5e4bf2ebf1972b13560e723e4be12fdf.ppt

- Количество слайдов: 29

Summary and Plans Tracker WG • Sensors (conveners DB and M. Mannelli) • Simulation and Layout (conveners D. Abbaneo and H. Cheung) • Cooling and mechanics (conveners K. Arndt and H. Postema) • Phase 1 Power (conveners K. Klein, S. Kwan) FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 1

Summary and Plans Tracker WG • Sensors (conveners DB and M. Mannelli) • Simulation and Layout (conveners D. Abbaneo and H. Cheung) • Cooling and mechanics (conveners K. Arndt and H. Postema) • Phase 1 Power (conveners K. Klein, S. Kwan) FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 1

Sensors • Sensors (conveners DB and M. Mannelli) • Experience from Tevatron compared to the Hamburg model. • Updates from RD 50, RD 39, Si. BT • Updates on submissions with Hamamatsu • Monolithic CMOS pixel detectors FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 2

Sensors • Sensors (conveners DB and M. Mannelli) • Experience from Tevatron compared to the Hamburg model. • Updates from RD 50, RD 39, Si. BT • Updates on submissions with Hamamatsu • Monolithic CMOS pixel detectors FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 2

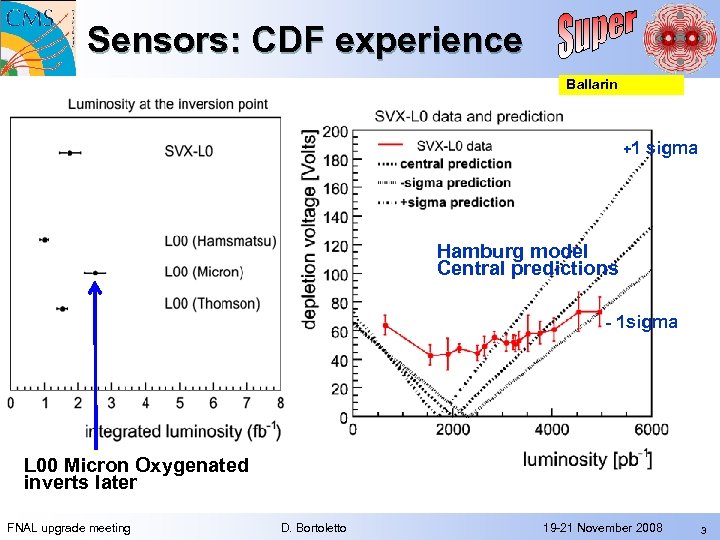

Sensors: CDF experience Ballarin +1 sigma Hamburg model Central predictions - 1 sigma L 00 Micron Oxygenated inverts later FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 3

Sensors: CDF experience Ballarin +1 sigma Hamburg model Central predictions - 1 sigma L 00 Micron Oxygenated inverts later FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 3

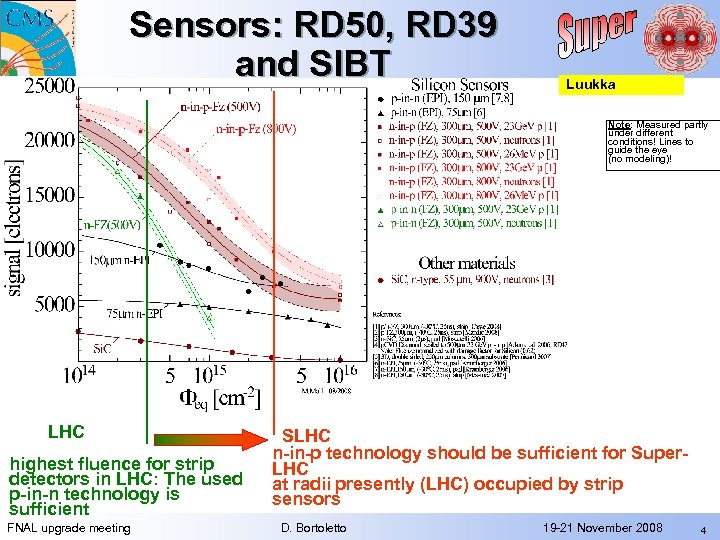

Sensors: RD 50, RD 39 and SIBT Luukka Note: Measured partly under different conditions! Lines to guide the eye (no modeling)! LHC highest fluence for strip detectors in LHC: The used p-in-n technology is sufficient SLHC n-in-p technology should be sufficient for Super. LHC at radii presently (LHC) occupied by strip sensors FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 4

Sensors: RD 50, RD 39 and SIBT Luukka Note: Measured partly under different conditions! Lines to guide the eye (no modeling)! LHC highest fluence for strip detectors in LHC: The used p-in-n technology is sufficient SLHC n-in-p technology should be sufficient for Super. LHC at radii presently (LHC) occupied by strip sensors FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 4

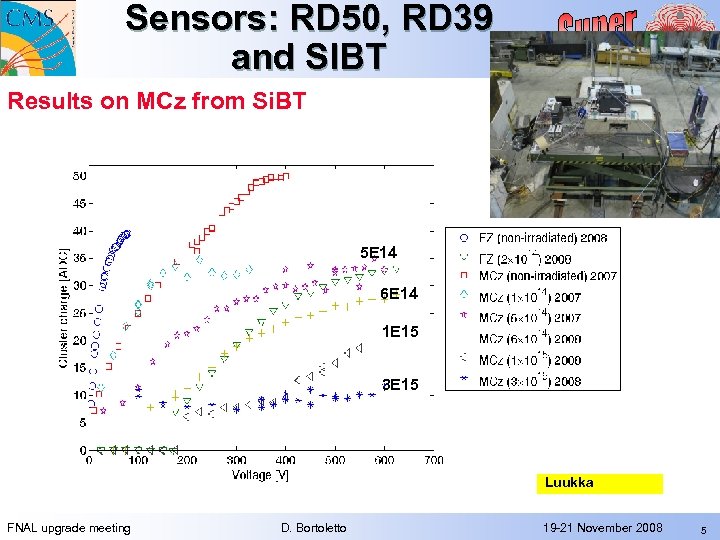

Sensors: RD 50, RD 39 and SIBT Results on MCz from Si. BT 5 E 14 6 E 14 1 E 15 3 E 15 Luukka FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 5

Sensors: RD 50, RD 39 and SIBT Results on MCz from Si. BT 5 E 14 6 E 14 1 E 15 3 E 15 Luukka FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 5

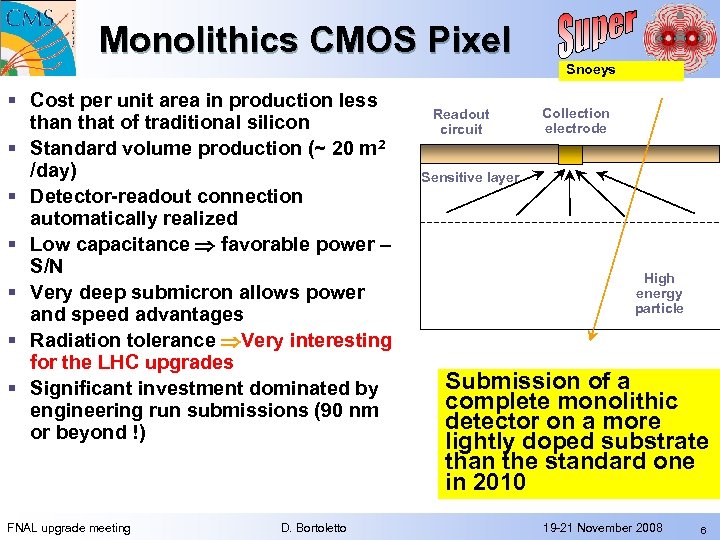

Monolithics CMOS Pixel Snoeys § Cost per unit area in production less than that of traditional silicon § Standard volume production (~ 20 m 2 /day) § Detector-readout connection automatically realized § Low capacitance favorable power – S/N § Very deep submicron allows power and speed advantages § Radiation tolerance Very interesting for the LHC upgrades § Significant investment dominated by engineering run submissions (90 nm or beyond !) Readout circuit Collection electrode Sensitive layer High energy particle Submission of a complete monolithic detector on a more lightly doped substrate than the standard one in 2010 FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 6

