da8a23cd983097932c9bf0393330adf0.ppt

- Количество слайдов: 40

Supply Chain Execution Systems Warehouse Management Systems Lecture Resource Adapted with permission from presentations by John Hill, © 2002, 2003 John M. Hill, ESYNC

Supply Chain Execution Systems Warehouse Management Systems Lecture Resource Adapted with permission from presentations by John Hill, © 2002, 2003 John M. Hill, ESYNC

Supply Chain Execution Systems (SCES) o o Manage inventory, space, material handling equipment, labor, and transportation resources in real time to assure timely, error-free fulfillment, delivery, and visibility of order status throughout the supply chain Matching material and information flow

Supply Chain Execution Systems (SCES) o o Manage inventory, space, material handling equipment, labor, and transportation resources in real time to assure timely, error-free fulfillment, delivery, and visibility of order status throughout the supply chain Matching material and information flow

SCES Impact Areas o o Fulfillment Delivery Visibility Responsiveness

SCES Impact Areas o o Fulfillment Delivery Visibility Responsiveness

Fulfillment and Delivery o o Material handling and controls n Right condition Auto. ID and data collection n Right material Supply chain execution systems n Right time People n Necessary for all of the above

Fulfillment and Delivery o o Material handling and controls n Right condition Auto. ID and data collection n Right material Supply chain execution systems n Right time People n Necessary for all of the above

Responsiveness o o The best decision making is executed on the basis of events as or before, not after, they occur Responsive logistics systems provide discipline and control that is based not only upon plans and performance goals, but also upon the dynamics of actual operations

Responsiveness o o The best decision making is executed on the basis of events as or before, not after, they occur Responsive logistics systems provide discipline and control that is based not only upon plans and performance goals, but also upon the dynamics of actual operations

SCES Components o o o Warehouse and Labor Management Transportation Management Yard Management International Trade Logistics Supply Chain Visibility and Event Management

SCES Components o o o Warehouse and Labor Management Transportation Management Yard Management International Trade Logistics Supply Chain Visibility and Event Management

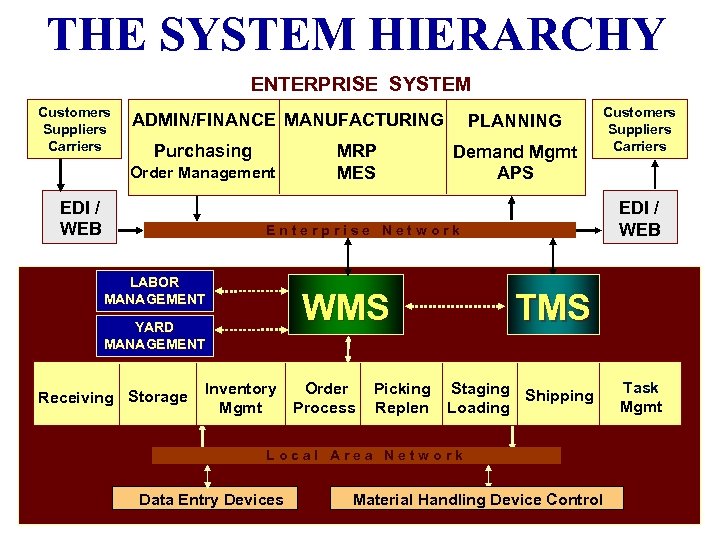

THE SYSTEM HIERARCHY ENTERPRISE SYSTEM Customers Suppliers Carriers ADMIN/FINANCE MANUFACTURING Purchasing Order Management EDI / WEB MRP MES PLANNING Demand Mgmt APS Customers Suppliers Carriers EDI / WEB Enterprise Network LABOR MANAGEMENT WMS YARD MANAGEMENT Receiving Storage Inventory Mgmt Order Process Picking Replen TMS Staging Shipping Loading Local Area Network Data Entry Devices Material Handling Device Control Task Mgmt

THE SYSTEM HIERARCHY ENTERPRISE SYSTEM Customers Suppliers Carriers ADMIN/FINANCE MANUFACTURING Purchasing Order Management EDI / WEB MRP MES PLANNING Demand Mgmt APS Customers Suppliers Carriers EDI / WEB Enterprise Network LABOR MANAGEMENT WMS YARD MANAGEMENT Receiving Storage Inventory Mgmt Order Process Picking Replen TMS Staging Shipping Loading Local Area Network Data Entry Devices Material Handling Device Control Task Mgmt

