1a2880f546f1ed56ffbe39c3b253c45f.ppt

- Количество слайдов: 49

Supply Chain Integration and e. Business Strategies David Simchi-Levi Professor of Engineering Systems Massachusetts Institute of Technology Tel: 617 -253 -6160 E-mail: dslevi@mit. edu

Outline • Review – Supply Chain Dynamics • A new Supply Chain Paradigm • Matching Products with Strategies • e-Business Opportunities ©Copyright 2002 D. Simchi-Levi

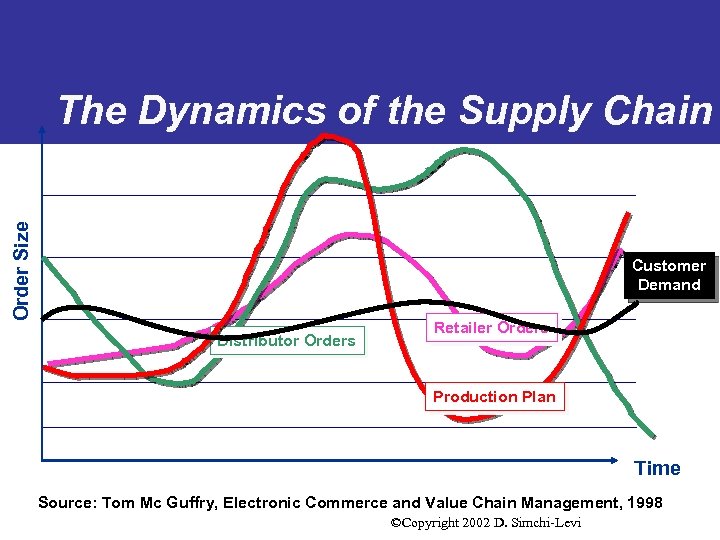

Order Size The Dynamics of the Supply Chain Customer Demand Distributor Orders Retailer Orders Production Plan Time Source: Tom Mc Guffry, Electronic Commerce and Value Chain Management, 1998 ©Copyright 2002 D. Simchi-Levi

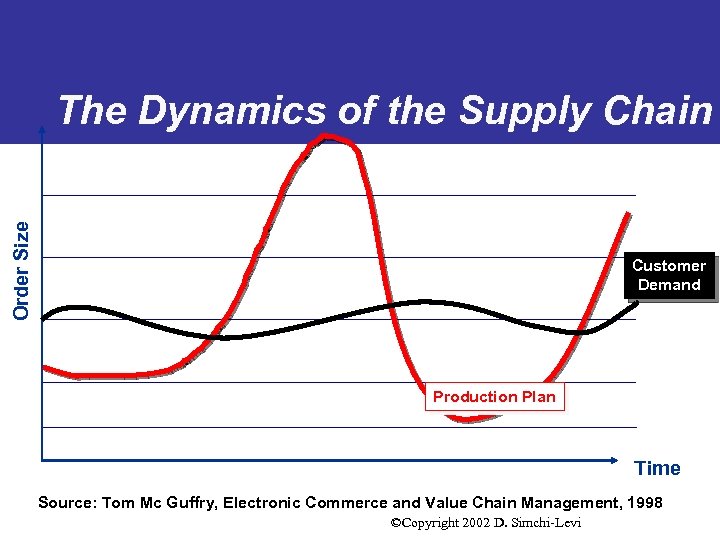

Order Size The Dynamics of the Supply Chain Customer Demand Production Plan Time Source: Tom Mc Guffry, Electronic Commerce and Value Chain Management, 1998 ©Copyright 2002 D. Simchi-Levi

What are the Causes…. • Promotional sales • Volume and Transportation discounts – Batching • • Inflated orders Demand Forecast Long cycle times Lack of Visibility to demand information ©Copyright 2002 D. Simchi-Levi

Consequences…. • Increased safety stock • Reduced service level • Inefficient allocation of resources • Increased transportation costs ©Copyright 2002 D. Simchi-Levi

