639aea6227c650001e96c67a333120d7.ppt

- Количество слайдов: 33

SUCCESSFULLY USING BIOMASS TO HARNESS RENEWABLE ENERGY IN AN EFFICIENT AND COST-EFFECTIVE WAY J. E. Naber and F. Goudriaan (BIOFUEL BV) HTU 2000 BIOFUEL B. V. 1

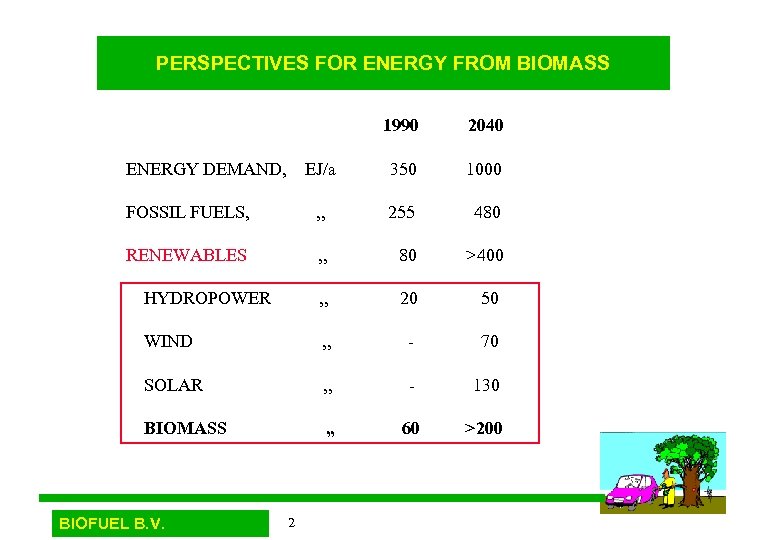

PERSPECTIVES FOR ENERGY FROM BIOMASS 1990 2040 EJ/a 350 1000 FOSSIL FUELS, „ 255 480 RENEWABLES „ 80 >400 HYDROPOWER „ 20 50 WIND „ - 70 SOLAR „ - 130 BIOMASS „ 60 >200 ENERGY DEMAND, BIOFUEL B. V. 2

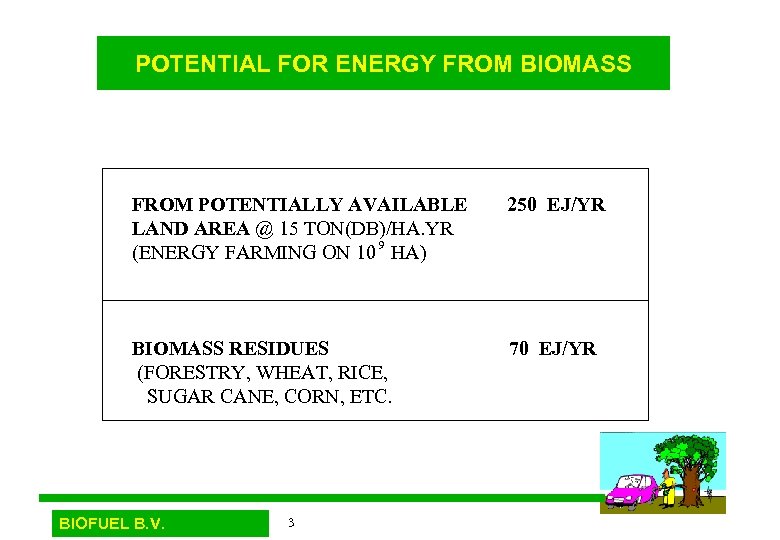

POTENTIAL FOR ENERGY FROM BIOMASS FROM POTENTIALLY AVAILABLE LAND AREA @ 15 TON(DB)/HA. YR 9 (ENERGY FARMING ON 10 HA) 250 EJ/YR BIOMASS RESIDUES (FORESTRY, WHEAT, RICE, SUGAR CANE, CORN, ETC. 70 EJ/YR BIOFUEL B. V. 3

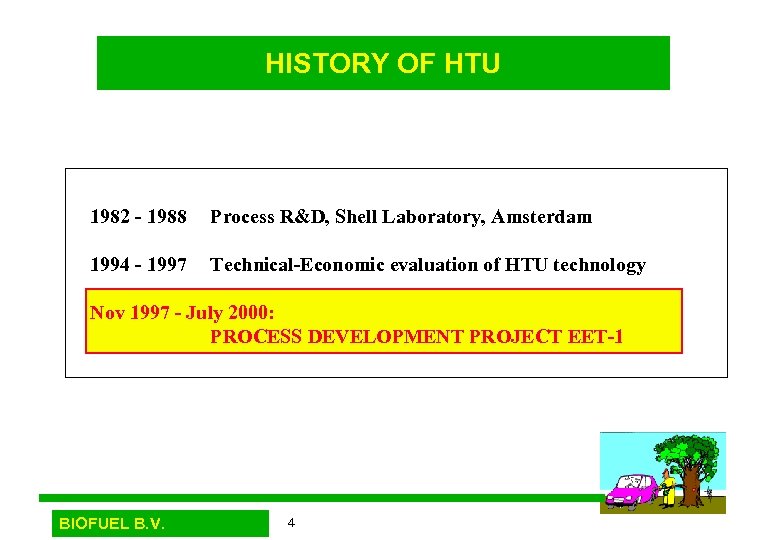

HISTORY OF HTU 1982 - 1988 Process R&D, Shell Laboratory, Amsterdam 1994 - 1997 Technical-Economic evaluation of HTU technology Nov 1997 - July 2000: PROCESS DEVELOPMENT PROJECT EET-1 BIOFUEL B. V. 4

