9734333df8b032b308b0723336fb0d42.ppt

- Количество слайдов: 32

Supply Chain Process Capability & Product Realization Process Strategy Streams IAQG General Assembly San Diego, April 7, 2006 Barbara O’Dell The Boeing Company IAQG Stream Leader Supply Chain Process Capability Bernard Lauras Airbus European Sector leader Product Realisation Process

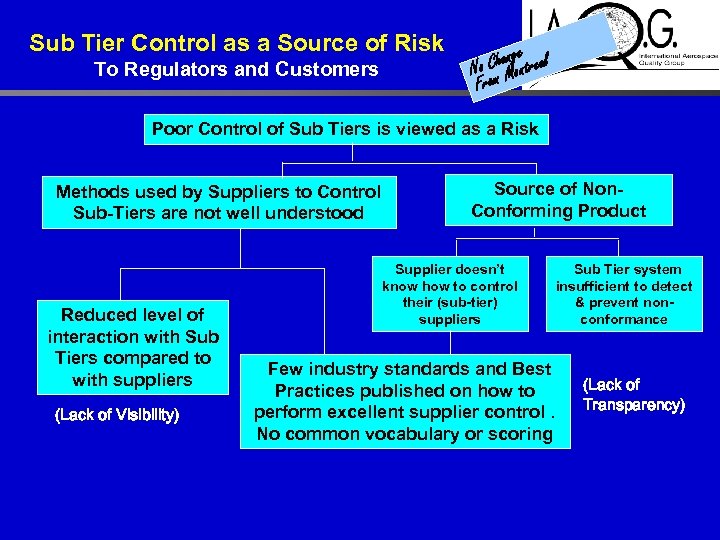

Sub Tier Control as a Source of Risk To Regulators and Customers e Changontreal No m M Fro Poor Control of Sub Tiers is viewed as a Risk Methods used by Suppliers to Control Sub-Tiers are not well understood Reduced level of interaction with Sub Tiers compared to with suppliers (Lack of Visibility) Source of Non. Conforming Product Supplier doesn’t know how to control their (sub-tier) suppliers Few industry standards and Best Practices published on how to perform excellent supplier control. No common vocabulary or scoring Sub Tier system insufficient to detect & prevent nonconformance (Lack of Transparency)

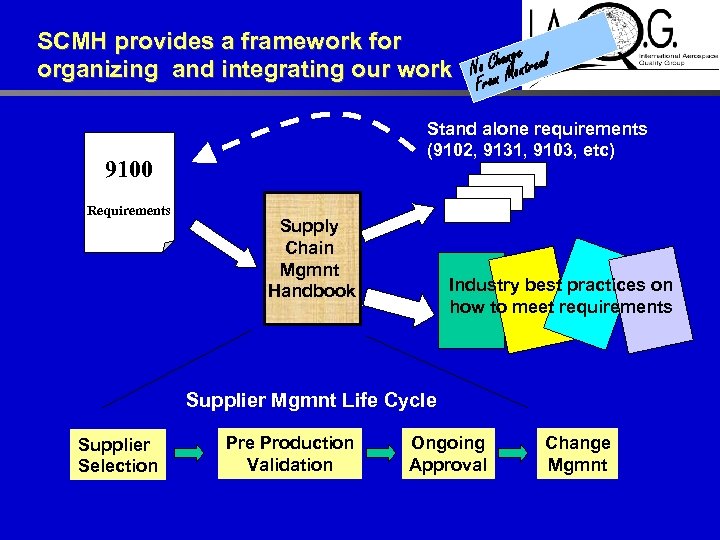

SCMH provides a framework for e Changontreal organizing and integrating our work Norom M F Stand alone requirements (9102, 9131, 9103, etc) 9100 Requirements Supply Chain Mgmnt Handbook Industry best practices on how to meet requirements Supplier Mgmnt Life Cycle Supplier Selection Pre Production Validation Ongoing Approval Change Mgmnt

