f7f68a8bfb228b43d78a96a8329d1d40.ppt

- Количество слайдов: 28

Superconducting Solenoids for COMET KEK Cryogenics Center, Osaka Univ. Kuno-san’s Team, J-PARC MLF Muon Group

Superconducting Solenoids for COMET KEK Cryogenics Center, Osaka Univ. Kuno-san’s Team, J-PARC MLF Muon Group

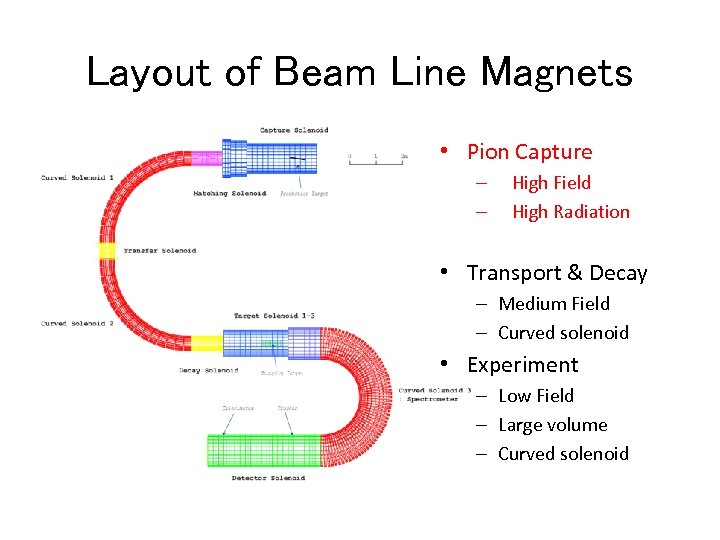

Layout of Beam Line Magnets • Pion Capture – – High Field High Radiation • Transport & Decay – Medium Field – Curved solenoid • Experiment – Low Field – Large volume – Curved solenoid

Layout of Beam Line Magnets • Pion Capture – – High Field High Radiation • Transport & Decay – Medium Field – Curved solenoid • Experiment – Low Field – Large volume – Curved solenoid

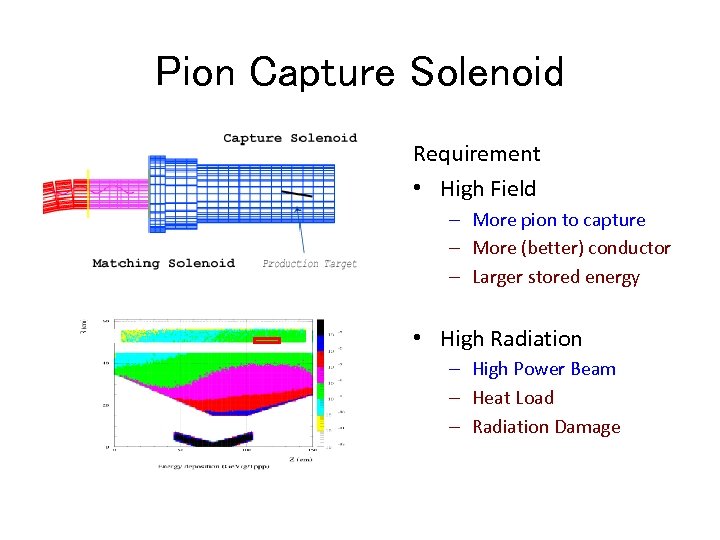

Pion Capture Solenoid Requirement • High Field – More pion to capture – More (better) conductor – Larger stored energy • High Radiation – High Power Beam – Heat Load – Radiation Damage

Pion Capture Solenoid Requirement • High Field – More pion to capture – More (better) conductor – Larger stored energy • High Radiation – High Power Beam – Heat Load – Radiation Damage

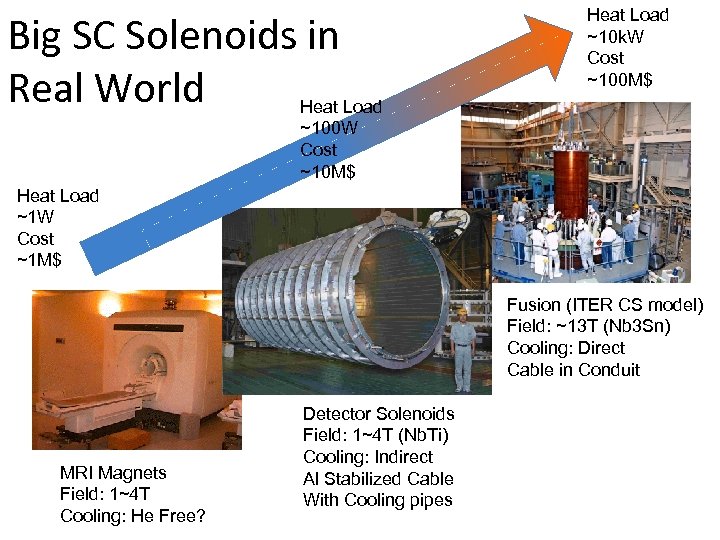

Big SC Solenoids in Real World Heat Load ~10 k. W Cost ~100 M$ ~100 W Cost ~10 M$ Heat Load ~1 W Cost ~1 M$ Fusion (ITER CS model) Field: ~13 T (Nb 3 Sn) Cooling: Direct Cable in Conduit MRI Magnets Field: 1~4 T Cooling: He Free? Detector Solenoids Field: 1~4 T (Nb. Ti) Cooling: Indirect Al Stabilized Cable With Cooling pipes