Monolithics CMOS Pixel Snoeys § Cost per unit area in production less than that of traditional silicon § Standard volume production (~ 20 m 2 /day) § Detector-readout connection automatically realized § Low capacitance favorable power – S/N § Very deep submicron allows power and speed advantages § Radiation tolerance Very interesting for the LHC upgrades § Significant investment dominated by engineering run submissions (90 nm or beyond !) Readout circuit Collection electrode Sensitive layer High energy particle Submission of a complete monolithic detector on a more lightly doped substrate than the standard one in 2010 FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 6

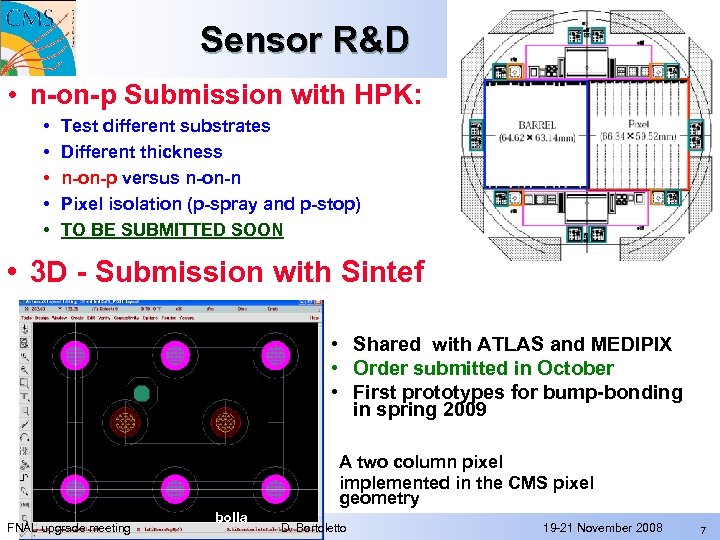

Sensor R&D • n-on-p Submission with HPK: • • • Test different substrates Different thickness n-on-p versus n-on-n Pixel isolation (p-spray and p-stop) TO BE SUBMITTED SOON • 3 D - Submission with Sintef • Shared with ATLAS and MEDIPIX • Order submitted in October • First prototypes for bump-bonding in spring 2009 A two column pixel implemented in the CMS pixel geometry bolla FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 7

Sensor R&D • n-on-p Submission with HPK: • • • Test different substrates Different thickness n-on-p versus n-on-n Pixel isolation (p-spray and p-stop) TO BE SUBMITTED SOON • 3 D - Submission with Sintef • Shared with ATLAS and MEDIPIX • Order submitted in October • First prototypes for bump-bonding in spring 2009 A two column pixel implemented in the CMS pixel geometry bolla FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 7

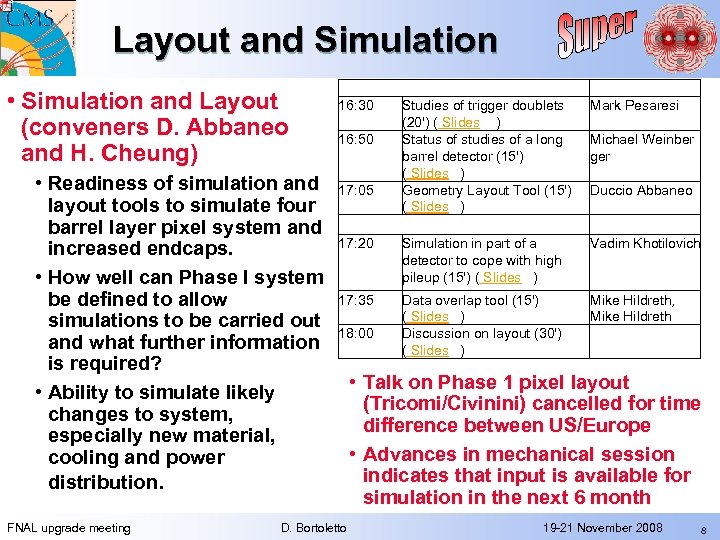

Layout and Simulation • Simulation and Layout (conveners D. Abbaneo and H. Cheung) • Readiness of simulation and layout tools to simulate four barrel layer pixel system and increased endcaps. • How well can Phase I system be defined to allow simulations to be carried out and what further information is required? • Ability to simulate likely changes to system, especially new material, cooling and power distribution. 16: 30 Studies of trigger doublets (20') ( Slides ) Status of studies of a long barrel detector (15') ( Slides ) Geometry Layout Tool (15') ( Slides ) Mark Pesaresi 17: 20 Simulation in part of a detector to cope with high pileup (15') ( Slides ) Vadim Khotilovich 17: 35 Data overlap tool (15') ( Slides ) Discussion on layout (30') ( Slides ) Mike Hildreth, Mike Hildreth 16: 50 17: 05 18: 00 Michael Weinber ger Duccio Abbaneo • Talk on Phase 1 pixel layout (Tricomi/Civinini) cancelled for time difference between US/Europe • Advances in mechanical session indicates that input is available for simulation in the next 6 month FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 8

Layout and Simulation • Simulation and Layout (conveners D. Abbaneo and H. Cheung) • Readiness of simulation and layout tools to simulate four barrel layer pixel system and increased endcaps. • How well can Phase I system be defined to allow simulations to be carried out and what further information is required? • Ability to simulate likely changes to system, especially new material, cooling and power distribution. 16: 30 Studies of trigger doublets (20') ( Slides ) Status of studies of a long barrel detector (15') ( Slides ) Geometry Layout Tool (15') ( Slides ) Mark Pesaresi 17: 20 Simulation in part of a detector to cope with high pileup (15') ( Slides ) Vadim Khotilovich 17: 35 Data overlap tool (15') ( Slides ) Discussion on layout (30') ( Slides ) Mike Hildreth, Mike Hildreth 16: 50 17: 05 18: 00 Michael Weinber ger Duccio Abbaneo • Talk on Phase 1 pixel layout (Tricomi/Civinini) cancelled for time difference between US/Europe • Advances in mechanical session indicates that input is available for simulation in the next 6 month FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 8

Cooling and Mechanics • Cooling and mechanics (conveners K. Arndt and H. Postema) • CO 2 cooling, constraints, improvements to the mechanics, mechanical design issues, such as sharing of information, documentation, experience of new materials, designs for improved material budget. • Changes to the mechanical structure for a four layer pixel system. • Extend the discussion of the kind of layout which Roland Horisberger described in the recent pixel upgrade meeting, about how this might be designed, built and how the cooling might be provided. • What are the implications for cooling plant and pressure/temperature of operation? What expertise is available in the collaboration, and where? FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 9

Cooling and Mechanics • Cooling and mechanics (conveners K. Arndt and H. Postema) • CO 2 cooling, constraints, improvements to the mechanics, mechanical design issues, such as sharing of information, documentation, experience of new materials, designs for improved material budget. • Changes to the mechanical structure for a four layer pixel system. • Extend the discussion of the kind of layout which Roland Horisberger described in the recent pixel upgrade meeting, about how this might be designed, built and how the cooling might be provided. • What are the implications for cooling plant and pressure/temperature of operation? What expertise is available in the collaboration, and where? FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 9

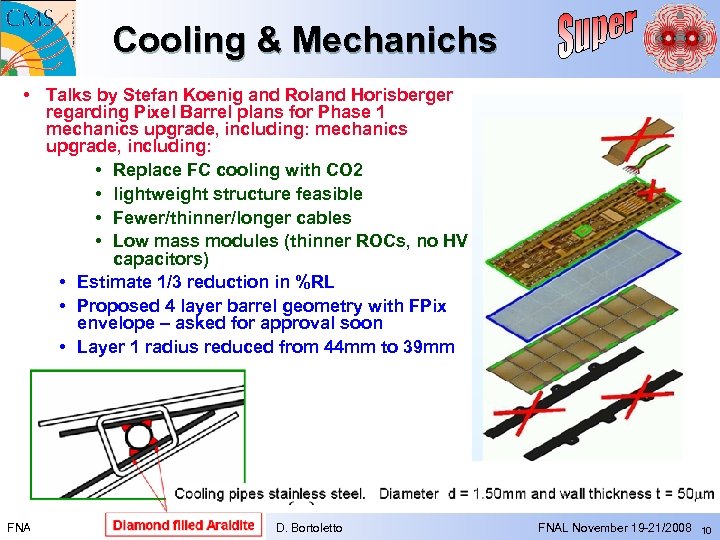

Cooling & Mechanichs • Talks by Stefan Koenig and Roland Horisberger regarding Pixel Barrel plans for Phase 1 mechanics upgrade, including: • Replace FC cooling with CO 2 • lightweight structure feasible • Fewer/thinner/longer cables • Low mass modules (thinner ROCs, no HV capacitors) • Estimate 1/3 reduction in %RL • Proposed 4 layer barrel geometry with FPix envelope – asked for approval soon • Layer 1 radius reduced from 44 mm to 39 mm FNAL Upgrade Meeting D. Bortoletto FNAL November 19 -21/2008 10

