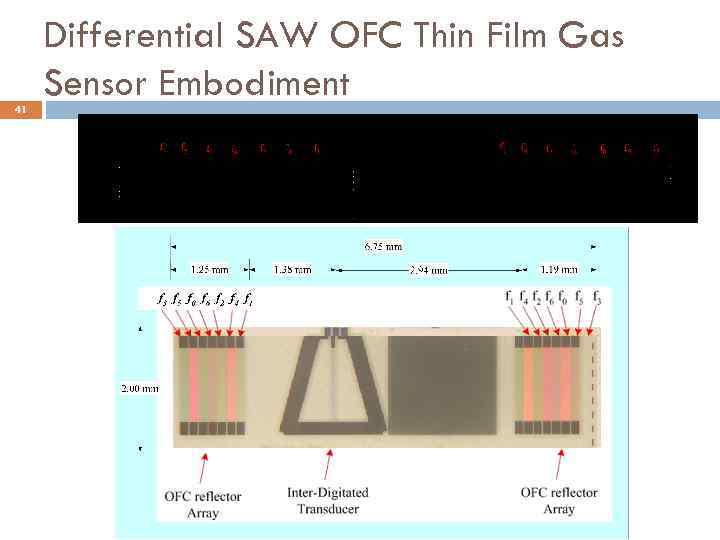

41 Differential SAW OFC Thin Film Gas Sensor Embodiment

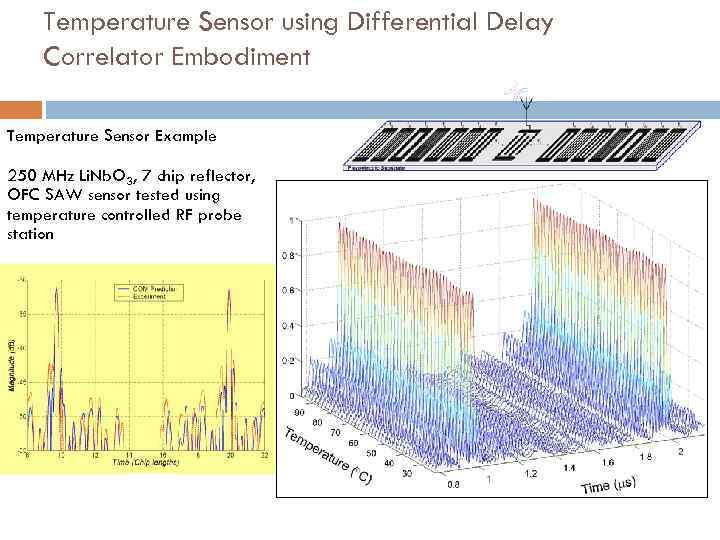

Temperature Sensor using Differential Delay Correlator Embodiment Temperature Sensor Example 250 MHz Li. Nb. O 3, 7 chip reflector, OFC SAW sensor tested using temperature controlled RF probe station 42

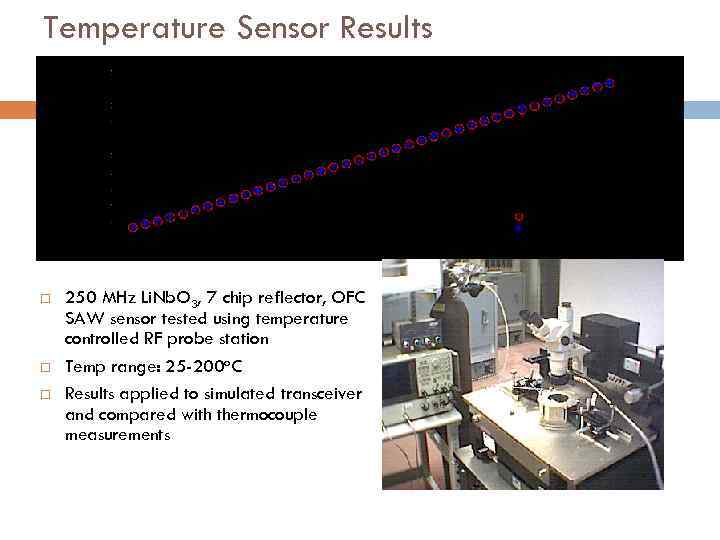

Temperature Sensor Results 250 MHz Li. Nb. O 3, 7 chip reflector, OFC SAW sensor tested using temperature controlled RF probe station Temp range: 25 -200 o. C Results applied to simulated transceiver and compared with thermocouple measurements 43