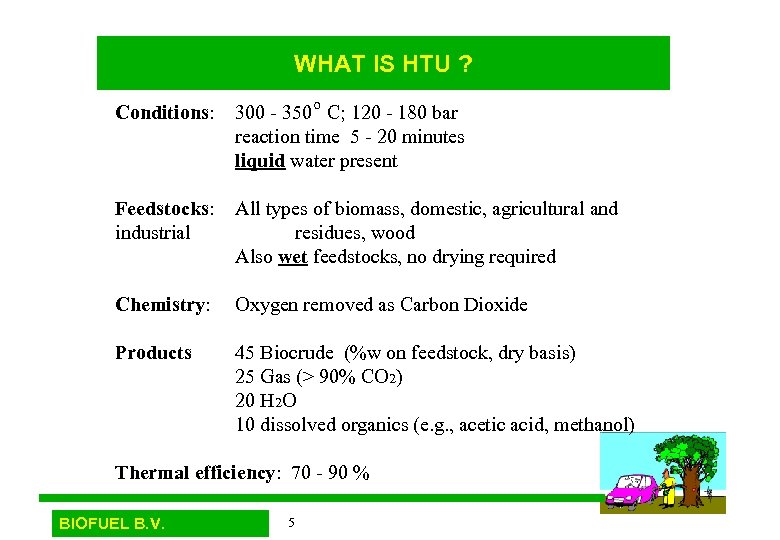

WHAT IS HTU ? Conditions: 300 - 350 o C; 120 - 180 bar reaction time 5 - 20 minutes liquid water present Feedstocks: industrial All types of biomass, domestic, agricultural and residues, wood Also wet feedstocks, no drying required Chemistry: Oxygen removed as Carbon Dioxide Products 45 Biocrude (%w on feedstock, dry basis) 25 Gas (> 90% CO 2) 20 H 2 O 10 dissolved organics (e. g. , acetic acid, methanol) Thermal efficiency: 70 - 90 % BIOFUEL B. V. 5

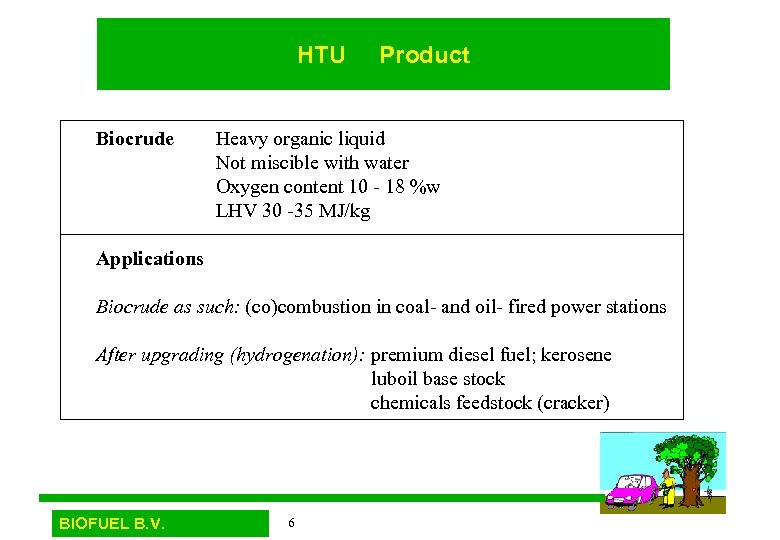

HTU Biocrude Product Heavy organic liquid Not miscible with water Oxygen content 10 - 18 %w LHV 30 -35 MJ/kg Applications Biocrude as such: (co)combustion in coal- and oil- fired power stations After upgrading (hydrogenation): premium diesel fuel; kerosene luboil base stock chemicals feedstock (cracker) BIOFUEL B. V. 6

HTU PRODUCT FLEXIBILITY • Direct combustion as a liquid (replacement of fossil fuels) • Combustion as a solid fuel (cofiring with coal) • Emulsified fuel (type “Orimulsion”) • Replacement of charcoal • Upgraded product BIOFUEL B. V. 7