Cooling & Mechanichs • Talks by Stefan Koenig and Roland Horisberger regarding Pixel Barrel plans for Phase 1 mechanics upgrade, including: • Replace FC cooling with CO 2 • lightweight structure feasible • Fewer/thinner/longer cables • Low mass modules (thinner ROCs, no HV capacitors) • Estimate 1/3 reduction in %RL • Proposed 4 layer barrel geometry with FPix envelope – asked for approval soon • Layer 1 radius reduced from 44 mm to 39 mm FNAL Upgrade Meeting D. Bortoletto FNAL November 19 -21/2008 10

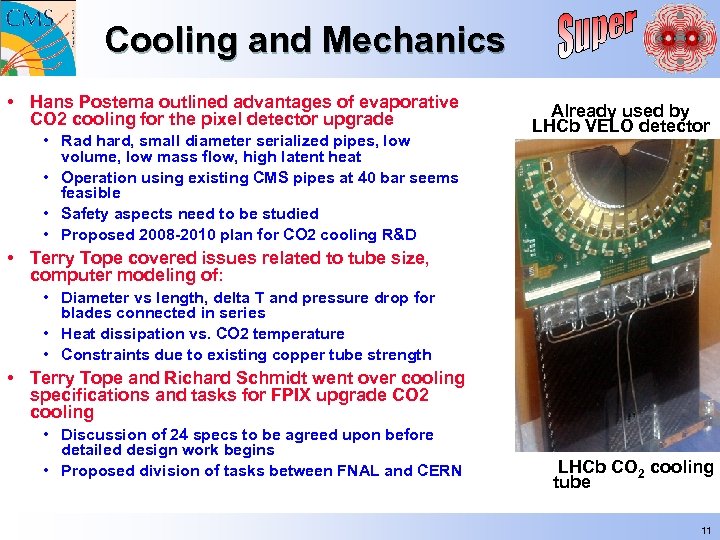

Cooling and Mechanics • Hans Postema outlined advantages of evaporative CO 2 cooling for the pixel detector upgrade • Rad hard, small diameter serialized pipes, low volume, low mass flow, high latent heat • Operation using existing CMS pipes at 40 bar seems feasible • Safety aspects need to be studied • Proposed 2008 -2010 plan for CO 2 cooling R&D Already used by LHCb VELO detector • Terry Tope covered issues related to tube size, computer modeling of: • Diameter vs length, delta T and pressure drop for blades connected in series • Heat dissipation vs. CO 2 temperature • Constraints due to existing copper tube strength • Terry Tope and Richard Schmidt went over cooling specifications and tasks for FPIX upgrade CO 2 cooling • Discussion of 24 specs to be agreed upon before detailed design work begins • Proposed division of tasks between FNAL and CERN LHCb CO 2 cooling tube 11

Cooling and Mechanics • Hans Postema outlined advantages of evaporative CO 2 cooling for the pixel detector upgrade • Rad hard, small diameter serialized pipes, low volume, low mass flow, high latent heat • Operation using existing CMS pipes at 40 bar seems feasible • Safety aspects need to be studied • Proposed 2008 -2010 plan for CO 2 cooling R&D Already used by LHCb VELO detector • Terry Tope covered issues related to tube size, computer modeling of: • Diameter vs length, delta T and pressure drop for blades connected in series • Heat dissipation vs. CO 2 temperature • Constraints due to existing copper tube strength • Terry Tope and Richard Schmidt went over cooling specifications and tasks for FPIX upgrade CO 2 cooling • Discussion of 24 specs to be agreed upon before detailed design work begins • Proposed division of tasks between FNAL and CERN LHCb CO 2 cooling tube 11

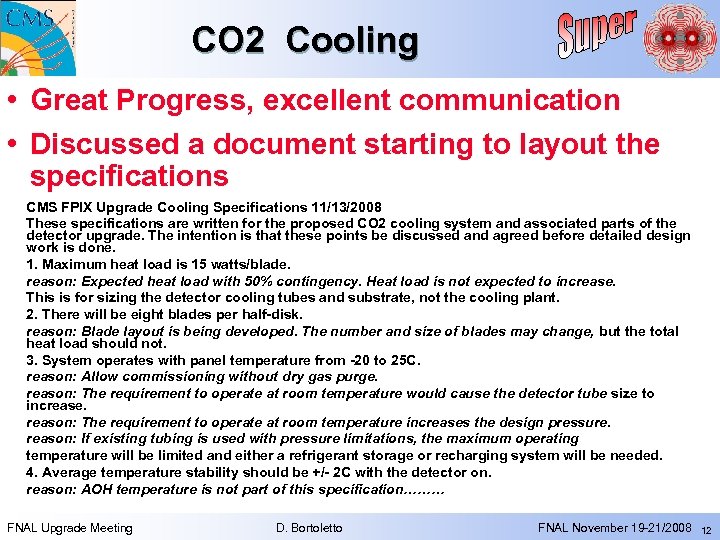

CO 2 Cooling • Great Progress, excellent communication • Discussed a document starting to layout the specifications CMS FPIX Upgrade Cooling Specifications 11/13/2008 These specifications are written for the proposed CO 2 cooling system and associated parts of the detector upgrade. The intention is that these points be discussed and agreed before detailed design work is done. 1. Maximum heat load is 15 watts/blade. reason: Expected heat load with 50% contingency. Heat load is not expected to increase. This is for sizing the detector cooling tubes and substrate, not the cooling plant. 2. There will be eight blades per half-disk. reason: Blade layout is being developed. The number and size of blades may change, but the total heat load should not. 3. System operates with panel temperature from -20 to 25 C. reason: Allow commissioning without dry gas purge. reason: The requirement to operate at room temperature would cause the detector tube size to increase. reason: The requirement to operate at room temperature increases the design pressure. reason: If existing tubing is used with pressure limitations, the maximum operating temperature will be limited and either a refrigerant storage or recharging system will be needed. 4. Average temperature stability should be +/- 2 C with the detector on. reason: AOH temperature is not part of this specification……… FNAL Upgrade Meeting D. Bortoletto FNAL November 19 -21/2008 12

CO 2 Cooling • Great Progress, excellent communication • Discussed a document starting to layout the specifications CMS FPIX Upgrade Cooling Specifications 11/13/2008 These specifications are written for the proposed CO 2 cooling system and associated parts of the detector upgrade. The intention is that these points be discussed and agreed before detailed design work is done. 1. Maximum heat load is 15 watts/blade. reason: Expected heat load with 50% contingency. Heat load is not expected to increase. This is for sizing the detector cooling tubes and substrate, not the cooling plant. 2. There will be eight blades per half-disk. reason: Blade layout is being developed. The number and size of blades may change, but the total heat load should not. 3. System operates with panel temperature from -20 to 25 C. reason: Allow commissioning without dry gas purge. reason: The requirement to operate at room temperature would cause the detector tube size to increase. reason: The requirement to operate at room temperature increases the design pressure. reason: If existing tubing is used with pressure limitations, the maximum operating temperature will be limited and either a refrigerant storage or recharging system will be needed. 4. Average temperature stability should be +/- 2 C with the detector on. reason: AOH temperature is not part of this specification……… FNAL Upgrade Meeting D. Bortoletto FNAL November 19 -21/2008 12

