cd30f5e58aa67d5ca9dc68a096ba3293.ppt

- Количество слайдов: 53

Supply Chain Strategy Chapter 10 © 2007 Pearson Education

Supply Chain Strategy Chapter 10 © 2007 Pearson Education

Supply Chain Ø Supply chain: The network of services, material, and information flows that link a firm’s customer relationship, order fulfillment, and supplier relationship processes to those of its supplier and customers. Ø Supply chain management: Developing a strategy to organize, control, and motivate the resources involved in the flow of services and materials within the supply chain. © 2007 Pearson Education

Supply Chain Ø Supply chain: The network of services, material, and information flows that link a firm’s customer relationship, order fulfillment, and supplier relationship processes to those of its supplier and customers. Ø Supply chain management: Developing a strategy to organize, control, and motivate the resources involved in the flow of services and materials within the supply chain. © 2007 Pearson Education

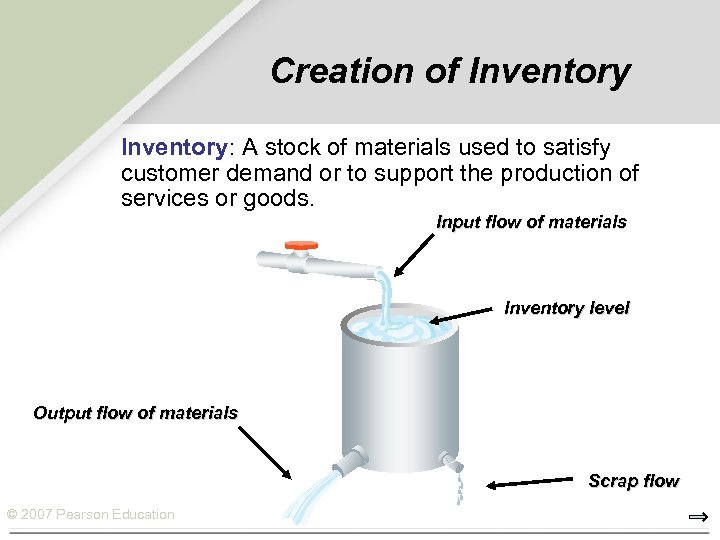

Creation of Inventory: A stock of materials used to satisfy customer demand or to support the production of services or goods. Input flow of materials Inventory level Output flow of materials Scrap flow © 2007 Pearson Education

Creation of Inventory: A stock of materials used to satisfy customer demand or to support the production of services or goods. Input flow of materials Inventory level Output flow of materials Scrap flow © 2007 Pearson Education

Supply Chain for Manufacturing Ø Raw materials (RM): The inventories needed for the production of services or goods. Ø Work-in-process (WIP): Items, such as components or assemblies, needed to produce a final product in manufacturing. Ø Finished goods (FG): The items in manufacturing plants, warehouses, and retail outlets that are sold to the firm’s customers. © 2007 Pearson Education

Supply Chain for Manufacturing Ø Raw materials (RM): The inventories needed for the production of services or goods. Ø Work-in-process (WIP): Items, such as components or assemblies, needed to produce a final product in manufacturing. Ø Finished goods (FG): The items in manufacturing plants, warehouses, and retail outlets that are sold to the firm’s customers. © 2007 Pearson Education

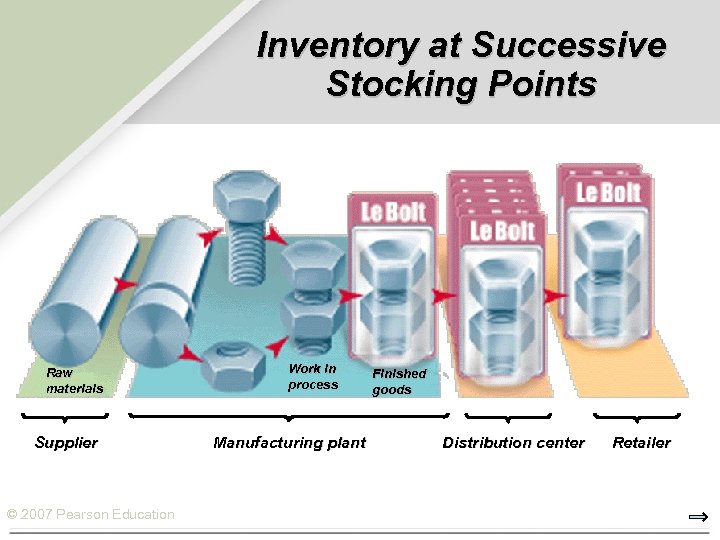

Inventory at Successive Stocking Points Raw materials Supplier © 2007 Pearson Education Work in process Manufacturing plant Finished goods Distribution center Retailer

Inventory at Successive Stocking Points Raw materials Supplier © 2007 Pearson Education Work in process Manufacturing plant Finished goods Distribution center Retailer

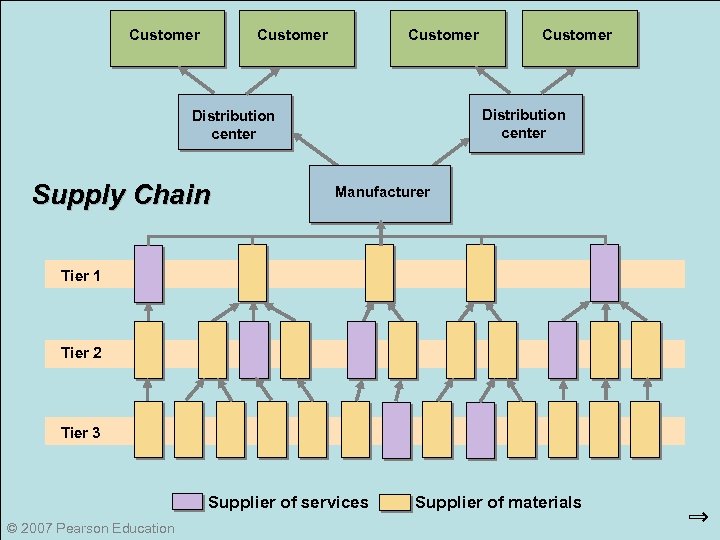

Customer Distribution center Supply Chain Customer Manufacturer Tier 1 Tier 2 Tier 3 © 2007 Pearson Education Supplier of services Supplier of materials

Customer Distribution center Supply Chain Customer Manufacturer Tier 1 Tier 2 Tier 3 © 2007 Pearson Education Supplier of services Supplier of materials

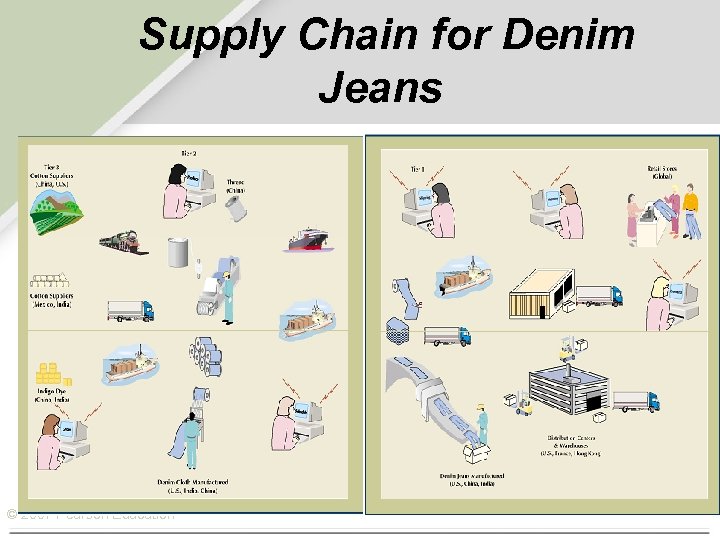

Supply Chain for Denim Jeans © 2007 Pearson Education

Supply Chain for Denim Jeans © 2007 Pearson Education

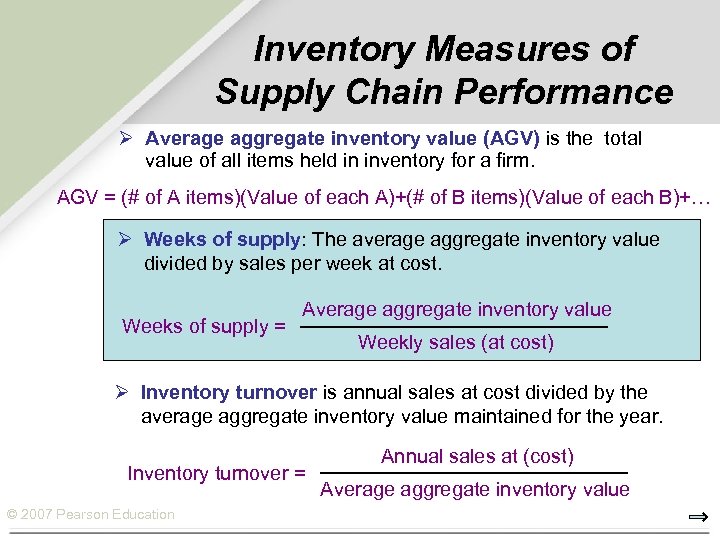

Inventory Measures of Supply Chain Performance Ø Average aggregate inventory value (AGV) is the total value of all items held in inventory for a firm. AGV = (# of A items)(Value of each A)+(# of B items)(Value of each B)+… Ø Weeks of supply: The average aggregate inventory value divided by sales per week at cost. Weeks of supply = Average aggregate inventory value Weekly sales (at cost) Ø Inventory turnover is annual sales at cost divided by the average aggregate inventory value maintained for the year. Inventory turnover = © 2007 Pearson Education Annual sales at (cost) Average aggregate inventory value