Big SC Solenoids in Real World Heat Load ~10 k. W Cost ~100 M$ ~100 W Cost ~10 M$ Heat Load ~1 W Cost ~1 M$ Fusion (ITER CS model) Field: ~13 T (Nb 3 Sn) Cooling: Direct Cable in Conduit MRI Magnets Field: 1~4 T Cooling: He Free? Detector Solenoids Field: 1~4 T (Nb. Ti) Cooling: Indirect Al Stabilized Cable With Cooling pipes

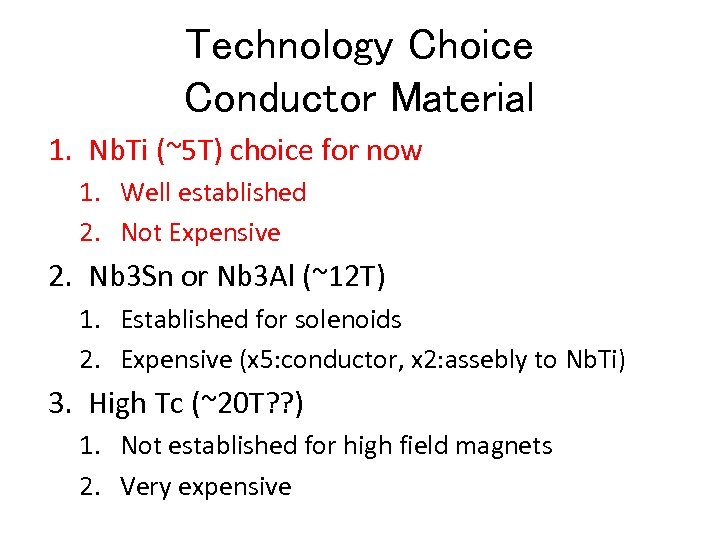

Technology Choice Conductor Material 1. Nb. Ti (~5 T) choice for now 1. Well established 2. Not Expensive 2. Nb 3 Sn or Nb 3 Al (~12 T) 1. Established for solenoids 2. Expensive (x 5: conductor, x 2: assebly to Nb. Ti) 3. High Tc (~20 T? ? ) 1. Not established for high field magnets 2. Very expensive

Technology Choice Conductor Material 1. Nb. Ti (~5 T) choice for now 1. Well established 2. Not Expensive 2. Nb 3 Sn or Nb 3 Al (~12 T) 1. Established for solenoids 2. Expensive (x 5: conductor, x 2: assebly to Nb. Ti) 3. High Tc (~20 T? ? ) 1. Not established for high field magnets 2. Very expensive

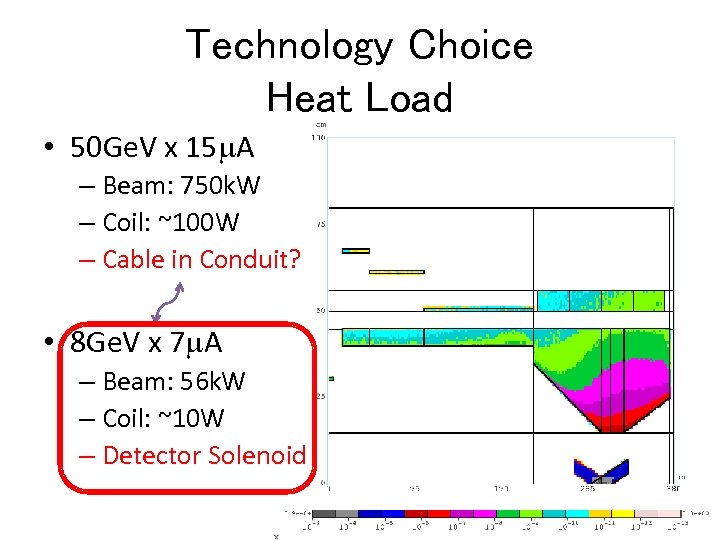

Technology Choice Heat Load • 50 Ge. V x 15 m. A – Beam: 750 k. W – Coil: ~100 W – Cable in Conduit? • 8 Ge. V x 7 m. A – Beam: 56 k. W – Coil: ~10 W – Detector Solenoid

Technology Choice Heat Load • 50 Ge. V x 15 m. A – Beam: 750 k. W – Coil: ~100 W – Cable in Conduit? • 8 Ge. V x 7 m. A – Beam: 56 k. W – Coil: ~10 W – Detector Solenoid