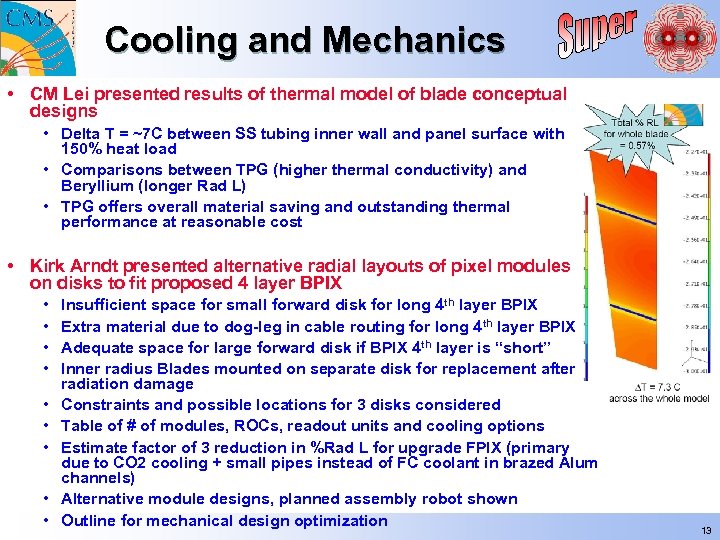

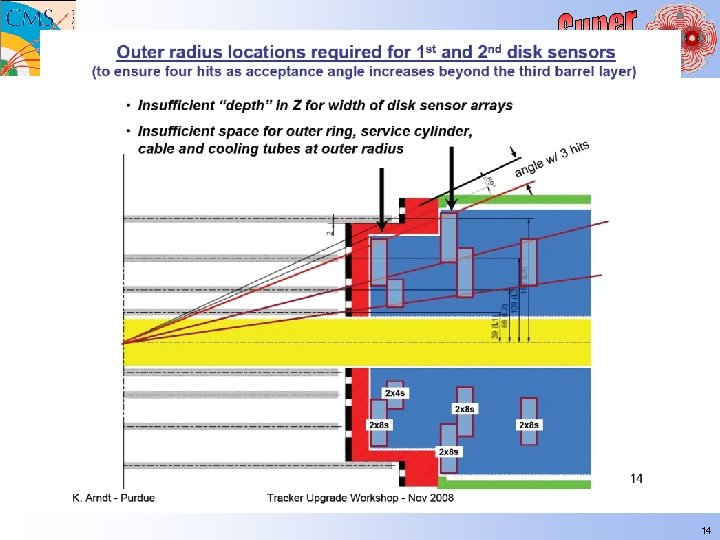

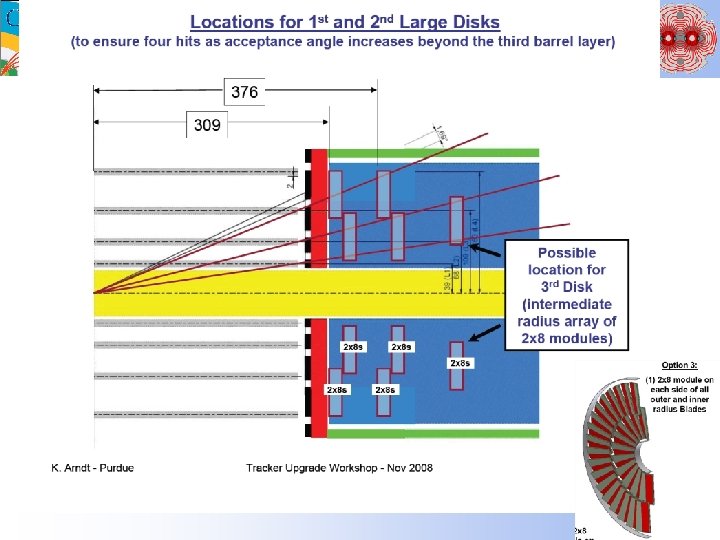

Cooling and Mechanics • CM Lei presented results of thermal model of blade conceptual designs • Delta T = ~7 C between SS tubing inner wall and panel surface with 150% heat load • Comparisons between TPG (higher thermal conductivity) and Beryllium (longer Rad L) • TPG offers overall material saving and outstanding thermal performance at reasonable cost • Kirk Arndt presented alternative radial layouts of pixel modules on disks to fit proposed 4 layer BPIX • • • Insufficient space for small forward disk for long 4 th layer BPIX Extra material due to dog-leg in cable routing for long 4 th layer BPIX Adequate space for large forward disk if BPIX 4 th layer is “short” Inner radius Blades mounted on separate disk for replacement after radiation damage Constraints and possible locations for 3 disks considered Table of # of modules, ROCs, readout units and cooling options Estimate factor of 3 reduction in %Rad L for upgrade FPIX (primary due to CO 2 cooling + small pipes instead of FC coolant in brazed Alum channels) Alternative module designs, planned assembly robot shown Outline for mechanical design optimization 13

Cooling and Mechanics • CM Lei presented results of thermal model of blade conceptual designs • Delta T = ~7 C between SS tubing inner wall and panel surface with 150% heat load • Comparisons between TPG (higher thermal conductivity) and Beryllium (longer Rad L) • TPG offers overall material saving and outstanding thermal performance at reasonable cost • Kirk Arndt presented alternative radial layouts of pixel modules on disks to fit proposed 4 layer BPIX • • • Insufficient space for small forward disk for long 4 th layer BPIX Extra material due to dog-leg in cable routing for long 4 th layer BPIX Adequate space for large forward disk if BPIX 4 th layer is “short” Inner radius Blades mounted on separate disk for replacement after radiation damage Constraints and possible locations for 3 disks considered Table of # of modules, ROCs, readout units and cooling options Estimate factor of 3 reduction in %Rad L for upgrade FPIX (primary due to CO 2 cooling + small pipes instead of FC coolant in brazed Alum channels) Alternative module designs, planned assembly robot shown Outline for mechanical design optimization 13

14

14

15

15

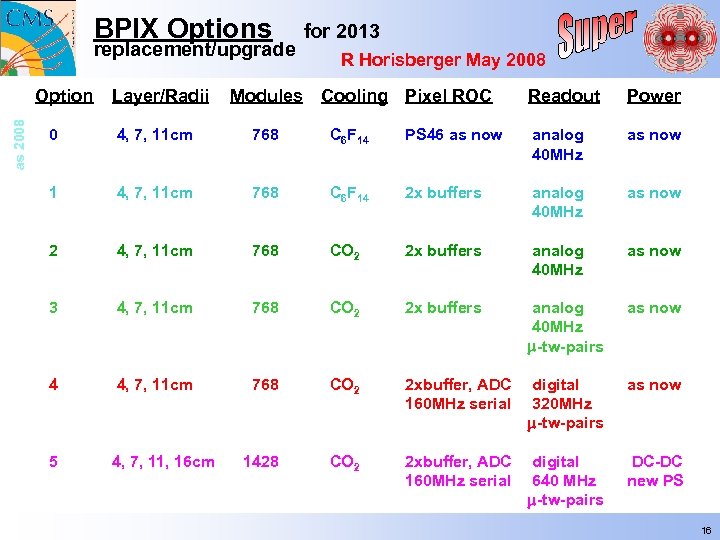

BPIX Options replacement/upgrade as 2008 Option Layer/Radii for 2013 R Horisberger May 2008 Modules Cooling Pixel ROC Readout Power 0 4, 7, 11 cm 768 C 6 F 14 PS 46 as now analog 40 MHz as now 1 4, 7, 11 cm 768 C 6 F 14 2 x buffers analog 40 MHz as now 2 4, 7, 11 cm 768 CO 2 2 x buffers analog 40 MHz as now 3 4, 7, 11 cm 768 CO 2 2 x buffers analog 40 MHz -tw-pairs as now 4 4, 7, 11 cm 768 CO 2 2 xbuffer, ADC 160 MHz serial digital 320 MHz -tw-pairs as now 5 4, 7, 11, 16 cm 1428 CO 2 2 xbuffer, ADC 160 MHz serial digital 640 MHz -tw-pairs DC-DC new PS 16

BPIX Options replacement/upgrade as 2008 Option Layer/Radii for 2013 R Horisberger May 2008 Modules Cooling Pixel ROC Readout Power 0 4, 7, 11 cm 768 C 6 F 14 PS 46 as now analog 40 MHz as now 1 4, 7, 11 cm 768 C 6 F 14 2 x buffers analog 40 MHz as now 2 4, 7, 11 cm 768 CO 2 2 x buffers analog 40 MHz as now 3 4, 7, 11 cm 768 CO 2 2 x buffers analog 40 MHz -tw-pairs as now 4 4, 7, 11 cm 768 CO 2 2 xbuffer, ADC 160 MHz serial digital 320 MHz -tw-pairs as now 5 4, 7, 11, 16 cm 1428 CO 2 2 xbuffer, ADC 160 MHz serial digital 640 MHz -tw-pairs DC-DC new PS 16

