cde7c3e395b303279af39004db846e4c.ppt

- Количество слайдов: 21

Supply Chain Management Holmes Miller 1999 Based on slides for Chase Acquilano and Jacobs Operations Management©for Competitive advantage Mc. Graw-Hill

Supply Chain Management ü What is it? ü Purchasing strategies ü Measuring Performance ü Bullwhip Effect ü Outsourcing ü Mass Customization

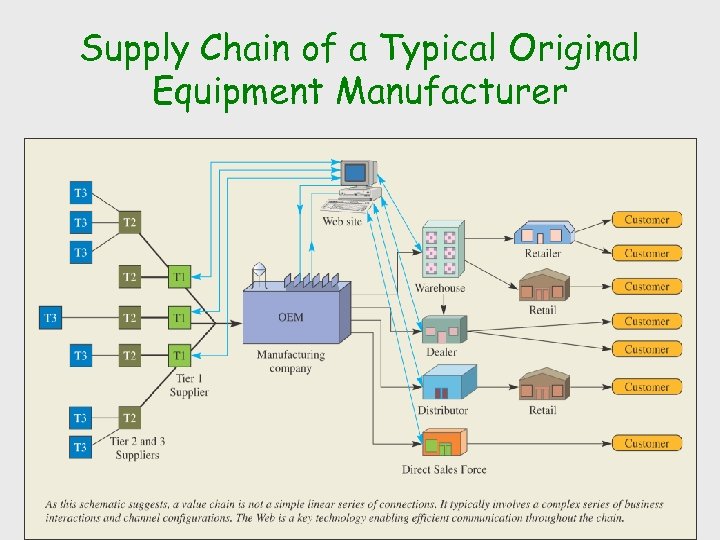

Supply Chain of a Typical Original Equipment Manufacturer

What is Supply-Chain Management? ü Supply-chain management äis a total system approach to managing the entire flow of information, materials, and services from raw-material suppliers through factories and warehouses to the end customer

Toyota’s Supply Chain

Digression ü Make vs. Buy ü Purchasing strategies ä Vertical integration ä Many suppliers ä Few suppliers ä Virtual company

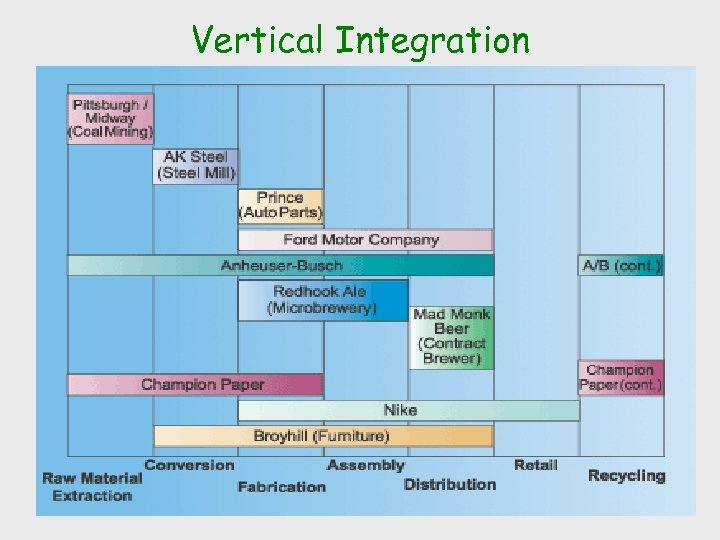

Vertical Integration

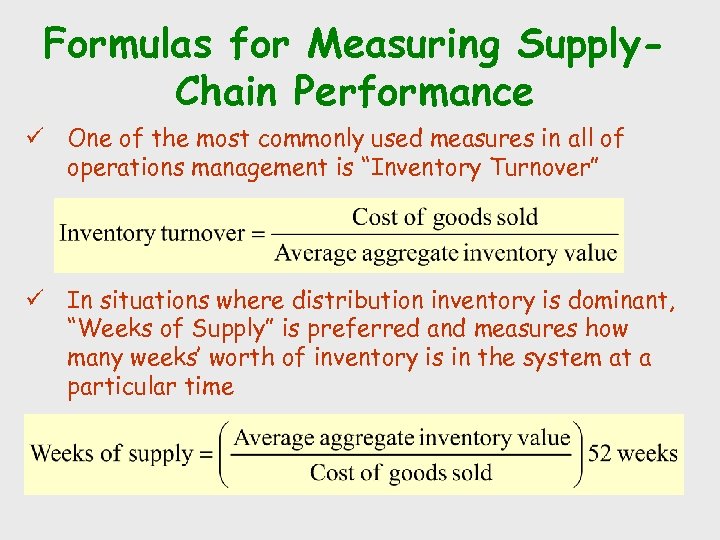

Formulas for Measuring Supply. Chain Performance ü One of the most commonly used measures in all of operations management is “Inventory Turnover” ü In situations where distribution inventory is dominant, “Weeks of Supply” is preferred and measures how many weeks’ worth of inventory is in the system at a particular time