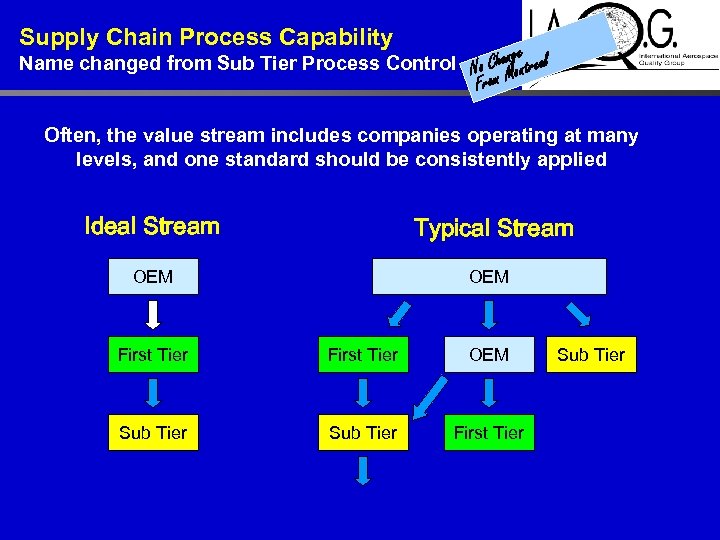

Supply Chain Process Capability e Name changed from Sub Tier Process Control No Changontreal M From Often, the value stream includes companies operating at many levels, and one standard should be consistently applied Ideal Stream Typical Stream OEM First Tier OEM Sub Tier First Tier Sub Tier

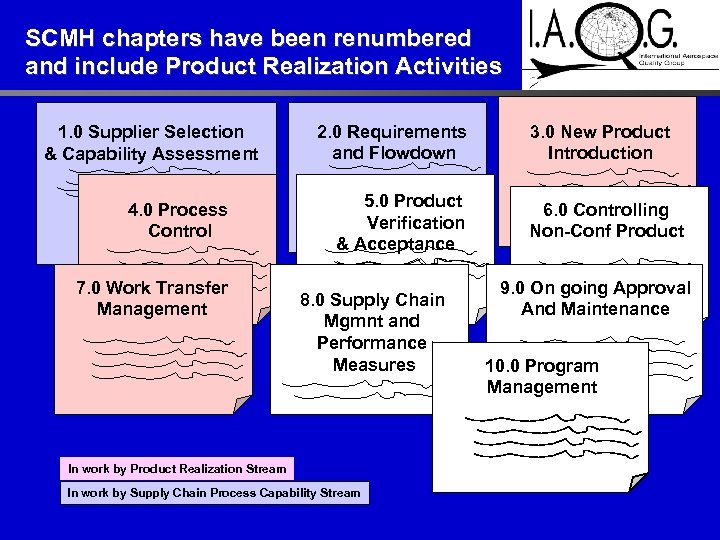

SCMH chapters have been renumbered and include Product Realization Activities 1. 0 Supplier Selection & Capability Assessment 4. 0 Process Control 7. 0 Work Transfer Management 2. 0 Requirements and Flowdown 5. 0 Product Verification & Acceptance 8. 0 Supply Chain Mgmnt and Performance Measures In work by Product Realization Stream In work by Supply Chain Process Capability Stream 3. 0 New Product Introduction 6. 0 Controlling Non-Conf Product 9. 0 On going Approval And Maintenance 10. 0 Program Management