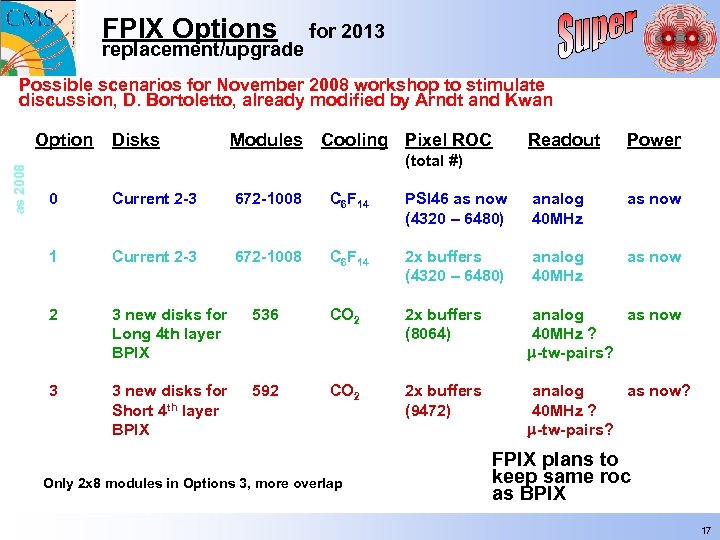

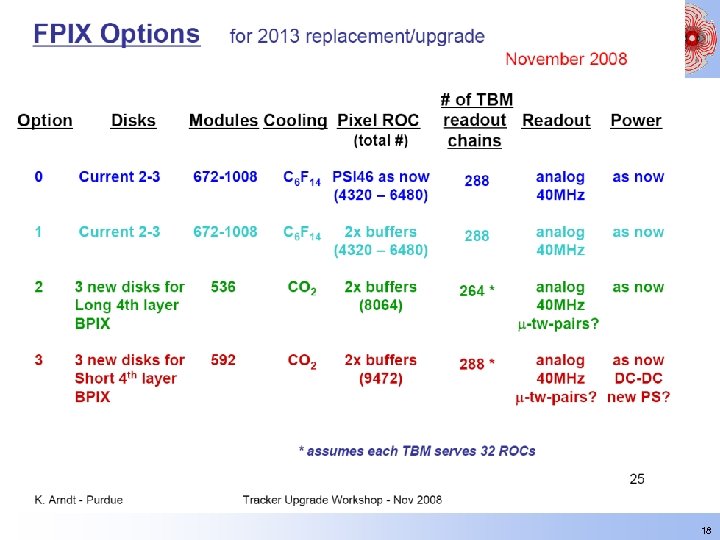

FPIX Options replacement/upgrade for 2013 Possible scenarios for November 2008 workshop to stimulate discussion, D. Bortoletto, already modified by Arndt and Kwan as 2008 Option Disks Modules Cooling Pixel ROC Readout Power (total #) 0 Current 2 -3 672 -1008 C 6 F 14 PSI 46 as now (4320 – 6480) analog 40 MHz as now 1 Current 2 -3 672 -1008 C 6 F 14 2 x buffers (4320 – 6480) analog 40 MHz as now 2 3 new disks for Long 4 th layer BPIX 536 CO 2 2 x buffers (8064) analog as now 40 MHz ? -tw-pairs? 3 3 new disks for Short 4 th layer BPIX 592 CO 2 2 x buffers (9472) analog as now? 40 MHz ? -tw-pairs? Only 2 x 8 modules in Options 3, more overlap FPIX plans to keep same roc as BPIX 17

FPIX Options replacement/upgrade for 2013 Possible scenarios for November 2008 workshop to stimulate discussion, D. Bortoletto, already modified by Arndt and Kwan as 2008 Option Disks Modules Cooling Pixel ROC Readout Power (total #) 0 Current 2 -3 672 -1008 C 6 F 14 PSI 46 as now (4320 – 6480) analog 40 MHz as now 1 Current 2 -3 672 -1008 C 6 F 14 2 x buffers (4320 – 6480) analog 40 MHz as now 2 3 new disks for Long 4 th layer BPIX 536 CO 2 2 x buffers (8064) analog as now 40 MHz ? -tw-pairs? 3 3 new disks for Short 4 th layer BPIX 592 CO 2 2 x buffers (9472) analog as now? 40 MHz ? -tw-pairs? Only 2 x 8 modules in Options 3, more overlap FPIX plans to keep same roc as BPIX 17

18

18

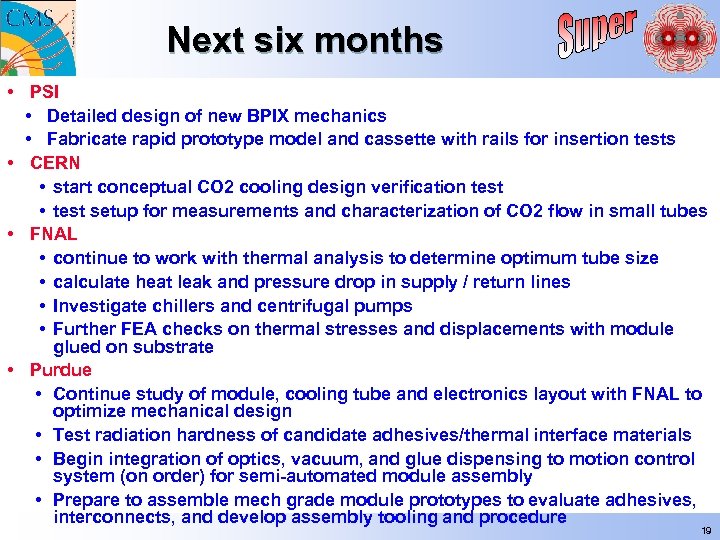

Next six months • PSI • Detailed design of new BPIX mechanics • Fabricate rapid prototype model and cassette with rails for insertion tests • CERN • start conceptual CO 2 cooling design verification test • test setup for measurements and characterization of CO 2 flow in small tubes • FNAL • continue to work with thermal analysis to determine optimum tube size • calculate heat leak and pressure drop in supply / return lines • Investigate chillers and centrifugal pumps • Further FEA checks on thermal stresses and displacements with module glued on substrate • Purdue • Continue study of module, cooling tube and electronics layout with FNAL to optimize mechanical design • Test radiation hardness of candidate adhesives/thermal interface materials • Begin integration of optics, vacuum, and glue dispensing to motion control system (on order) for semi-automated module assembly • Prepare to assemble mech grade module prototypes to evaluate adhesives, interconnects, and develop assembly tooling and procedure 19

Next six months • PSI • Detailed design of new BPIX mechanics • Fabricate rapid prototype model and cassette with rails for insertion tests • CERN • start conceptual CO 2 cooling design verification test • test setup for measurements and characterization of CO 2 flow in small tubes • FNAL • continue to work with thermal analysis to determine optimum tube size • calculate heat leak and pressure drop in supply / return lines • Investigate chillers and centrifugal pumps • Further FEA checks on thermal stresses and displacements with module glued on substrate • Purdue • Continue study of module, cooling tube and electronics layout with FNAL to optimize mechanical design • Test radiation hardness of candidate adhesives/thermal interface materials • Begin integration of optics, vacuum, and glue dispensing to motion control system (on order) for semi-automated module assembly • Prepare to assemble mech grade module prototypes to evaluate adhesives, interconnects, and develop assembly tooling and procedure 19