The Bullwhip Effect: Managerial Insights • Exists, in part, due to the retailer’s need to estimate the mean and variance of demand. • The increase in variability is an increasing function of the lead time. • The more complicated the demand models and the forecasting techniques, the greater the increase. • Centralized demand information can reduce the bullwhip effect, but will not eliminate it. ©Copyright 2002 D. Simchi-Levi

Coping with the Bullwhip Effect in Leading Companies • Reduce Variability and Uncertainty - POS - Sharing Information - Year-round low pricing • Reduce Lead Times - EDI - Cross Docking • Alliance Arrangements – Vendor managed inventory – On-site vendor representatives ©Copyright 2002 D. Simchi-Levi

Example: Quick Response at Benetton • Benetton, the Italian sportswear manufacturer, was founded in 1964. In 1975 Benetton had 200 stores across Italy. • Ten years later, the company expanded to the U. S. , Japan and Eastern Europe. Sales in 1991 reached 2 trillion. • Many attribute Benetton’s success to successful use of communication and information technologies. ©Copyright 2002 D. Simchi-Levi

Example: Quick Response at Benetton • Benetton uses an effective strategy, referred to as Quick Response, in which manufacturing, warehousing, sales and retailers are linked together. In this strategy a Benetton retailer reorders a product through a direct link with Benetton’s mainframe computer in Italy. • Using this strategy, Benetton is capable of shipping a new order in only four weeks, several week earlier than most of its competitors. ©Copyright 2002 D. Simchi-Levi

How Does Benetton Cope with the Bullwhip Effect? 1. Integrated Information Systems • Global EDI network that links agents with production and inventory information • EDI order transmission to HQ • EDI linkage with air carriers • Data linked to manufacturing 2. Coordinated Planning • Frequent review allows fast reaction • Integrated distribution strategy ©Copyright 2002 D. Simchi-Levi

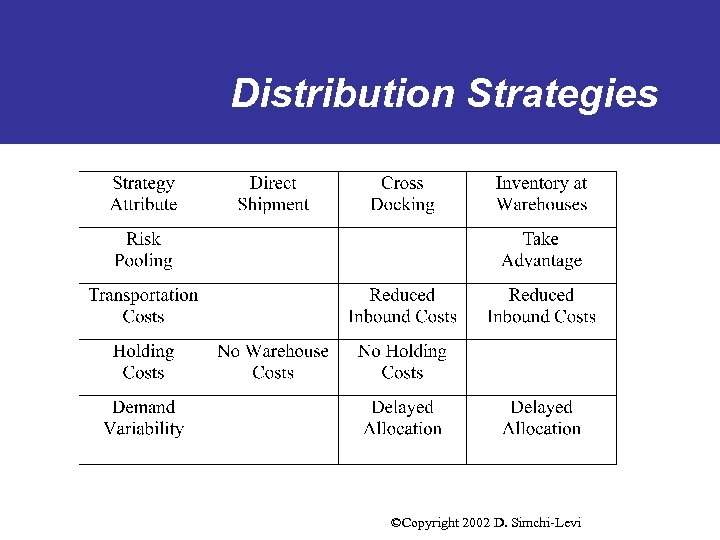

Distribution Strategies • Warehousing • Direct Shipping – No DC needed – Lead times reduced – “smaller trucks” – no risk pooling effects • Cross-Docking ©Copyright 2002 D. Simchi-Levi

Cross Docking In 1979, Kmart was the king of the retail industry with 1891 stores and average revenues per store of $7. 25 million • At that time Wal-Mart was a small niche retailer in the South with only 229 stores and average revenues about half of those Kmart stores. • Ten years later, Wal-Mart transformed itself; it has the highest sales per square foot, inventory turnover and operating profit of any discount retailer. Today Wal-Mart is the largest and highest profit retailer in the world. ©Copyright 2002 D. Simchi-Levi