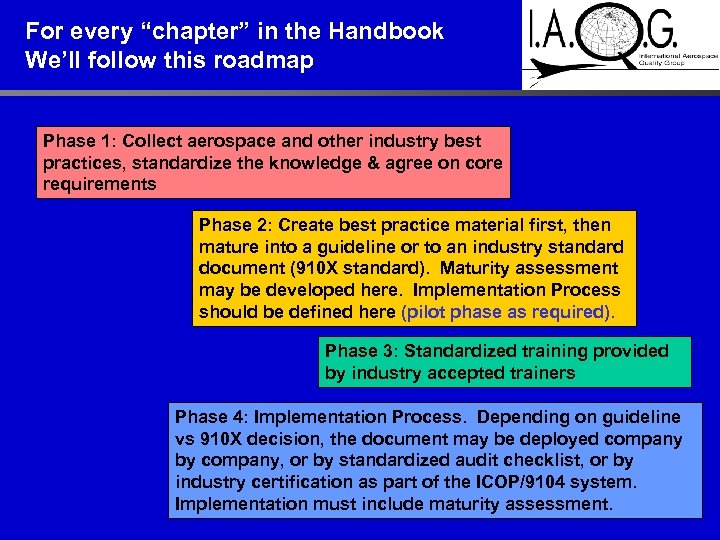

For every “chapter” in the Handbook We’ll follow this roadmap Phase 1: Collect aerospace and other industry best practices, standardize the knowledge & agree on core requirements Phase 2: Create best practice material first, then mature into a guideline or to an industry standard document (910 X standard). Maturity assessment may be developed here. Implementation Process should be defined here (pilot phase as required). Phase 3: Standardized training provided by industry accepted trainers Phase 4: Implementation Process. Depending on guideline vs 910 X decision, the document may be deployed company by company, or by standardized audit checklist, or by industry certification as part of the ICOP/9104 system. Implementation must include maturity assessment.

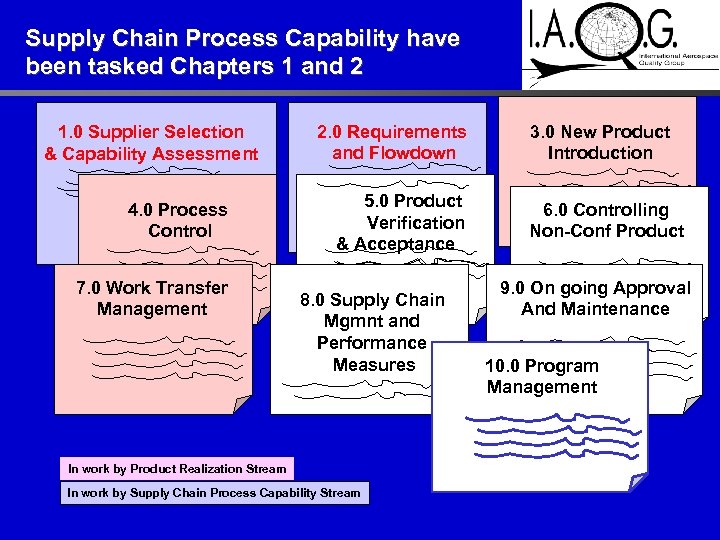

Supply Chain Process Capability have been tasked Chapters 1 and 2 1. 0 Supplier Selection & Capability Assessment 4. 0 Process Control 7. 0 Work Transfer Management 2. 0 Requirements and Flowdown 5. 0 Product Verification & Acceptance 8. 0 Supply Chain Mgmnt and Performance Measures In work by Product Realization Stream In work by Supply Chain Process Capability Stream 3. 0 New Product Introduction 6. 0 Controlling Non-Conf Product 9. 0 On going Approval And Maintenance 10. 0 Program Management