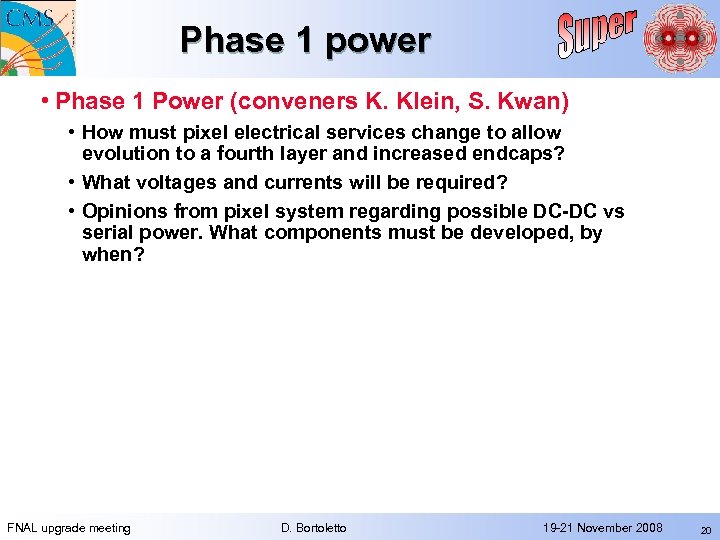

Phase 1 power • Phase 1 Power (conveners K. Klein, S. Kwan) • How must pixel electrical services change to allow evolution to a fourth layer and increased endcaps? • What voltages and currents will be required? • Opinions from pixel system regarding possible DC-DC vs serial power. What components must be developed, by when? FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 20

Phase 1 power • Phase 1 Power (conveners K. Klein, S. Kwan) • How must pixel electrical services change to allow evolution to a fourth layer and increased endcaps? • What voltages and currents will be required? • Opinions from pixel system regarding possible DC-DC vs serial power. What components must be developed, by when? FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 20

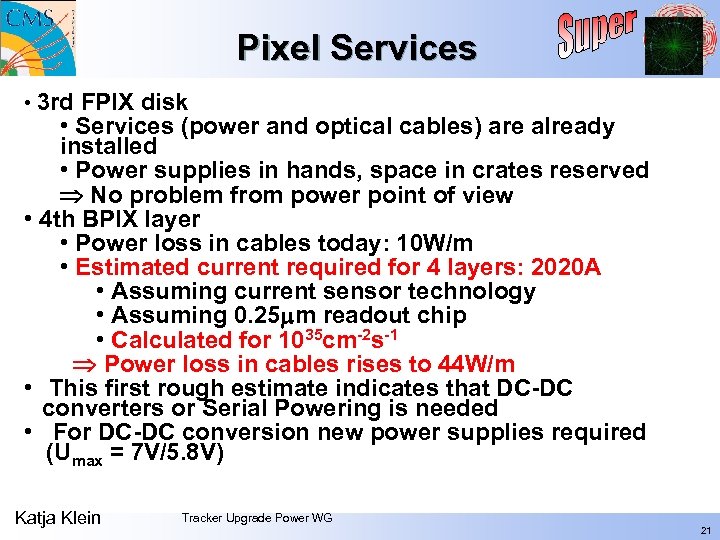

Pixel Services • 3 rd FPIX disk • Services (power and optical cables) are already installed • Power supplies in hands, space in crates reserved No problem from power point of view • 4 th BPIX layer • Power loss in cables today: 10 W/m • Estimated current required for 4 layers: 2020 A • Assuming current sensor technology • Assuming 0. 25 m readout chip • Calculated for 1035 cm-2 s-1 Power loss in cables rises to 44 W/m • This first rough estimate indicates that DC-DC converters or Serial Powering is needed • For DC-DC conversion new power supplies required (Umax = 7 V/5. 8 V) Katja Klein Tracker Upgrade Power WG 21

Pixel Services • 3 rd FPIX disk • Services (power and optical cables) are already installed • Power supplies in hands, space in crates reserved No problem from power point of view • 4 th BPIX layer • Power loss in cables today: 10 W/m • Estimated current required for 4 layers: 2020 A • Assuming current sensor technology • Assuming 0. 25 m readout chip • Calculated for 1035 cm-2 s-1 Power loss in cables rises to 44 W/m • This first rough estimate indicates that DC-DC converters or Serial Powering is needed • For DC-DC conversion new power supplies required (Umax = 7 V/5. 8 V) Katja Klein Tracker Upgrade Power WG 21

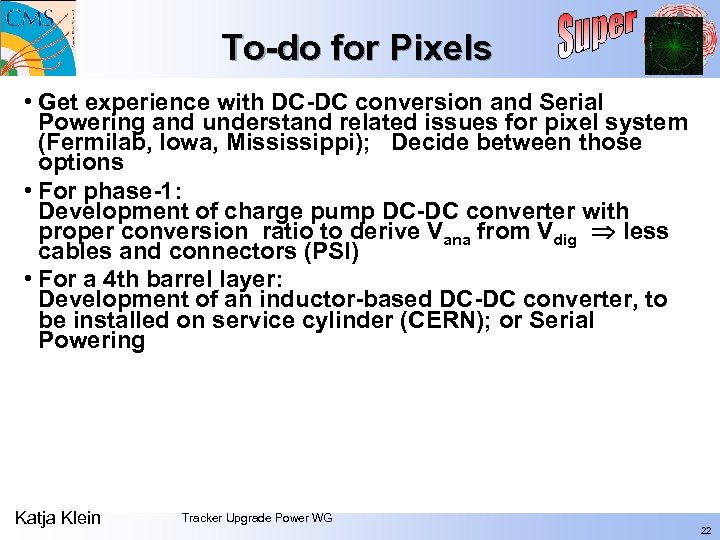

To-do for Pixels • Get experience with DC-DC conversion and Serial Powering and understand related issues for pixel system (Fermilab, Iowa, Mississippi); Decide between those options • For phase-1: Development of charge pump DC-DC converter with proper conversion ratio to derive Vana from Vdig less cables and connectors (PSI) • For a 4 th barrel layer: Development of an inductor-based DC-DC converter, to be installed on service cylinder (CERN); or Serial Powering Katja Klein Tracker Upgrade Power WG 22

To-do for Pixels • Get experience with DC-DC conversion and Serial Powering and understand related issues for pixel system (Fermilab, Iowa, Mississippi); Decide between those options • For phase-1: Development of charge pump DC-DC converter with proper conversion ratio to derive Vana from Vdig less cables and connectors (PSI) • For a 4 th barrel layer: Development of an inductor-based DC-DC converter, to be installed on service cylinder (CERN); or Serial Powering Katja Klein Tracker Upgrade Power WG 22

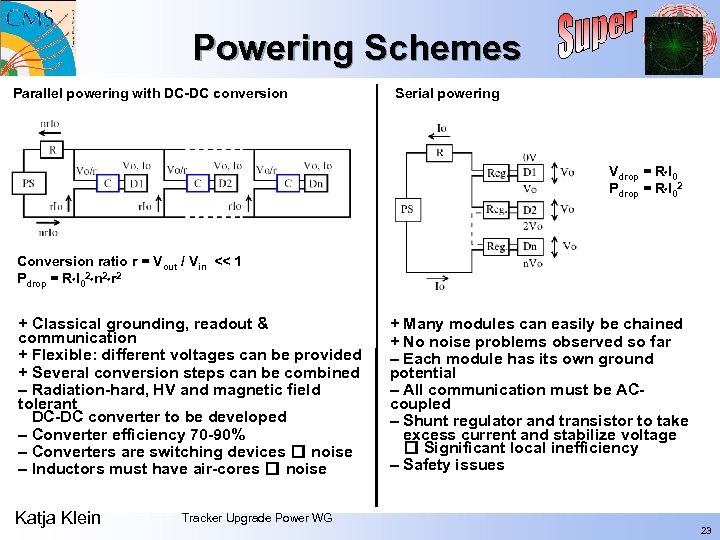

Powering Schemes Parallel powering with DC-DC conversion Serial powering Vdrop = R I 0 Pdrop = R I 02 Conversion ratio r = Vout / Vin << 1 Pdrop = R I 02 n 2 r 2 + Classical grounding, readout & communication + Flexible: different voltages can be provided + Several conversion steps can be combined – Radiation-hard, HV and magnetic field tolerant DC-DC converter to be developed – Converter efficiency 70 -90% – Converters are switching devices noise – Inductors must have air-cores noise Katja Klein + Many modules can easily be chained + No noise problems observed so far – Each module has its own ground potential – All communication must be ACcoupled – Shunt regulator and transistor to take excess current and stabilize voltage Significant local inefficiency – Safety issues Tracker Upgrade Power WG 23

