455cb62d6bff1b40fe7862e4dd57dd8d.ppt

- Количество слайдов: 26

Successfully Developing & Managing Wastewater Pipeline/ Manhole Condition Assessment & Rehabilitation Programs Presented from a municipal perspective… Presented by: Jeff Maier, P. E. Metro Wastewater Reclamation District Denver, Colorado

Successfully Developing & Managing Wastewater Pipeline/ Manhole Condition Assessment & Rehabilitation Programs Presented from a municipal perspective… Presented by: Jeff Maier, P. E. Metro Wastewater Reclamation District Denver, Colorado

The challenges municipalities are facing: Ø ASCE’s 2009 Report Card for America’s Infrastructure: Grade for Wastewater Infrastructure is a “D –” Ø Cost effective asset management programs are more important than ever Ø Doing more with less is the new normal Ø Tighter EPA & CDPHE regulations Ø Funding issues & aging systems

The challenges municipalities are facing: Ø ASCE’s 2009 Report Card for America’s Infrastructure: Grade for Wastewater Infrastructure is a “D –” Ø Cost effective asset management programs are more important than ever Ø Doing more with less is the new normal Ø Tighter EPA & CDPHE regulations Ø Funding issues & aging systems

The importance of condition assessment and rehabilitation Ø Understanding your system is vital – wastewater infrastructure is crumbling! Ø Out of site, out of mind is no longer acceptable Ø Critical component of successful asset management and budgeting Ø Regulatory compliance issues Ø Operation & Maintenance requirements Ø Knowledge about your system = good decision making

The importance of condition assessment and rehabilitation Ø Understanding your system is vital – wastewater infrastructure is crumbling! Ø Out of site, out of mind is no longer acceptable Ø Critical component of successful asset management and budgeting Ø Regulatory compliance issues Ø Operation & Maintenance requirements Ø Knowledge about your system = good decision making

Benefits of effective condition assessment and rehabilitation Ø Reduces overflows, violations & failures Ø Prioritizes repair and maintenance efforts Ø Reduces emergency repairs or dig & replace Ø Modern technologies utilize trenchless condition assessment and rehabilitation techniques Ø Can save a lot of money!

Benefits of effective condition assessment and rehabilitation Ø Reduces overflows, violations & failures Ø Prioritizes repair and maintenance efforts Ø Reduces emergency repairs or dig & replace Ø Modern technologies utilize trenchless condition assessment and rehabilitation techniques Ø Can save a lot of money!

Attributes of a successful condition assessment & rehab program Goals and responsibilities are defined Ø Organized & methodical Ø Administered by qualified staff and/or consultants Ø Uses available modern technologies Ø QA/QC is paramount Ø Reduces risk Ø Helps asset management & maintenance efforts Ø Improves capital expenditure planning Ø

Attributes of a successful condition assessment & rehab program Goals and responsibilities are defined Ø Organized & methodical Ø Administered by qualified staff and/or consultants Ø Uses available modern technologies Ø QA/QC is paramount Ø Reduces risk Ø Helps asset management & maintenance efforts Ø Improves capital expenditure planning Ø

Condition Assessment Technologies & Management Techniques Available Ø CCTV inspection Ø Advanced Pipe Condition Assessment Systems (Redzone, Cleanflow, PPR, etc. ) Ø Pole Cameras Ø Manual and Entry Inspection Methods Ø Database systems for inspection information storage Ø GIS interfaces & state-of-the-art inspection software Ø Consistent rating systems (NASSCO’s PACP & MACP)

Condition Assessment Technologies & Management Techniques Available Ø CCTV inspection Ø Advanced Pipe Condition Assessment Systems (Redzone, Cleanflow, PPR, etc. ) Ø Pole Cameras Ø Manual and Entry Inspection Methods Ø Database systems for inspection information storage Ø GIS interfaces & state-of-the-art inspection software Ø Consistent rating systems (NASSCO’s PACP & MACP)