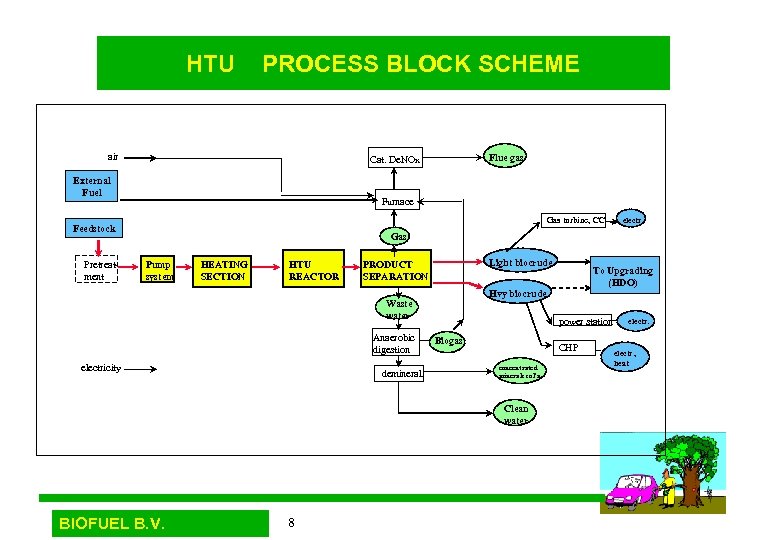

HTU PROCESS BLOCK SCHEME air External Fuel Furnace Gas turbine, CC Feedstock Pretreatment Flue gas Cat. De. NOx electr. Gas Pump system HEATING SECTION HTU REACTOR Light biocrude PRODUCT SEPARATION Hvy biocrude Waste water Anaerobic digestion electricity demineral. power station Biogas CHP concentrated minerals sol’n Clean water BIOFUEL B. V. 8 To Upgrading (HDO) electr. , heat

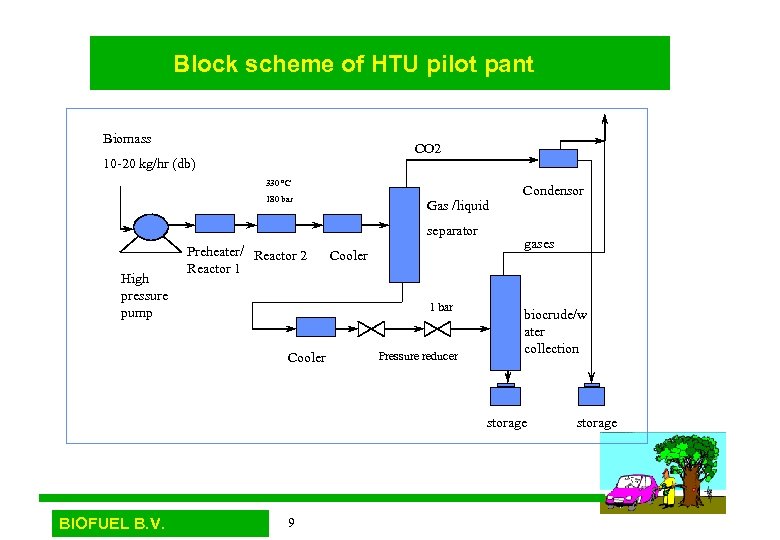

Block scheme of of HTU pilot plant Block scheme HTU pilot pant Biomass CO 2 10 -20 kg/hr (db) 330 °C 180 bar Gas /liquid separator High pressure pump Preheater/ Reactor 2 Reactor 1 Cooler 1 bar Cooler Pressure reducer Condensor gases biocrude/w ater collection storage BIOFUEL B. V. 9 storage

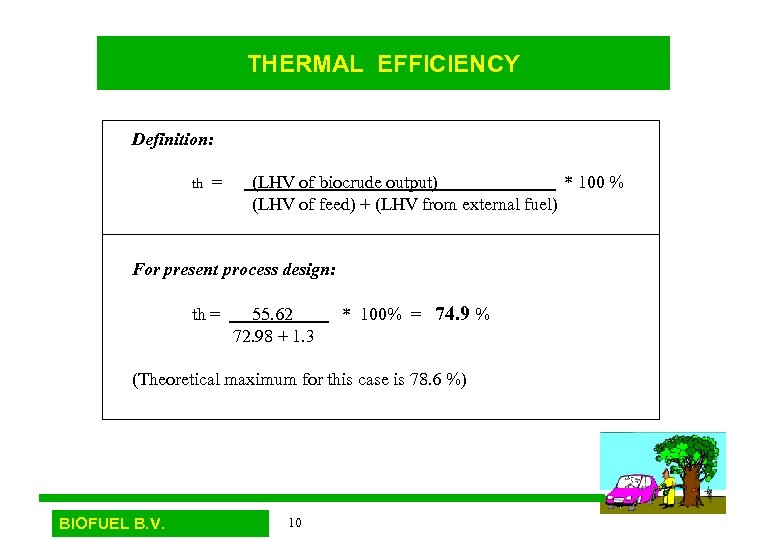

THERMAL EFFICIENCY Definition: th = (LHV of biocrude output) * 100 % (LHV of feed) + (LHV from external fuel) For present process design: th = 55. 62 72. 98 + 1. 3 * 100% = 74. 9 % (Theoretical maximum for this case is 78. 6 %) BIOFUEL B. V. 10