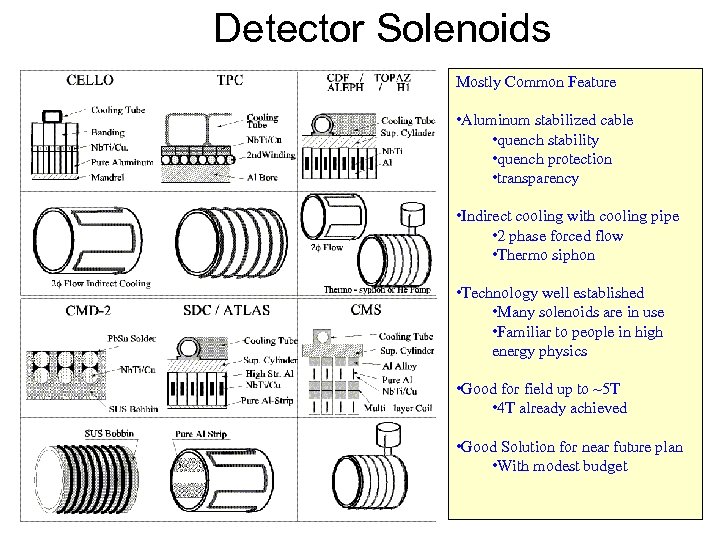

Detector Solenoids Mostly Common Feature • Aluminum stabilized cable • quench stability • quench protection • transparency • Indirect cooling with cooling pipe • 2 phase forced flow • Thermo siphon • Technology well established • Many solenoids are in use • Familiar to people in high energy physics • Good for field up to ~5 T • 4 T already achieved • Good Solution for near future plan • With modest budget

Detector Solenoids Mostly Common Feature • Aluminum stabilized cable • quench stability • quench protection • transparency • Indirect cooling with cooling pipe • 2 phase forced flow • Thermo siphon • Technology well established • Many solenoids are in use • Familiar to people in high energy physics • Good for field up to ~5 T • 4 T already achieved • Good Solution for near future plan • With modest budget

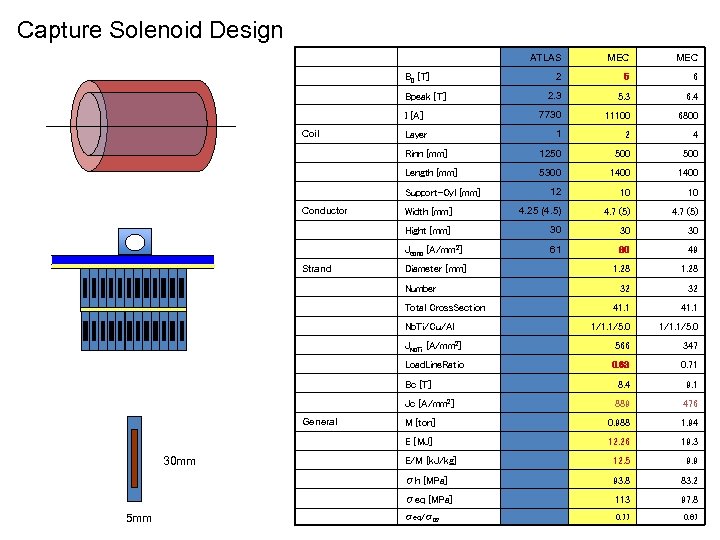

Capture Solenoid Design ATLAS MEC 2 5 6 2. 3 5. 3 6. 4 7730 11100 6800 1 2 4 Rinn [mm] 1250 500 Length [mm] 5300 1400 12 10 10 Width [mm] 4. 25 (4. 5) 4. 7 (5) Hight [mm] 30 30 30 Jcond [A/mm 2] 61 80 49 1. 28 32 32 41. 1 1/1. 1/5. 0 JNb. Ti [A/mm 2] 566 347 Load. Line. Ratio 0. 63 0. 71 Bc [T] 8. 4 9. 1 Jc [A/mm 2] 889 476 M [ton] 0. 988 1. 94 E [MJ] 12. 26 19. 3 E/M [k. J/kg] 12. 5 9. 9 σh [MPa] 93. 8 83. 2 σeq [MPa] 113 97. 8 σeq/σ0. 2 0. 77 0. 67 B 0 [T] Bpeak [T] I [A] Coil Layer Support-Cyl [mm] Conductor Strand Diameter [mm] Number Total Cross. Section Nb. Ti/Cu/Al General 30 mm 5 mm

Capture Solenoid Design ATLAS MEC 2 5 6 2. 3 5. 3 6. 4 7730 11100 6800 1 2 4 Rinn [mm] 1250 500 Length [mm] 5300 1400 12 10 10 Width [mm] 4. 25 (4. 5) 4. 7 (5) Hight [mm] 30 30 30 Jcond [A/mm 2] 61 80 49 1. 28 32 32 41. 1 1/1. 1/5. 0 JNb. Ti [A/mm 2] 566 347 Load. Line. Ratio 0. 63 0. 71 Bc [T] 8. 4 9. 1 Jc [A/mm 2] 889 476 M [ton] 0. 988 1. 94 E [MJ] 12. 26 19. 3 E/M [k. J/kg] 12. 5 9. 9 σh [MPa] 93. 8 83. 2 σeq [MPa] 113 97. 8 σeq/σ0. 2 0. 77 0. 67 B 0 [T] Bpeak [T] I [A] Coil Layer Support-Cyl [mm] Conductor Strand Diameter [mm] Number Total Cross. Section Nb. Ti/Cu/Al General 30 mm 5 mm