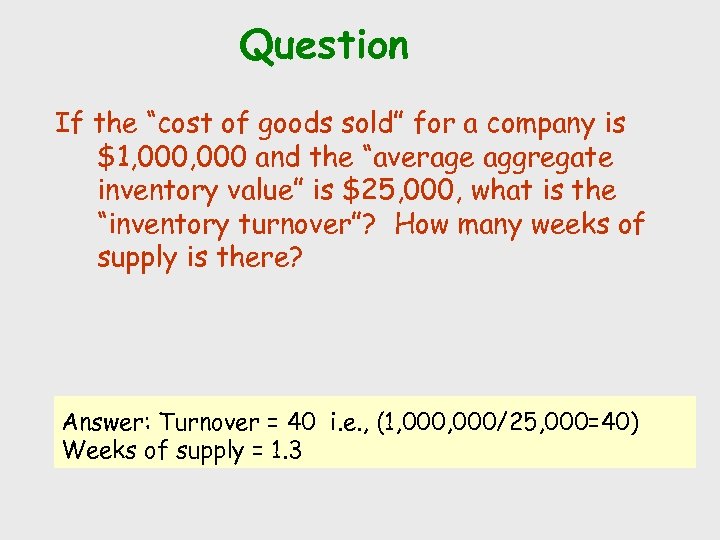

Question If the “cost of goods sold” for a company is $1, 000 and the “average aggregate inventory value” is $25, 000, what is the “inventory turnover”? How many weeks of supply is there? Answer: Turnover = 40 i. e. , (1, 000/25, 000=40) Weeks of supply = 1. 3

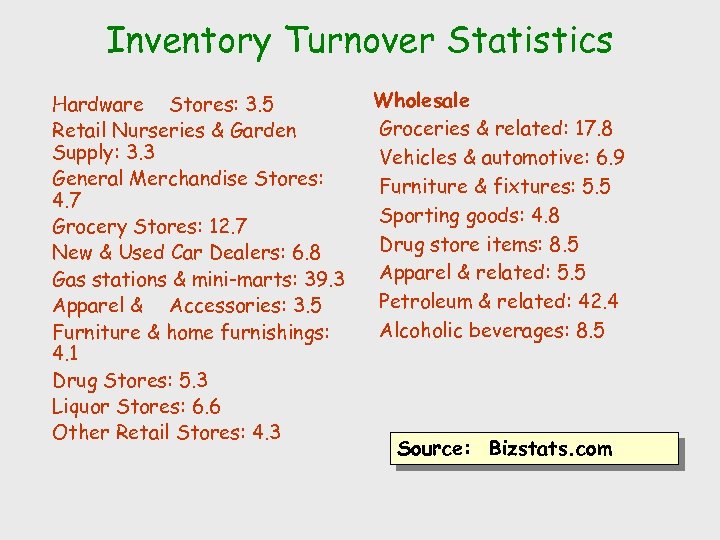

Inventory Turnover Statistics Hardware Stores: 3. 5 Retail Nurseries & Garden Supply: 3. 3 General Merchandise Stores: 4. 7 Grocery Stores: 12. 7 New & Used Car Dealers: 6. 8 Gas stations & mini-marts: 39. 3 Apparel & Accessories: 3. 5 Furniture & home furnishings: 4. 1 Drug Stores: 5. 3 Liquor Stores: 6. 6 Other Retail Stores: 4. 3 Wholesale Groceries & related: 17. 8 Vehicles & automotive: 6. 9 Furniture & fixtures: 5. 5 Sporting goods: 4. 8 Drug store items: 8. 5 Apparel & related: 5. 5 Petroleum & related: 42. 4 Alcoholic beverages: 8. 5 Source: Bizstats. com

The Impact of Variability ü The Bullwhip Effect ü Tailoring the supply chain to the type of product