Warehouse Management Systems o Manages warehouse inventory, space, equipment, and labor resources to direct the flow of materials and information from receiving and putaway to light assembly, order picking, value-added processing and shipment

Warehouse Management Systems o Manages warehouse inventory, space, equipment, and labor resources to direct the flow of materials and information from receiving and putaway to light assembly, order picking, value-added processing and shipment

WMS History o o o o 1975: First WMS installed at J. C. Penney. 1986: First WMS installation in “C” on a UNIX platform. 1990’s: Hundreds of new stock locator & WMS systems; Windows NT platform emerges. 1995: MHIA WMS product section formed. 1999: First WMS company reaches annual revenues of $100 million. 2000: Expanded suites with TMS & SCV. Today: User-configurability & scalability remain key differentiators.

WMS History o o o o 1975: First WMS installed at J. C. Penney. 1986: First WMS installation in “C” on a UNIX platform. 1990’s: Hundreds of new stock locator & WMS systems; Windows NT platform emerges. 1995: MHIA WMS product section formed. 1999: First WMS company reaches annual revenues of $100 million. 2000: Expanded suites with TMS & SCV. Today: User-configurability & scalability remain key differentiators.

WMS Functions o Receiving n n n o Putaway n n n o Blind ASN/EDI Conventional or Automatic Dedicated, Random or Hybrid Location Selection: System or Operator Put Confirmation Picking and Shipping n n Pick by Order, Batch, Wave Pick Confirmation Shipping Check Lists Manifests, Bills of Lading

WMS Functions o Receiving n n n o Putaway n n n o Blind ASN/EDI Conventional or Automatic Dedicated, Random or Hybrid Location Selection: System or Operator Put Confirmation Picking and Shipping n n Pick by Order, Batch, Wave Pick Confirmation Shipping Check Lists Manifests, Bills of Lading

WMS Differentiators o o o Order Planning & Scheduling Unit of Measure Conversion Location Management / Slotting Inventory Allocation Shelf Life Monitoring Lot & Serial Number Tracking o o o o Cartonization Cycle Counting Replenishment & Consolidation Task Assignment & Monitoring Reverse Logistics Scalability & Configurability Upgrade Support

WMS Differentiators o o o Order Planning & Scheduling Unit of Measure Conversion Location Management / Slotting Inventory Allocation Shelf Life Monitoring Lot & Serial Number Tracking o o o o Cartonization Cycle Counting Replenishment & Consolidation Task Assignment & Monitoring Reverse Logistics Scalability & Configurability Upgrade Support

WMS Setup o Product Files n n n o Location Files n n o o Descriptions Dimensions Units of Measure Bills of Material Substitutions Numbering / Sequencing Dimensions / Capacity Equipment Files Employee Files

WMS Setup o Product Files n n n o Location Files n n o o Descriptions Dimensions Units of Measure Bills of Material Substitutions Numbering / Sequencing Dimensions / Capacity Equipment Files Employee Files

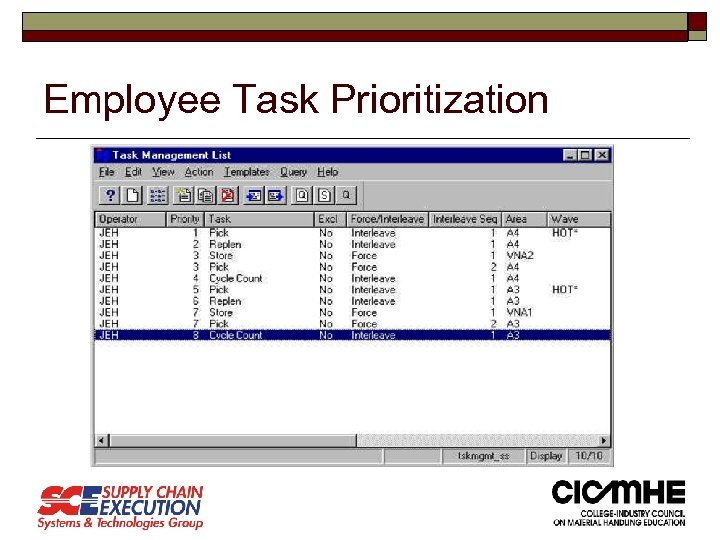

Employee Task Prioritization

Employee Task Prioritization

Workload Management o Equipment Profiles o Material Profiles o Location Profiles o Operator / Equipment Matrices o Operator / Task Priorities o Labor Standards