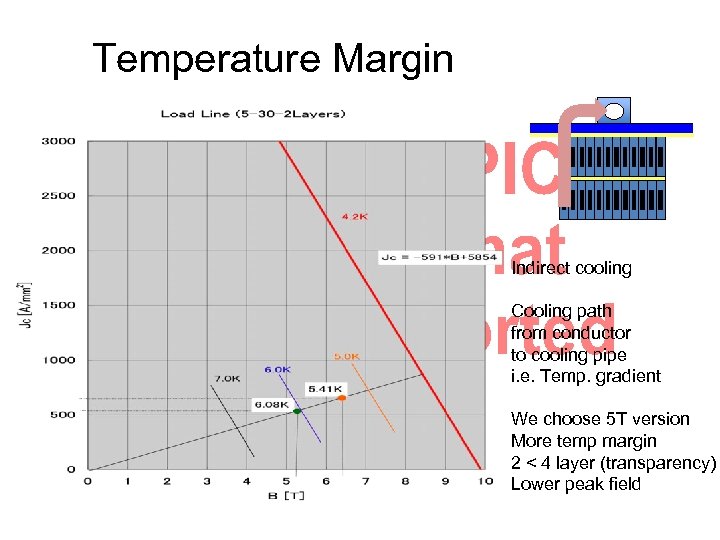

Temperature Margin Indirect cooling Cooling path from conductor to cooling pipe i. e. Temp. gradient We choose 5 T version More temp margin 2 < 4 layer (transparency) Lower peak field

Temperature Margin Indirect cooling Cooling path from conductor to cooling pipe i. e. Temp. gradient We choose 5 T version More temp margin 2 < 4 layer (transparency) Lower peak field

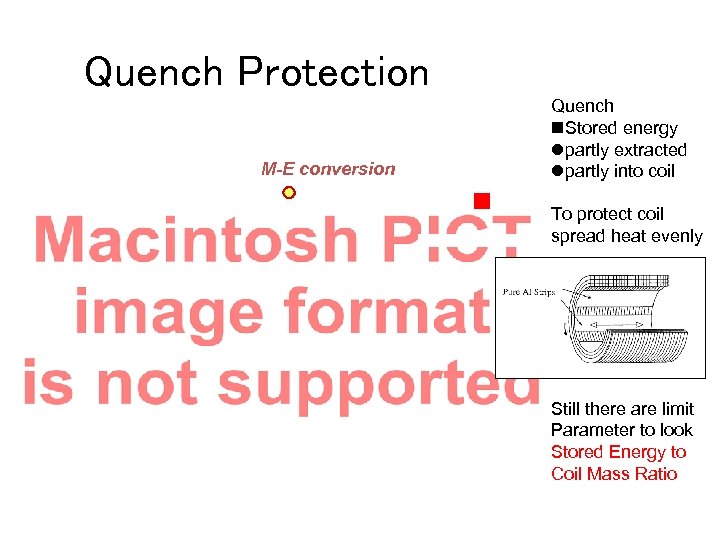

Quench Protection M-E conversion Quench n. Stored energy lpartly extracted lpartly into coil To protect coil spread heat evenly Still there are limit Parameter to look Stored Energy to Coil Mass Ratio

Quench Protection M-E conversion Quench n. Stored energy lpartly extracted lpartly into coil To protect coil spread heat evenly Still there are limit Parameter to look Stored Energy to Coil Mass Ratio

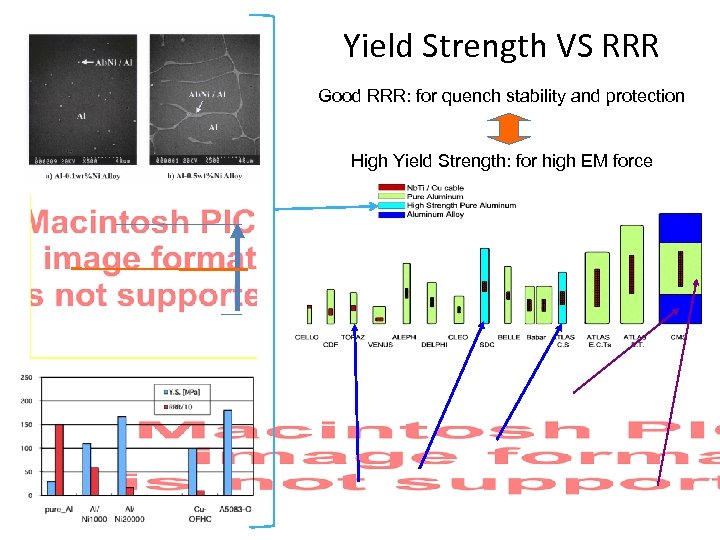

Yield Strength VS RRR Good RRR: for quench stability and protection High Yield Strength: for high EM force

Yield Strength VS RRR Good RRR: for quench stability and protection High Yield Strength: for high EM force