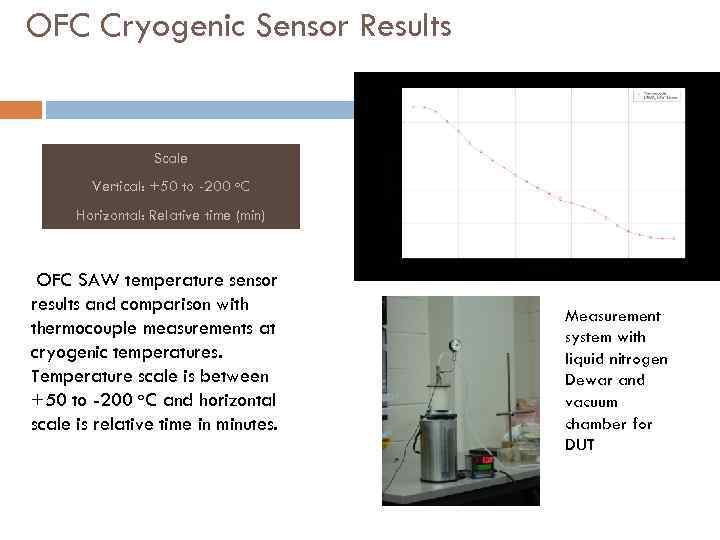

OFC Cryogenic Sensor Results Scale Vertical: +50 to -200 o. C Horizontal: Relative time (min) OFC SAW temperature sensor results and comparison with thermocouple measurements at cryogenic temperatures. Temperature scale is between +50 to -200 o. C and horizontal scale is relative time in minutes. Measurement system with liquid nitrogen Dewar and vacuum chamber for DUT 44

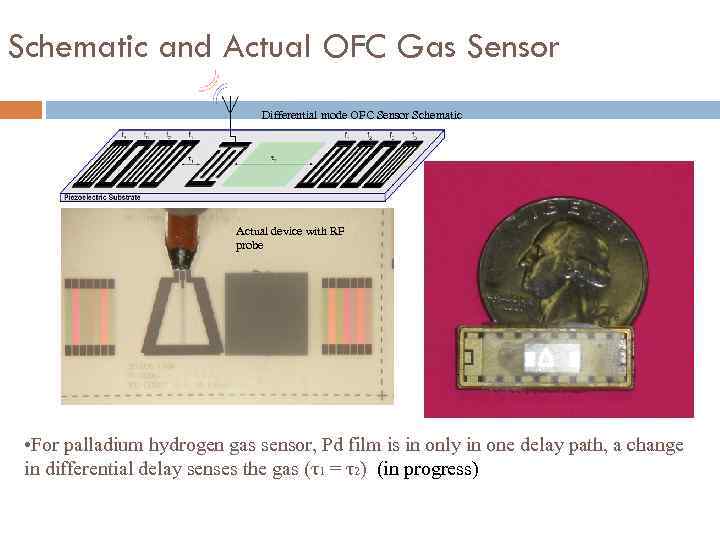

Schematic and Actual OFC Gas Sensor Differential mode OFC Sensor Schematic Actual device with RF probe • For palladium hydrogen gas sensor, Pd film is in only in one delay path, a change in differential delay senses the gas (τ1 = τ2) (in progress) 45

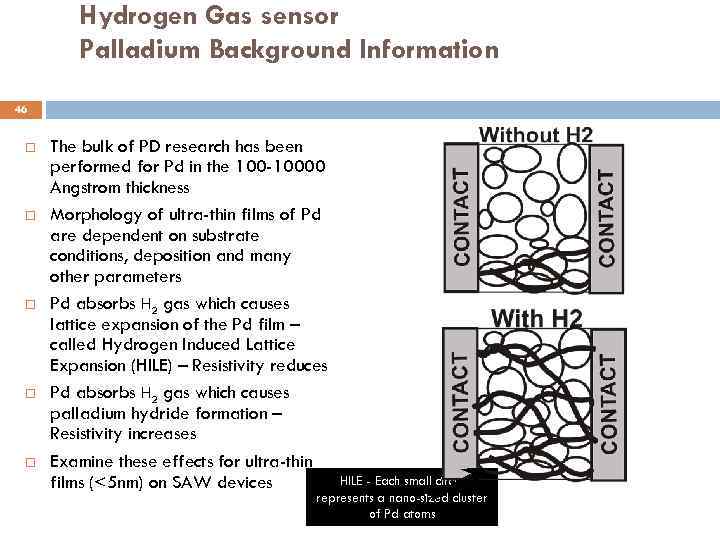

Hydrogen Gas sensor Palladium Background Information 46 The bulk of PD research has been performed for Pd in the 100 -10000 Angstrom thickness Morphology of ultra-thin films of Pd are dependent on substrate conditions, deposition and many other parameters Pd absorbs H 2 gas which causes lattice expansion of the Pd film – called Hydrogen Induced Lattice Expansion (HILE) – Resistivity reduces Pd absorbs H 2 gas which causes palladium hydride formation – Resistivity increases Examine these effects for ultra-thin films (<5 nm) on SAW devices HILE - Each small circle represents a nano-sized cluster of Pd atoms