Upgrading of biocrude by HDO • Principle of catalytic Hydrodeoxygenation has been demonstrated • Upgrading cost compensated by higher product value • Diesel fraction has excellent ignition properties • Potential applications: • Transport fuel • • BIOFUEL B. V. Kerosine Fuel in high-efficient gas turbine Feedstock for chemicals (via ethylene cracker) Etc. etc. 11

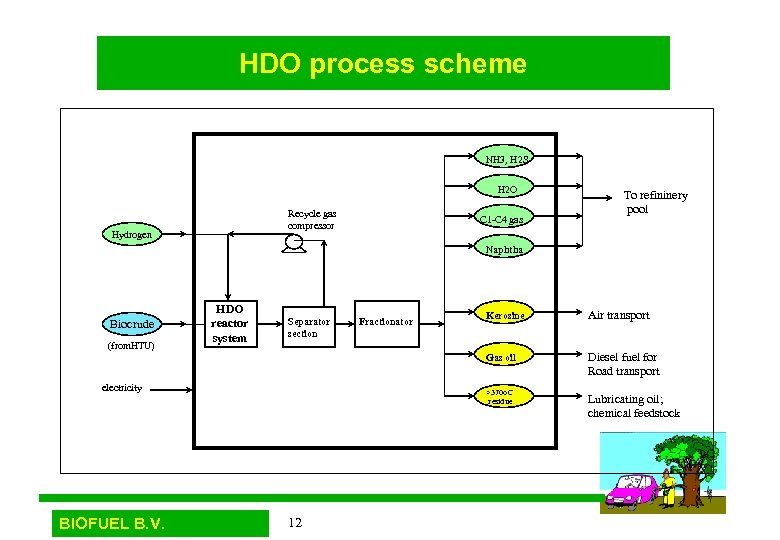

HDO process scheme NH 3, H 2 S H 2 O Recycle gas compressor Hydrogen C 1 -C 4 gas To refininery pool Naphtha HDO reactor system (from. HTU) Separator section electricity BIOFUEL B. V. Fractionator Kerosine Air transport Gas oil Biocrude Diesel fuel for Road transport >370 o. C residue 12 Lubricating oil; chemical feedstock

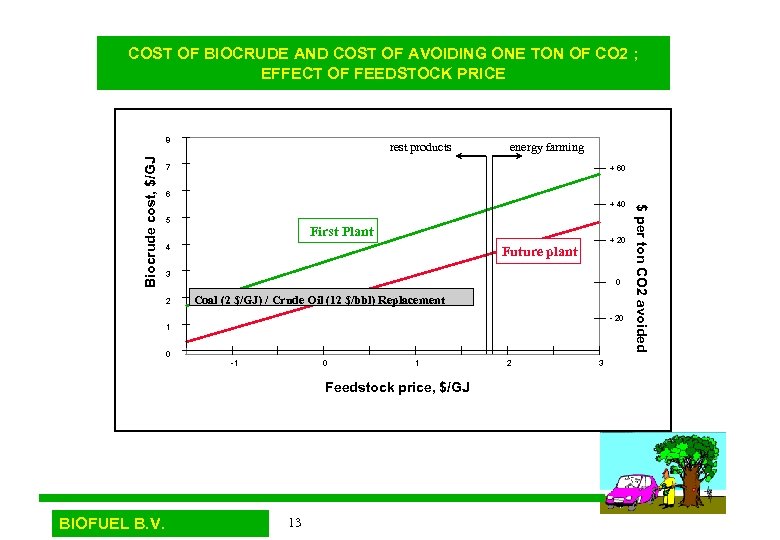

COST OF BIOCRUDE AND COST OF AVOIDING ONE TON OF CO 2 ; EFFECT OF FEEDSTOCK PRICE rest products energy farming 7 + 60 6 + 40 5 First Plant 4 + 20 Future plant 3 2 0 Coal (2 $/GJ) / Crude Oil (12 $/bbl) Replacement - 20 1 0 -1 0 1 Feedstock price, $/GJ BIOFUEL B. V. 13 2 3 $ per ton CO 2 avoided Biocrude cost, $/GJ 8

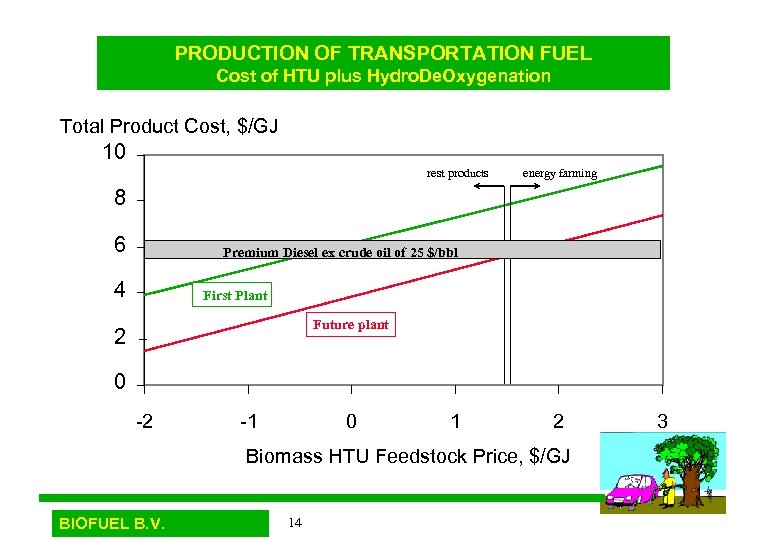

PRODUCTION OF TRANSPORTATION FUEL Cost of HTU plus Hydro. De. Oxygenation Total Product Cost, $/GJ 10 rest products energy farming 8 6 Premium Diesel ex crude oil of 25 $/bbl 4 First Plant Future plant 2 0 -2 -1 0 1 2 Biomass HTU Feedstock Price, $/GJ BIOFUEL B. V. 14 3