Workload Management o Equipment Profiles o Material Profiles o Location Profiles o Operator / Equipment Matrices o Operator / Task Priorities o Labor Standards

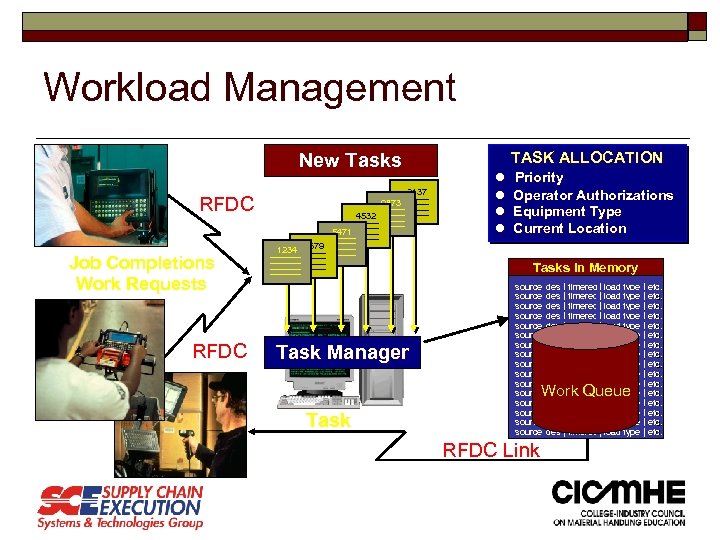

Workload Management TASK ALLOCATION New Tasks 2137 RFDC 9873 4532 5471 Job Completions Work Requests RFDC Priority Operator Authorizations Equipment Type Current Location 1234 3679 Tasks in Memory Task Manager source |dest | time- eq | load type | etc. req r source |dest | time- eq | load type | etc. req r Work Queue Task RFDC Link

Workload Management TASK ALLOCATION New Tasks 2137 RFDC 9873 4532 5471 Job Completions Work Requests RFDC Priority Operator Authorizations Equipment Type Current Location 1234 3679 Tasks in Memory Task Manager source |dest | time- eq | load type | etc. req r source |dest | time- eq | load type | etc. req r Work Queue Task RFDC Link

Material Handling Interfaces o o o o Conveyor Sortation Palletizer AGVs Pick (Pack)-To-Light Carousel AS/RS

Material Handling Interfaces o o o o Conveyor Sortation Palletizer AGVs Pick (Pack)-To-Light Carousel AS/RS

Systems Interfaces o o o o Purchasing Order Management MRP / MES Labor Standards / LMS Load Planning Freight Rating / TMS Slotting

Systems Interfaces o o o o Purchasing Order Management MRP / MES Labor Standards / LMS Load Planning Freight Rating / TMS Slotting

Receiving o o o o ASNs / Purchase Order Receiving Carrier Appointment Scheduling Pre-Tagged Receipts Blind (Unanticipated) Receipts Load Tagging/Labeling Quality Assurance Returns

Receiving o o o o ASNs / Purchase Order Receiving Carrier Appointment Scheduling Pre-Tagged Receipts Blind (Unanticipated) Receipts Load Tagging/Labeling Quality Assurance Returns