Powering Schemes Parallel powering with DC-DC conversion Serial powering Vdrop = R I 0 Pdrop = R I 02 Conversion ratio r = Vout / Vin << 1 Pdrop = R I 02 n 2 r 2 + Classical grounding, readout & communication + Flexible: different voltages can be provided + Several conversion steps can be combined – Radiation-hard, HV and magnetic field tolerant DC-DC converter to be developed – Converter efficiency 70 -90% – Converters are switching devices noise – Inductors must have air-cores noise Katja Klein + Many modules can easily be chained + No noise problems observed so far – Each module has its own ground potential – All communication must be ACcoupled – Shunt regulator and transistor to take excess current and stabilize voltage Significant local inefficiency – Safety issues Tracker Upgrade Power WG 23

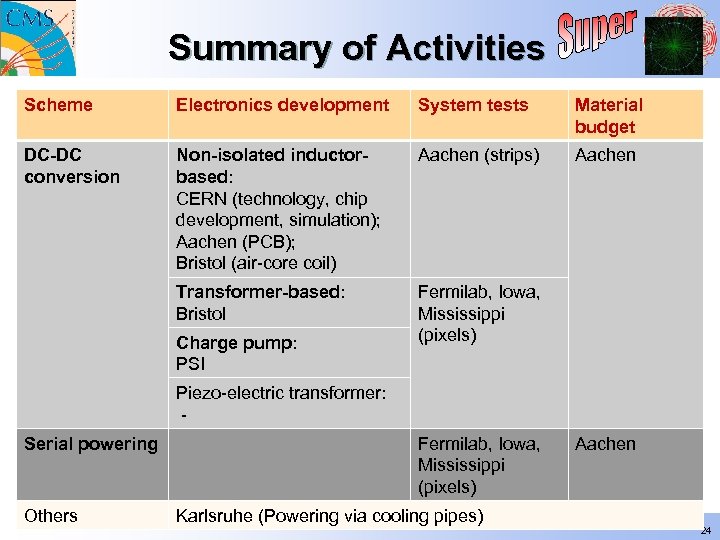

Summary of Activities Scheme Electronics development System tests Material budget DC-DC conversion Non-isolated inductorbased: CERN (technology, chip development, simulation); Aachen (PCB); Bristol (air-core coil) Aachen (strips) Aachen Transformer-based: Bristol Fermilab, Iowa, Mississippi (pixels) Charge pump: PSI Piezo-electric transformer: Serial powering Others Katja Klein Fermilab, Iowa, Mississippi (pixels) Tracker Upgrade Power WG Karlsruhe (Powering via cooling pipes) Aachen 24 24

Summary of Activities Scheme Electronics development System tests Material budget DC-DC conversion Non-isolated inductorbased: CERN (technology, chip development, simulation); Aachen (PCB); Bristol (air-core coil) Aachen (strips) Aachen Transformer-based: Bristol Fermilab, Iowa, Mississippi (pixels) Charge pump: PSI Piezo-electric transformer: Serial powering Others Katja Klein Fermilab, Iowa, Mississippi (pixels) Tracker Upgrade Power WG Karlsruhe (Powering via cooling pipes) Aachen 24 24

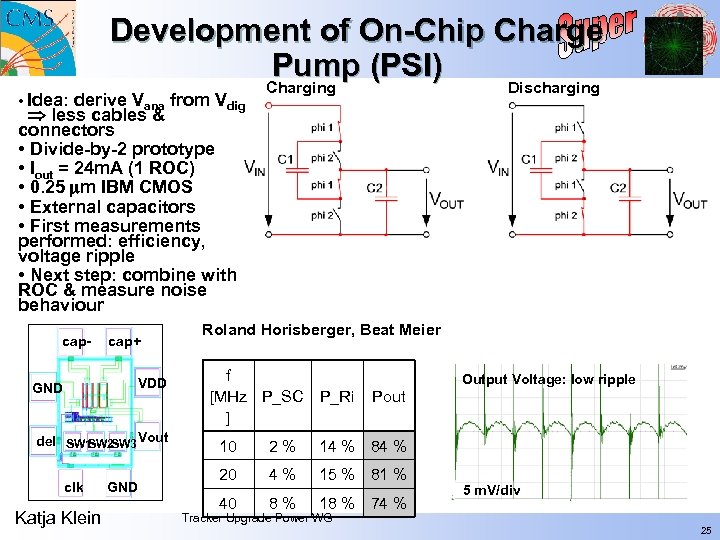

Development of On-Chip Charge Pump (PSI) • Idea: derive Vana from Vdig less cables & connectors • Divide-by-2 prototype • Iout = 24 m. A (1 ROC) • 0. 25 m IBM CMOS • External capacitors • First measurements performed: efficiency, voltage ripple • Next step: combine with ROC & measure noise behaviour cap- cap+ VDD GND del SW 1 SW 3 Vout SW 2 clk Katja Klein GND Charging Discharging Roland Horisberger, Beat Meier f [MHz P_SC ] Output Voltage: low ripple P_Ri Pout 10 2 % 14 % 84 % 20 4 % 15 % 81 % 40 8 % 18 % 74 % 5 m. V/div Tracker Upgrade Power WG 25

Development of On-Chip Charge Pump (PSI) • Idea: derive Vana from Vdig less cables & connectors • Divide-by-2 prototype • Iout = 24 m. A (1 ROC) • 0. 25 m IBM CMOS • External capacitors • First measurements performed: efficiency, voltage ripple • Next step: combine with ROC & measure noise behaviour cap- cap+ VDD GND del SW 1 SW 3 Vout SW 2 clk Katja Klein GND Charging Discharging Roland Horisberger, Beat Meier f [MHz P_SC ] Output Voltage: low ripple P_Ri Pout 10 2 % 14 % 84 % 20 4 % 15 % 81 % 40 8 % 18 % 74 % 5 m. V/div Tracker Upgrade Power WG 25

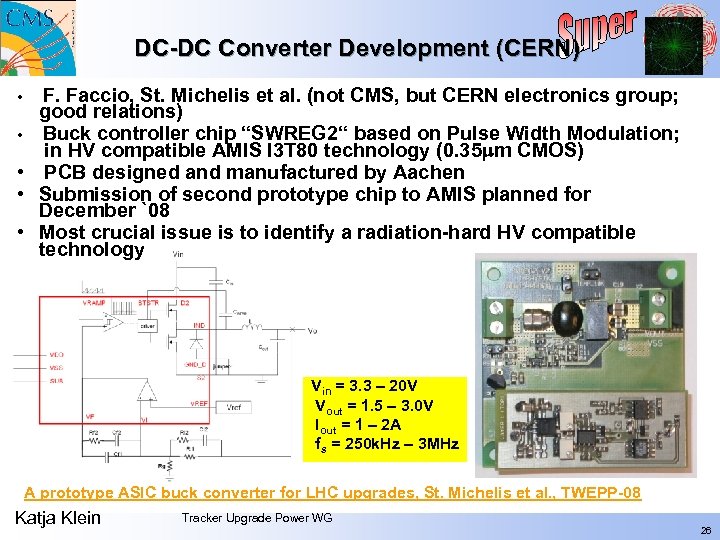

DC-DC Converter Development (CERN) F. Faccio, St. Michelis et al. (not CMS, but CERN electronics group; good relations) • Buck controller chip “SWREG 2“ based on Pulse Width Modulation; in HV compatible AMIS I 3 T 80 technology (0. 35 m CMOS) • PCB designed and manufactured by Aachen • Submission of second prototype chip to AMIS planned for December `08 • Most crucial issue is to identify a radiation-hard HV compatible technology • Vin = 3. 3 – 20 V Vout = 1. 5 – 3. 0 V Iout = 1 – 2 A fs = 250 k. Hz – 3 MHz A prototype ASIC buck converter for LHC upgrades, St. Michelis et al. , TWEPP-08 Katja Klein Tracker Upgrade Power WG 26

DC-DC Converter Development (CERN) F. Faccio, St. Michelis et al. (not CMS, but CERN electronics group; good relations) • Buck controller chip “SWREG 2“ based on Pulse Width Modulation; in HV compatible AMIS I 3 T 80 technology (0. 35 m CMOS) • PCB designed and manufactured by Aachen • Submission of second prototype chip to AMIS planned for December `08 • Most crucial issue is to identify a radiation-hard HV compatible technology • Vin = 3. 3 – 20 V Vout = 1. 5 – 3. 0 V Iout = 1 – 2 A fs = 250 k. Hz – 3 MHz A prototype ASIC buck converter for LHC upgrades, St. Michelis et al. , TWEPP-08 Katja Klein Tracker Upgrade Power WG 26

