eb35d9055cc8830c3316199347cd2f22.ppt

- Количество слайдов: 7

Supplier Management

Supplier Management

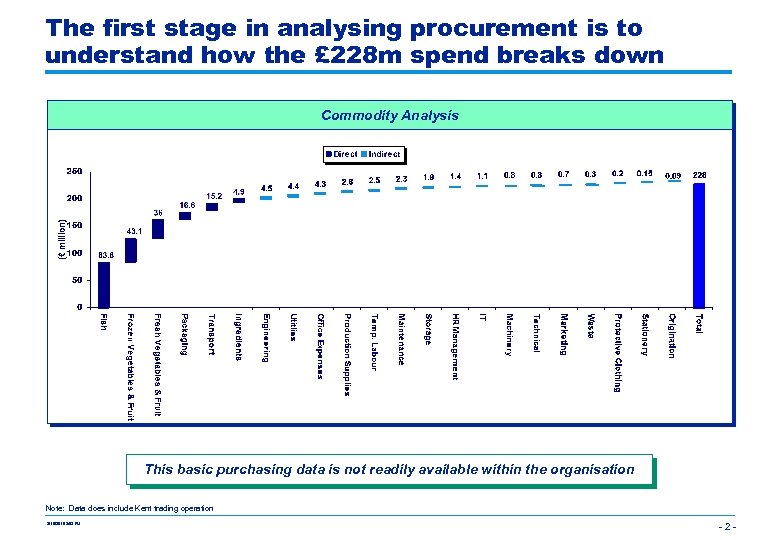

The first stage in analysing procurement is to understand how the £ 228 m spend breaks down Commodity Analysis This basic purchasing data is not readily available within the organisation Note: Data does include Kent trading operation 3/15/2018 2: 02 PM -2 -

The first stage in analysing procurement is to understand how the £ 228 m spend breaks down Commodity Analysis This basic purchasing data is not readily available within the organisation Note: Data does include Kent trading operation 3/15/2018 2: 02 PM -2 -