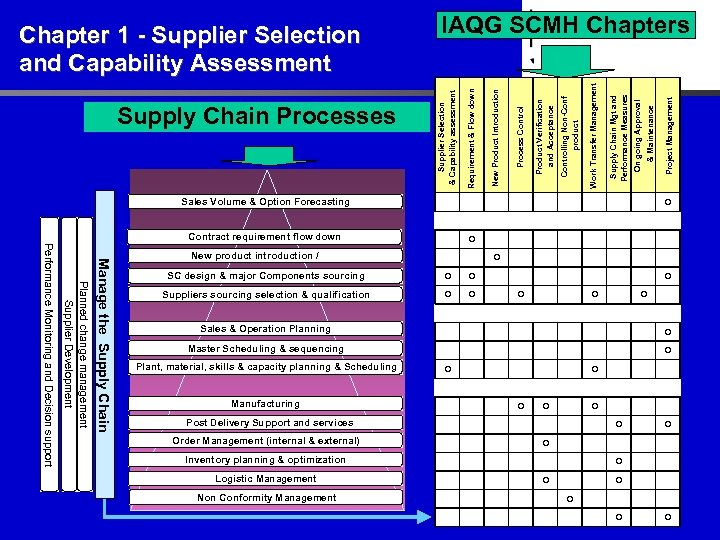

Sales Volume & Option Forecasting Project Management & Maintenance On going Approval Supply Chain Mgt and Performance Measures Work Transfer Management Controlling Non-Conf product Product Verification and Acceptance Process Control New Product Introduction Requirement & Flow down Supply Chain Processes IAQG SCMH Chapters Supplier Selection & Capability assessment Chapter 1 - Supplier Selection and Capability Assessment O Contract requirement flow down Manage the Supply Chain Planned change management Supplier Development Performance Monitoring and Decision support O New product introduction /LCM / O SC design & major Components sourcing O O Suppliers sourcing selection & qualification O O O Sales & Operation Planning O Master Scheduling & sequencing O Plant, material, skills & capacity planning & Scheduling Manufacturing O O O Post Delivery Support and services Post Delivery Support Order Management (internal & external) O O Inventory planning & optimization Logistic Management Non Conformity Management O O O O

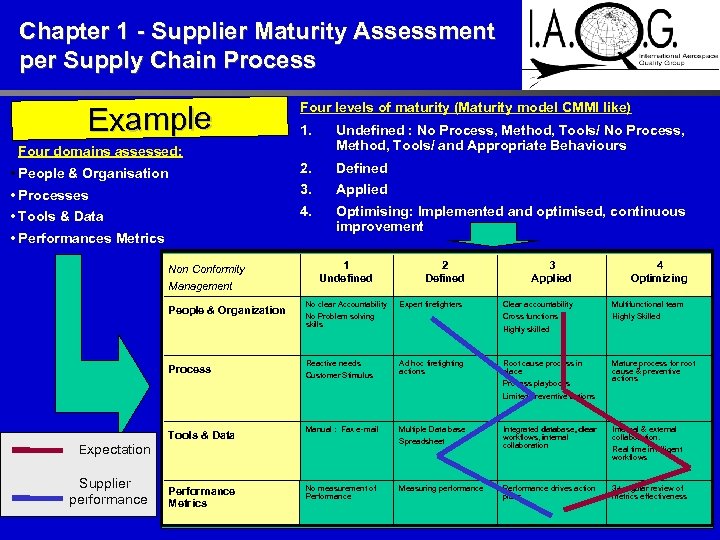

Chapter 1 - Supplier Maturity Assessment per Supply Chain Process Example Four levels of maturity (Maturity model CMMI like) 1. Undefined : No Process, Method, Tools/ and Appropriate Behaviours • Processes 2. 3. Defined Applied • Tools & Data 4. Optimising: Implemented and optimised, continuous improvement Four domains assessed: • People & Organisation • Performances Metrics Non Conformity Management People & Organization Process 1 Undefined No clear Accountability 2 Defined Expert firefighters Customer Stimulus 4 Optimizing Clear accountability Multifunctional team Cross functions No Problem solving skills Reactive needs 3 Applied Highly Skilled Highly skilled Ad hoc firefighting actions Root cause process in place Process playbooks Mature process for root cause & preventive actions Limited preventive actions Expectation Supplier performance Tools & Data Performance Metrics Manual : Fax e-mail Multiple Data base Spreadsheet No measurement of Performance Measuring performance Integrated database, clear workflows, internal collaboration Internal & external collaboration. Performance drives action plans 3+ regular review of metrics effectiveness Real time intelligent workflows

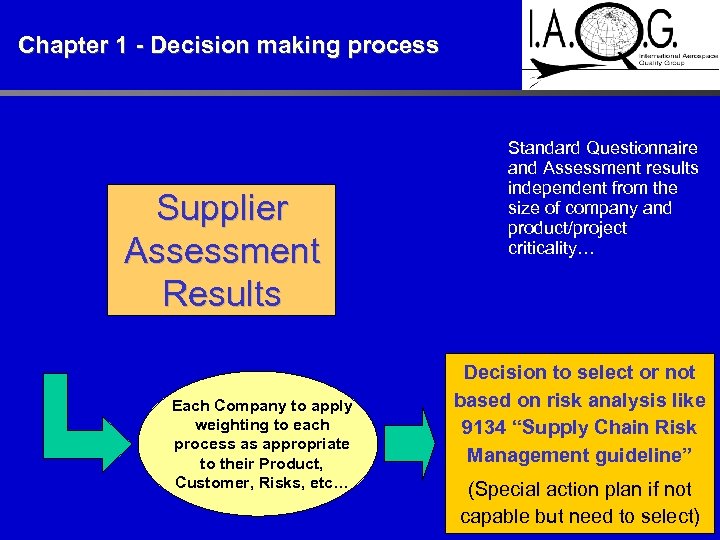

Chapter 1 - Decision making process Supplier Assessment Results Each Company to apply weighting to each process as appropriate to their Product, Customer, Risks, etc… Standard Questionnaire and Assessment results independent from the size of company and product/project criticality… Decision to select or not based on risk analysis like 9134 “Supply Chain Risk Management guideline” (Special action plan if not capable but need to select)