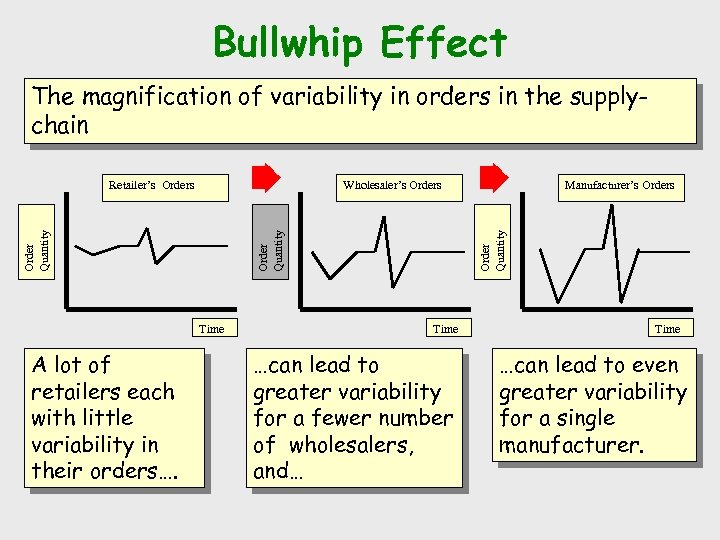

Bullwhip Effect The magnification of variability in orders in the supplychain Time A lot of retailers each with little variability in their orders…. Manufacturer’s Order Quantity Wholesaler’s Order Quantity Retailer’s Orders Time …can lead to greater variability for a fewer number of wholesalers, and… Time …can lead to even greater variability for a single manufacturer.

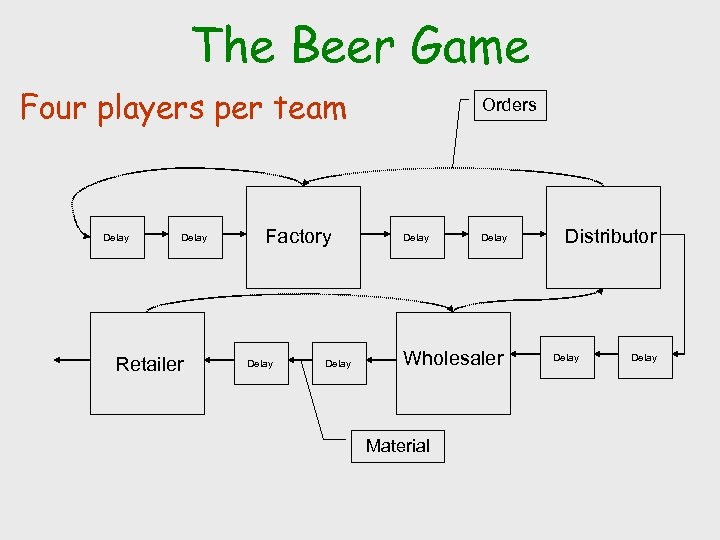

The Beer Game Four players per team Delay Retailer Factory Delay Orders Delay Wholesaler Material Distributor Delay

Supply Chain Design Strategy Based on concepts developed by Marshall Fischer at Wharton (Penn) ü Functional Products ä ä Staples that people buy at retail outlets Predictable demand long life cycles Physical costs Strategy: Minimize physical costs ü Innovative Products ä Life cycle is just a few months (e. g. fashion clothes & computers) ä Demand is unpredictable ä Market mediation costs (inventory & stockouts) ä Strategy: Maximize responsiveness & flexibility

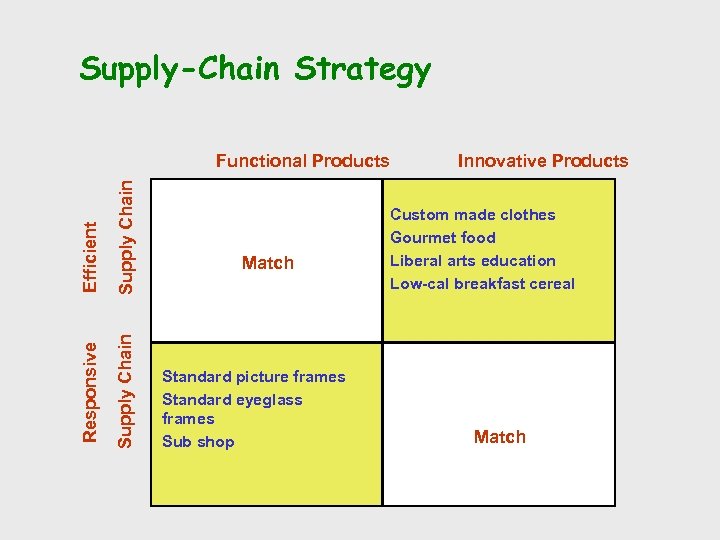

Supply-Chain Strategy Efficient Supply Chain Responsive Supply Chain Functional Products Match Standard picture frames Standard eyeglass frames Sub shop Innovative Products Custom made clothes Gourmet food Liberal arts education Low-cal breakfast cereal Match