What accounts for Wal-Mart’s remarkable success • The starting point was a relentless focus on satisfying customer needs; Wal-Mart goal was simply to provide customers access to goods when and where they want them and to develop cost structures that enable competitive pricing • The key to achieving this goal was to make the way the company replenished inventory the centerpiece of its strategy. ©Copyright 2002 D. Simchi-Levi

What accounts for Wal-Mart’s remarkable success? • This was obtained by using a logistics technique known as cross-docking. Here goods are continuously delivered to Wal-Mart’s warehouses where they are dispatched to stores without ever sitting in inventory. • This strategy reduced Wal-Mart’s cost of sales significantly and made it possible to offer everyday low prices to their customers. ©Copyright 2002 D. Simchi-Levi

Characteristics of Cross-Docking: • Goods spend at most 48 hours in the warehouse, • Avoids inventory and handling costs, • Wal-Mart delivers about 85% of its goods through its warehouse system, compared to about 50% for Kmart, • Stores trigger orders for products. ©Copyright 2002 D. Simchi-Levi

System Characteristics: • Very difficult to manage, • Requires linking Wal-Mart’s distribution centers, suppliers and stores to guarantee that any order is processed and executed in a matter of hours, • Wal-Mart operates a private satellitecommunications system that sends point-ofsale data to all its vendors allowing them to have a clear vision of sales at the stores ©Copyright 2002 D. Simchi-Levi

System Characteristics: • Need a fast and responsive transportation system: • Wal-Mart has a dedicated fleet of 2000 trucks that serve their 19 warehouses • This allows them to – ship goods from warehouses to stores in less than 48 hours – replenish stores twice a week on average. ©Copyright 2002 D. Simchi-Levi

Distribution Strategies ©Copyright 2002 D. Simchi-Levi

Supply Chain Integration - Dealing with Conflicting Goals • • • Lot Size vs. Inventory vs. Transportation Lead Time vs. Transportation Product Variety vs. Inventory Cost vs. Customer Service ©Copyright 2002 D. Simchi-Levi

The Future is Not What it Used to Be • A new e-Business Model – Reduce cost – Increase Profit – Increase service level – Increase flexibility ©Copyright 2002 D. Simchi-Levi

Reality is Different…. . • Amazon. com Example – – – Founded in 1995; 1 st Internet purchase for most people 1996: $16 M Sales, $6 M Loss 1999: $1. 6 B Sales, $720 M Loss 2000: $2. 7 B Sales, $1. 4 B Loss Last quarter of 2001: $50 M Profit • Total debt: $2. 2 B • Peapod Example – – Founded 1989 140, 000 members, largest on-line grocer Revenue tripled to $73 million in 1999 1 st Quarter of 2000: $25 M Sales, Loss: $8 M ©Copyright 2002 D. Simchi-Levi

Reality is Different…. • Dell Example: – Dell Computer has outperformed the competition in terms of shareholder value growth over the eight years period, 1988 -1996, by over 3, 000% (see Anderson and Lee, 1999) ©Copyright 2002 D. Simchi-Levi

Reality is Different…. • Cisco Example: – Cisco’s Internet based business model has been instrumental in our ability to quadruple in size from fiscal 1994 to fiscal 1998 ($1. 3 B to over $8 B), hire approximately 1000 new employees per quarter and saving $560 M annually in business expenses (Peter Solvik, CIO Cisco) ©Copyright 2002 D. Simchi-Levi

The e- Business Model • e-Business is a collection of business models and processes motivated by Internet technology, and focusing on improving the extended enterprise performance – e-commerce is part of e-Business – Internet technology is the driver of the business change – The focus is on the extended enterprise: • Intra-organizational • Business to Consumer (B 2 C) • Business to Business (B 2 B) ©Copyright 2002 D. Simchi-Levi

A new Supply Chain Paradigm • A shift from a Push System. . . – Production decisions are based on forecast • …to a Push-Pull System ©Copyright 2002 D. Simchi-Levi

