9ad4a5ec2928c7c261dbb58c9b26522a.ppt

- Количество слайдов: 29

Supply Chain Council & Supply Chain Operations Reference (SCOR) Model Overview Scott Stephens Chief Technology Officer Supply-Chain Council, Inc. 303 Freeport Road Pittsburgh, PA 15215 USA www. supply-chain. org Version 5. 0 a August, 2001

Supply Chain Council & Supply Chain Operations Reference (SCOR) Model Overview Scott Stephens Chief Technology Officer Supply-Chain Council, Inc. 303 Freeport Road Pittsburgh, PA 15215 USA www. supply-chain. org Version 5. 0 a August, 2001

Supply Chain Management – Changing Times Eighteen months ago – “boom” ® Central issues ® Revenue Capture ® Demand forecast ® Speed ® One month ago – “bust” ® Central Issues ® Cost ® Inventory ® Now – Uncertainty ® Emerging Issues ® Just-in-case vs. just-in-time ® Consumer confidence ® Supply chain management is now a watchword in business, Wall Street, and in the news media ® Version 5. 0 a August, 2001 2

Supply Chain Management – Changing Times Eighteen months ago – “boom” ® Central issues ® Revenue Capture ® Demand forecast ® Speed ® One month ago – “bust” ® Central Issues ® Cost ® Inventory ® Now – Uncertainty ® Emerging Issues ® Just-in-case vs. just-in-time ® Consumer confidence ® Supply chain management is now a watchword in business, Wall Street, and in the news media ® Version 5. 0 a August, 2001 2

Supply Chain Management & The Supply Chain Council Version 5. 0 a August, 2001

Supply Chain Management & The Supply Chain Council Version 5. 0 a August, 2001

• The SCC is an independent, not-for-profit, global corporation with membership open to all companies and organizations interested in applying and advancing state-of-the-art supply chain management systems and practices. • Over 700 Company Members • Cross-industry representation • Chapters in Australia/New Zealand, Europe, Japan, Korea, Latin America, and South East Asia with petitions for additional chapters pending. • Over 30 new members per month • The Supply-Chain Council (SCC) has developed and endorsed the Supply Chain Operations Reference-model (SCOR) as the crossindustry standard for supply chain management The SCC was organized in 1996 by Pittiglio Rabin Todd & Mc. Grath (PRTM) and Advanced Manufacturing Research (AMR), and initially included 69 voluntary member companies Version 5. 0 a August, 2001 4

• The SCC is an independent, not-for-profit, global corporation with membership open to all companies and organizations interested in applying and advancing state-of-the-art supply chain management systems and practices. • Over 700 Company Members • Cross-industry representation • Chapters in Australia/New Zealand, Europe, Japan, Korea, Latin America, and South East Asia with petitions for additional chapters pending. • Over 30 new members per month • The Supply-Chain Council (SCC) has developed and endorsed the Supply Chain Operations Reference-model (SCOR) as the crossindustry standard for supply chain management The SCC was organized in 1996 by Pittiglio Rabin Todd & Mc. Grath (PRTM) and Advanced Manufacturing Research (AMR), and initially included 69 voluntary member companies Version 5. 0 a August, 2001 4

SCC Organization - Chapters and Staffing Seoul, Korea Pittsburgh, PA Bayer Headquarters *Executive Director Korean Management Assoc. Tokyo, Japan Hitachi Mexico City, Latin America Singapore–South. East Asia Intel Sydney Australia / New Zealand – Accantia Version 5. 0 a August, 2001 EXEL Under Development: Hong Kong, India 5 Amsterdam. Europe Siemens

SCC Organization - Chapters and Staffing Seoul, Korea Pittsburgh, PA Bayer Headquarters *Executive Director Korean Management Assoc. Tokyo, Japan Hitachi Mexico City, Latin America Singapore–South. East Asia Intel Sydney Australia / New Zealand – Accantia Version 5. 0 a August, 2001 EXEL Under Development: Hong Kong, India 5 Amsterdam. Europe Siemens

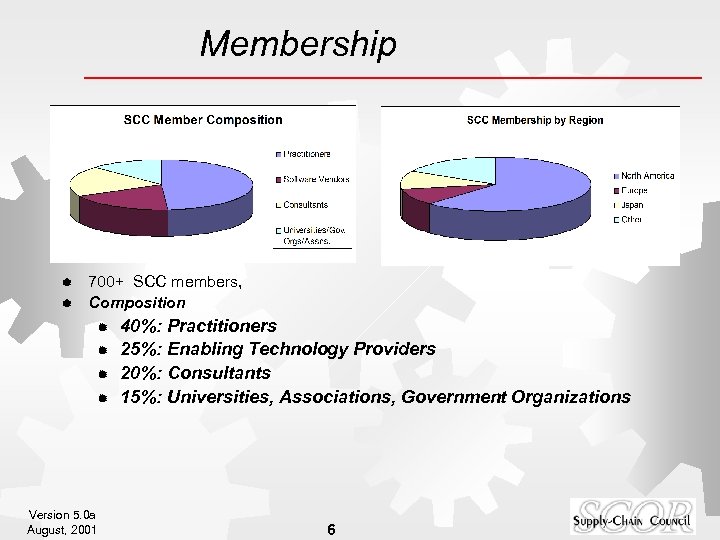

Membership 700+ SCC members, ® Composition ® ® ® Version 5. 0 a August, 2001 40%: Practitioners 25%: Enabling Technology Providers 20%: Consultants 15%: Universities, Associations, Government Organizations 6

Membership 700+ SCC members, ® Composition ® ® ® Version 5. 0 a August, 2001 40%: Practitioners 25%: Enabling Technology Providers 20%: Consultants 15%: Universities, Associations, Government Organizations 6

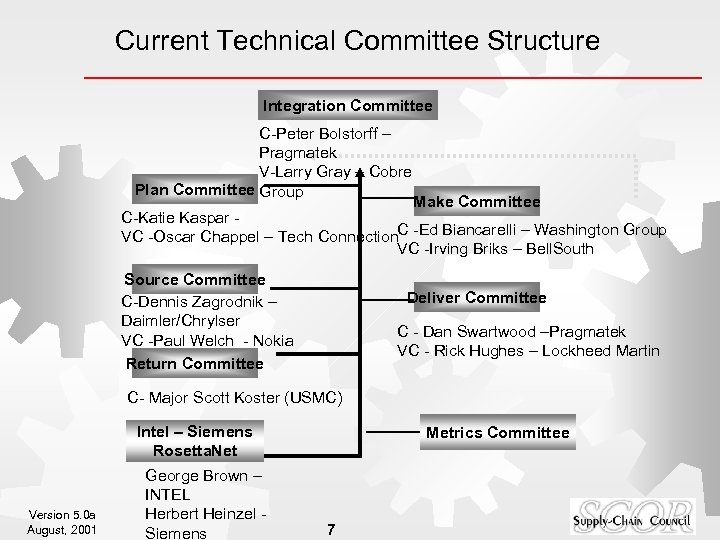

Current Technical Committee Structure Integration Committee C-Peter Bolstorff – Pragmatek V-Larry Gray – Cobre Plan Committee Group Make Committee C-Katie Kaspar - VC -Oscar Chappel – Tech Connection. C -Ed Biancarelli – Washington Group VC -Irving Briks – Bell. South Source Committee C-Dennis Zagrodnik – Daimler/Chrylser VC -Paul Welch - Nokia Return Committee Deliver Committee C - Dan Swartwood –Pragmatek VC - Rick Hughes – Lockheed Martin C- Major Scott Koster (USMC) Intel – Siemens Rosetta. Net Version 5. 0 a August, 2001 George Brown – INTEL Herbert Heinzel - Siemens Metrics Committee 7