Exercise ü Go to the Mc-Graw Hill “Company Tours” link on the course’s “web links” page ü Select a functional and innovative product and take the tour of its operations – for example: ä Functional: Canadian Springs Water ä Innovative: Corbin Motorcycle Saddles ü From what you see, identify supply chain issues ü Are there any potential mismatches? ü Discuss and present results to the class.

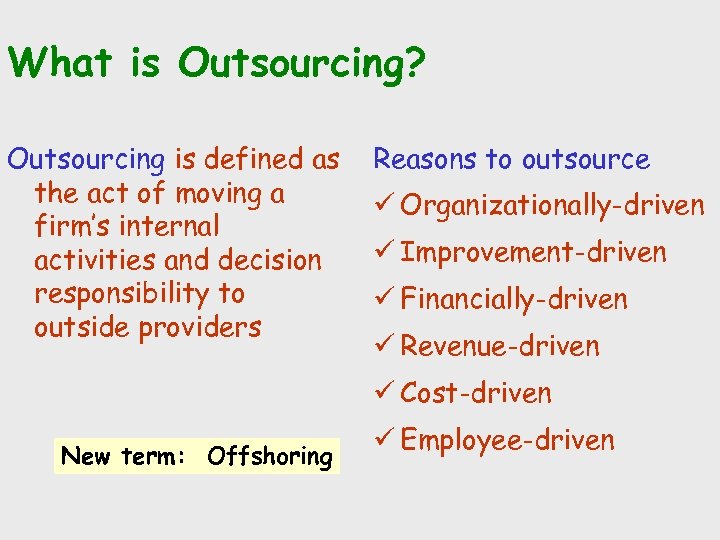

What is Outsourcing? Outsourcing is defined as the act of moving a firm’s internal activities and decision responsibility to outside providers Reasons to outsource ü Organizationally-driven ü Improvement-driven ü Financially-driven ü Revenue-driven ü Cost-driven New term: Offshoring ü Employee-driven

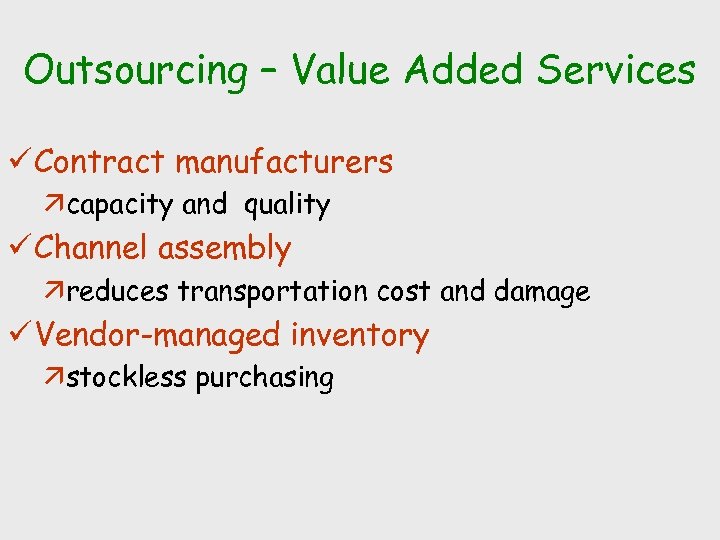

Outsourcing – Value Added Services ü Contract manufacturers äcapacity and quality ü Channel assembly äreduces transportation cost and damage ü Vendor-managed inventory ästockless purchasing