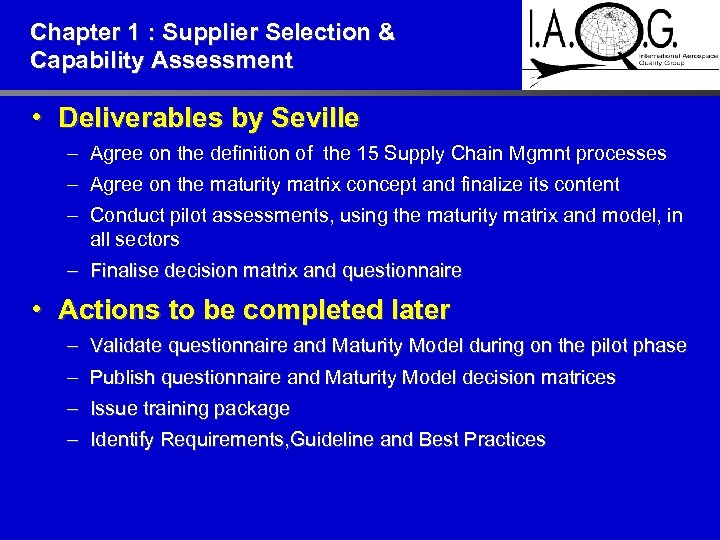

Chapter 1 : Supplier Selection & Capability Assessment • Deliverables by Seville – Agree on the definition of the 15 Supply Chain Mgmnt processes – Agree on the maturity matrix concept and finalize its content – Conduct pilot assessments, using the maturity matrix and model, in all sectors – Finalise decision matrix and questionnaire • Actions to be completed later – Validate questionnaire and Maturity Model during on the pilot phase – Publish questionnaire and Maturity Model decision matrices – Issue training package – Identify Requirements, Guideline and Best Practices

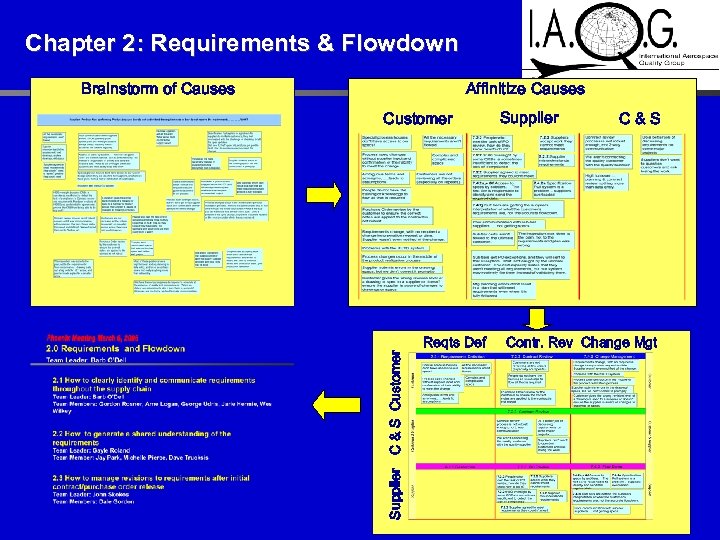

Chapter 2: Requirements & Flowdown Brainstorm of Causes Affinitize Causes Customer Supplier C&S Supplier C & S Customer Suppliers Produce Non-conforming Product because they do not understand the requirements or do not receive the requirements. WHY? Reqts Def Contr. Rev Change Mgt

Chapter 2. 0 Requirements and Flowdown 2. 1 How to clearly identify and communicate requirements throughout the supply chain 2. 2 How to generate a shared understanding of the requirements 2. 3 How to manage revisions to requirements after initial contract/purchase order release