Inventory Measures of Supply Chain Performance Ø Average aggregate inventory value (AGV) is the total value of all items held in inventory for a firm. AGV = (# of A items)(Value of each A)+(# of B items)(Value of each B)+… Ø Weeks of supply: The average aggregate inventory value divided by sales per week at cost. Weeks of supply = Average aggregate inventory value Weekly sales (at cost) Ø Inventory turnover is annual sales at cost divided by the average aggregate inventory value maintained for the year. Inventory turnover = © 2007 Pearson Education Annual sales at (cost) Average aggregate inventory value

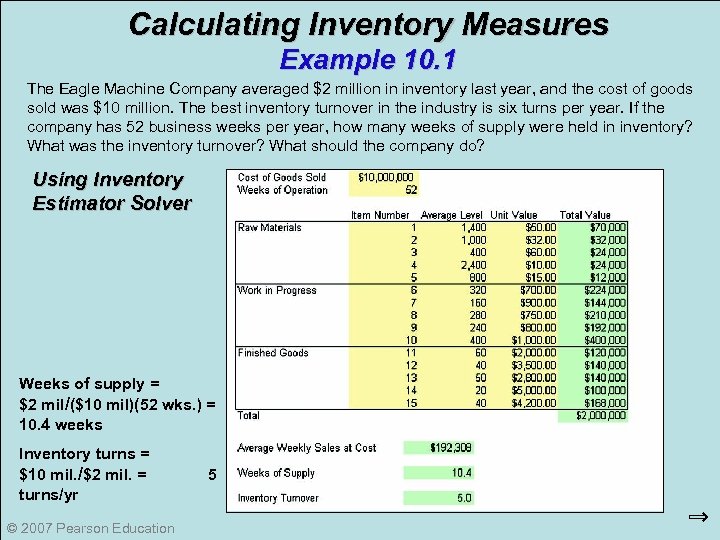

Calculating Inventory Measures Example 10. 1 The Eagle Machine Company averaged $2 million in inventory last year, and the cost of goods sold was $10 million. The best inventory turnover in the industry is six turns per year. If the company has 52 business weeks per year, how many weeks of supply were held in inventory? What was the inventory turnover? What should the company do? Using Inventory Estimator Solver Weeks of supply = $2 mil/($10 mil)(52 wks. ) = 10. 4 weeks Inventory turns = $10 mil. /$2 mil. = turns/yr © 2007 Pearson Education 5

Calculating Inventory Measures Example 10. 1 The Eagle Machine Company averaged $2 million in inventory last year, and the cost of goods sold was $10 million. The best inventory turnover in the industry is six turns per year. If the company has 52 business weeks per year, how many weeks of supply were held in inventory? What was the inventory turnover? What should the company do? Using Inventory Estimator Solver Weeks of supply = $2 mil/($10 mil)(52 wks. ) = 10. 4 weeks Inventory turns = $10 mil. /$2 mil. = turns/yr © 2007 Pearson Education 5

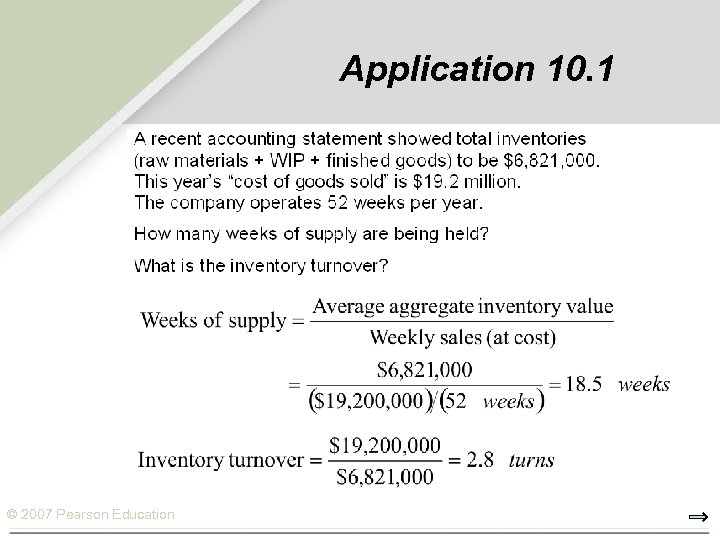

Application 10. 1 © 2007 Pearson Education

Application 10. 1 © 2007 Pearson Education

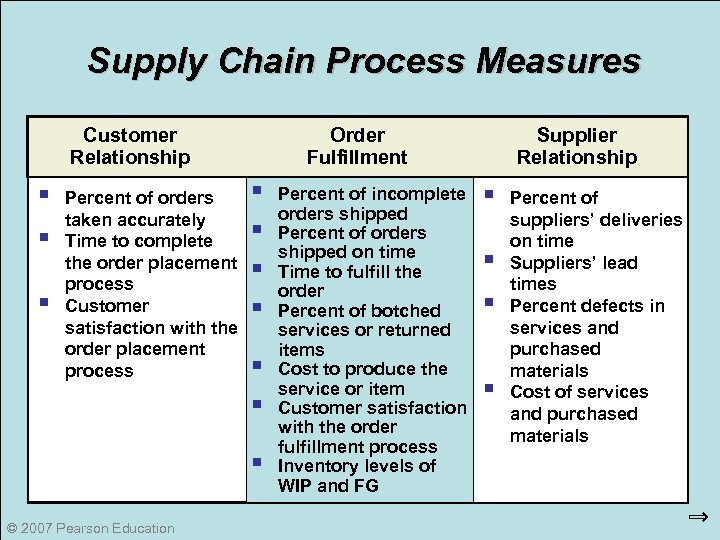

Supply Chain Process Measures Order Fulfillment Customer Relationship § § § Percent of orders taken accurately Time to complete the order placement process Customer satisfaction with the order placement process § § § § © 2007 Pearson Education Percent of incomplete orders shipped Percent of orders shipped on time Time to fulfill the order Percent of botched services or returned items Cost to produce the service or item Customer satisfaction with the order fulfillment process Inventory levels of WIP and FG Supplier Relationship § § Percent of suppliers’ deliveries on time Suppliers’ lead times Percent defects in services and purchased materials Cost of services and purchased materials

Supply Chain Process Measures Order Fulfillment Customer Relationship § § § Percent of orders taken accurately Time to complete the order placement process Customer satisfaction with the order placement process § § § § © 2007 Pearson Education Percent of incomplete orders shipped Percent of orders shipped on time Time to fulfill the order Percent of botched services or returned items Cost to produce the service or item Customer satisfaction with the order fulfillment process Inventory levels of WIP and FG Supplier Relationship § § Percent of suppliers’ deliveries on time Suppliers’ lead times Percent defects in services and purchased materials Cost of services and purchased materials

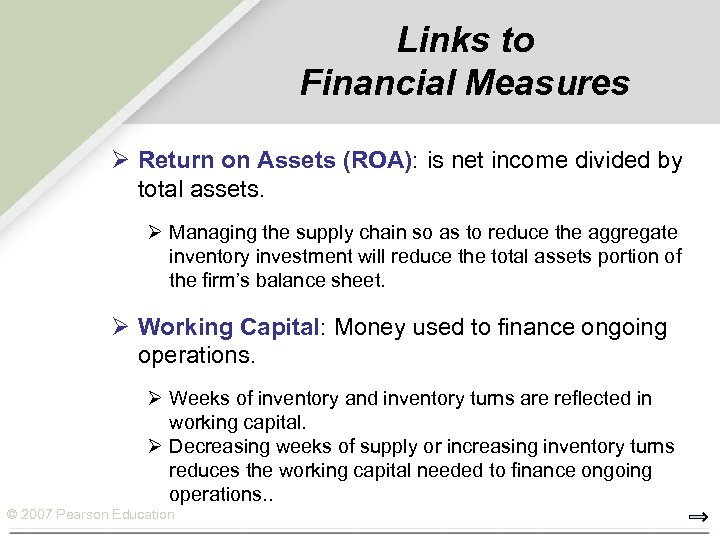

Links to Financial Measures Ø Return on Assets (ROA): is net income divided by total assets. Ø Managing the supply chain so as to reduce the aggregate inventory investment will reduce the total assets portion of the firm’s balance sheet. Ø Working Capital: Money used to finance ongoing operations. Ø Weeks of inventory and inventory turns are reflected in working capital. Ø Decreasing weeks of supply or increasing inventory turns reduces the working capital needed to finance ongoing operations. . © 2007 Pearson Education

Links to Financial Measures Ø Return on Assets (ROA): is net income divided by total assets. Ø Managing the supply chain so as to reduce the aggregate inventory investment will reduce the total assets portion of the firm’s balance sheet. Ø Working Capital: Money used to finance ongoing operations. Ø Weeks of inventory and inventory turns are reflected in working capital. Ø Decreasing weeks of supply or increasing inventory turns reduces the working capital needed to finance ongoing operations. . © 2007 Pearson Education

Links to Financial Measures Ø Cost of Goods Sold: Buying materials at a better price, or transforming them more efficiently, improves a firm’s cost of goods sold measure and ultimately its net income. Ø Total Revenue: Increasing the percent of on-time deliveries to customers increases total revenue because satisfied customers will buy more services and products. Ø Cash Flow: Cash-to-cash is the time lag between paying for the services and materials needed to produce a service or product and receiving payment for it. Ø The shorter the time lag, the better the cash flow position of the firm because it needs less working capital. © 2007 Pearson Education

Links to Financial Measures Ø Cost of Goods Sold: Buying materials at a better price, or transforming them more efficiently, improves a firm’s cost of goods sold measure and ultimately its net income. Ø Total Revenue: Increasing the percent of on-time deliveries to customers increases total revenue because satisfied customers will buy more services and products. Ø Cash Flow: Cash-to-cash is the time lag between paying for the services and materials needed to produce a service or product and receiving payment for it. Ø The shorter the time lag, the better the cash flow position of the firm because it needs less working capital. © 2007 Pearson Education