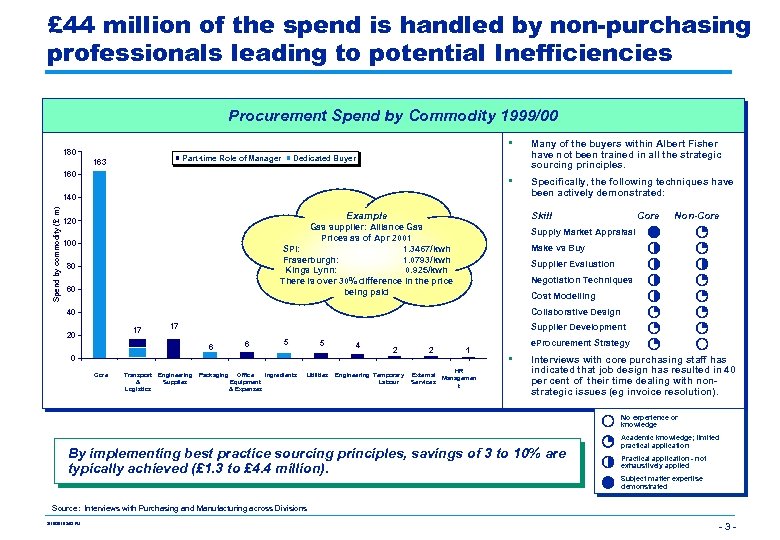

£ 44 million of the spend is handled by non-purchasing professionals leading to potential Inefficiencies Procurement Spend by Commodity 1999/00 • Part-time Role of Manager 163 Many of the buyers within Albert Fisher have not been trained in all the strategic sourcing principles. • 180 Specifically, the following techniques have been actively demonstrated: Dedicated Buyer 160 Spend by commodity (£ m) 140 Skill Example 120 Gas supplier: Alliance Gas Prices as of Apr 2001 SPI: 1. 3467/kwh Fraserburgh: 1. 0793/kwh Kings Lynn: 0. 925/kwh There is over 30% difference in the price being paid 100 80 60 Core Non-Core Supply Market Appraisal Make vs Buy Supplier Evaluation Negotiation Techniques Cost Modelling Collaborative Design 40 17 20 17 Supplier Development 6 6 5 5 4 0 Core Transport & Logistics Packaging Engineering Supplies Office Packaging Office Ingredients Equipment & Expenses Utilities Engineering 2 2 1 Temporary HRHR Temporary External Labour Services Management Labour t e. Procurement Strategy • Interviews with core purchasing staff has indicated that job design has resulted in 40 per cent of their time dealing with nonstrategic issues (eg invoice resolution). No experience or knowledge By implementing best practice sourcing principles, savings of 3 to 10% are typically achieved (£ 1. 3 to £ 4. 4 million). Academic knowledge; limited practical application Practical application - not exhaustively applied Subject matter expertise demonstrated Source: Interviews with Purchasing and Manufacturing across Divisions 3/15/2018 2: 02 PM -3 -

£ 44 million of the spend is handled by non-purchasing professionals leading to potential Inefficiencies Procurement Spend by Commodity 1999/00 • Part-time Role of Manager 163 Many of the buyers within Albert Fisher have not been trained in all the strategic sourcing principles. • 180 Specifically, the following techniques have been actively demonstrated: Dedicated Buyer 160 Spend by commodity (£ m) 140 Skill Example 120 Gas supplier: Alliance Gas Prices as of Apr 2001 SPI: 1. 3467/kwh Fraserburgh: 1. 0793/kwh Kings Lynn: 0. 925/kwh There is over 30% difference in the price being paid 100 80 60 Core Non-Core Supply Market Appraisal Make vs Buy Supplier Evaluation Negotiation Techniques Cost Modelling Collaborative Design 40 17 20 17 Supplier Development 6 6 5 5 4 0 Core Transport & Logistics Packaging Engineering Supplies Office Packaging Office Ingredients Equipment & Expenses Utilities Engineering 2 2 1 Temporary HRHR Temporary External Labour Services Management Labour t e. Procurement Strategy • Interviews with core purchasing staff has indicated that job design has resulted in 40 per cent of their time dealing with nonstrategic issues (eg invoice resolution). No experience or knowledge By implementing best practice sourcing principles, savings of 3 to 10% are typically achieved (£ 1. 3 to £ 4. 4 million). Academic knowledge; limited practical application Practical application - not exhaustively applied Subject matter expertise demonstrated Source: Interviews with Purchasing and Manufacturing across Divisions 3/15/2018 2: 02 PM -3 -