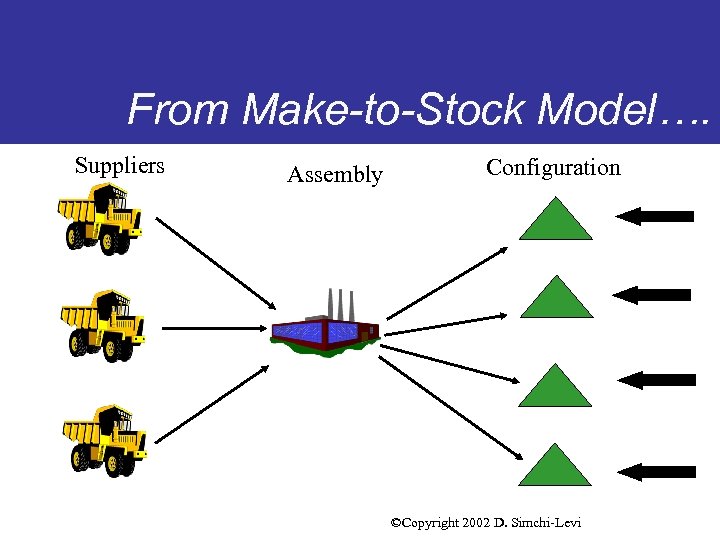

From Make-to-Stock Model…. Suppliers Assembly Configuration ©Copyright 2002 D. Simchi-Levi

Demand Forecast • The three principles of all forecasting techniques: – Forecasts are always wrong – The longer the forecast horizon the worst is the forecast – Aggregate forecasts are more accurate • The Risk Pooling Concept ©Copyright 2002 D. Simchi-Levi

A new Supply Chain Paradigm • A shift from a Push System. . . – Production decisions are based on forecast • …to a Push-Pull System ©Copyright 2002 D. Simchi-Levi

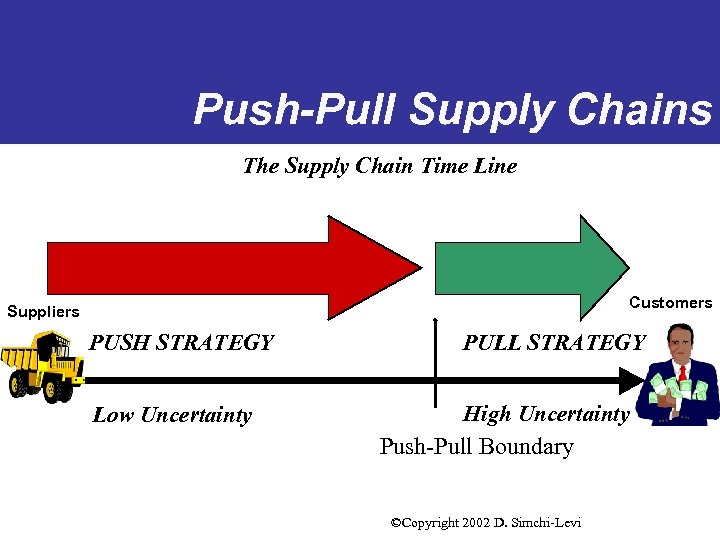

Push-Pull Supply Chains The Supply Chain Time Line Customers Suppliers PUSH STRATEGY Low Uncertainty PULL STRATEGY High Uncertainty Push-Pull Boundary ©Copyright 2002 D. Simchi-Levi

A new Supply Chain Paradigm • A shift from a Push System. . . – Production decisions are based on forecast • …to a Push-Pull System – Parts inventory is replenished based on forecasts – Assembly is based on accurate customer demand ©Copyright 2002 D. Simchi-Levi