Supply Chain Dynamics Ø Supply chain dynamics can wreak havoc on supply chain performance measures. Ø Actions of downstream supply chain members can affect the operations of upstream members. Ø The bullwhip effect: The phenomenon in supply chains whereby ordering patterns experience increasing variance as you proceed upstream in the chain. © 2007 Pearson Education

Supply Chain Dynamics Ø Supply chain dynamics can wreak havoc on supply chain performance measures. Ø Actions of downstream supply chain members can affect the operations of upstream members. Ø The bullwhip effect: The phenomenon in supply chains whereby ordering patterns experience increasing variance as you proceed upstream in the chain. © 2007 Pearson Education

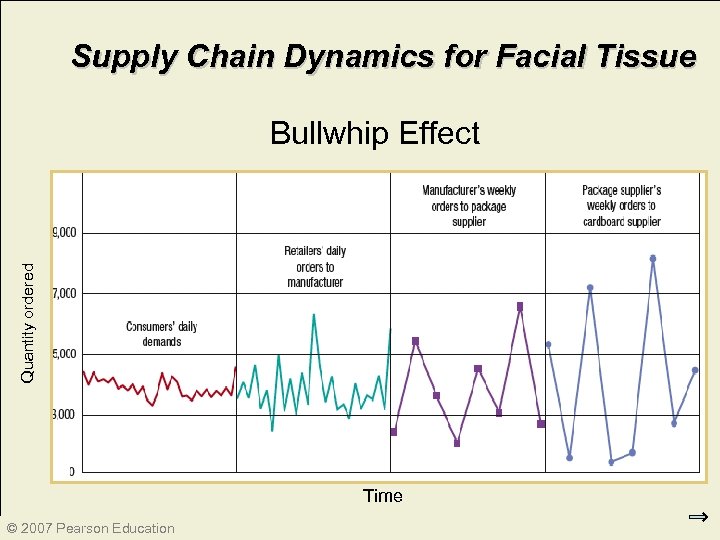

Supply Chain Dynamics for Facial Tissue Quantity ordered Bullwhip Effect © 2007 Pearson Education Time

Supply Chain Dynamics for Facial Tissue Quantity ordered Bullwhip Effect © 2007 Pearson Education Time

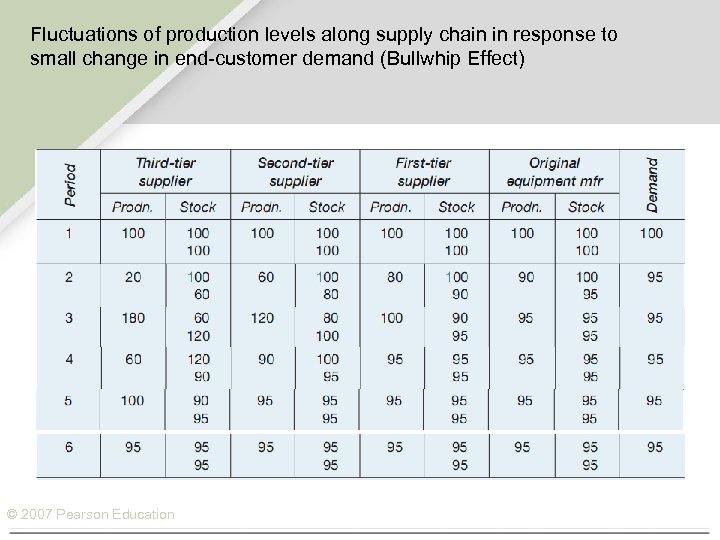

Fluctuations of production levels along supply chain in response to small change in end-customer demand (Bullwhip Effect) © 2007 Pearson Education

Fluctuations of production levels along supply chain in response to small change in end-customer demand (Bullwhip Effect) © 2007 Pearson Education

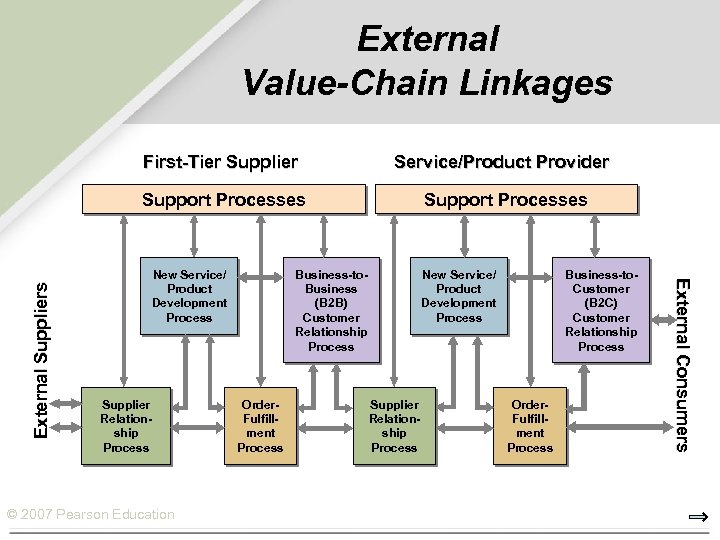

External Value-Chain Linkages Service/Product Provider Support Processes New Service/ Product Development Process Supplier Relationship Process © 2007 Pearson Education New Service/ Product Development Process Business-to. Business (B 2 B) Customer Relationship Process Order. Fulfillment Process Supplier Relationship Process Business-to. Customer (B 2 C) Customer Relationship Process Order. Fulfillment Process External Consumers External Suppliers First-Tier Supplier

External Value-Chain Linkages Service/Product Provider Support Processes New Service/ Product Development Process Supplier Relationship Process © 2007 Pearson Education New Service/ Product Development Process Business-to. Business (B 2 B) Customer Relationship Process Order. Fulfillment Process Supplier Relationship Process Business-to. Customer (B 2 C) Customer Relationship Process Order. Fulfillment Process External Consumers External Suppliers First-Tier Supplier

External Causes of Supply Chain Disruption Ø Volume changes. Ø Customers may change ordered quantity or delivery date. Ø Service and product mix changes. Ø Customers may change the mix of ordered items. Ø Late deliveries can force a switch in production schedules. Ø Underfilled shipments. Ø Partial shipments can cause a switch in production schedule or quantity produced. © 2007 Pearson Education

External Causes of Supply Chain Disruption Ø Volume changes. Ø Customers may change ordered quantity or delivery date. Ø Service and product mix changes. Ø Customers may change the mix of ordered items. Ø Late deliveries can force a switch in production schedules. Ø Underfilled shipments. Ø Partial shipments can cause a switch in production schedule or quantity produced. © 2007 Pearson Education

Internal Causes of Supply Chain Disruption Ø Internally generated shortages of parts. Ø Engineering changes to the design of services or products are disruptive. Ø New service or product introductions disrupt the supply chain and may require a new supply chain. Ø Service or product promotions may create a demand spike. Ø Information errors such as demand forecast errors, faulty inventory counts, or miscommunication with suppliers. © 2007 Pearson Education

Internal Causes of Supply Chain Disruption Ø Internally generated shortages of parts. Ø Engineering changes to the design of services or products are disruptive. Ø New service or product introductions disrupt the supply chain and may require a new supply chain. Ø Service or product promotions may create a demand spike. Ø Information errors such as demand forecast errors, faulty inventory counts, or miscommunication with suppliers. © 2007 Pearson Education

The Customer Relationship Process E-Commerce and the Marketing Process Ø Electronic Commerce (e-commerce) is the application of information and communication technology anywhere along the value chain of business processes. Ø Business-to-Consumer Systems (B 2 C) allows customers to transact business over the Internet. Ø Business-to-Business Systems (B 2 B) involves commerce between firms. Ø The biggest growth area, it is currently about 70% of the regular economy. © 2007 Pearson Education

The Customer Relationship Process E-Commerce and the Marketing Process Ø Electronic Commerce (e-commerce) is the application of information and communication technology anywhere along the value chain of business processes. Ø Business-to-Consumer Systems (B 2 C) allows customers to transact business over the Internet. Ø Business-to-Business Systems (B 2 B) involves commerce between firms. Ø The biggest growth area, it is currently about 70% of the regular economy. © 2007 Pearson Education

The Customer Relationship Process E-Commerce and the Order Placement Process Ø Cost reduction: Using the Internet can reduce the costs of processing orders. Ø Revenue flow increase: Reduction in the time lag associated with billing the customer or waiting for checks. Ø Global Access: Available 24 hours a day. Ø Price flexibility: Prices can easily be changed as the need arises. © 2007 Pearson Education

The Customer Relationship Process E-Commerce and the Order Placement Process Ø Cost reduction: Using the Internet can reduce the costs of processing orders. Ø Revenue flow increase: Reduction in the time lag associated with billing the customer or waiting for checks. Ø Global Access: Available 24 hours a day. Ø Price flexibility: Prices can easily be changed as the need arises. © 2007 Pearson Education

The Order Fulfillment Process Inventory Placement Ø Centralized placement: Keeping all the inventory at one location such as a firm’s manufacturing plant or a warehouse and shipping directly to customers. Ø Inventory pooling is a reduction in inventory and safety stock because of the merging of variable demands from customers. Ø A higher than expected demand from one customer can be offset by a lower-than-expected demand from another. Ø A disadvantage is the added cost of shipping smaller, uneconomical quantities directly to customers over long distances © 2007 Pearson Education

The Order Fulfillment Process Inventory Placement Ø Centralized placement: Keeping all the inventory at one location such as a firm’s manufacturing plant or a warehouse and shipping directly to customers. Ø Inventory pooling is a reduction in inventory and safety stock because of the merging of variable demands from customers. Ø A higher than expected demand from one customer can be offset by a lower-than-expected demand from another. Ø A disadvantage is the added cost of shipping smaller, uneconomical quantities directly to customers over long distances © 2007 Pearson Education