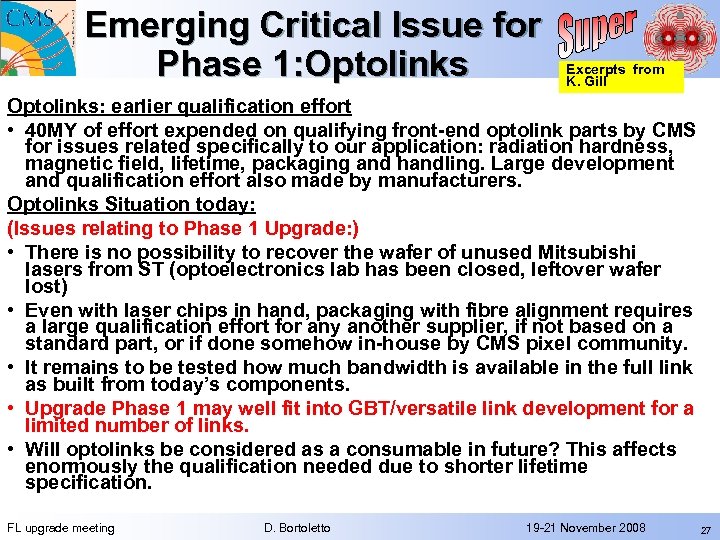

Emerging Critical Issue for Phase 1: Optolinks Excerpts from K. Gill Optolinks: earlier qualification effort • 40 MY of effort expended on qualifying front-end optolink parts by CMS for issues related specifically to our application: radiation hardness, magnetic field, lifetime, packaging and handling. Large development and qualification effort also made by manufacturers. Optolinks Situation today: (Issues relating to Phase 1 Upgrade: ) • There is no possibility to recover the wafer of unused Mitsubishi lasers from ST (optoelectronics lab has been closed, leftover wafer lost) • Even with laser chips in hand, packaging with fibre alignment requires a large qualification effort for any another supplier, if not based on a standard part, or if done somehow in-house by CMS pixel community. • It remains to be tested how much bandwidth is available in the full link as built from today’s components. • Upgrade Phase 1 may well fit into GBT/versatile link development for a limited number of links. • Will optolinks be considered as a consumable in future? This affects enormously the qualification needed due to shorter lifetime specification. FL upgrade meeting D. Bortoletto 19 -21 November 2008 27

Emerging Critical Issue for Phase 1: Optolinks Excerpts from K. Gill Optolinks: earlier qualification effort • 40 MY of effort expended on qualifying front-end optolink parts by CMS for issues related specifically to our application: radiation hardness, magnetic field, lifetime, packaging and handling. Large development and qualification effort also made by manufacturers. Optolinks Situation today: (Issues relating to Phase 1 Upgrade: ) • There is no possibility to recover the wafer of unused Mitsubishi lasers from ST (optoelectronics lab has been closed, leftover wafer lost) • Even with laser chips in hand, packaging with fibre alignment requires a large qualification effort for any another supplier, if not based on a standard part, or if done somehow in-house by CMS pixel community. • It remains to be tested how much bandwidth is available in the full link as built from today’s components. • Upgrade Phase 1 may well fit into GBT/versatile link development for a limited number of links. • Will optolinks be considered as a consumable in future? This affects enormously the qualification needed due to shorter lifetime specification. FL upgrade meeting D. Bortoletto 19 -21 November 2008 27

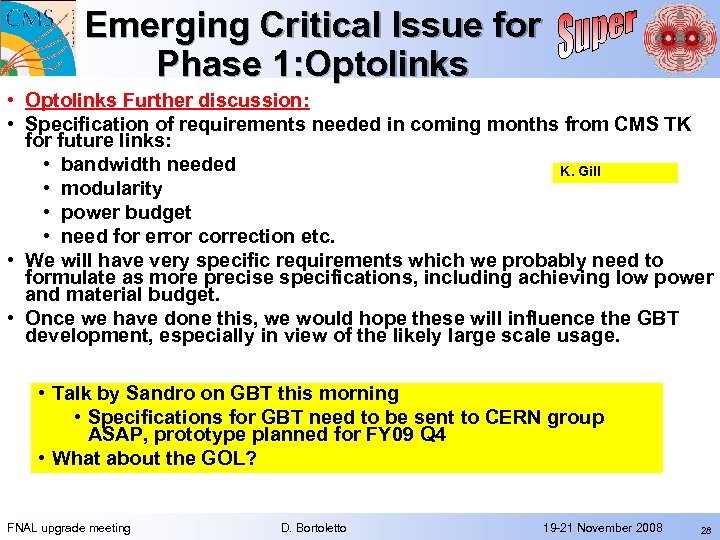

Emerging Critical Issue for Phase 1: Optolinks • Optolinks Further discussion: • Specification of requirements needed in coming months from CMS TK for future links: • bandwidth needed K. Gill • modularity • power budget • need for error correction etc. • We will have very specific requirements which we probably need to formulate as more precise specifications, including achieving low power and material budget. • Once we have done this, we would hope these will influence the GBT development, especially in view of the likely large scale usage. • Talk by Sandro on GBT this morning • Specifications for GBT need to be sent to CERN group ASAP, prototype planned for FY 09 Q 4 • What about the GOL? FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 28

Emerging Critical Issue for Phase 1: Optolinks • Optolinks Further discussion: • Specification of requirements needed in coming months from CMS TK for future links: • bandwidth needed K. Gill • modularity • power budget • need for error correction etc. • We will have very specific requirements which we probably need to formulate as more precise specifications, including achieving low power and material budget. • Once we have done this, we would hope these will influence the GBT development, especially in view of the likely large scale usage. • Talk by Sandro on GBT this morning • Specifications for GBT need to be sent to CERN group ASAP, prototype planned for FY 09 Q 4 • What about the GOL? FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 28

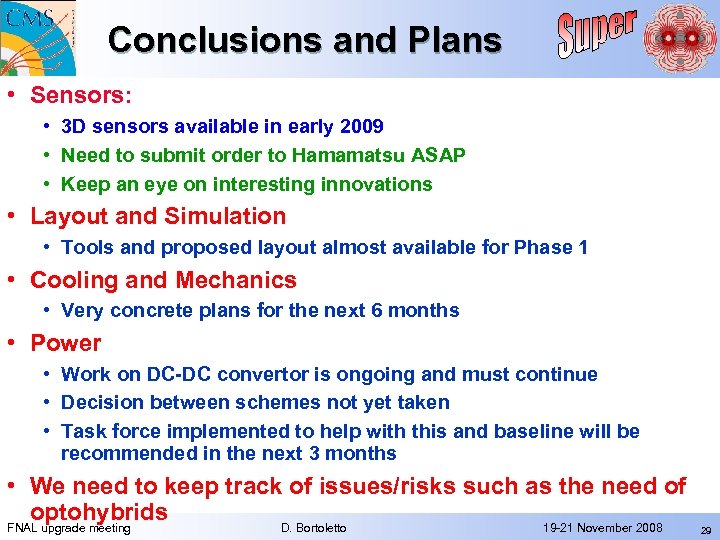

Conclusions and Plans • Sensors: • 3 D sensors available in early 2009 • Need to submit order to Hamamatsu ASAP • Keep an eye on interesting innovations • Layout and Simulation • Tools and proposed layout almost available for Phase 1 • Cooling and Mechanics • Very concrete plans for the next 6 months • Power • Work on DC-DC convertor is ongoing and must continue • Decision between schemes not yet taken • Task force implemented to help with this and baseline will be recommended in the next 3 months • We need to keep track of issues/risks such as the need of optohybrids FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 29

Conclusions and Plans • Sensors: • 3 D sensors available in early 2009 • Need to submit order to Hamamatsu ASAP • Keep an eye on interesting innovations • Layout and Simulation • Tools and proposed layout almost available for Phase 1 • Cooling and Mechanics • Very concrete plans for the next 6 months • Power • Work on DC-DC convertor is ongoing and must continue • Decision between schemes not yet taken • Task force implemented to help with this and baseline will be recommended in the next 3 months • We need to keep track of issues/risks such as the need of optohybrids FNAL upgrade meeting D. Bortoletto 19 -21 November 2008 29