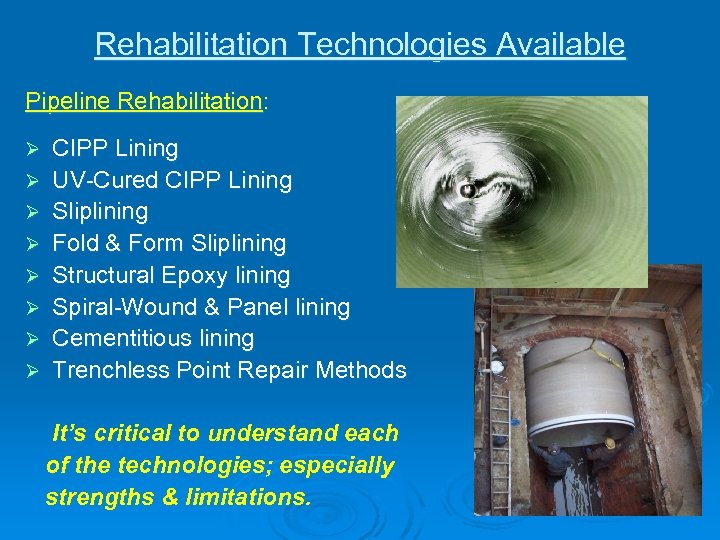

Rehabilitation Technologies Available Pipeline Rehabilitation: Ø Ø Ø Ø CIPP Lining UV-Cured CIPP Lining Sliplining Fold & Form Sliplining Structural Epoxy lining Spiral-Wound & Panel lining Cementitious lining Trenchless Point Repair Methods It’s critical to understand each of the technologies; especially strengths & limitations.

Rehabilitation Technologies Available Pipeline Rehabilitation: Ø Ø Ø Ø CIPP Lining UV-Cured CIPP Lining Sliplining Fold & Form Sliplining Structural Epoxy lining Spiral-Wound & Panel lining Cementitious lining Trenchless Point Repair Methods It’s critical to understand each of the technologies; especially strengths & limitations.

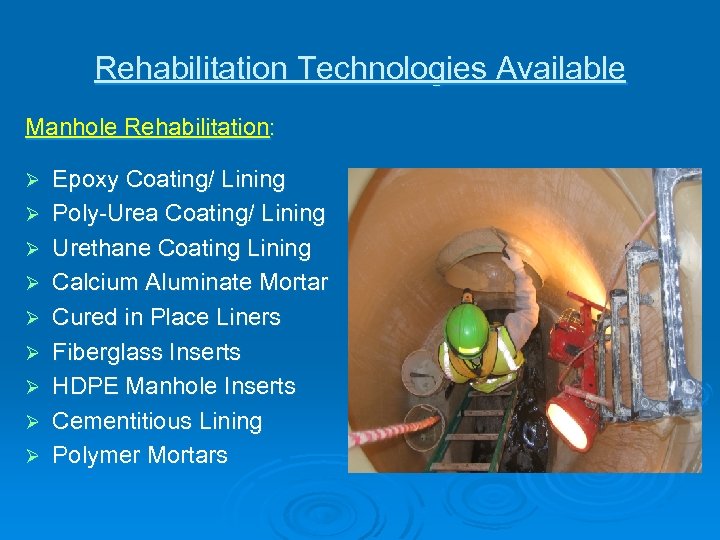

Rehabilitation Technologies Available Manhole Rehabilitation: Ø Ø Ø Ø Ø Epoxy Coating/ Lining Poly-Urea Coating/ Lining Urethane Coating Lining Calcium Aluminate Mortar Cured in Place Liners Fiberglass Inserts HDPE Manhole Inserts Cementitious Lining Polymer Mortars

Rehabilitation Technologies Available Manhole Rehabilitation: Ø Ø Ø Ø Ø Epoxy Coating/ Lining Poly-Urea Coating/ Lining Urethane Coating Lining Calcium Aluminate Mortar Cured in Place Liners Fiberglass Inserts HDPE Manhole Inserts Cementitious Lining Polymer Mortars

Metro Wastewater’s Interceptor & Manhole Condition Assessment & Rehab Program Ø Systematic, consistent, & cost-effect approach to assessing & rehabilitating pipe and manhole conditions Ø In-house developed program Ø Collaborative effort between Engineering, Comprehensive Planning, and Operations & Maintenance (O&M) Departments Ø Balances operational, financial, and engineering needs