The Order Fulfillment Process Inventory Placement Ø Forward placement is locating stock closer to customers at a warehouse, wholesaler, or retailer. Ø Two advantages: faster delivery times and reduced transportation Ø Disadvantage: larger overall inventories because safety stock for the item must increase to take care of uncertain demands at each distribution center © 2007 Pearson Education

The Order Fulfillment Process Inventory Placement Ø Forward placement is locating stock closer to customers at a warehouse, wholesaler, or retailer. Ø Two advantages: faster delivery times and reduced transportation Ø Disadvantage: larger overall inventories because safety stock for the item must increase to take care of uncertain demands at each distribution center © 2007 Pearson Education

The Order Fulfillment Process Vendor-Managed Inventories Ø Vendor-managed inventories (VMI): An extreme application of forward placement involving locating inventories at the customer’s facilities. Ø Key ingredients are: Ø Collaborative effort requires trust & accountability. Ø Cost savings is realized by eliminating excess inventory. Ø Customer service: The supplier is frequently on site for improved response times and reducing stockouts. Ø Written agreement on procedures, methods, and schedules are clearly specified. © 2007 Pearson Education

The Order Fulfillment Process Vendor-Managed Inventories Ø Vendor-managed inventories (VMI): An extreme application of forward placement involving locating inventories at the customer’s facilities. Ø Key ingredients are: Ø Collaborative effort requires trust & accountability. Ø Cost savings is realized by eliminating excess inventory. Ø Customer service: The supplier is frequently on site for improved response times and reducing stockouts. Ø Written agreement on procedures, methods, and schedules are clearly specified. © 2007 Pearson Education

Order Fulfillment Programs Ø Continuous Replenishment Program (CRP) A VMI method in which the supplier monitors the customer’s inventory levels and replenishes stock as needed. Ø Radio Frequency Identification (RFID) method for identifying items through the use of radio signals from a tag attached to an item. © 2007 Pearson Education A

Order Fulfillment Programs Ø Continuous Replenishment Program (CRP) A VMI method in which the supplier monitors the customer’s inventory levels and replenishes stock as needed. Ø Radio Frequency Identification (RFID) method for identifying items through the use of radio signals from a tag attached to an item. © 2007 Pearson Education A

Distribution Processes Ø Ownership: Rather than negotiate with a contract carrier, a firm has the most control over the distribution process if it owns and operates it, thereby becoming a private carrier. Ø Firms may use a combination of the five basic modes of transportation: truck, train, ship, pipeline, and airplane. Ø Cross-Docking: The packing of products on incoming shipments so that they can be easily sorted at intermediate warehouses for outgoing shipments based on their final destinations. Ø Items are carried from the incoming-vehicle docking point to the outgoing-vehicle docking point without being stored in inventory at the warehouse. © 2007 Pearson Education

Distribution Processes Ø Ownership: Rather than negotiate with a contract carrier, a firm has the most control over the distribution process if it owns and operates it, thereby becoming a private carrier. Ø Firms may use a combination of the five basic modes of transportation: truck, train, ship, pipeline, and airplane. Ø Cross-Docking: The packing of products on incoming shipments so that they can be easily sorted at intermediate warehouses for outgoing shipments based on their final destinations. Ø Items are carried from the incoming-vehicle docking point to the outgoing-vehicle docking point without being stored in inventory at the warehouse. © 2007 Pearson Education

The Supplier Relationship Process Ø The sourcing process qualifies, selects, manages the contracts, and evaluates suppliers. Ø The design collaboration process focuses on jointly designing new services or products with key suppliers, seeking to eliminate costly delays and mistakes incurred when many suppliers concurrently, but independently, design service packages or manufactured components. Ø The information exchange process facilitates the exchange of pertinent operating information, such as forecasts, schedules, and inventory levels between the firm and its supplier. © 2007 Pearson Education

The Supplier Relationship Process Ø The sourcing process qualifies, selects, manages the contracts, and evaluates suppliers. Ø The design collaboration process focuses on jointly designing new services or products with key suppliers, seeking to eliminate costly delays and mistakes incurred when many suppliers concurrently, but independently, design service packages or manufactured components. Ø The information exchange process facilitates the exchange of pertinent operating information, such as forecasts, schedules, and inventory levels between the firm and its supplier. © 2007 Pearson Education

Supplier Selection and Certification Ø Green purchasing: The process of identifying, assessing, and managing the flow of environmental waste and finding ways to reduce it and minimize its impact on the environment. Ø Supplier certification programs verify that potential suppliers have the capability to provide the services or materials the buyer firm requires. © 2007 Pearson Education

Supplier Selection and Certification Ø Green purchasing: The process of identifying, assessing, and managing the flow of environmental waste and finding ways to reduce it and minimize its impact on the environment. Ø Supplier certification programs verify that potential suppliers have the capability to provide the services or materials the buyer firm requires. © 2007 Pearson Education

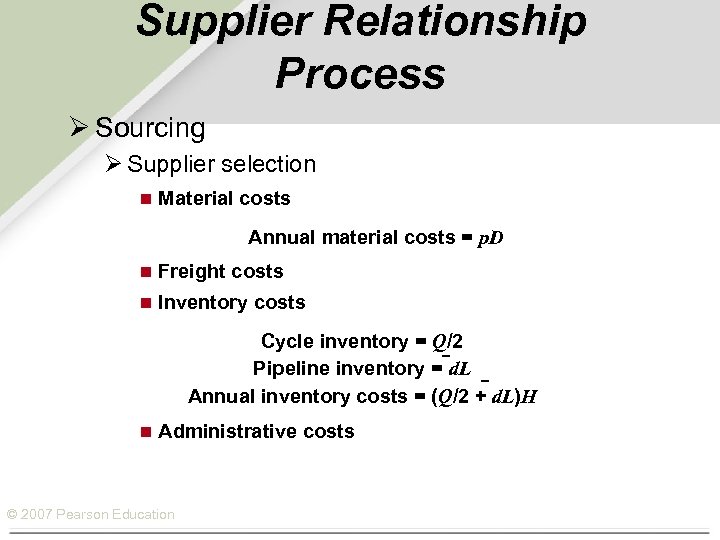

Supplier Relationship Process Ø Sourcing Ø Supplier selection n Material costs Annual material costs = p. D n Freight costs n Inventory costs Cycle inventory = Q/2 Pipeline inventory = d. L Annual inventory costs = (Q/2 + d. L)H n Administrative costs © 2007 Pearson Education

Supplier Relationship Process Ø Sourcing Ø Supplier selection n Material costs Annual material costs = p. D n Freight costs n Inventory costs Cycle inventory = Q/2 Pipeline inventory = d. L Annual inventory costs = (Q/2 + d. L)H n Administrative costs © 2007 Pearson Education

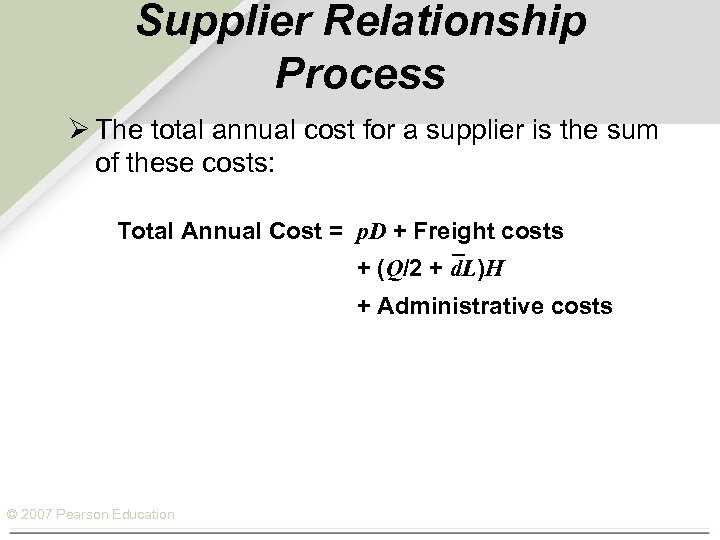

Supplier Relationship Process Ø The total annual cost for a supplier is the sum of these costs: Total Annual Cost = p. D + Freight costs + (Q/2 + d. L)H + Administrative costs © 2007 Pearson Education

Supplier Relationship Process Ø The total annual cost for a supplier is the sum of these costs: Total Annual Cost = p. D + Freight costs + (Q/2 + d. L)H + Administrative costs © 2007 Pearson Education