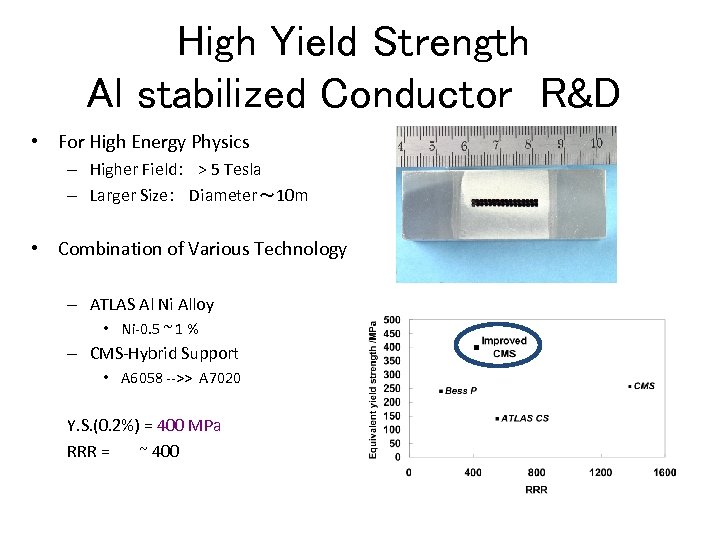

High Yield Strength Al stabilized Conductor R&D • For High Energy Physics – Higher Field: > 5 Tesla – Larger Size: Diameter〜 10 m • Combination of Various Technology – ATLAS Al Ni Alloy • Ni-0. 5 ~ 1 % – CMS-Hybrid Support • A 6058 -->> A 7020 Y. S. (0. 2%) = 400 MPa RRR = ~ 400

High Yield Strength Al stabilized Conductor R&D • For High Energy Physics – Higher Field: > 5 Tesla – Larger Size: Diameter〜 10 m • Combination of Various Technology – ATLAS Al Ni Alloy • Ni-0. 5 ~ 1 % – CMS-Hybrid Support • A 6058 -->> A 7020 Y. S. (0. 2%) = 400 MPa RRR = ~ 400

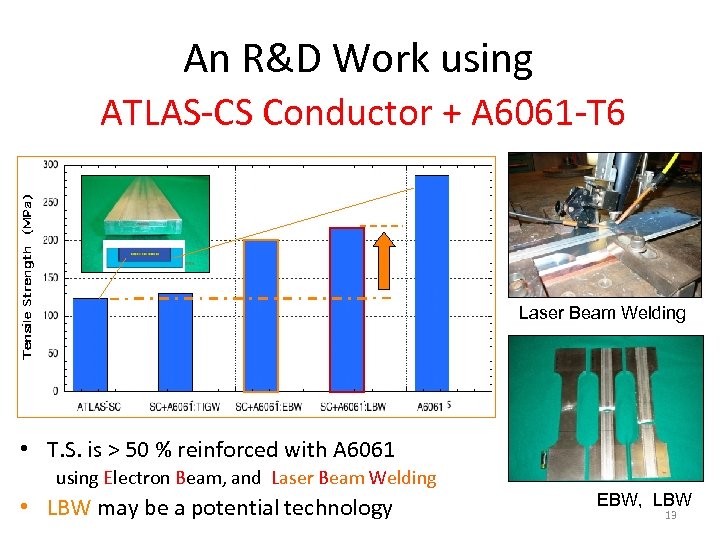

An R&D Work using ATLAS-CS Conductor + A 6061 -T 6 Laser Beam Welding • T. S. is > 50 % reinforced with A 6061 using Electron Beam, and Laser Beam Welding • LBW may be a potential technology EBW, LBW 13

An R&D Work using ATLAS-CS Conductor + A 6061 -T 6 Laser Beam Welding • T. S. is > 50 % reinforced with A 6061 using Electron Beam, and Laser Beam Welding • LBW may be a potential technology EBW, LBW 13

Refrigerator • Cryocoolers (GM or pulse tube) may not be strong enough • Maybe Helium refrigerator plant needed

Refrigerator • Cryocoolers (GM or pulse tube) may not be strong enough • Maybe Helium refrigerator plant needed

Guideline for magnet design • Optimize the magnetic field design below 6 T – As base-line, using Nb. Ti superconductor • (with a future option for > 10 T Nb 3 Sn, Nb 3 Al magnet for the pion capture solenoid) • Apply “thin solenoid” design concept with Alstabilized superconductor and indirect-cooling to – Minimize radiation heating, – Refer technology established at, • ATLAS, BESS, and CMS Solenoid

Guideline for magnet design • Optimize the magnetic field design below 6 T – As base-line, using Nb. Ti superconductor • (with a future option for > 10 T Nb 3 Sn, Nb 3 Al magnet for the pion capture solenoid) • Apply “thin solenoid” design concept with Alstabilized superconductor and indirect-cooling to – Minimize radiation heating, – Refer technology established at, • ATLAS, BESS, and CMS Solenoid

Toward Higher Field • Al-stabilized Nb 3 Sn/Nb 3 Al Solenoid beyond 10 T • An R&D may be proposed in cooperation with NIFS.

Toward Higher Field • Al-stabilized Nb 3 Sn/Nb 3 Al Solenoid beyond 10 T • An R&D may be proposed in cooperation with NIFS.