Chapter 2 - Requirements and Flowdown • Deliverables by Seville: – Connect to others doing similar work (Missile Defense Agency, Space Quality Improvement Council) to see if we can combine efforts – Communicate our work to others (AIA, ASQ) – Collect best practices and white papers from aerospace and other industries • Actions to be completed later – Benchmark Medical Device Industry and SEA on Requirements & Flowdown – Publish guidelines/best practices by June 07

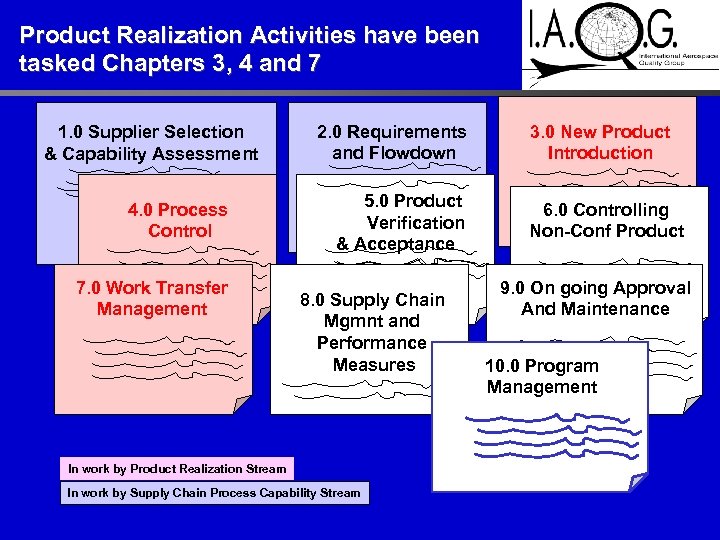

Product Realization Activities have been tasked Chapters 3, 4 and 7 1. 0 Supplier Selection & Capability Assessment 4. 0 Process Control 7. 0 Work Transfer Management 2. 0 Requirements and Flowdown 5. 0 Product Verification & Acceptance 8. 0 Supply Chain Mgmnt and Performance Measures In work by Product Realization Stream In work by Supply Chain Process Capability Stream 3. 0 New Product Introduction 6. 0 Controlling Non-Conf Product 9. 0 On going Approval And Maintenance 10. 0 Program Management

Chapter 3 – New Product Introduction e Changontreal No m M Fro • Background: § The Aerospace Industry developed a successful product introduction process based on a 20%-80% outsource ratio and the industry has migrated to a 80%-20% outsource ratio § This change was gradual and a change in the product introduction process was not undertaken • Corrective Action proposed: § Develop a product introduction process that accurately predicts supplier performance at production levels

Chapter 3 – New Product Introduction • Status: – Benchmarking performed: • Dell computers • Toyota USA • Knowles (Medical) – Lessons learned and brainstorming have produced Sub -chapters headings

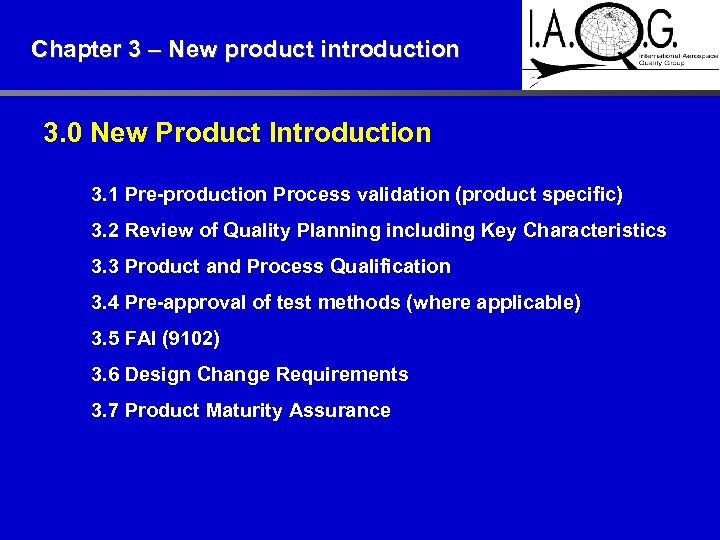

Chapter 3 – New product introduction 3. 0 New Product Introduction 3. 1 Pre-production Process validation (product specific) 3. 2 Review of Quality Planning including Key Characteristics 3. 3 Product and Process Qualification 3. 4 Pre-approval of test methods (where applicable) 3. 5 FAI (9102) 3. 6 Design Change Requirements 3. 7 Product Maturity Assurance