Current Technical Committee Structure Integration Committee C-Peter Bolstorff – Pragmatek V-Larry Gray – Cobre Plan Committee Group Make Committee C-Katie Kaspar - VC -Oscar Chappel – Tech Connection. C -Ed Biancarelli – Washington Group VC -Irving Briks – Bell. South Source Committee C-Dennis Zagrodnik – Daimler/Chrylser VC -Paul Welch - Nokia Return Committee Deliver Committee C - Dan Swartwood –Pragmatek VC - Rick Hughes – Lockheed Martin C- Major Scott Koster (USMC) Intel – Siemens Rosetta. Net Version 5. 0 a August, 2001 George Brown – INTEL Herbert Heinzel - Siemens Metrics Committee 7

Supply-Chain Operations Reference-model (SCOR) Overview Version 5. 0 a August, 2001

Supply-Chain Operations Reference-model (SCOR) Overview Version 5. 0 a August, 2001

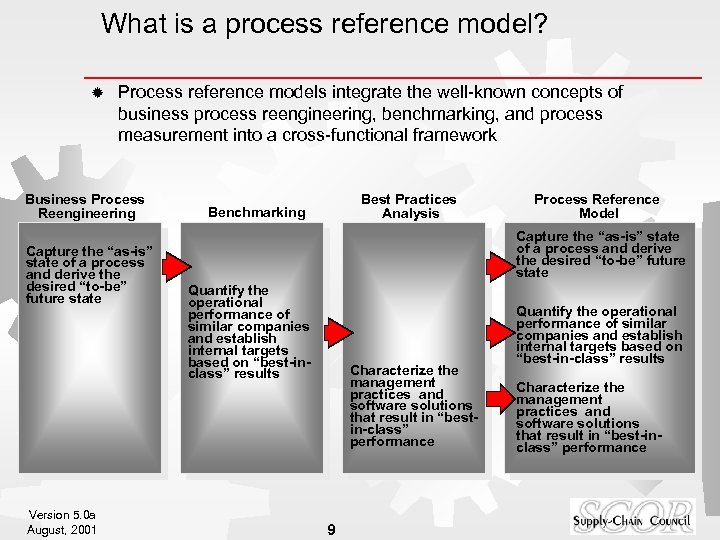

What is a process reference model? ® Process reference models integrate the well-known concepts of business process reengineering, benchmarking, and process measurement into a cross-functional framework Business Process Reengineering Capture the “as-is” state of a process and derive the desired “to-be” future state Version 5. 0 a August, 2001 Best Practices Analysis Benchmarking Process Reference Model Capture the “as-is” state of a process and derive the desired “to-be” future state Quantify the operational performance of similar companies and establish internal targets based on “best-inclass” results Characterize the management practices and software solutions that result in “bestin-class” performance 9 Quantify the operational performance of similar companies and establish internal targets based on “best-in-class” results Characterize the management practices and software solutions that result in “best-inclass” performance

What is a process reference model? ® Process reference models integrate the well-known concepts of business process reengineering, benchmarking, and process measurement into a cross-functional framework Business Process Reengineering Capture the “as-is” state of a process and derive the desired “to-be” future state Version 5. 0 a August, 2001 Best Practices Analysis Benchmarking Process Reference Model Capture the “as-is” state of a process and derive the desired “to-be” future state Quantify the operational performance of similar companies and establish internal targets based on “best-inclass” results Characterize the management practices and software solutions that result in “bestin-class” performance 9 Quantify the operational performance of similar companies and establish internal targets based on “best-in-class” results Characterize the management practices and software solutions that result in “best-inclass” performance

Version 5. 0 a August, 2001 10

Version 5. 0 a August, 2001 10

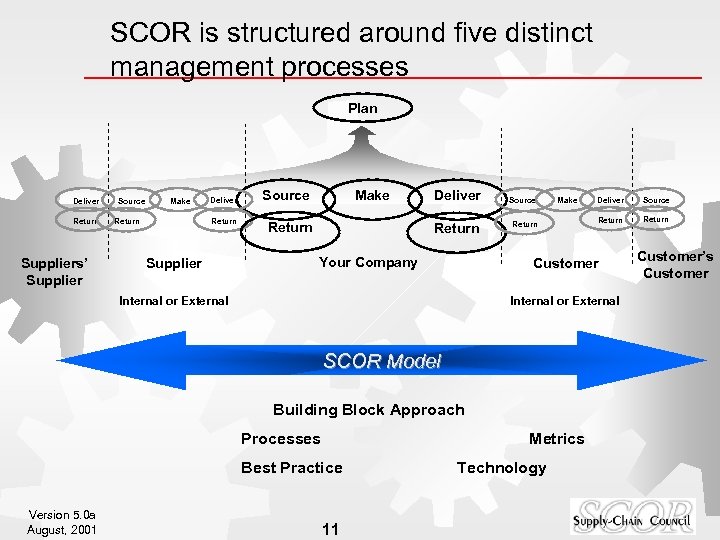

SCOR is structured around five distinct management processes Plan Deliver Return Suppliers’ Supplier Source Make Return Deliver Return Your Company Source Make Return Source Return Customer Internal or External SCOR Model Building Block Approach Processes Metrics Best Practice Version 5. 0 a August, 2001 Deliver 11 Technology Customer’s Customer

SCOR is structured around five distinct management processes Plan Deliver Return Suppliers’ Supplier Source Make Return Deliver Return Your Company Source Make Return Source Return Customer Internal or External SCOR Model Building Block Approach Processes Metrics Best Practice Version 5. 0 a August, 2001 Deliver 11 Technology Customer’s Customer

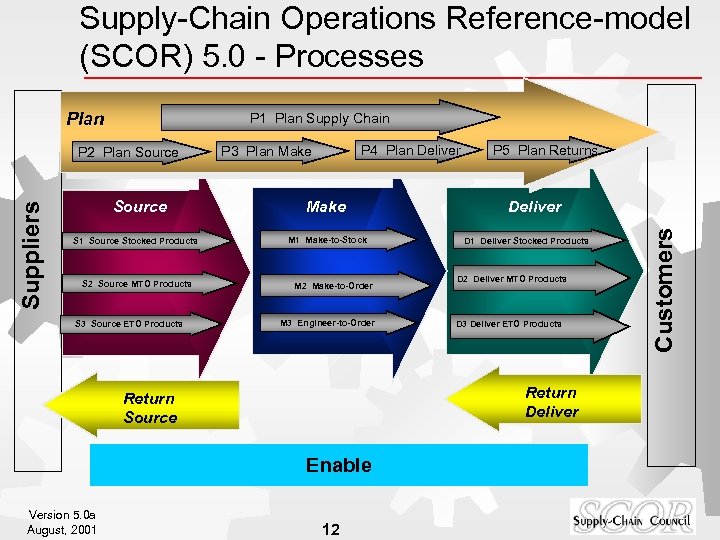

Supply-Chain Operations Reference-model (SCOR) 5. 0 - Processes Plan P 1 Plan Supply Chain Source S 1 Source Stocked Products S 2 Source MTO Products S 3 Source ETO Products P 4 Plan Deliver P 3 Plan Make M 1 Make-to-Stock M 2 Make-to-Order M 3 Engineer-to-Order Deliver D 1 Deliver Stocked Products D 2 Deliver MTO Products D 3 Deliver ETO Products Return Deliver Return Source Enable Version 5. 0 a August, 2001 P 5 Plan Returns 12 Customers Suppliers P 2 Plan Source