Metro Wastewater’s Interceptor & Manhole Condition Assessment & Rehab Program Ø Systematic, consistent, & cost-effect approach to assessing & rehabilitating pipe and manhole conditions Ø In-house developed program Ø Collaborative effort between Engineering, Comprehensive Planning, and Operations & Maintenance (O&M) Departments Ø Balances operational, financial, and engineering needs

Metro Wastewater’s Interceptor & Manhole Condition Assessment Program Ø Ø Ø Pipes inspected mainly by using CCTV In-house CCTV using MWRD crews 5 -category pipe condition rating system 3 -category manhole condition rating system Manholes surface & entry inspected Utilizes advanced condition assessment technologies Program utilizes customized database system and GIS interface

Metro Wastewater’s Interceptor & Manhole Condition Assessment Program Ø Ø Ø Pipes inspected mainly by using CCTV In-house CCTV using MWRD crews 5 -category pipe condition rating system 3 -category manhole condition rating system Manholes surface & entry inspected Utilizes advanced condition assessment technologies Program utilizes customized database system and GIS interface

Defined Departmental Roles & Workflow Ø O&M Department – Televise pipelines (CCTV), inspect manholes/ structures, enter inspection info into database, initial condition rating Ø Engineering Department – Review CCTV footage, follow-up inspection of manholes, assign final condition rating, generate prioritization list & reports, design & manage rehabilitation project, research new technologies Ø Comprehensive Planning – Review rehabilitation prioritization lists & reports, update & manage Capital Expenditure Schedule Interdepartmental Cooperation & Responsibility: Results in successful in-house condition assessment and rehabilitation program.

Defined Departmental Roles & Workflow Ø O&M Department – Televise pipelines (CCTV), inspect manholes/ structures, enter inspection info into database, initial condition rating Ø Engineering Department – Review CCTV footage, follow-up inspection of manholes, assign final condition rating, generate prioritization list & reports, design & manage rehabilitation project, research new technologies Ø Comprehensive Planning – Review rehabilitation prioritization lists & reports, update & manage Capital Expenditure Schedule Interdepartmental Cooperation & Responsibility: Results in successful in-house condition assessment and rehabilitation program.

Program Components: CCTV Inspection Ø CCTV video inspections: Minimum of 10% of pipe segments annually Ø 10 year video cycle for entire interceptor system Ø CCTV work performed in-house by O&M Department crews Ø In-house CCTV ensures consistency, eliminates scheduling issues, & ultimately saves money Ø Customized 5 -category rating system

Program Components: CCTV Inspection Ø CCTV video inspections: Minimum of 10% of pipe segments annually Ø 10 year video cycle for entire interceptor system Ø CCTV work performed in-house by O&M Department crews Ø In-house CCTV ensures consistency, eliminates scheduling issues, & ultimately saves money Ø Customized 5 -category rating system

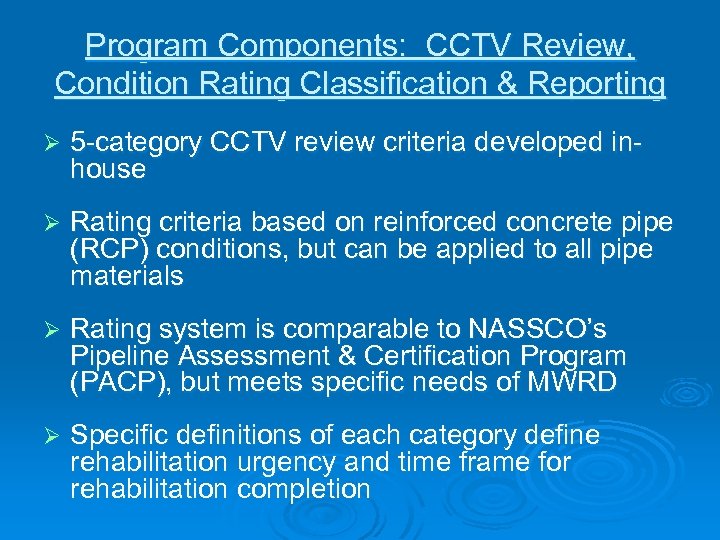

Program Components: CCTV Review, Condition Rating Classification & Reporting Ø 5 -category CCTV review criteria developed inhouse Ø Rating criteria based on reinforced concrete pipe (RCP) conditions, but can be applied to all pipe materials Ø Rating system is comparable to NASSCO’s Pipeline Assessment & Certification Program (PACP), but meets specific needs of MWRD Ø Specific definitions of each category define rehabilitation urgency and time frame for rehabilitation completion