HTU R&D PROGRAM GO / NO GO ITEMS • Pressurizing • Continuous integrated operation of pilot plant CRITICAL ITEMS • Heating - up • Oil/water separation • Product properties / applications • Effluent treatment DATA FOR DESIGN • Phase equilibria • Physical properties, esp. at reactor/separator conditions BIOFUEL B. V. 15

Process Development Work in autoclaves, • 10 ml, 1 liter, 2 liter • Testing of feedstocks and process conditions Continuous pilot plant • capacity 20 kg/hour (dry basis) • commissioning 1 July 1999 • first product prepared: 24 November 1999 BIOFUEL B. V. 16

Development project EET-1 Mission: Design data for demonstration plant, validated in continuous pilot plant Time period: 1 November 1997 - 31 July 2000 Cost and funding: Subsidy 3 M$ (Dutch Min. of Economic Affairs, EET programme) Stork E&C (Now Jacobs) Shell Nederland TNO, BTG, Biofuel Total BIOFUEL B. V. 17 1 1 1 6 M$

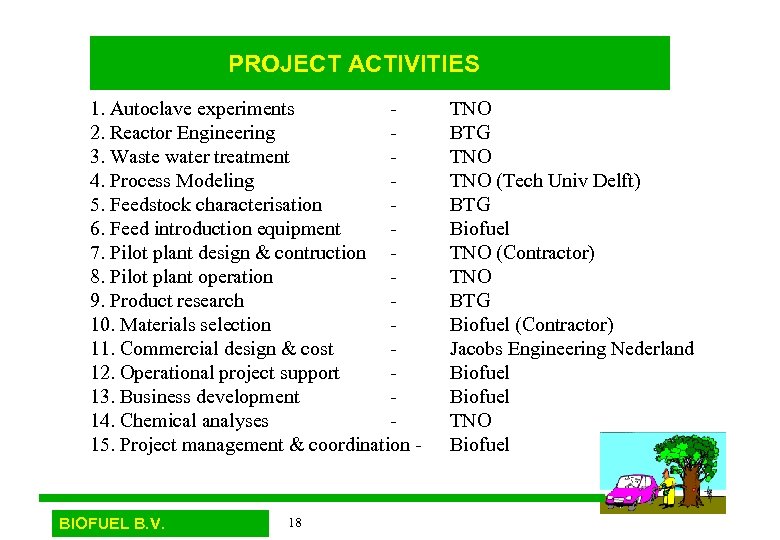

PROJECT ACTIVITIES 1. Autoclave experiments 2. Reactor Engineering 3. Waste water treatment 4. Process Modeling 5. Feedstock characterisation 6. Feed introduction equipment 7. Pilot plant design & contruction 8. Pilot plant operation 9. Product research 10. Materials selection 11. Commercial design & cost 12. Operational project support 13. Business development 14. Chemical analyses 15. Project management & coordination - BIOFUEL B. V. 18 TNO BTG TNO (Tech Univ Delft) BTG Biofuel TNO (Contractor) TNO BTG Biofuel (Contractor) Jacobs Engineering Nederland Biofuel TNO Biofuel

PROCESS DESIGN CASE STUDY Basic process design by Jacobs Engineering Nederland Process scheme, Mass & Heat Balances: ASPEN PLUS flowsheeter All disciplines involved, incl. layout Case study: Feedstock: Intake Capacity: Sugar beet pulp, 22 %w dry matter 130, 000 tonnes/year (dry basis) Focus on heat integration, thermal efficiency BIOFUEL B. V. 19

RESULTS OF EET-1 PROJECT • Pilot plant construction completed • Pilot plant operation: - process principles verified - most initial problems solved - 200 kg biocrude produced • Pressurizing of feedstock successfully proven with commercial prototype pump • Data on thermodynamics and phase equilibria obtained; model operational • Waste water treatment routes defined • Product: various applications explored • Process design and cost estimation completed • Fundamental research to start: NWO – Japan project. BIOFUEL B. V. 20