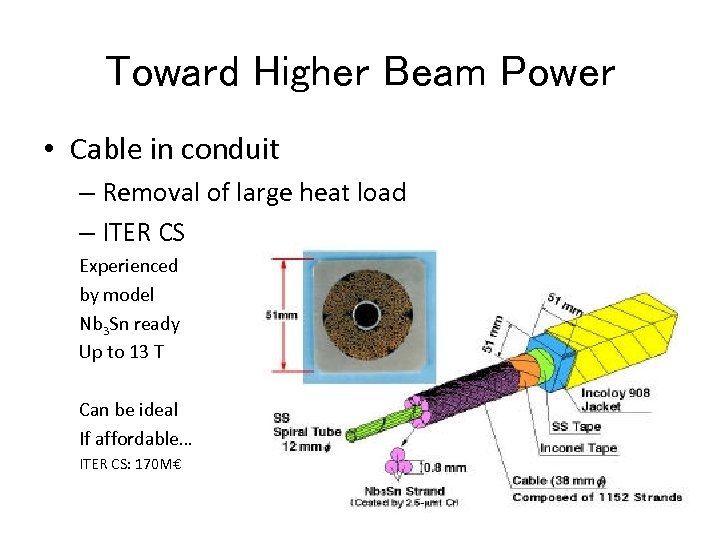

Toward Higher Beam Power • Cable in conduit – Removal of large heat load – ITER CS Experienced by model Nb 3 Sn ready Up to 13 T Can be ideal If affordable… ITER CS: 170 M€

Toward Higher Beam Power • Cable in conduit – Removal of large heat load – ITER CS Experienced by model Nb 3 Sn ready Up to 13 T Can be ideal If affordable… ITER CS: 170 M€

Capture Solenoid Summary & Issues • For Pion Capture Solenoid for J-PARC – Detector Solenoid Technologies can be good solution • Field ~5 T, Heat Load ~10 W (Beam Power ~56 k. W) – More advanced technologies are also available • with some more money… • Issues – High Radiation Doze • Insulation material: Organic < 107 Gy – High Neutron Fluence • Al and Cu: Resistivity change • Superconductor: Jc change

Capture Solenoid Summary & Issues • For Pion Capture Solenoid for J-PARC – Detector Solenoid Technologies can be good solution • Field ~5 T, Heat Load ~10 W (Beam Power ~56 k. W) – More advanced technologies are also available • with some more money… • Issues – High Radiation Doze • Insulation material: Organic < 107 Gy – High Neutron Fluence • Al and Cu: Resistivity change • Superconductor: Jc change

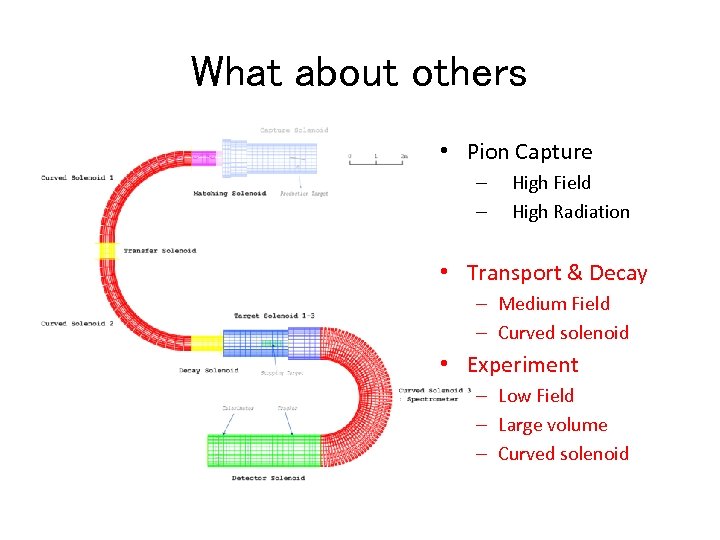

What about others • Pion Capture – – High Field High Radiation • Transport & Decay – Medium Field – Curved solenoid • Experiment – Low Field – Large volume – Curved solenoid

What about others • Pion Capture – – High Field High Radiation • Transport & Decay – Medium Field – Curved solenoid • Experiment – Low Field – Large volume – Curved solenoid

Transport solenoid • COMET is not the only project needing muon transport solenoid • Even in J-PARC there is a similar curved solenoid needed – J-PARC MLF muon beam line – Lot of similarity in spec – Joint R&D • Osaka Univ • KEK muon group • KEK cryogenics center

Transport solenoid • COMET is not the only project needing muon transport solenoid • Even in J-PARC there is a similar curved solenoid needed – J-PARC MLF muon beam line – Lot of similarity in spec – Joint R&D • Osaka Univ • KEK muon group • KEK cryogenics center

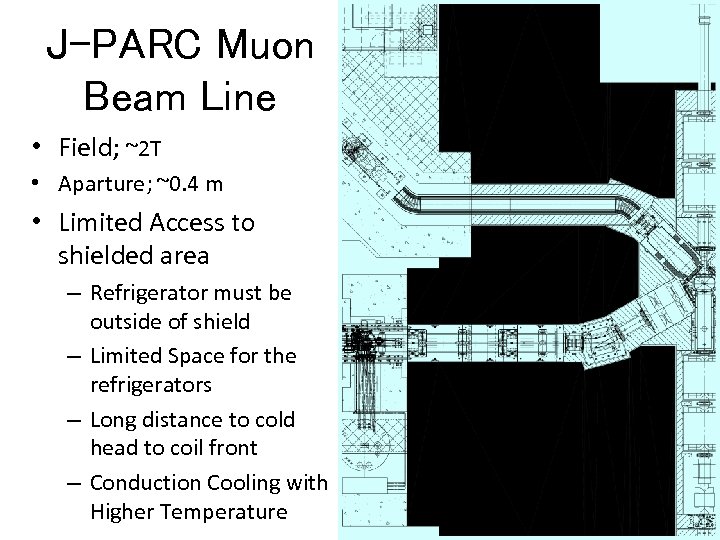

J-PARC Muon Beam Line • Field; ~2 T • Aparture; ~0. 4 m • Limited Access to shielded area – Refrigerator must be outside of shield – Limited Space for the refrigerators – Long distance to cold head to coil front – Conduction Cooling with Higher Temperature