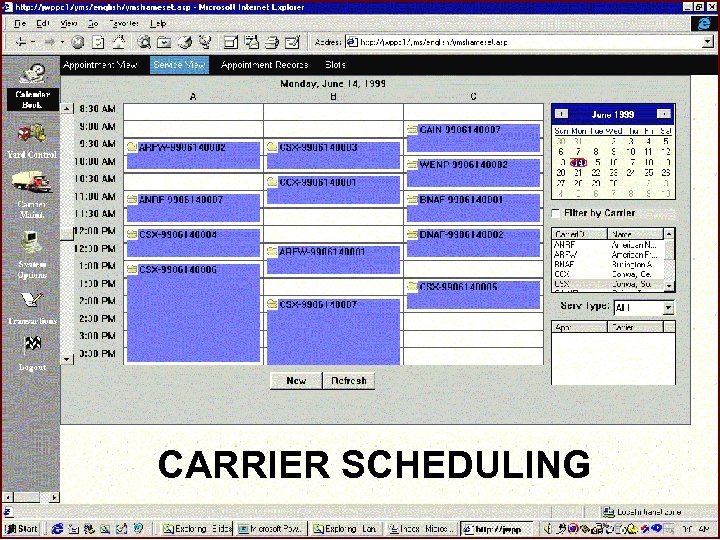

CARRIER SCHEDULING

CARRIER SCHEDULING

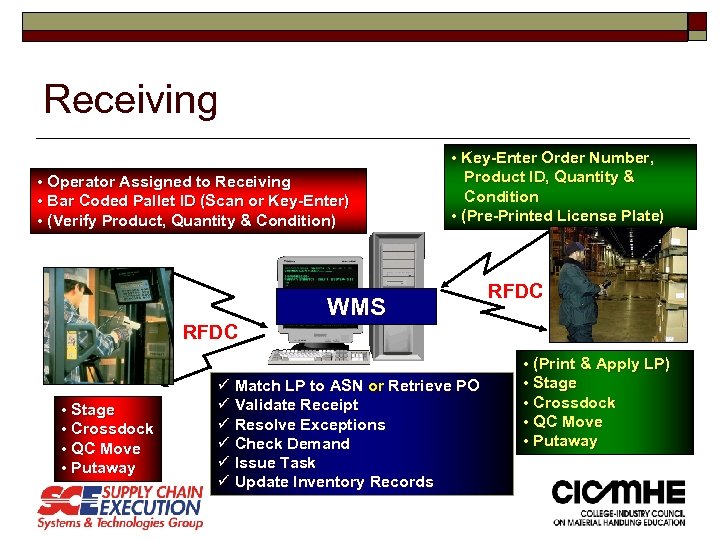

Receiving • Operator Assigned to Receiving • Bar Coded Pallet ID (Scan or Key-Enter) • (Verify Product, Quantity & Condition) RFDC • Stage • Crossdock • QC Move • Putaway • Key-Enter Order Number, Product ID, Quantity & Condition • (Pre-Printed License Plate) WMS ü Match LP to ASN or Retrieve PO ü Validate Receipt ü Resolve Exceptions ü Check Demand ü Issue Task ü Update Inventory Records RFDC • (Print & Apply LP) • Stage • Crossdock • QC Move • Putaway

Receiving • Operator Assigned to Receiving • Bar Coded Pallet ID (Scan or Key-Enter) • (Verify Product, Quantity & Condition) RFDC • Stage • Crossdock • QC Move • Putaway • Key-Enter Order Number, Product ID, Quantity & Condition • (Pre-Printed License Plate) WMS ü Match LP to ASN or Retrieve PO ü Validate Receipt ü Resolve Exceptions ü Check Demand ü Issue Task ü Update Inventory Records RFDC • (Print & Apply LP) • Stage • Crossdock • QC Move • Putaway

Reverse Logistics HOLIDAYS 2000 e. Sales: $6 Billion Returns: $900 Million Source: Biz. Rate. com Warehouse Wasteland or Competitive Edge?

Reverse Logistics HOLIDAYS 2000 e. Sales: $6 Billion Returns: $900 Million Source: Biz. Rate. com Warehouse Wasteland or Competitive Edge?

Storage and Putaway o o o Location Selection Override Location Confirmation Crossdocking Relocation Consolidation

Storage and Putaway o o o Location Selection Override Location Confirmation Crossdocking Relocation Consolidation