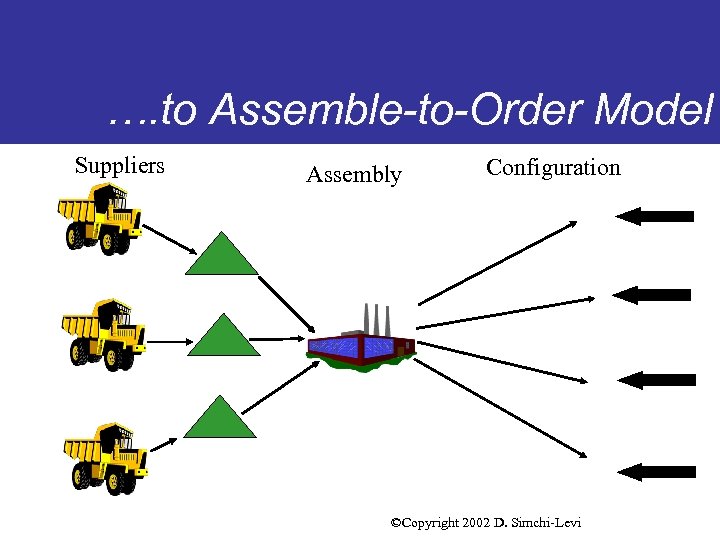

…. to Assemble-to-Order Model Suppliers Assembly Configuration ©Copyright 2002 D. Simchi-Levi

Business models in the Book Industry • From Push Systems. . . – Barnes and Noble • . . . To Pull Systems – Amazon. com, 1996 -1999 • And, finally to Push-Pull Systems – Amazon. com, 1999 -present • 7 warehouses, 3 M sq. ft. , ©Copyright 2002 D. Simchi-Levi

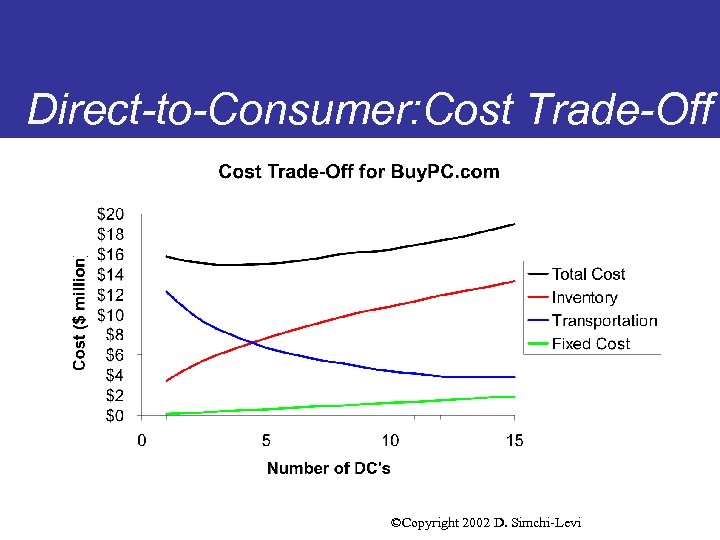

Direct-to-Consumer: Cost Trade-Off ©Copyright 2002 D. Simchi-Levi

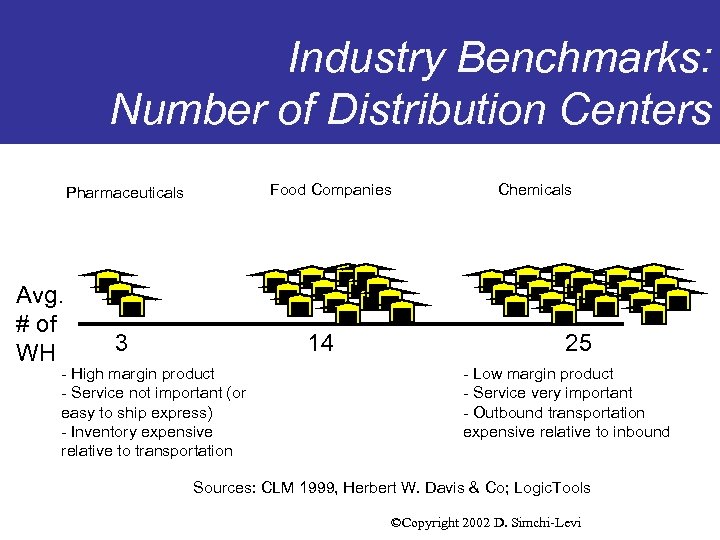

Industry Benchmarks: Number of Distribution Centers Food Companies Pharmaceuticals Avg. # of WH 3 14 - High margin product - Service not important (or easy to ship express) - Inventory expensive relative to transportation Chemicals 25 - Low margin product - Service very important - Outbound transportation expensive relative to inbound Sources: CLM 1999, Herbert W. Davis & Co; Logic. Tools ©Copyright 2002 D. Simchi-Levi