Supply-Chain Operations Reference-model (SCOR) 5. 0 - Processes Plan P 1 Plan Supply Chain Source S 1 Source Stocked Products S 2 Source MTO Products S 3 Source ETO Products P 4 Plan Deliver P 3 Plan Make M 1 Make-to-Stock M 2 Make-to-Order M 3 Engineer-to-Order Deliver D 1 Deliver Stocked Products D 2 Deliver MTO Products D 3 Deliver ETO Products Return Deliver Return Source Enable Version 5. 0 a August, 2001 P 5 Plan Returns 12 Customers Suppliers P 2 Plan Source

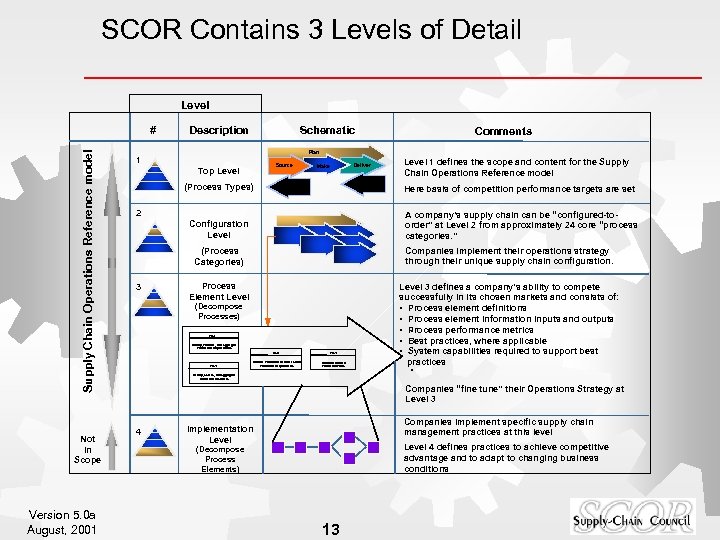

SCOR Contains 3 Levels of Detail Level Supply Chain Operations Reference model # Not in Scope Version 5. 0 a August, 2001 Description Schematic Comments Plan 1 Source Top Level (Process Types) Deliver Make Return 2 Level 1 defines the scope and content for the Supply Chain Operations Reference model Here basis of competition performance targets are set A company’s supply chain can be “configured-toorder” at Level 2 from approximately 24 core “process categories. ” Configuration Level (Process Categories) 3 Companies implement their operations strategy through their unique supply chain configuration. Process Element Level 3 defines a company’s ability to compete successfully in its chosen markets and consists of: • Process element definitions • Process element information inputs and outputs • Process performance metrics • • Best practices, where applicable • System capabilities required to support best practices • (Decompose Processes) P 3. 1 Identify, Prioritize, and Aggregate Production Requirements P 3. 3 P 3. 2 Balance Production Resources with Production Requirements P 3. 4 Establish Detailed Production Plans Identify, Assess, and Aggregate Production Resources Companies “fine tune” their Operations Strategy at Level 3 4 Companies implement specific supply chain management practices at this level Implementation Level 4 defines practices to achieve competitive advantage and to adapt to changing business conditions (Decompose Process Elements) 13

SCOR Contains 3 Levels of Detail Level Supply Chain Operations Reference model # Not in Scope Version 5. 0 a August, 2001 Description Schematic Comments Plan 1 Source Top Level (Process Types) Deliver Make Return 2 Level 1 defines the scope and content for the Supply Chain Operations Reference model Here basis of competition performance targets are set A company’s supply chain can be “configured-toorder” at Level 2 from approximately 24 core “process categories. ” Configuration Level (Process Categories) 3 Companies implement their operations strategy through their unique supply chain configuration. Process Element Level 3 defines a company’s ability to compete successfully in its chosen markets and consists of: • Process element definitions • Process element information inputs and outputs • Process performance metrics • • Best practices, where applicable • System capabilities required to support best practices • (Decompose Processes) P 3. 1 Identify, Prioritize, and Aggregate Production Requirements P 3. 3 P 3. 2 Balance Production Resources with Production Requirements P 3. 4 Establish Detailed Production Plans Identify, Assess, and Aggregate Production Resources Companies “fine tune” their Operations Strategy at Level 3 4 Companies implement specific supply chain management practices at this level Implementation Level 4 defines practices to achieve competitive advantage and to adapt to changing business conditions (Decompose Process Elements) 13

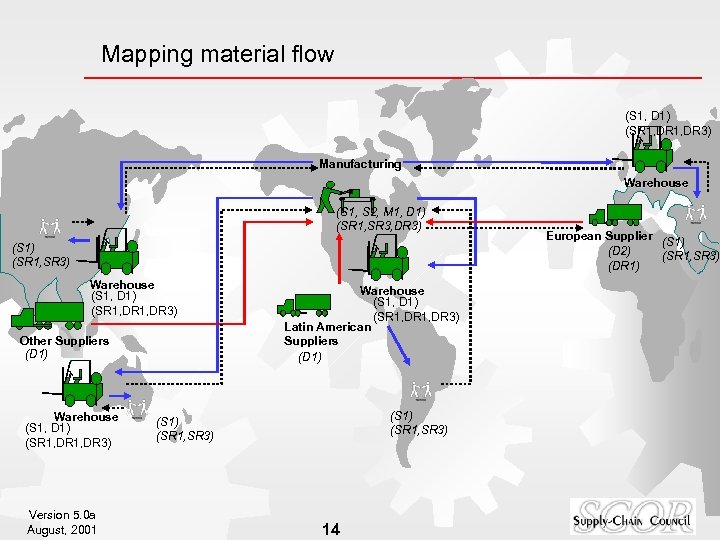

Mapping material flow (S 1, D 1) (SR 1, DR 3) Manufacturing Warehouse (S 1, S 2, M 1, D 1) (SR 1, SR 3, DR 3) (S 1) (SR 1, SR 3) Warehouse (S 1, D 1) (SR 1, DR 3) Other Suppliers (D 1) Warehouse (S 1, D 1) (SR 1, DR 3) Version 5. 0 a August, 2001 Warehouse (S 1, D 1) (SR 1, DR 3) Latin American Suppliers (D 1) (SR 1, SR 3) (S 1) (SR 1, SR 3) 14 European Supplier (S 1) (D 2) (SR 1, SR 3) (DR 1)