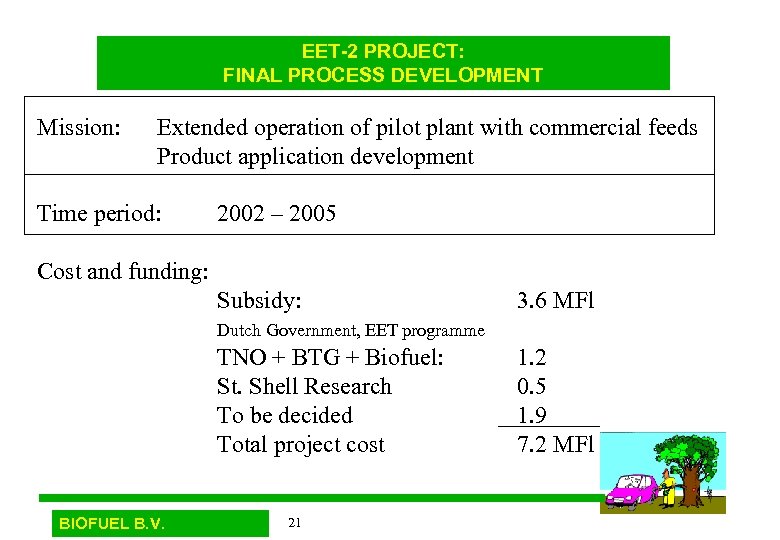

EET-2 PROJECT: FINAL PROCESS DEVELOPMENT Mission: Extended operation of pilot plant with commercial feeds Product application development Time period: 2002 – 2005 Cost and funding: Subsidy: 3. 6 MFl Dutch Government, EET programme TNO + BTG + Biofuel: St. Shell Research To be decided Total project cost BIOFUEL B. V. 21 1. 2 0. 5 1. 9 7. 2 MFl

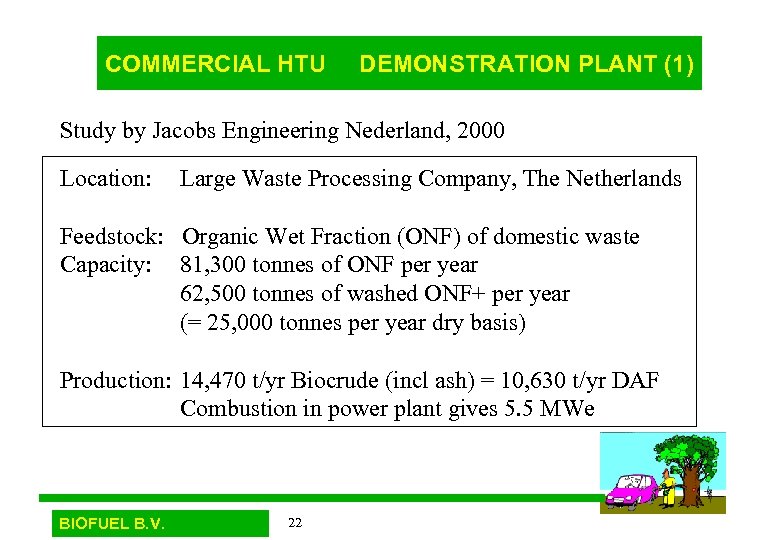

COMMERCIAL HTU DEMONSTRATION PLANT (1) Study by Jacobs Engineering Nederland, 2000 Location: Large Waste Processing Company, The Netherlands Feedstock: Organic Wet Fraction (ONF) of domestic waste Capacity: 81, 300 tonnes of ONF per year 62, 500 tonnes of washed ONF+ per year (= 25, 000 tonnes per year dry basis) Production: 14, 470 t/yr Biocrude (incl ash) = 10, 630 t/yr DAF Combustion in power plant gives 5. 5 MWe BIOFUEL B. V. 22

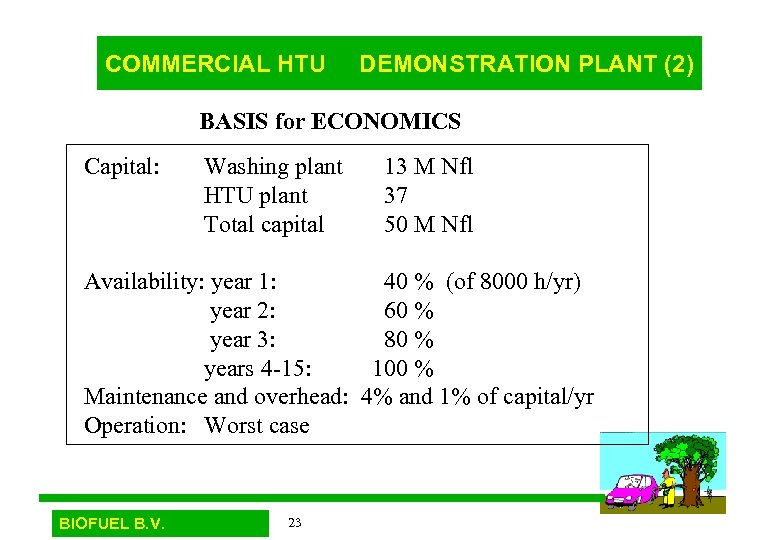

COMMERCIAL HTU DEMONSTRATION PLANT (2) BASIS for ECONOMICS Capital: Washing plant HTU plant Total capital 13 M Nfl 37 50 M Nfl Availability: year 1: 40 % (of 8000 h/yr) year 2: 60 % year 3: 80 % years 4 -15: 100 % Maintenance and overhead: 4% and 1% of capital/yr Operation: Worst case BIOFUEL B. V. 23