Business models in the Grocery Industry • From Push Systems. . . – Supermarket supply chain • . . . To Pull Systems – Peapod, 1989 -1999 • Stock outs 8% to 10% • And, finally to Push-Pull Systems – Peapod, 1999 -present • Dedicated warehouses • Stock outs less than 2% ©Copyright 2002 D. Simchi-Levi

Business models in the Grocery Industry • Key Challenges for e-grocer: – Transportation cost • Density of customers – Very short order cycle times • Less than 12 hours – Difficult to compete on cost • Must provide some added value such as convenience ©Copyright 2002 D. Simchi-Levi

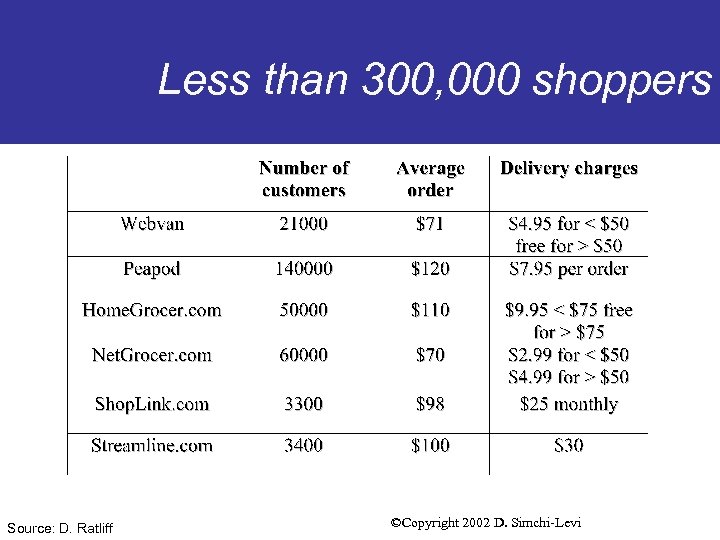

Less than 300, 000 shoppers Source: D. Ratliff ©Copyright 2002 D. Simchi-Levi

A New Type of Home Grocer • grocerystreet. com – On-line window for retailers – The on-line grocer picks products at the store – Customer can pick products at the store or pay for delivery ©Copyright 2002 D. Simchi-Levi

e-Business in the Retail Industry • Brick-&-Mortar companies establish Virtual retail stores – Wal-Mart, K-Mart, Barnes and Noble • Use a hybrid approach in stocking – High volume/fast moving products for local storage – Low volume/slow moving products for browsing and purchase on line • Channel Conflict Issues ©Copyright 2002 D. Simchi-Levi

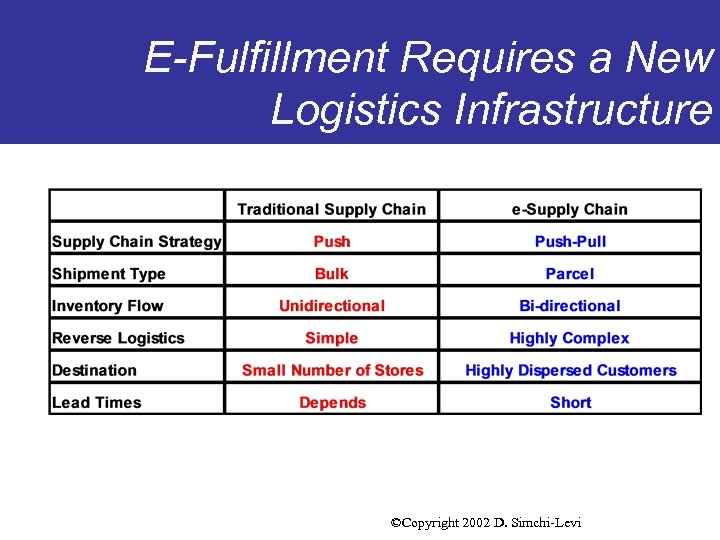

E-Fulfillment Requires a New Logistics Infrastructure ©Copyright 2002 D. Simchi-Levi