Program Components: CCTV Review, Condition Rating Classification & Reporting Ø 5 -category CCTV review criteria developed inhouse Ø Rating criteria based on reinforced concrete pipe (RCP) conditions, but can be applied to all pipe materials Ø Rating system is comparable to NASSCO’s Pipeline Assessment & Certification Program (PACP), but meets specific needs of MWRD Ø Specific definitions of each category define rehabilitation urgency and time frame for rehabilitation completion

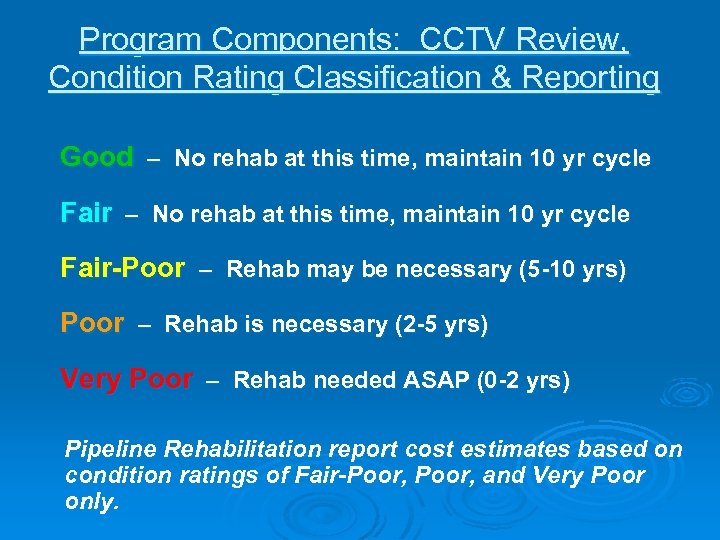

Program Components: CCTV Review, Condition Rating Classification & Reporting Good – No rehab at this time, maintain 10 yr cycle Fair-Poor – Rehab may be necessary (5 -10 yrs) Poor – Rehab is necessary (2 -5 yrs) Very Poor – Rehab needed ASAP (0 -2 yrs) Pipeline Rehabilitation report cost estimates based on condition ratings of Fair-Poor, and Very Poor only.

Program Components: CCTV Review, Condition Rating Classification & Reporting Good – No rehab at this time, maintain 10 yr cycle Fair-Poor – Rehab may be necessary (5 -10 yrs) Poor – Rehab is necessary (2 -5 yrs) Very Poor – Rehab needed ASAP (0 -2 yrs) Pipeline Rehabilitation report cost estimates based on condition ratings of Fair-Poor, and Very Poor only.

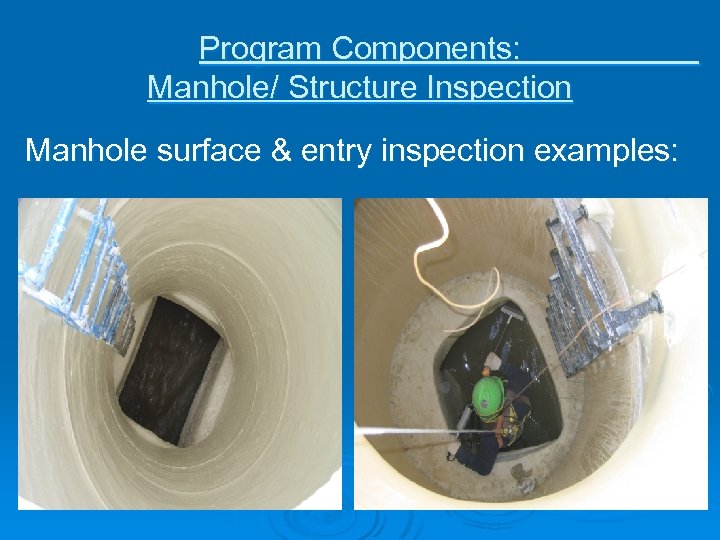

Program Components: Manhole/ Structure Inspection Manhole surface & entry inspection examples:

Program Components: Manhole/ Structure Inspection Manhole surface & entry inspection examples:

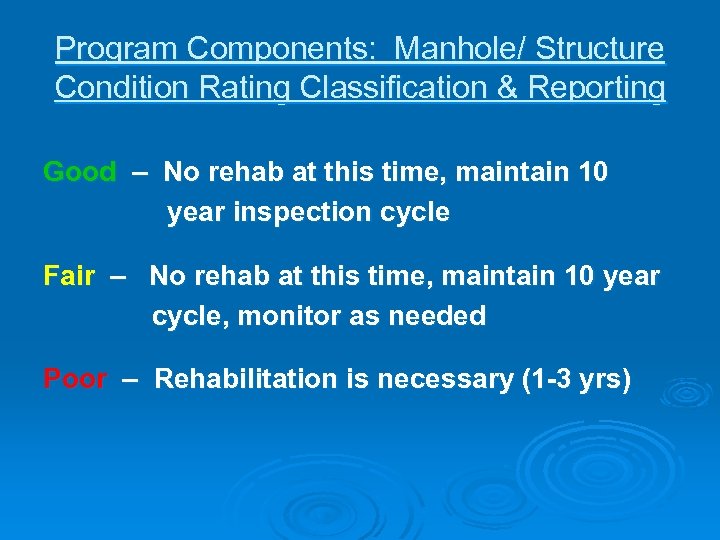

Program Components: Manhole/ Structure Condition Rating Classification & Reporting Good – No rehab at this time, maintain 10 year inspection cycle Fair – No rehab at this time, maintain 10 year cycle, monitor as needed Poor – Rehabilitation is necessary (1 -3 yrs)

Program Components: Manhole/ Structure Condition Rating Classification & Reporting Good – No rehab at this time, maintain 10 year inspection cycle Fair – No rehab at this time, maintain 10 year cycle, monitor as needed Poor – Rehabilitation is necessary (1 -3 yrs)

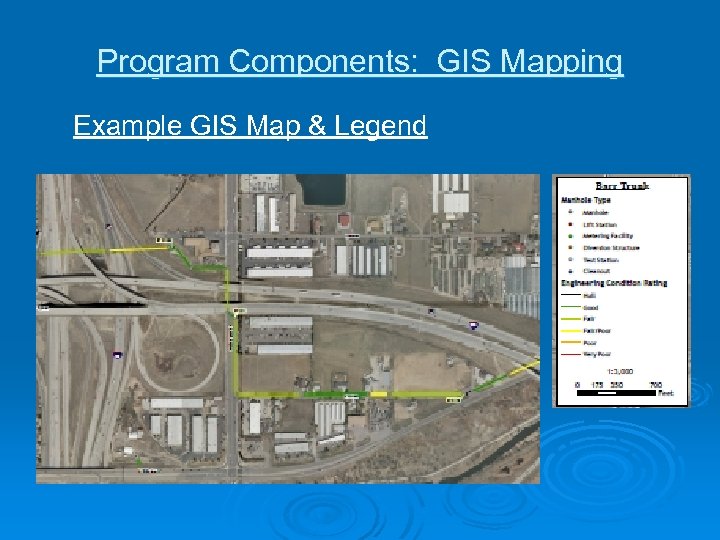

Program Components: GIS Mapping Example GIS Map & Legend

Program Components: GIS Mapping Example GIS Map & Legend

Program Components: Interceptor Infrastructure System Database (IIS) CCTV & Manhole inspection data maintained real-time in IIS database Ø IIS database developed in-house Ø Oracle based system Ø Manages inspection data, physical pipe & manhole info, and GIS system Ø Streamlined condition assessment program Ø Access searchable pipe & manhole/ structure condition information Ø