Mapping material flow (S 1, D 1) (SR 1, DR 3) Manufacturing Warehouse (S 1, S 2, M 1, D 1) (SR 1, SR 3, DR 3) (S 1) (SR 1, SR 3) Warehouse (S 1, D 1) (SR 1, DR 3) Other Suppliers (D 1) Warehouse (S 1, D 1) (SR 1, DR 3) Version 5. 0 a August, 2001 Warehouse (S 1, D 1) (SR 1, DR 3) Latin American Suppliers (D 1) (SR 1, SR 3) (S 1) (SR 1, SR 3) 14 European Supplier (S 1) (D 2) (SR 1, SR 3) (DR 1)

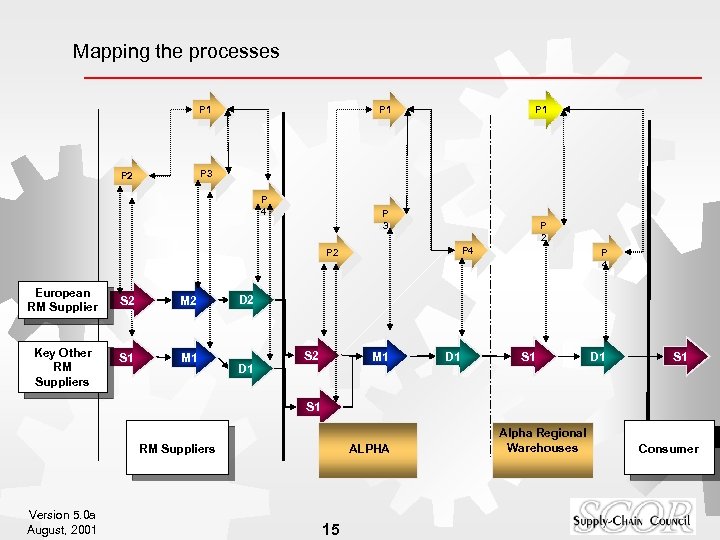

Mapping the processes P 1 P 1 P 3 P 2 P 4 P 2 European RM Supplier Key Other RM Suppliers S 2 M 2 S 1 M 1 P 4 D 2 D 1 S 2 M 1 D 1 S 1 S 1 RM Suppliers Version 5. 0 a August, 2001 ALPHA 15 Alpha Regional Warehouses Consumer

Mapping the processes P 1 P 1 P 3 P 2 P 4 P 2 European RM Supplier Key Other RM Suppliers S 2 M 2 S 1 M 1 P 4 D 2 D 1 S 2 M 1 D 1 S 1 S 1 RM Suppliers Version 5. 0 a August, 2001 ALPHA 15 Alpha Regional Warehouses Consumer

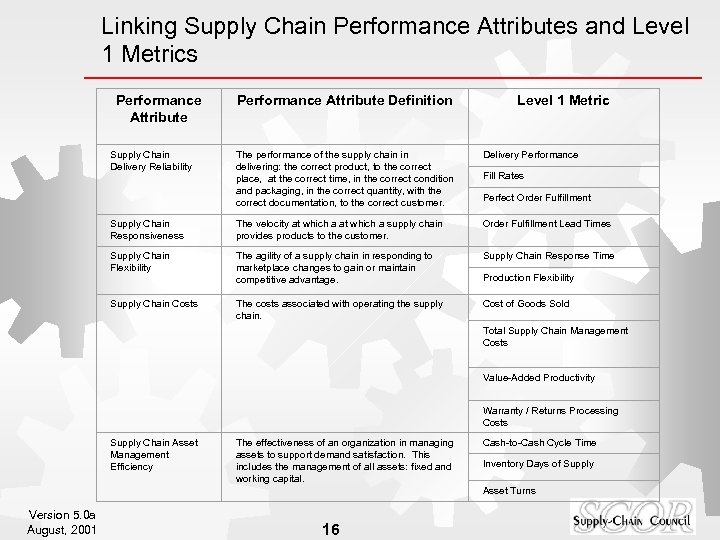

Linking Supply Chain Performance Attributes and Level 1 Metrics Performance Attribute Supply Chain Delivery Reliability Performance Attribute Definition Level 1 Metric The performance of the supply chain in delivering: the correct product, to the correct place, at the correct time, in the correct condition and packaging, in the correct quantity, with the correct documentation, to the correct customer. Delivery Performance Supply Chain Responsiveness The velocity at which a supply chain provides products to the customer. Order Fulfillment Lead Times Supply Chain Flexibility The agility of a supply chain in responding to marketplace changes to gain or maintain competitive advantage. Supply Chain Response Time Supply Chain Costs The costs associated with operating the supply chain. Cost of Goods Sold Fill Rates Perfect Order Fulfillment Production Flexibility Total Supply Chain Management Costs Value-Added Productivity Warranty / Returns Processing Costs Supply Chain Asset Management Efficiency Version 5. 0 a August, 2001 The effectiveness of an organization in managing assets to support demand satisfaction. This includes the management of all assets: fixed and working capital. 16 Cash-to-Cash Cycle Time Inventory Days of Supply Asset Turns

Linking Supply Chain Performance Attributes and Level 1 Metrics Performance Attribute Supply Chain Delivery Reliability Performance Attribute Definition Level 1 Metric The performance of the supply chain in delivering: the correct product, to the correct place, at the correct time, in the correct condition and packaging, in the correct quantity, with the correct documentation, to the correct customer. Delivery Performance Supply Chain Responsiveness The velocity at which a supply chain provides products to the customer. Order Fulfillment Lead Times Supply Chain Flexibility The agility of a supply chain in responding to marketplace changes to gain or maintain competitive advantage. Supply Chain Response Time Supply Chain Costs The costs associated with operating the supply chain. Cost of Goods Sold Fill Rates Perfect Order Fulfillment Production Flexibility Total Supply Chain Management Costs Value-Added Productivity Warranty / Returns Processing Costs Supply Chain Asset Management Efficiency Version 5. 0 a August, 2001 The effectiveness of an organization in managing assets to support demand satisfaction. This includes the management of all assets: fixed and working capital. 16 Cash-to-Cash Cycle Time Inventory Days of Supply Asset Turns