Wal-Mart’s e-fulfillment Strategy • Wal-Mart has always prided itself in its in-house distribution operations. • Thus, it was a huge surprise when the company announced that it plans to hire an outside firm to handle order fulfillment and warehousing for it’s online store Wal-Mart. com, which the retailer launched in the fall of 1999. • Filling orders behind the scenes of Wal-Mart’s cyberstore is Fingerhut Business Services. Fingerhut will provide Internet order fulfillment, warehousing, shipment, payment processing, customer service and merchandise returns. ©Copyright 2002 D. Simchi-Levi

E-Fulfillment • Is it a new concept? • What is the difference between on-line and catalogue selling? • Consider for instance Land’s End which has both channels ©Copyright 2002 D. Simchi-Levi

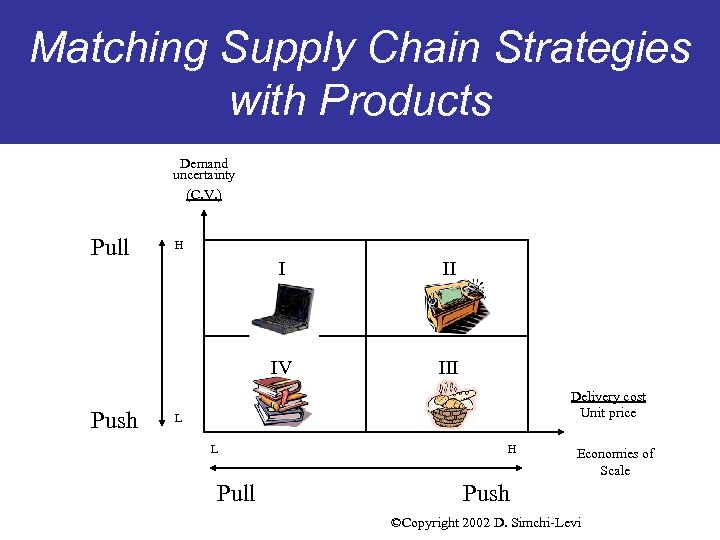

Matching Supply Chain Strategies with Products Demand uncertainty (C. V. ) Pull H I II Computer IV Push III Delivery cost Unit price L L Pull H Economies of Scale Push ©Copyright 2002 D. Simchi-Levi