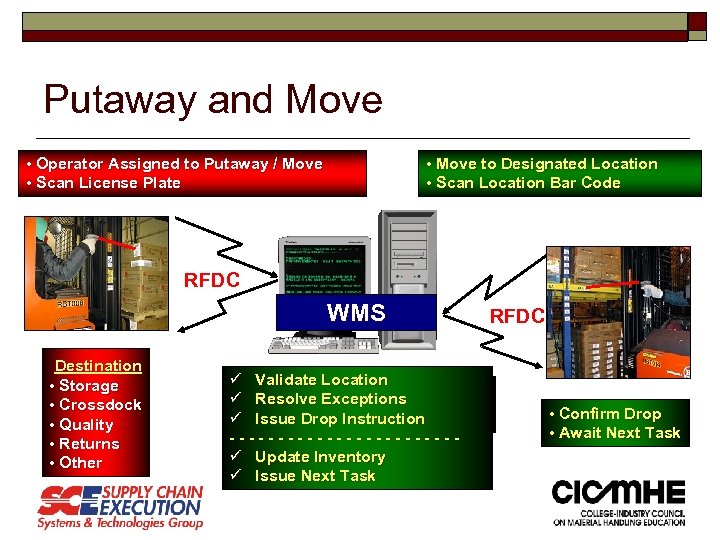

Putaway and Move • Operator Assigned to Putaway / Move • Scan License Plate • Move to Designated Location • Scan Location Bar Code RFDC WMS Destination • Storage • Crossdock • Quality • Returns • Other ü Validate Location ü Resolve Exceptions ü Check Demand for Product ü Issue Drop Instruction -ü -Issue -Move - - - - - Task ü Update Inventory ü Issue Next Task RFDC • Confirm Drop • Await Next Task

Putaway and Move • Operator Assigned to Putaway / Move • Scan License Plate • Move to Designated Location • Scan Location Bar Code RFDC WMS Destination • Storage • Crossdock • Quality • Returns • Other ü Validate Location ü Resolve Exceptions ü Check Demand for Product ü Issue Drop Instruction -ü -Issue -Move - - - - - Task ü Update Inventory ü Issue Next Task RFDC • Confirm Drop • Await Next Task

Inventory Management o Lot, Date Code, and Serial Number Tracking o Shelf-Life Monitoring and Rotation o Catch Weighing o Routine and Exception Cycle Counting o Full Physicals

Inventory Management o Lot, Date Code, and Serial Number Tracking o Shelf-Life Monitoring and Rotation o Catch Weighing o Routine and Exception Cycle Counting o Full Physicals

Replenishment o o o Forward Pick Locations Floating Forward Pick Replenishment Trigger Controls Demand Replenishment Batch Replenishment Reslotting

Replenishment o o o Forward Pick Locations Floating Forward Pick Replenishment Trigger Controls Demand Replenishment Batch Replenishment Reslotting

Pick Planning o o o Host Download Format and Frequency Wave and Batch Planning Material Allocation Order / Shipment Release Changes and Cancellations

Pick Planning o o o Host Download Format and Frequency Wave and Batch Planning Material Allocation Order / Shipment Release Changes and Cancellations

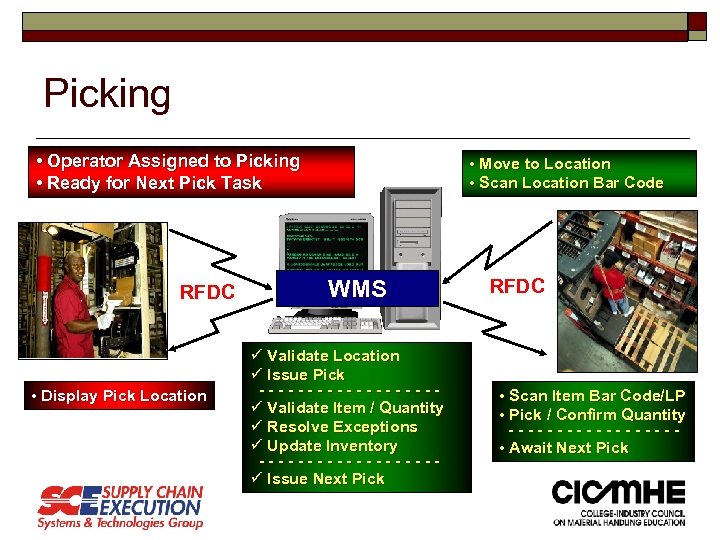

Picking • Operator Assigned to Picking • Ready for Next Pick Task RFDC • Display Pick Location • Move to Location • Scan Location Bar Code WMS ü Validate Location ü Issue Pick ---------ü Validate Item / Quantity ü Resolve Exceptions ü Update Inventory ---------ü Issue Next Pick RFDC • Scan Item Bar Code/LP • Pick / Confirm Quantity --------- • Await Next Pick

Picking • Operator Assigned to Picking • Ready for Next Pick Task RFDC • Display Pick Location • Move to Location • Scan Location Bar Code WMS ü Validate Location ü Issue Pick ---------ü Validate Item / Quantity ü Resolve Exceptions ü Update Inventory ---------ü Issue Next Pick RFDC • Scan Item Bar Code/LP • Pick / Confirm Quantity --------- • Await Next Pick