Chapter 3 - New product introduction • Deliverables by Seville: – Confirm sub-chapters headings, resolve overlaps with other chapters – Collect best practices from IAQG and other companies • Actions to be completed later – Publish guidelines/best practices by June 07

Chapter 4 - Process Control e Changontreal No m M Fro • 9103 (Variation Management of Key Characteristics) not sufficiently and adequately deployed § Value not clearly identified or understood Lack of buy-in § All functions to be involved, not only Quality § Training required § Need to explain how to apply 9103 based upon supplier & product complexity Lack of skills

Chapter 4 - Process Control • Since Montreal, EAQG has worked on 9103 education package: – Common part (key concepts with IAQG banner) for all companies using the training – Some area to be adapted by each company when training its staff or its suppliers (examples, tools, forms, etc…) – Education package content: § § • Will focus on value of doing it and risks and/or costs of not doing it Should take difficulties of doing it into consideration Work is on going

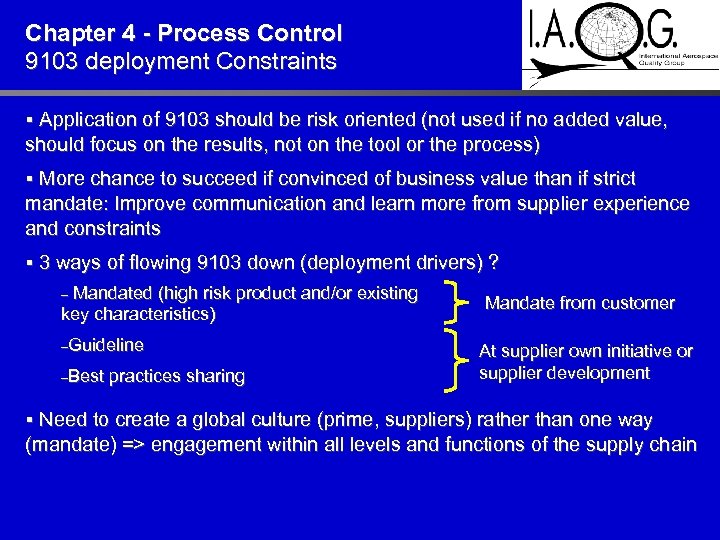

Chapter 4 - Process Control 9103 deployment Constraints § Application of 9103 should be risk oriented (not used if no added value, should focus on the results, not on the tool or the process) § More chance to succeed if convinced of business value than if strict mandate: Improve communication and learn more from supplier experience and constraints § 3 ways of flowing 9103 down (deployment drivers) ? Mandated (high risk product and/or existing key characteristics) – –Guideline –Best practices sharing Mandate from customer At supplier own initiative or supplier development § Need to create a global culture (prime, suppliers) rather than one way (mandate) => engagement within all levels and functions of the supply chain

Chapter 4 - Process Control Further Actions • Measure the effectiveness of 9103 deployment and its benefits on the overall business • Build on lessons learned – – – See how to define key characteristics Introduce concept of FAI stage 1 (initial) and stage 2 (confirm capability at ramp up) Evaluate how to use 9103 results to optimize design for manufacturing

Chapter 4 - Process Control Interconnection between several topics “Global Process Control” brainstorming : We can build from 9103 but shall not limit to it and shall not consider it as the only key factor of success