J-PARC Muon Beam Line • Field; ~2 T • Aparture; ~0. 4 m • Limited Access to shielded area – Refrigerator must be outside of shield – Limited Space for the refrigerators – Long distance to cold head to coil front – Conduction Cooling with Higher Temperature

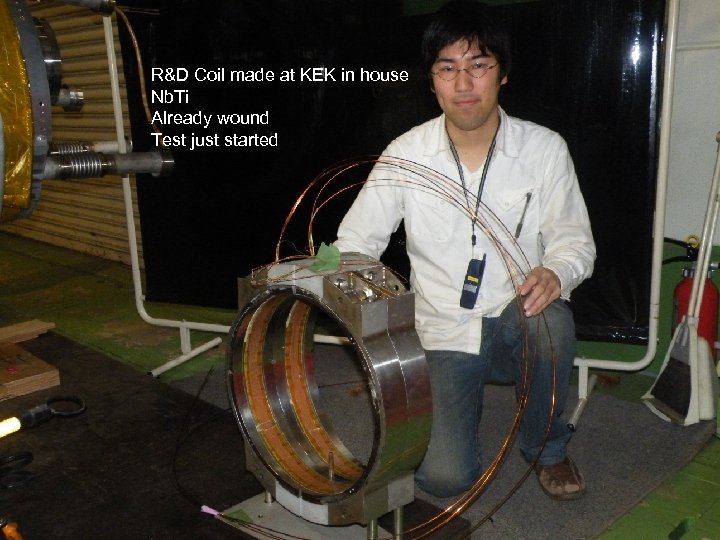

Trial. R&D Coil made at KEK in house Winding of Curved Section Nb. Ti with Mg. B 2 conductor Already wound Test • Purchase just started two kinds of Mg. B 2 conductor from Columbus SC – 1 is the 1. 13 mm diameter round wire • Will be wound by a company – 2 is the 1. 5 * 2. 5 mm square wire • Will be wound by Nakahara and Adachi at KEK • They will be wound this winter and Tested in next spring

Trial. R&D Coil made at KEK in house Winding of Curved Section Nb. Ti with Mg. B 2 conductor Already wound Test • Purchase just started two kinds of Mg. B 2 conductor from Columbus SC – 1 is the 1. 13 mm diameter round wire • Will be wound by a company – 2 is the 1. 5 * 2. 5 mm square wire • Will be wound by Nakahara and Adachi at KEK • They will be wound this winter and Tested in next spring

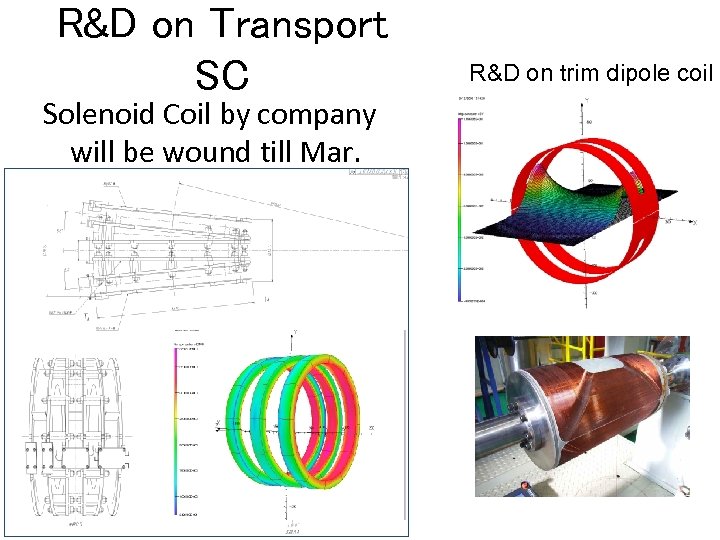

R&D on Transport SC Solenoid Coil by company will be wound till Mar. R&D on trim dipole coil

R&D on Transport SC Solenoid Coil by company will be wound till Mar. R&D on trim dipole coil

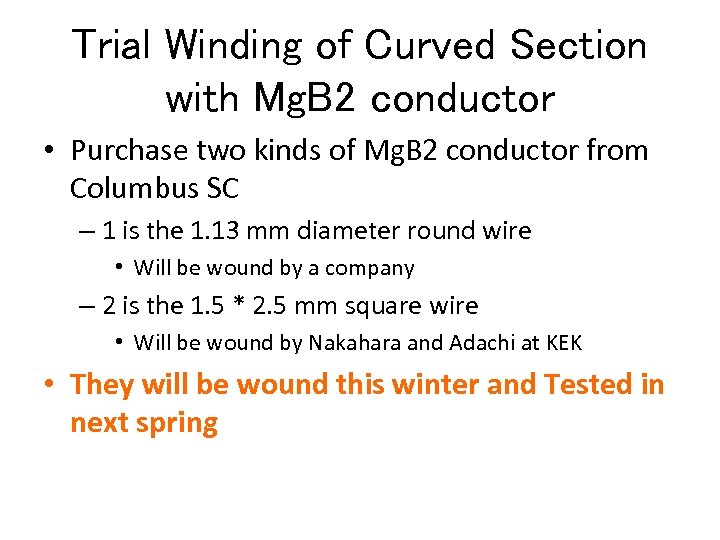

Trial Winding of Curved Section with Mg. B 2 conductor • Purchase two kinds of Mg. B 2 conductor from Columbus SC – 1 is the 1. 13 mm diameter round wire • Will be wound by a company – 2 is the 1. 5 * 2. 5 mm square wire • Will be wound by Nakahara and Adachi at KEK • They will be wound this winter and Tested in next spring