Staging and Shipping o o o o Trailer Scheduling / Processing Staging Location Management Staged Load Confirmation Door / Truck Verification Shipping Labels Manifests / Bills of Lading Shipment Confirmation

Staging and Shipping o o o o Trailer Scheduling / Processing Staging Location Management Staged Load Confirmation Door / Truck Verification Shipping Labels Manifests / Bills of Lading Shipment Confirmation

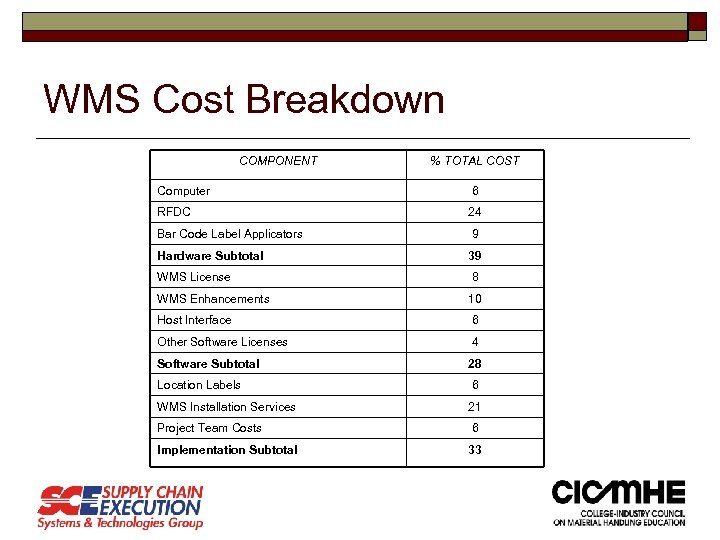

WMS Cost Breakdown COMPONENT % TOTAL COST Computer 6 RFDC 24 Bar Code Label Applicators 9 Hardware Subtotal 39 WMS License 8 WMS Enhancements 10 Host Interface 6 Other Software Licenses 4 Software Subtotal 28 Location Labels 6 WMS Installation Services 21 Project Team Costs 6 Implementation Subtotal 33

WMS Cost Breakdown COMPONENT % TOTAL COST Computer 6 RFDC 24 Bar Code Label Applicators 9 Hardware Subtotal 39 WMS License 8 WMS Enhancements 10 Host Interface 6 Other Software Licenses 4 Software Subtotal 28 Location Labels 6 WMS Installation Services 21 Project Team Costs 6 Implementation Subtotal 33

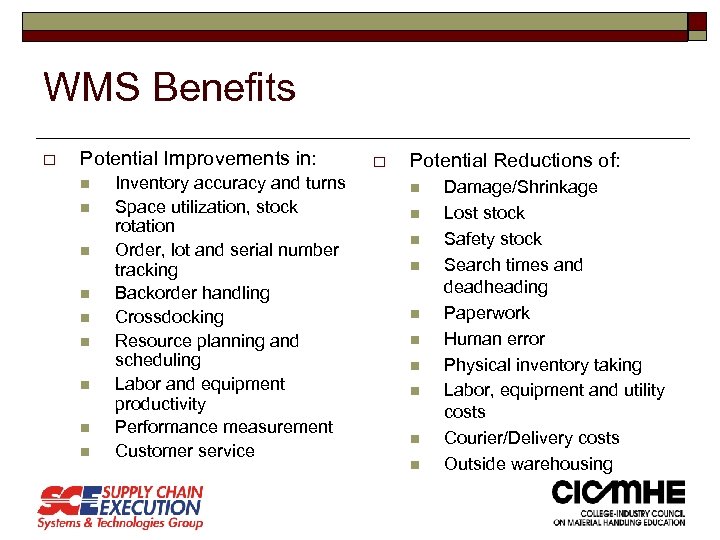

WMS Benefits o Potential Improvements in: n n n n n Inventory accuracy and turns Space utilization, stock rotation Order, lot and serial number tracking Backorder handling Crossdocking Resource planning and scheduling Labor and equipment productivity Performance measurement Customer service o Potential Reductions of: n n n n n Damage/Shrinkage Lost stock Safety stock Search times and deadheading Paperwork Human error Physical inventory taking Labor, equipment and utility costs Courier/Delivery costs Outside warehousing