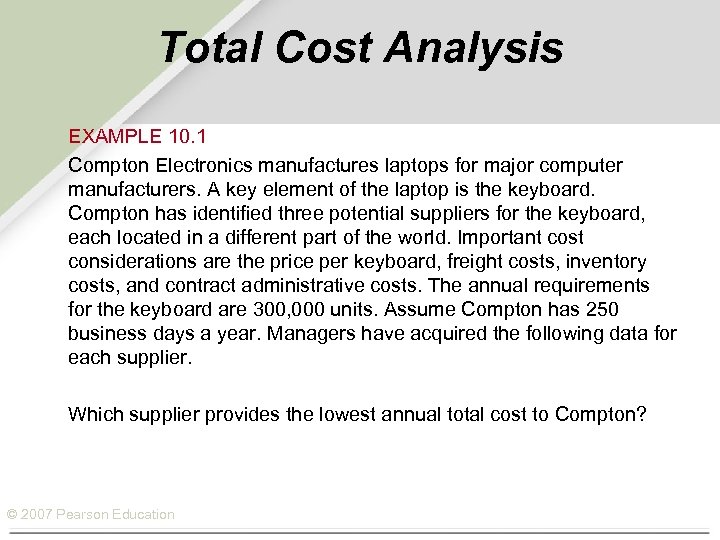

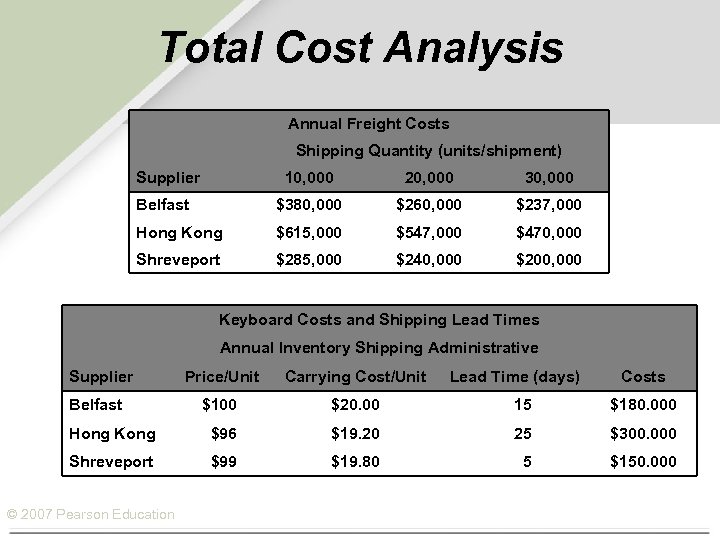

Total Cost Analysis EXAMPLE 10. 1 Compton Electronics manufactures laptops for major computer manufacturers. A key element of the laptop is the keyboard. Compton has identified three potential suppliers for the keyboard, each located in a different part of the world. Important cost considerations are the price per keyboard, freight costs, inventory costs, and contract administrative costs. The annual requirements for the keyboard are 300, 000 units. Assume Compton has 250 business days a year. Managers have acquired the following data for each supplier. Which supplier provides the lowest annual total cost to Compton? © 2007 Pearson Education

Total Cost Analysis EXAMPLE 10. 1 Compton Electronics manufactures laptops for major computer manufacturers. A key element of the laptop is the keyboard. Compton has identified three potential suppliers for the keyboard, each located in a different part of the world. Important cost considerations are the price per keyboard, freight costs, inventory costs, and contract administrative costs. The annual requirements for the keyboard are 300, 000 units. Assume Compton has 250 business days a year. Managers have acquired the following data for each supplier. Which supplier provides the lowest annual total cost to Compton? © 2007 Pearson Education

Total Cost Analysis Annual Freight Costs Shipping Quantity (units/shipment) Supplier 10, 000 20, 000 30, 000 Belfast $380, 000 $260, 000 $237, 000 Hong Kong $615, 000 $547, 000 $470, 000 Shreveport $285, 000 $240, 000 $200, 000 Keyboard Costs and Shipping Lead Times Annual Inventory Shipping Administrative Supplier Price/Unit Carrying Cost/Unit $100 $20. 00 15 $180. 000 Hong Kong $96 $19. 20 25 $300. 000 Shreveport $99 $19. 80 5 $150. 000 Belfast © 2007 Pearson Education Lead Time (days) Costs

Total Cost Analysis Annual Freight Costs Shipping Quantity (units/shipment) Supplier 10, 000 20, 000 30, 000 Belfast $380, 000 $260, 000 $237, 000 Hong Kong $615, 000 $547, 000 $470, 000 Shreveport $285, 000 $240, 000 $200, 000 Keyboard Costs and Shipping Lead Times Annual Inventory Shipping Administrative Supplier Price/Unit Carrying Cost/Unit $100 $20. 00 15 $180. 000 Hong Kong $96 $19. 20 25 $300. 000 Shreveport $99 $19. 80 5 $150. 000 Belfast © 2007 Pearson Education Lead Time (days) Costs

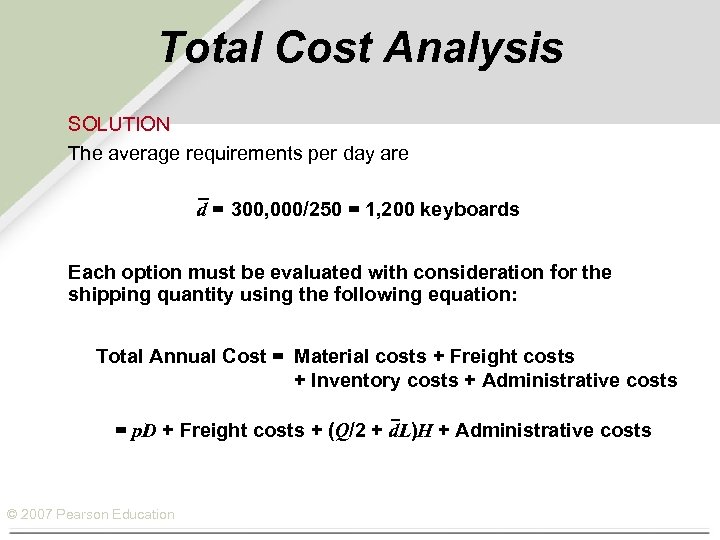

Total Cost Analysis SOLUTION The average requirements per day are d = 300, 000/250 = 1, 200 keyboards Each option must be evaluated with consideration for the shipping quantity using the following equation: Total Annual Cost = Material costs + Freight costs + Inventory costs + Administrative costs = p. D + Freight costs + (Q/2 + d. L)H + Administrative costs © 2007 Pearson Education

Total Cost Analysis SOLUTION The average requirements per day are d = 300, 000/250 = 1, 200 keyboards Each option must be evaluated with consideration for the shipping quantity using the following equation: Total Annual Cost = Material costs + Freight costs + Inventory costs + Administrative costs = p. D + Freight costs + (Q/2 + d. L)H + Administrative costs © 2007 Pearson Education

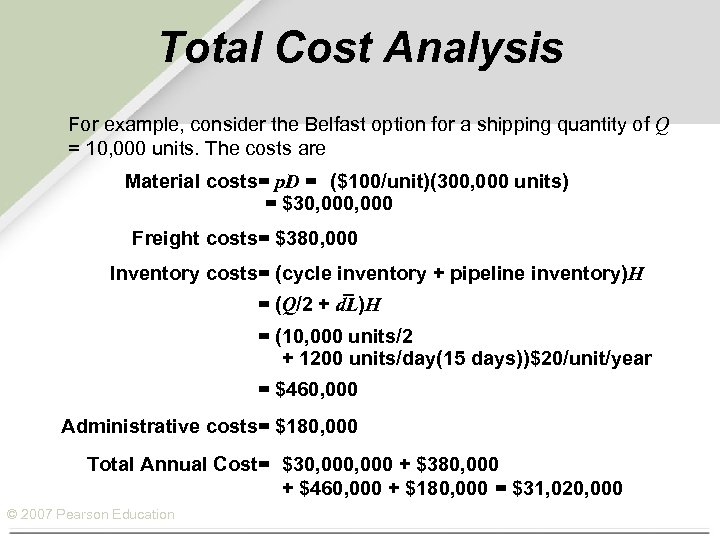

Total Cost Analysis For example, consider the Belfast option for a shipping quantity of Q = 10, 000 units. The costs are Material costs= p. D = ($100/unit)(300, 000 units) = $30, 000 Freight costs= $380, 000 Inventory costs= (cycle inventory + pipeline inventory)H = (Q/2 + d. L)H = (10, 000 units/2 + 1200 units/day(15 days))$20/unit/year = $460, 000 Administrative costs= $180, 000 Total Annual Cost= $30, 000 + $380, 000 + $460, 000 + $180, 000 = $31, 020, 000 © 2007 Pearson Education

Total Cost Analysis For example, consider the Belfast option for a shipping quantity of Q = 10, 000 units. The costs are Material costs= p. D = ($100/unit)(300, 000 units) = $30, 000 Freight costs= $380, 000 Inventory costs= (cycle inventory + pipeline inventory)H = (Q/2 + d. L)H = (10, 000 units/2 + 1200 units/day(15 days))$20/unit/year = $460, 000 Administrative costs= $180, 000 Total Annual Cost= $30, 000 + $380, 000 + $460, 000 + $180, 000 = $31, 020, 000 © 2007 Pearson Education

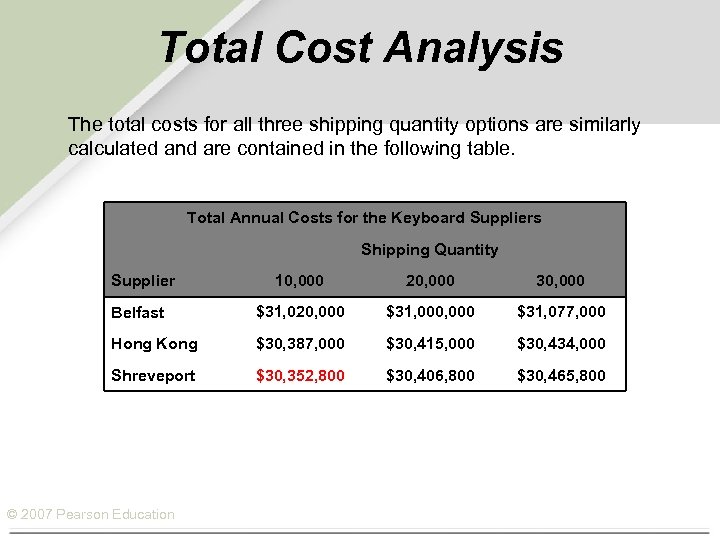

Total Cost Analysis The total costs for all three shipping quantity options are similarly calculated and are contained in the following table. Total Annual Costs for the Keyboard Suppliers Shipping Quantity Supplier 10, 000 20, 000 30, 000 Belfast $31, 020, 000 $31, 077, 000 Hong Kong $30, 387, 000 $30, 415, 000 $30, 434, 000 Shreveport $30, 352, 800 $30, 406, 800 $30, 465, 800 © 2007 Pearson Education