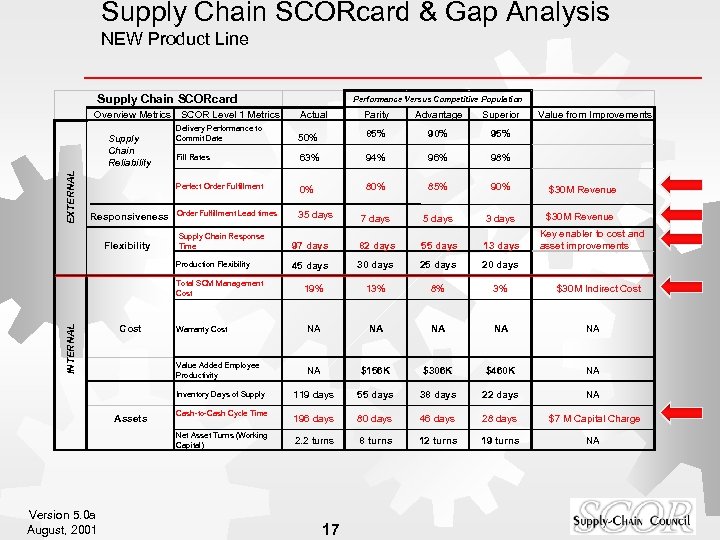

Supply Chain SCORcard & Gap Analysis NEW Product Line Supply Chain SCORcard Overview Metrics SCOR Level 1 Metrics Responsiveness Actual Parity Advantage Superior Delivery Performance to Commit Date 50% 85% 90% 95% Fill Rates 63% 94% 96% 98% Perfect Order Fulfillment Supply Chain Reliability EXTERNAL Performance Versus Competitive Population 0% 85% 90% Order Fulfillment Lead times 35 days 7 days 5 days 3 days Value from Improvements $30 M Revenue Key enabler to cost and asset improvements Supply Chain Response Time 97 days 82 days 55 days 13 days Production Flexibility 45 days 30 days 25 days 20 days 19% 13% 8% 3% Warranty Cost NA NA NA Value Added Employee Productivity NA $156 K $306 K $460 K NA Inventory Days of Supply Flexibility 119 days 55 days 38 days 22 days NA 196 days 80 days 46 days 28 days $7 M Capital Charge 2. 2 turns 8 turns 12 turns 19 turns NA INTERNAL Total SCM Management Cost Assets Cash-to-Cash Cycle Time Net Asset Turns (Working Capital) Version 5. 0 a August, 2001 17 $30 M Indirect Cost

Supply Chain SCORcard & Gap Analysis NEW Product Line Supply Chain SCORcard Overview Metrics SCOR Level 1 Metrics Responsiveness Actual Parity Advantage Superior Delivery Performance to Commit Date 50% 85% 90% 95% Fill Rates 63% 94% 96% 98% Perfect Order Fulfillment Supply Chain Reliability EXTERNAL Performance Versus Competitive Population 0% 85% 90% Order Fulfillment Lead times 35 days 7 days 5 days 3 days Value from Improvements $30 M Revenue Key enabler to cost and asset improvements Supply Chain Response Time 97 days 82 days 55 days 13 days Production Flexibility 45 days 30 days 25 days 20 days 19% 13% 8% 3% Warranty Cost NA NA NA Value Added Employee Productivity NA $156 K $306 K $460 K NA Inventory Days of Supply Flexibility 119 days 55 days 38 days 22 days NA 196 days 80 days 46 days 28 days $7 M Capital Charge 2. 2 turns 8 turns 12 turns 19 turns NA INTERNAL Total SCM Management Cost Assets Cash-to-Cash Cycle Time Net Asset Turns (Working Capital) Version 5. 0 a August, 2001 17 $30 M Indirect Cost

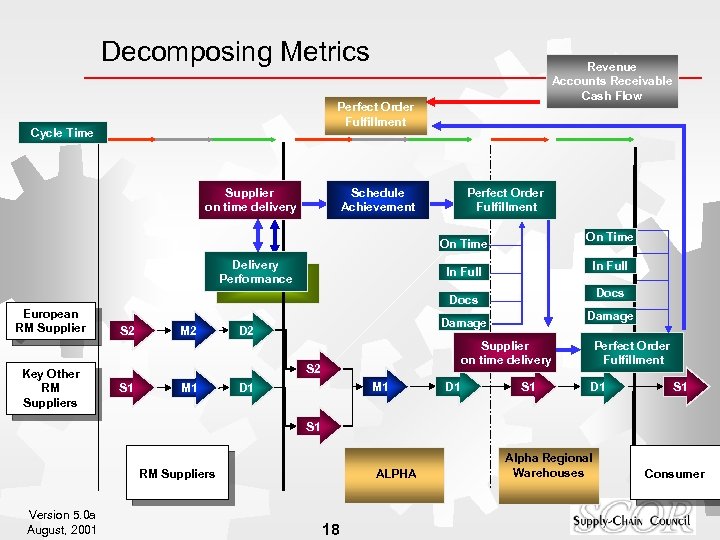

Decomposing Metrics Revenue Accounts Receivable Cash Flow Perfect Order Fulfillment Cycle Time Supplier on time delivery Schedule Achievement Perfect Order Fulfillment On Time Delivery Performance In Full Docs European RM Supplier Key Other RM Suppliers S 2 M 2 Supplier on time delivery S 2 S 1 M 1 Damage D 2 M 1 D 1 S 1 Perfect Order Fulfillment D 1 S 1 RM Suppliers Version 5. 0 a August, 2001 ALPHA 18 Alpha Regional Warehouses Consumer

Decomposing Metrics Revenue Accounts Receivable Cash Flow Perfect Order Fulfillment Cycle Time Supplier on time delivery Schedule Achievement Perfect Order Fulfillment On Time Delivery Performance In Full Docs European RM Supplier Key Other RM Suppliers S 2 M 2 Supplier on time delivery S 2 S 1 M 1 Damage D 2 M 1 D 1 S 1 Perfect Order Fulfillment D 1 S 1 RM Suppliers Version 5. 0 a August, 2001 ALPHA 18 Alpha Regional Warehouses Consumer

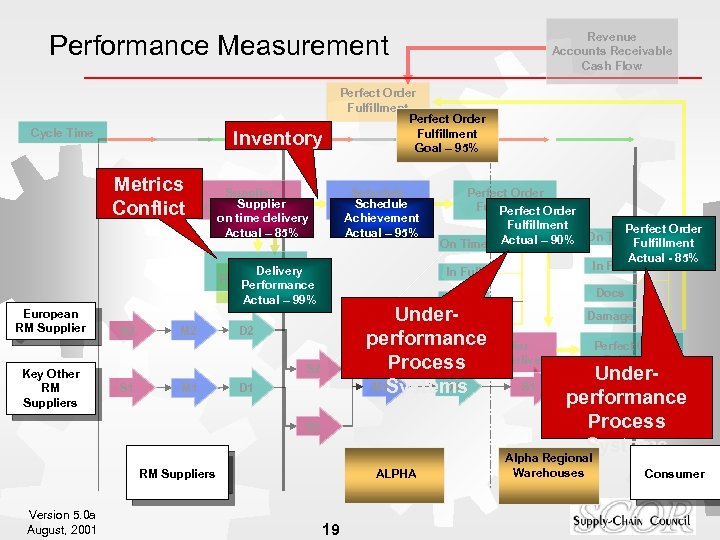

Performance Measurement Cycle Time Inventory Metrics Conflict Perfect Order Fulfillment Goal – 95% Supplier on time delivery Actual – 85% Schedule Achievement Actual – 95% Delivery Performance Actual – 99% European RM Supplier Key Other RM Suppliers S 2 M 1 On Time Fulfillment Perfect Order Actual – 90% On Time. Fulfillment In Full Under. Damage performance Supplier on time delivery Process D 1 M 1 Systems D 2 D 1 RM Suppliers ALPHA 19 Actual - 85% Docs S 1 Version 5. 0 a August, 2001 Perfect Order Fulfillment Order Perfect In Full S 2 S 1 Revenue Accounts Receivable Cash Flow Damage Perfect Order Fulfillment Under. S 1 performance Process Systems D 1 Alpha Regional Warehouses Consumer