WMS Benefits o Potential Improvements in: n n n n n Inventory accuracy and turns Space utilization, stock rotation Order, lot and serial number tracking Backorder handling Crossdocking Resource planning and scheduling Labor and equipment productivity Performance measurement Customer service o Potential Reductions of: n n n n n Damage/Shrinkage Lost stock Safety stock Search times and deadheading Paperwork Human error Physical inventory taking Labor, equipment and utility costs Courier/Delivery costs Outside warehousing

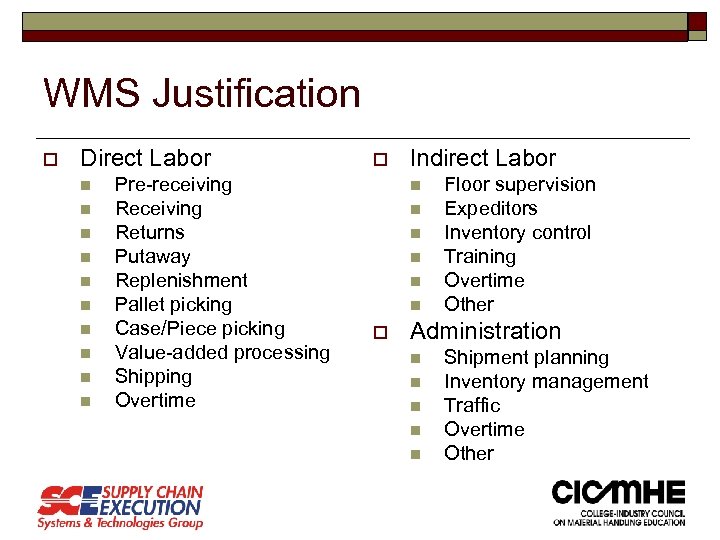

WMS Justification o Direct Labor n n n n n Pre-receiving Returns Putaway Replenishment Pallet picking Case/Piece picking Value-added processing Shipping Overtime o Indirect Labor n n n o Floor supervision Expeditors Inventory control Training Overtime Other Administration n n Shipment planning Inventory management Traffic Overtime Other

WMS Justification o Direct Labor n n n n n Pre-receiving Returns Putaway Replenishment Pallet picking Case/Piece picking Value-added processing Shipping Overtime o Indirect Labor n n n o Floor supervision Expeditors Inventory control Training Overtime Other Administration n n Shipment planning Inventory management Traffic Overtime Other

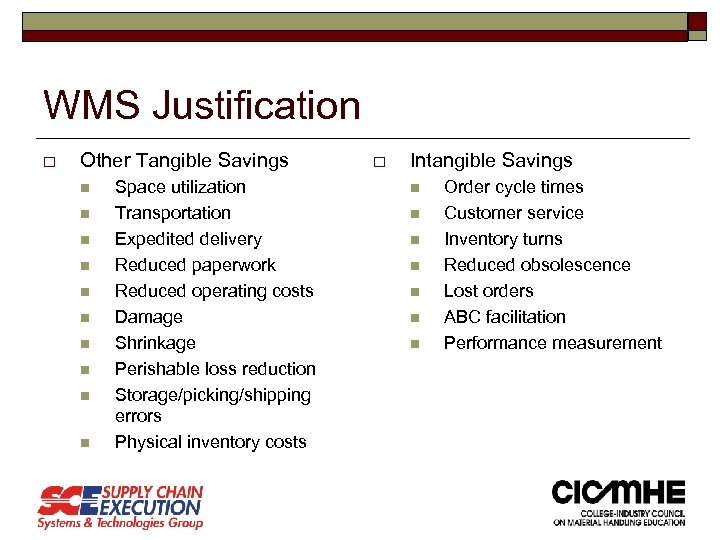

WMS Justification o Other Tangible Savings n n n n n Space utilization Transportation Expedited delivery Reduced paperwork Reduced operating costs Damage Shrinkage Perishable loss reduction Storage/picking/shipping errors Physical inventory costs o Intangible Savings n n n n Order cycle times Customer service Inventory turns Reduced obsolescence Lost orders ABC facilitation Performance measurement

WMS Justification o Other Tangible Savings n n n n n Space utilization Transportation Expedited delivery Reduced paperwork Reduced operating costs Damage Shrinkage Perishable loss reduction Storage/picking/shipping errors Physical inventory costs o Intangible Savings n n n n Order cycle times Customer service Inventory turns Reduced obsolescence Lost orders ABC facilitation Performance measurement