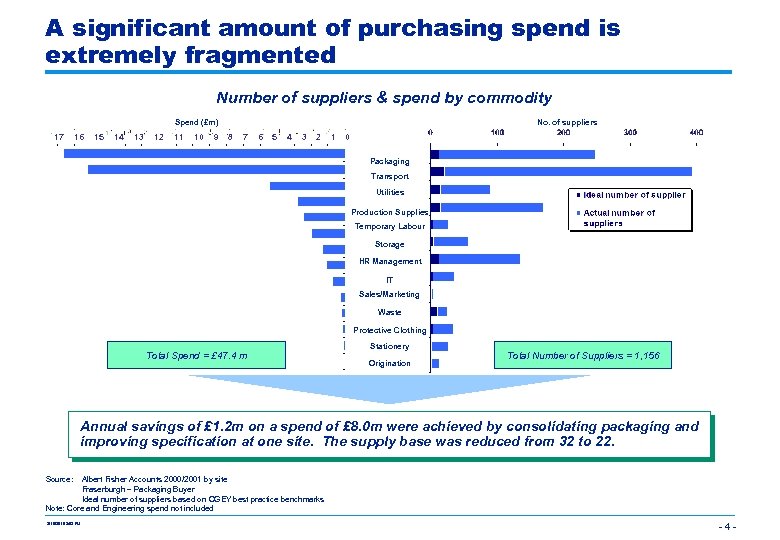

A significant amount of purchasing spend is extremely fragmented Number of suppliers & spend by commodity Spend (£m) 17 16 15 14 13 12 11 10 9 No. of suppliers 8 7 6 5 4 3 2 1 0 Packaging Transport Utilities Production Supplies Temporary Labour Storage HR Management IT Sales/Marketing Waste Protective Clothing Total Spend = £ 47. 4 m Stationery Origination Total Number of Suppliers = 1, 156 Annual savings of £ 1. 2 m on a spend of £ 8. 0 m were achieved by consolidating packaging and improving specification at one site. The supply base was reduced from 32 to 22. Source: Albert Fisher Accounts 2000/2001 by site Fraserburgh – Packaging Buyer Ideal number of suppliers based on CGEY best practice benchmarks Note: Core and Engineering spend not included 3/15/2018 2: 02 PM -4 -

A significant amount of purchasing spend is extremely fragmented Number of suppliers & spend by commodity Spend (£m) 17 16 15 14 13 12 11 10 9 No. of suppliers 8 7 6 5 4 3 2 1 0 Packaging Transport Utilities Production Supplies Temporary Labour Storage HR Management IT Sales/Marketing Waste Protective Clothing Total Spend = £ 47. 4 m Stationery Origination Total Number of Suppliers = 1, 156 Annual savings of £ 1. 2 m on a spend of £ 8. 0 m were achieved by consolidating packaging and improving specification at one site. The supply base was reduced from 32 to 22. Source: Albert Fisher Accounts 2000/2001 by site Fraserburgh – Packaging Buyer Ideal number of suppliers based on CGEY best practice benchmarks Note: Core and Engineering spend not included 3/15/2018 2: 02 PM -4 -

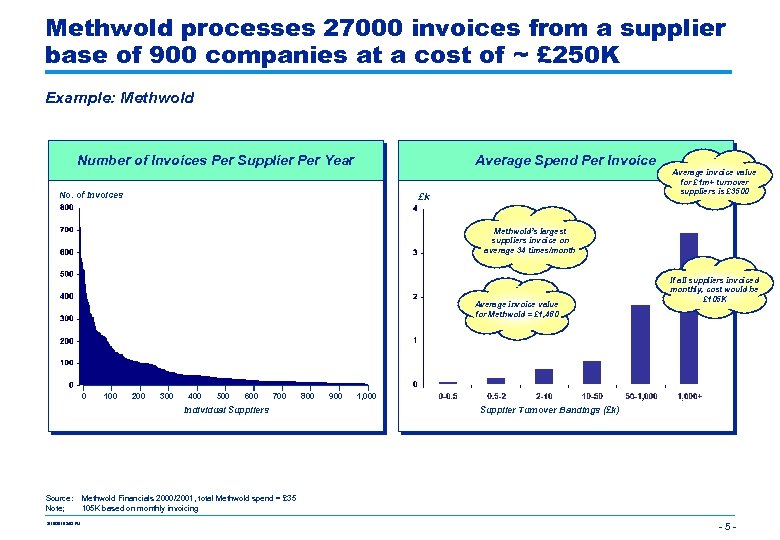

Methwold processes 27000 invoices from a supplier base of 900 companies at a cost of ~ £ 250 K Example: Methwold Number of Invoices Per Supplier Per Year Average Spend Per Invoice No. of Invoices £k Average invoice value for £ 1 m+ turnover suppliers is £ 3500 Methwold’s largest suppliers invoice on average 34 times/month Average invoice value for Methwold = £ 1, 480 0 100 200 300 400 500 600 700 Individual Suppliers Source: Note; 3/15/2018 2: 02 PM 800 900 If all suppliers invoiced monthly, cost would be £ 105 K 1, 000 Supplier Turnover Bandings (£k) Methwold Financials 2000/2001, total Methwold spend = £ 35 105 K based on monthly invoicing -5 -