Performance Measurement Cycle Time Inventory Metrics Conflict Perfect Order Fulfillment Goal – 95% Supplier on time delivery Actual – 85% Schedule Achievement Actual – 95% Delivery Performance Actual – 99% European RM Supplier Key Other RM Suppliers S 2 M 1 On Time Fulfillment Perfect Order Actual – 90% On Time. Fulfillment In Full Under. Damage performance Supplier on time delivery Process D 1 M 1 Systems D 2 D 1 RM Suppliers ALPHA 19 Actual - 85% Docs S 1 Version 5. 0 a August, 2001 Perfect Order Fulfillment Order Perfect In Full S 2 S 1 Revenue Accounts Receivable Cash Flow Damage Perfect Order Fulfillment Under. S 1 performance Process Systems D 1 Alpha Regional Warehouses Consumer

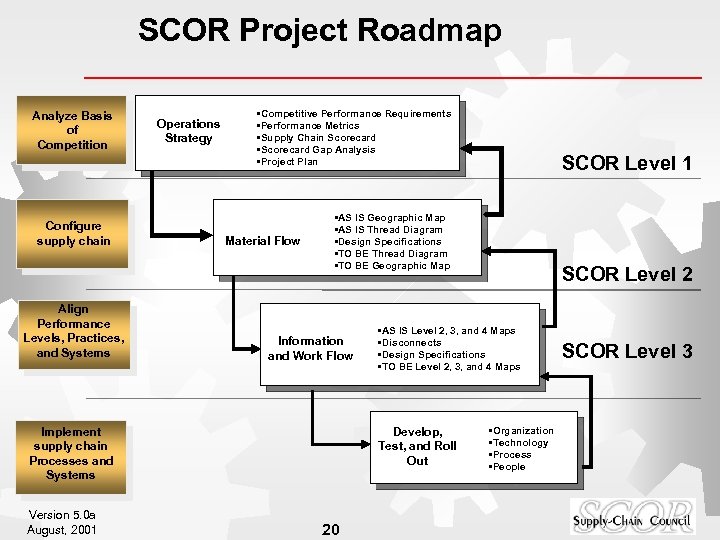

SCOR Project Roadmap Analyze Basis of Competition Configure supply chain Align Performance Levels, Practices, and Systems Operations Strategy • Competitive Performance Requirements • Performance Metrics • Supply Chain Scorecard • Scorecard Gap Analysis • Project Plan Material Flow • AS IS Geographic Map • AS IS Thread Diagram • Design Specifications • TO BE Thread Diagram • TO BE Geographic Map Information and Work Flow Implement supply chain Processes and Systems Version 5. 0 a August, 2001 SCOR Level 1 • AS IS Level 2, 3, and 4 Maps • Disconnects • Design Specifications • TO BE Level 2, 3, and 4 Maps Develop, Test, and Roll Out 20 SCOR Level 2 • Organization • Technology • Process • People SCOR Level 3

SCOR Project Roadmap Analyze Basis of Competition Configure supply chain Align Performance Levels, Practices, and Systems Operations Strategy • Competitive Performance Requirements • Performance Metrics • Supply Chain Scorecard • Scorecard Gap Analysis • Project Plan Material Flow • AS IS Geographic Map • AS IS Thread Diagram • Design Specifications • TO BE Thread Diagram • TO BE Geographic Map Information and Work Flow Implement supply chain Processes and Systems Version 5. 0 a August, 2001 SCOR Level 1 • AS IS Level 2, 3, and 4 Maps • Disconnects • Design Specifications • TO BE Level 2, 3, and 4 Maps Develop, Test, and Roll Out 20 SCOR Level 2 • Organization • Technology • Process • People SCOR Level 3

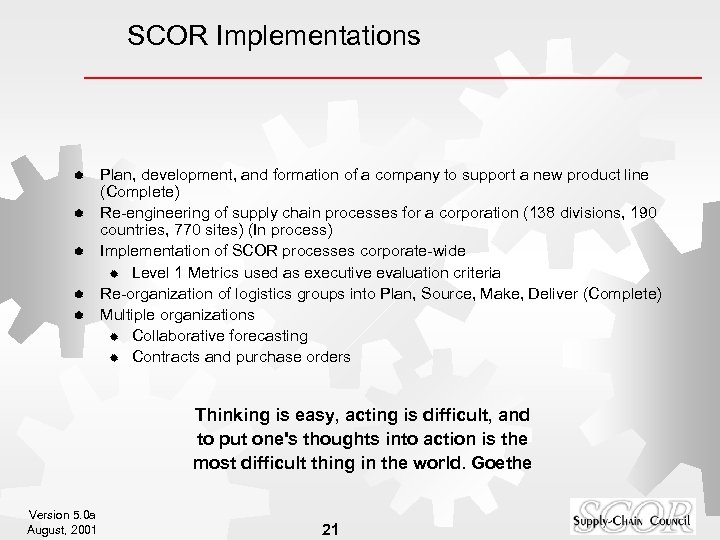

SCOR Implementations ® ® ® Plan, development, and formation of a company to support a new product line (Complete) Re-engineering of supply chain processes for a corporation (138 divisions, 190 countries, 770 sites) (In process) Implementation of SCOR processes corporate-wide ® Level 1 Metrics used as executive evaluation criteria Re-organization of logistics groups into Plan, Source, Make, Deliver (Complete) Multiple organizations ® Collaborative forecasting ® Contracts and purchase orders Thinking is easy, acting is difficult, and to put one's thoughts into action is the most difficult thing in the world. Goethe Version 5. 0 a August, 2001 21

SCOR Implementations ® ® ® Plan, development, and formation of a company to support a new product line (Complete) Re-engineering of supply chain processes for a corporation (138 divisions, 190 countries, 770 sites) (In process) Implementation of SCOR processes corporate-wide ® Level 1 Metrics used as executive evaluation criteria Re-organization of logistics groups into Plan, Source, Make, Deliver (Complete) Multiple organizations ® Collaborative forecasting ® Contracts and purchase orders Thinking is easy, acting is difficult, and to put one's thoughts into action is the most difficult thing in the world. Goethe Version 5. 0 a August, 2001 21

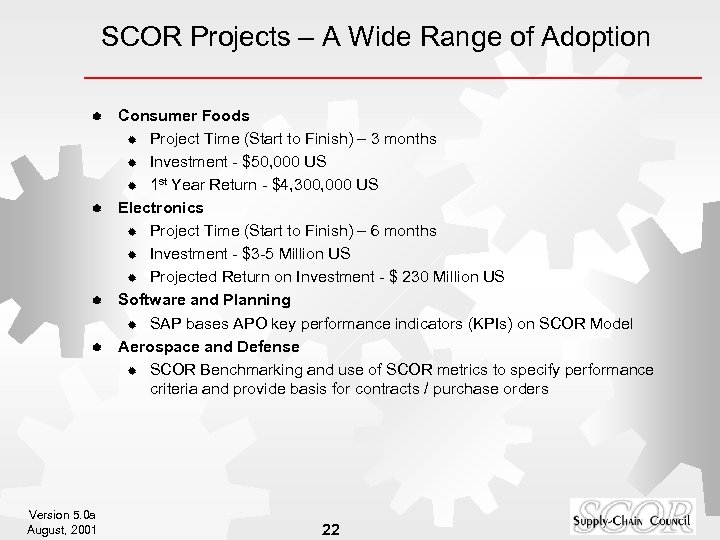

SCOR Projects – A Wide Range of Adoption Consumer Foods ® Project Time (Start to Finish) – 3 months ® Investment - $50, 000 US ® 1 st Year Return - $4, 300, 000 US ® Electronics ® Project Time (Start to Finish) – 6 months ® Investment - $3 -5 Million US ® Projected Return on Investment - $ 230 Million US ® Software and Planning ® SAP bases APO key performance indicators (KPIs) on SCOR Model ® Aerospace and Defense ® SCOR Benchmarking and use of SCOR metrics to specify performance criteria and provide basis for contracts / purchase orders ® Version 5. 0 a August, 2001 22