Program Components: Interceptor Infrastructure System Database (IIS) CCTV & Manhole inspection data maintained real-time in IIS database Ø IIS database developed in-house Ø Oracle based system Ø Manages inspection data, physical pipe & manhole info, and GIS system Ø Streamlined condition assessment program Ø Access searchable pipe & manhole/ structure condition information Ø

Program Components: Supplemental Pipe Coring Activities Core drill sampling on selected pipe segments Ø Coring used to confirm remaining pipe thickness Ø Candidates for coring are pipe segments that may be rated in either category (i. e. fair-poor or poor) Ø Coring work done by outside contractor Ø Info entered into IIS database, compare to existing data & reevaluate current condition rating Ø Samples used to verify & check CCTV rating system Ø

Program Components: Supplemental Pipe Coring Activities Core drill sampling on selected pipe segments Ø Coring used to confirm remaining pipe thickness Ø Candidates for coring are pipe segments that may be rated in either category (i. e. fair-poor or poor) Ø Coring work done by outside contractor Ø Info entered into IIS database, compare to existing data & reevaluate current condition rating Ø Samples used to verify & check CCTV rating system Ø

Research & Development New Condition Assessment Technologies Ø Ongoing research of non-destructive methods to determine pipe condition & wall thickness Ø Laser profiling, sonar systems, & combo assessment technologies (Red. Zone, Clean. Flow. PPR) Ø Will replace supplemental coring Ø Will help improve rehabilitation prioritization CCTV will still provide majority of inspection information (CCTV ~90%, new method ~10%)

Research & Development New Condition Assessment Technologies Ø Ongoing research of non-destructive methods to determine pipe condition & wall thickness Ø Laser profiling, sonar systems, & combo assessment technologies (Red. Zone, Clean. Flow. PPR) Ø Will replace supplemental coring Ø Will help improve rehabilitation prioritization CCTV will still provide majority of inspection information (CCTV ~90%, new method ~10%)

Research & Development Testing & Product Evaluation Ø MWRD’s 6 -Step Manhole/ Concrete Rehabilitation Product Evaluation Program l l l Ø In-house developed program Evaluates products and applicators Helps ensure QA/QC Severe Wastewater Analysis Test (SWAT) l l l Evaluates coating/lining effectiveness & longevity in severe wastewater headspace environments Laboratory and real-life test comparisons Accelerated test chamber & electrical impedance tests

Research & Development Testing & Product Evaluation Ø MWRD’s 6 -Step Manhole/ Concrete Rehabilitation Product Evaluation Program l l l Ø In-house developed program Evaluates products and applicators Helps ensure QA/QC Severe Wastewater Analysis Test (SWAT) l l l Evaluates coating/lining effectiveness & longevity in severe wastewater headspace environments Laboratory and real-life test comparisons Accelerated test chamber & electrical impedance tests

Long-term Capital Expenditure Planning Interceptor Pipes Ø Assumes pipes will be rehabilitated with CIPP lining for cost estimating purposes Ø Other rehab methods considered during design (slip lining, fold & form, epoxy-lined, etc. ) Ø Cost estimates based on past MWRD rehab projects Ø Historical CIPP cost data for pipe sizes 8”-60” Ø Current MWRD CIPP cost estimate data (installed price): 8”- 30” = $3. 75 per in/ft 31” – 41” = $4. 50 per in/ft 42” – 60”+ = $6. 00 per in/ft

Long-term Capital Expenditure Planning Interceptor Pipes Ø Assumes pipes will be rehabilitated with CIPP lining for cost estimating purposes Ø Other rehab methods considered during design (slip lining, fold & form, epoxy-lined, etc. ) Ø Cost estimates based on past MWRD rehab projects Ø Historical CIPP cost data for pipe sizes 8”-60” Ø Current MWRD CIPP cost estimate data (installed price): 8”- 30” = $3. 75 per in/ft 31” – 41” = $4. 50 per in/ft 42” – 60”+ = $6. 00 per in/ft