Methwold processes 27000 invoices from a supplier base of 900 companies at a cost of ~ £ 250 K Example: Methwold Number of Invoices Per Supplier Per Year Average Spend Per Invoice No. of Invoices £k Average invoice value for £ 1 m+ turnover suppliers is £ 3500 Methwold’s largest suppliers invoice on average 34 times/month Average invoice value for Methwold = £ 1, 480 0 100 200 300 400 500 600 700 Individual Suppliers Source: Note; 3/15/2018 2: 02 PM 800 900 If all suppliers invoiced monthly, cost would be £ 105 K 1, 000 Supplier Turnover Bandings (£k) Methwold Financials 2000/2001, total Methwold spend = £ 35 105 K based on monthly invoicing -5 -

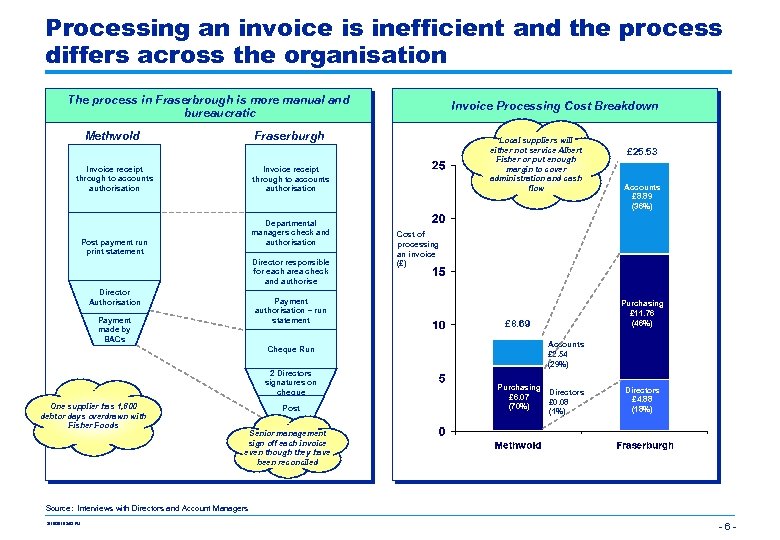

Processing an invoice is inefficient and the process differs across the organisation The process in Fraserbrough is more manual and bureaucratic Methwold Fraserburgh Invoice receipt through to accounts authorisation Local suppliers will either not service Albert Fisher or put enough margin to cover administration and cash flow Invoice receipt through to accounts authorisation Departmental managers check and authorisation Post payment run print statement Director responsible for each area check and authorise Director Authorisation Payment authorisation – run statement Payment made by BACs Cheque Run 2 Directors signatures on cheque One supplier has 1, 800 debtor days overdrawn with Fisher Foods Invoice Processing Cost Breakdown Post £ 25. 53 Accounts £ 8. 89 (36%) Cost of processing an invoice (£) Purchasing £ 11. 76 (46%) £ 8. 69 Accounts £ 2. 54 (29%) Purchasing Directors £ 6. 07 £ 0. 08 (70%) (1%) Directors £ 4. 88 (18%) Senior management sign off each invoice even though they have been reconciled Source: Interviews with Directors and Account Managers 3/15/2018 2: 02 PM -6 -

Processing an invoice is inefficient and the process differs across the organisation The process in Fraserbrough is more manual and bureaucratic Methwold Fraserburgh Invoice receipt through to accounts authorisation Local suppliers will either not service Albert Fisher or put enough margin to cover administration and cash flow Invoice receipt through to accounts authorisation Departmental managers check and authorisation Post payment run print statement Director responsible for each area check and authorise Director Authorisation Payment authorisation – run statement Payment made by BACs Cheque Run 2 Directors signatures on cheque One supplier has 1, 800 debtor days overdrawn with Fisher Foods Invoice Processing Cost Breakdown Post £ 25. 53 Accounts £ 8. 89 (36%) Cost of processing an invoice (£) Purchasing £ 11. 76 (46%) £ 8. 69 Accounts £ 2. 54 (29%) Purchasing Directors £ 6. 07 £ 0. 08 (70%) (1%) Directors £ 4. 88 (18%) Senior management sign off each invoice even though they have been reconciled Source: Interviews with Directors and Account Managers 3/15/2018 2: 02 PM -6 -