SCOR Projects – A Wide Range of Adoption Consumer Foods ® Project Time (Start to Finish) – 3 months ® Investment - $50, 000 US ® 1 st Year Return - $4, 300, 000 US ® Electronics ® Project Time (Start to Finish) – 6 months ® Investment - $3 -5 Million US ® Projected Return on Investment - $ 230 Million US ® Software and Planning ® SAP bases APO key performance indicators (KPIs) on SCOR Model ® Aerospace and Defense ® SCOR Benchmarking and use of SCOR metrics to specify performance criteria and provide basis for contracts / purchase orders ® Version 5. 0 a August, 2001 22

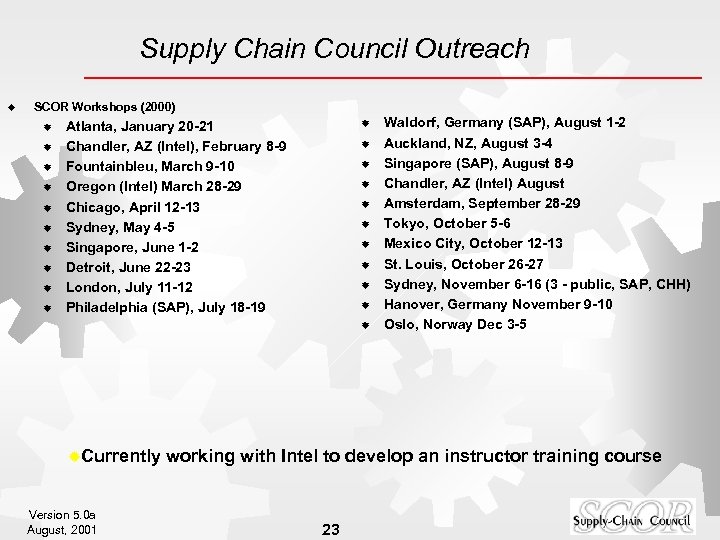

Supply Chain Council Outreach ® SCOR Workshops (2000) ® ® ® Atlanta, January 20 -21 Chandler, AZ (Intel), February 8 -9 Fountainbleu, March 9 -10 Oregon (Intel) March 28 -29 Chicago, April 12 -13 Sydney, May 4 -5 Singapore, June 1 -2 Detroit, June 22 -23 London, July 11 -12 Philadelphia (SAP), July 18 -19 ® ® ®Currently Version 5. 0 a August, 2001 Waldorf, Germany (SAP), August 1 -2 Auckland, NZ, August 3 -4 Singapore (SAP), August 8 -9 Chandler, AZ (Intel) August Amsterdam, September 28 -29 Tokyo, October 5 -6 Mexico City, October 12 -13 St. Louis, October 26 -27 Sydney, November 6 -16 (3 - public, SAP, CHH) Hanover, Germany November 9 -10 Oslo, Norway Dec 3 -5 working with Intel to develop an instructor training course 23

Supply Chain Council Outreach ® SCOR Workshops (2000) ® ® ® Atlanta, January 20 -21 Chandler, AZ (Intel), February 8 -9 Fountainbleu, March 9 -10 Oregon (Intel) March 28 -29 Chicago, April 12 -13 Sydney, May 4 -5 Singapore, June 1 -2 Detroit, June 22 -23 London, July 11 -12 Philadelphia (SAP), July 18 -19 ® ® ®Currently Version 5. 0 a August, 2001 Waldorf, Germany (SAP), August 1 -2 Auckland, NZ, August 3 -4 Singapore (SAP), August 8 -9 Chandler, AZ (Intel) August Amsterdam, September 28 -29 Tokyo, October 5 -6 Mexico City, October 12 -13 St. Louis, October 26 -27 Sydney, November 6 -16 (3 - public, SAP, CHH) Hanover, Germany November 9 -10 Oslo, Norway Dec 3 -5 working with Intel to develop an instructor training course 23

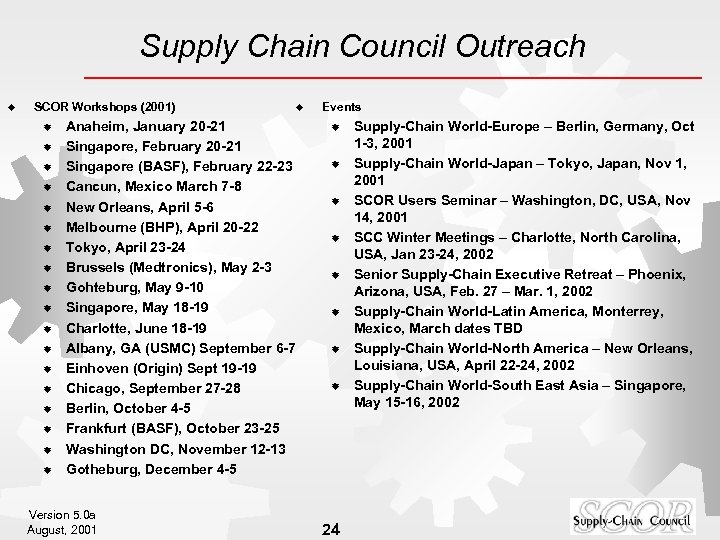

Supply Chain Council Outreach ® SCOR Workshops (2001) ® ® ® ® ® Anaheim, January 20 -21 Singapore, February 20 -21 Singapore (BASF), February 22 -23 Cancun, Mexico March 7 -8 New Orleans, April 5 -6 Melbourne (BHP), April 20 -22 Tokyo, April 23 -24 Brussels (Medtronics), May 2 -3 Gohteburg, May 9 -10 Singapore, May 18 -19 Charlotte, June 18 -19 Albany, GA (USMC) September 6 -7 Einhoven (Origin) Sept 19 -19 Chicago, September 27 -28 Berlin, October 4 -5 Frankfurt (BASF), October 23 -25 Washington DC, November 12 -13 Gotheburg, December 4 -5 Version 5. 0 a August, 2001 Events ® ® ® ® 24 Supply-Chain World-Europe – Berlin, Germany, Oct 1 -3, 2001 Supply-Chain World-Japan – Tokyo, Japan, Nov 1, 2001 SCOR Users Seminar – Washington, DC, USA, Nov 14, 2001 SCC Winter Meetings – Charlotte, North Carolina, USA, Jan 23 -24, 2002 Senior Supply-Chain Executive Retreat – Phoenix, Arizona, USA, Feb. 27 – Mar. 1, 2002 Supply-Chain World-Latin America, Monterrey, Mexico, March dates TBD Supply-Chain World-North America – New Orleans, Louisiana, USA, April 22 -24, 2002 Supply-Chain World-South East Asia – Singapore, May 15 -16, 2002