Total Cost Analysis The total costs for all three shipping quantity options are similarly calculated and are contained in the following table. Total Annual Costs for the Keyboard Suppliers Shipping Quantity Supplier 10, 000 20, 000 30, 000 Belfast $31, 020, 000 $31, 077, 000 Hong Kong $30, 387, 000 $30, 415, 000 $30, 434, 000 Shreveport $30, 352, 800 $30, 406, 800 $30, 465, 800 © 2007 Pearson Education

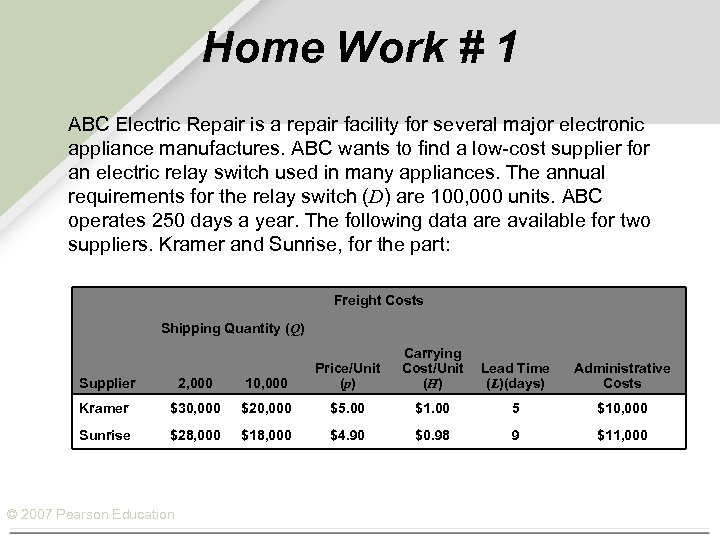

Home Work # 1 ABC Electric Repair is a repair facility for several major electronic appliance manufactures. ABC wants to find a low-cost supplier for an electric relay switch used in many appliances. The annual requirements for the relay switch (D) are 100, 000 units. ABC operates 250 days a year. The following data are available for two suppliers. Kramer and Sunrise, for the part: Freight Costs Shipping Quantity (Q) Supplier 2, 000 10, 000 Price/Unit (p) Carrying Cost/Unit (H) Kramer $30, 000 $20, 000 $5. 00 $1. 00 5 $10, 000 Sunrise $28, 000 $18, 000 $4. 90 $0. 98 9 $11, 000 © 2007 Pearson Education Lead Time (L)(days) Administrative Costs

Home Work # 1 ABC Electric Repair is a repair facility for several major electronic appliance manufactures. ABC wants to find a low-cost supplier for an electric relay switch used in many appliances. The annual requirements for the relay switch (D) are 100, 000 units. ABC operates 250 days a year. The following data are available for two suppliers. Kramer and Sunrise, for the part: Freight Costs Shipping Quantity (Q) Supplier 2, 000 10, 000 Price/Unit (p) Carrying Cost/Unit (H) Kramer $30, 000 $20, 000 $5. 00 $1. 00 5 $10, 000 Sunrise $28, 000 $18, 000 $4. 90 $0. 98 9 $11, 000 © 2007 Pearson Education Lead Time (L)(days) Administrative Costs

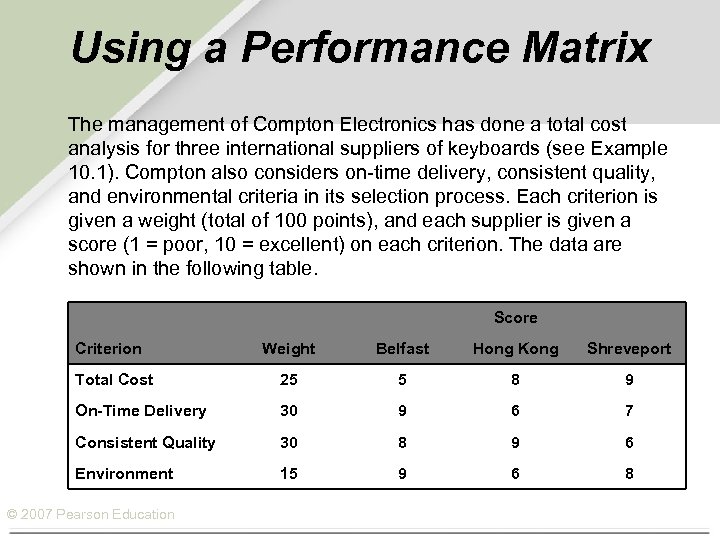

Using a Performance Matrix The management of Compton Electronics has done a total cost analysis for three international suppliers of keyboards (see Example 10. 1). Compton also considers on-time delivery, consistent quality, and environmental criteria in its selection process. Each criterion is given a weight (total of 100 points), and each supplier is given a score (1 = poor, 10 = excellent) on each criterion. The data are shown in the following table. Score Criterion Weight Belfast Hong Kong Shreveport Total Cost 25 5 8 9 On-Time Delivery 30 9 6 7 Consistent Quality 30 8 9 6 Environment 15 9 6 8 © 2007 Pearson Education

Using a Performance Matrix The management of Compton Electronics has done a total cost analysis for three international suppliers of keyboards (see Example 10. 1). Compton also considers on-time delivery, consistent quality, and environmental criteria in its selection process. Each criterion is given a weight (total of 100 points), and each supplier is given a score (1 = poor, 10 = excellent) on each criterion. The data are shown in the following table. Score Criterion Weight Belfast Hong Kong Shreveport Total Cost 25 5 8 9 On-Time Delivery 30 9 6 7 Consistent Quality 30 8 9 6 Environment 15 9 6 8 © 2007 Pearson Education

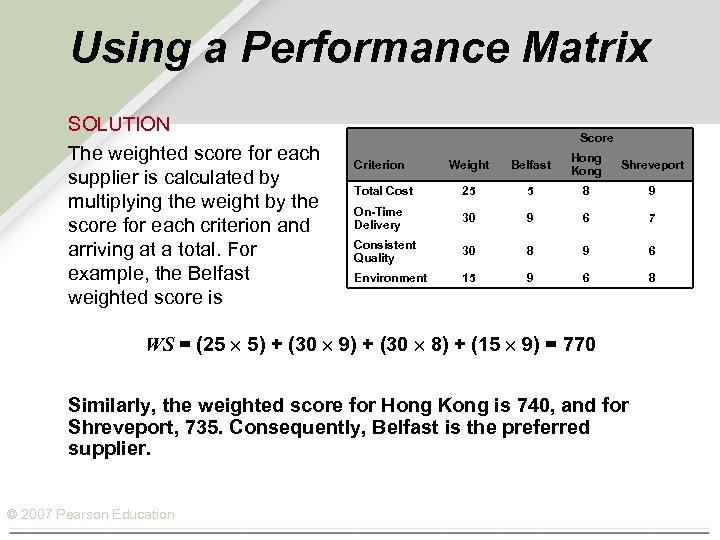

Using a Performance Matrix SOLUTION The weighted score for each supplier is calculated by multiplying the weight by the score for each criterion and arriving at a total. For example, the Belfast weighted score is Score Weight Belfast Hong Kong Shreveport Total Cost 25 5 8 9 On-Time Delivery 30 9 6 7 Consistent Quality 30 8 9 6 Environment 15 9 6 8 Criterion WS = (25 5) + (30 9) + (30 8) + (15 9) = 770 Similarly, the weighted score for Hong Kong is 740, and for Shreveport, 735. Consequently, Belfast is the preferred supplier. © 2007 Pearson Education

Using a Performance Matrix SOLUTION The weighted score for each supplier is calculated by multiplying the weight by the score for each criterion and arriving at a total. For example, the Belfast weighted score is Score Weight Belfast Hong Kong Shreveport Total Cost 25 5 8 9 On-Time Delivery 30 9 6 7 Consistent Quality 30 8 9 6 Environment 15 9 6 8 Criterion WS = (25 5) + (30 9) + (30 8) + (15 9) = 770 Similarly, the weighted score for Hong Kong is 740, and for Shreveport, 735. Consequently, Belfast is the preferred supplier. © 2007 Pearson Education

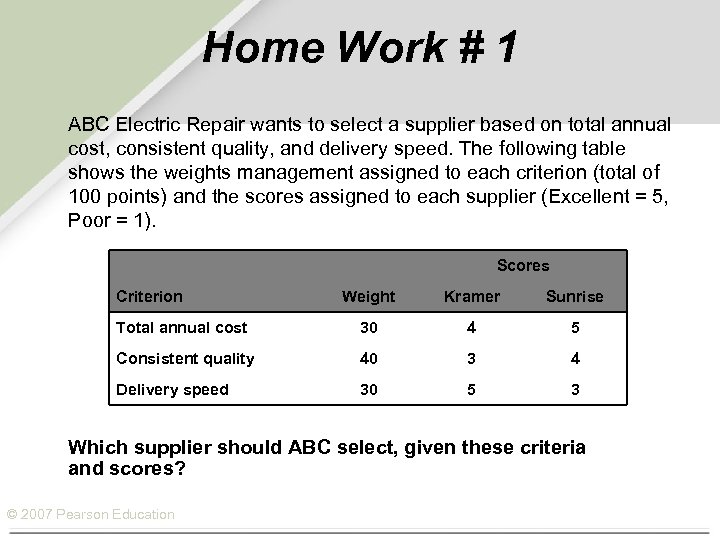

Home Work # 1 ABC Electric Repair wants to select a supplier based on total annual cost, consistent quality, and delivery speed. The following table shows the weights management assigned to each criterion (total of 100 points) and the scores assigned to each supplier (Excellent = 5, Poor = 1). Scores Criterion Weight Kramer Sunrise Total annual cost 30 4 5 Consistent quality 40 3 4 Delivery speed 30 5 3 Which supplier should ABC select, given these criteria and scores? © 2007 Pearson Education