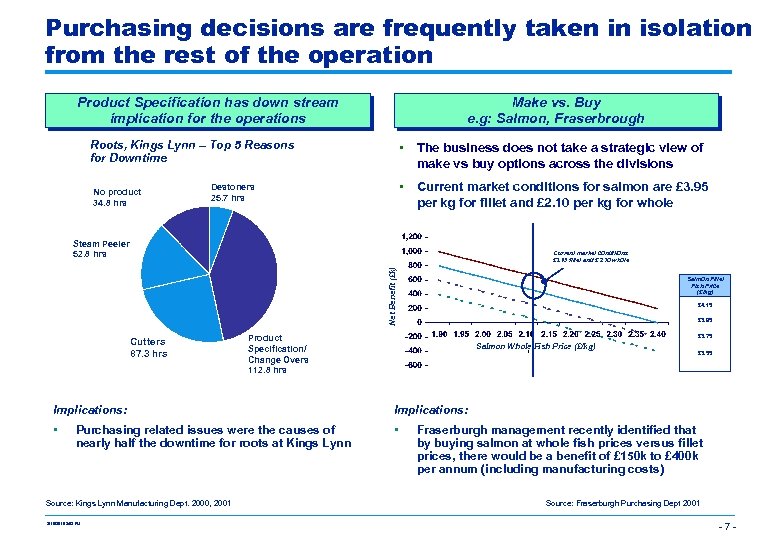

Purchasing decisions are frequently taken in isolation from the rest of the operation Product Specification has down stream implication for the operations Make vs. Buy e. g: Salmon, Fraserbrough Roots, Kings Lynn – Top 5 Reasons for Downtime No product 34. 8 hrs • The business does not take a strategic view of make vs buy options across the divisions • Current market conditions for salmon are £ 3. 95 per kg for fillet and £ 2. 10 per kg for whole Destoners 25. 7 hrs Steam Peeler 52. 8 hrs Net Benefit (£k) Current market conditions £ 3. 95 fillet and £ 2. 10 whole Cutters 87. 3 hrs Salmon Fillet Fish Price (£/kg) £ 4. 15 £ 3. 95 Product Specification/ Change Overs 112. 8 hrs £ 3. 75 Salmon Whole Fish Price (£/kg) Implications: • • £ 3. 55 Purchasing related issues were the causes of nearly half the downtime for roots at Kings Lynn Source: Kings Lynn Manufacturing Dept. 2000, 2001 3/15/2018 2: 03 PM Fraserburgh management recently identified that by buying salmon at whole fish prices versus fillet prices, there would be a benefit of £ 150 k to £ 400 k per annum (including manufacturing costs) Source: Fraserburgh Purchasing Dept 2001 -7 -

Purchasing decisions are frequently taken in isolation from the rest of the operation Product Specification has down stream implication for the operations Make vs. Buy e. g: Salmon, Fraserbrough Roots, Kings Lynn – Top 5 Reasons for Downtime No product 34. 8 hrs • The business does not take a strategic view of make vs buy options across the divisions • Current market conditions for salmon are £ 3. 95 per kg for fillet and £ 2. 10 per kg for whole Destoners 25. 7 hrs Steam Peeler 52. 8 hrs Net Benefit (£k) Current market conditions £ 3. 95 fillet and £ 2. 10 whole Cutters 87. 3 hrs Salmon Fillet Fish Price (£/kg) £ 4. 15 £ 3. 95 Product Specification/ Change Overs 112. 8 hrs £ 3. 75 Salmon Whole Fish Price (£/kg) Implications: • • £ 3. 55 Purchasing related issues were the causes of nearly half the downtime for roots at Kings Lynn Source: Kings Lynn Manufacturing Dept. 2000, 2001 3/15/2018 2: 03 PM Fraserburgh management recently identified that by buying salmon at whole fish prices versus fillet prices, there would be a benefit of £ 150 k to £ 400 k per annum (including manufacturing costs) Source: Fraserburgh Purchasing Dept 2001 -7 -