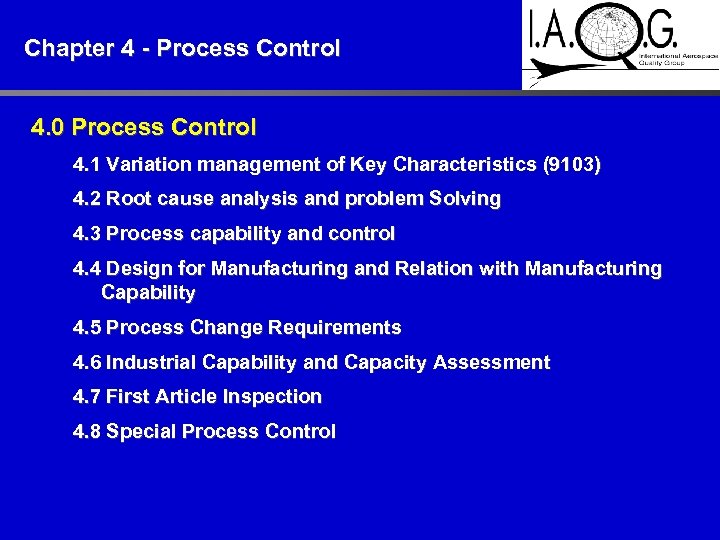

Chapter 4 - Process Control 4. 0 Process Control 4. 1 Variation management of Key Characteristics (9103) 4. 2 Root cause analysis and problem Solving 4. 3 Process capability and control 4. 4 Design for Manufacturing and Relation with Manufacturing Capability 4. 5 Process Change Requirements 4. 6 Industrial Capability and Capacity Assessment 4. 7 First Article Inspection 4. 8 Special Process Control

Chapter 4 - Process Control Proposed Short Term Action plan • Deliverables by Seville: – Finalize 9103 education package – Be ready for deployment of the 9103 training • Actions to be completed later – Start to work on Root Cause Analysis and Problem solving – Evaluate the effectiveness of 9103 deployment – Reviewing opportunity for Process Control improvement based on feedback from deployment (industry expectations) – Build on 9103 (evolution of the standard or complementary standards or methodology)

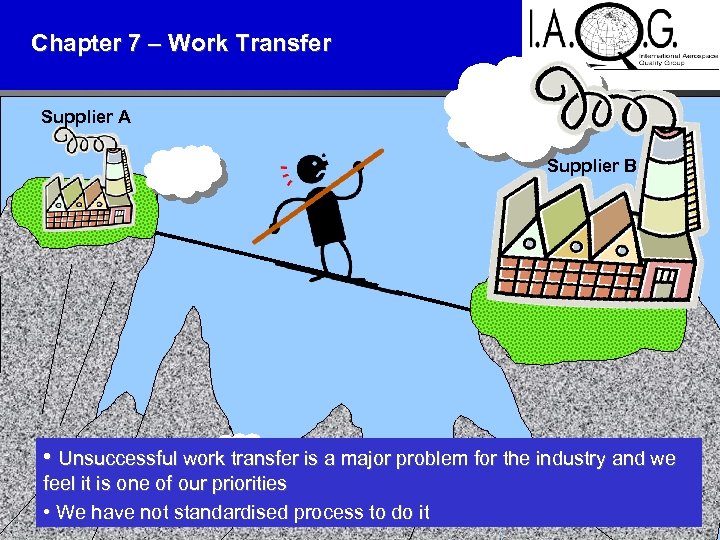

Chapter 7 – Work Transfer Supplier A Supplier B • Unsuccessful work transfer is a major problem for the industry and we feel it is one of our priorities • We have not standardised process to do it

Chapter 7 – Work Transfer • Collected Industry Best Practices (Benchmarking) – Dell computers – Toyota USA – Knowles (Medical) • Standardize Knowledge and Lessons learned – Pre-transition Program Planning • Pre-production meeting(s) – upfront effort – – Multidiscipline Team (Agreement: quality, eng. , purch. ) Capture Hidden Factory – Last Article audit (product and process) Receiving Supplier Process Capability & Assessment Supplier Development – as required

Chapter 7 – Work Transfer • Deliverables in Seville: – Confirm sub-chapters headings – Identify overlaps, existing/needed standards – Collect best practices from IAQG and other companies • Actions to be completed later – Develop a transition process from best practices, ensuring risks are identified and mitigated prior to the work transfer decision and launch – Publish guidelines/best practices by June 07

Supply Chain Management Handbook Next steps • Finalize Chapter Headings and Sub Chapter titles and content/objectives to eliminate overlaps, improve clarity and integration (June 06) • SAE has provided a “public web space” for our team to communicate with the general public on our progress. We will populate this web space in coordination with the IAQG communications team

9734333df8b032b308b0723336fb0d42.ppt