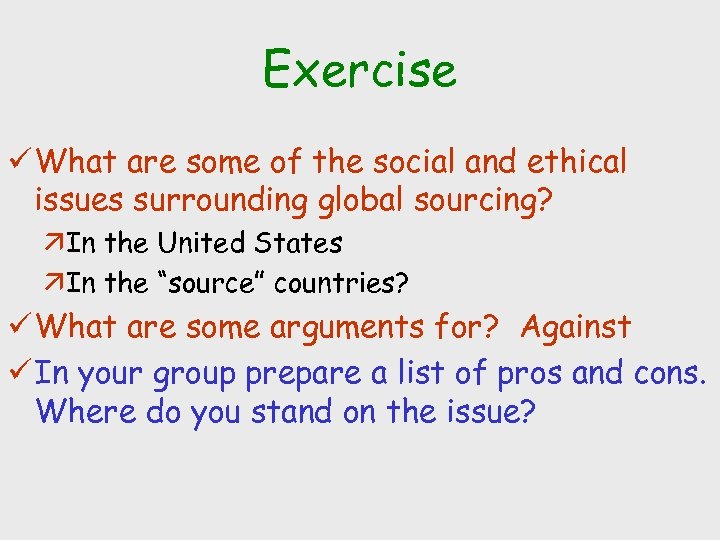

Exercise ü What are some of the social and ethical issues surrounding global sourcing? äIn the United States äIn the “source” countries? ü What are some arguments for? Against ü In your group prepare a list of pros and cons. Where do you stand on the issue?

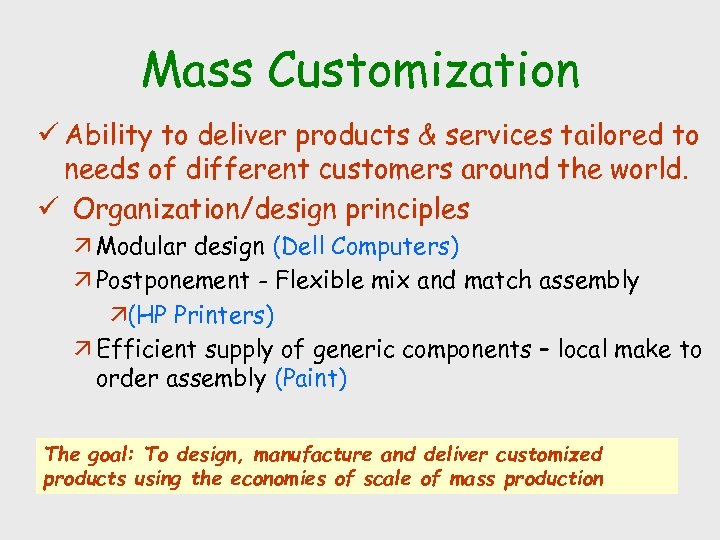

Mass Customization ü Ability to deliver products & services tailored to needs of different customers around the world. ü Organization/design principles ä Modular design (Dell Computers) ä Postponement - Flexible mix and match assembly ä(HP Printers) ä Efficient supply of generic components – local make to order assembly (Paint) The goal: To design, manufacture and deliver customized products using the economies of scale of mass production

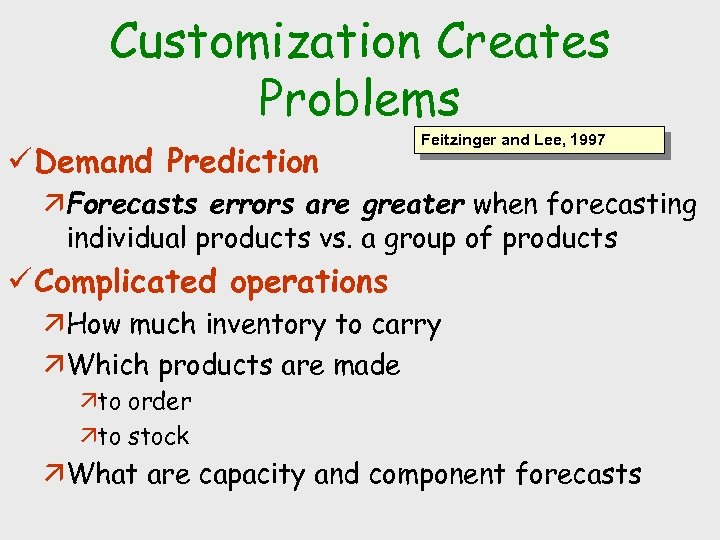

Customization Creates Problems ü Demand Prediction Feitzinger and Lee, 1997 äForecasts errors are greater when forecasting individual products vs. a group of products ü Complicated operations äHow much inventory to carry äWhich products are made äto order äto stock äWhat are capacity and component forecasts

cde7c3e395b303279af39004db846e4c.ppt