Home Work # 1 ABC Electric Repair wants to select a supplier based on total annual cost, consistent quality, and delivery speed. The following table shows the weights management assigned to each criterion (total of 100 points) and the scores assigned to each supplier (Excellent = 5, Poor = 1). Scores Criterion Weight Kramer Sunrise Total annual cost 30 4 5 Consistent quality 40 3 4 Delivery speed 30 5 3 Which supplier should ABC select, given these criteria and scores? © 2007 Pearson Education

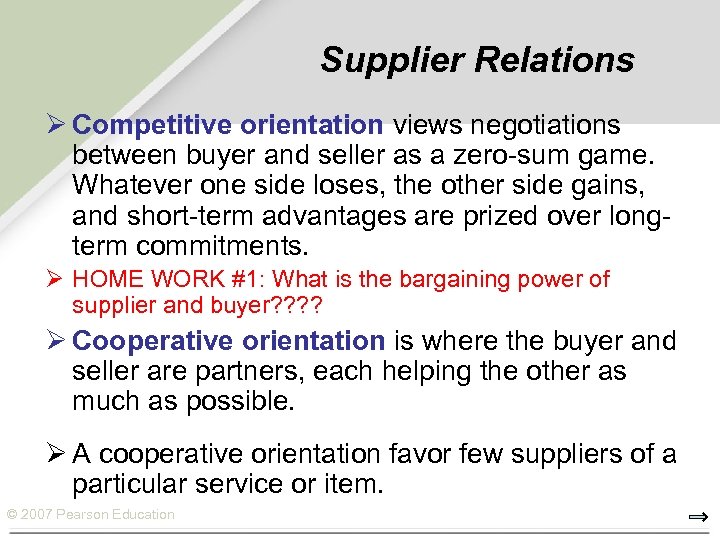

Supplier Relations Ø Competitive orientation views negotiations between buyer and seller as a zero-sum game. Whatever one side loses, the other side gains, and short-term advantages are prized over longterm commitments. Ø HOME WORK #1: What is the bargaining power of supplier and buyer? ? Ø Cooperative orientation is where the buyer and seller are partners, each helping the other as much as possible. Ø A cooperative orientation favor few suppliers of a particular service or item. © 2007 Pearson Education

Supplier Relations Ø Competitive orientation views negotiations between buyer and seller as a zero-sum game. Whatever one side loses, the other side gains, and short-term advantages are prized over longterm commitments. Ø HOME WORK #1: What is the bargaining power of supplier and buyer? ? Ø Cooperative orientation is where the buyer and seller are partners, each helping the other as much as possible. Ø A cooperative orientation favor few suppliers of a particular service or item. © 2007 Pearson Education

Supplier Relations, Cooperative orientation… Ø One advantage of reducing the number of suppliers in the supply chain is a reduction in the complexity of managing them. Ø However, this may increase the risk of an interruption in the supply. It also means less opportunity to drive a good bargain unless the buyer has a lot of clout Ø Sole sourcing is the awarding of a contract for a service or item to only one supplier. © 2007 Pearson Education

Supplier Relations, Cooperative orientation… Ø One advantage of reducing the number of suppliers in the supply chain is a reduction in the complexity of managing them. Ø However, this may increase the risk of an interruption in the supply. It also means less opportunity to drive a good bargain unless the buyer has a lot of clout Ø Sole sourcing is the awarding of a contract for a service or item to only one supplier. © 2007 Pearson Education

Centralized versus Localized Buying Ø Centralized purchasing is a method of procurement of all types of materials, supplies, equipment etc. through a single department (not necessarily centrally located) under the direct control and superintendence of one responsible person. Ø Localized /Decentralized Purchasing means that divisions or smaller areas of an organization have their own purchasing dept. © 2007 Pearson Education

Centralized versus Localized Buying Ø Centralized purchasing is a method of procurement of all types of materials, supplies, equipment etc. through a single department (not necessarily centrally located) under the direct control and superintendence of one responsible person. Ø Localized /Decentralized Purchasing means that divisions or smaller areas of an organization have their own purchasing dept. © 2007 Pearson Education

Advantages of centralized buying Ø increases purchasing clout. Savings can be significant, often 10% or more. Ø Increased buying power can mean getting better service, ensuring long-term supply availability, or developing new supplier capability. Ø Bulk buying strengthens the bargaining position of the buyer. Ø Advantage of the quantity discount can be tapped. Ø It will reduce the inventory carrying costs Ø Lower transportation cost per unit. . Ø Duplication of efforts in buying function is eliminated Ø Skill development of purchase head Ø No competition within units Ø Easy to procure from foreign supplier © 2007 Pearson Education

Advantages of centralized buying Ø increases purchasing clout. Savings can be significant, often 10% or more. Ø Increased buying power can mean getting better service, ensuring long-term supply availability, or developing new supplier capability. Ø Bulk buying strengthens the bargaining position of the buyer. Ø Advantage of the quantity discount can be tapped. Ø It will reduce the inventory carrying costs Ø Lower transportation cost per unit. . Ø Duplication of efforts in buying function is eliminated Ø Skill development of purchase head Ø No competition within units Ø Easy to procure from foreign supplier © 2007 Pearson Education

Disadvantages of centralized buying Ø Problem when specific requirement needed Ø Delay in receiving the materials (Longer. Lead Time) Ø Problems to use local resources in small quantity Ø Helps for autocratic management style Ø Central purchasing staff may not be expert in buying various types of items Ø Loss of local control Ø Creates another level of hierarchy Ø Suitable more for small organization © 2007 Pearson Education

Disadvantages of centralized buying Ø Problem when specific requirement needed Ø Delay in receiving the materials (Longer. Lead Time) Ø Problems to use local resources in small quantity Ø Helps for autocratic management style Ø Central purchasing staff may not be expert in buying various types of items Ø Loss of local control Ø Creates another level of hierarchy Ø Suitable more for small organization © 2007 Pearson Education

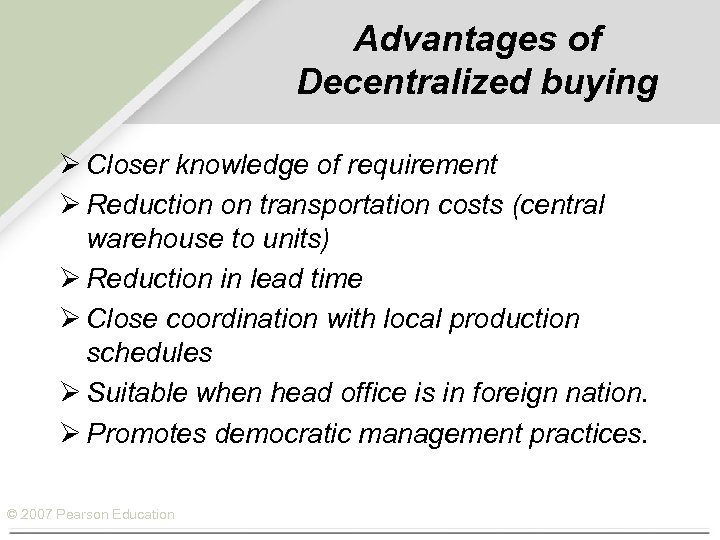

Advantages of Decentralized buying Ø Closer knowledge of requirement Ø Reduction on transportation costs (central warehouse to units) Ø Reduction in lead time Ø Close coordination with local production schedules Ø Suitable when head office is in foreign nation. Ø Promotes democratic management practices. © 2007 Pearson Education

Advantages of Decentralized buying Ø Closer knowledge of requirement Ø Reduction on transportation costs (central warehouse to units) Ø Reduction in lead time Ø Close coordination with local production schedules Ø Suitable when head office is in foreign nation. Ø Promotes democratic management practices. © 2007 Pearson Education

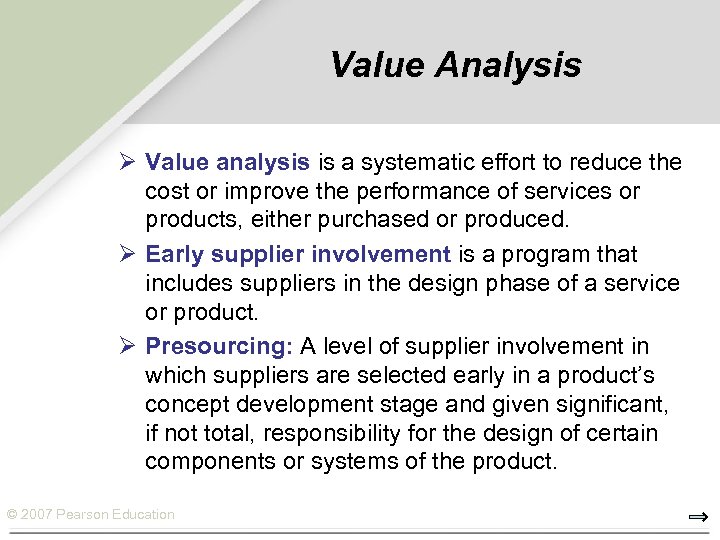

Value Analysis Ø Value analysis is a systematic effort to reduce the cost or improve the performance of services or products, either purchased or produced. Ø Early supplier involvement is a program that includes suppliers in the design phase of a service or product. Ø Presourcing: A level of supplier involvement in which suppliers are selected early in a product’s concept development stage and given significant, if not total, responsibility for the design of certain components or systems of the product. © 2007 Pearson Education