Supply Chain Council Outreach ® SCOR Workshops (2001) ® ® ® ® ® Anaheim, January 20 -21 Singapore, February 20 -21 Singapore (BASF), February 22 -23 Cancun, Mexico March 7 -8 New Orleans, April 5 -6 Melbourne (BHP), April 20 -22 Tokyo, April 23 -24 Brussels (Medtronics), May 2 -3 Gohteburg, May 9 -10 Singapore, May 18 -19 Charlotte, June 18 -19 Albany, GA (USMC) September 6 -7 Einhoven (Origin) Sept 19 -19 Chicago, September 27 -28 Berlin, October 4 -5 Frankfurt (BASF), October 23 -25 Washington DC, November 12 -13 Gotheburg, December 4 -5 Version 5. 0 a August, 2001 Events ® ® ® ® 24 Supply-Chain World-Europe – Berlin, Germany, Oct 1 -3, 2001 Supply-Chain World-Japan – Tokyo, Japan, Nov 1, 2001 SCOR Users Seminar – Washington, DC, USA, Nov 14, 2001 SCC Winter Meetings – Charlotte, North Carolina, USA, Jan 23 -24, 2002 Senior Supply-Chain Executive Retreat – Phoenix, Arizona, USA, Feb. 27 – Mar. 1, 2002 Supply-Chain World-Latin America, Monterrey, Mexico, March dates TBD Supply-Chain World-North America – New Orleans, Louisiana, USA, April 22 -24, 2002 Supply-Chain World-South East Asia – Singapore, May 15 -16, 2002

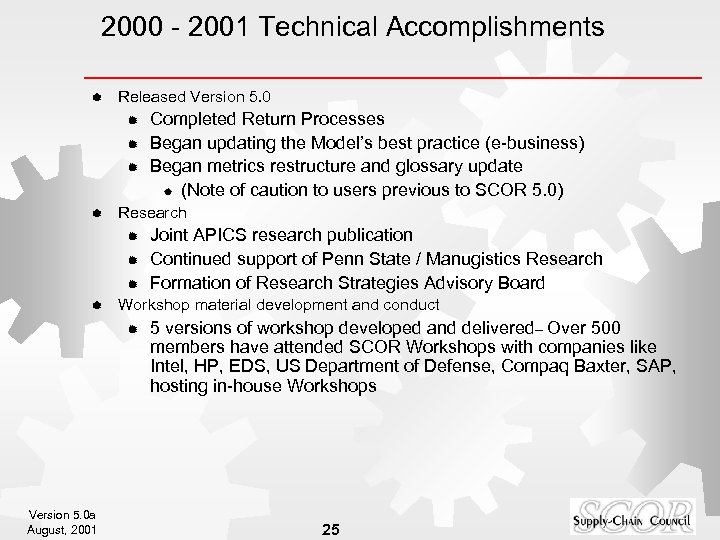

2000 - 2001 Technical Accomplishments ® Released Version 5. 0 ® ® Research ® ® Joint APICS research publication Continued support of Penn State / Manugistics Research Formation of Research Strategies Advisory Board Workshop material development and conduct ® Version 5. 0 a August, 2001 Completed Return Processes Began updating the Model’s best practice (e-business) Began metrics restructure and glossary update ® (Note of caution to users previous to SCOR 5. 0) 5 versions of workshop developed and delivered– Over 500 members have attended SCOR Workshops with companies like Intel, HP, EDS, US Department of Defense, Compaq Baxter, SAP, hosting in-house Workshops 25

2000 - 2001 Technical Accomplishments ® Released Version 5. 0 ® ® Research ® ® Joint APICS research publication Continued support of Penn State / Manugistics Research Formation of Research Strategies Advisory Board Workshop material development and conduct ® Version 5. 0 a August, 2001 Completed Return Processes Began updating the Model’s best practice (e-business) Began metrics restructure and glossary update ® (Note of caution to users previous to SCOR 5. 0) 5 versions of workshop developed and delivered– Over 500 members have attended SCOR Workshops with companies like Intel, HP, EDS, US Department of Defense, Compaq Baxter, SAP, hosting in-house Workshops 25

SCOR Model Timeline - 6. 0 ® After completing Version 5. 0 changes committees began working Version 6. 0 - tentatively scheduled for release in Spring 2002 ® ® Version 5. 0 a August, 2001 Metrics Revision and Decomposition Trees Return – Metrics and Best Practice Complete Best Practice and e-Business Improvement Collaboration 26

SCOR Model Timeline - 6. 0 ® After completing Version 5. 0 changes committees began working Version 6. 0 - tentatively scheduled for release in Spring 2002 ® ® Version 5. 0 a August, 2001 Metrics Revision and Decomposition Trees Return – Metrics and Best Practice Complete Best Practice and e-Business Improvement Collaboration 26

SCOR Model Directions Changes anticipated to shift from structural issues to implementation issues ® Product Development ® Customer/Supplier Relationship Management ® Import / Export ® E-business ® Reverse logistics / warranty returns ® Inventory optimization ® Service environment ® Synchronizing advanced planning and business planning ® Special Industry Groups / International Chapters ® Finance and metrics ® Benchmarking regional issues ® Version 5. 0 a August, 2001 27

SCOR Model Directions Changes anticipated to shift from structural issues to implementation issues ® Product Development ® Customer/Supplier Relationship Management ® Import / Export ® E-business ® Reverse logistics / warranty returns ® Inventory optimization ® Service environment ® Synchronizing advanced planning and business planning ® Special Industry Groups / International Chapters ® Finance and metrics ® Benchmarking regional issues ® Version 5. 0 a August, 2001 27

SCC provides the forum - SCOR documents the learning ® ® ® Version 5. 0 a August, 2001 Process Model provides a toolset for rapidly modeling and understanding the supply chain Metrics provide a toolset for evaluating the supply chain and rapidly identifying high value opportunities Best practices and features provide a candidate list of improvement options The SCOR Model is the only model of its type that links these elements and provides a means for assessment of the supply chain outside of the individual organization Council members have demonstrated dramatic implementation successes in virtually every industry in every region of the world. The pace and number of SCOR implementations is accelerating and more organizations are adopting SCOR as the framework for their supply chain improvements. 28

SCC provides the forum - SCOR documents the learning ® ® ® Version 5. 0 a August, 2001 Process Model provides a toolset for rapidly modeling and understanding the supply chain Metrics provide a toolset for evaluating the supply chain and rapidly identifying high value opportunities Best practices and features provide a candidate list of improvement options The SCOR Model is the only model of its type that links these elements and provides a means for assessment of the supply chain outside of the individual organization Council members have demonstrated dramatic implementation successes in virtually every industry in every region of the world. The pace and number of SCOR implementations is accelerating and more organizations are adopting SCOR as the framework for their supply chain improvements. 28

The Bottom Line - Council members have demonstrated dramatic implementation successes in virtually every industry in every region of the world. ® The pace and number of SCOR implementations is accelerating and more organizations are adopting SCOR as the framework for their supply chain improvements. ® Version 5. 0 a August, 2001 29

The Bottom Line - Council members have demonstrated dramatic implementation successes in virtually every industry in every region of the world. ® The pace and number of SCOR implementations is accelerating and more organizations are adopting SCOR as the framework for their supply chain improvements. ® Version 5. 0 a August, 2001 29