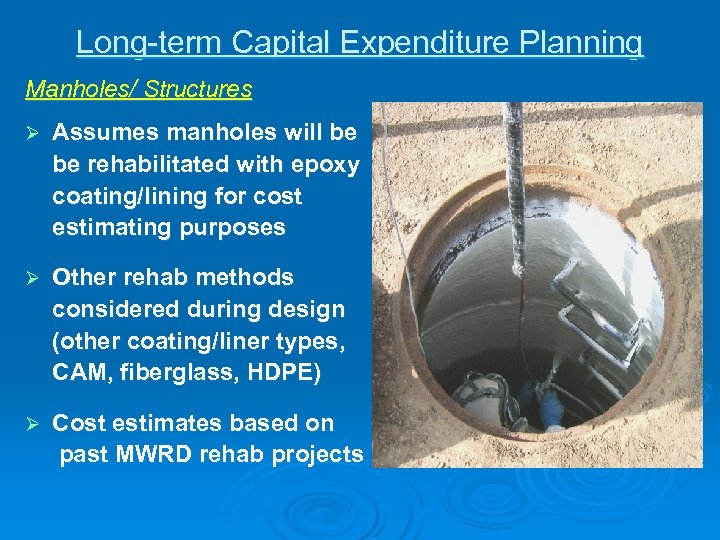

Long-term Capital Expenditure Planning Manholes/ Structures Ø Assumes manholes will be be rehabilitated with epoxy coating/lining for cost estimating purposes Ø Other rehab methods considered during design (other coating/liner types, CAM, fiberglass, HDPE) Ø Cost estimates based on past MWRD rehab projects

Long-term Capital Expenditure Planning Manholes/ Structures Ø Assumes manholes will be be rehabilitated with epoxy coating/lining for cost estimating purposes Ø Other rehab methods considered during design (other coating/liner types, CAM, fiberglass, HDPE) Ø Cost estimates based on past MWRD rehab projects

Prioritization for Pipe & Manhole Rehabilitation Projects Ø Pipe segments rated “very poor” will be repaired on priority basis (i. e. next available rehab project) Ø Adjoining “poor” segments will be added when shared bypass pumping cost savings can be realized Ø Assumed that only 75% of “poor” and “fair-poor” rated pipes will ever reach “very poor” condition Ø Projected timing for when pipe segment or manhole will deteriorate and reach “poor” or “very poor” is considered Ø Manholes rated as “poor” will be repaired on priority basis (i. e. next available rehab project) Ø 10 -year Capital Expenditure Schedule updated accordingly

Prioritization for Pipe & Manhole Rehabilitation Projects Ø Pipe segments rated “very poor” will be repaired on priority basis (i. e. next available rehab project) Ø Adjoining “poor” segments will be added when shared bypass pumping cost savings can be realized Ø Assumed that only 75% of “poor” and “fair-poor” rated pipes will ever reach “very poor” condition Ø Projected timing for when pipe segment or manhole will deteriorate and reach “poor” or “very poor” is considered Ø Manholes rated as “poor” will be repaired on priority basis (i. e. next available rehab project) Ø 10 -year Capital Expenditure Schedule updated accordingly

Conclusions Ø A well-run Condition Assessment & Rehabilitation Program provides a systematic, consistent, & costeffective approach to asset management Ø Supports long term capital expenditure planning Ø Effective in forecasting future maintenance needs, prioritizing resource allocation, and costs based on inspection & condition assessment ratings Ø Reduces potential overflows, violations & failures Ø Utilizes trenchless technology Ø Can save a lot of money!

Conclusions Ø A well-run Condition Assessment & Rehabilitation Program provides a systematic, consistent, & costeffective approach to asset management Ø Supports long term capital expenditure planning Ø Effective in forecasting future maintenance needs, prioritizing resource allocation, and costs based on inspection & condition assessment ratings Ø Reduces potential overflows, violations & failures Ø Utilizes trenchless technology Ø Can save a lot of money!

Questions? Jeff Maier, P. E. Metro Wastewater Reclamation District Denver, Colorado 303 -286 -3285

Questions? Jeff Maier, P. E. Metro Wastewater Reclamation District Denver, Colorado 303 -286 -3285