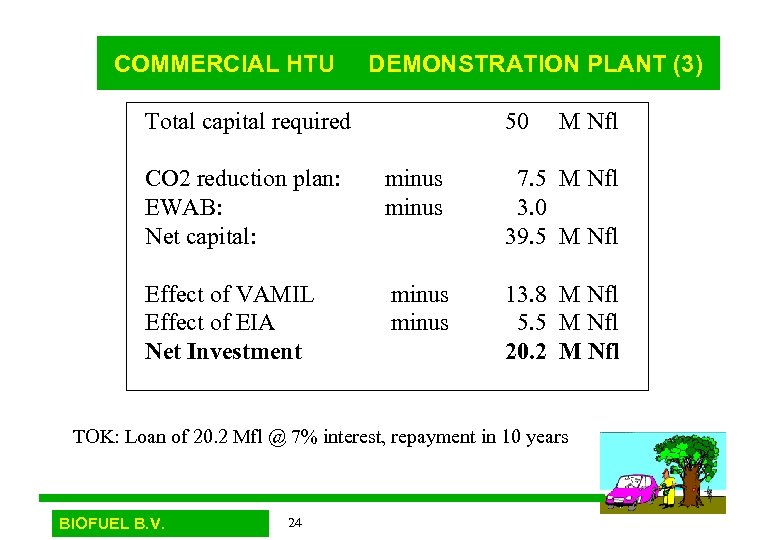

COMMERCIAL HTU DEMONSTRATION PLANT (3) Total capital required 50 M Nfl CO 2 reduction plan: EWAB: Net capital: minus 7. 5 M Nfl 3. 0 39. 5 M Nfl Effect of VAMIL Effect of EIA Net Investment minus 13. 8 M Nfl 5. 5 M Nfl 20. 2 M Nfl TOK: Loan of 20. 2 Mfl @ 7% interest, repayment in 10 years BIOFUEL B. V. 24

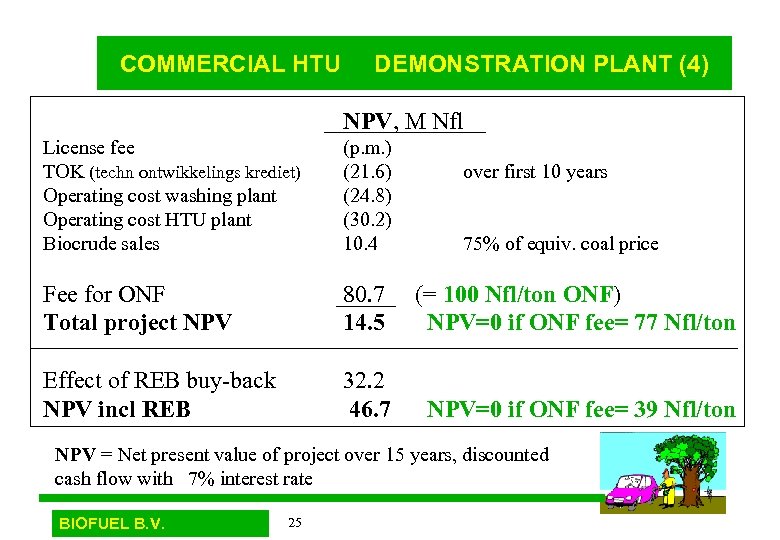

COMMERCIAL HTU DEMONSTRATION PLANT (4) NPV, M Nfl License fee TOK (techn ontwikkelings krediet) Operating cost washing plant Operating cost HTU plant Biocrude sales (p. m. ) (21. 6) (24. 8) (30. 2) 10. 4 Fee for ONF Total project NPV 80. 7 14. 5 (= 100 Nfl/ton ONF) NPV=0 if ONF fee= 77 Nfl/ton Effect of REB buy-back NPV incl REB 32. 2 46. 7 NPV=0 if ONF fee= 39 Nfl/ton over first 10 years 75% of equiv. coal price NPV = Net present value of project over 15 years, discounted cash flow with 7% interest rate BIOFUEL B. V. 25

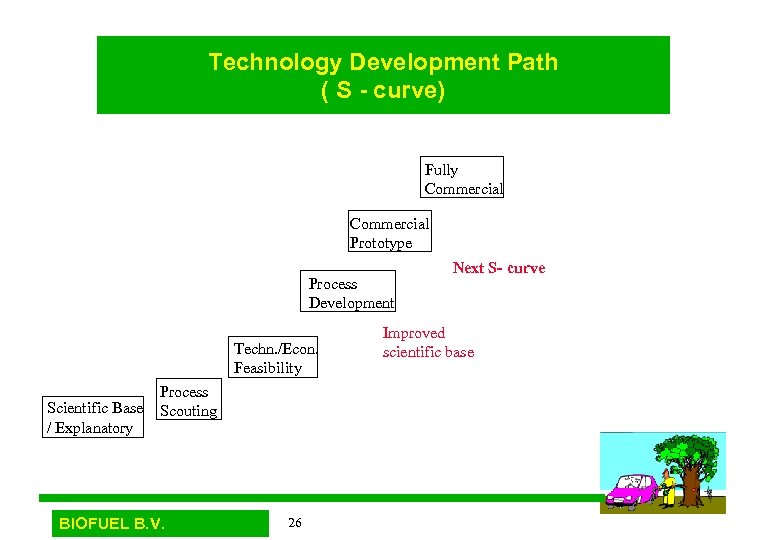

Technology Development Path ( S - curve) Fully Commercial Prototype Process Development Techn. /Econ. Feasibility Scientific Base / Explanatory Process Scouting BIOFUEL B. V. 26 Next S- curve Improved scientific base