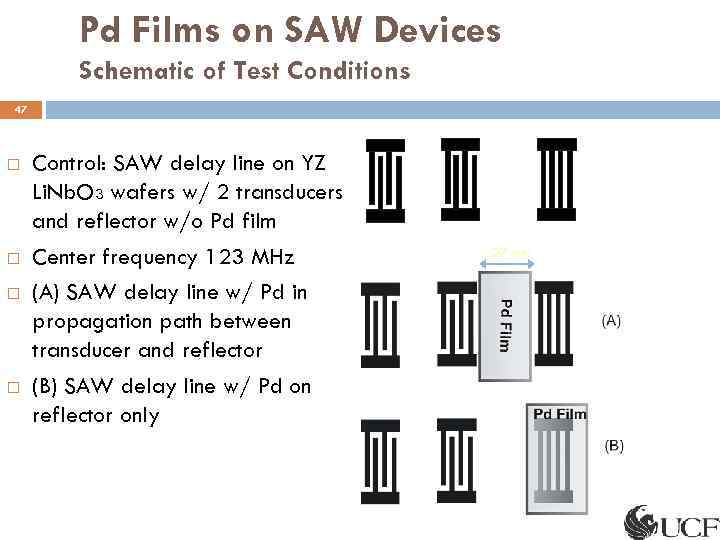

Pd Films on SAW Devices Schematic of Test Conditions 47 Control: SAW delay line on YZ Li. Nb. O 3 wafers w/ 2 transducers and reflector w/o Pd film Center frequency 123 MHz (A) SAW delay line w/ Pd in propagation path between transducer and reflector (B) SAW delay line w/ Pd on reflector only 1. 27 mm

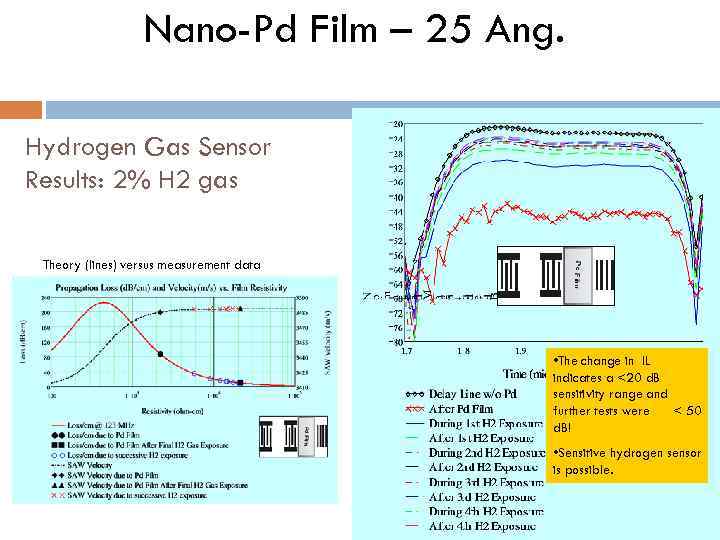

Nano-Pd Film – 25 Ang. Hydrogen Gas Sensor Results: 2% H 2 gas Theory (lines) versus measurement data • The change in IL indicates a <20 d. B sensitivity range and further tests were < 50 d. B! • Sensitive hydrogen sensor is possible. 48

Applications Current efforts include OFC SAW liquid level, hydrogen gas, pressure and temperature sensors Multi-sensor spread spectrum systems Cryogenic sensing High temperature sensing Space applications Turbine generators Harsh environments Ultra Wide band (UWB) Communication UWB OFC transducers Potentially many others 49

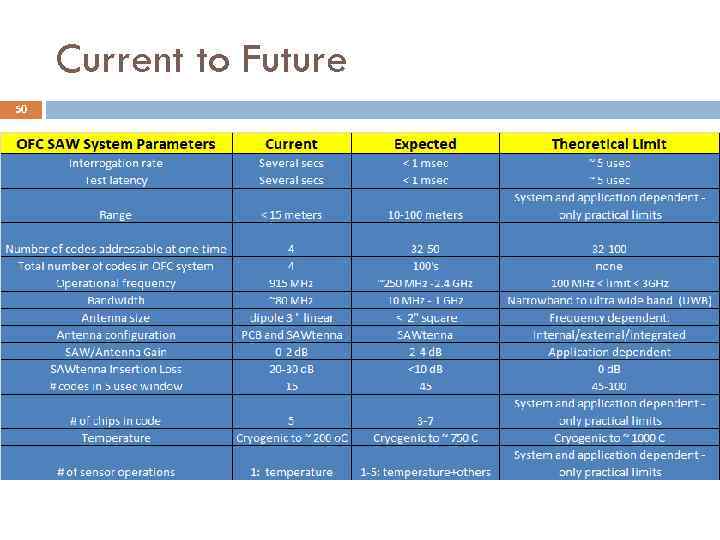

Current to Future 50

Vision for Future 51 • • • Multiple access, SAW RFID sensors SAW RFID sensor loss approaching 6 d. B – Unidirectional transducers – Low loss reflectors New and novel coding New and novel sensors New materials for high temperature (1000 o. C) and harsh environments SAW sensors in test space flight and support operations in 1 to 5 years

surfaceacousticwavesawbasedsensors-130307092419-phpapp02.pptx