WMS Benchmarking o o Order Fulfillment Inventory Management Warehouse Productivity Transportation Performance

WMS Benchmarking o o Order Fulfillment Inventory Management Warehouse Productivity Transportation Performance

Order Fulfillment Measures o o o On-time Delivery Order Fill Rate Order Accuracy Line Accuracy Order Cycle Time Perfect Order Completion Percentage

Order Fulfillment Measures o o o On-time Delivery Order Fill Rate Order Accuracy Line Accuracy Order Cycle Time Perfect Order Completion Percentage

Inventory Management Measures o o o Inventory Accuracy Damaged Inventory Days On Hand Storage Utilization Dock to Stock Time Inventory Visibility

Inventory Management Measures o o o Inventory Accuracy Damaged Inventory Days On Hand Storage Utilization Dock to Stock Time Inventory Visibility

Warehouse Productivity Measures o o o Orders per Hour Lines per Hour Items per Hour Cost per Order Cost as % of Sales

Warehouse Productivity Measures o o o Orders per Hour Lines per Hour Items per Hour Cost per Order Cost as % of Sales

Transportation Performance Measures o o o o On-time Deliveries Damage Demurrage Cost Percentage Assessorials Cost Percentage Missed Appointments Percentage Freight Bill Accuracy Cost per Order Cost as % of Sales

Transportation Performance Measures o o o o On-time Deliveries Damage Demurrage Cost Percentage Assessorials Cost Percentage Missed Appointments Percentage Freight Bill Accuracy Cost per Order Cost as % of Sales

Creating a Responsive WMS o Use contemporary ADC technology and systems to assure n n n o Accurate execution of receiving, storage, and move tasks Error-free picking, replenishment, and shipping Traceability Provide seamless interfaces to other corporate systems to assure n Real-time visibility of inventory availability o n n o by SKU, quantity, lot number, serial number and shelf life by location Real-time order confirmation and status for customers Event-driven exception handling Facilitate a quick match of available resources to current and expected inbound, replenishment, and outbound workload n n Select the best operators and equipment for tasks based upon proximity, skill sets and priority Task operators to immediately store or cross-dock receipts

Creating a Responsive WMS o Use contemporary ADC technology and systems to assure n n n o Accurate execution of receiving, storage, and move tasks Error-free picking, replenishment, and shipping Traceability Provide seamless interfaces to other corporate systems to assure n Real-time visibility of inventory availability o n n o by SKU, quantity, lot number, serial number and shelf life by location Real-time order confirmation and status for customers Event-driven exception handling Facilitate a quick match of available resources to current and expected inbound, replenishment, and outbound workload n n Select the best operators and equipment for tasks based upon proximity, skill sets and priority Task operators to immediately store or cross-dock receipts

Creating a Responsive WMS o o o o o Support returns processing and reverse logistics Use task interleaving to minimize deadheading Improve order consolidation, wave planning, inventory allocation, and pick sequencing Identify consolidation opportunities to free space and reduce outside storage requirements Support bill of material, work order, and value-added processing Update inventory records as events occur Provide accuracy that allows replacement of full physicals with scheduled cycle counts Time stamp each transaction and identify the operator who performed it Provide feedback to the workforce and support performance measurement Measure supplier and carrier performance

Creating a Responsive WMS o o o o o Support returns processing and reverse logistics Use task interleaving to minimize deadheading Improve order consolidation, wave planning, inventory allocation, and pick sequencing Identify consolidation opportunities to free space and reduce outside storage requirements Support bill of material, work order, and value-added processing Update inventory records as events occur Provide accuracy that allows replacement of full physicals with scheduled cycle counts Time stamp each transaction and identify the operator who performed it Provide feedback to the workforce and support performance measurement Measure supplier and carrier performance

WMS Trends o o Further industry consolidation as well as alliances with enterprise systems providers Activity based costing and management Embedded profiling tools for space use analysis to facilitate relayout and inventory slotting Object-oriented tool kits for requirements modeling and WMS development

WMS Trends o o Further industry consolidation as well as alliances with enterprise systems providers Activity based costing and management Embedded profiling tools for space use analysis to facilitate relayout and inventory slotting Object-oriented tool kits for requirements modeling and WMS development