NEXT S - CURVE Focussed fundamental studies on principles • Chemical and physical characteristics of biomass feedstocks in relation to hydrothermal conversion (Wageningen Agricultural University) • Organic chenmistry: Reaction paths and kinetics with representative components and conditions (Delft University of Technology) • Reaction engineering models/ complex kinetics (Twente University) • Thermodynamics (Delft University of Technology) BIOFUEL B. V. 27

HTU-related work in Japan NIRE: Dr. Shin-ya Yokoyama Ms. Dr. Tomoko Ogi Publications since 1985 Upgrading of biomass residues and sewage sludge For sewage sludge: continuous bench scale unit, 15 kg/h, ca. 1988 process development unit, 5 tons/day Cooperation with: Japan Organo Co. , Ltd, Dr. Akira Suzuki; contacts since 1991 Ebara corp. Institute for cellulose Industry, Bandung Indonesia, publication 1998 BIOFUEL B. V. 28

NWO – Japan Project NWO = Dutch Government Agency for Fundamental Scientific Research Commemoration of 400 years contacts Japan – the Netherlands Multimillion Treaty on fundamental research on renewable energy. Netherlands: 4 out of 20 projects are on HTU fundamentals Japan: Involvement of NIRE BIOFUEL B. V. 29

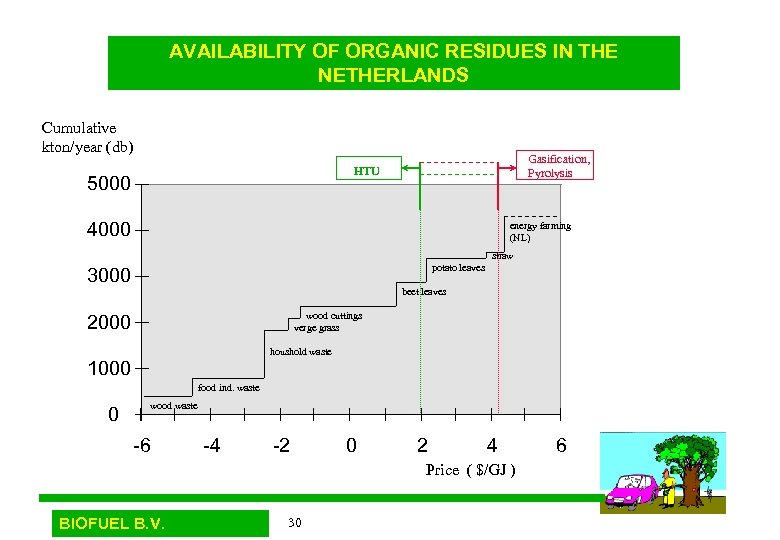

AVAILABILITY OF ORGANIC RESIDUES IN THE NETHERLANDS Cumulative kton/year (db) Gasification, Pyrolysis HTU 5000 4000 energy farming (NL) straw potato leaves 3000 beet leaves wood cuttings verge grass 2000 houshold waste 1000 food ind. waste 0 wood waste -6 -4 -2 0 2 4 Price ( $/GJ ) BIOFUEL B. V. 30 6

HTU OPPORTUNITIES 1 - The Netherlands • Industrial organic waste and residues • Organic household waste • Poultry litter • Manure 1. 8 Million tons/a (db) 1. 1 , , 0. 5 , , 2. 0 , , (combination with anaerobic digestion) TOTAL BIOFUEL B. V. 5. 4 Million tons/a (db) 31

HTU OPPORTUNITIES 2 - Europe • Agricultural / Industrial Residues 200 Million tons/a (db) (Source: Eurec agency, 1996) • Short-term niches for HTU: - Olive Oil Industry - Organic household waste (from centralized waste separation) 3 - 5 Million tons/a (db) 26 ktons/a (db) per 250, 000 inhabitants - Residues from sugar and beer production. BIOFUEL B. V. 32

HTU OPPORTUNITIES 3 - World • Agricultural and industrial residues (Source: “Renewable Energy; sources for fuels and electricity”, 1993) • Future organic household waste (own tentative estimate) • Short-term niches for HTU: - Organic household waste - Bagasse (> 100 Mtons/a) - Forestry residues from existing plantations - Coir dust BIOFUEL B. V. 33 4, 000 Million tons/a (db) (approx. 70 EJ/a) 800 Million tons/a (db)

639aea6227c650001e96c67a333120d7.ppt