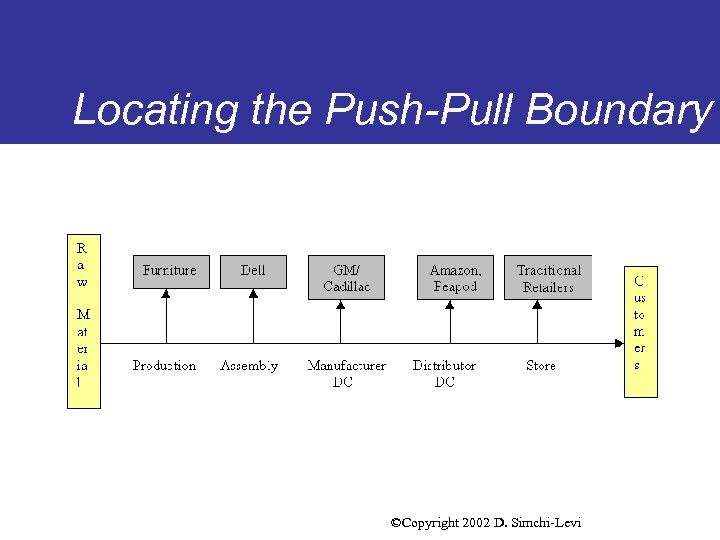

Locating the Push-Pull Boundary ©Copyright 2002 D. Simchi-Levi

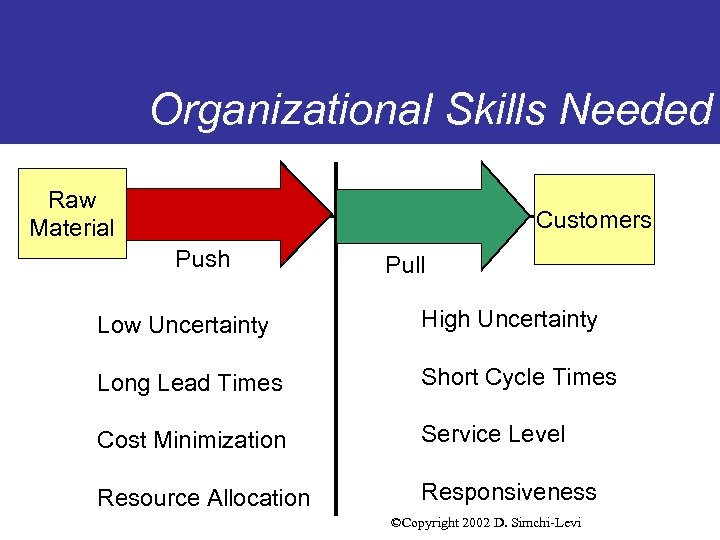

Organizational Skills Needed Raw Material Customers Push Pull Low Uncertainty High Uncertainty Long Lead Times Short Cycle Times Cost Minimization Service Level Resource Allocation Responsiveness ©Copyright 2002 D. Simchi-Levi

e-Business Opportunities: • Reduce Facility Costs – Eliminate retail/distributor sites • Reduce Inventory Costs – Apply the risk-pooling concept • Centralized stocking • Postponement of product differentiation • Use Dynamic Pricing Strategies to Improve Supply Chain Performance ©Copyright 2002 D. Simchi-Levi

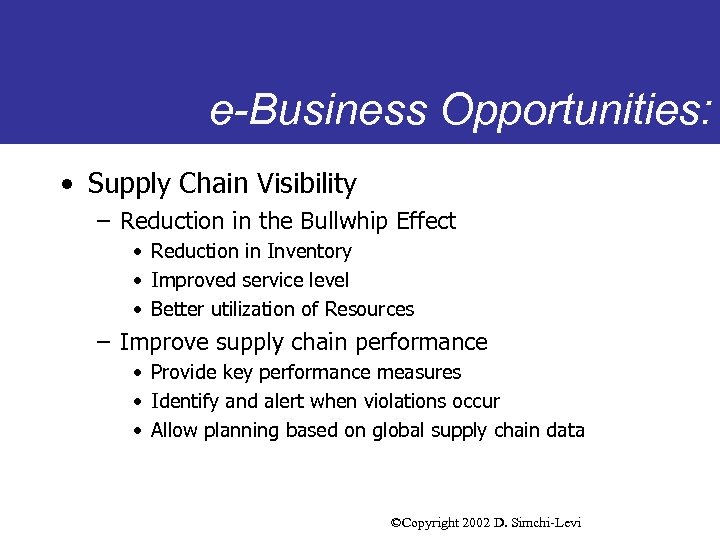

e-Business Opportunities: • Supply Chain Visibility – Reduction in the Bullwhip Effect • Reduction in Inventory • Improved service level • Better utilization of Resources – Improve supply chain performance • Provide key performance measures • Identify and alert when violations occur • Allow planning based on global supply chain data ©Copyright 2002 D. Simchi-Levi

©Copyright 2002 D. Simchi-Levi

1a2880f546f1ed56ffbe39c3b253c45f.ppt