Value Analysis Ø Value analysis is a systematic effort to reduce the cost or improve the performance of services or products, either purchased or produced. Ø Early supplier involvement is a program that includes suppliers in the design phase of a service or product. Ø Presourcing: A level of supplier involvement in which suppliers are selected early in a product’s concept development stage and given significant, if not total, responsibility for the design of certain components or systems of the product. © 2007 Pearson Education

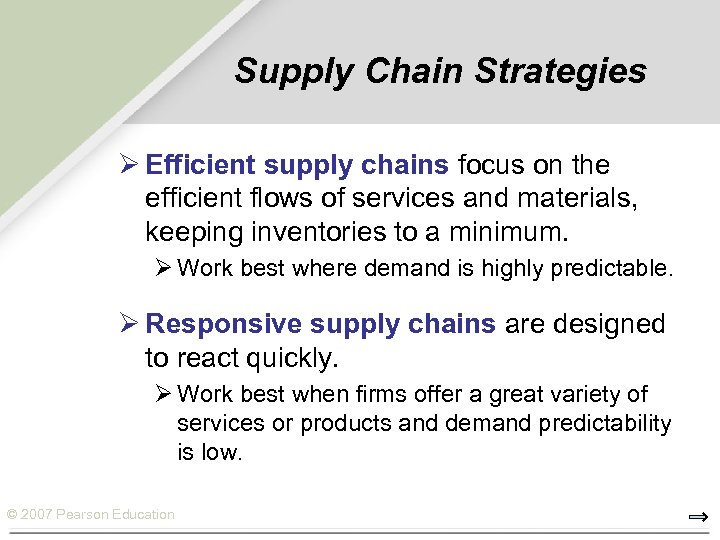

Supply Chain Strategies Ø Efficient supply chains focus on the efficient flows of services and materials, keeping inventories to a minimum. Ø Work best where demand is highly predictable. Ø Responsive supply chains are designed to react quickly. Ø Work best when firms offer a great variety of services or products and demand predictability is low. © 2007 Pearson Education

Supply Chain Strategies Ø Efficient supply chains focus on the efficient flows of services and materials, keeping inventories to a minimum. Ø Work best where demand is highly predictable. Ø Responsive supply chains are designed to react quickly. Ø Work best when firms offer a great variety of services or products and demand predictability is low. © 2007 Pearson Education

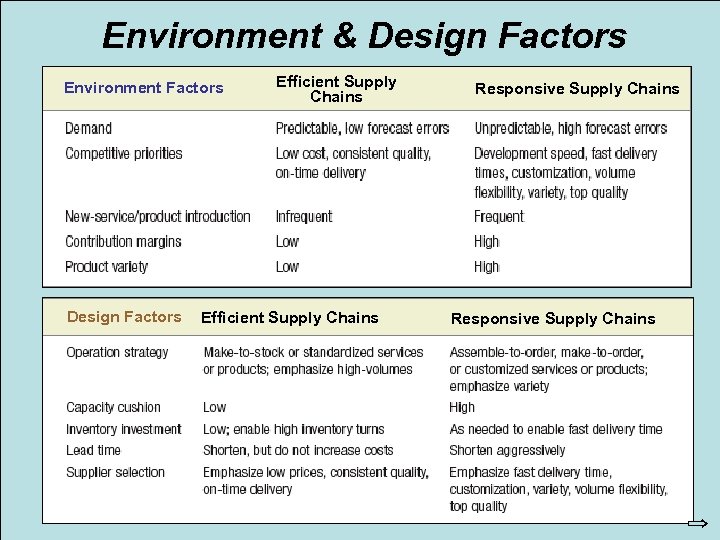

Environment & Design Factors Environment Factors Design Factors © 2007 Pearson Education Efficient Supply Chains Responsive Supply Chains

Environment & Design Factors Environment Factors Design Factors © 2007 Pearson Education Efficient Supply Chains Responsive Supply Chains

Mass Customization Ø Mass Customization: A strategy whereby a firm’s flexible processes generate a wide variety of personalized services or products at reasonably low costs. Ø Competitive advantages: Ø Managing customer relationships. It requires detailed inputs from customers so that the ideal service or product can be produced. Ø Eliminating finished goods inventory. Producing to a customer’s order eliminates finished goods inventory. Ø Increasing perceived value. It increases the perceived value of services or products. Ø Ø Postponement is when some of the final activities in the provision of a service or product are delayed until the orders are received. Channel assembly is when members of the distribution channel act as if they were assembly stations in the factory. © 2007 Pearson Education

Mass Customization Ø Mass Customization: A strategy whereby a firm’s flexible processes generate a wide variety of personalized services or products at reasonably low costs. Ø Competitive advantages: Ø Managing customer relationships. It requires detailed inputs from customers so that the ideal service or product can be produced. Ø Eliminating finished goods inventory. Producing to a customer’s order eliminates finished goods inventory. Ø Increasing perceived value. It increases the perceived value of services or products. Ø Ø Postponement is when some of the final activities in the provision of a service or product are delayed until the orders are received. Channel assembly is when members of the distribution channel act as if they were assembly stations in the factory. © 2007 Pearson Education

Outsourcing Ø A Make-or-buy decision is a managerial choice between whether to outsource a process or do it inhouse. Ø Outsourcing: Paying suppliers and distributors to perform processes and provide needed services and materials. Ø Vertical integration: Ø Backward integration is a firm’s movement upstream toward the sources of raw materials, parts, and services through acquisitions. Ø Forward integration is acquiring more channels of distribution, such as distribution centers (warehouses) and retail stores, or even business customers. © 2007 Pearson Education

Outsourcing Ø A Make-or-buy decision is a managerial choice between whether to outsource a process or do it inhouse. Ø Outsourcing: Paying suppliers and distributors to perform processes and provide needed services and materials. Ø Vertical integration: Ø Backward integration is a firm’s movement upstream toward the sources of raw materials, parts, and services through acquisitions. Ø Forward integration is acquiring more channels of distribution, such as distribution centers (warehouses) and retail stores, or even business customers. © 2007 Pearson Education

Offshoring Ø Offshoring is a supply chain strategy that involves moving processes to another country. Factors that influence the offshoring decision include: ØComparative labor costs ØLogistics costs ØLabor Laws and Unions ØTariffs and Taxes ØInternet ØPitfalls of offshoring include: ØNot making a good-faith effort to fix the existing process ØTechnology transfer ØDifficulties integrating processes © 2007 Pearson Education

Offshoring Ø Offshoring is a supply chain strategy that involves moving processes to another country. Factors that influence the offshoring decision include: ØComparative labor costs ØLogistics costs ØLabor Laws and Unions ØTariffs and Taxes ØInternet ØPitfalls of offshoring include: ØNot making a good-faith effort to fix the existing process ØTechnology transfer ØDifficulties integrating processes © 2007 Pearson Education

Virtual Supply Chains Ø Virtual Supply Chain: Outsourcing some part of the entire order fulfillment process with the help of sophisticated, Webbased information technology support packages. Ø Benefits include: Ø Reduced investment in inventories and order fulfillment infrastructure. Ø Greater service or product variety without the overhead of one’s own order fulfillment process. Ø Lower costs due to economies of scale. The supplier typically handles more volume than does the firm doing the outsourcing. Ø Lower transportation costs. With drop shipping in a virtual supply chain, the only transportation cost is shipping the goods from the wholesaler to the customer. © 2007 Pearson Education

Virtual Supply Chains Ø Virtual Supply Chain: Outsourcing some part of the entire order fulfillment process with the help of sophisticated, Webbased information technology support packages. Ø Benefits include: Ø Reduced investment in inventories and order fulfillment infrastructure. Ø Greater service or product variety without the overhead of one’s own order fulfillment process. Ø Lower costs due to economies of scale. The supplier typically handles more volume than does the firm doing the outsourcing. Ø Lower transportation costs. With drop shipping in a virtual supply chain, the only transportation cost is shipping the goods from the wholesaler to the customer. © 2007 Pearson Education

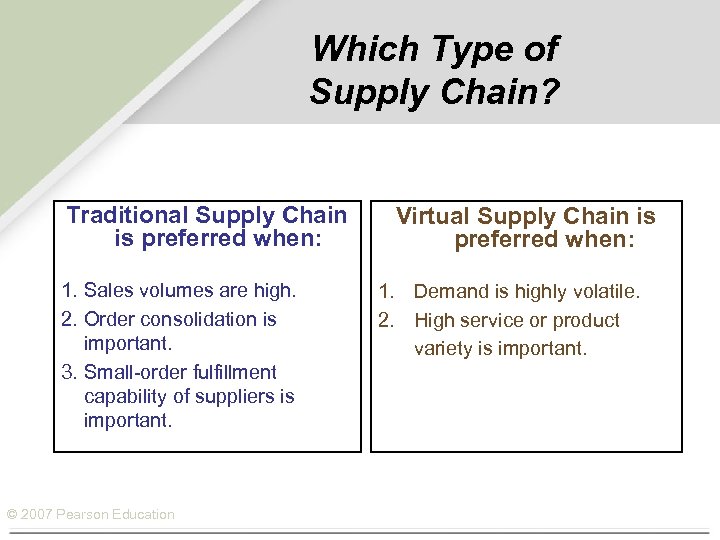

Which Type of Supply Chain? Traditional Supply Chain is preferred when: 1. Sales volumes are high. 2. Order consolidation is important. 3. Small-order fulfillment capability of suppliers is important. © 2007 Pearson Education Virtual Supply Chain is preferred when: 1. Demand is highly volatile. 2. High service or product variety is important.

Which Type of Supply Chain? Traditional Supply Chain is preferred when: 1. Sales volumes are high. 2. Order consolidation is important. 3. Small-order fulfillment capability of suppliers is important. © 2007 Pearson Education Virtual Supply Chain is preferred when: 1. Demand is highly volatile. 2. High service or product variety is important.