Trial Winding of Curved Section with Mg. B 2 conductor • Purchase two kinds of Mg. B 2 conductor from Columbus SC – 1 is the 1. 13 mm diameter round wire • Will be wound by a company – 2 is the 1. 5 * 2. 5 mm square wire • Will be wound by Nakahara and Adachi at KEK • They will be wound this winter and Tested in next spring

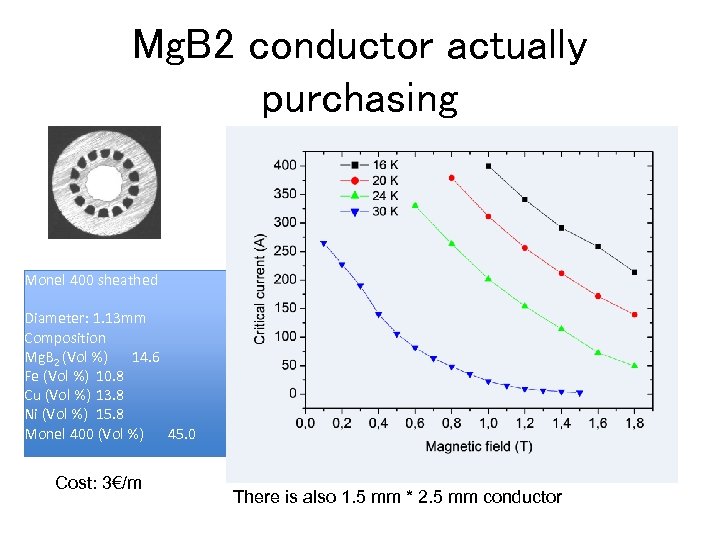

Mg. B 2 conductor actually purchasing Monel 400 sheathed Diameter: 1. 13 mm Composition Mg. B 2 (Vol %) 14. 6 Fe (Vol %) 10. 8 Cu (Vol %) 13. 8 Ni (Vol %) 15. 8 Monel 400 (Vol %) 45. 0 Cost: 3€/m There is also 1. 5 mm * 2. 5 mm conductor

Mg. B 2 conductor actually purchasing Monel 400 sheathed Diameter: 1. 13 mm Composition Mg. B 2 (Vol %) 14. 6 Fe (Vol %) 10. 8 Cu (Vol %) 13. 8 Ni (Vol %) 15. 8 Monel 400 (Vol %) 45. 0 Cost: 3€/m There is also 1. 5 mm * 2. 5 mm conductor

Themal Conductivity and Specific Heat of Cu and Al Thermal Conductivity: ~ 3 times better Cp: about 10 times larger Nb. Ti Mg. B 2

Themal Conductivity and Specific Heat of Cu and Al Thermal Conductivity: ~ 3 times better Cp: about 10 times larger Nb. Ti Mg. B 2

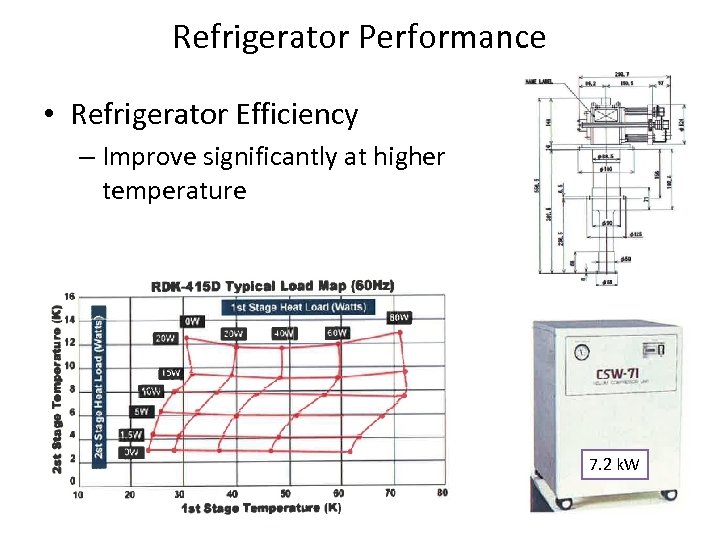

Refrigerator Performance • Refrigerator Efficiency – Improve significantly at higher temperature 7. 2 k. W

Refrigerator Performance • Refrigerator Efficiency – Improve significantly at higher temperature 7. 2 k. W

Transport Solenoid Summary • Mg. B 2 can be a good candidate – Operation Temperature 10~20 K – Better Refrigerator Performance – Best Thermal Conductivity – Better Specific Heat – Good Cost saving solution

Transport Solenoid Summary • Mg. B 2 can be a good candidate – Operation Temperature 10~20 K – Better Refrigerator Performance – Best Thermal Conductivity – Better Specific Heat – Good Cost saving solution